Patents

Literature

67results about How to "Realize fine processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

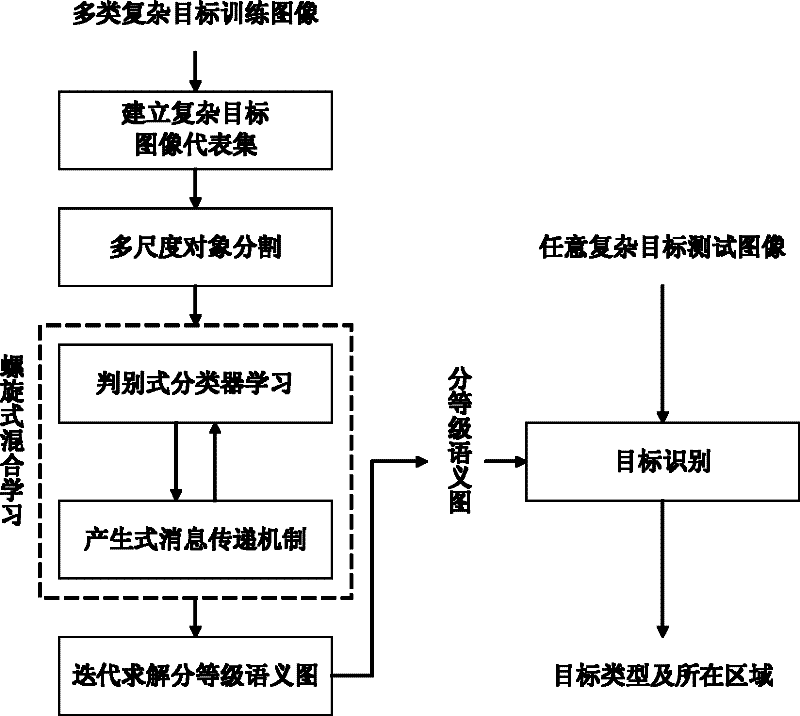

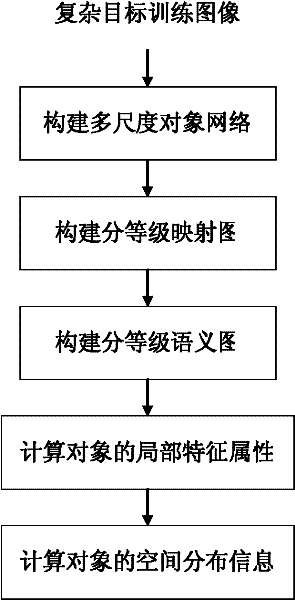

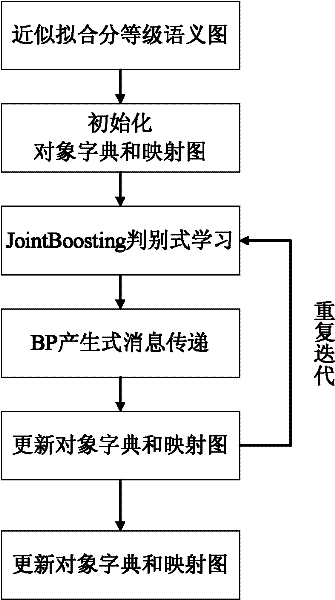

Automatic complicated target identification method based on hierarchical object semantic graph

InactiveCN102542302ARealize fine processingImprove robustnessCharacter and pattern recognitionDiscriminantGoal recognition

The invention discloses an automatic complicated target identification method based on a hierarchical object semantic graph, and relates to a target identification technology. The automatic complicated target identification method comprises the following steps of: establishing a multi-class complicated target image representative set; performing multi-scale partitioning on an image of a training set, gradually calculating characteristic information of each part object, and constructing a hierarchical semantic graph; counting partial characteristic attributes of objects by using a judgment type classifier by adopting a spiral mixed learning mode, calculating interactive influence among the objects by combining a generation type message transmission mechanism, and deducing and calculating the hierarchical semantic graph; and resolving a target of interest in the image by using the hierarchical object semantic graph obtained by learning, and realizing positioning, extraction and type identification of a plurality of classes of complicated targets. The method is relatively high in intelligentization degree; and requirements for identifying a plurality of classes of complicated targetsin natural and remotely sensed scene images and explaining the images can be met.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

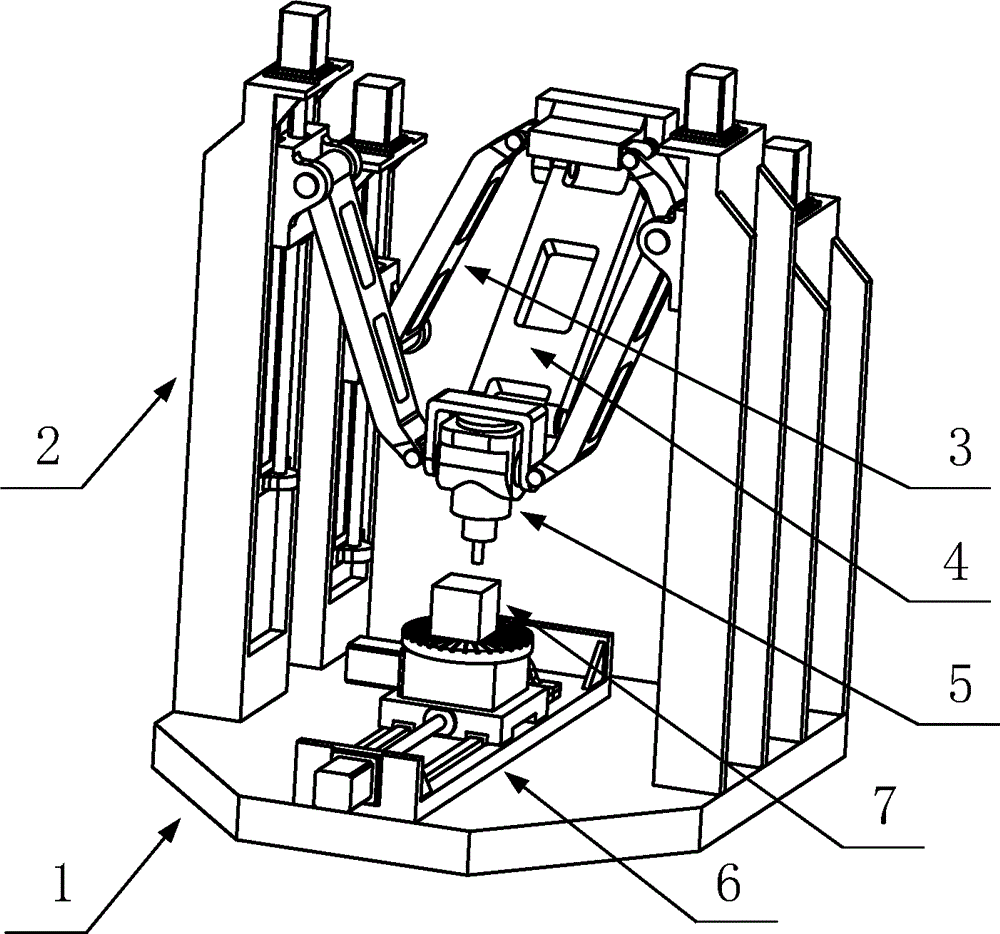

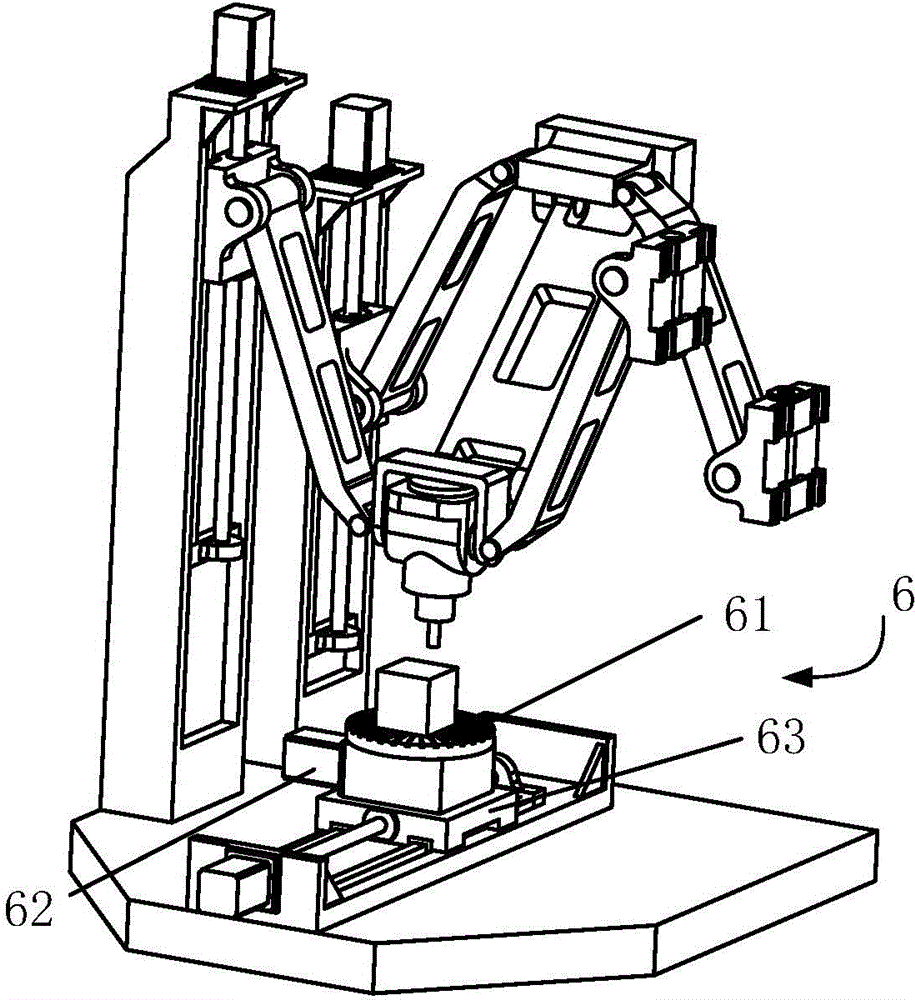

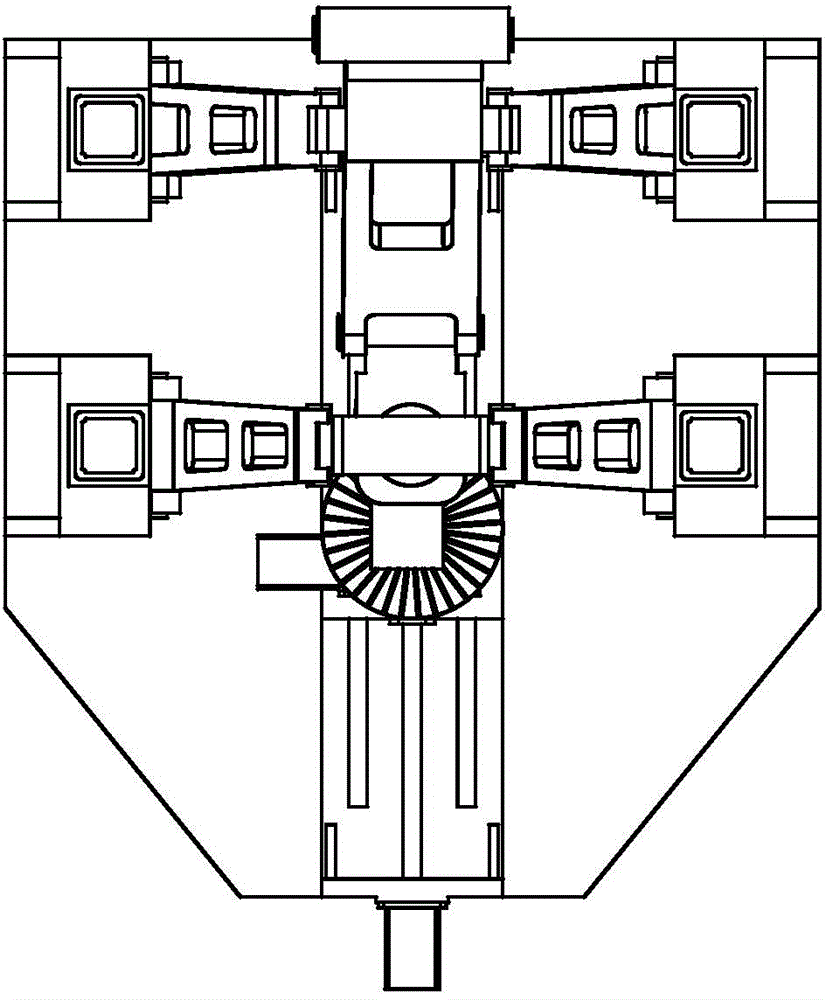

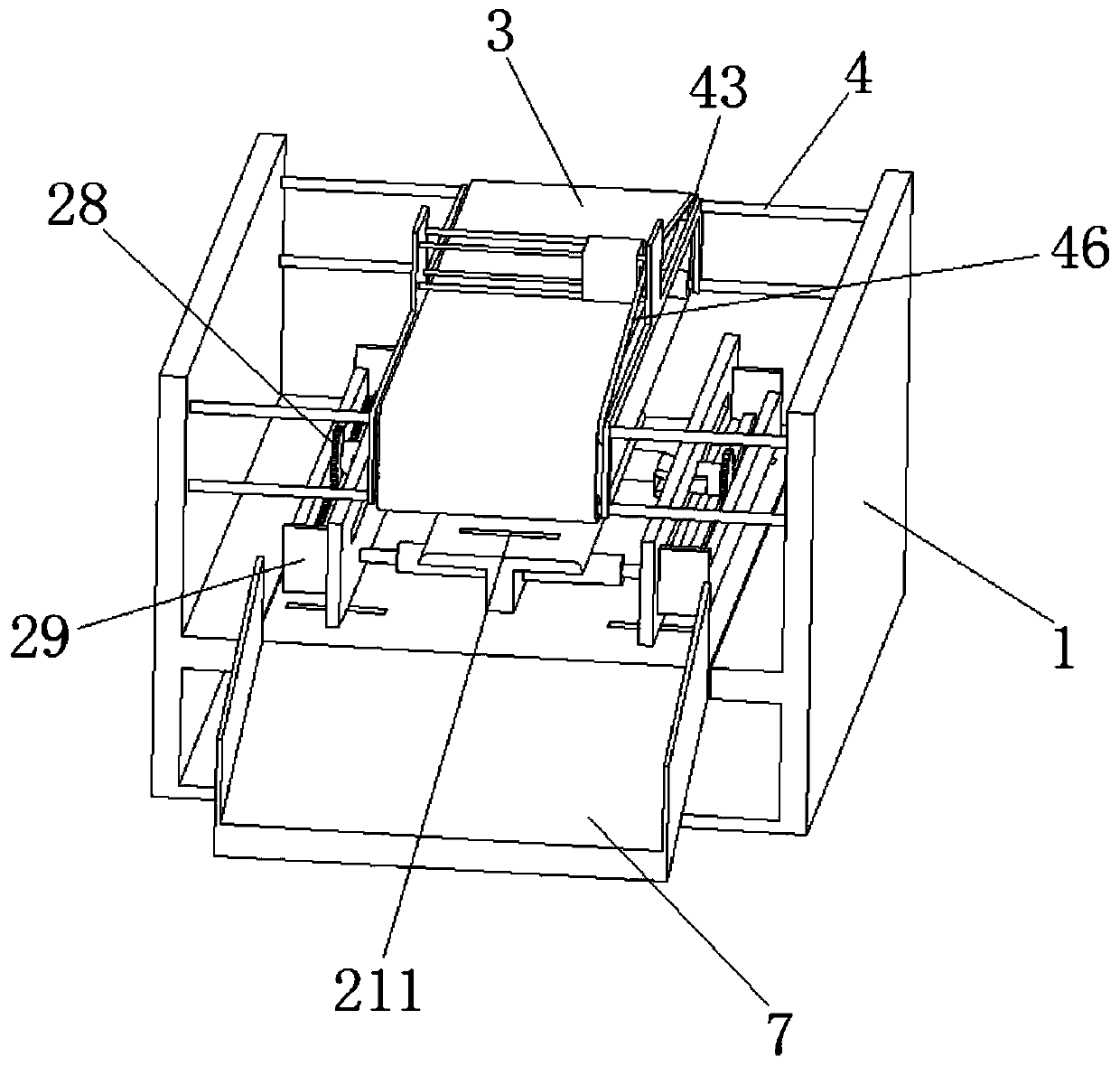

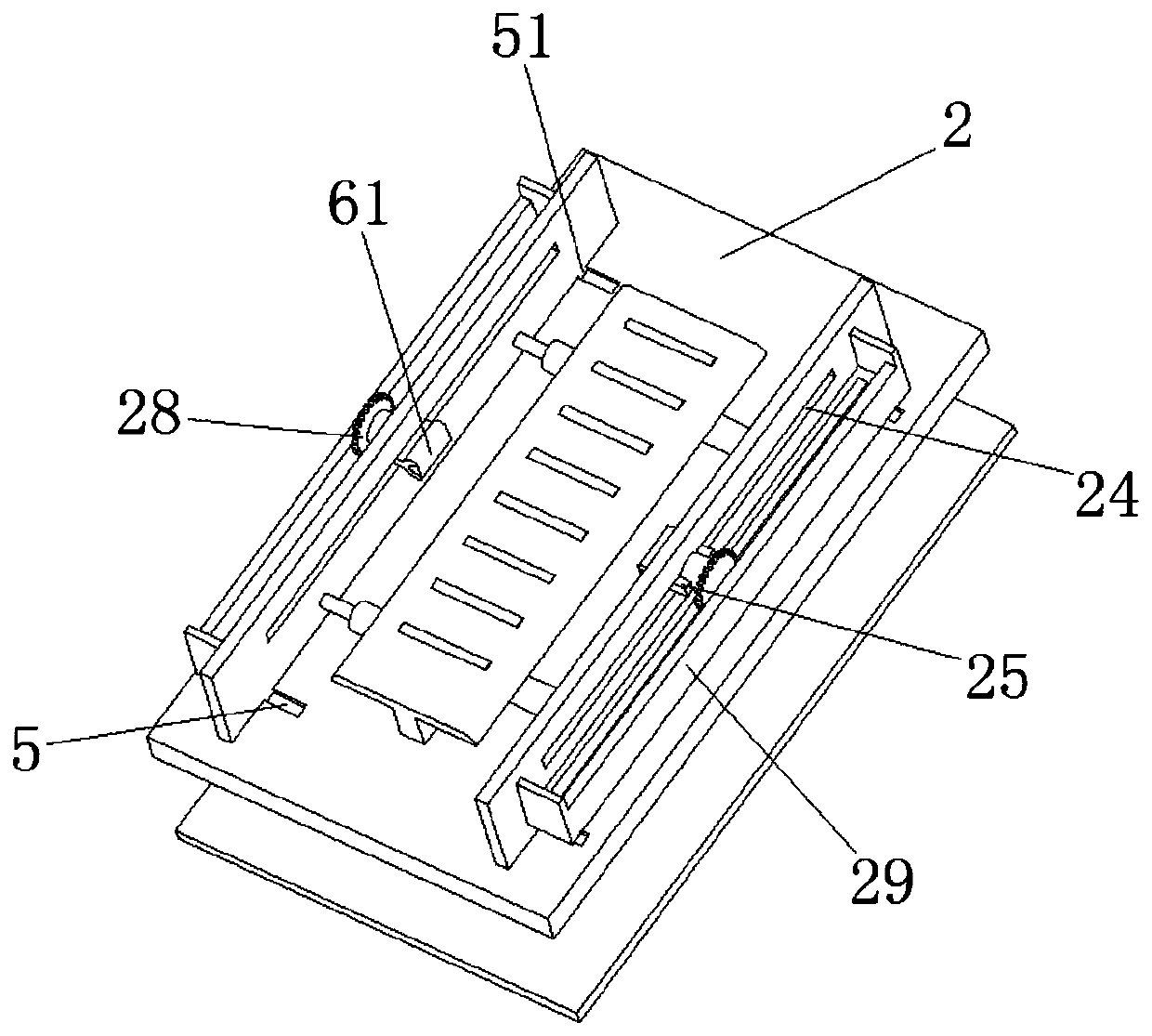

Parallel machine tool capable of realizing five-axis processing

InactiveCN103978393ASimple structureLarge working space/mechanism volume ratioProgramme-controlled manipulatorFeeding apparatusClosed loopDegrees of freedom

The invention discloses a parallel machine tool capable of realizing five-axis machining. The parallel machine tool comprises a tool body, a front parallel mechanism, a rear parallel mechanism, a serial connecting rod group, a two-degree-of-freedom worktable and an end executor, wherein the front parallel mechanism and the rear parallel mechanism have basically the same structures and respectively comprise two upright posts which are symmetrically arranged, a moving platform and two branched chains connected between the upright posts and the moving platform; the two branched chains have the same structural forms; each branched chain is provided with a linear driving unit; the moving platforms of the front parallel mechanism and the rear parallel mechanism are connected with the serial connecting rod group through two parallel hinges to form a space parallel closed loop mechanism; the space parallel closed loop mechanism realizes two moving degrees of freedom and two rotating degrees of freedom of the end executor through four driving units; the two-degree-of-freedom worktable comprises a linear sliding table and a rotating table arranged on the sliding table. The parallel machine tool disclosed by the invention can realize five-axis or six-axis linking and has better five-axis processing capability.

