Patents

Literature

73results about How to "Ensure food hygiene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

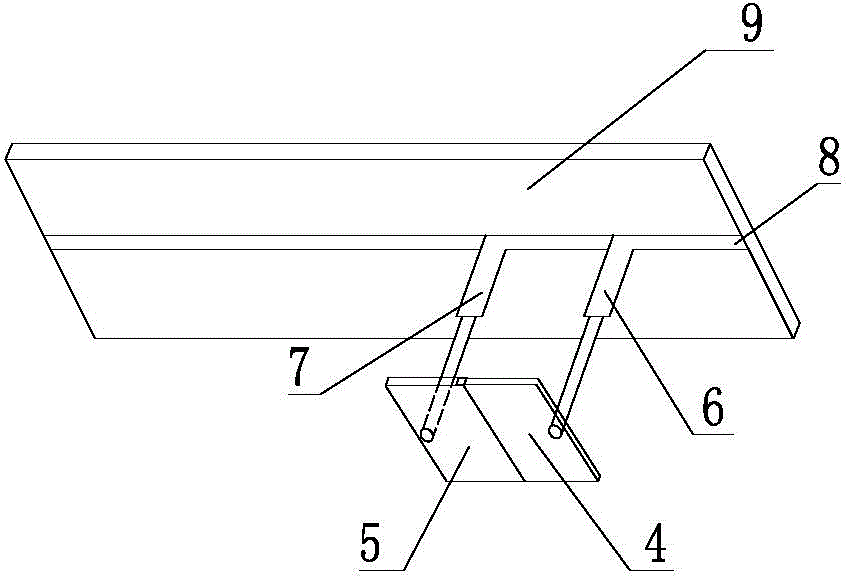

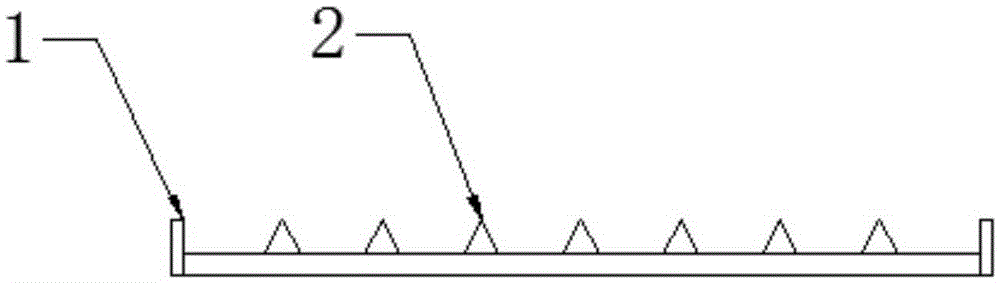

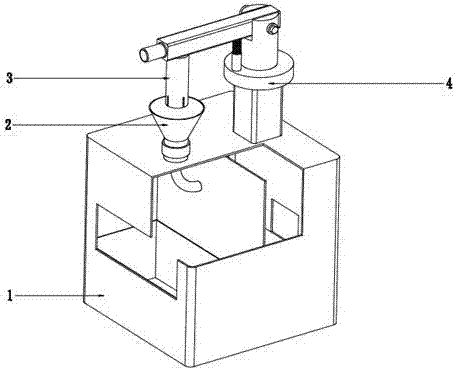

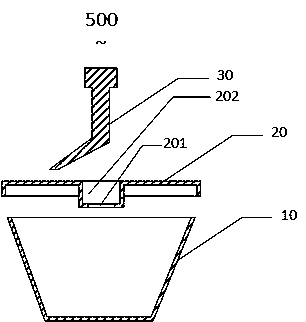

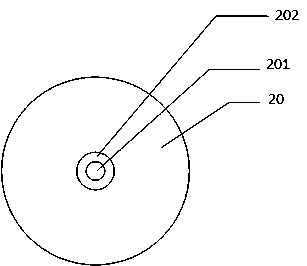

Cutter for food cutting machine

InactiveCN102581861AIncrease productivitySave human effortMetal working apparatusEngineeringKnife blades

The invention discloses a cutter for a food cutting machine, which comprises a cutter and a pressure roller close to the cutter. The pressure roller rotates around a fixed shaft, and the bottom end of the pressure roller is higher than that of a cutter blade. When food passes through the bottom end of the pressure roller and is cut by the cutter blade, the pressure roller rolls around the shaft to provide a downward pressure, and the cutter used with the food cutting machine can replace manual operation for food cutting, so that operating efficiency is greatly improved, production cost is reduced, and safety of operators and food sanitation are guaranteed.

