Highland barley processing technology

A processing technology, highland barley rice technology, applied in grain processing, application, grain milling, etc., can solve the problems of poor color and low quality of highland barley rice, achieve mechanized operations, ensure food hygiene, and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

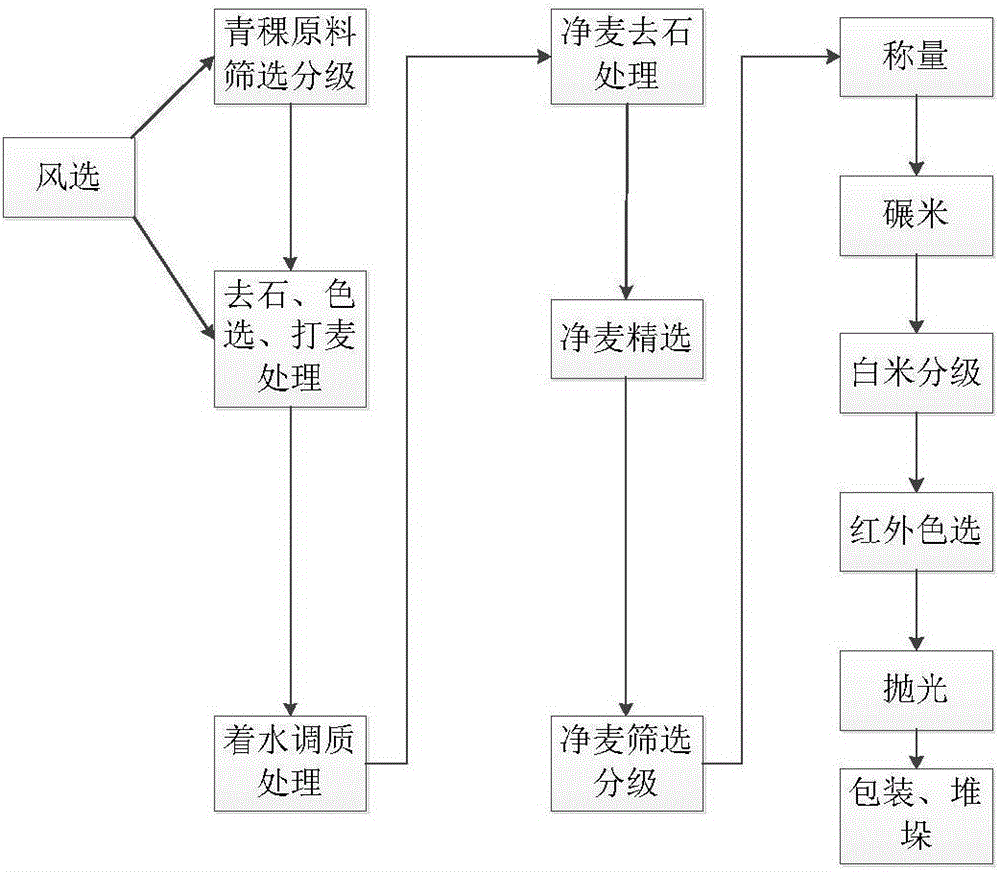

[0047] A kind of highland barley processing technology, such as figure 1 As shown, in order, the steps are as follows:

[0048] (1) Raw grain reception: this step can be selected according to the actual highland barley raw materials;

[0049] (2) Cleaning of wool wheat:

[0050] A. Screening and grading treatment: remove impurities in raw highland barley grains, and at the same time grade highland barley grains, separate and recycle unqualified highland barley grains;

[0051] B. The highland barley grains obtained in the above step (1) are subjected to stone removal, color sorting, and threshing: remove side-by-side stones, black highland barley, white highland barley, moldy grains, glass particles, plastic particles and other foreign-colored impurities, and remove surface dust other impurities;

[0052] C. Water conditioning treatment: put the highland barley grains obtained in the above step (2) into the moistening granary for water adjustment, and leave the warehouse afte...

Embodiment 21

[0074] A kind of highland barley rice processing technology, different from embodiment 1, when step C is implemented, after moistening the grain, the water content of highland barley grains is 15% of its weight, and the whole rice rate is about 81.7%.

Embodiment 22

[0076] A kind of highland barley rice processing technology, different from embodiment 1, when step C is implemented, after the grain moistening is completed, the water content of highland barley grains is 16% of its weight, and the whole rice rate is about 82.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com