Owner:TIANJIN UNIV

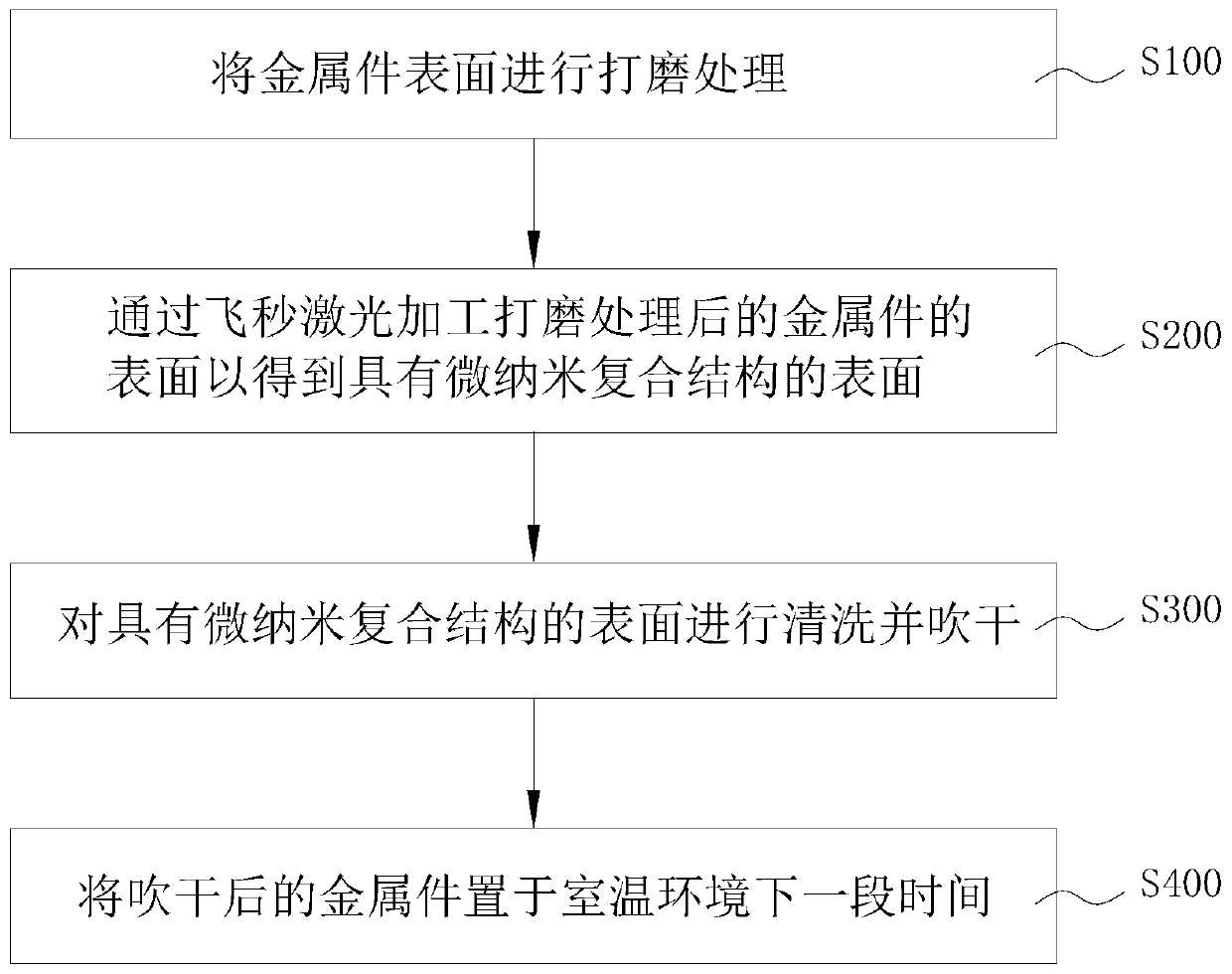

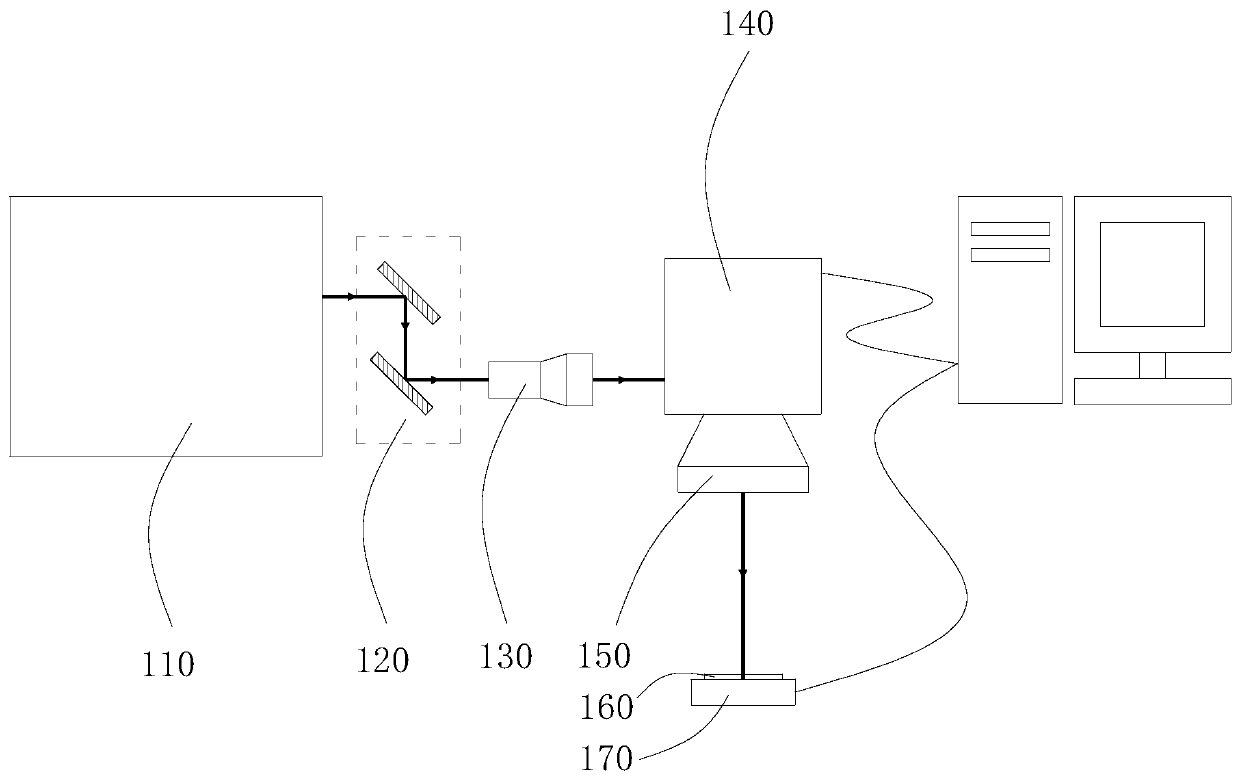

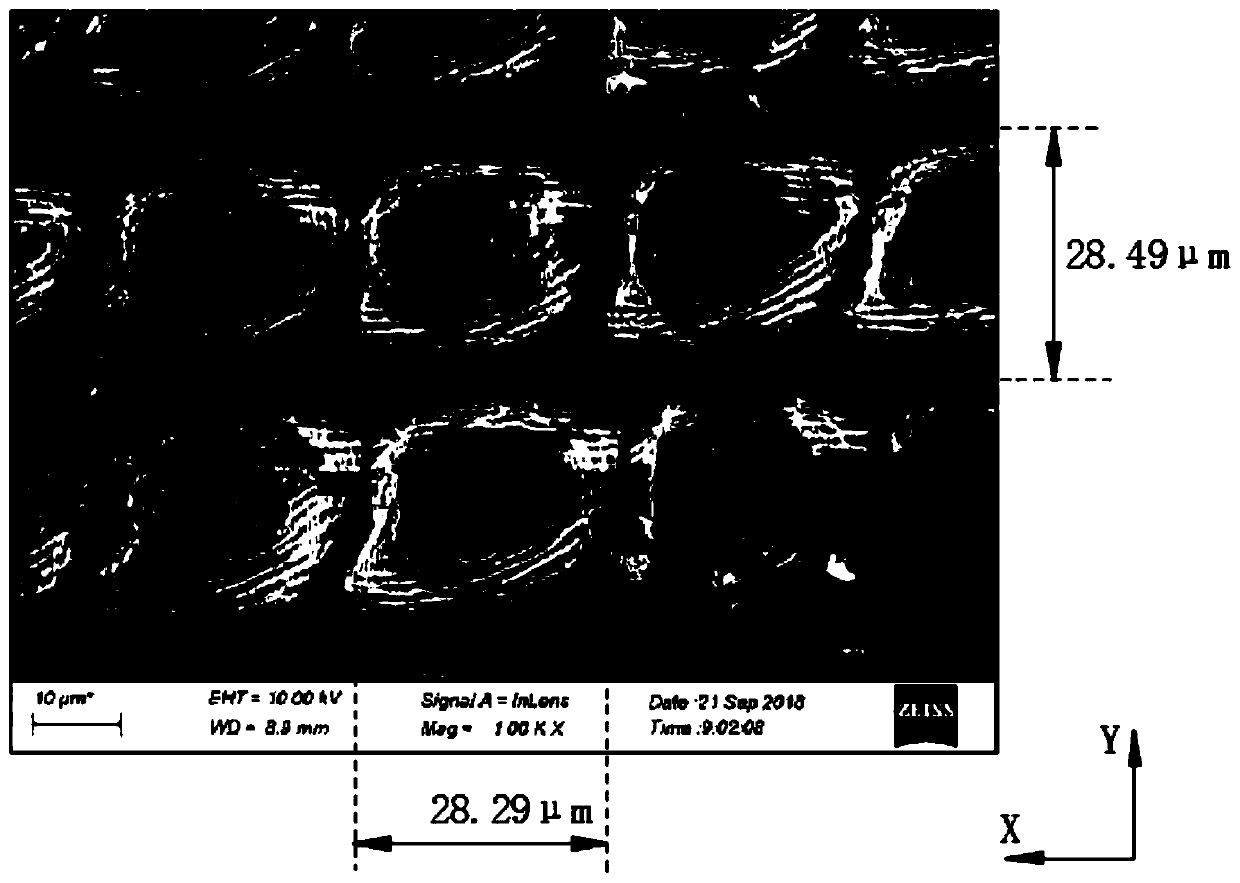

Method for metal surface treatment through femtosecond laser

InactiveCN109954966ARealize fine processingShort pulse durationLaser beam welding apparatusMicro nanoRoom temperature

The invention relates to a method for metal surface treatment through femtosecond laser. The method for metal surface treatment through the femtosecond laser comprises the following steps that polishing treatment is carried out on the surface of a metal piece; the femtosecond laser is used for machining the polished metal piece surface so that a surface with a micro-nano composite structure can beobtained; the surface with the micro-nano composite structure is washed and blow-dried; and the blow-dried metal piece is put at the room-temperature environment for a period of time. According to the method, complex following surface machining treatment procedures are not needed, the metal piece only needs to be kept at the room temperature for a period of time, an excellent surface hydrophobiceffect can be achieved, the process is simple, the machining efficiency is high, and the surface hydrophobic performance of the workpiece is good.

Owner:HANS LASER TECH IND GRP CO LTD

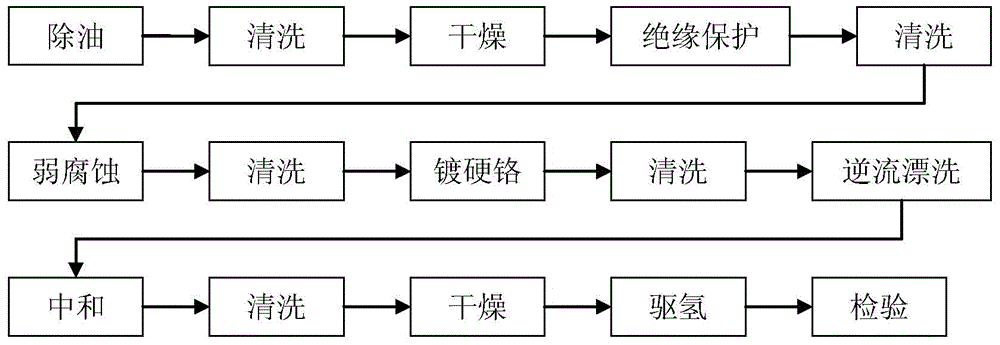

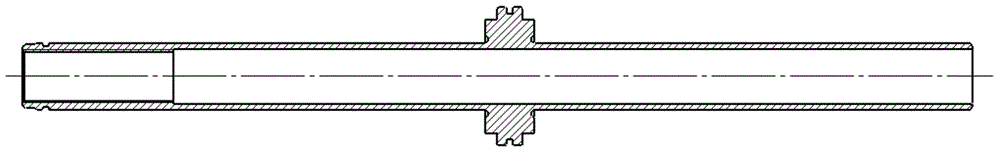

Hard chromium plating method and solution formula for piston rod class parts

The invention belongs to the field of chemical engineering and particularly relates to a hard chromium plating method and solution formula for piston rod class parts. The objective is to solve the problem that when a piston rod is produced, the quality of a hard chromium coating produced by a traditional electric chromium plating technology is not ideal, and the current efficiency is low. The method comprises the following steps: first, removing oil; then, washing, drying and carrying out insulation protection; after washing, carrying out weak corrosion; washing, and then, plating hard chromium; after washing, carrying out backflow bleaching, after neutralization, washing and drying; and after removing hydrogen, carrying out test. The hard chromium plating solution formula comprises 200-225g / L of CrO3, 2.3-2.5g / L of H2SO4 and 3-6g / L of Cr3+. The hard chromium plating method and solution formula are more suitable for piston rod class parts, particularly the production of hard chromium films of 30GrMnSiA materials. Moreover, the CrO3 content in the formula is reduced, so that the cost is reduced, and environmental pollution is reduced.

Owner:北京实验工厂有限责任公司 +1

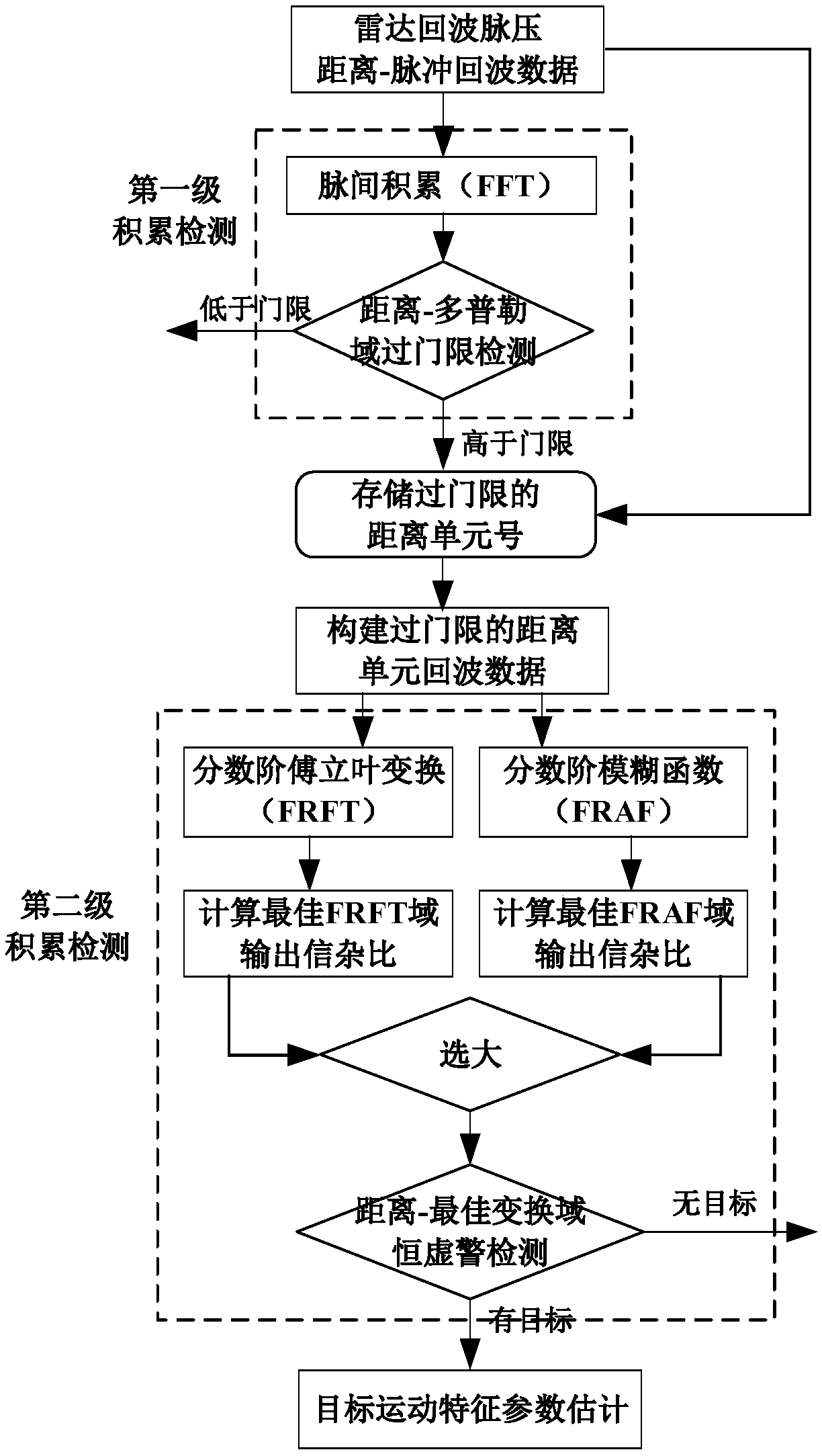

Radar maneuvering target fast fine processing method based on graded accumulative detection

ActiveCN109001708AImprove SCRImprove detection performanceWave based measurement systemsDetection performanceAmbiguity function

The invention relates to a radar maneuvering target fast fine processing method based on graded accumulative detection, and belongs to the technical field of the radar signal processing and detection.The method comprises the following steps: firstly performing Fourier transform, comparing with a primary threshold under a high-false alarm probability condition, and then performing fractional Fourier transform and fractional ambiguity function operation on a distance unit echo after exceeding the threshold in parallel, selecting the optimal transform domain corresponding to the large output signal to clutter ratio to form the distance-optimal transform domain two-dimension data; regarding the amplitude thereof as the detection statistics, comparing the detection statistics with the primarythreshold under the low-false-alarm probability condition and judging, thereby accomplishing the maneuvering target detection. The processing is performed only in a few distance units exceeding the primary threshold, thereby reducing the operation burden while guaranteeing high detection performance; multiple movement parameters of the maneuvering target can be accurately estimated, such as speed,acceleration and jerk, and the fast fine processing of the maneuvering target is realized.