Owner:BEIJING LUOKE MACHINERY

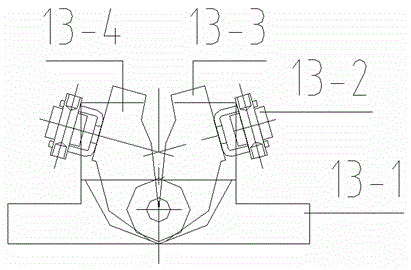

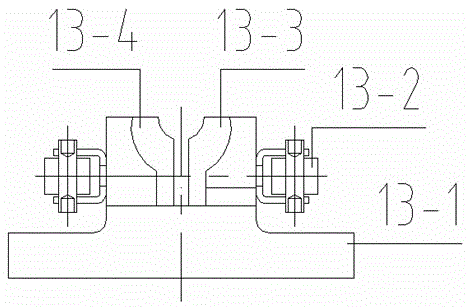

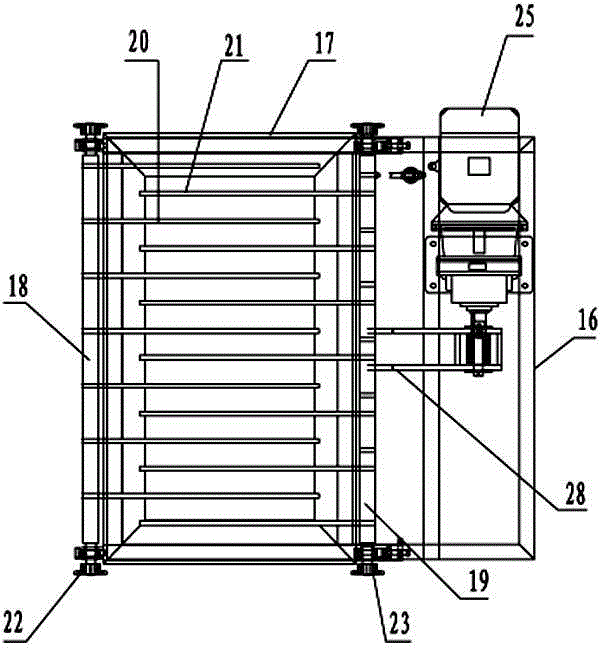

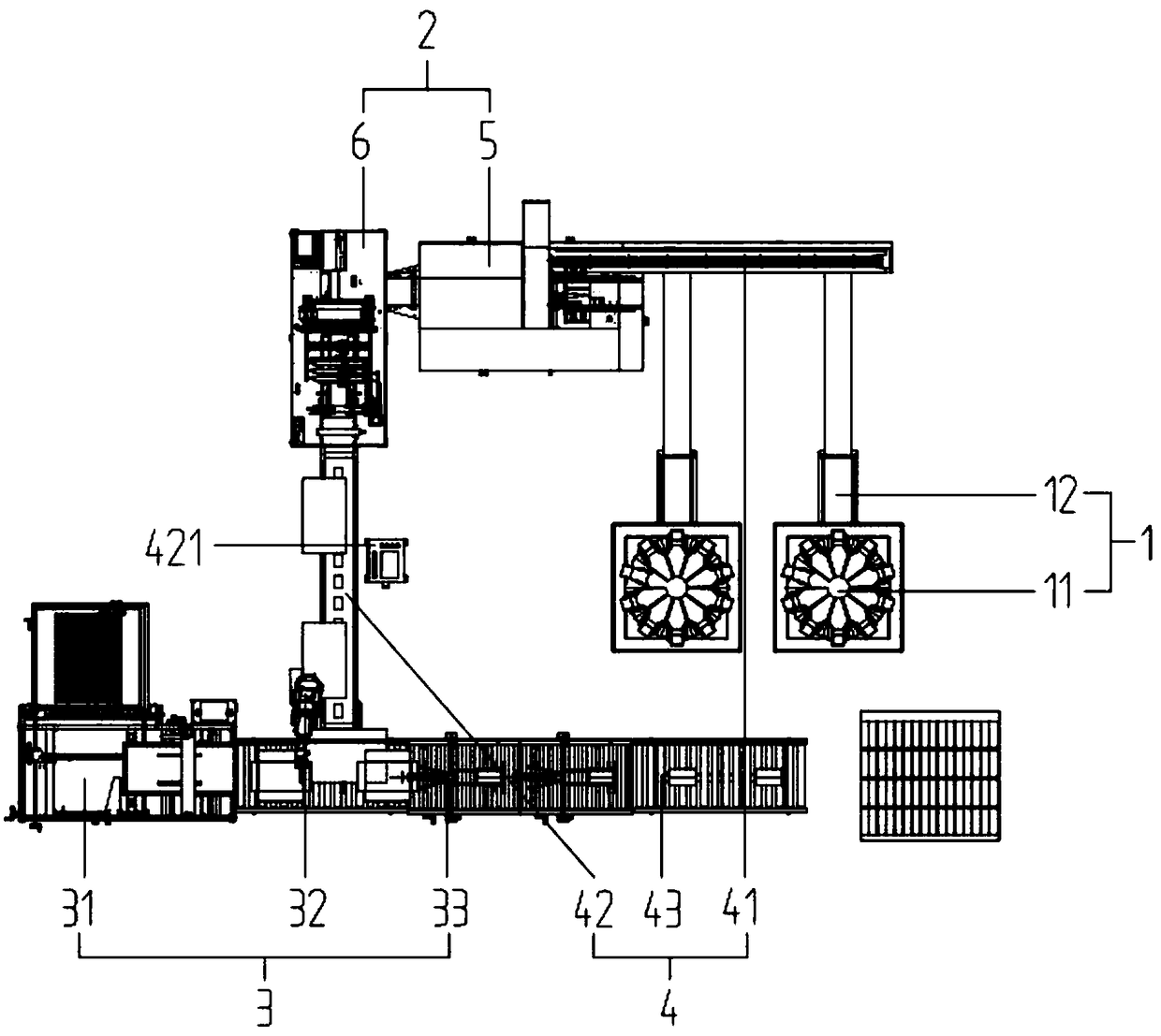

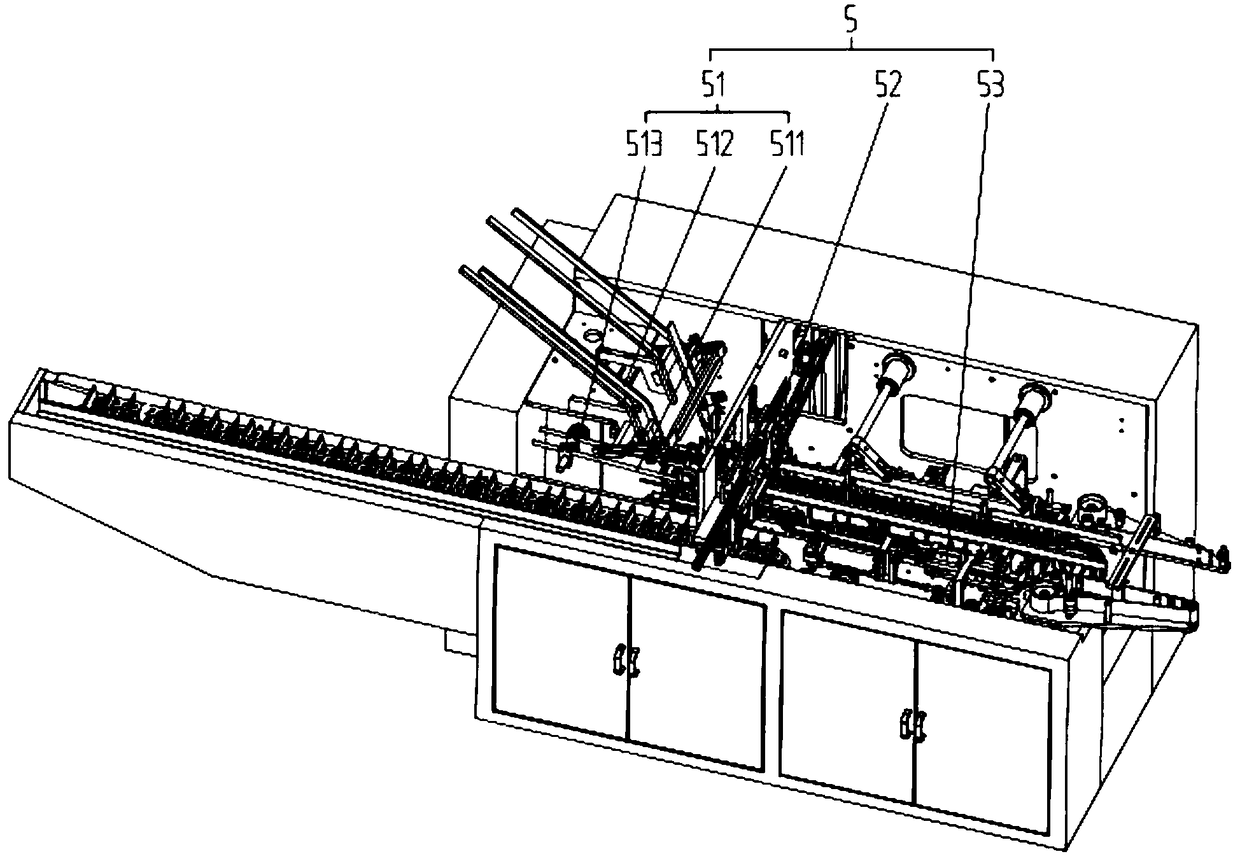

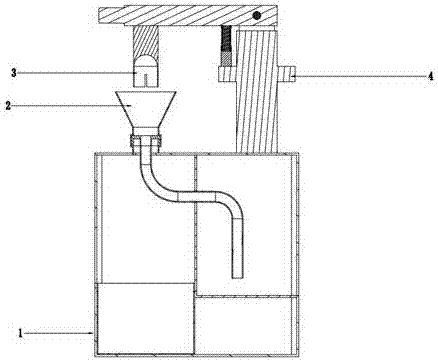

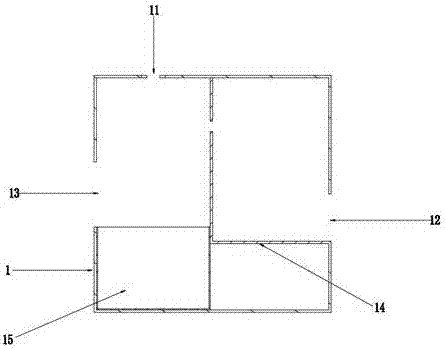

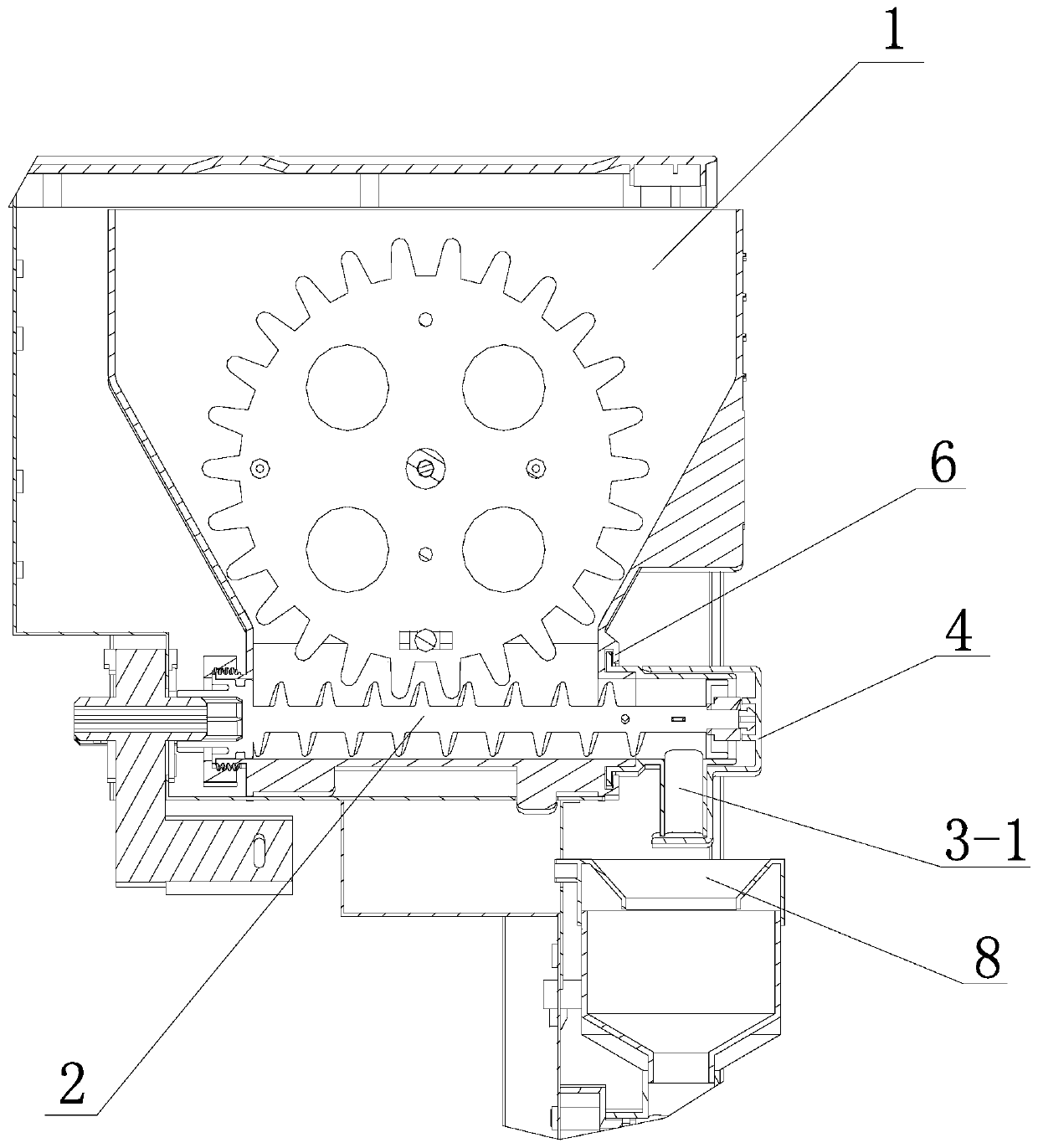

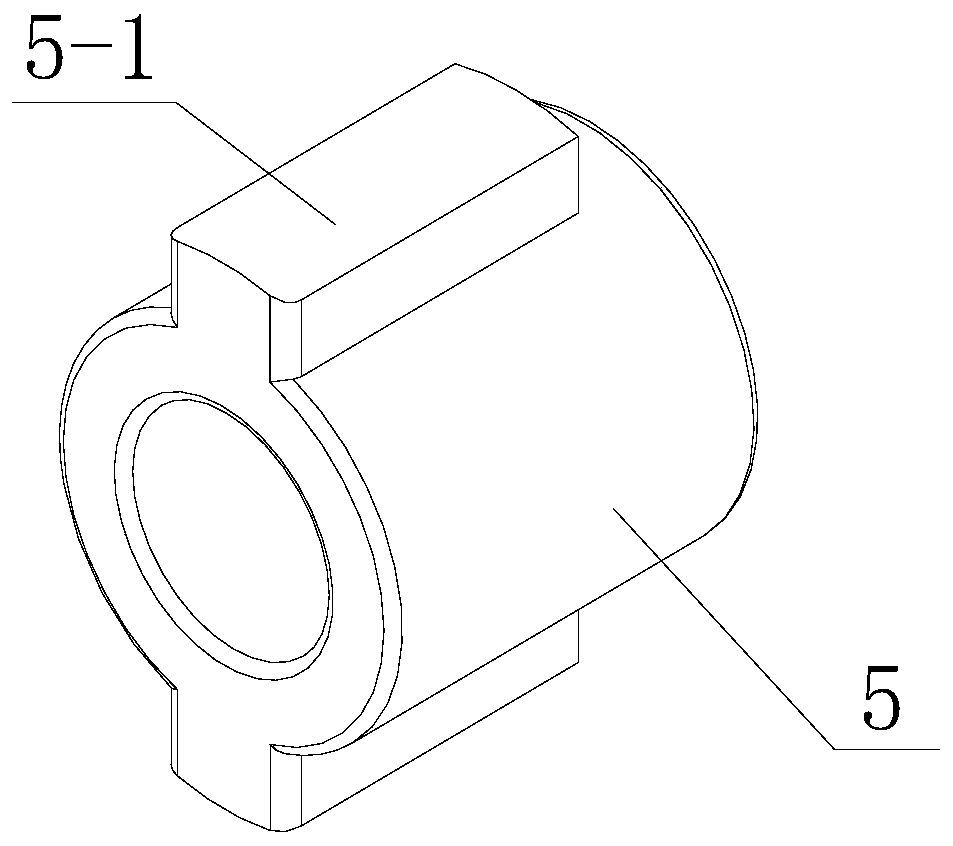

Automatic positioning holding device and automatic splitting machine for areca nuts

The invention discloses an automatic positioning holding device for processing areca nuts and an automatic splitting machine for the areca nuts, and belongs to the technical field of food processing devices. A holder fixed to a conveying chain and an elastic clamping device fixed to a machine frame are designed to be matched, and the process that the areca nuts are clamped and fed into a cutter to be split is completed during the relative movement. Two hoppers are arranged on the automatic splitting machine for the areca nuts, the two hoppers are connected through a conveying chain with a stopping block, and the feeding height is reduced; a distributing wheel is installed in a conveying hopper to replace manual conveying. By means of the automatic positioning holding device and the automatic splitting machine for the areca nuts, labor is replaced with a machine, and workers are liberated from complicated labor. The number of the workers is decreased, cost is reduced, floor space is reduced, production efficiency is improved, safety is improved, and food hygiene is guaranteed. The machine is compact and reasonable in design and convenient to operate and maintain. Parts in contact with food are manufactured through food-grade materials, and safe and sanitary effects are achieved.

Owner:所广博

Processing method for convenient rice wine soaking duck food

The invention relates to a processing method for convenient rice wine soaking duck food, which belongs to the technical field of meat product processing. A fresh or frozen duck without viscera serves as raw materials, and the duck is orderly processed into rice wine sauce, a duck neck, a duck tongue and duck wings to obtain the convenient rice wine soaking duck food. The processing technology andparameters, brine and a drunk brine formula are determined. The fishy smell of the raw materials is eliminated by precooking and rising modes, the wine soaking time is shortened with a vacuum wine soaking slot, and the wine soaking consistency is enhanced. The vacuum packaging is integrated with a high temperature sterilization technology to ensure the food hygiene and the guarantee period. Soup made of the duck skeleton is used for processing the convenient rice wine soaking duck food so as to enhance the utilization ratio of the raw materials. The convenient rice wine soaking duck food has the flavors of the duck, the duck neck, the duck tongue or the duck wings and the rice wine, and has strong flavor of rice wine but no preservatives. The package of the convenient rice wine soaking duck food is small, and the convenient rice wine soaking duck food can be instantly eaten after being opened. The convenient rice wine soaking duck food is stored at the normal temperature, and the guarantee period of the convenient rice wine soaking duck food is longer than or equal to six months.

