System and method for testing performance of thin-film material under electricity/heat/force coupling action

A thin film material and testing system technology, which is applied in thermal analysis of materials, material analysis, material analysis through electromagnetic means, etc., can solve the difficulty of testing mechanical and electrical performance indicators of thin film materials, real-time observation, and performance testing And other issues

Inactive Publication Date: 2010-12-01

INST OF METAL RESEARCH - CHINESE ACAD OF SCI

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the thickness of the two-dimensional thin film material and the width of the interconnection wiring of the integrated circuit in the range of microns or even nanometers, it brings many difficulties to its performance test, and various exquisite experiments designed by people cannot solve the problem of improper sample clamping and testing The problem of low precision, let alone real-time observation

This makes it impossible to test the mechanical and electrical performance indicators of thin film materials.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Login to View More

Abstract

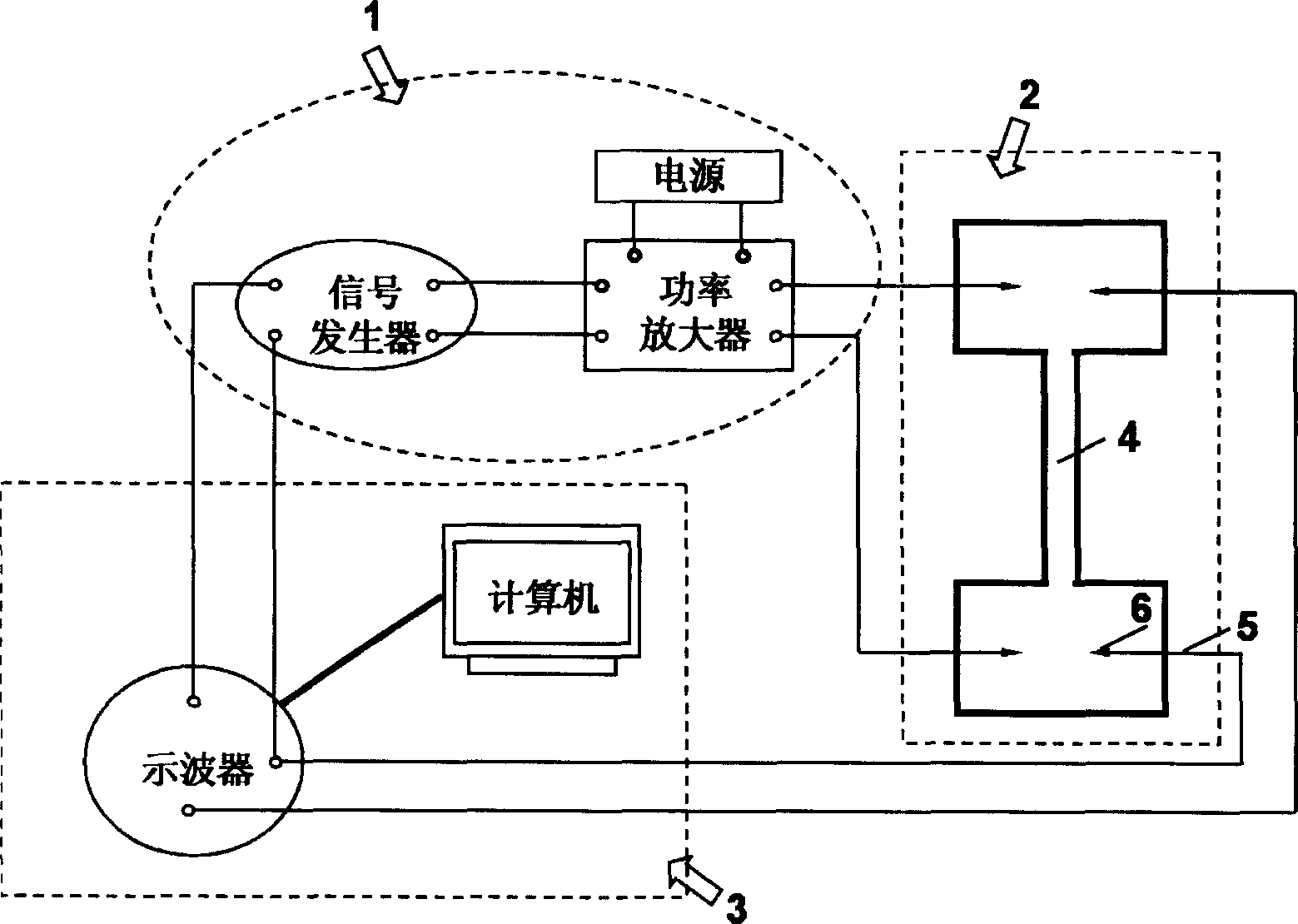

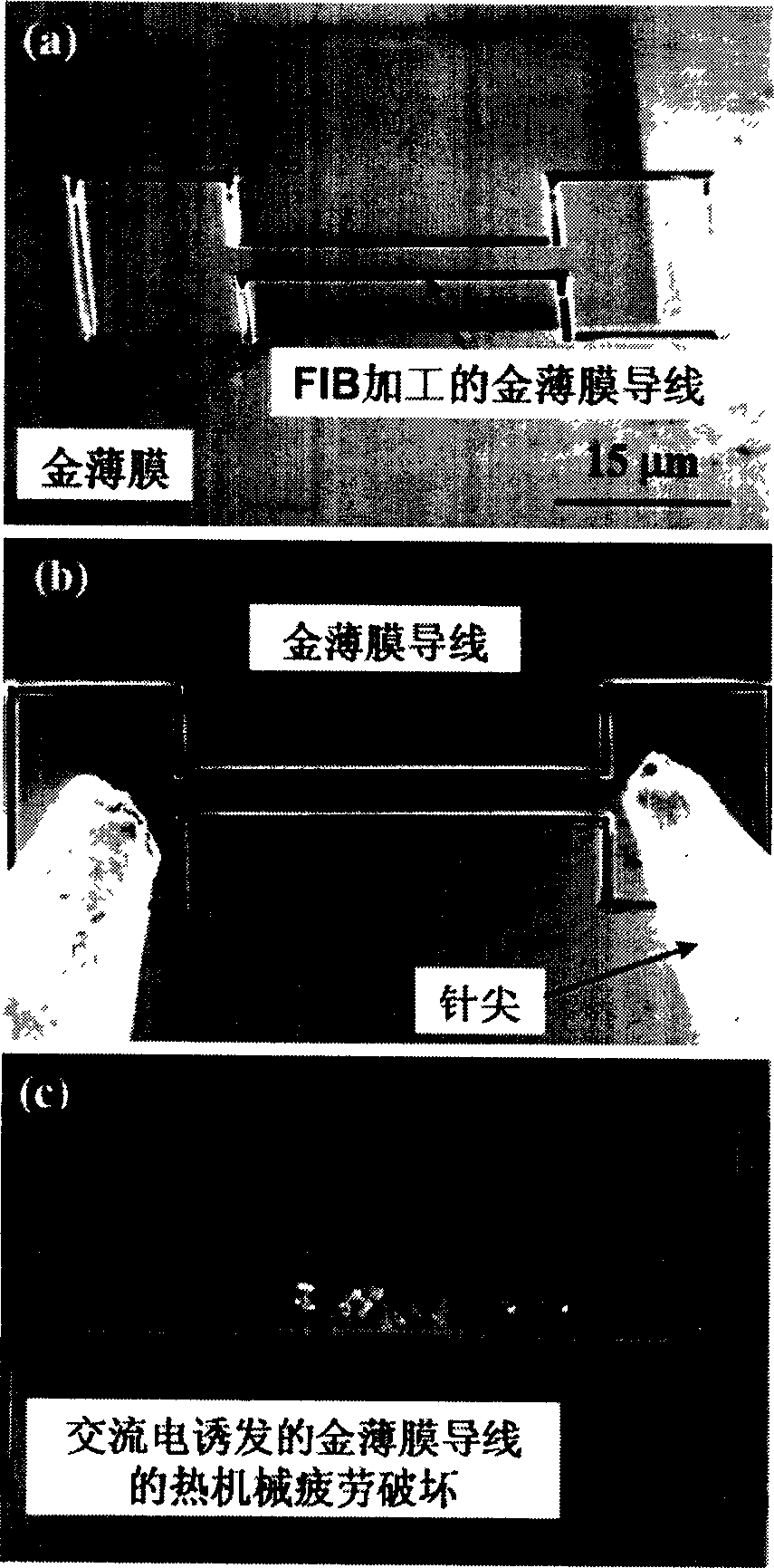

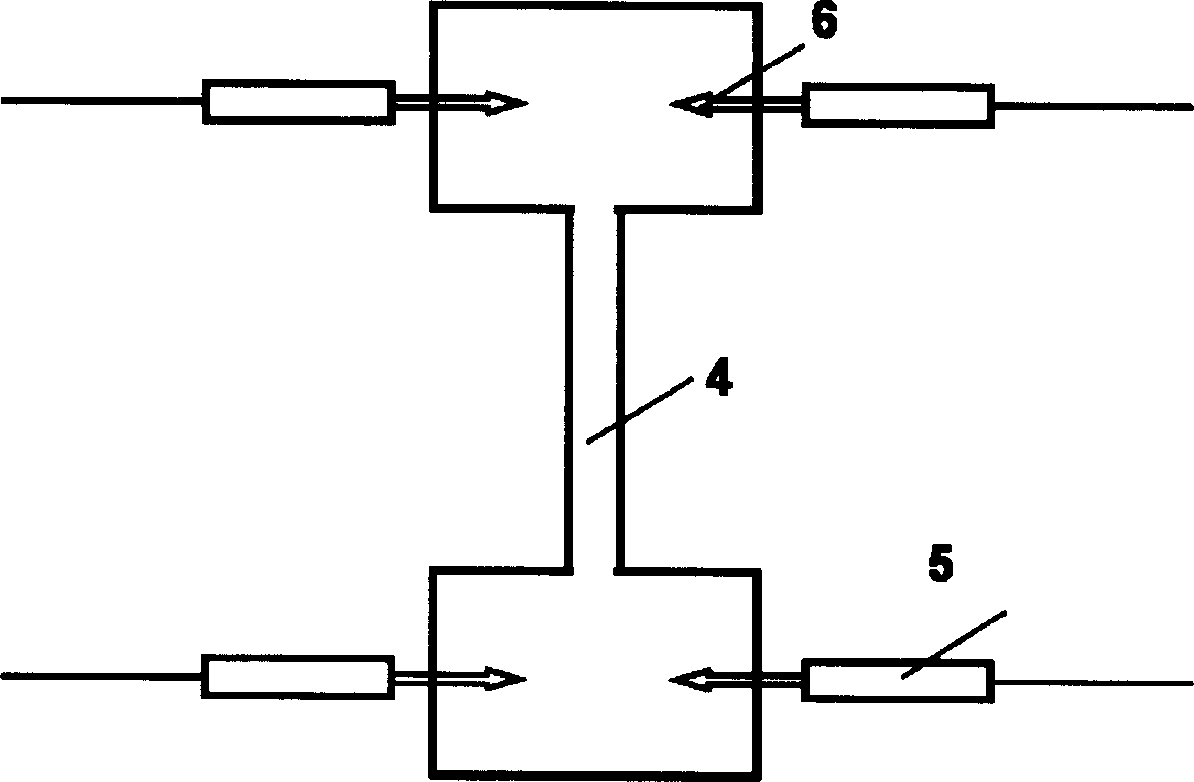

The invention relates to the system set of the character original test and appraise and the test method for the film with micro / nanometer scale, metallic interlink film used in integrate circuit and lead in the action of electric / heat / force coupling. The system provides the film material with micro / nanometer scale produced in the original position. In the action of electric / force / heat coupling byusing the AC / DC test material, the mechanics, physics character and the three-dimensional representation in original position are reached. By using the joule heat in metal line generated by AC and the heat cycle stress formed by the thermal expansion coefficient difference between the film and base body, the hot fag load on metal film, the micro observation and FIB three-dimensional representation, the film with micro / nanometer scale and every low dimension lead are tested and appraised. The system in the invention has the original production, character test and representation, so the mechanics and electromigration character of material are tested.

Description

Performance test system and test method of film material under electric / thermal / mechanical coupling Technical field The present invention relates to the establishment of a power-up system for two-dimensional thin-film materials, and specifically relates to a coupling effect on two-dimensional thin-film materials such as micro / nano-scale thin-film materials and metalized interconnect films for integrated circuits. The construction and performance test methods of the performance test system under Background technique Thin-film materials are widely used in the fields of large-scale integrated circuit interconnection wiring and micro / nano electromechanical systems. Because of their long-term work under the conditions of the interaction of electricity and heat, the thin-film materials and the substrate are often made of different materials. , The difference in the thermal expansion coefficient of the material will inevitably lead to thermal stress in the film material. Therefore, t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N33/00G01N27/00G01N25/00G01N19/00

Inventor 张广平张滨于庆源

Owner INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com