Owner:NAVAL AERONAUTICAL UNIV

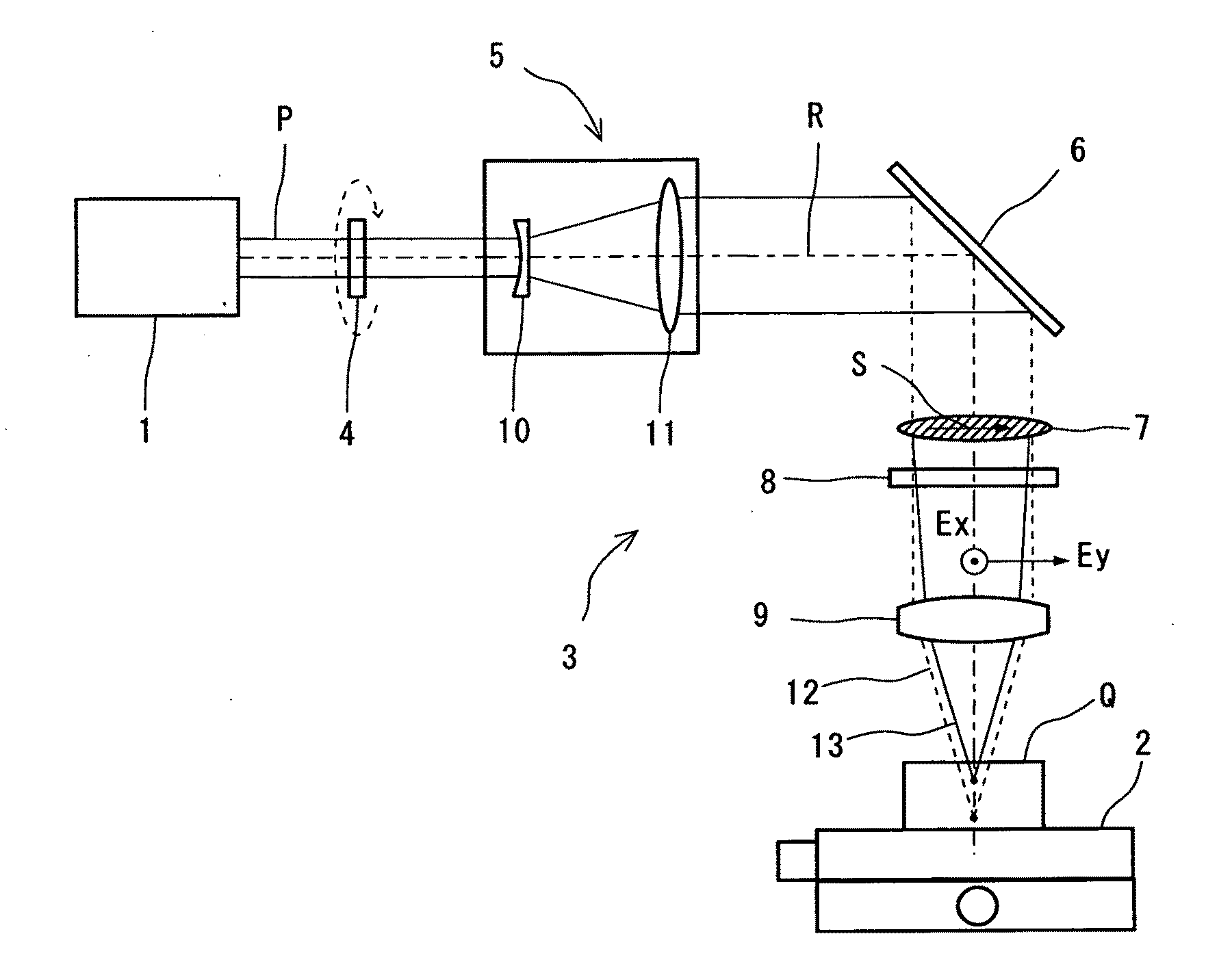

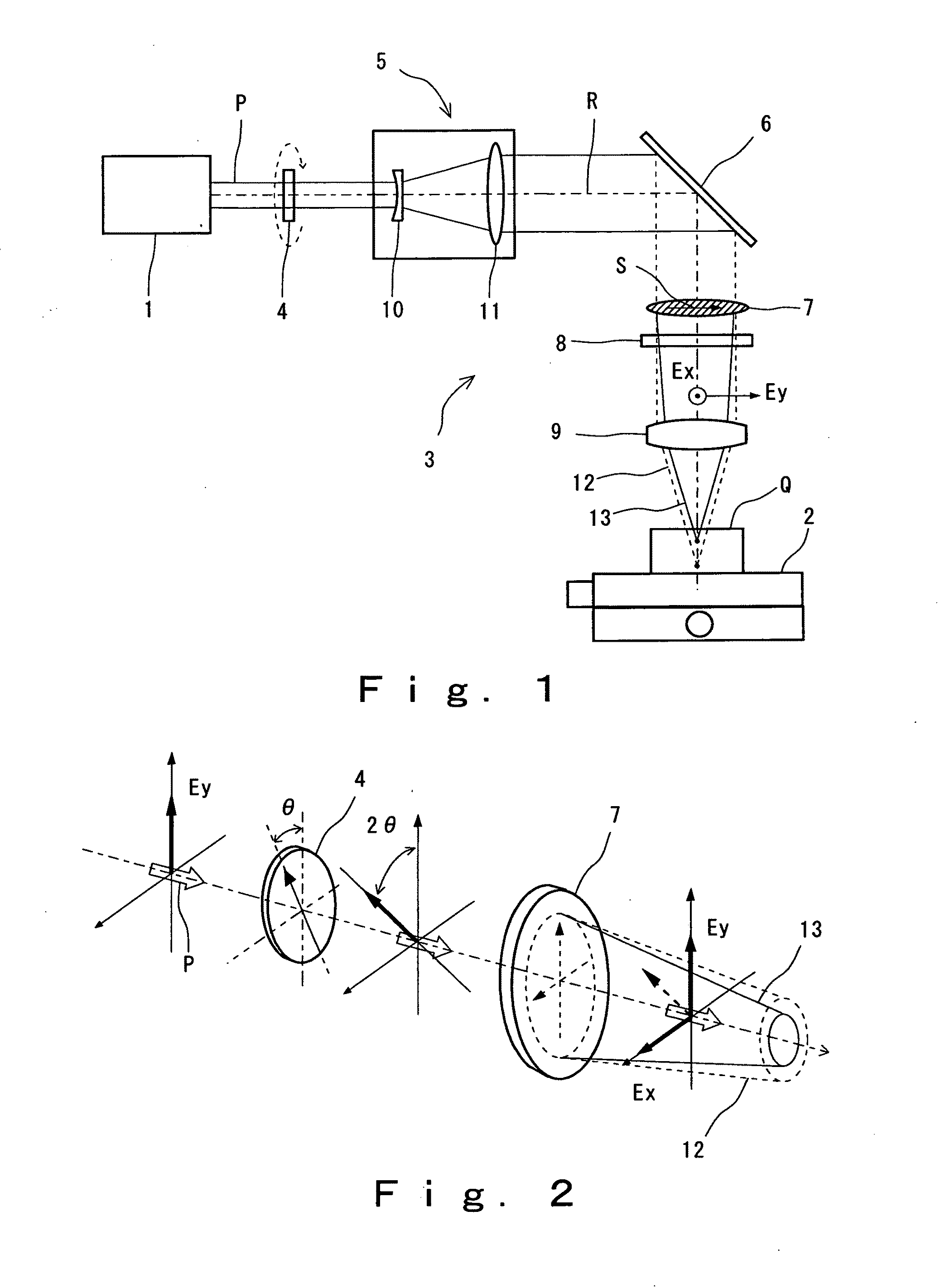

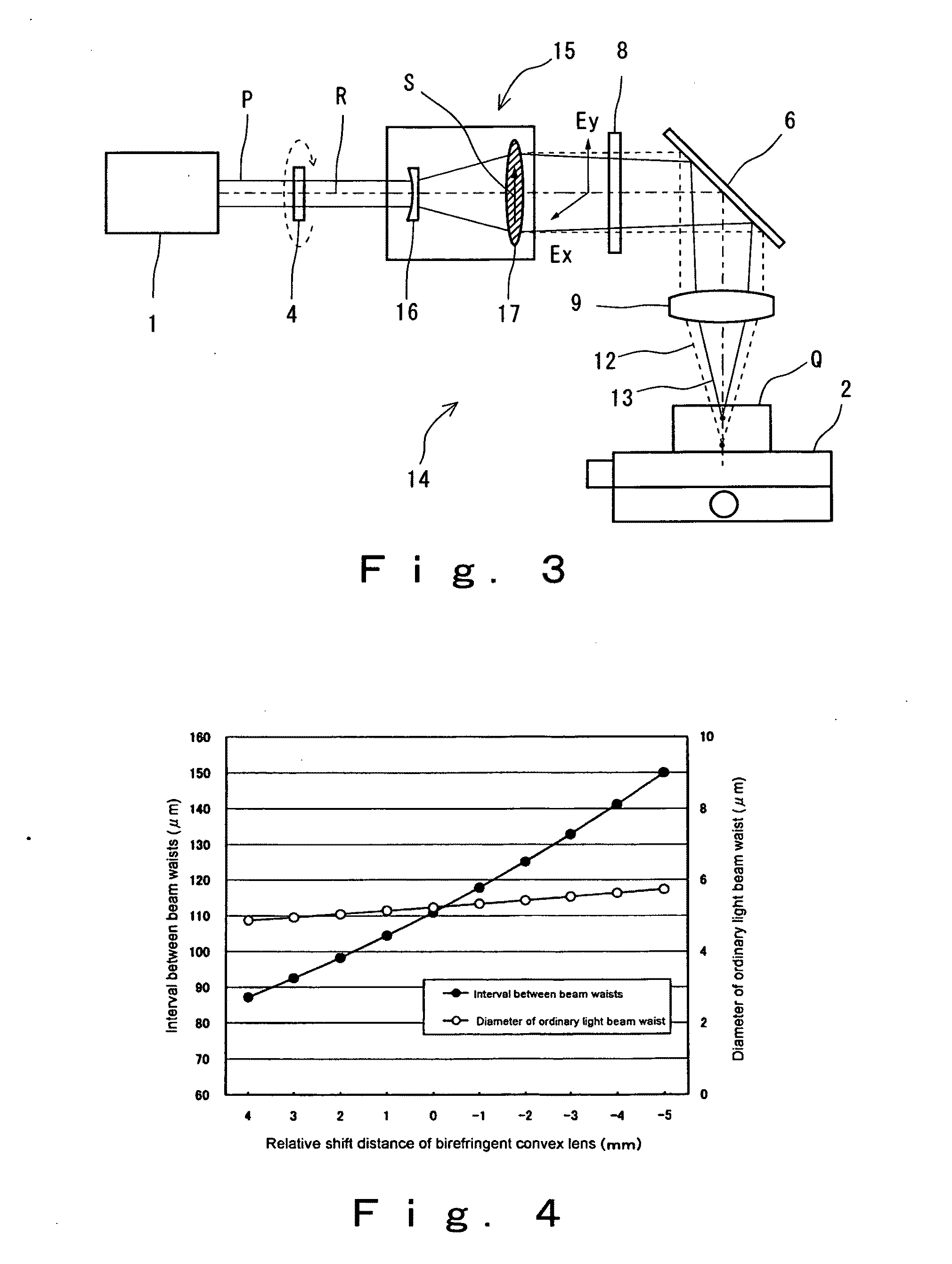

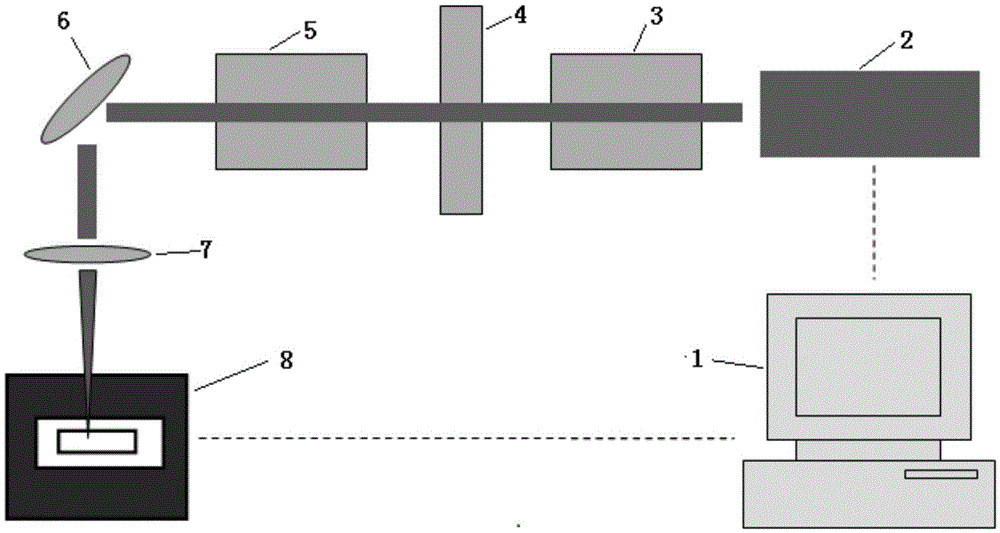

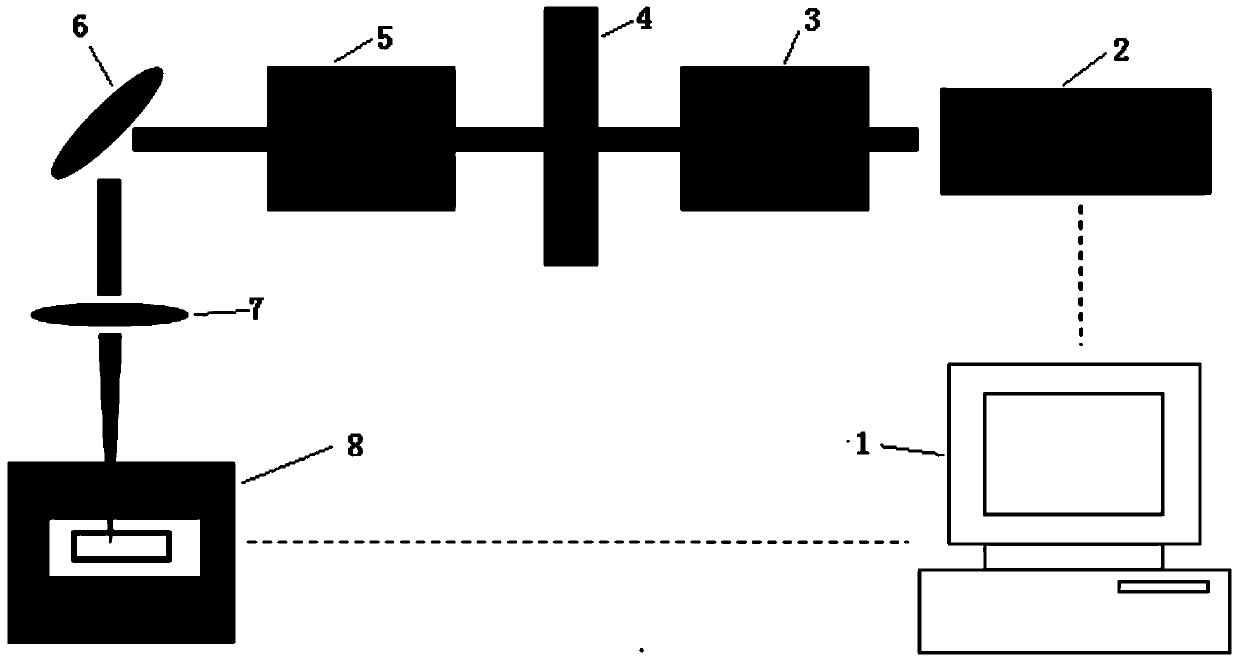

Laser irradiation device and laser processing method

ActiveUS20120012758A1Less taperLarge depth of focusLaser detailsWelding/soldering/cutting articlesBeam expanderLaser processing

Provided is a laser irradiation device for use in laser processing, and a laser processing method performed using the same. Provided is a laser irradiation device including: a light source that emits a laser beam; and an irradiation optical system which has one or a plurality of lenses, and is provided for light-guiding and light-converging of the laser beam emitted from the light source to the target substance, in which a birefringent material is used as a material entity of at least one lens of the irradiation optical system. Also provided is a laser processing method. The irradiation optical system may have a beam expander having a first lens that is a concave lens or a convex lens, and a second lens that is a convex lens, in the order along the laser-beam travel direction, the beam expander being configured so as to make the interval between the first lens and the second lens variable, in which a birefringent material may be used as a material entity of the first lens and / or the second lens. Thus, the interval between the lenses can be changed by a convenient operation, whereby relative positions between the plurality of beam waists (interval) can be easily regulated.

Owner:SEISHIN TRADING

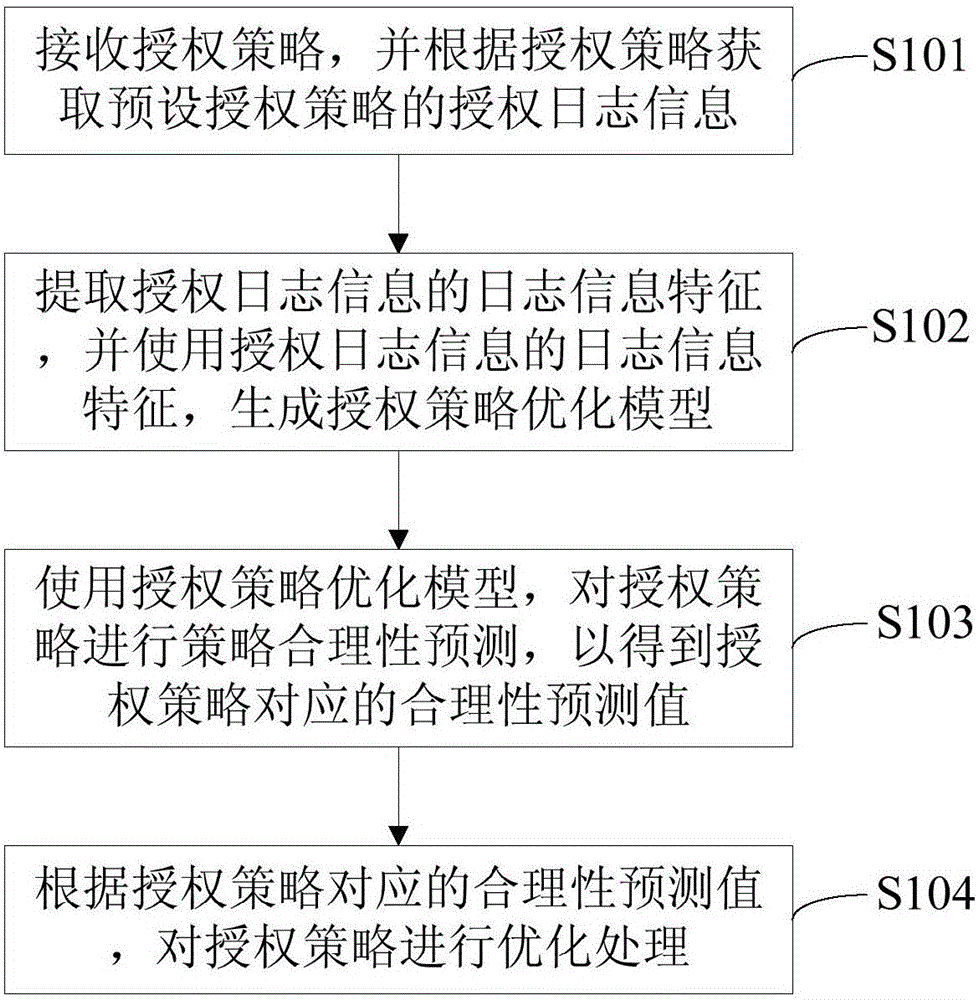

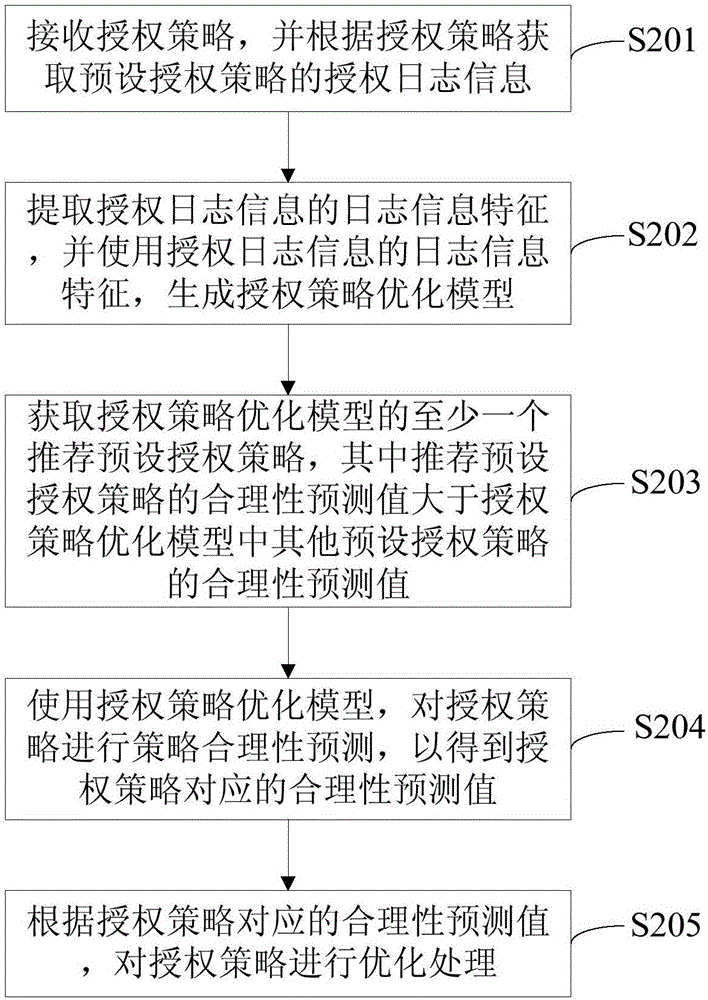

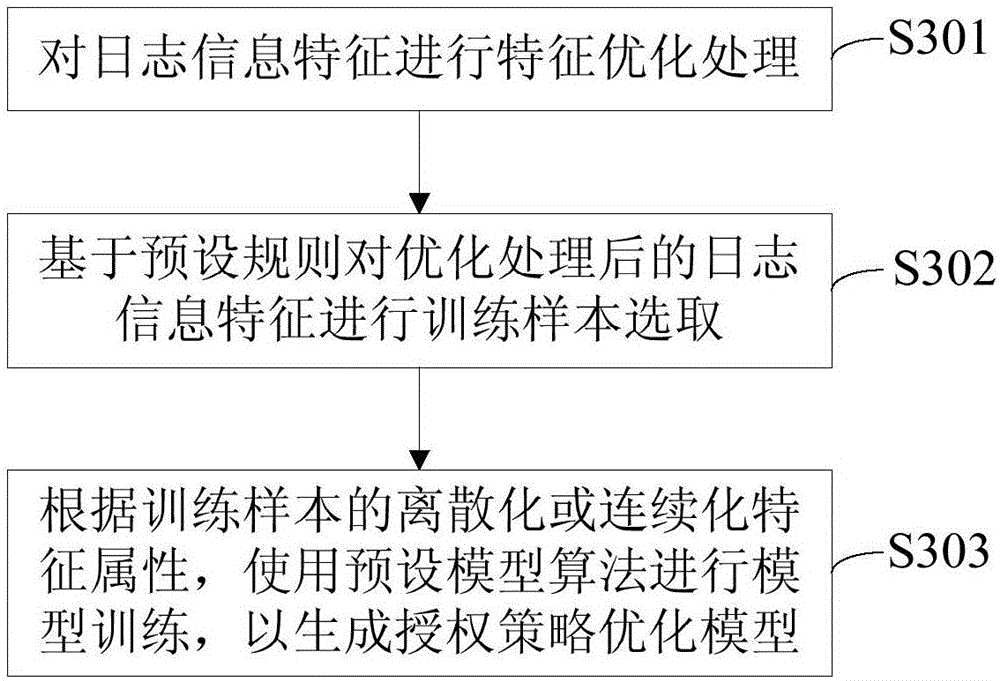

Authorization strategy optimization method and authorization strategy optimization device

ActiveCN106778303ARealize fine processingDigital data protectionTransmissionAuthorizationComputer science

The invention provides an authorization strategy optimization method. The method comprises the following steps: receiving authorization strategies and obtaining authorization log information of default authorization strategies according to the authorization strategies; extracting log information characteristics of the authorization log information and generating an authorization strategy optimization model by using the log information characteristics of the authorization log information; carrying out strategy rationality prediction on the authorization strategies by using the authorization strategy optimization model to obtain rationality prediction values corresponding to the authorization strategies; and optimizing the authorization strategies according to the rationality prediction values corresponding to the authorization strategies. The invention also provides an authorization strategy optimization device. The authorization strategy optimization method and the authorization strategy optimization device are capable of generating the authorization strategy optimization model in real time to carrying out the rationality prediction on the authorization strategies, optimizing the authorization strategies by using recommended default authorization strategies and finely processing the optimization of the authorization strategies.

Owner:TENCENT TECH (SHENZHEN) CO LTD

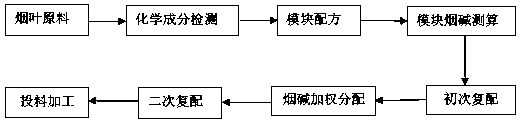

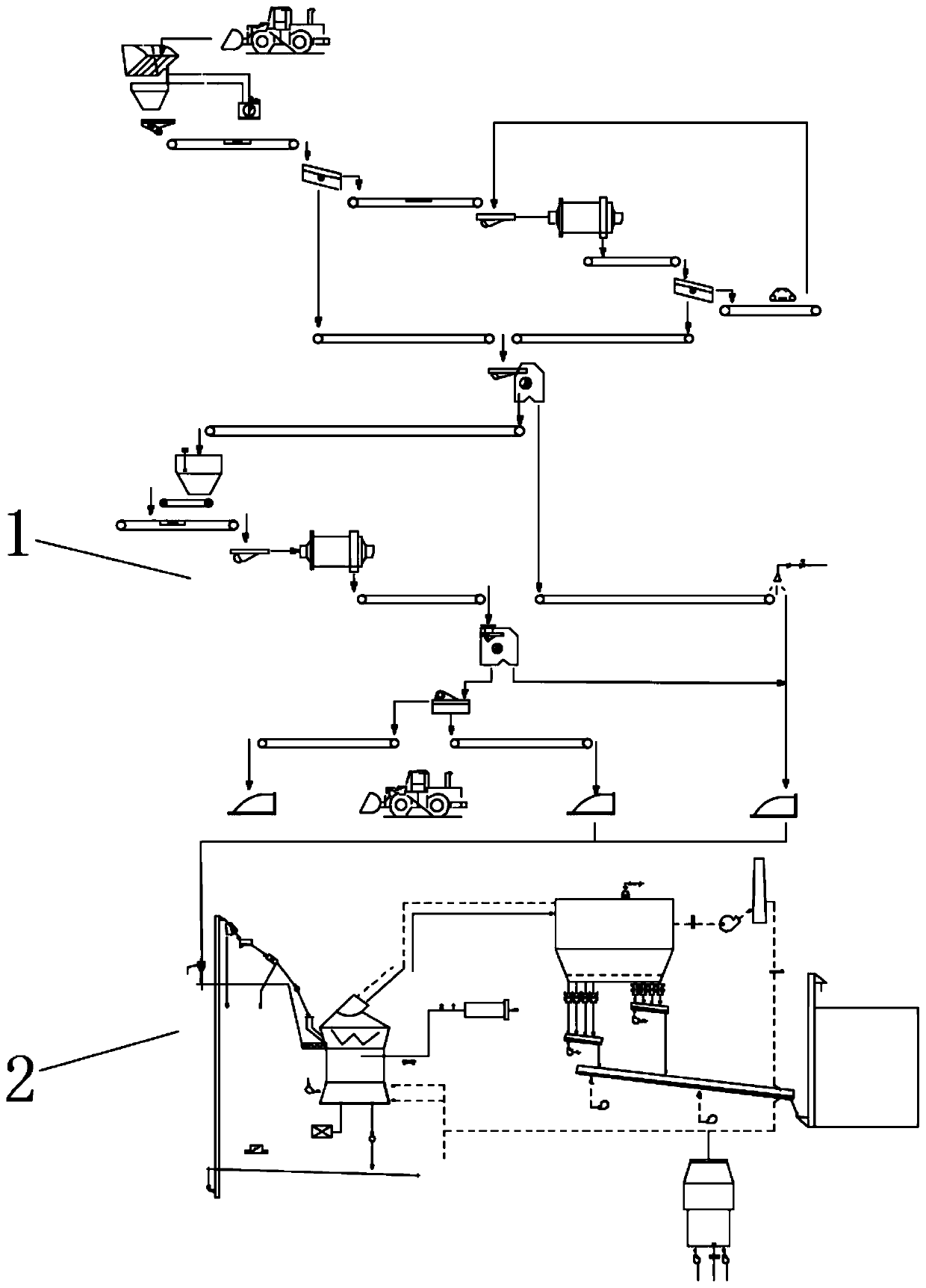

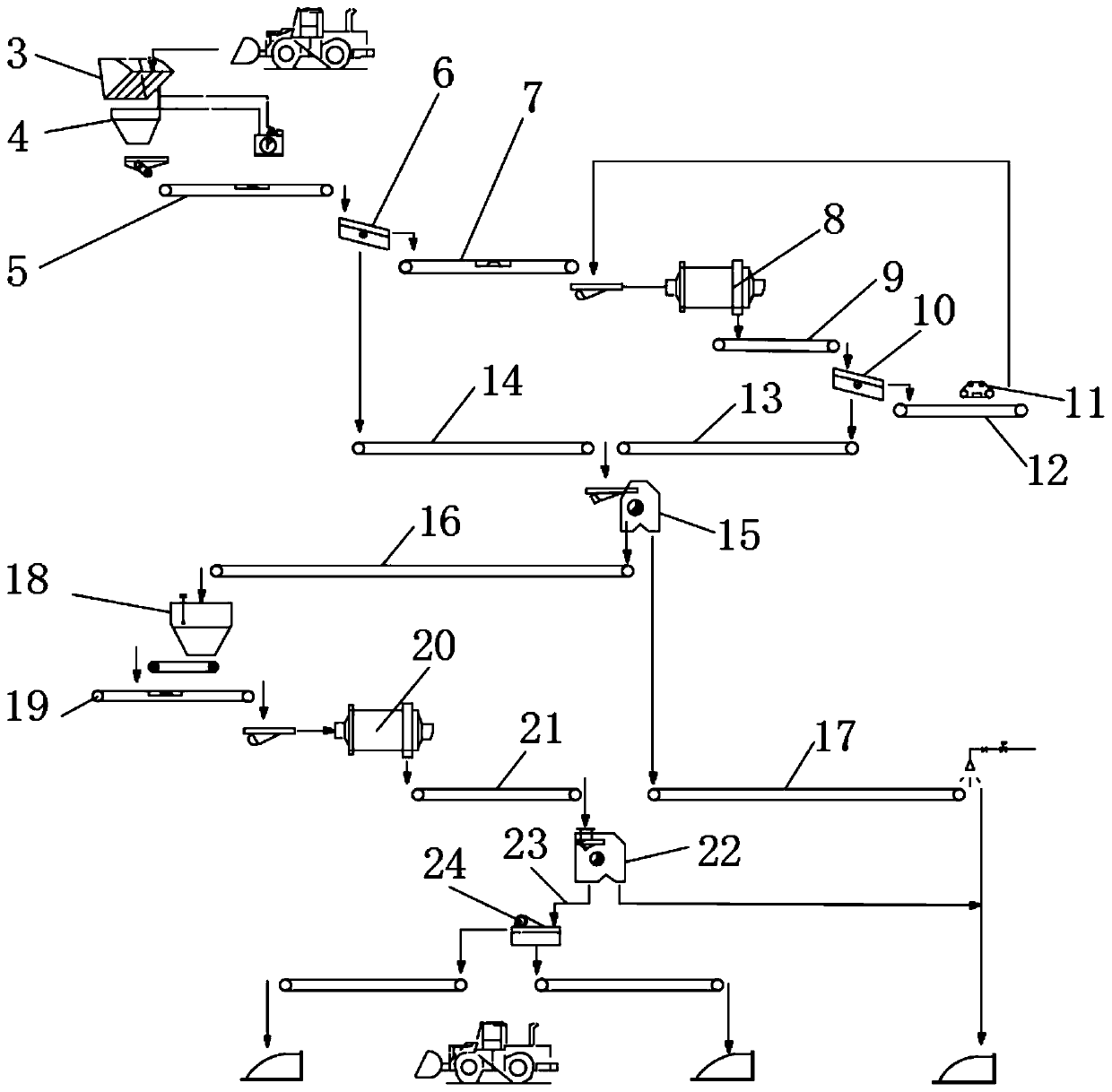

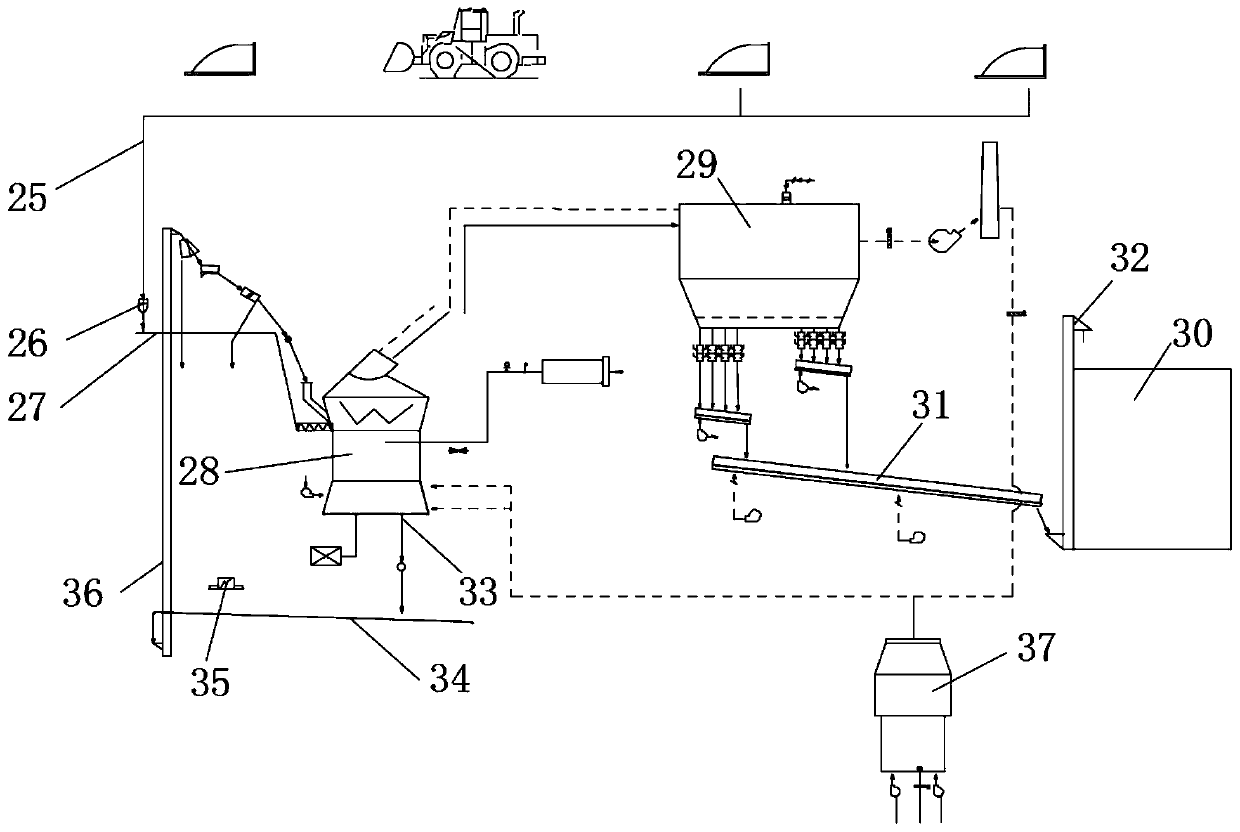

Multi-level tobacco leaf module threshing and re-baking feeding processing method

ActiveCN109077342AConsistent nicotine contentGuaranteed uniformityTobacco preparationChemical compositionSingle level

The invention relates to a multi-level tobacco leaf module threshing and re-baking feeding processing method, and belongs to the technical field of threshing and re-baking production. The object of the method is to solve the problems that after the processing of a threshing and re-baking conventional feeding processing mode of a multi-level tobacco leaf module formula, the variation coefficient offinished strip nicotine is large, and the processing mode of overhead storage feeding is limited by the number of tobacco leaf levels in the multi-level tobacco leaf module formula; the method is applicable to the multi-level tobacco leaf module formula composed of multi-level tobacco leaves with a number of more than 20 levels, according to chemical compositions and the module formula of single-level tobacco leaves in a formula module, and secondary compounding is conducted on the multi-level tobacco leaf module formula, so that the content of nicotine in each layer of tobacco leaves entering a pre-matching cabinet is even and stable; the method can be cooperated with threshing re-baking conventional feeding and overhead storage feeding modes to achieve the fine processing of the nicotine in the threshing and re-baking feeding tobacco leaves, the nicotine variation coefficient of the threshing and re-baking finished strips is greatly reduced, and the homogenization processing of thenicotine of the feeding tobacco leaves can be achieved.

