Laser ablation processing method for quartz crystal

A quartz crystal and laser etching technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as poor dimensional accuracy, difficulty in productization, and easy breakage, to achieve neat and accurate edges, and eliminate negative Influence, the effect of weakening the negative influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

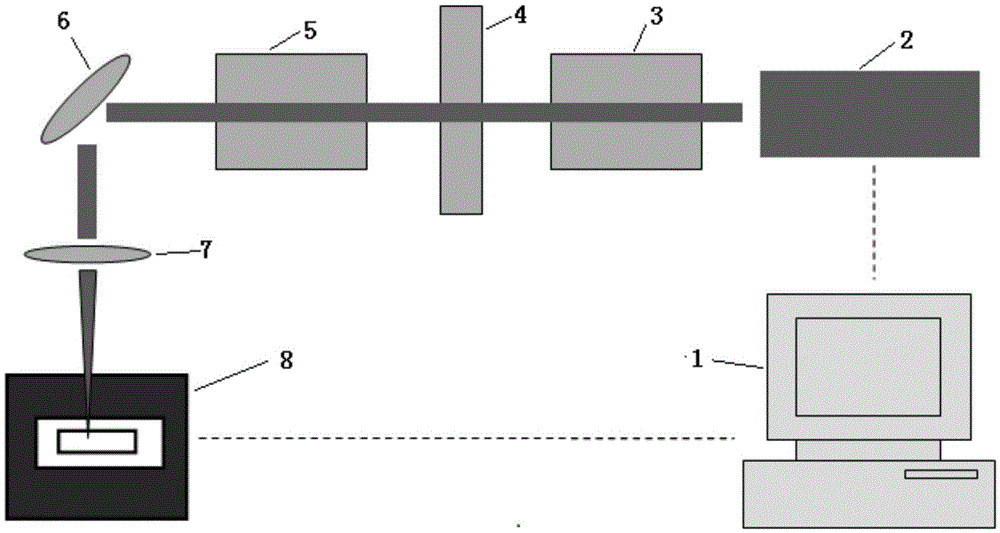

Image

Examples

Embodiment 1

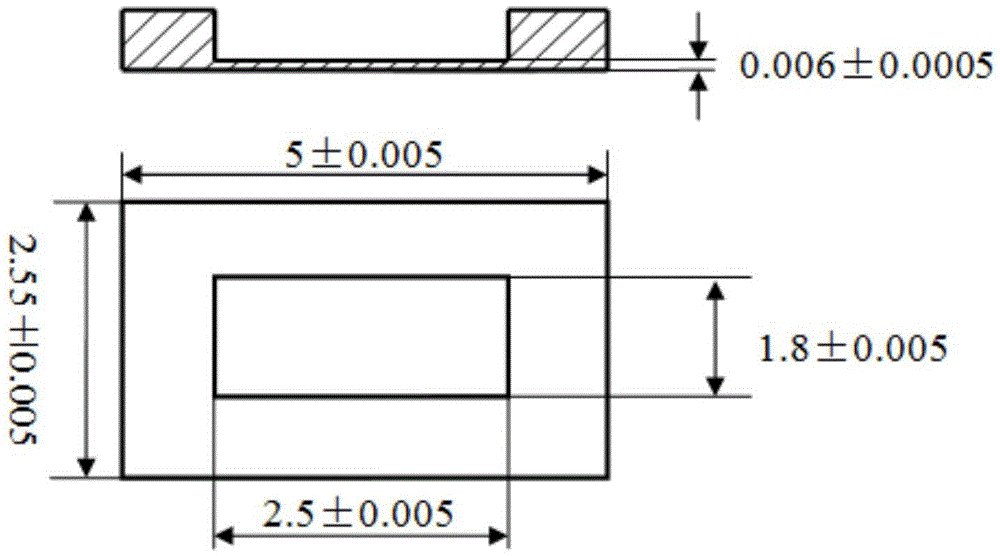

[0053] Using a laser to locally thin a quartz crystal sheet with a size of 5.00mm×2.55mm×0.100mm and a surface roughness of 200nm, the following is obtained: figure 2 The shown groove bottom wall of 2.500mm×1.800mm×0.006mm includes the following steps:

[0054] Prepare the laser:

[0055] Choose lasers that can excite short pulse lasers with a pulse width of 5ps to 20ps;

[0056] The laser pulse repetition frequency is selected as 160kHz, and the output power of the laser is selected as 800mW;

[0057] The control mode of the laser is selected as the windows (software trigger) control mode, and the control right of the laser gate is handed over to the laser processing control software;

[0058] Prepare control software:

[0059] Start the laser processing control software;

[0060] Laser focus correction, search and correction of laser focus, so that the focus of the laser and the focus of the observation lens are at the same height;

[0061] The lens is aligned, and the...

Embodiment 2

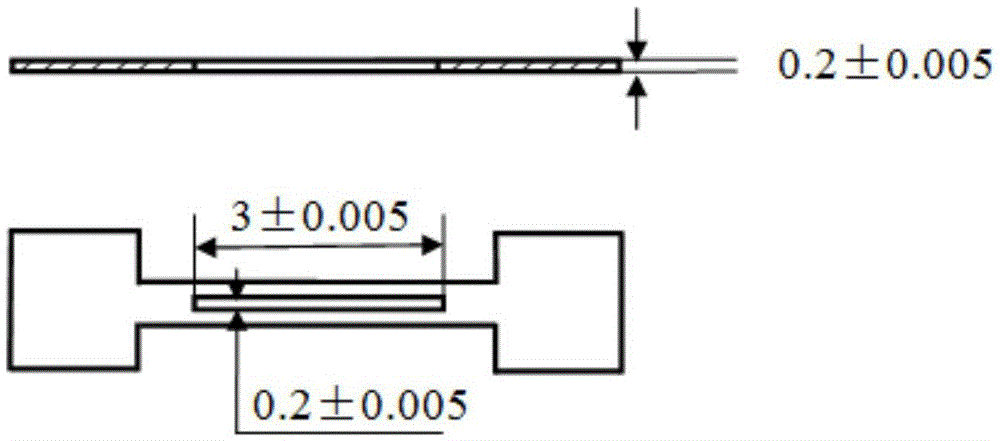

[0085] Use laser to realize such as image 3 The tuning fork shown contains a slot of 3.000mm x 0.200mm x 0.200mm. Include the following steps:

[0086] Prepare the laser:

[0087] Select the laser, the laser can excite the laser with a pulse width of 5ps ~ 20ps;

[0088] The pulse repetition frequency is 200kHz, and the output power of the laser is selected as 900mW;

[0089] The control mode of the laser is selected as windows (software trigger) control mode;

[0090] Prepare control software:

[0091] Start the laser processing control software;

[0092] Laser focus correction, search and correction of laser focus, so that the focus of the laser and the focus of the observation lens are at the same height;

[0093] The lens is aligned, and the focus of the observation lens and the focus of the focusing galvanometer are compensated in the horizontal direction, so that the center of the focusing galvanometer coincides with the center of the field of view of the observat...

Embodiment 3

[0117] Example 1 was repeated, except that the pulse repetition frequency was 50 kHz, the output power of the laser was 300 mW, and the scanning speed of the laser beam was 50 mm / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com