Owner:QIONGZHOU UNIVERSITY +1

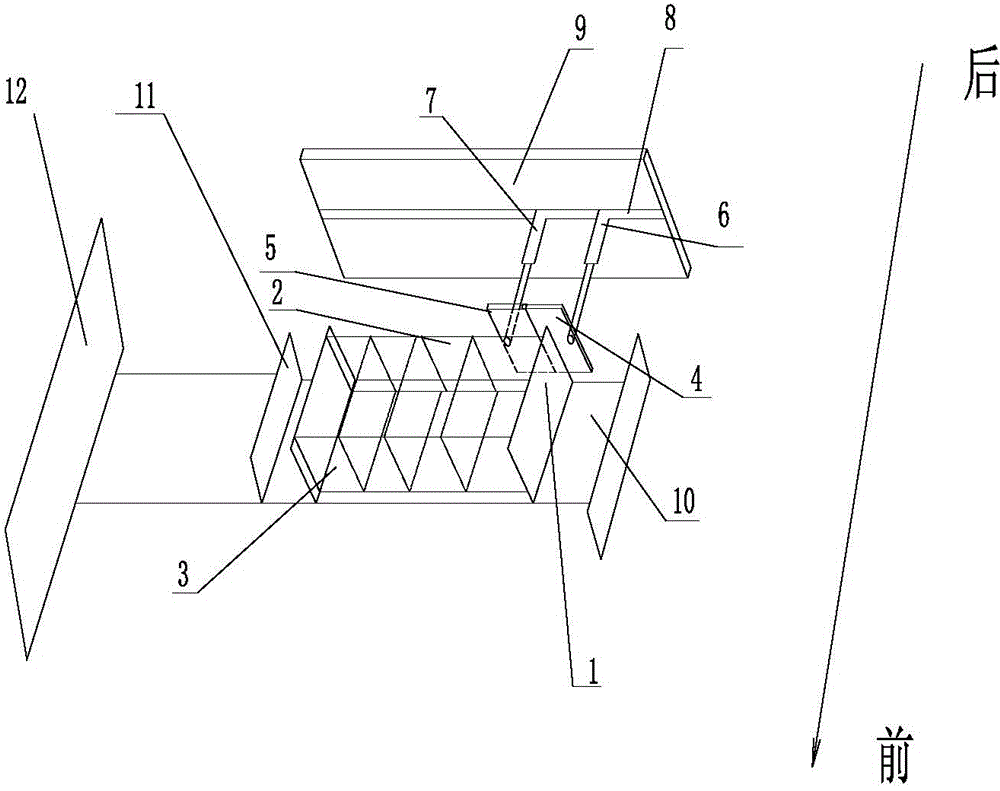

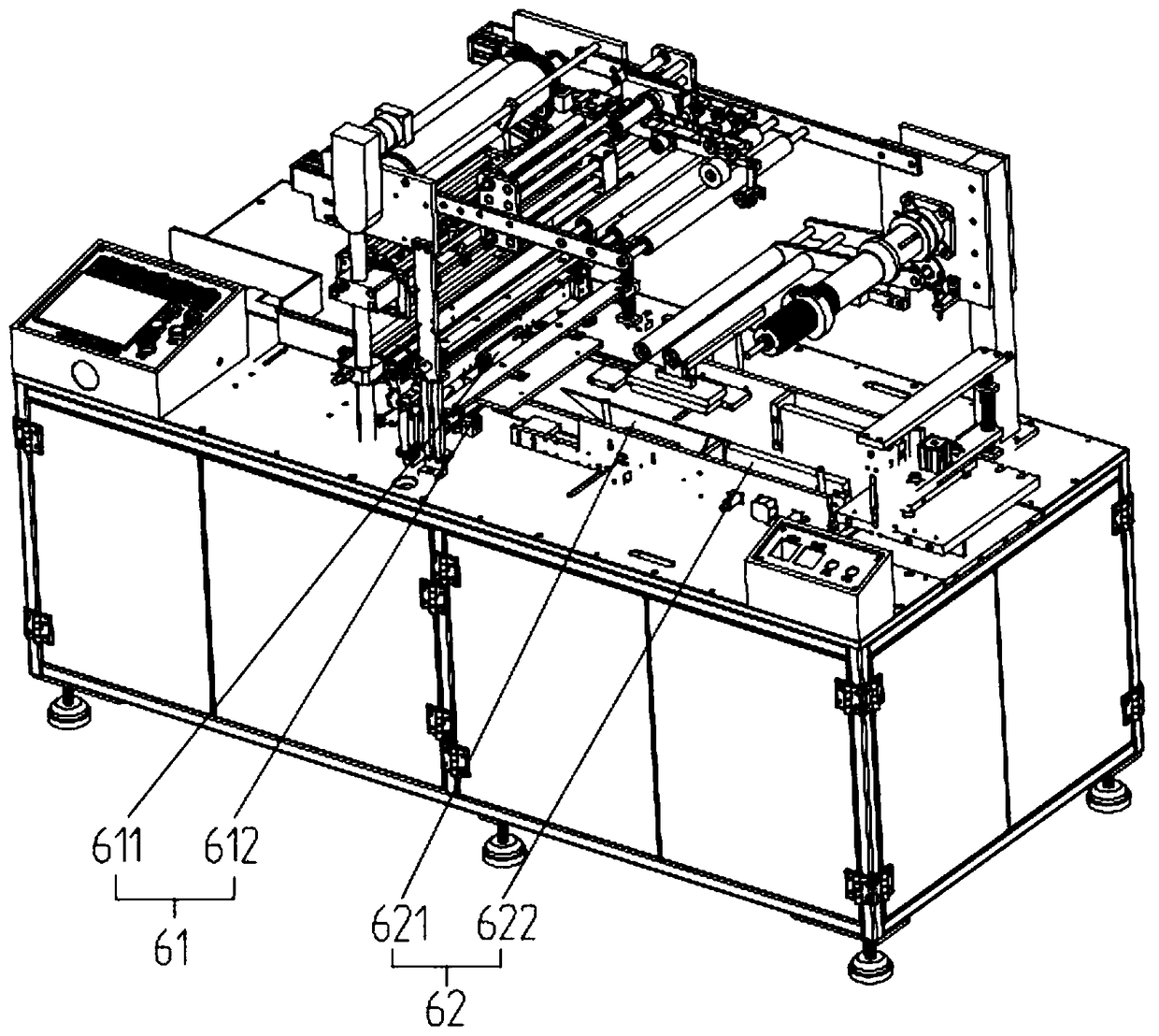

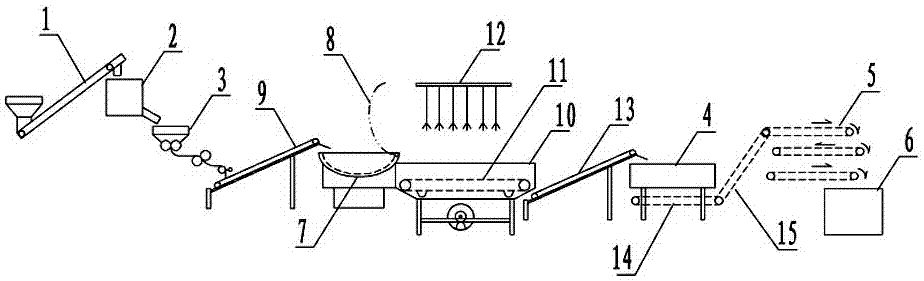

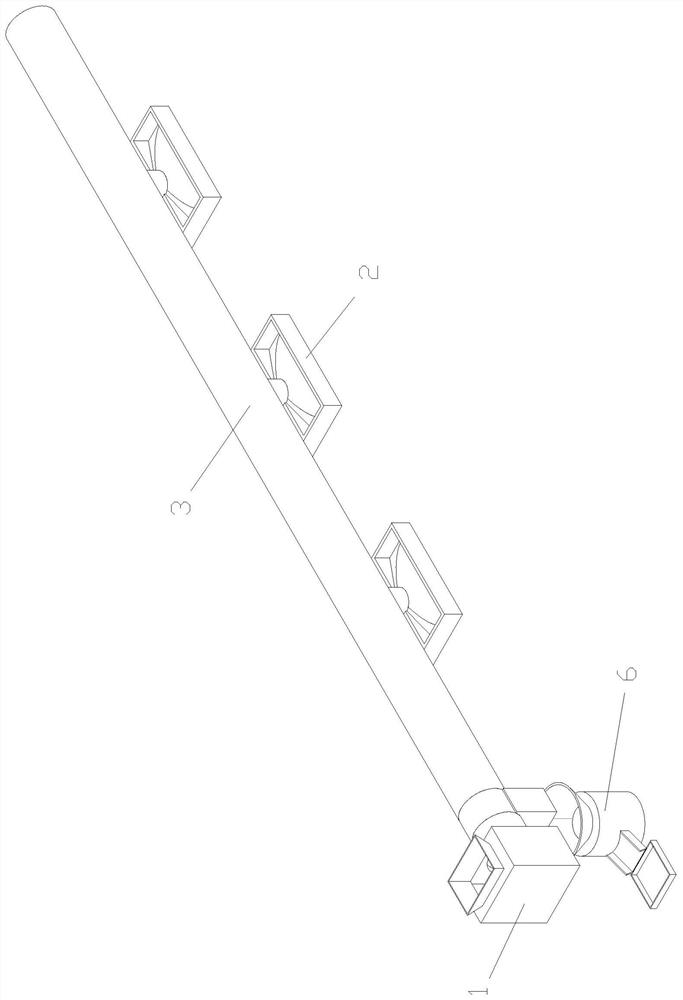

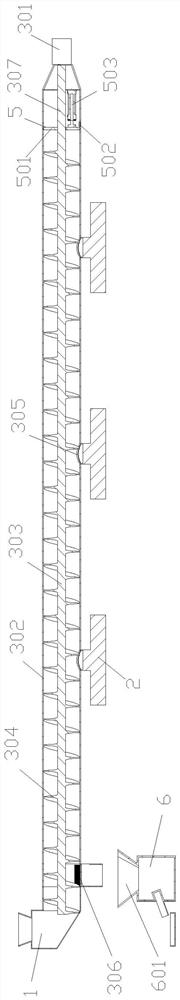

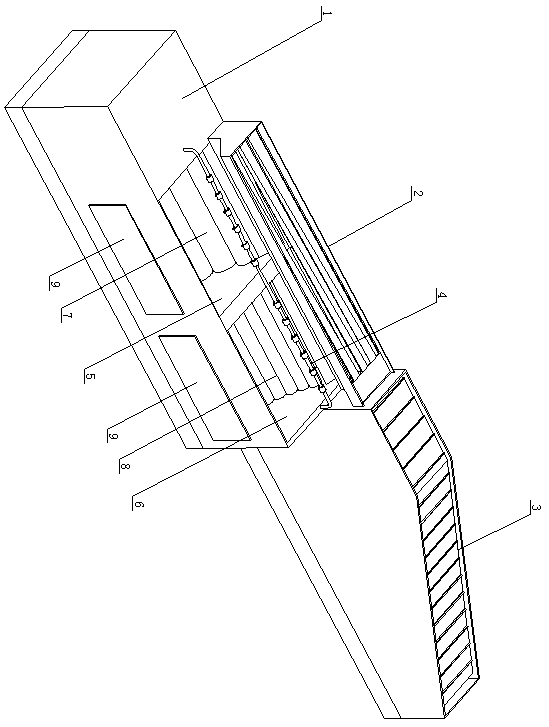

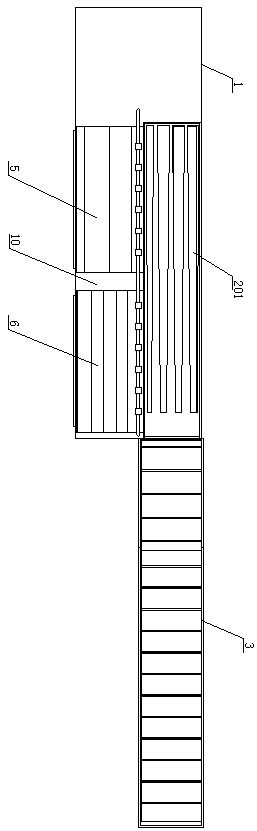

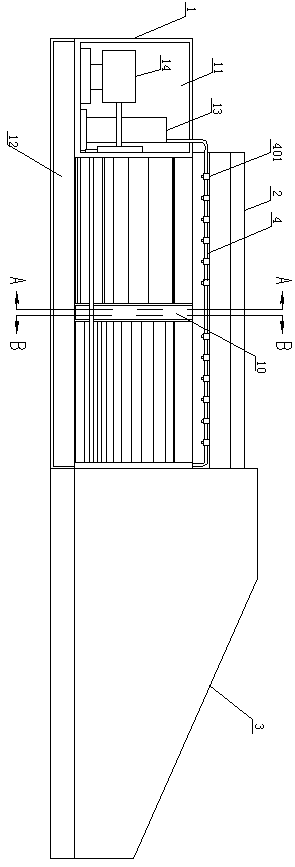

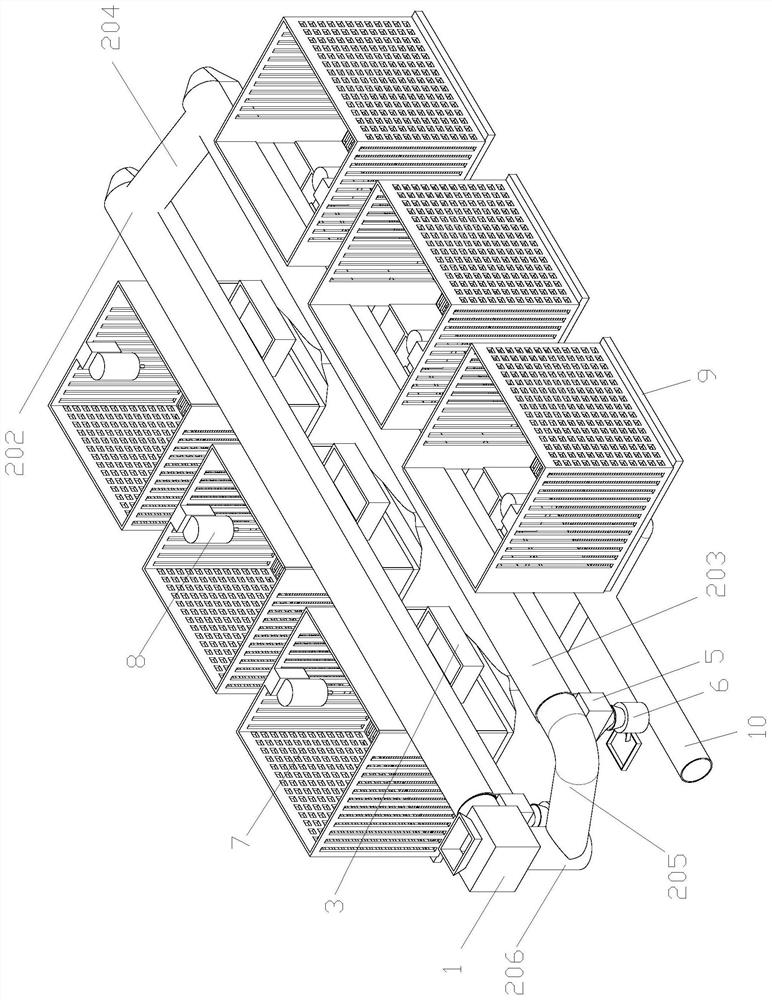

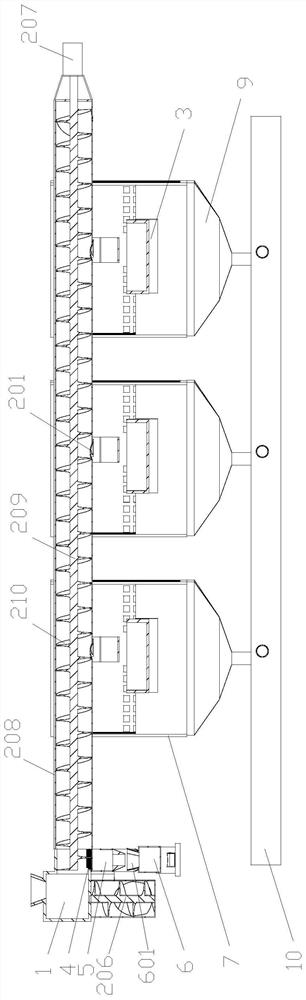

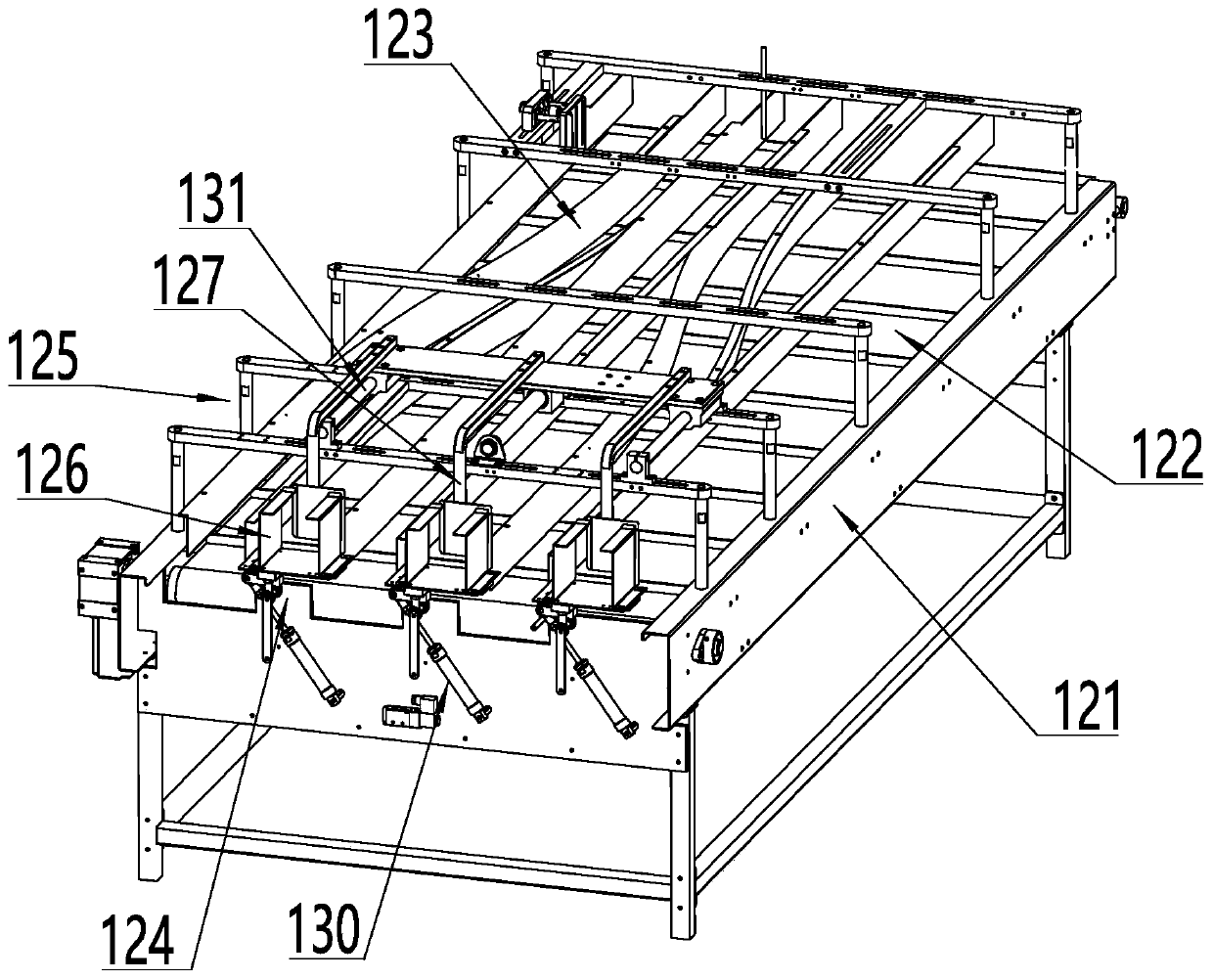

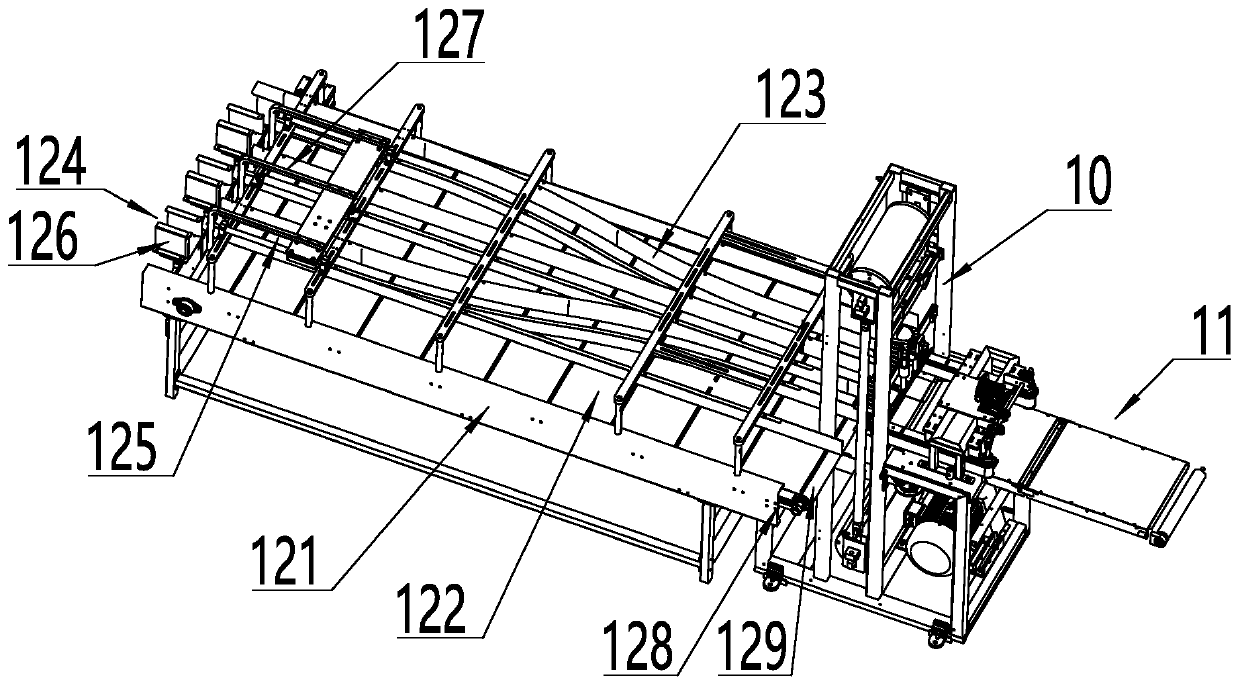

Continuous production method of hot-and-dry noodles, and special production line

ActiveCN104431781AReduce the number of manpower usedEnsure food hygieneFood preparationDough processingFood sanitationAutomation

The invention discloses a continuous production method of hot-and-dry noodles. The continuous production method comprises the following steps: mixing flour, salt and alkali at proper ratio, and then conveying the raw materials in a noodle stirring machine, adding starch, water and the like, mixing into a dough and proofing for certain time, then rolling the dough into noodles, carrying out cooking, cooling, dispersing, oil-spraying and airing, and then packaging to obtain the finished product. The invention further discloses a special production line of the production method. The continuous production method and the special production line disclosed by the invention have the advantages that the industrialized production of hot-and-dry noodles can be realized, and mechanical automation continuous production is realized from all working procedures including stirring, rolling, cutting, cooking, cooling, dispersing and oil-spraying, packaging and the like, thus the use amount of manpower is greatly reduced, and the food sanitation of the products is also ensured. Meanwhile, the quality of the products realizes consistence and stability, and the production efficiency is increased.