Owner:HONGTA TOBACCO GRP

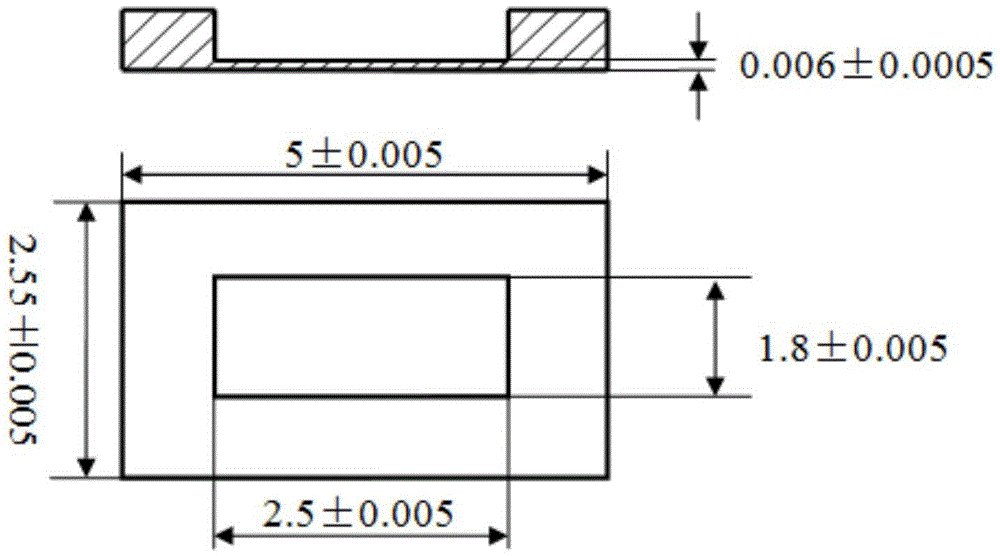

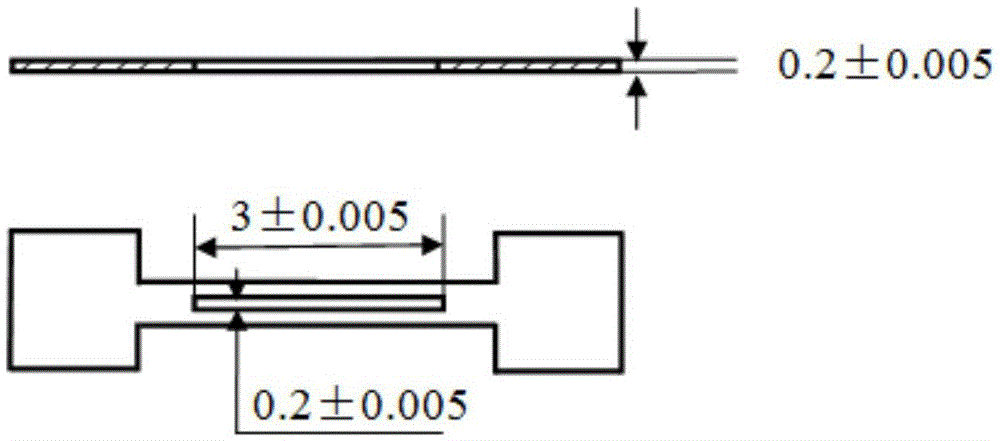

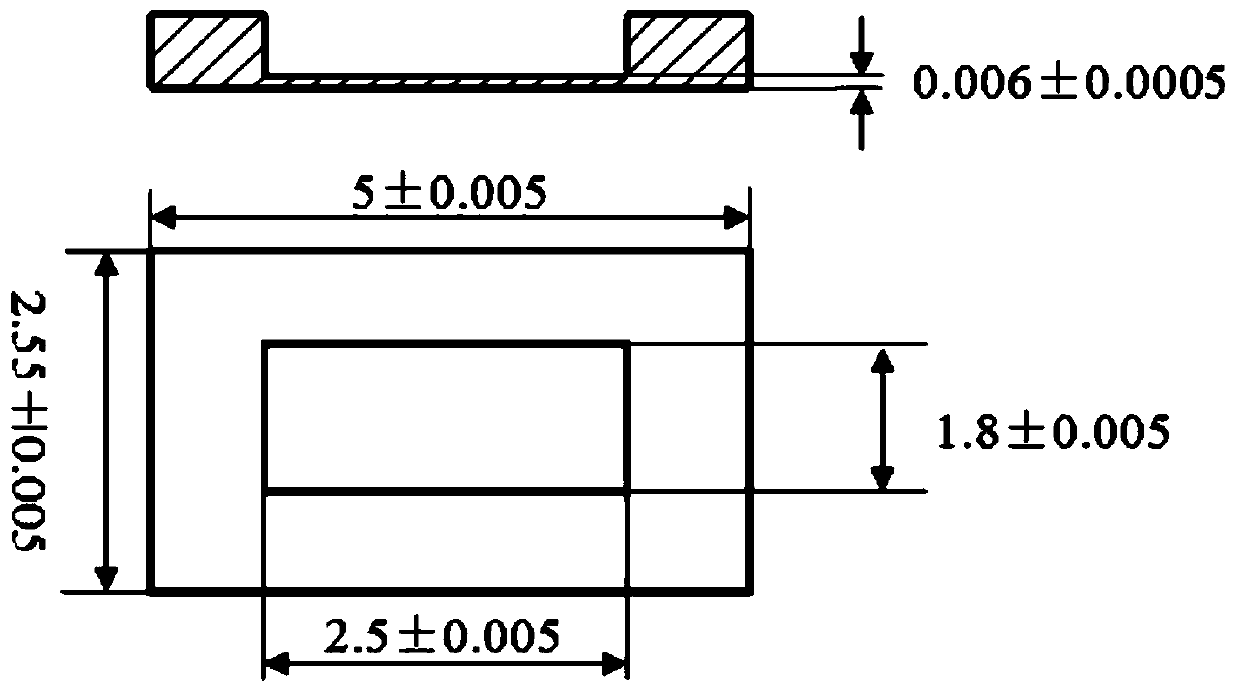

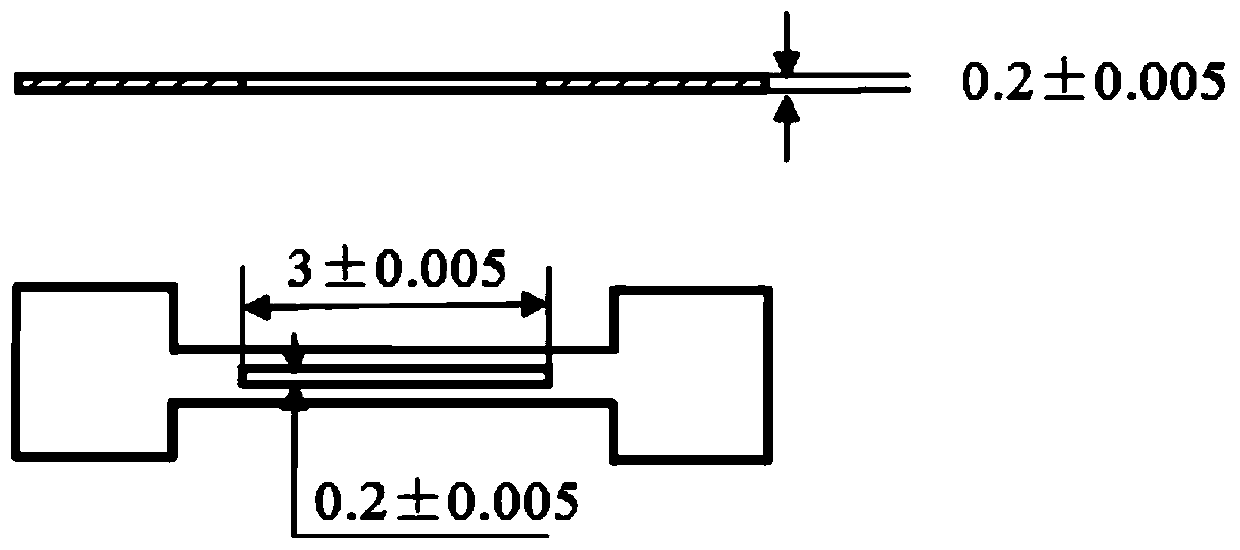

Laser ablation processing method for quartz crystal

ActiveCN105522281AAddress mechanical strength requirementsAddressing Accuracy RequirementsLaser beam welding apparatusMicrometerBase frequency

The invention discloses a laser ablation processing method for quartz crystal. The laser ablation processing method specifically comprises the steps of selecting lasers, preparing control software, designing processing drawings, carrying out laser ablation, carrying out post-processing treatment and carrying out detection. The method for processing the quartz crystal is designed on the basis of limitation to the condition of each step, the quartz crystal can be effectively processed for forming various shapes and can be thinned through the processing method, the thickness of the thinned quartz crystal is small, the corresponding base frequency is high, and the strength of the processed quartz crystal is high. In addition, the processing method is simple, the processing accuracy is high, and the processing dimensional accuracy of the quartz crystal can be controlled to be within the range of + / - 5 micrometers.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

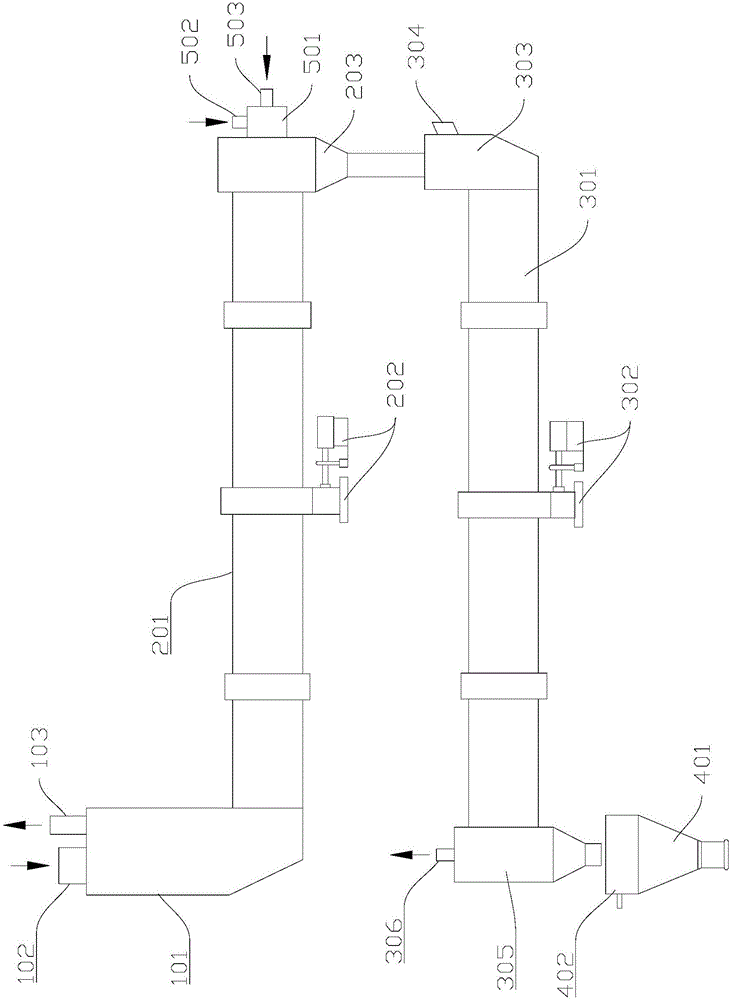

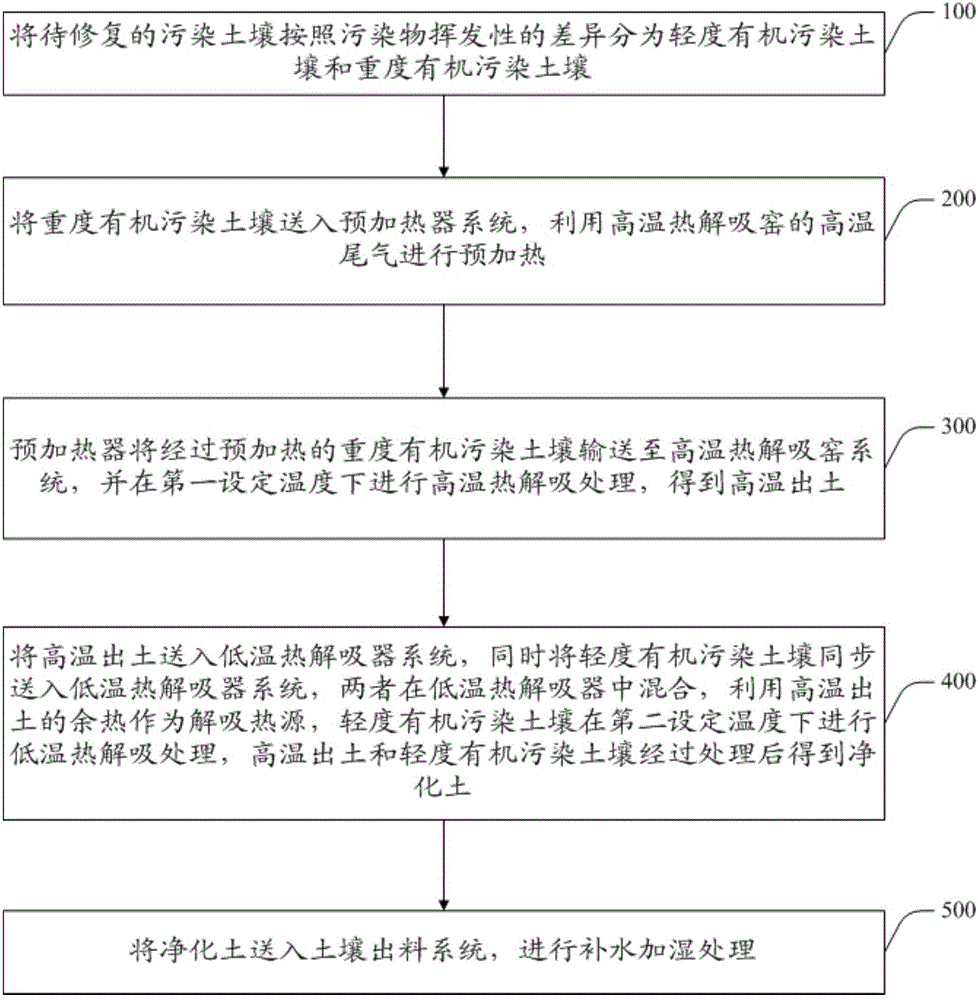

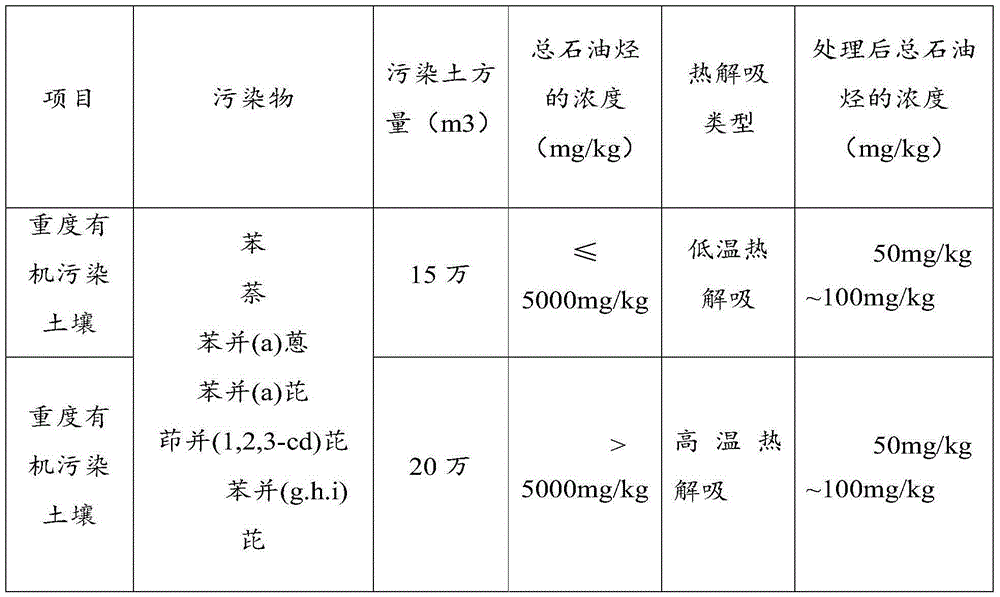

Classified thermal desorption repair system and technology of organic contaminated soil

ActiveCN105080958ARealize fine processingEfficient repairContaminated soil reclamationThermal energySoil remediation

The invention relates to the technical field of contaminated soil remediation, particularly to a classified thermal desorption repair system and technology of organic contaminated soil. The classified thermal desorption repair system of organic contaminated soil comprises a preheater system, a high-temperature thermal desorption kiln system, a low-temperature thermal desorption device system and a soil discharging system, wherein the preheater system, the high-temperature thermal desorption kiln system, the low-temperature thermal desorption device system and the soil discharging system are communicated in sequence. According to the classified thermal desorption repair system and technology of organic contaminated soil, the high-temperature tail gas generated by the high-temperature thermal desorption kiln system is fully used through arranging the preheater system, so that the use ratio of thermal energy is improved; organic contaminated soil with different degrees of contamination is treated through the high-temperature thermal desorption kiln system and the low-temperature thermal desorption device system, so that the energy consumption of thermal desorption treatment is greatly decreased, and the operation cost is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

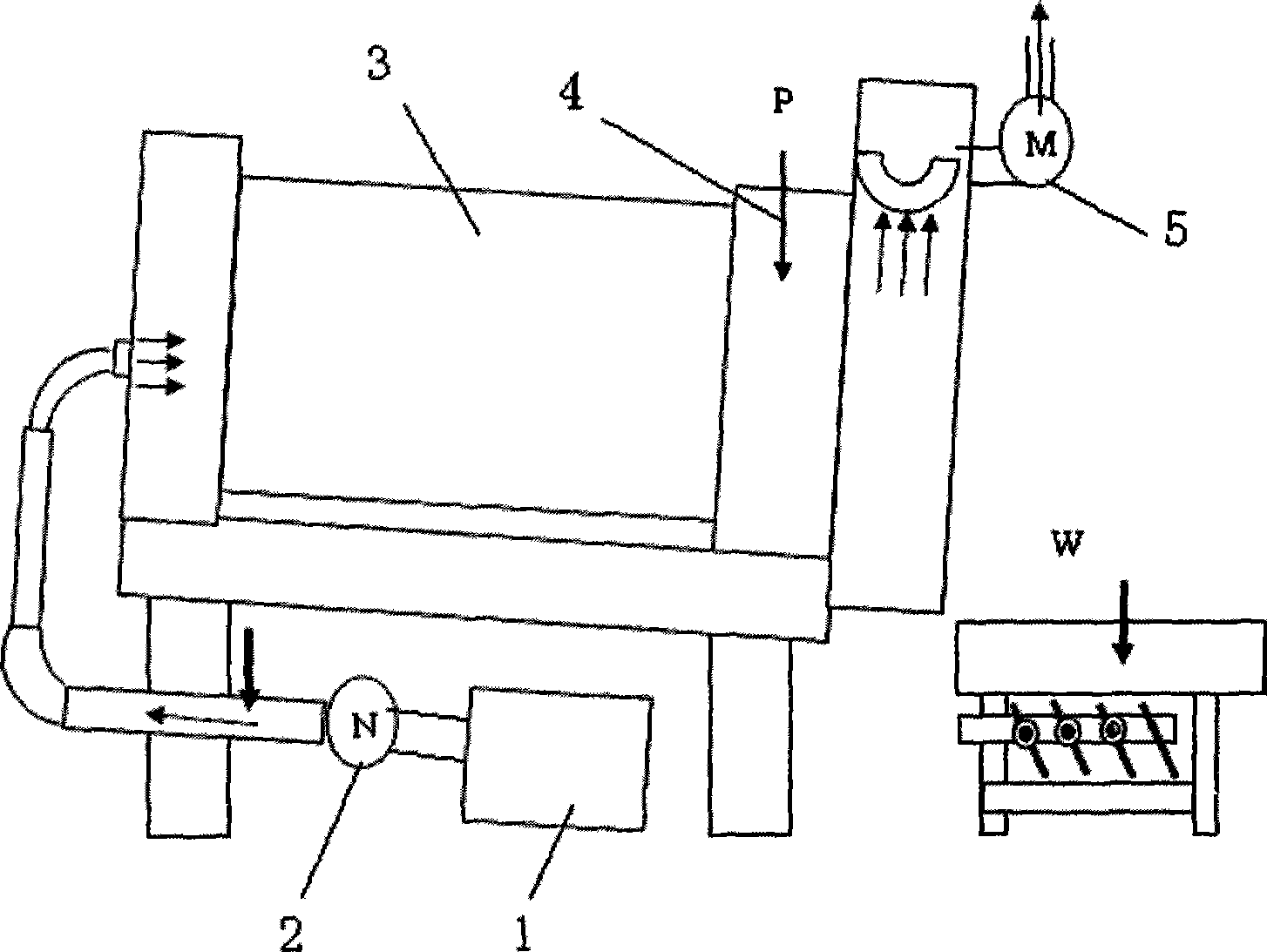

Method and device for carrying drum-type drying and accurate processing of tobacco shred

ActiveCN101480271AGuarantee normal and stable operationImprove stabilityTobacco preparationProduct processingAir volume

The invention discloses a method for drying tobacco shreds in a drum way and accurately processing the tobacco shreds. The discharging end of a drum cut-tobacco drier is provided with a pressure detector, firstly, corresponding drum wall temperature, hot air temperature T1, hot air amount N, and moisture removing opening M are set according to the processing characteristics of the cigarette, the preheating is started, and the tobacco shreds can be gone into production after the temperature in the drum reaches the set requirement; secondly, the tobacco shreds are gone into production, the steam consumption is tracked and regulated so as to enable the steam consumption to be quickly stabilized to the set requirement, material water W at a discharge port during the processing is on the low side and or the high side, the moisture removing opening M is quickly regulated and the change of internal pressure P is monitored, if the P value exceeds a certain limitation, the hot air amount N is tracked and regulated so as to enable the temperature of the drum wall to be stabilized to the requirement of the processing parameter of the product. The method can effectively improve the stability, the uniformity and the controllability of the drum drying processing of tobacco shreds, realizes the drying accurate processing of the tobacco shreds, and realizes that the device of the method has simple structure, convenient manufacture and reliable performance.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Preparation method of glucose/glutamic acid Maillard reaction flavor for cigarettes

ActiveCN104178345ARich smoke aromaImprove aromaTobacco preparationEssential-oils/perfumesBiotechnologyMaillard reaction

The invention relates to the technical field of flavors for cigarettes, and particularly discloses a preparation method of a glucose / glutamic acid Maillard reaction flavor for cigarettes, which is characterized in that by using glucose and glutamic acid as raw materials, the material ratio, reaction solvent, reaction time, reaction temperature and system pH are controlled, and the products are graded and separated to obtain the low-molecular-weight volatile product capable of effectively improving sensation quality of cigarettes and the high-molecular-weight product with the molecular weight of 3-6kD. The accurate control on the cigarette glucose / glutamic acid Maillard reaction process and the fine after-treatment on the products are performed to obtain the low-molecular volatile products with favorable cigarette perfuming effect and the high-molecular products, thereby implementing fine processing of glucose / glutamic acid Maillard reaction, and enhancing the application value of the reaction products in cigarette perfuming.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

