Cherry pedicle-removing and stoning device

A pitting device and cherry technology, applied in fruit pitting devices, solid separation, grading, etc., can solve the problems of low pedicel removal rate, pulp waste, pulp damage, etc., to achieve fine processing, reduce labor intensity, and improve processing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

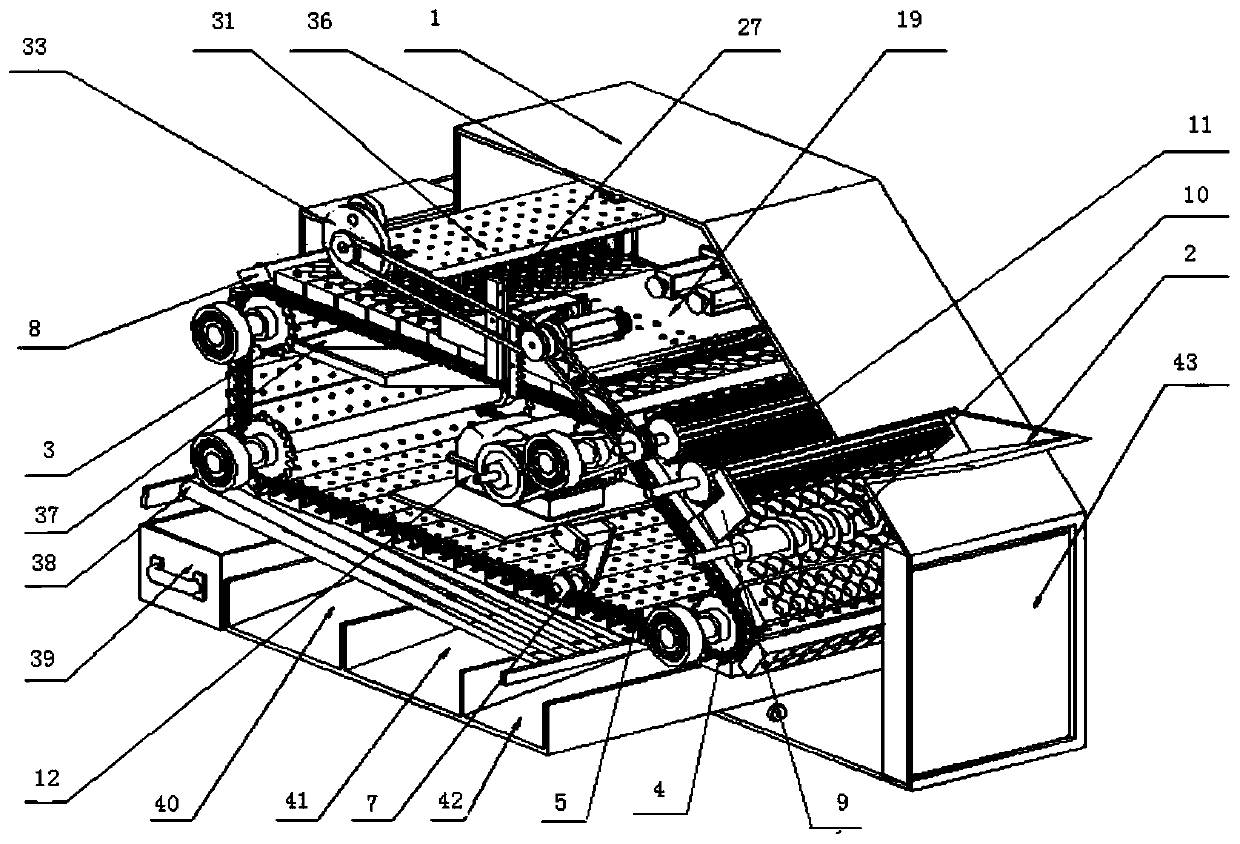

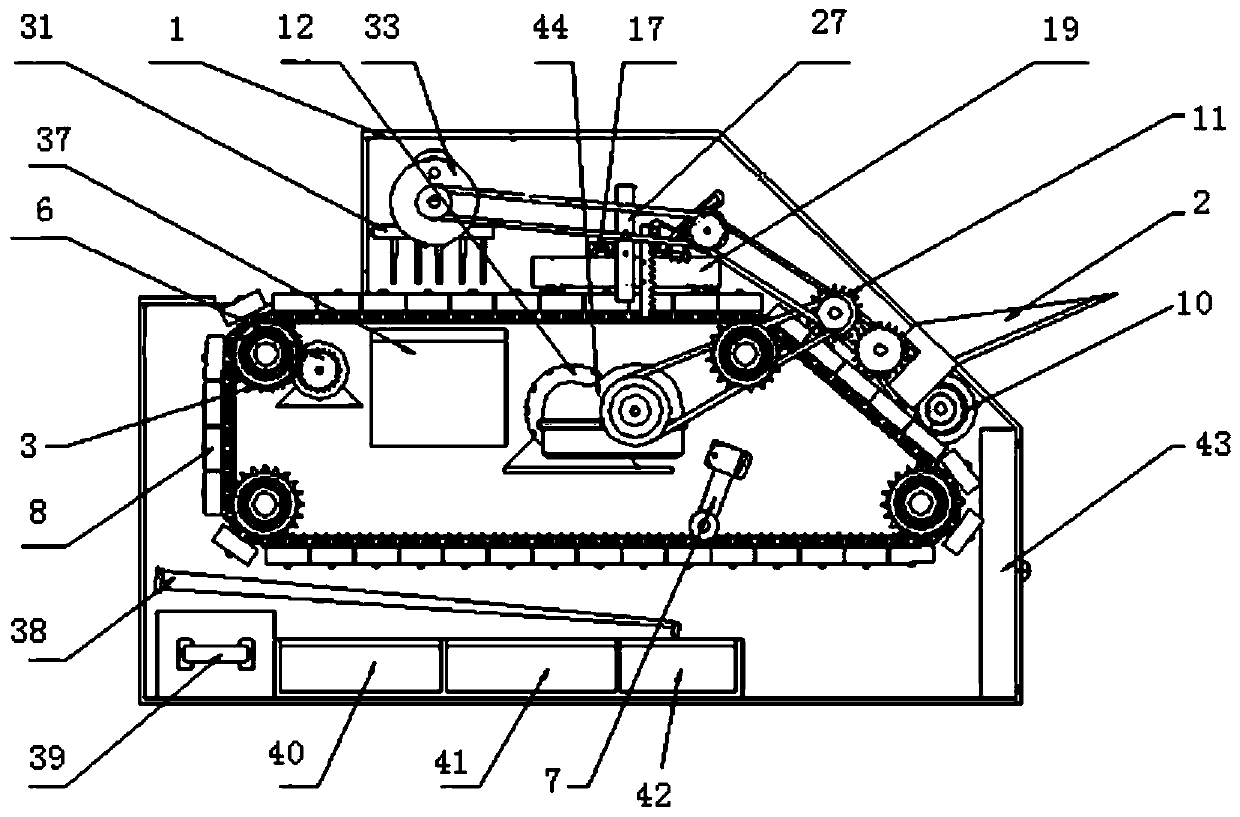

[0048] A device for removing stems and pits of cherries, such as Figure 1-13 As shown, including a frame 1, a transport mechanism is installed in the frame, a centralizing mechanism is installed at the material inlet of the frame, along the transport direction of the transport mechanism, the top of the transport mechanism is successively provided with a pedicle removal mechanism and As for the denucleating mechanism, a screening mechanism is arranged under the transport mechanism.

[0049] One side of the frame is provided with a material inlet, and the outlet of the material inlet is provided with a feeding plate 2 arranged obliquely, and the cherries can fall into the transport mechanism through the material inlet through the material feeding plate.

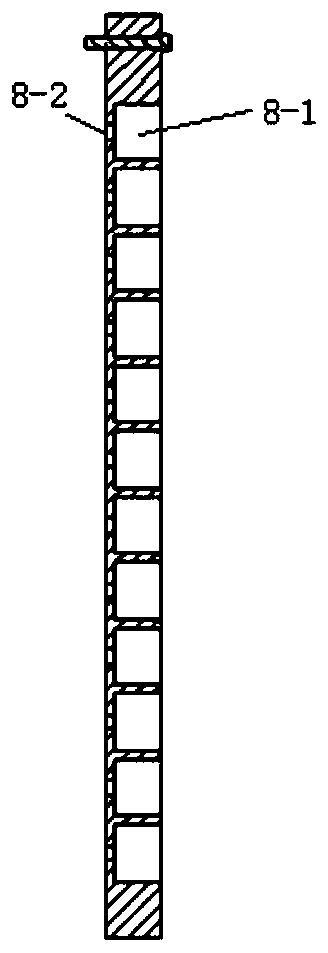

[0050] The transport mechanism adopts two sets of chain transmission mechanisms located on both sides inside the frame, and the chain transmission mechanism includes a driving sprocket 3, a plurality of driven sprockets 4 and ...

Embodiment 2

[0072] This embodiment discloses a working method of a device for removing stems and pits of cherries: the operator pours the cherries from the feeding port into the transport mechanism inside the frame, and the cherries are self-positioned into the storage tank under the action of gravity, and the brush is placed Driven by the second motor to rotate, each cherry can enter a storage tank, and the fruit stems are facing outwards and kept consistent. The conjugated rotary auger can disperse the middle cherries to both sides to prevent the accumulation of cherries in the middle of the conveying plate , the cherries are transported to the right below the destalking mechanism driven by the transportation mechanism, the transportation mechanism stops working, the first push-pull electromagnet and the second push-pull electromagnet are energized, and the two push-pull electromagnets move towards each other, driving the first despeding electromagnet The plate mechanism and the second p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com