Owner:郑州孔河天地食品有限公司

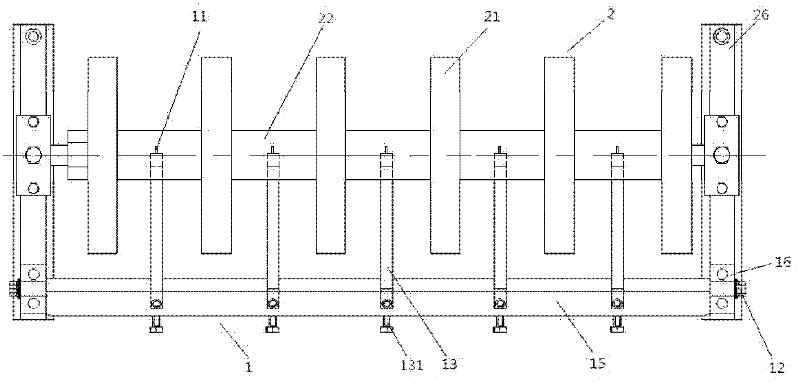

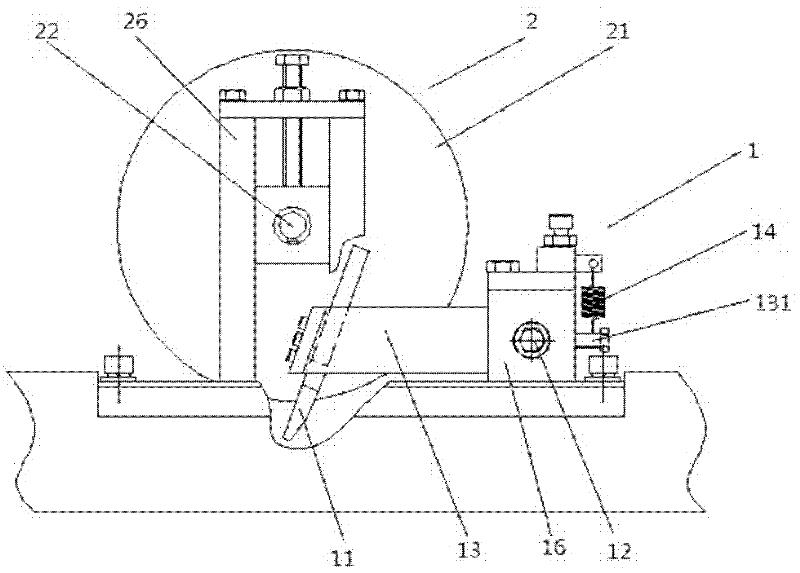

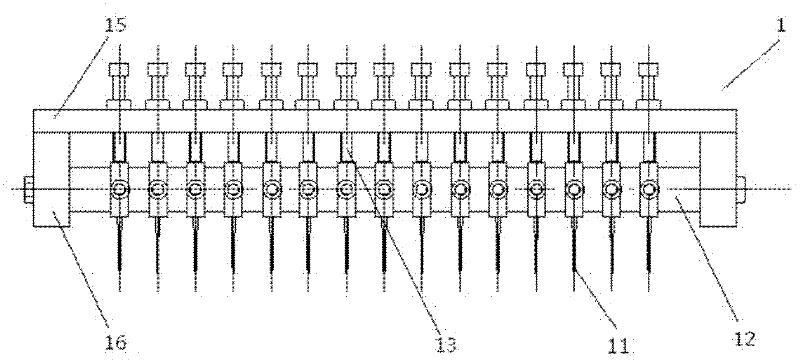

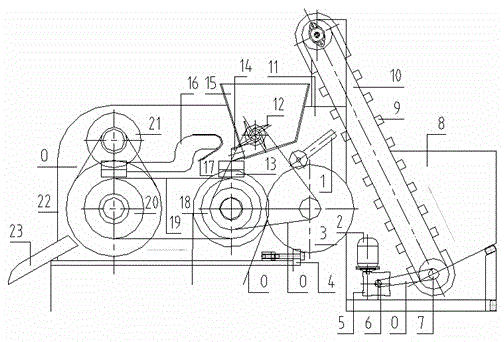

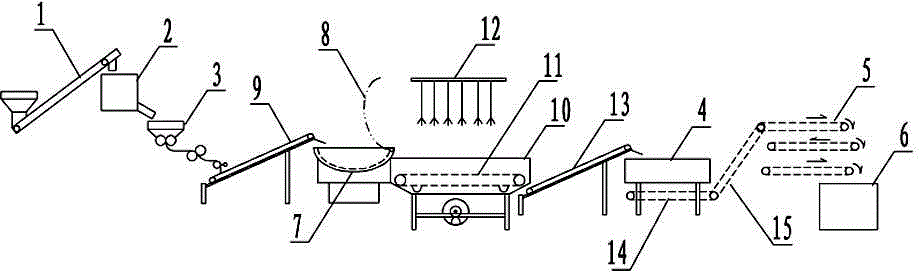

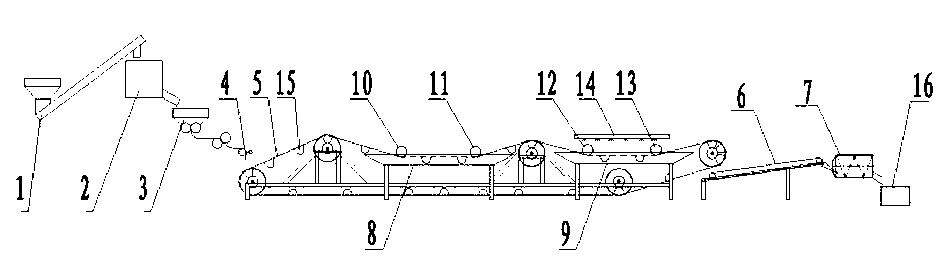

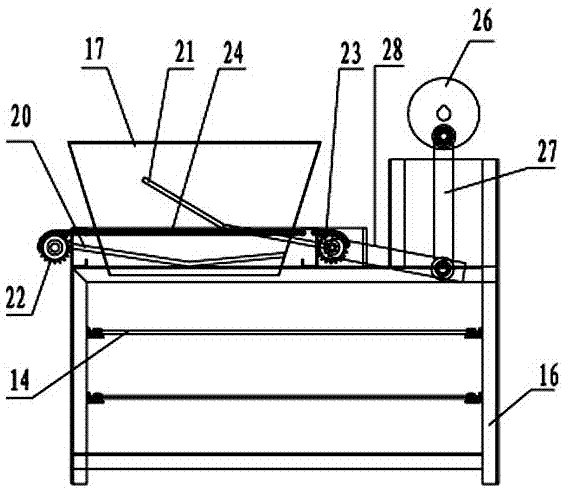

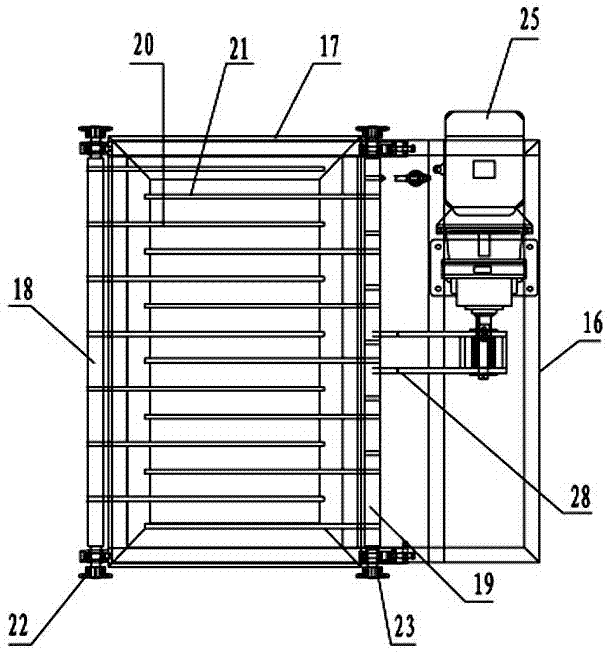

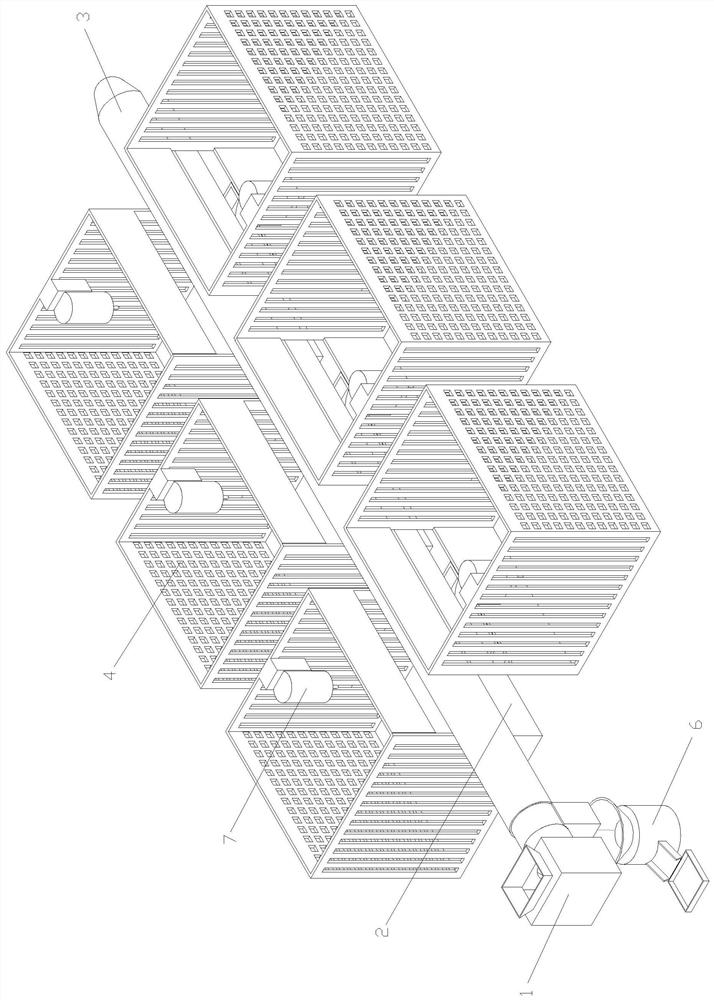

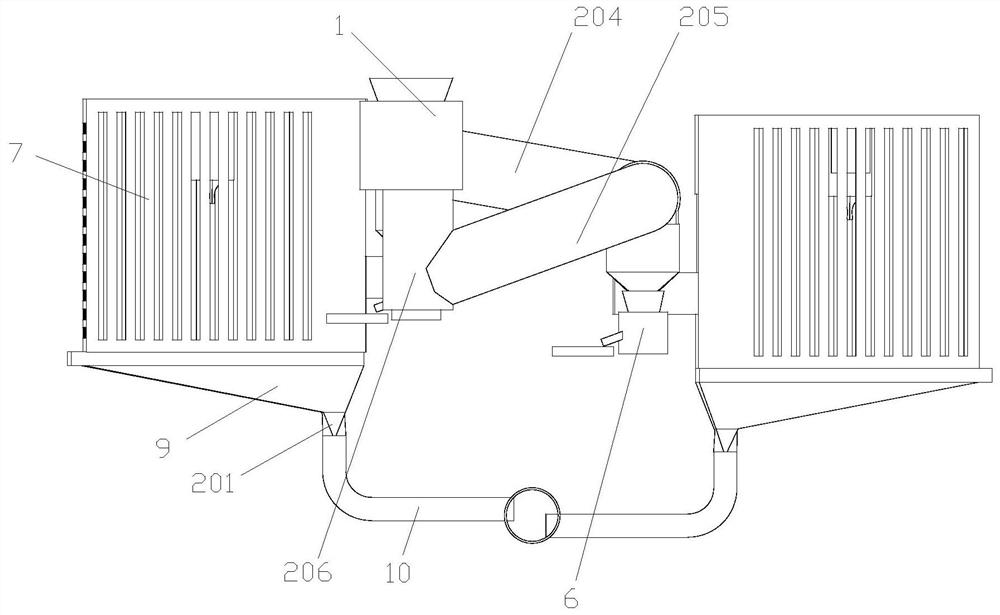

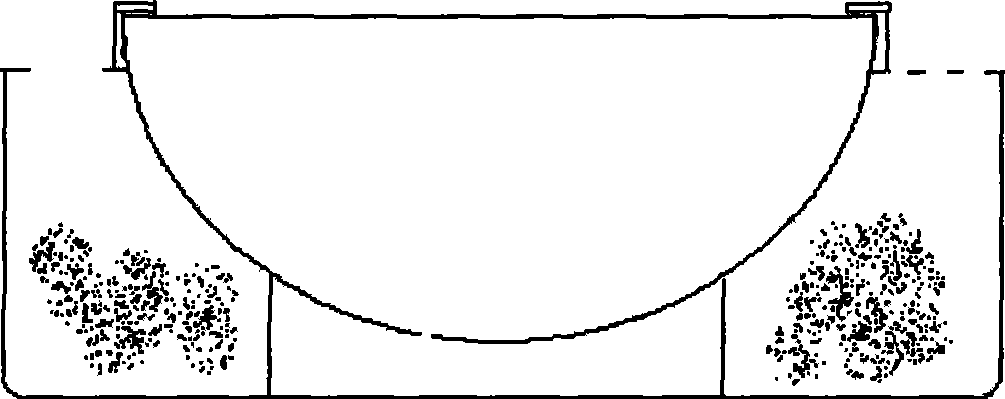

Large-scale hot-dry noodle continuous production line

InactiveCN102793109AReduce the number of manpower usedEnsure food hygieneFood preparationContinuous productionFood hygiene

The invention discloses a large-scale hot-dry noodle continuous production line which comprises a flour conveyer; a material outlet of the flour conveyer is connected with a material inlet of a flour stirring machine; a material outlet of the flour stirring machine is connected with a material inlet of a dough sheeter; a noodle shearing device is disposed below a material outlet of the dough sheeter, and the noodle shearing device is located above a material inlet end of a string bag conveying chain; a material outlet end of the string bag conveying chain is connected with the inlet of the flour stirring machine through a conveyer belt; a boiling water pot and a cold water pot are orderly disposed below the string bag conveying chain from the material inlet end to the material outlet end with intervals; guide rollers are respectively disposed at two ends of the boiling water pot and the cold water pot along a vertical direction; and the string bag conveying chain passes through the inner cavities of the boiling water pot and the cold water pot below the guide rollers. The production line of the invention has the advantages that the production line realizes industrial production of hot-dry noodle, greatly reduces the quantity of used persons, and thus ensures product food hygiene. Meanwhile, the product quality is consistent before and after, and is stable, and the production efficiency is improved.

Owner:郑州朱屯米粉食品有限公司

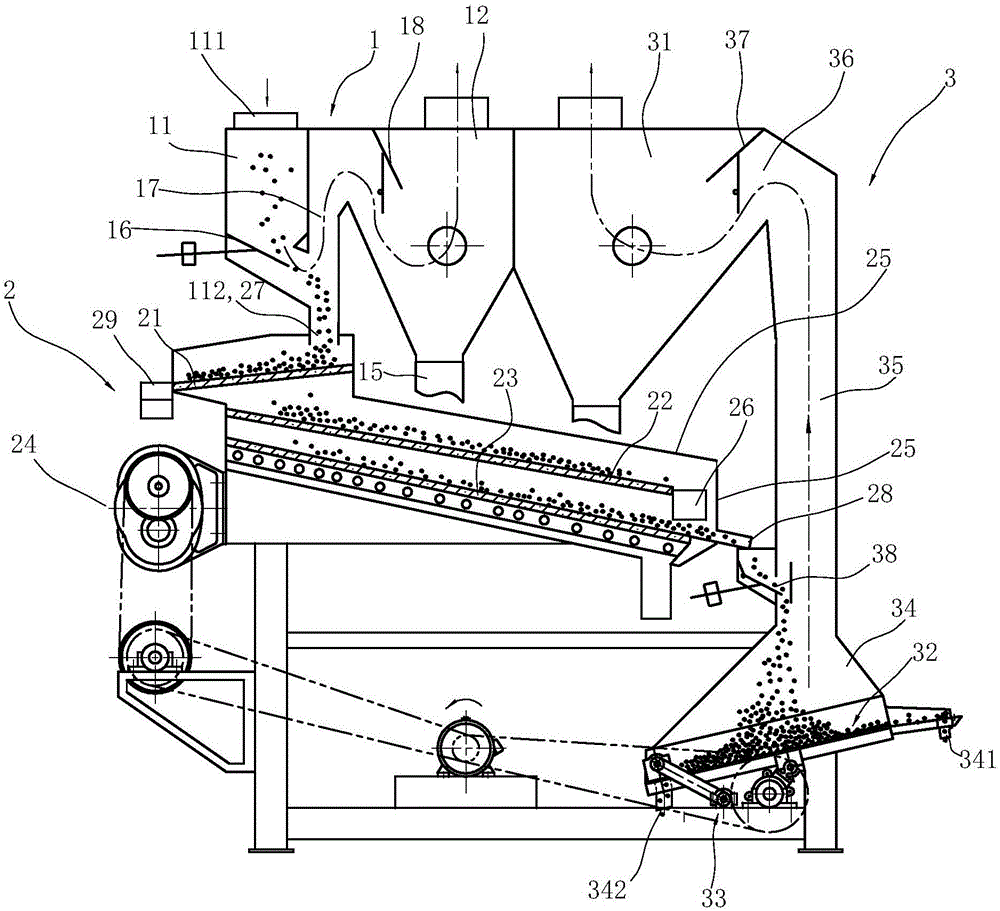

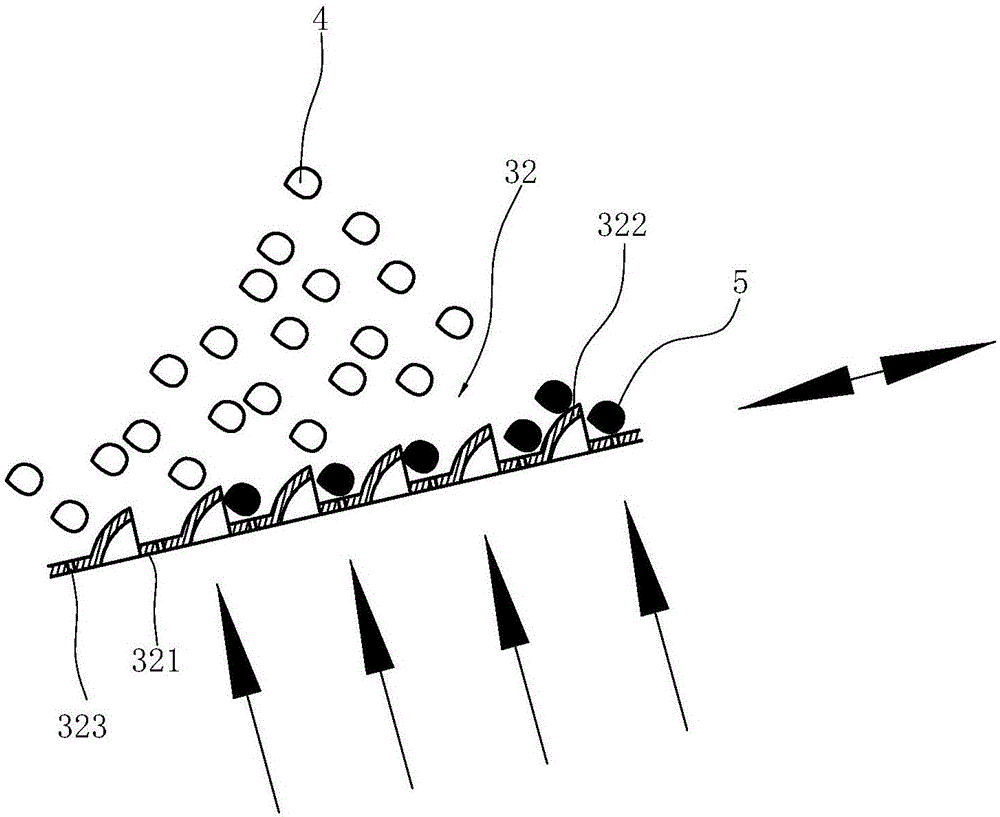

Automatic grain screening machine

The invention relates to an automatic grain screening machine which is characterized in that the screening machine comprises an induced draft separation device, a screening separation device and a stone removal separation device, the induced draft separation device is used for removing light impurities in grains; the screening separation device is positioned downstream the induced draft separation device and used for screening impurities lager than grain particles and sand particles smaller than the grain particles, and the stone removal separation device is positioned downstream the screening separation device and used for removing abreast stones in the grains. Compared with the prior art, the automatic grain screening machine can completely screen all impurities in the grains, the impurities are cleanly removed, and food sanitation is effectively ensured.