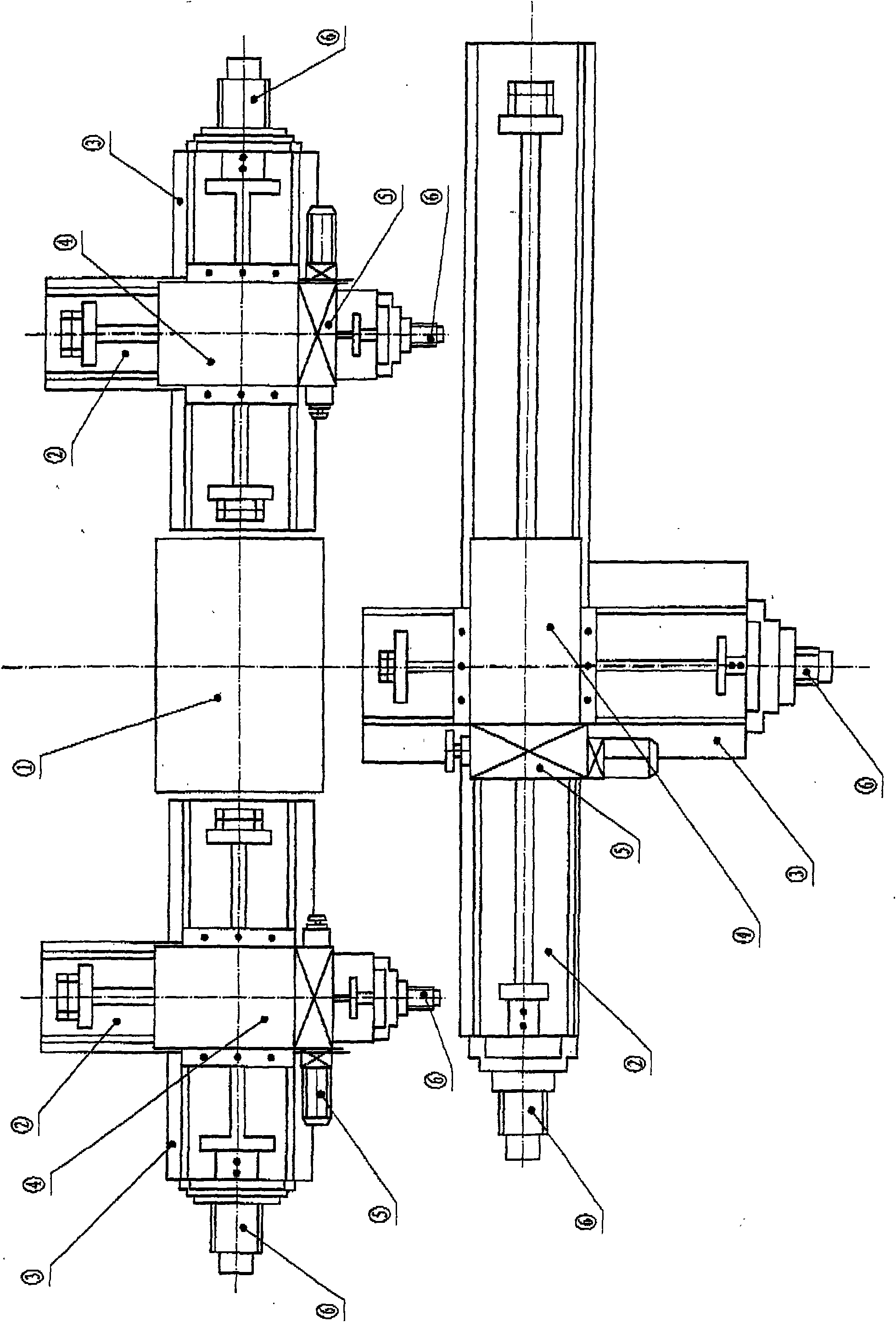

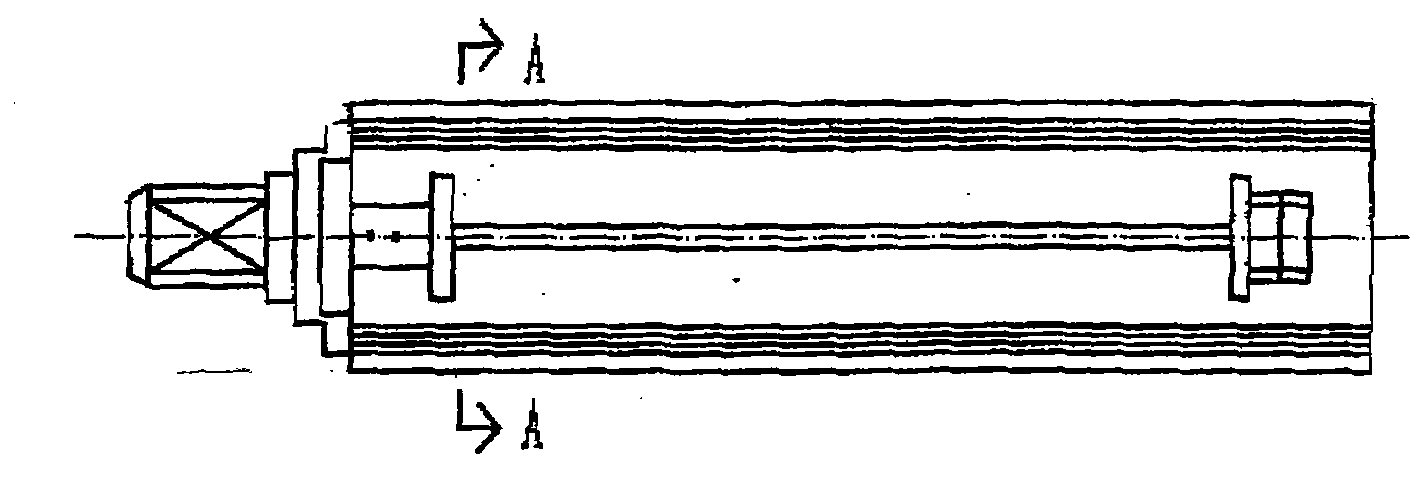

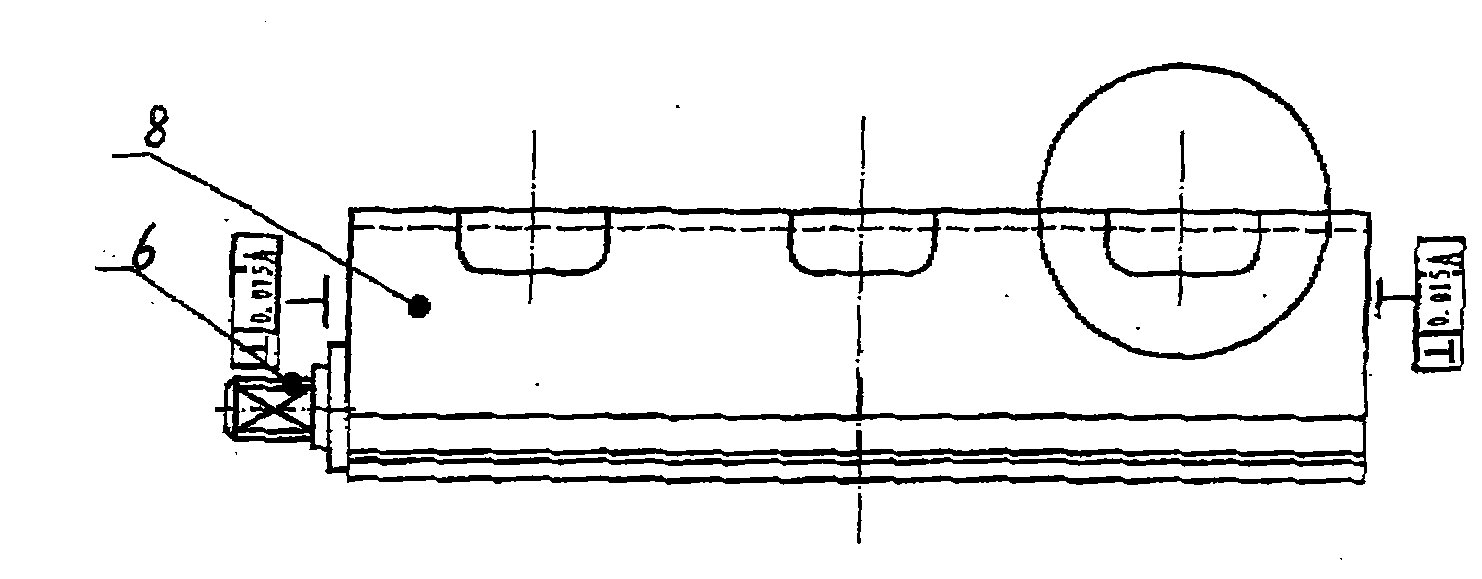

Digital control polyhedrical milling and drilling machine

InactiveCN101987417ARealize fine processingAchieve positioningOther manufacturing equipments/toolsLarge fixed membersEngineeringDigital control

The invention relates to a digital control polyhedrical milling and drilling machine. Left and right sides of a workbench are symmetrically provided with a set of milling and drilling mechanisms, and the rear part of the workbench is also provided with a set of milling and drilling mechanisms; each set of milling and drilling mechanisms comprises a base, a bearing plate, a stand column, a milling head and a driving device, wherein the bearing plate is installed on a guide rail of a machine bed and can slide along the guide rail; the stand column is installed on the guide rail of the bearing plate and on the base and can slide along the guide rail; the milling head is installed on the guide rail of the stand column and can slide along the guide rail; the machine bed is provided with the driving device capable of driving the bearing plate to move left and right; the bearing plate is provided with the driving device capable of driving the stand column to move forwards and backwards; and the stand column is provided with the driving device capable of driving the milling head to move up and down. The invention has the advantages of working forwards and backwards as well as left and right according to the size of a workpiece and synchronously carrying out milling and drilling processing on the workpiece and being capable of realizing locating and polyhedrical cutting of medium and large workpieces, therefore, fine processing of multi-dimensional curved surfaces of various products is realized.

Owner:天津晋华机床有限公司

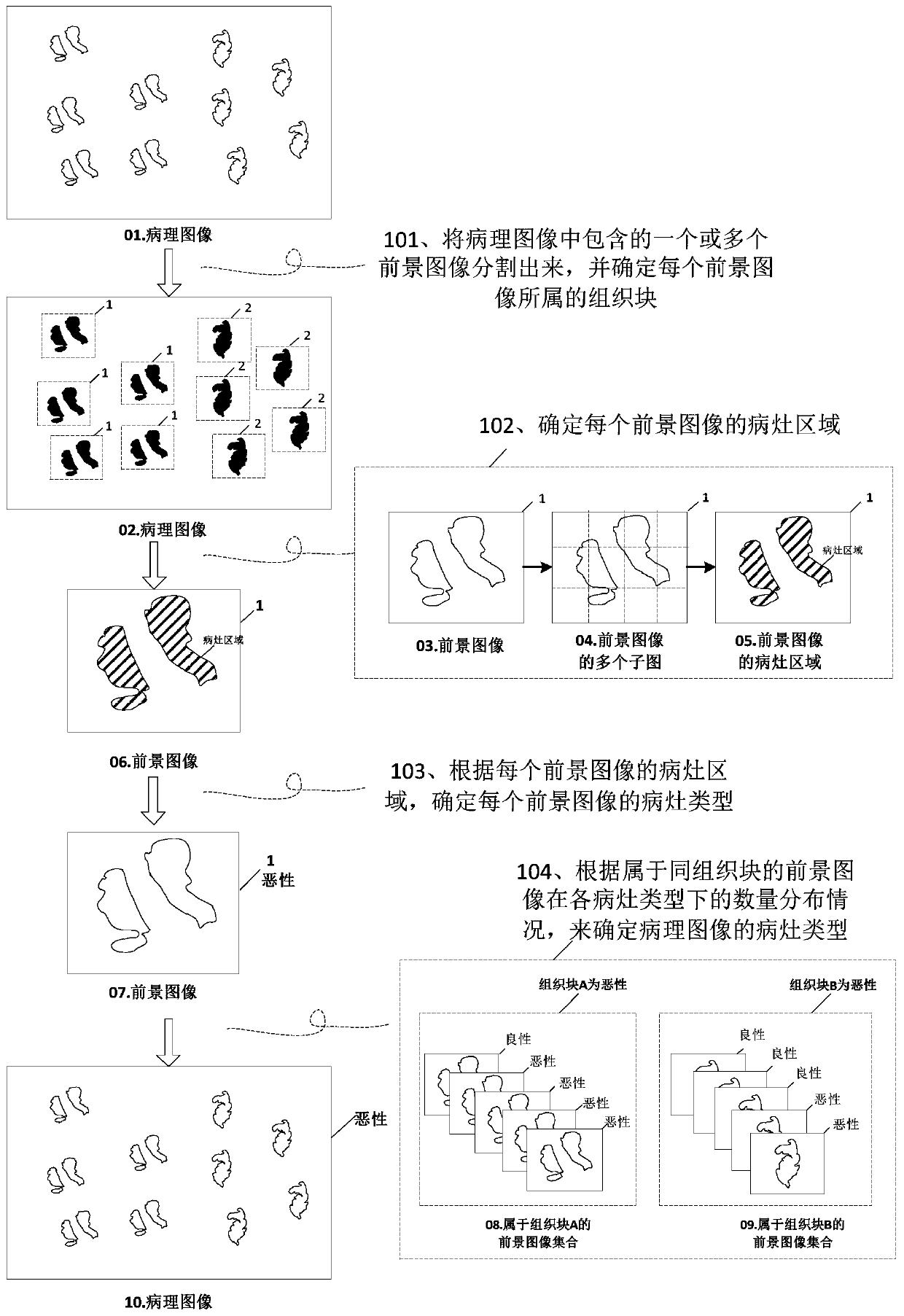

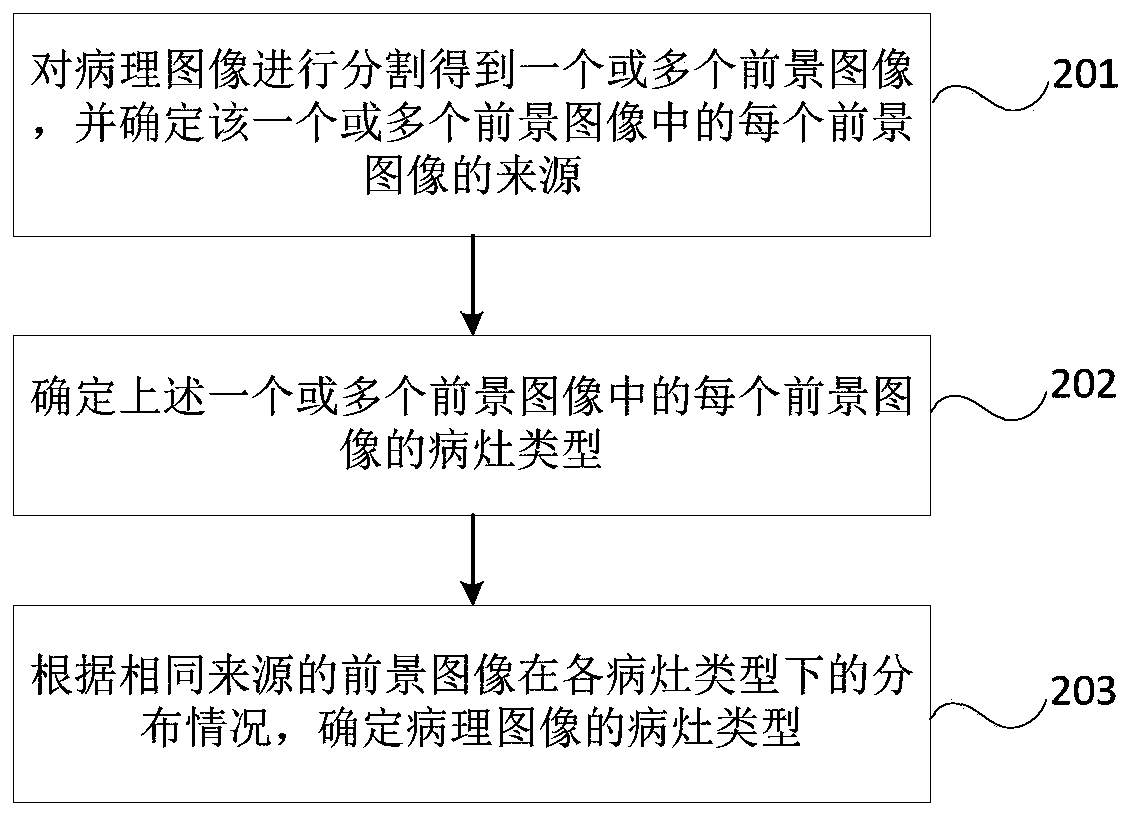

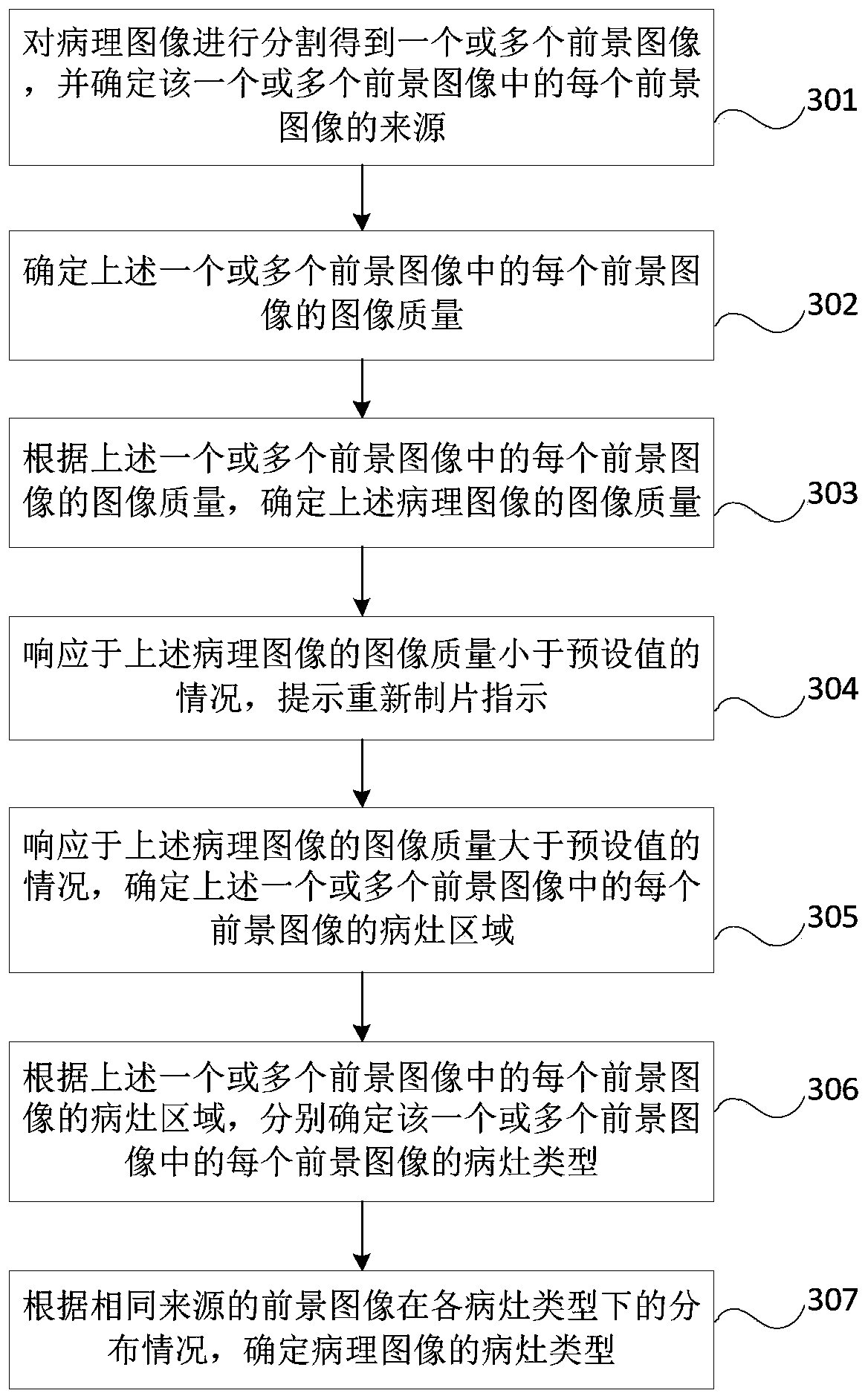

Image processing method and device and storage medium

The invention discloses an image processing method and device and a storage medium, and the method comprises the steps: carrying out the segmentation of a pathological image, obtaining one or more foreground images, and determining the source of each foreground image in the one or more foreground images; determining a focus type of each foreground image in the one or more foreground images; and determining the focus type of the pathological image according to the distribution condition of the foreground image with the same source under each focus type. The slice image of the tissue block, namely the foreground image, is segmented from the background in the pathological image. The focus type of the foreground image and the tissue block to which the foreground image belongs are determined, and then the focus type of the pathological image is determined according to the distribution condition of the foreground image belonging to the same tissue block under each focus type.

Owner:SHANGHAI SENSETIME INTELLIGENT TECH CO LTD

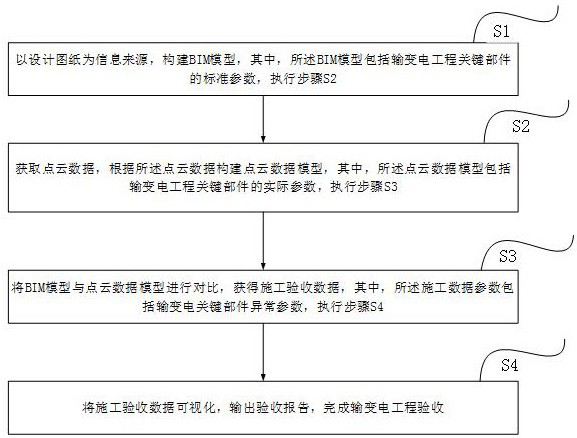

Power transmission and transformation project acceptance method based on BIM and point cloud measurement

PendingCN113538660ARapid completion acceptanceEfficient completion acceptanceImage enhancementImage analysisPoint cloudUncrewed vehicle

The invention relates to the technical field of power transmission and transformation project acceptance, in particular to a power transmission and transformation project acceptance method based on BIM and point cloud measurement. The method comprises the following steps: S1, building a BIM model with a design drawing as an information source, wherein the BIM model comprises standard parameters of key parts of a power transmission and transformation project; S2, acquiring point cloud data, and constructing a point cloud data model according to the point cloud data, wherein the point cloud data model comprises actual parameters of the key parts of the power transmission and transformation project; S3, comparing the BIM model with the point cloud data model to obtain construction acceptance data; and S4, visualizing the construction acceptance data, outputting an acceptance report, and completing the acceptance of the power transmission and transformation project. According to the power transmission and transformation project acceptance method based on the autonomous flight of unmanned aerial vehicles and three-dimensional laser point cloud, the BIM model and the point cloud data model are compared and analyzed, and rapid and efficient acceptance of the power transmission and transformation project is achieved.

Owner:国网江苏省电力有限公司建设分公司

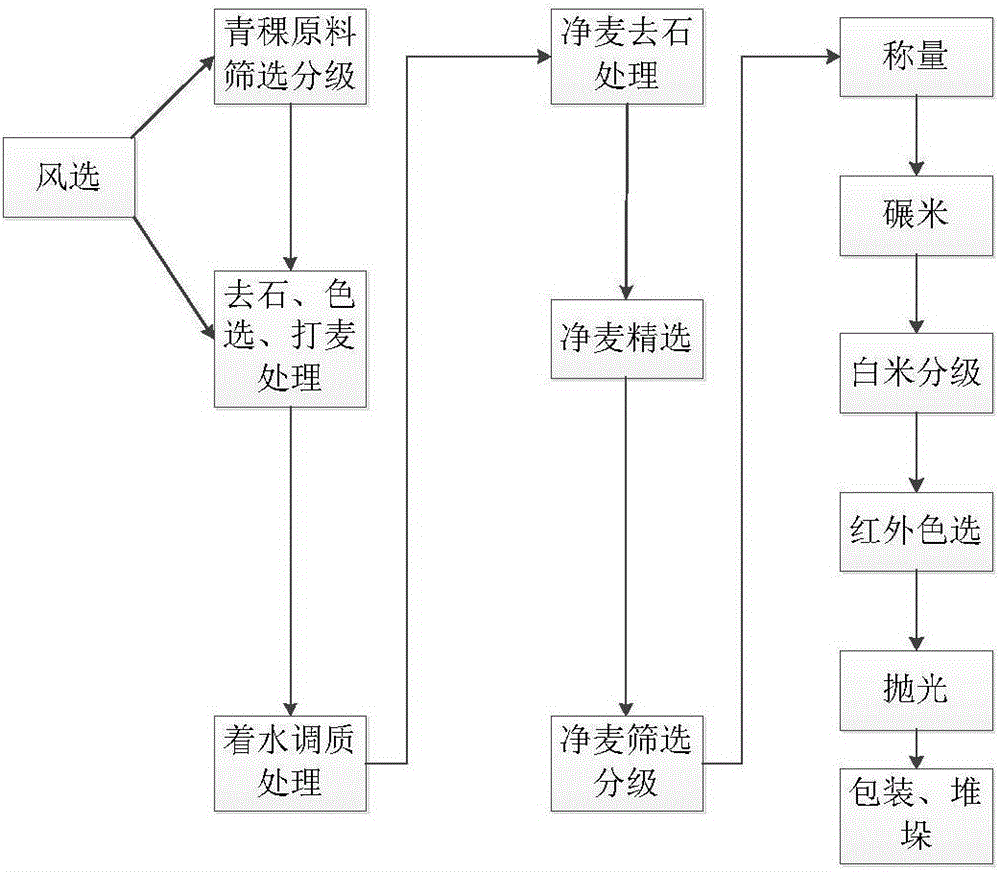

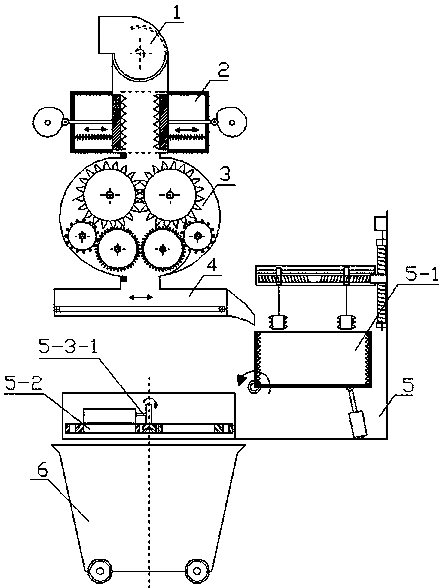

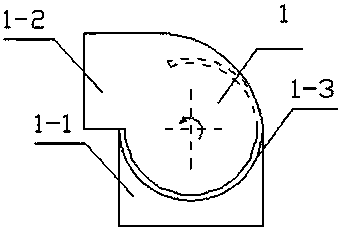

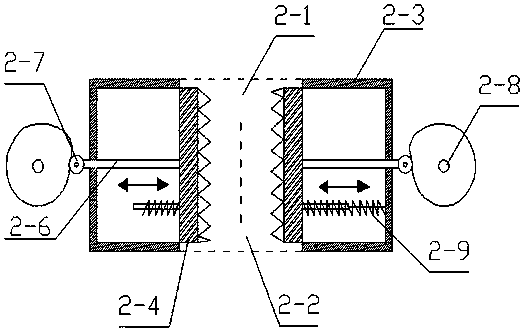

Highland barley processing technology

ActiveCN106000515AGuaranteed machining accuracyReduce broken rice rateGrain huskingGrain polishingBroken riceHygiene

The invention provides a highland barley processing technology which comprises a highland barley milling section. The technology is characterized by further comprising color sorting carried out on milled highland barley. A fine sorting function is added in the moisten highland barley cleaning process, and therefore foreign grains, incomplete grains, round beans and buckwheat can be separated out; in the highland barley milling section, four to seven emery rolls and one to two iron rolls are combined to work, the whole rice percentage can reach 80% and is improved by more than 10%, processing precision is ensured, the broken rice rate is reduced, and fine processing is achieved; before fine highland barley is packaged, color sorting for fine highland barely is increased, it is ensured that the product contains no impurity or incomplete grains such as immature grains, grains damaged by insects, spotted grains, mildew grains and brown rice grains, and food safety and dietetic hygiene are ensured; the finished product is automatically stacked after being packaged, the number of workers of enterprises is greatly reduced, the labor intensity is reduced, and mechanical work is achieved. All the working procedures can be completed through machines, and fine, large-scale and automatic production of highland barley can be achieved.

