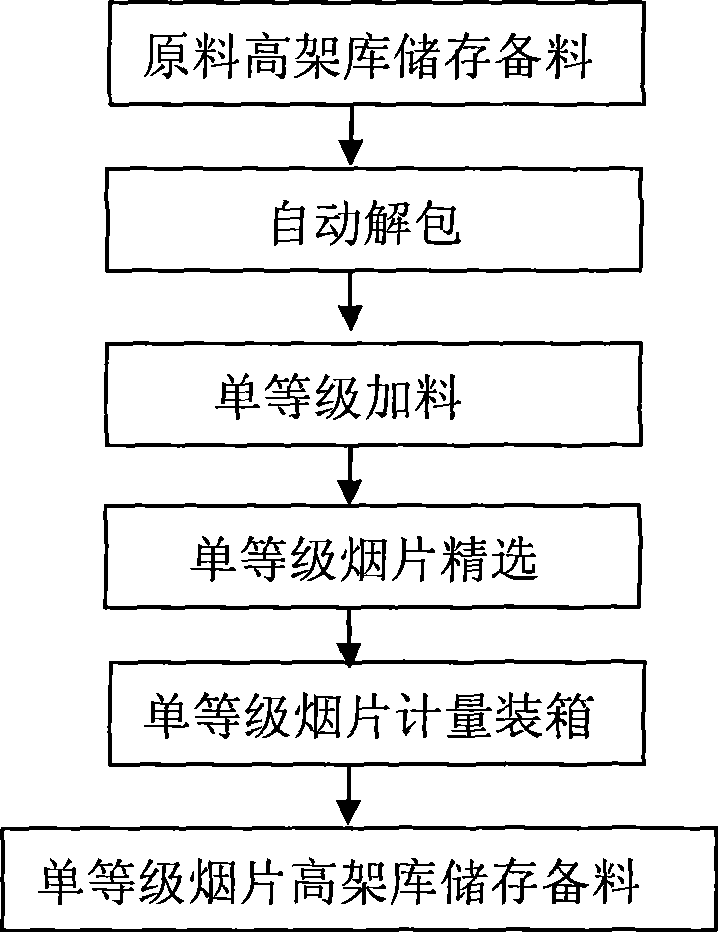

Single-grade treatment process of tobacco leaf raw material

A treatment process and grade technology, applied in the direction of tobacco, tobacco preparation, application, etc., can solve the problems of quality improvement, poor mixing uniformity, and timely replenishment of rejected substances, so as to achieve fine processing and improve the purity of tobacco sheets , the effect of improving the quality of tobacco leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] The process and production organization of the present invention are as follows: first calculate the number of packing boxes of each grade according to the batch size, batch weight and formula ratio, three 12000kg batches with a total weight of 36000kg, according to the example Yunnan X3F 3600kg, Yunnan C4L 5400kg, Hunan X4F 3600kg, Hunan C3L 1800kg, Hunan B3F 7200kg, Hunan C4L 3600kg, Guizhou B3F 3600kg, Fujian B3F 1800kg, Henan X3F 1800kg, Henan C3L 1800kg; the standard weight of each package is 200kg, that is, Yunnan X3F 18 boxes, Yunnan C4L 27 boxes , Hunan X4F 18 boxes, Hunan C3L 9 boxes, Hunan B3F 36 boxes, Hunan C4L 18 boxes, Guizhou B3F 18 boxes, Fujian B3F 9 boxes, Henan X3F 9 boxes, Henan C3L 9 boxes. One day in advance, each grade is input one by one according to the calculated amount, and the input amount is appropriately greater than the production plan demand to ensure sufficient raw materials for official production; after automatic unpacking, loose feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com