Owner:NINGBO CHANGRONG BREWING EQUIP

Full-automatic sushi machine

The invention discloses a full-automatic sushi machine which comprises a bottom plate; a sushi forming device is fixed on the upper surface of the bottom plate; a nori conveying device is fixed next one side of the sushi forming device; a sushi push-out device is fixed under the nori conveying device; a cylindrical connection barrel is fixed right above the sushi forming device; a discharge port of a rice feeding device is connected with a first opening in the outer lateral surface of the connection barrel; a dried meat floss feeding device is connected with a second opening in the outer lateral surface of the connection barrel; the upper bottom surface of the connection barrel is connected with a discharge port of a sliced cucumber feeding device; and a sushi finished product conveying device is fixed on the other side of the sushi forming device and at a position opposite to the nori conveying device. The invention provides the full-automatic sushi machine which continuously and stably works, is high in efficiency and can sell immediately after making.

Owner:NANTONG UNIVERSITY

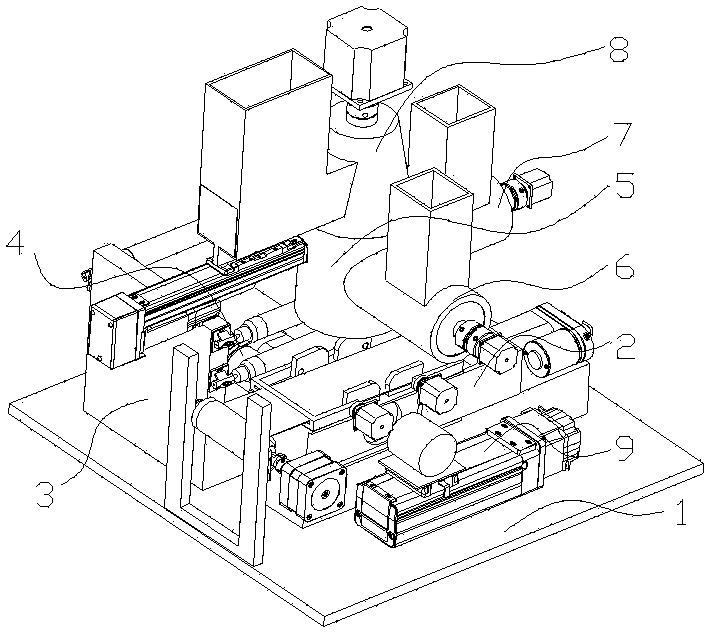

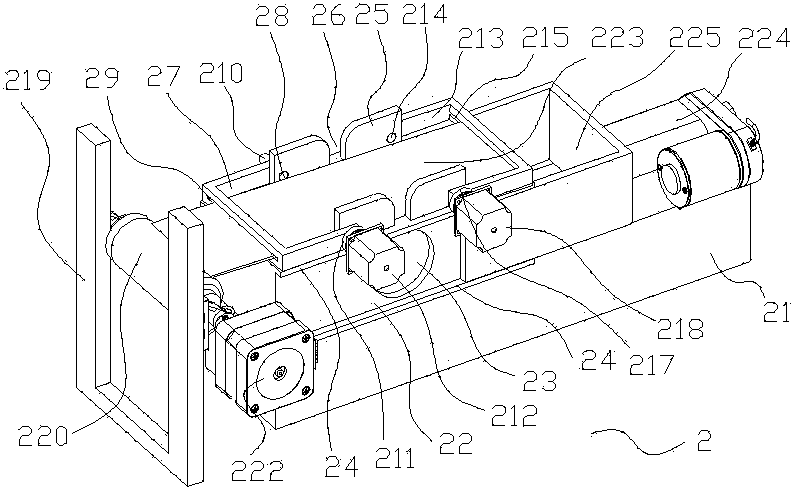

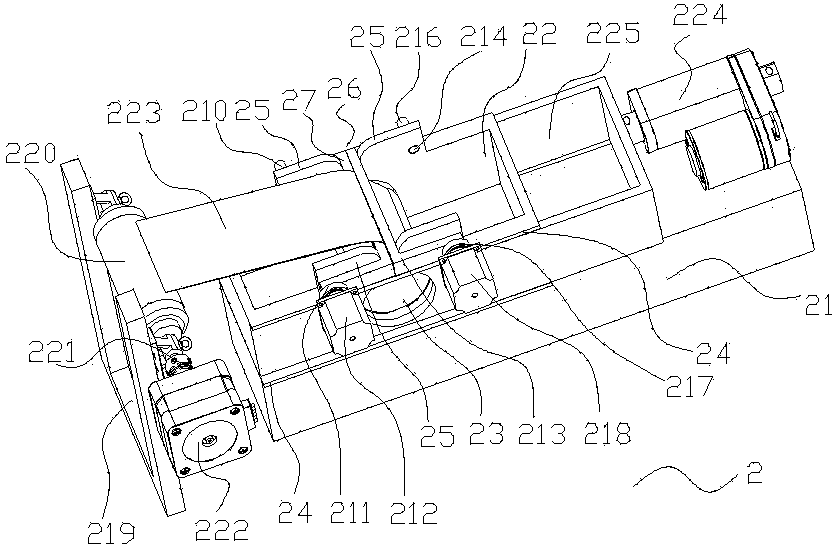

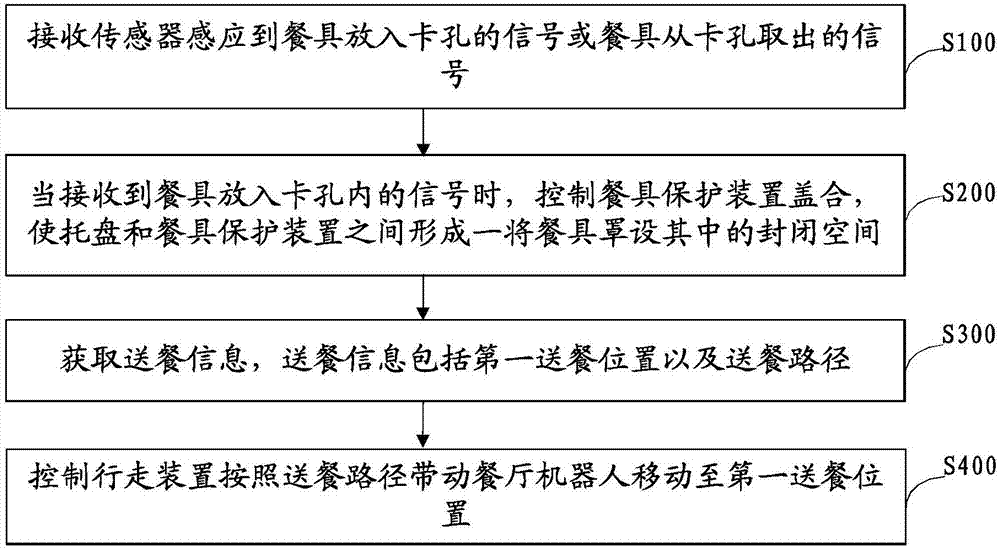

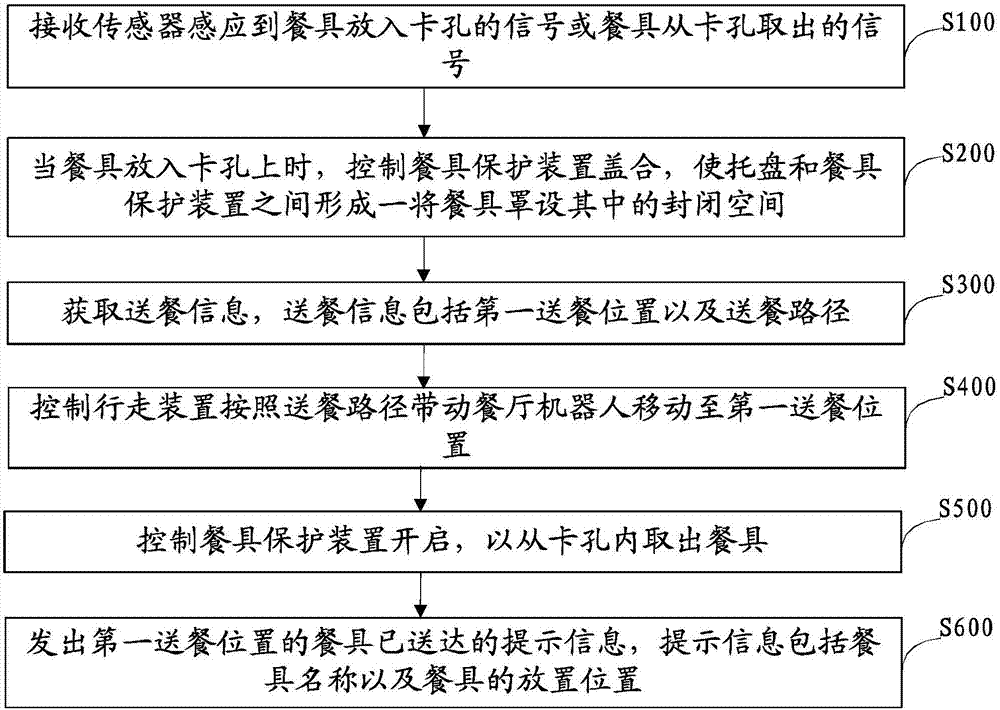

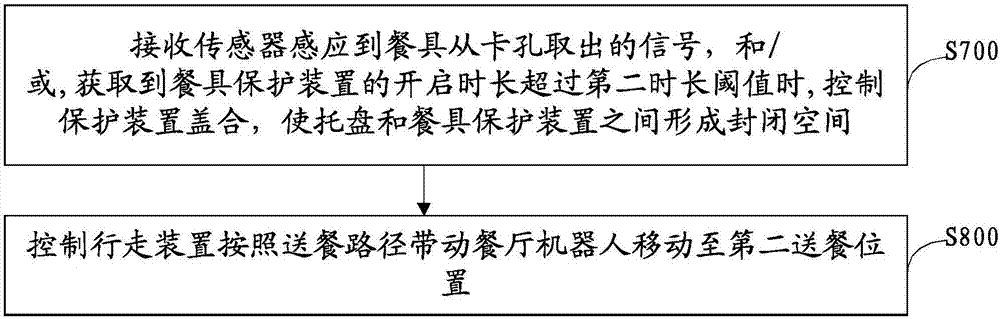

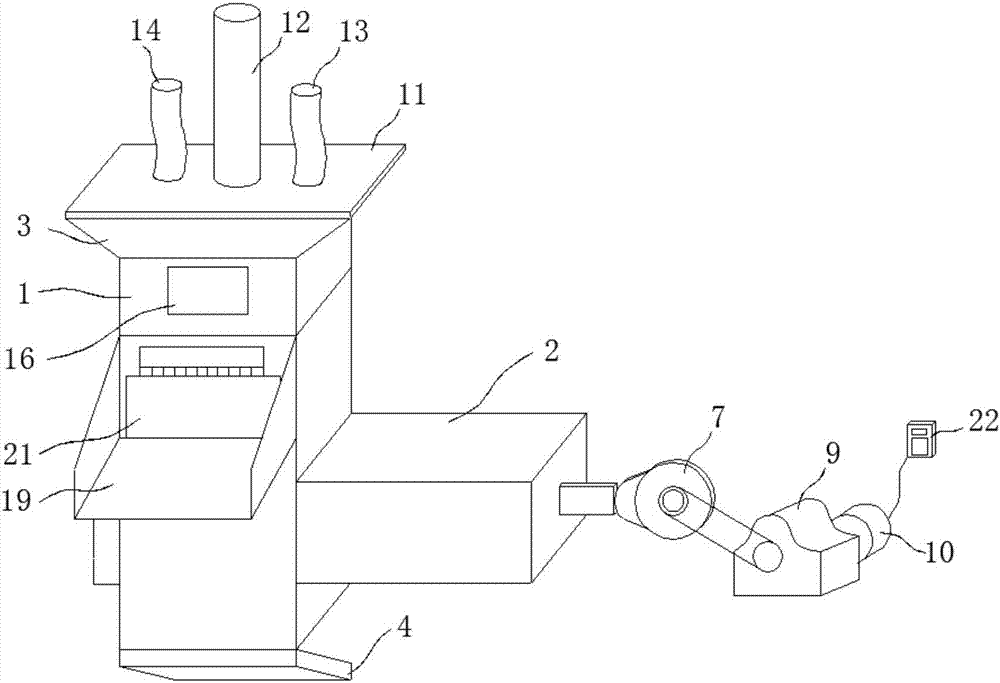

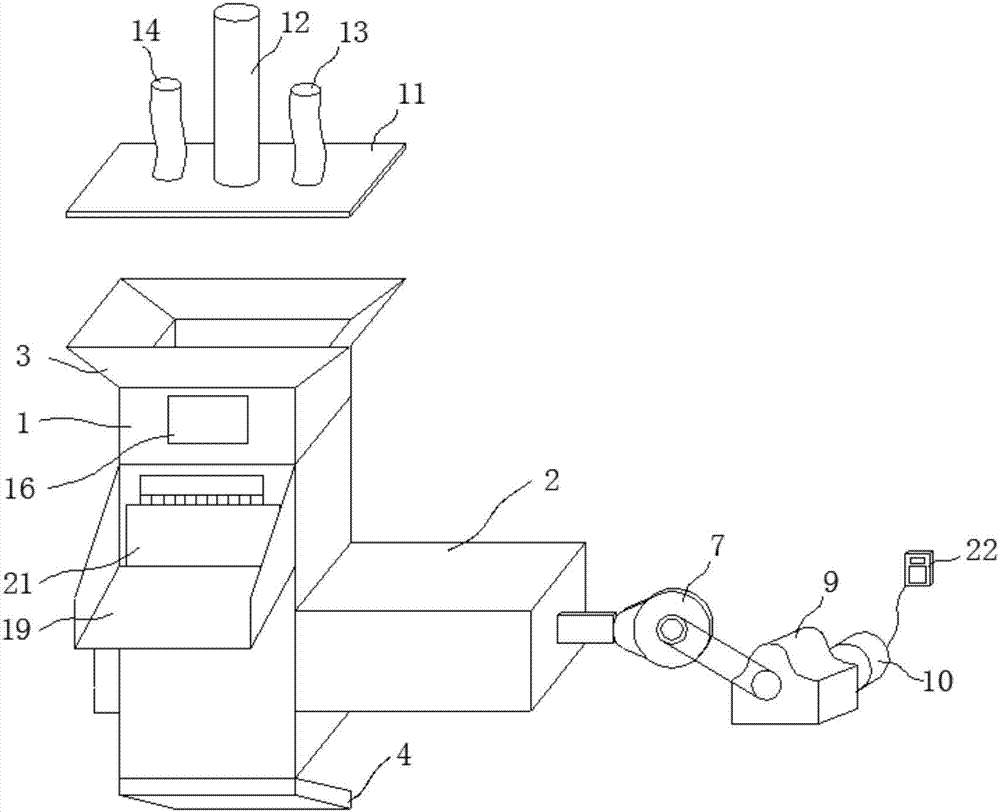

Restaurant robot and meal delivery method thereof

PendingCN107953343AEasy to useDetection is accurate and specificManipulatorPhysical medicine and rehabilitationPhysical therapy