Owner:WUXI DADONG GRAIN ENG TECH CO LTD

Traditional Chinese medicinal material smashing device and using method thereof

InactiveCN108339598ARealize fine processingRealize fine crushingCleaning using toolsGrain treatmentsControl systemTraditional medicine

The invention provides a traditional Chinese medicinal material smashing device and a using method thereof. The traditional Chinese medicinal material smashing device comprises a traditional Chinese medicinal material putting device, a traditional Chinese medicinal material first-stage crushing device, a traditional Chinese medicinal material second-stage crushing device, a transmission device, atraditional Chinese medicinal material refined crushing device, another transmission device and a control system. Through carrying out first-stage crushing, second-stage crushing and refined crushingoperation on the traditional Chinese medicinal material, the traditional Chinese medicinal material smashing device and the using method realize intelligent and refined treatment on the traditional Chinese medicinal material, are simple in technology and convenient to operate, easily realize large-scale treatment and realize efficient and refined crushing to the traditional Chinese medicinal material.

Owner:张清华

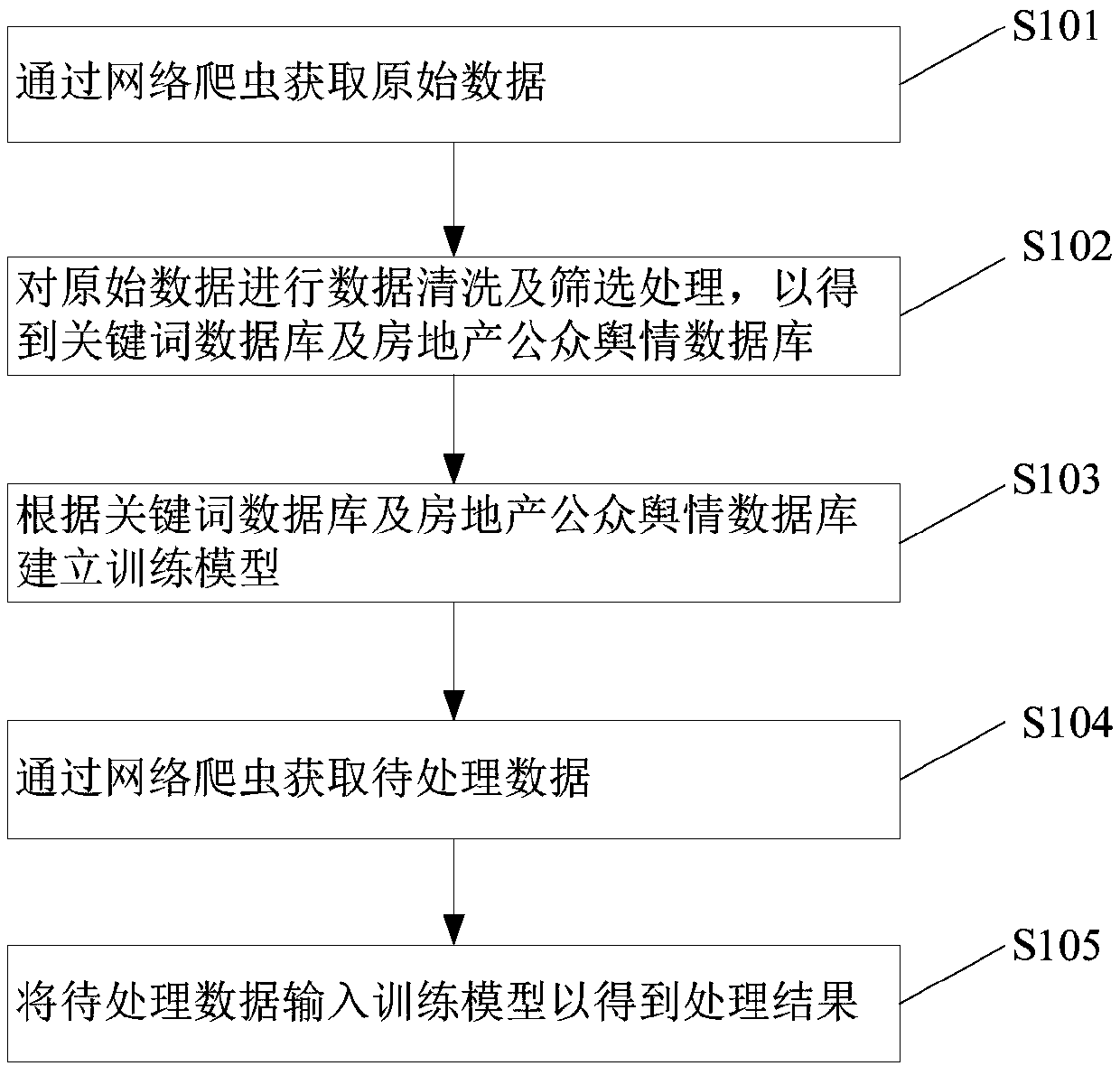

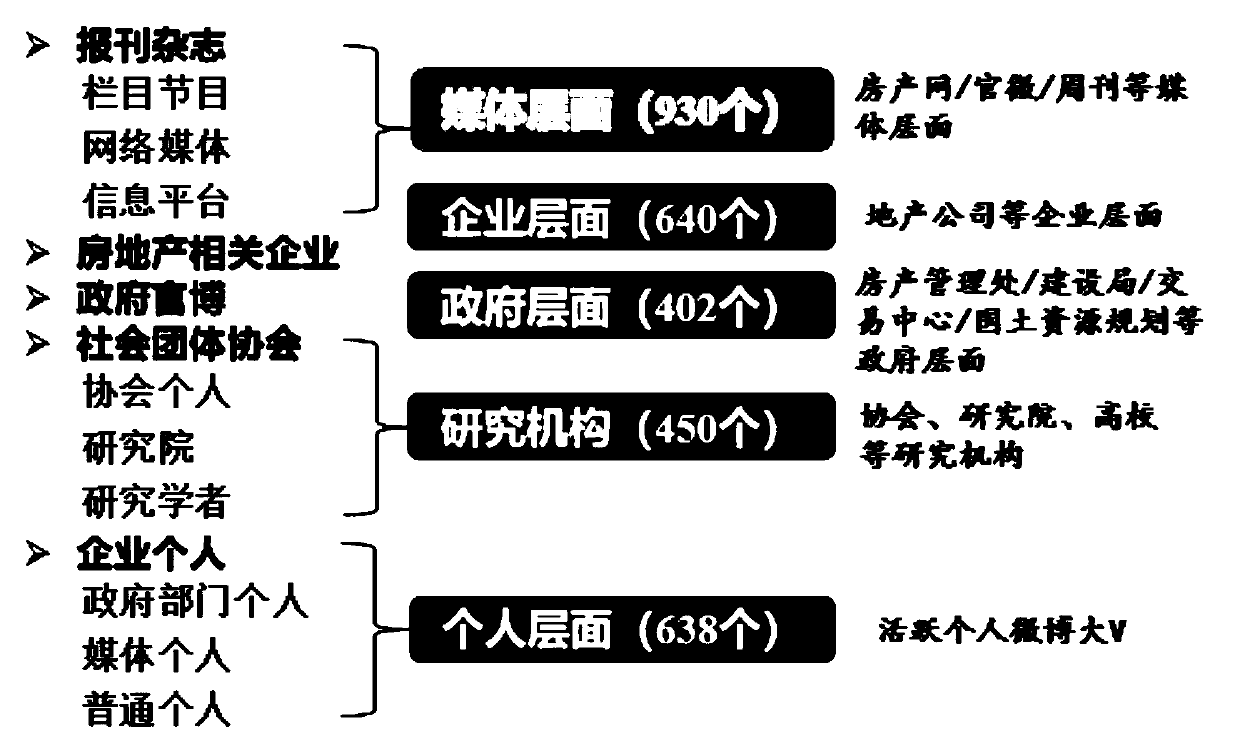

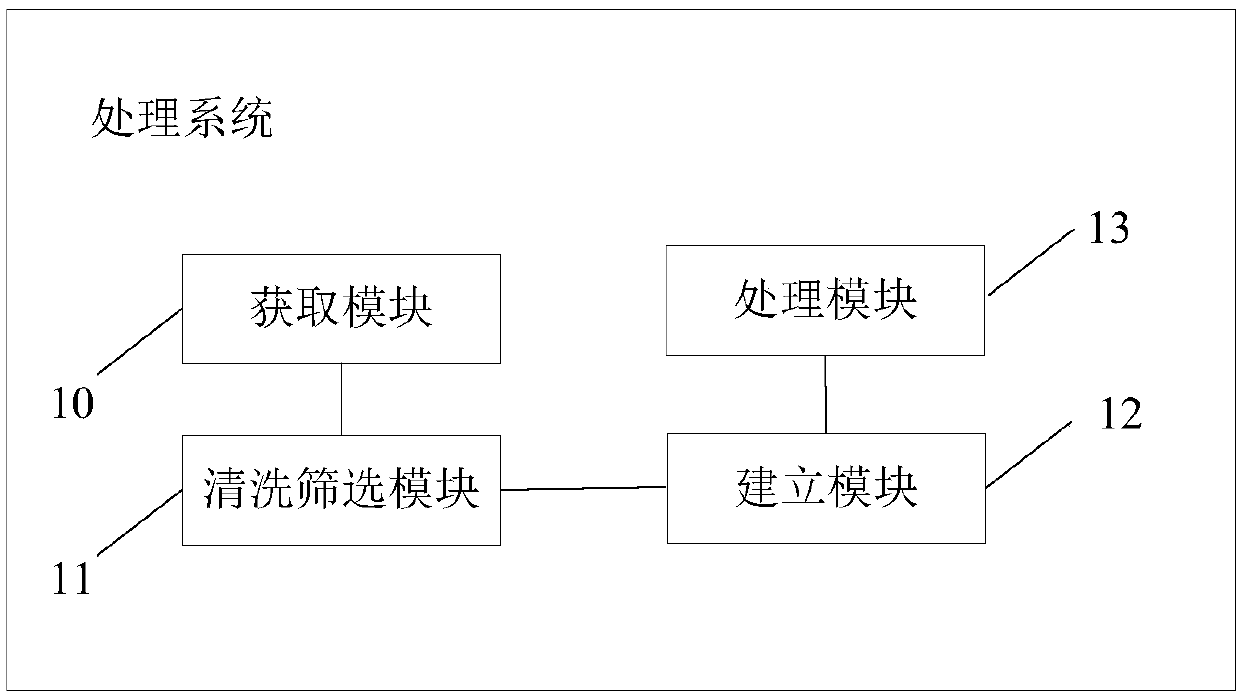

Big-data processing method and system based on real-estate industry

ActiveCN108509492ARealize fine processingGuaranteed accuracyData processing applicationsData miningOriginal dataEngineering

The embodiment of the invention discloses a big-data processing method and system based on a real-estate industry. The method includes: obtaining raw data through a web crawler; carrying out data cleaning and screening processing on the raw data to obtain a keyword database and a real-estate public-sentiment database; establishing a training model according to the keyword database and the real-estate public-sentiment database; obtaining to-be-processed data through the web crawler; and inputting the to-be-processed data to the training model to obtain a processing result. By implementing the embodiment of the invention, refinement processing on the data is realized, and a guarantee is provided for accuracy of subsequent real-estate industry expectation based on the data.

Owner:郑长敬

Air conditioner indoor unit panel manufacturing surface fine treatment method

ActiveCN111421430AImprove machining accuracyImprove processing efficiencyGrinding drivesHeating and ventilation casings/coversHydraulic cylinderGear wheel

The invention relates to the field of production and machining, in particular to an air conditioner indoor unit panel manufacturing surface fine treatment method. According to the method, a polishingtreatment device is used, the polishing treatment device comprises a support, an operation table and a polishing belt, wherein first hydraulic cylinders are symmetrically and fixedly connected in thesupport, a T-shaped supporting frame is fixedly connected to the top of the operation table, second hydraulic cylinders are symmetrically and fixedly connected to the two sides of the supporting frame, adjusting walls are fixedly connected to the output ends of the second hydraulic cylinders, first sliding grooves are formed in the adjusting walls, first sliding blocks are inserted into the firstsliding grooves, clamping arms are fixedly connected to the corresponding ends of the first sliding blocks, the ends, away from the clamping arms, of the first sliding blocks are fixedly connected with first rotating motors of a double-shaft structure, one ends of the first rotating motors are fixedly connected with first gears, one sides of the adjusting walls are fixedly connected with limitinggrooves, and tooth grooves are formed in the limiting grooves. The method is convenient to operate, good in fine treatment effect and suitable for popularization.

Owner:中山市有信新材料有限公司

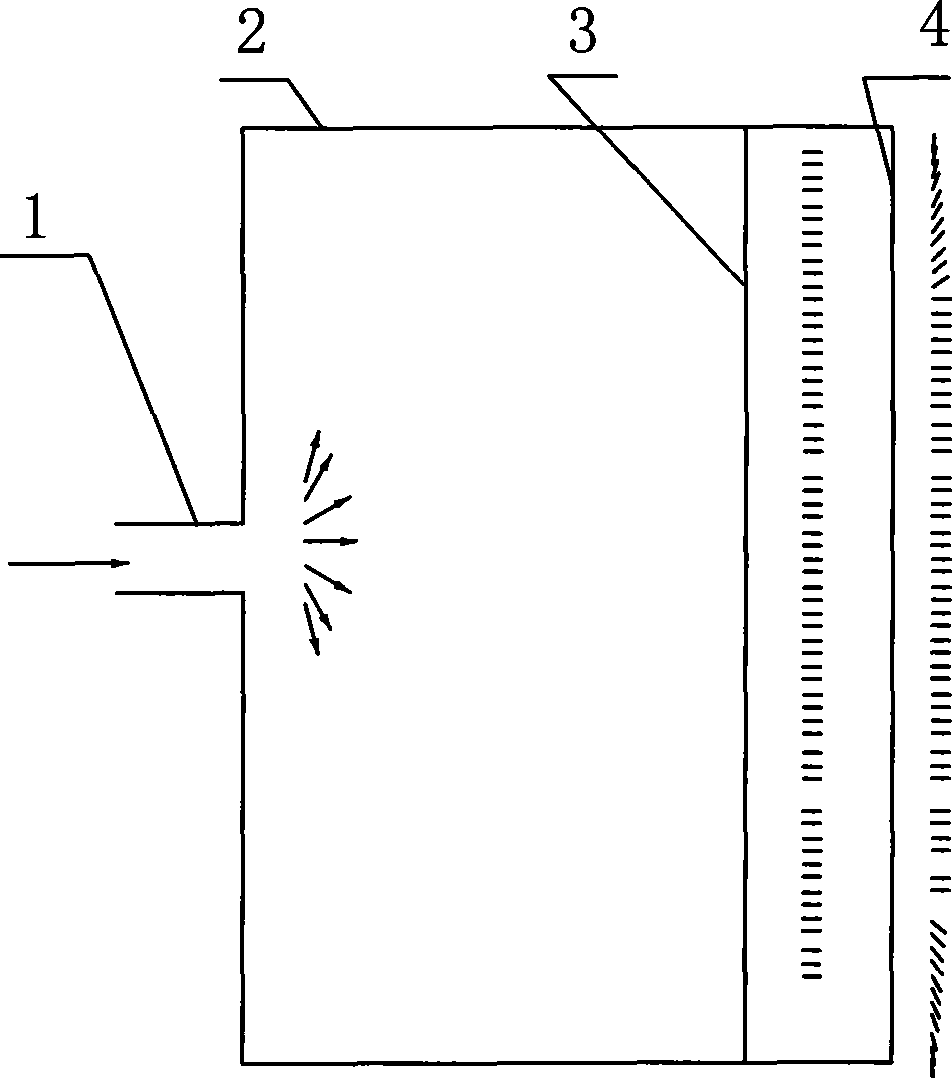

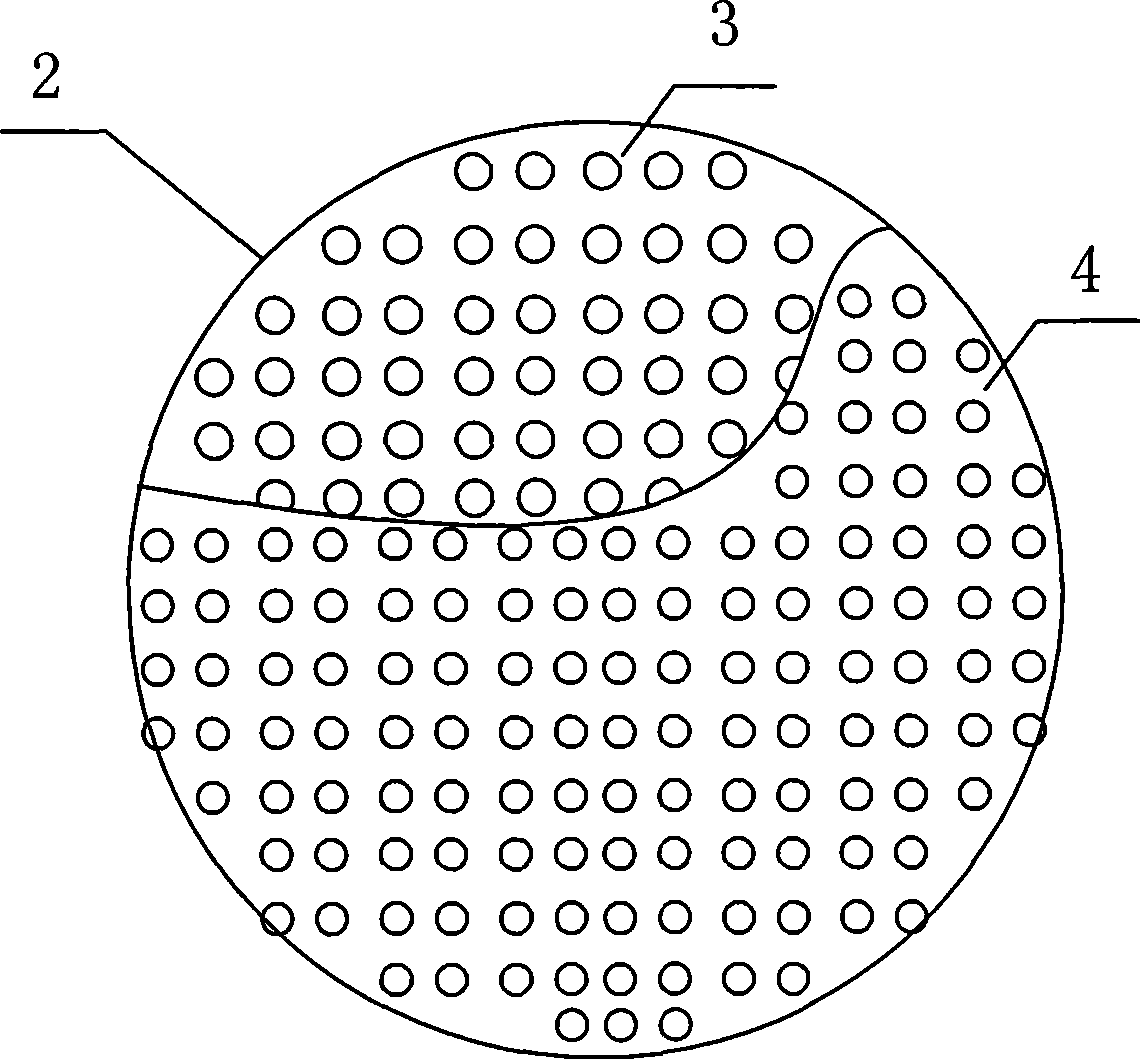

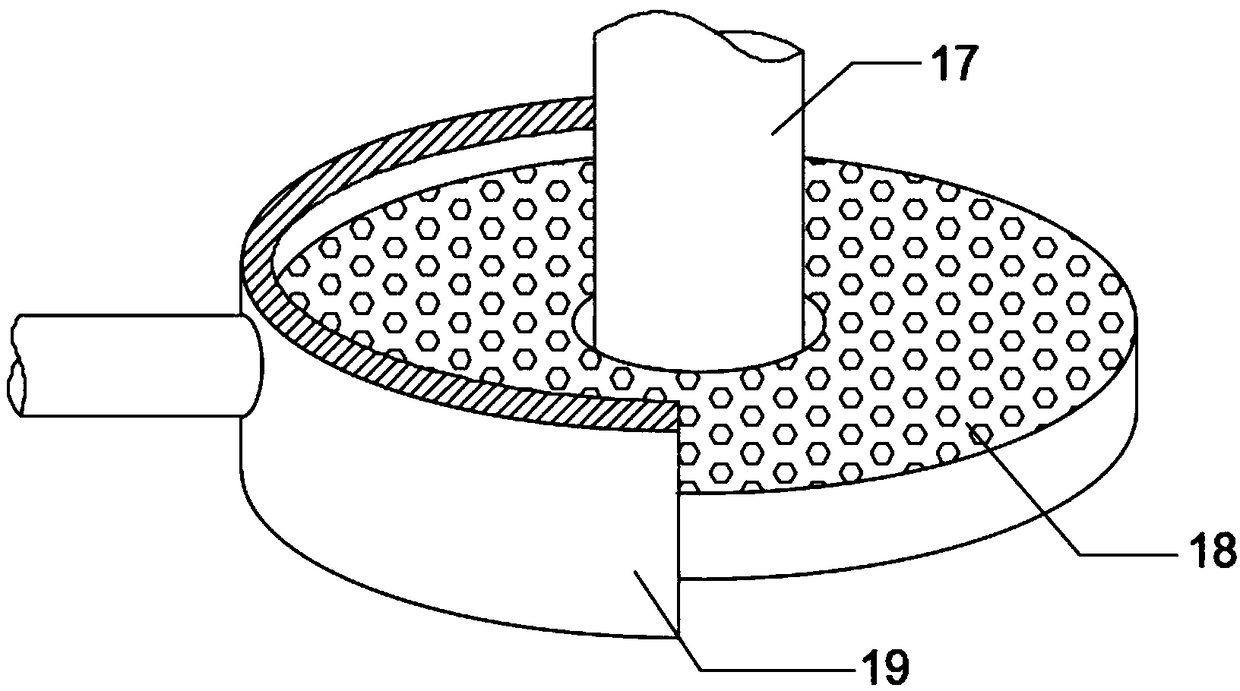

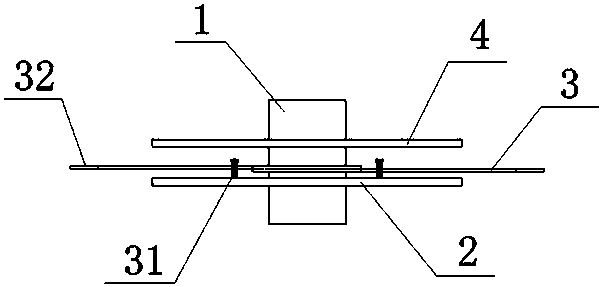

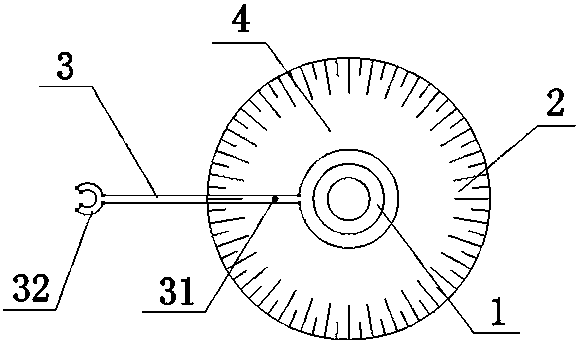

Low-flow speed steam nozzle for processing tobacco

The invention discloses a low flow speed steam nozzle for tobacco processing, which comprises a steam pipeline (1), wherein the steam pipeline (1) is connected with a straight cylinder type nozzle (2) of which the diameter is multiple times larger than that of the steam pipeline (1); and the outer layer of an outlet of the straight cylinder type nozzle (2) is provided with a second level mesh choke plate (4), the inner layer thereof is provided with a first level mesh choke plate (3), the aperture of meshes on the first level mesh choke plate (3) is larger than that of the meshes on the second level mesh choke plate (4), and the number of the meshes on the second level mesh choke plate (4) is more than that of the meshes on the first level mesh choke plate (3). The low flow speed steam nozzle for tobacco processing can achieve loosening and dampening precision processing of tobacco flakes in a common loosening and dampening machine, can effectively improve the stability and evenness of the loosening and dampening precision processing of the tobacco flakes, and achieve the fine processing of tobacco leaves; besides, the low flow speed steam nozzle has the advantages of simple structure, convenient manufacture and reliable performance.

Owner:CHINA TOBACCO HUNAN INDAL CORP

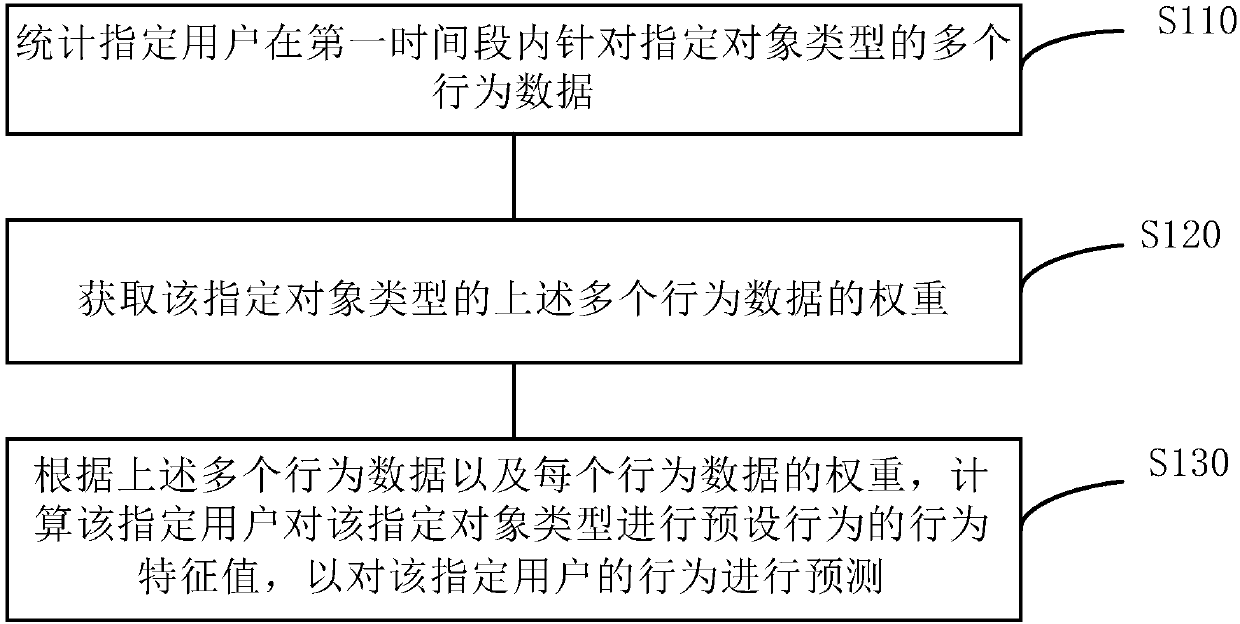

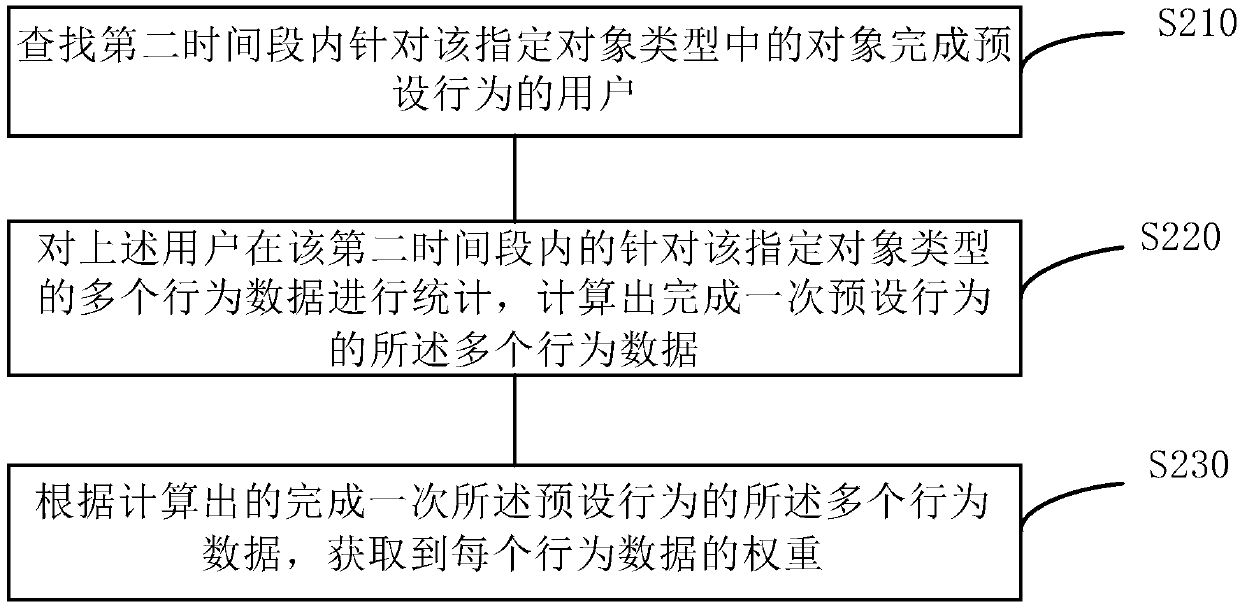

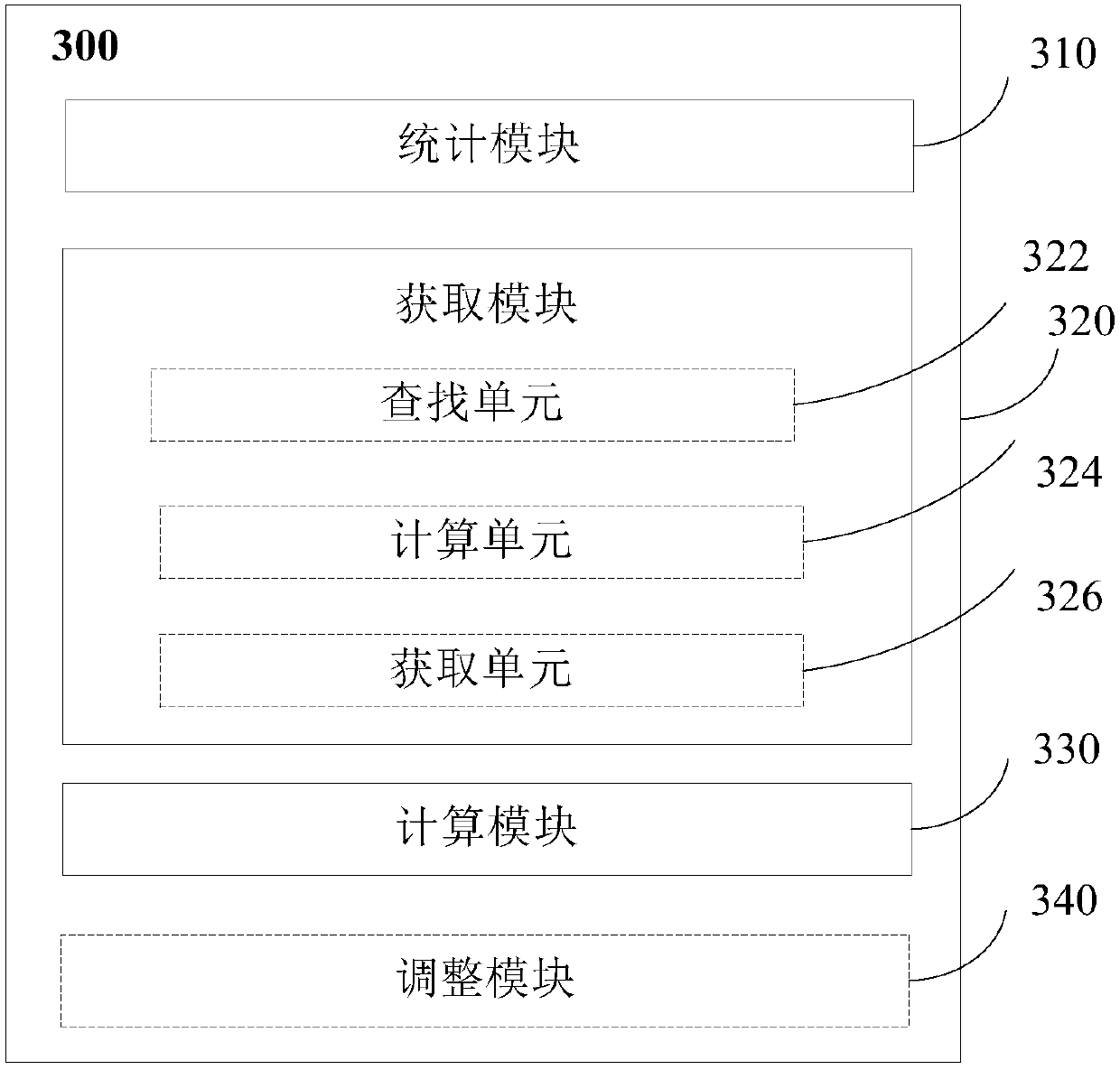

Behavior data processing method and device and electronic equipment

ActiveCN107741967ARealize fine processingSpecial data processing applicationsMarket data gatheringSimulationData mining

The invention discloses a behavior data processing method and device and electronic equipment. The method comprises the steps that by counting a plurality of behavior data of a specified user on a specified object type in a first time period through statistics, the weights of the behavior data of the specified object type are obtained; according to the behavior data and the weight of each behaviordata, the behavior characteristic value of a preset behavior of the specified user on the specified object type is calculated, so that the behavior of the specified user is predicted, and the behavior data can be finely processed by means of the weight of the behavior data; moreover, the behavior of the user can be predicted through the weight of the behavior data and the behavior data.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

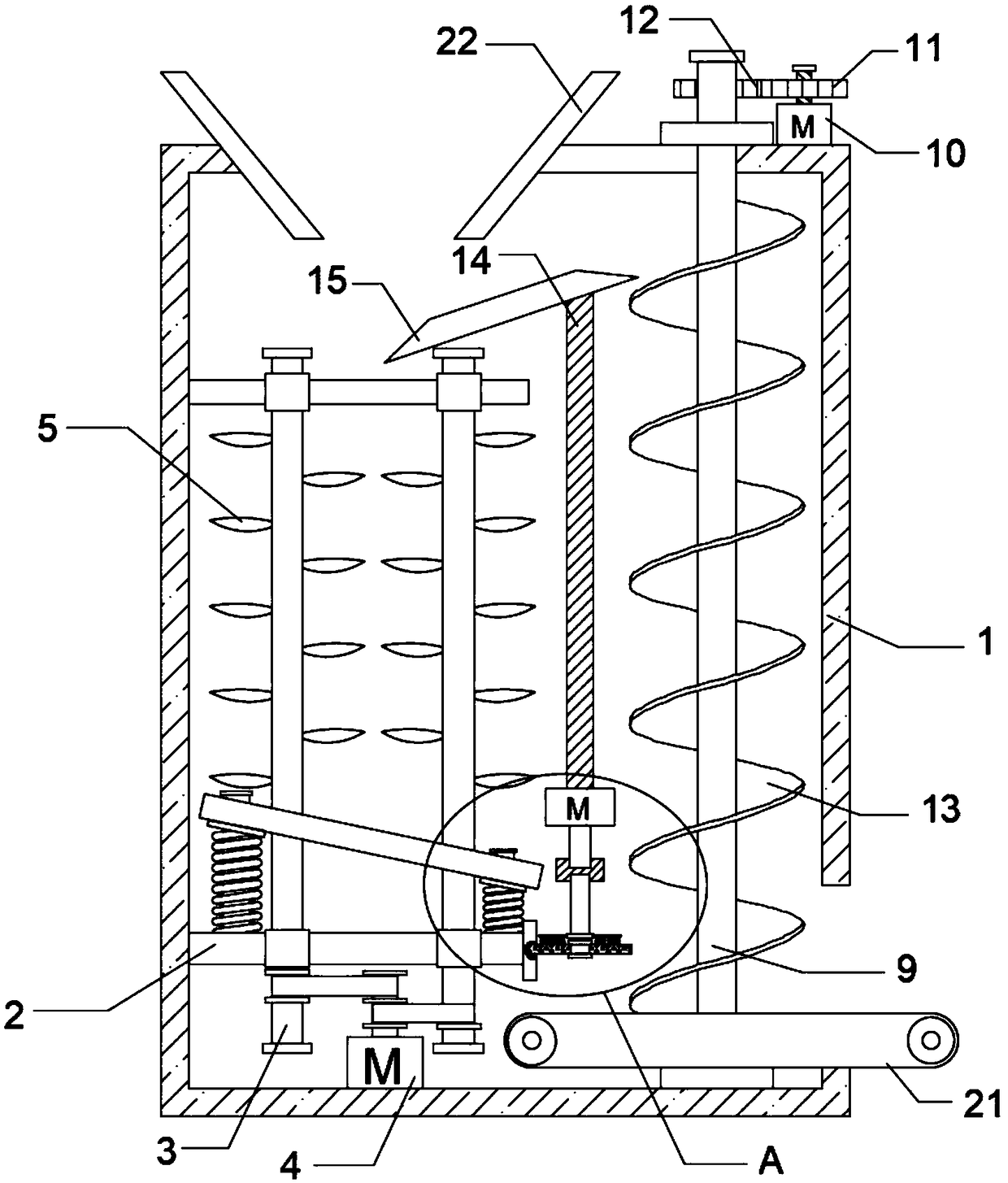

Cherry pedicle-removing and stoning device

InactiveCN109907331ARealize fine processingImprove processing efficiencyFruit stoningFood treatmentScrew conveyorEngineering

The invention relates to a cherry pedicle-removing and stoning device which comprises a rack. A transporting mechanism, a centralizing mechanism, a pedicle-removing mechanism, a stoning mechanism anda screening mechanism are mounted in the rack, the transporting mechanism has multiple placement grooves, a leaking hole is formed in the bottom of each placement groove, the centralizing mechanism ismounted at a feeding port of the rack and comprises a rotatable conjugated rotating screw conveyor and a hairbrush, the pedicle-removing mechanism is mounted above the transporting mechanism and comprises two pedicle-removing plate mechanisms capable of utilizing a clamping driving mechanism to be in opposite or away motion, each pedicle-removing plate mechanism is provided with multiple pedicle-removing plates, the pedicle-removing plates of the pedicle-removing plate mechanisms are in staggered distribution, and the pedicle-removing plate mechanisms are connected with a lifting mechanism; afixing plate is fixed on the rack, the stoning mechanism is mounted above the transporting mechanism and has multiple punch needles matched with the placement grooves in position and connected with astoning driving mechanism, and the screening mechanism is mounted below the transporting mechanism. The cherry pedicle-removing and stoning device is high in working efficiency and low in labor intensity.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

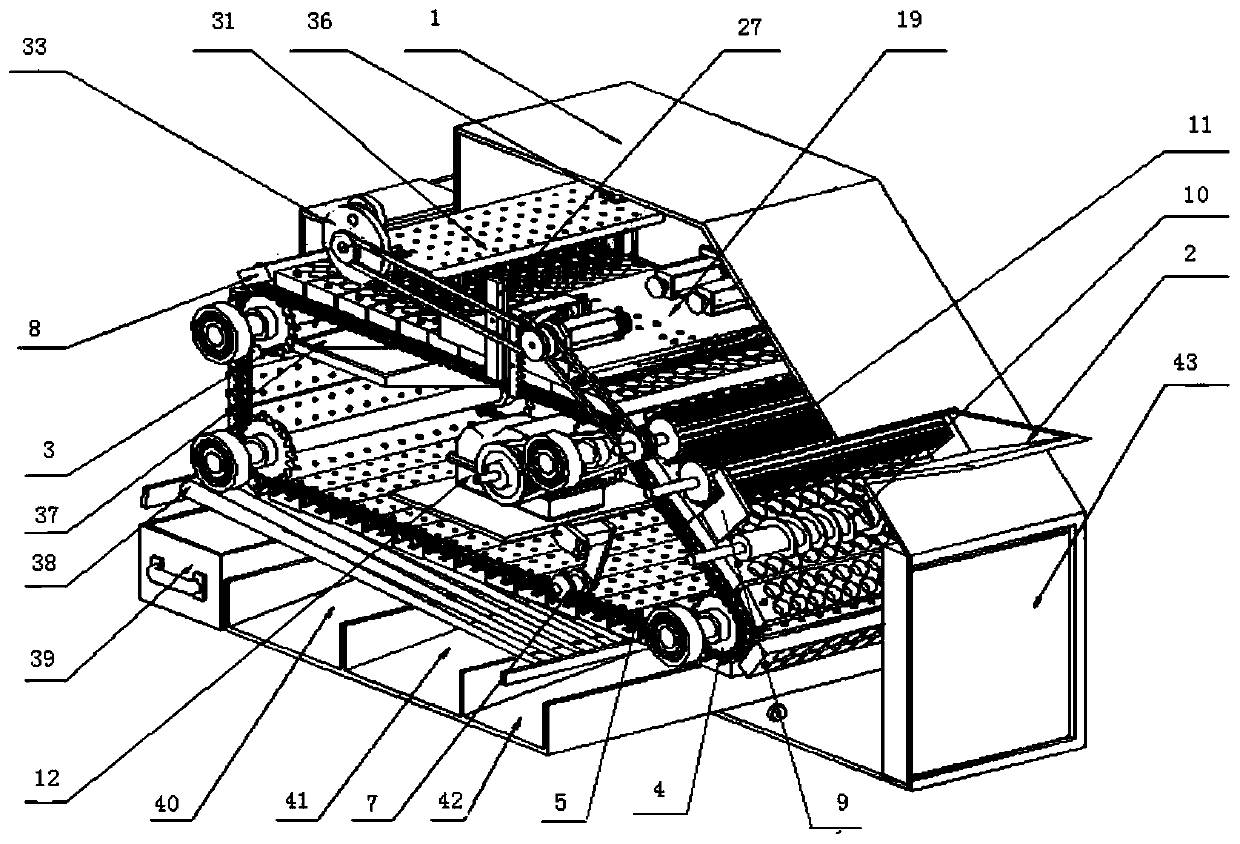

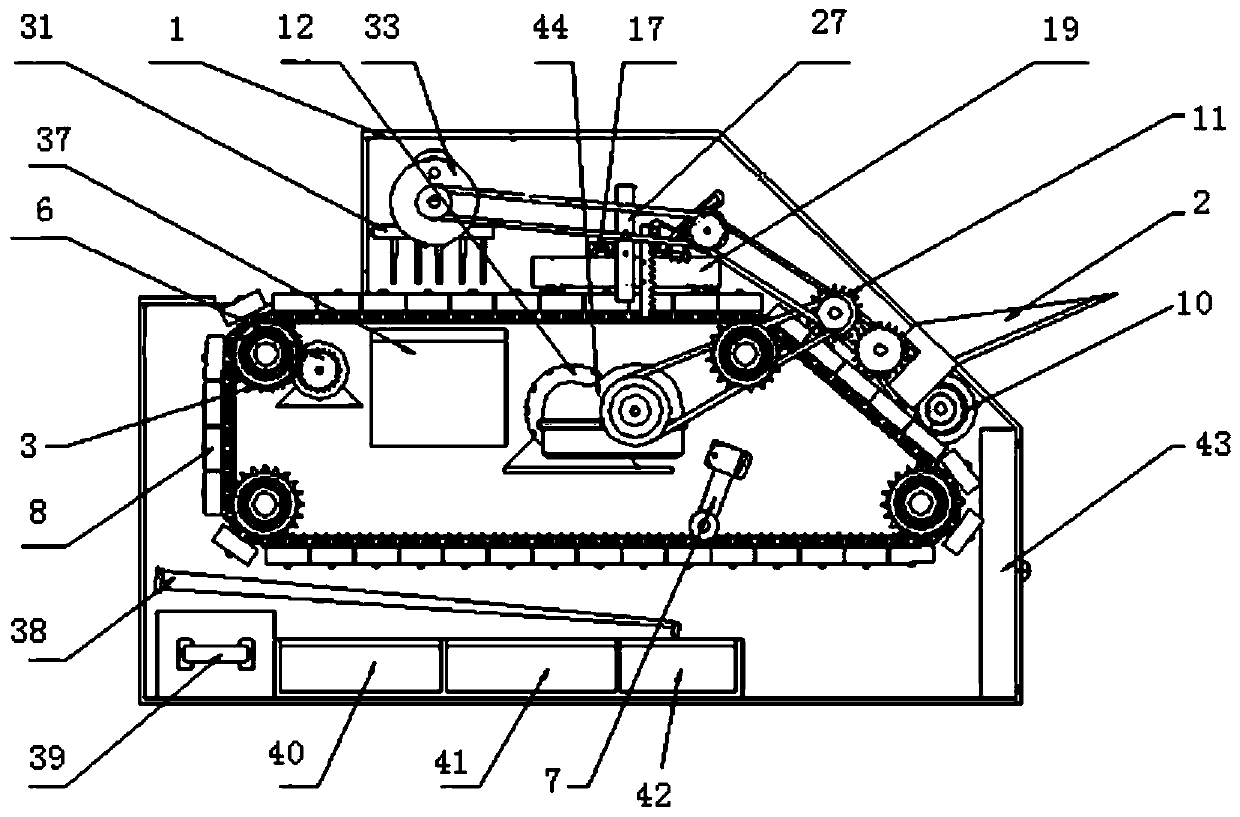

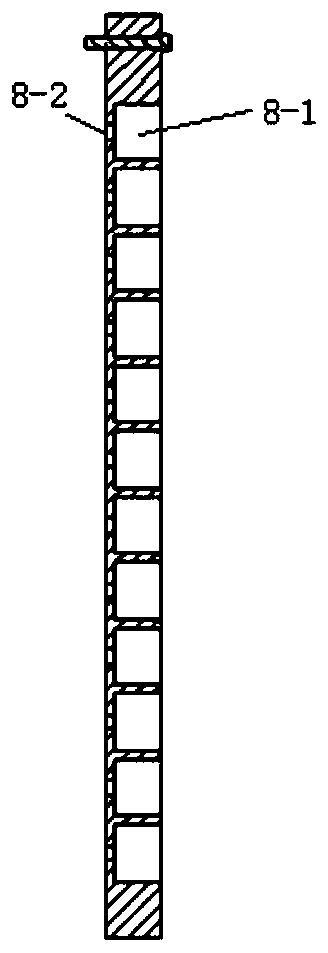

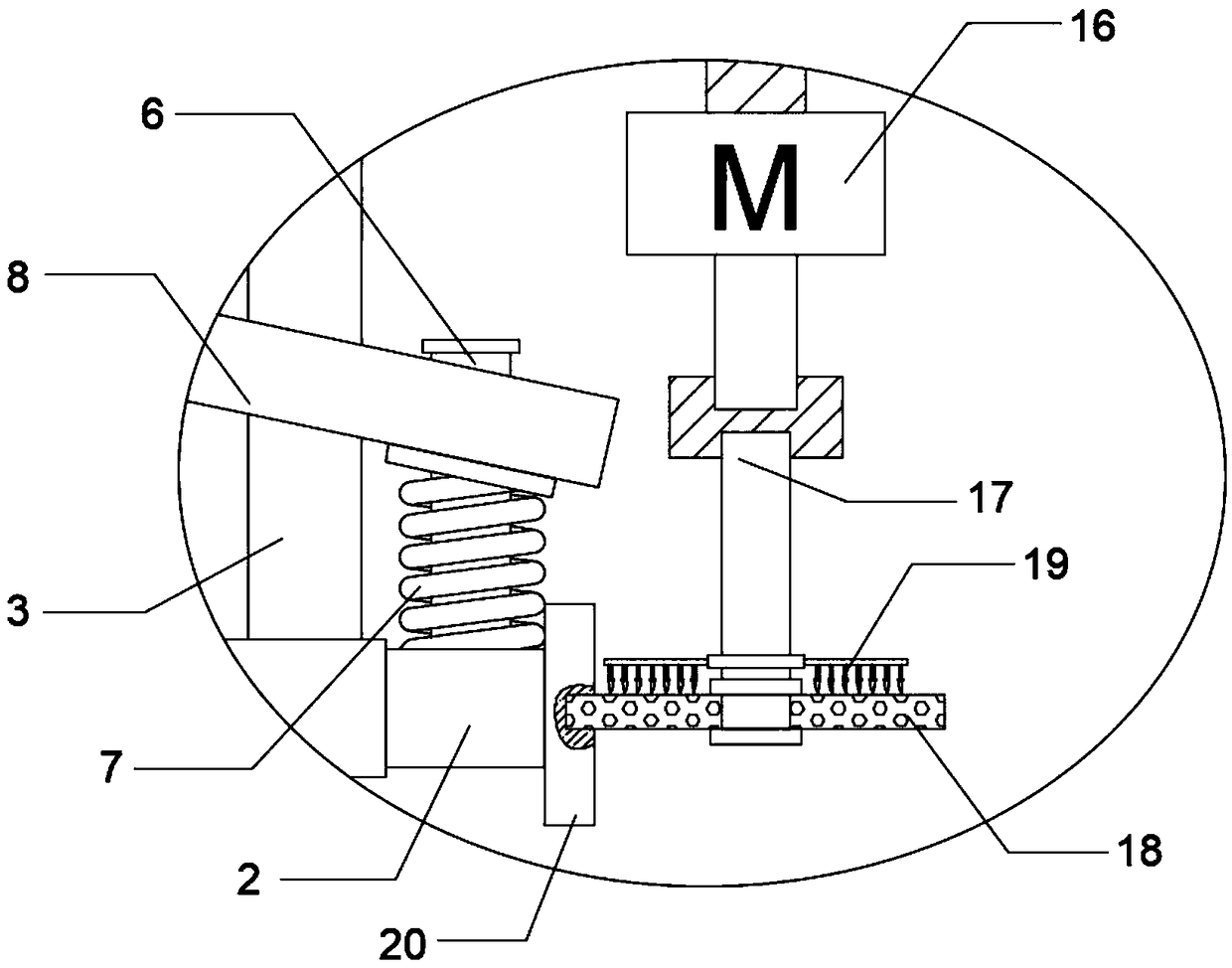

Standing-type straw recycling machine

InactiveCN108966867AFlexible shippingImplement classification processingSievingScreeningEngineeringLarge size

The invention discloses a standing-type straw recycling machine, and the recycling machine comprises a housing. The interior of the housing is symmetrically provided with two support plates in a welding manner. Moreover, the two support plates are symmetrically and rotatingly sleeved by two rotating shafts, and the lower end of the housing is provided with a first-stage servo motor. One of the twosupport blocks is symmetrically provided with four limiting rods through welding, and the four limiting rods are sleeved by springs. The four limiting rods are jointly sleeved by transition plates ina sliding manner. One side, far from the support plates, of the housing is provided with a vertical rod, and the upper end of the vertical rod is provided with a second-stage servo motor. According to the invention, a rimer which rotates at a high speed is used for the repeated cutting and smashing of straws, and the interior of the recycling machine is provided with a filtering disc selection device for the screening and distinguishing of the straws in different sizes. Moreover, a flood dragon transportation device is used for the repeated recycling and smashing of the large-size straws, soas to achieve the full smashing of the straws, thereby facilitating the fine processing of the smashed materials of the straws.