The invention discloses a restaurant robot and a meal delivery method thereof. A tableware storing device of the restaurant robot is arranged on a machine seat of the robot and comprises a tray; a tableware protection device is arranged on the tray; at least one clamping hole for storing tableware is formed in the tray, and the clamping holes are used for fixing the tableware; and sensors and a controller are electrically connected. The meal delivery method of the restaurant robot comprises the steps that signals that the sensors sense the situation that the tableware is placed in the clampingholes or signals that sensors sense the situation that the tableware is taken out from the clamping holes are received; when the tableware is placed in the clamping holes, the tableware protection device is controlled to be closed in a covering mode, so that a closed space covering the tableware is formed between the tray and the tableware protection device; meal delivery information is obtained,wherein the meal delivery information comprises a first meal delivery position and a meal delivery path; and a walking device is controlled to drive the restaurant robot to move to the first meal delivery position according to the meal delivery path. According to the restaurant robot, intelligent operation of meal taking and delivering can be achieved, using is more convenient, the situation thatcustomers take the tableware mistakenly can be avoided, and food hygiene can be further guaranteed.

Owner:GEER TECH CO LTD

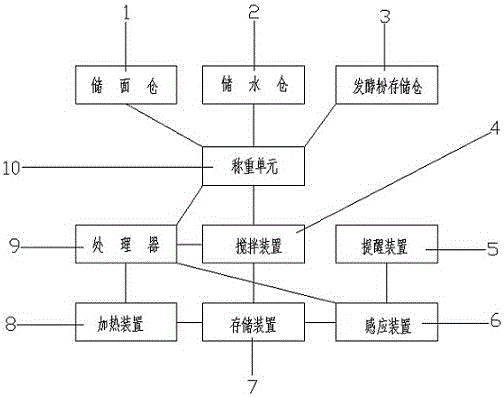

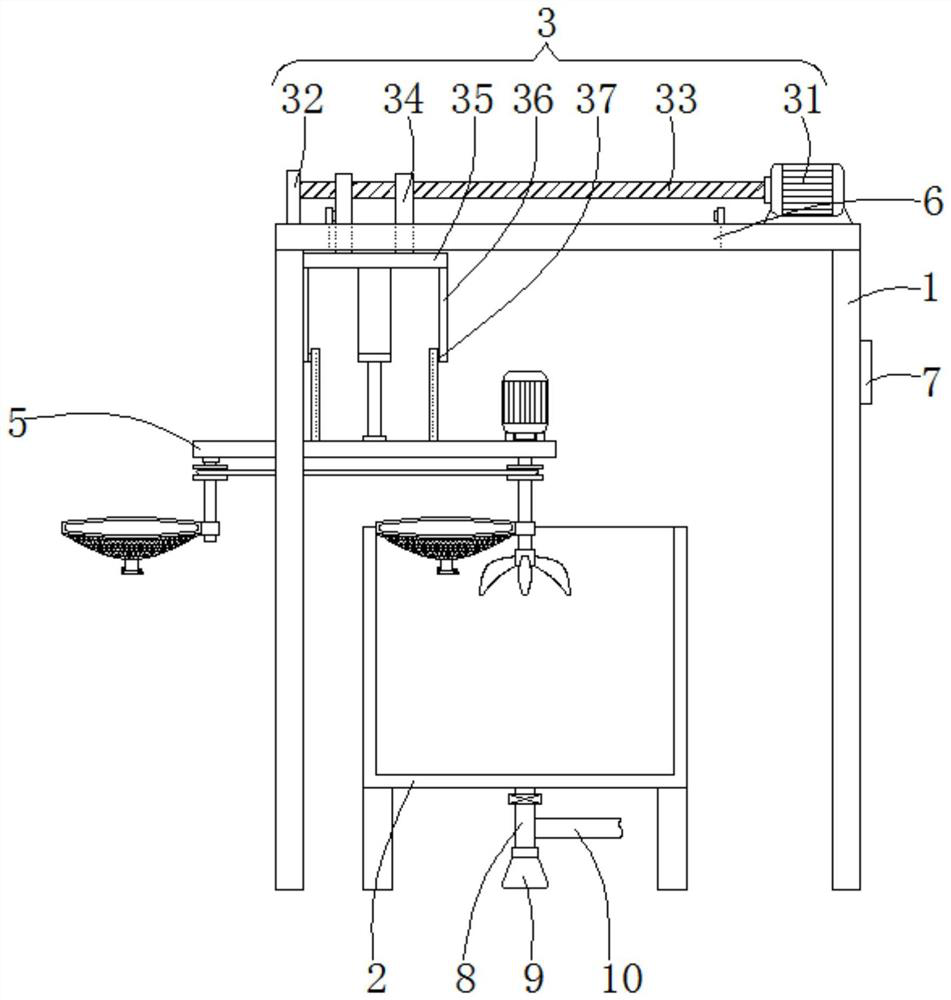

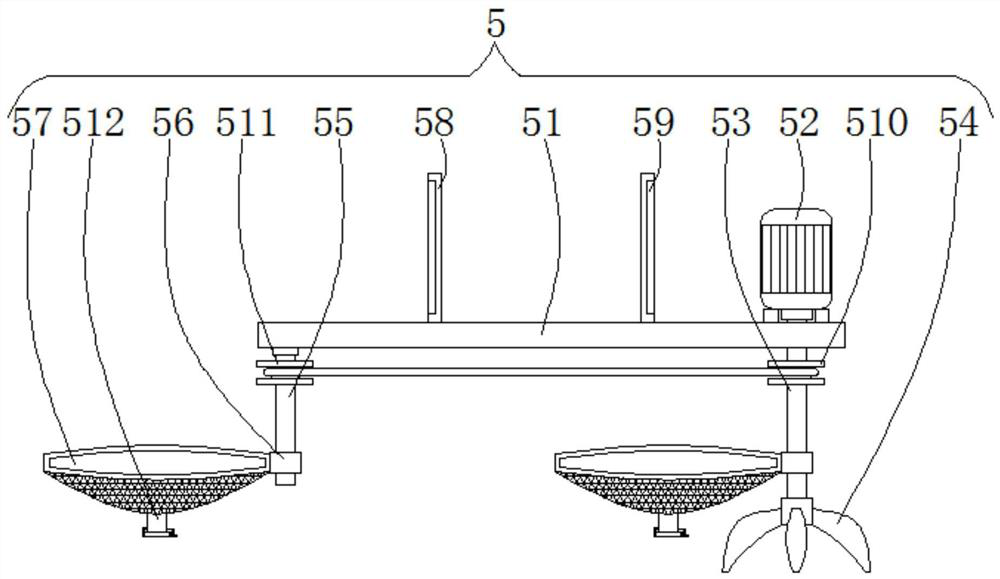

Intelligent fermentation dough mixer

InactiveCN106577902AEasy to useEnsure food hygieneMixing/kneading structural elementsProversYeastFermentation

The invention belongs to the field of food processing, and particularly relates to an intelligent fermentation dough mixer. The intelligent fermentation dough mixer comprises a flour storing warehouse, a water storing warehouse, a yeast storing warehouse, a stirring device, a reminding device, an induction device, a storage device, a heating device, a processor and a weighing unit. The intelligent fermentation dough mixer disclosed by the invention has the function of automatically adding corresponding flour, water and yeast in proportion as needed for stirring, and then according to the temperature of periphery environment, judges whether uniform-stirred flour needs to be heated, so that the flour reaches temperature at which fermentation is performed relatively conveniently. After fermentation is finished, the function of heating is automatically closed, and reminding is realized.

Owner:郑州特别有效营销管理咨询有限公司

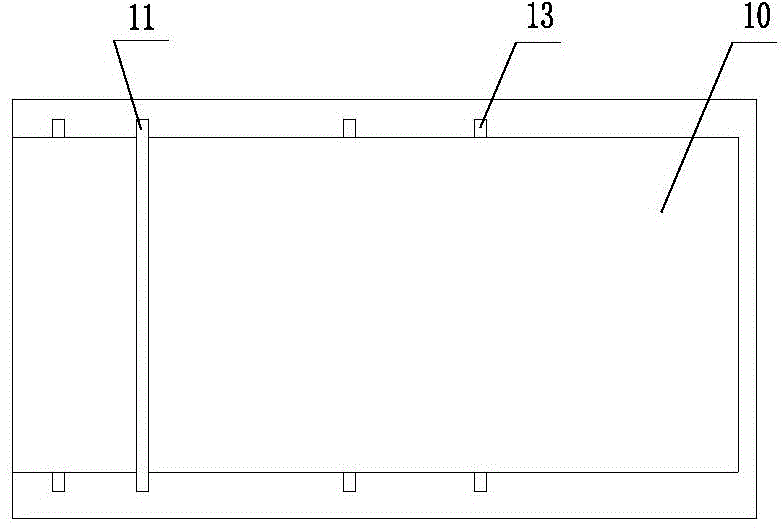

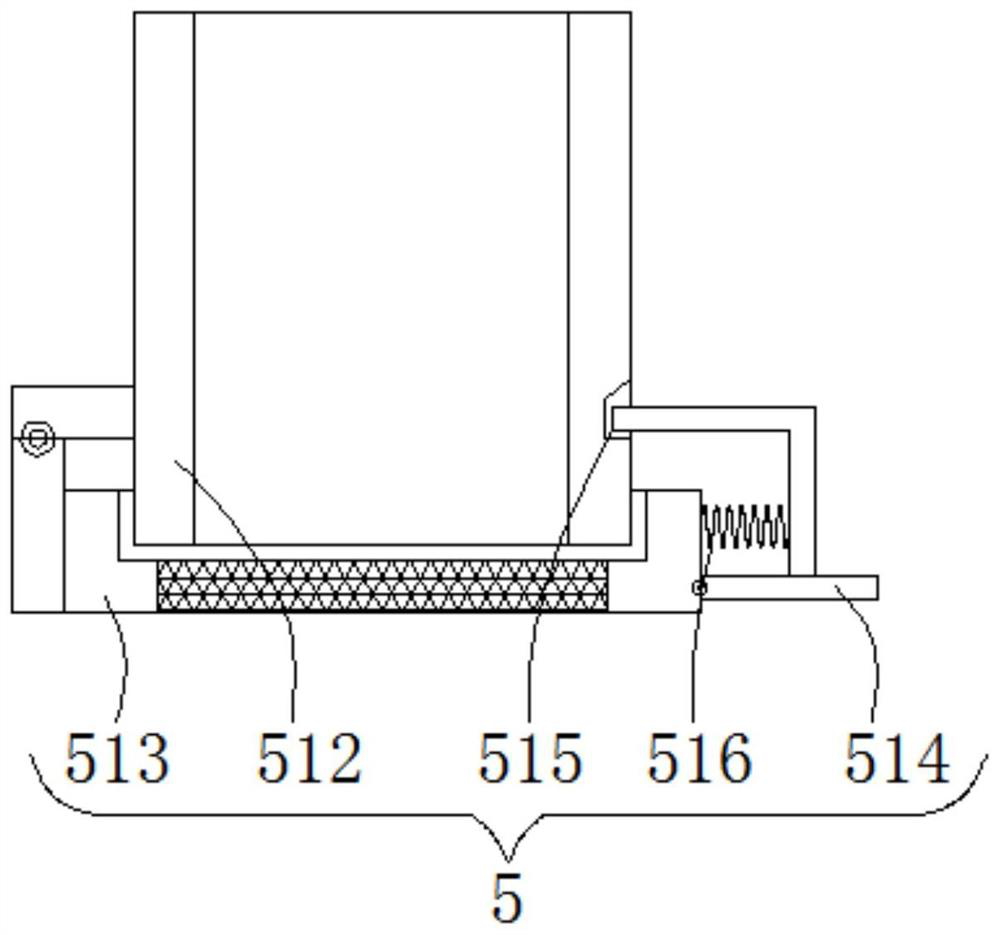

Vegetable distribution box, automatic feeding mechanism and manufacturing method

InactiveCN104856559ARealize automatic feeding actionSimple structureCooking vesselsBody right sideAutomatic control

Provided are a vegetable distribution box, an automatic feeding mechanism and a manufacturing method. The vegetable distribution box and the automatic feeding mechanism are characterized in that the vegetable distribution box is placed on a supporting plate and at the horizontal front portion of a pushing plate, the supporting plate and a cooking robot shell body right side stand plate are vertically fixed, the roots of a right telescopic rod and a left telescopic rod of the automatic feeding mechanism are embedded into a sliding way, the front ends of the telescopic rods vertically fix the pushing plate respectively, the roots of the telescopic rods are in circuit connection with servo motors respectively, and pneumatic valves are arranged in the middle of the telescopic rods. The manufacturing method comprises the steps that an operation panel of a cooking robot is in circuit connection with a programmable logic controller (PLC) for automatic feeding controlling, a power supply is connected with motor protectors, a frequency converter and a servo motor respectively through general control switches, a breaker connected with the general control switches is connected with a transformer, a voltage-stabilizing power supply, the PLC and the operation panel, and the output ends of the PLC are connected with the frequency converters, the motor, a relay and the pneumatic valves respectively. The shortcomings that manual vegetable distribution is needed in an existing vegetable distribution link are overcome, the cooking robot fully achieves automatic control, easiness, accuracy and sanitation are achieved, and efficiency and quality are improved.