Owner:姚旭东

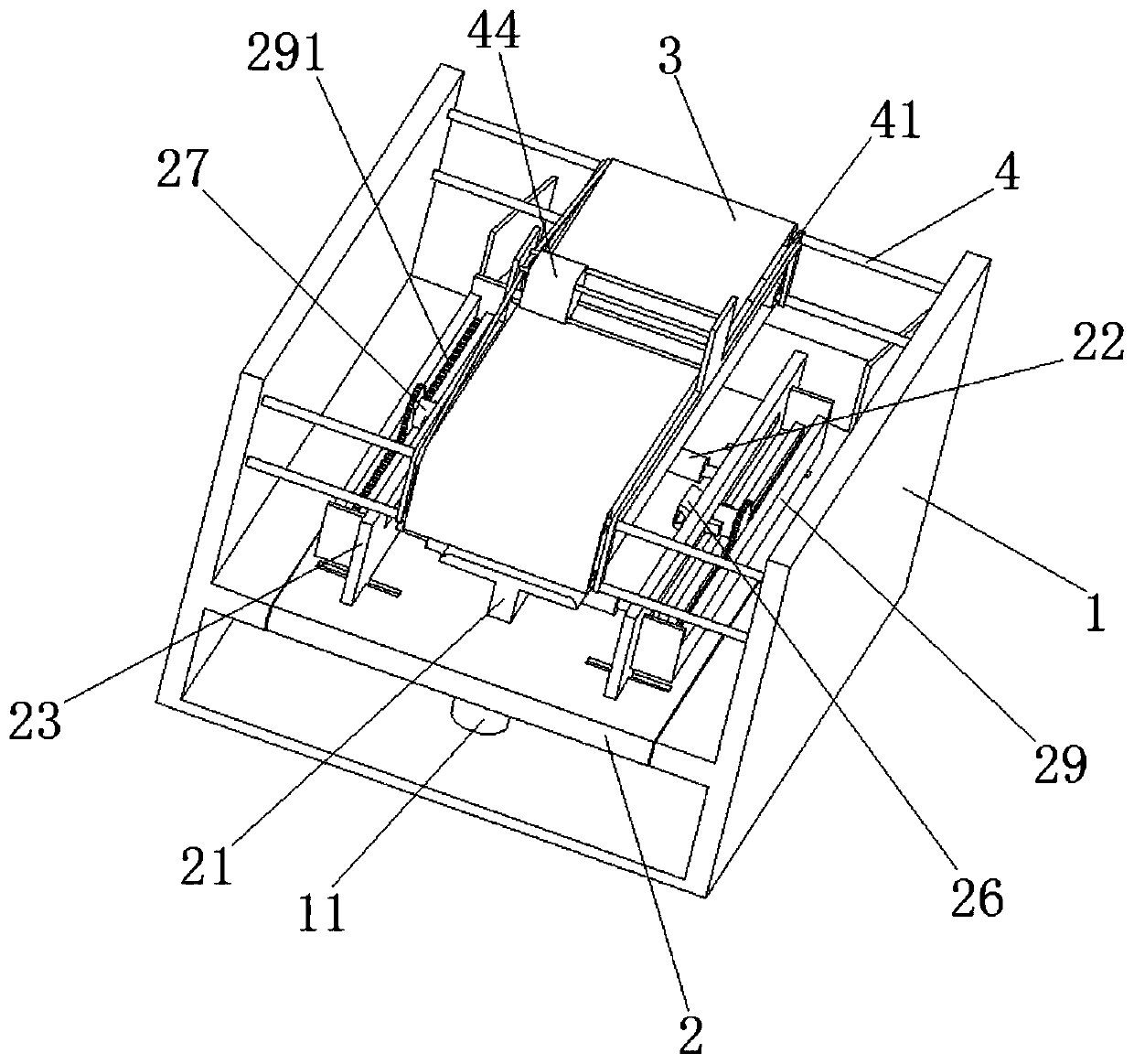

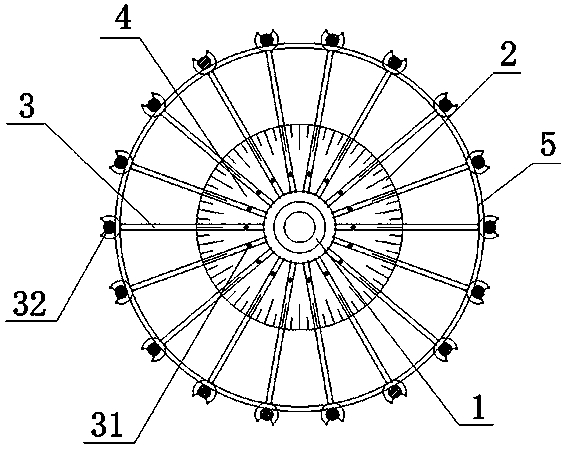

Device and processing method for fine processing of reinforcing cage with arbitrary pile diameter

InactiveCN108442710ARealize fine processingPrecise positioningBuilding material handlingCircular discEngineering

The invention discloses a device and processing method for fine processing of a reinforcing cage with the arbitrary pile diameter. The device comprises a central shaft, an angle divider, telescopic rotary supporting rods and a positioning chuck, wherein the central shaft is a steel pipe with a certain length, and external threads are formed in the outer circle of the central shaft; the angle divider is a stainless steel disc with a diameter of phi 500 mm, the disk is marked with scale lines, and the angle divider is fixed into a whole with the central shaft; the telescopic rotary supporting rods can control adjacent angles of main reinforcement of the reinforcing cage according to the scale lines on the angle divider, and adjust the length according to the pile diameter of the reinforcingcage to be machined; and the positioning chuck is a stainless steel disc, and the telescopic rotating supporting rods are fixed on the angle divider by the positioning chuck through central threads. According to the device, the disc with the scale lines is used as the angle divider and matched with the telescopic rotary supporting rods, main reinforcement spacing of the reinforcing cage with any specification can be equally divided, and the main reinforcement can be accurately positioned through buckles at the ends of the supporting rods. Two to three devices are used together, and fine processing of the reinforcing cage with the arbitrary pile diameter can be realized.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

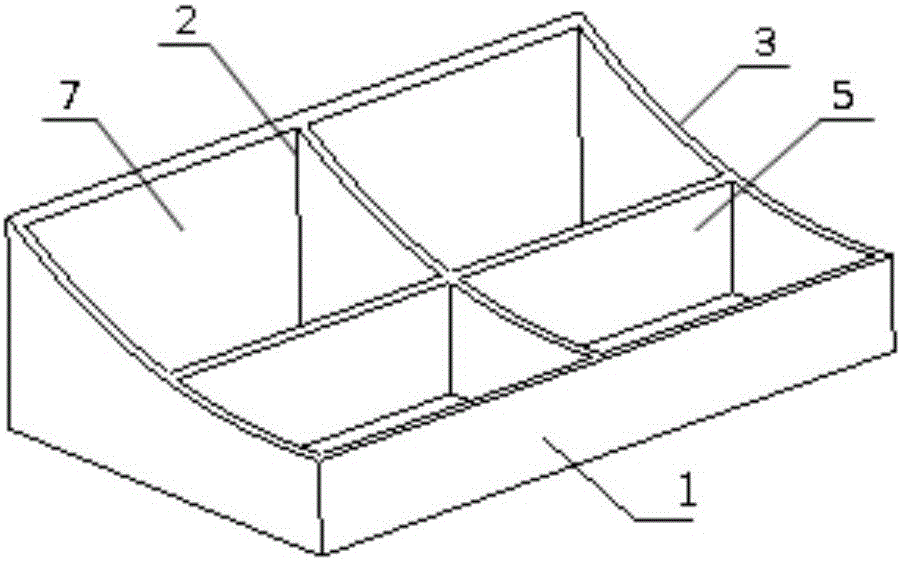

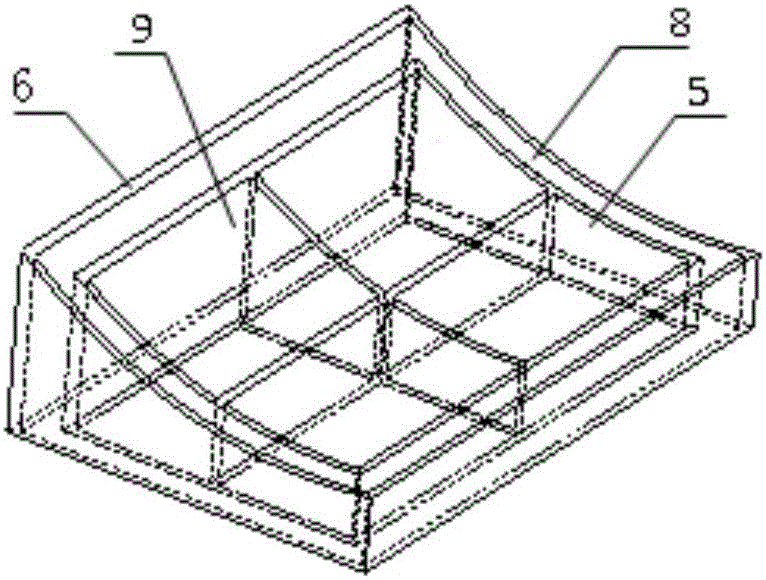

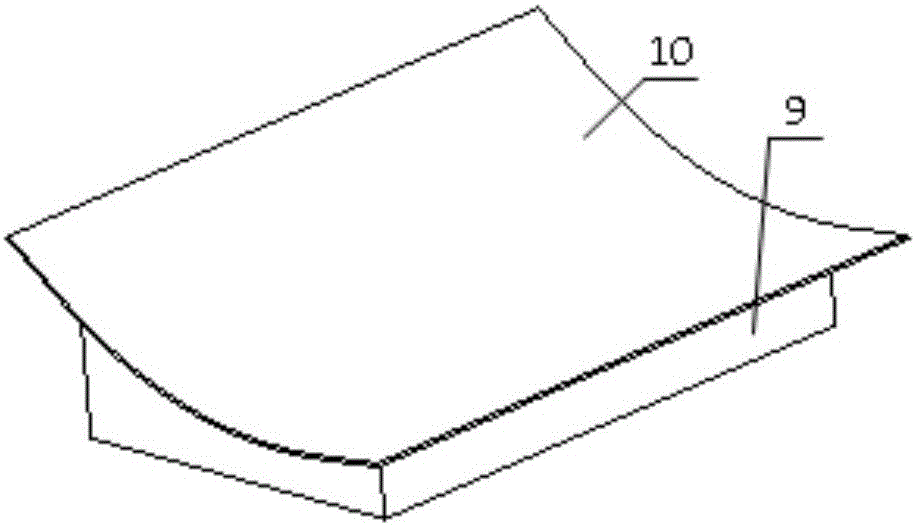

Processing method for sheet curve surface of composite forming mold

ActiveCN106112396AUniversal applicabilityRealize fine processingGround installationsAirplaneMetallurgy

The invention provides a processing method for the sheet curve surface of a composite forming mold. The processing method adapts to manufacturing of various medium-large composite forming molds. The processing method mainly includes the first step of manufacturing of a basic mold, the second step of the first time of forming of the sheet curve surface, and the third step of the second time of forming of the sheet curve surface. By means of the method, refined processing on a curve surface sheet with the thickness being 6 mm or below of the large composite forming mold is achieved by utilizing the methods and principles of thermoplastic forming, hydraulic forming and secondary numerical control processing, and the method has the general applicability to processing and manufacturing of airplane composite forming molds.

Owner:XI'AN AIRCRAFT INTERNATIONAL

Steel slag combined grinding system and method

The invention provides a steel slag combined grinding system and method. The steel slag combined grinding system comprises a fine grinding device and a superfine grinding device; the fine grinding device comprises a receptacle trough, a first vibration screen, a steel slag magnetic drum classificator, a buffer bin, a second rod mill, a magnetic separator and a third vibration screen; and the superfine grinding device comprises a metering device, a feeding belt conveyor, a steel slag vertical mill, a dust collector and a steel slag warehouse. Fine treatment of steel slag is achieved, space waste and environment pollution are reduced, the steel slag is subjected to multiple crushing, magnetic separation and screening, energy consumption can be reduced, slag and iron are separated, the iron and the slag can be secondarily utilized, and economic benefits are increased; multiple products can be formed through technologies such as multiple screening, magnetic separation and rod milling, anddifferent demands of markets can be met; and free-state calcium in the steel slag is reduced through multiple grinding of the steel slag vertical mill, the steel slag can be efficiently ground, activity of finished products is improved, and product competitiveness is enhanced.

Owner:天津亿诚集团有限公司

A kind of laser etching processing method of quartz crystal

ActiveCN105522281BRealize fine processingMinimize and eliminate negative effectsLaser beam welding apparatusMicrometerBase frequency

The invention discloses a laser ablation processing method for quartz crystal. The laser ablation processing method specifically comprises the steps of selecting lasers, preparing control software, designing processing drawings, carrying out laser ablation, carrying out post-processing treatment and carrying out detection. The method for processing the quartz crystal is designed on the basis of limitation to the condition of each step, the quartz crystal can be effectively processed for forming various shapes and can be thinned through the processing method, the thickness of the thinned quartz crystal is small, the corresponding base frequency is high, and the strength of the processed quartz crystal is high. In addition, the processing method is simple, the processing accuracy is high, and the processing dimensional accuracy of the quartz crystal can be controlled to be within the range of + / - 5 micrometers.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

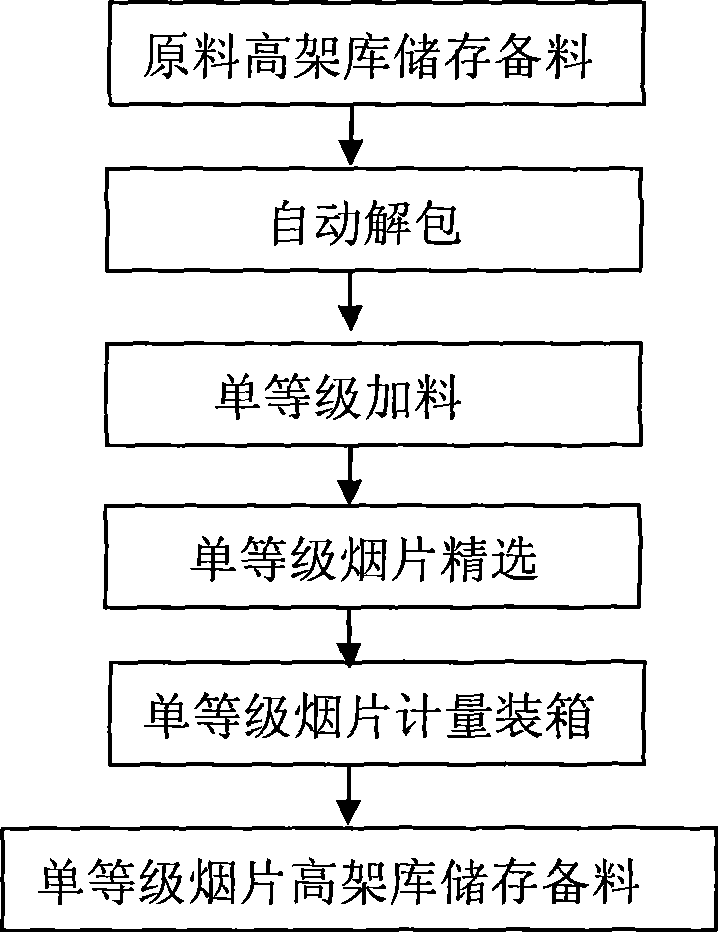

Single-grade treatment process of tobacco leaf raw material

The invention discloses a single grade treating process for a tobacco raw material, which adopts processing means such as applying functional liquor, finely selecting, quantitatively accommodating and storing, and the like in sequence aiming at formula tobacco. A pre-treatment link is established before the tobacco is put into formal shredding production. The invention also discloses an implementation procedure for realizing single grade treatment of the tobacco raw material. The process can effectively improve the purity of tobacco flakes by finely selecting the tobacco, can improve the quality of the tobacco with pertinence by applying the liquor with different components, and improve the accuracy of formula weight by quantitatively accommodating so as to achieve fine processing for the tobacco.

Owner:CHINA TOBACCO HUNAN INDAL CORP

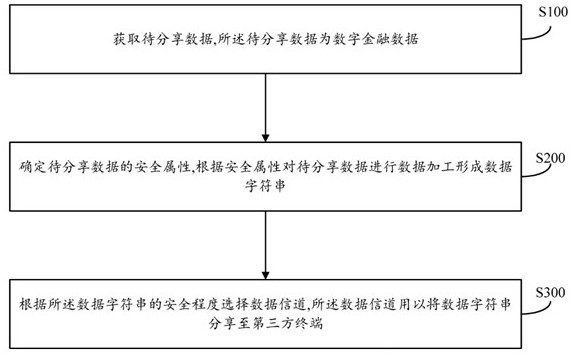

Digital financial data sharing method

ActiveCN113254975AImprove securityHigh specificityDigital data protectionData transmissionData channel

The invention relates to a digital financial data sharing method, and the method comprises the steps of obtaining to-be-shared data which is digital financial data; determining a security attribute of the to-be-shared data, and performing data processing on the to-be-shared data according to the security attribute to form a data character string; selecting a data channel according to the security degree of the data character string, wherein the data channel is used for sharing the data character string to a third-party terminal; setting four security levels in the central control unit, determining the length of the character string increased at the data tail end according to the security level of the to-be-transmitted data, and selecting the corresponding data channel according to the actual length of the character string for data transmission, so that data sharing is realized, the security of data sharing is improved, the data transmission channel is matched based on the security degree of the to-be-shared data and the characteristics of the data channel, the specificity of data sharing is improved, and the security of data transmission is further improved.

Owner:湖南三湘银行股份有限公司

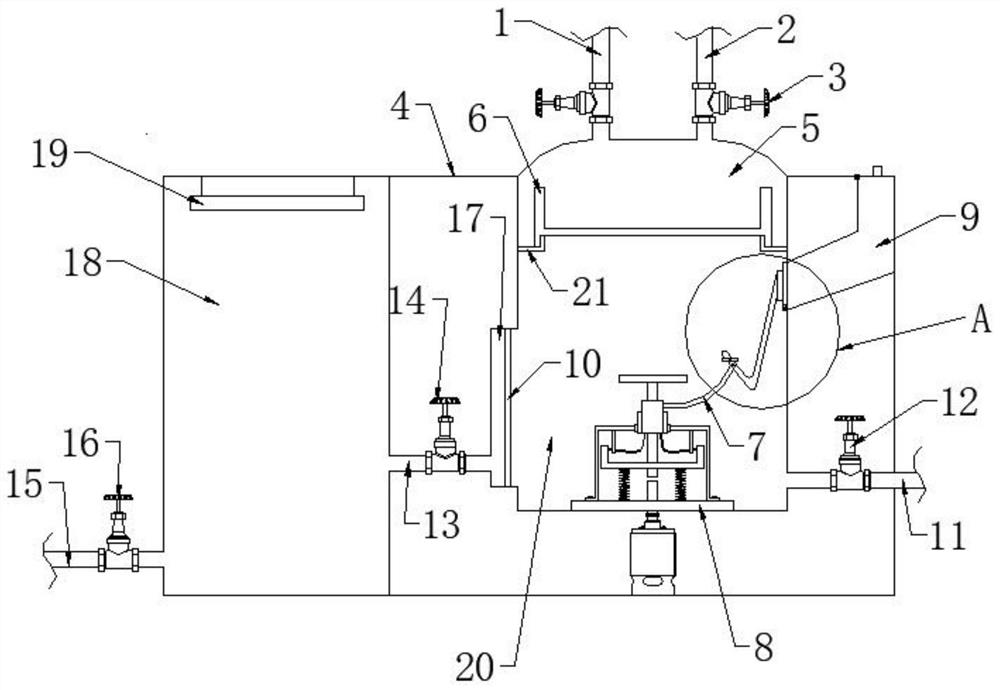

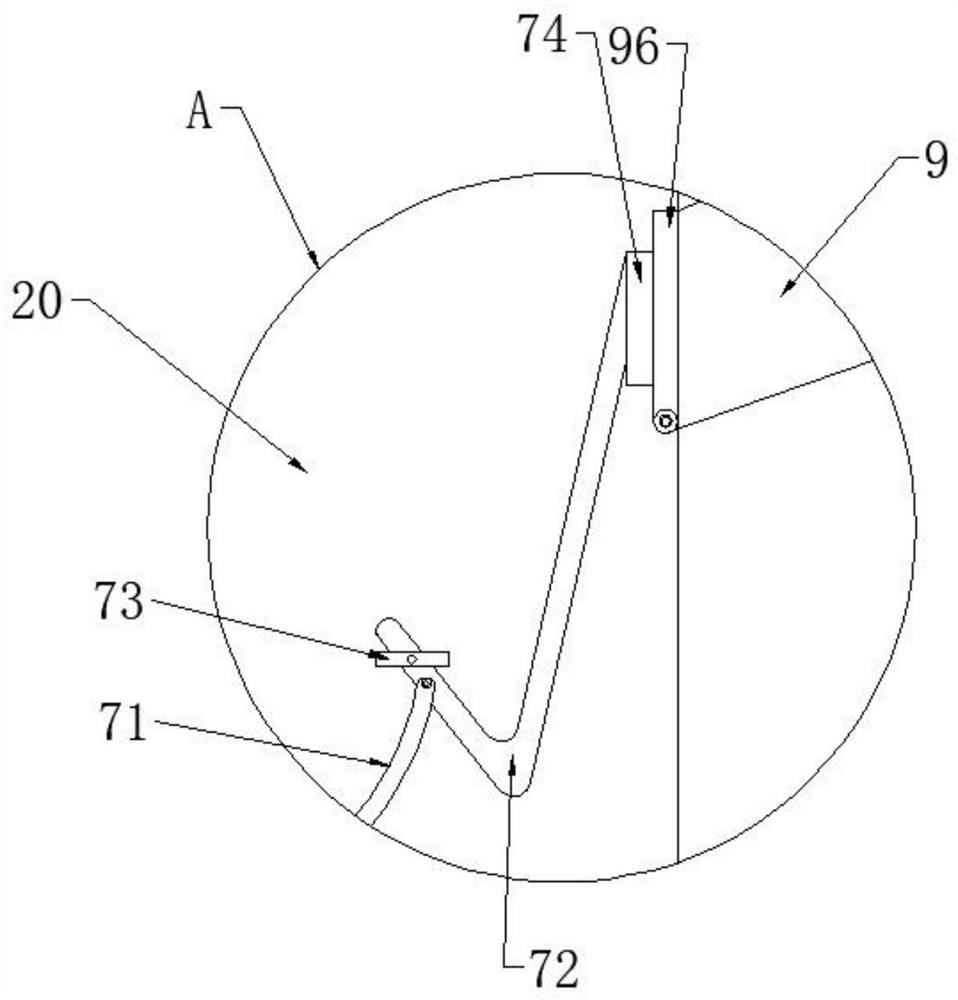

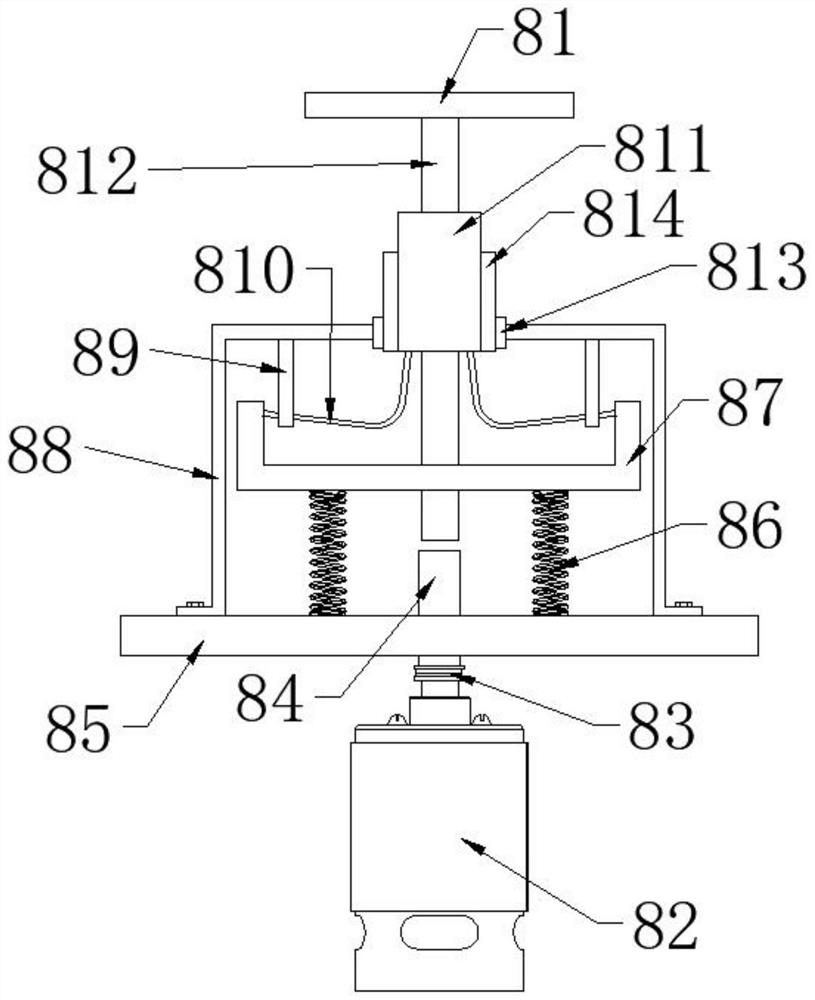

Domestic sewage treatment device and method thereof

InactiveCN112174402ARealize fine processingAchieve recyclingWater/sewage treatment by irradiationSpecific water treatment objectivesHand washingSewage treatment

The invention discloses a domestic sewage treatment device, which comprises a device box shell, a kitchen sewage inlet pipe and a hand washing sink sewage inlet pipe, wherein a filter cavity and a limiting groove are formed in the device box shell, a filter assembly is clamped in the limiting groove, a purification cavity is formed below the filter assembly, a stirring mechanism is arranged at thebottom of the purification cavity, the right side of the stirring mechanism is fixedly connected with a water treatment agent box through a guide mechanism, a sewage outlet pipe is arranged on the right side wall in the purification cavity, a water outlet is formed in the left side wall in the purification cavity, a filter screen b is fixedly connected into the water outlet, a water outlet pipe ais arranged at the left end of the water outlet, a disinfection and sterilization cavity is formed in the left end of the water outlet pipe a, an ultraviolet sterilization lamp is fixedly connected to the top of the disinfection and sterilization cavity through bolts, a water outlet pipe b is arranged on the lower portion of the left side of the disinfection and sterilization cavity, domestic sewage is treated through the filtering cavity, the purification cavity and the disinfection and sterilization cavity, the domestic sewage can be recycled, and water resources are saved.

Owner:NANJING HANERSI BIOLOGY TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com