Owner:沈阳精力传动设备有限公司

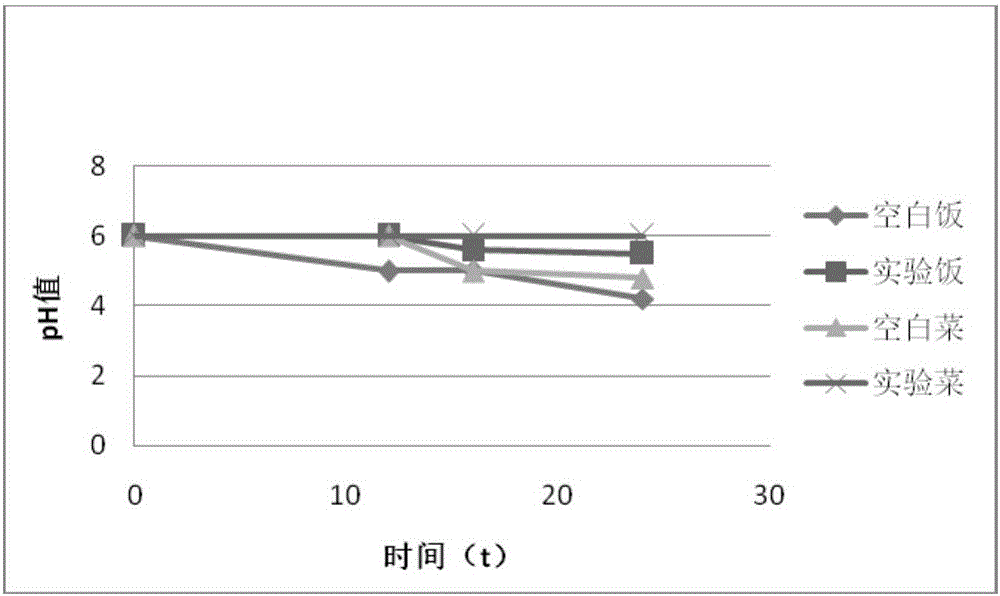

Room-temperature food preservation sheet and preparing method thereof

InactiveCN105767840APlay a role in keeping freshNo smellFood preservationNatural extract food ingredientsWoven fabricHoneysuckle

The invention discloses a room-temperature food preservation sheet.The preservation sheet is formed by an adsorption carrier with an anti-bacterial extraction solution adsorbed.Water absorbent paper or non-woven fabric or a thin wood sheet meeting the food safety standard serves as the adsorption carrier.The anti-bacterial extraction solution is formed by mixing a camellia seed meal extraction solution and a plant mixture extraction solution, wherein the plant mixture is prepared from orange peel, tea leaves, pomegranate peel, flowers of chrysanthemum morifolium ramat, honeysuckle flowers and mint.The preservation sheet can be placed on a room-temperature and heated box lunch, pastries and other foods, and common bacteria such as escherichia coli, staphylococcus aureus and bacillus subtilis can be inhibited within a certain time at the room temperature.By means of the antibacterial effect of natural extract, the product can perform the preservation effect on foods at the room temperature or under heat preservation even the foods are not put into a refrigerator, and the method is convenient to implement, simple and capable of preventing peculiar smells and guaranteeing good sanitation.

Owner:ZHEJIANG CHINESE MEDICAL UNIVERSITY

Tea packaging production line

PendingCN109051065AEnsure food hygieneWrappers shrinkageWrapper twisting/gatheringProduction lineCarton

The invention relates to a tea packaging production line. The tea packaging production line comprises a multi-head weighing and canning system, an automatic boxing and film packaging system, an automatic carton packaging system and a conveying system which are connected in sequence; the conveying system comprises a first conveying device, a second conveying device and a third conveying device, andthe conveying speed of the first conveying device is the same as the conveying speed of the second conveying device; the multi-head weighing and canning system comprises canning machines and conveyorbelts, and discharge outlets of the canning machines are located over the conveyor belt; the automatic boxing and film packaging system comprises a boxing machine and a film packaging machine, the output end of the boxing machine is communicated with the feeding end of the film packaging machine, and the discharge end of the film packaging machine is connected with the second conveying device; and the automatic carton packaging system comprises a carton opening machine, a manipulator device and a cover sealing and adhesive tape sticking integrated device. According to the tea packaging production line, the processes of bagging, boxing and carton packaging of tea are automatically achieved, and a lot of manpower for repeated operation is not needed; and workers do not need to make contactwith tea in the whole process, and therefore food sanitation is guaranteed.

Owner:浙江武义博德机械有限公司

Raw material selecting device based on sesame seed candy production

InactiveCN112845347AReduce workloadImprove efficiencyCleaning using liquidsFood treatmentProcess engineeringFood sanitation

The invention discloses a raw material selecting device based on sesame seed candy production. The raw material selecting device comprises a supporting frame and a cleaning box; the top of the supporting frame is fixedly connected with a driving assembly; the bottom of the driving assembly penetrates through the supporting frame and extends to the bottom of the supporting frame; the bottom of the driving assembly is fixedly connected with a telescopic rod; the bottom end of the telescopic rod is fixedly connected with a material selecting assembly; and the material selecting assembly comprises a first fixing plate. The invention relates to the technical field of sesame seed candy production. According to the raw material selecting device based on sesame seed candy production, the material selecting assembly is arranged at the bottom of the supporting frame, the material selecting assembly can extend into the cleaning box to clean and collect raw materials, and manual material selection and collection are not needed, so that the workload of workers is reduced; two leakage screens cooperate, so that the efficiency is higher, and meanwhile, the material selection efficiency is also improved; and in the material selection process, the raw materials are directly cleaned, so that the cleanness of the raw materials is ensured, and the food sanitation is ensured.

Owner:贵州绿加绿食品有限公司

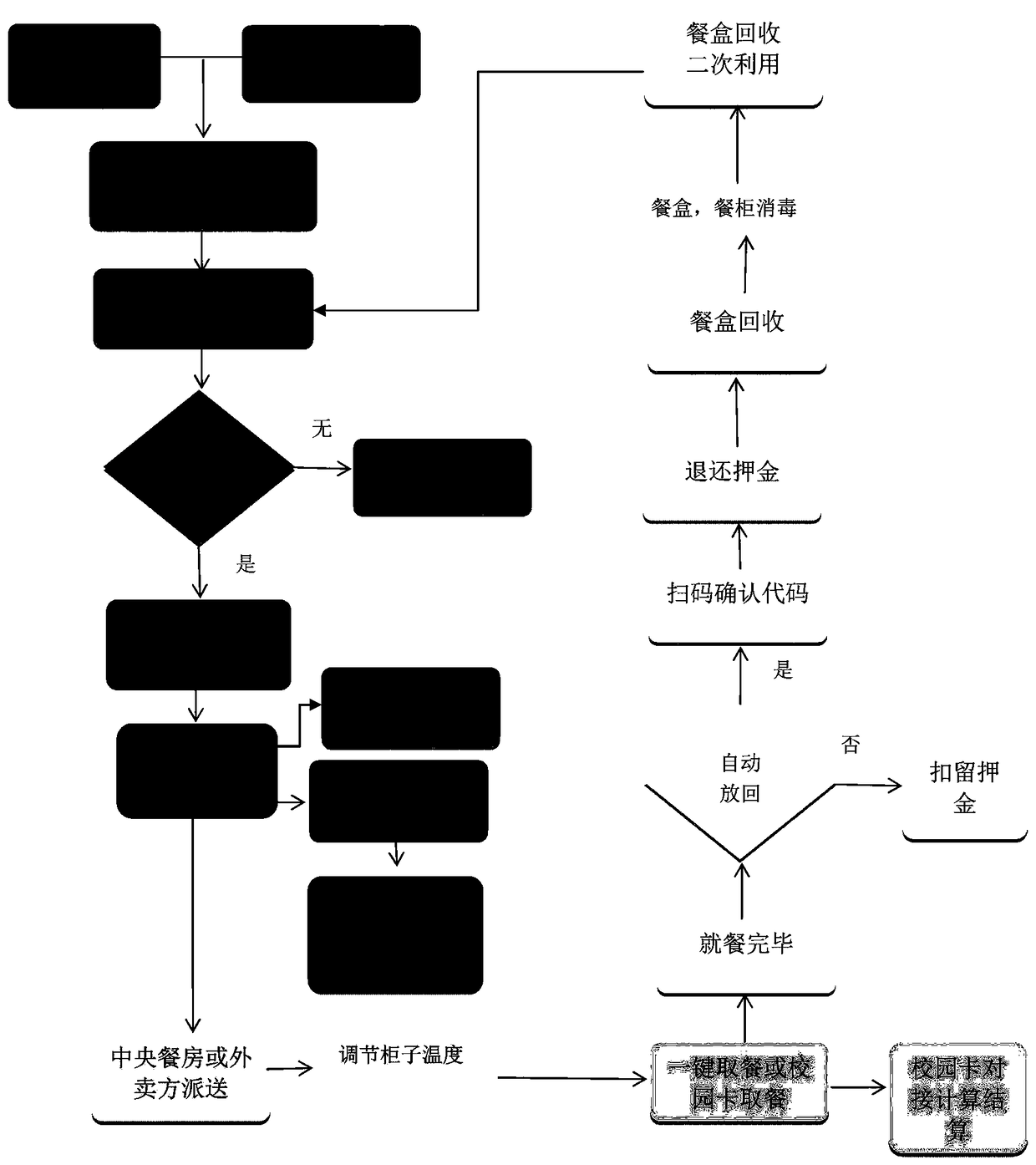

O2O technology-based catering service system for colleges and universities

InactiveCN108921478AConvenient way to eatFast way to eatApparatus for meter-controlled dispensingLogisticsEngineeringService system

The invention provides an O2O technology-based catering service system for colleges and universities. The system is characterized by being applied to a consumer end, a server end, a storage end and amerchant end which are connected through a network; the consumer end sends catering requirement information to the storage end; the storage end judges a spare empty cabinet and feeds back informationto the consumer end; if the remaining empty cabinets exist, the consumer end edits and sends the generated catering requirement information to the merchant end; the merchant end responds to the catering requirement information and then feeds back the catering requirement information to the server end; the server end receives the catering requirement information, sends the catering requirement information to the storage end and feeds back arrival information to the consumer end; and the storage end sends the catering arrival information to the consumer end.

Owner:ZAOZHUANG UNIV

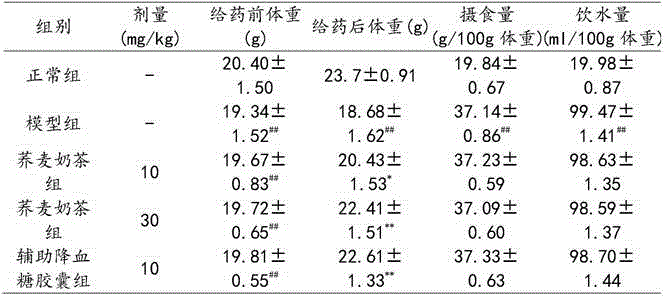

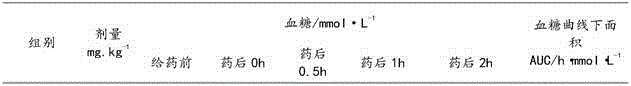

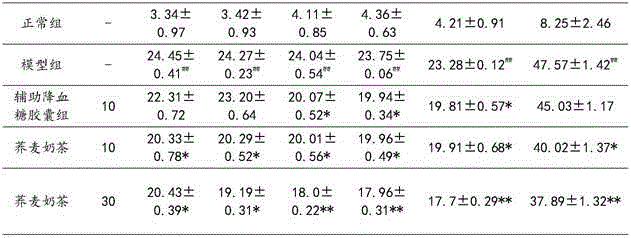

Health-care milky tea and preparation method thereof

InactiveCN106819223AAvoid destructionAvoid damageMilk preparationPre-extraction tea treatmentPolygonum fagopyrumAdditive ingredient

The invention discloses health-care milky tea and a preparation method thereof. The health-care milky tea is prepared by processing dried skim milk, sweet buckwheat, tartary buckwheat, tea, linseed, raffinose, edible salt and edible sugar according to certain formula proportion. Meanwhile, the invention further discloses the preparation method of the milky tea. The health-care milky tea disclosed by the invention more completely keeps nutritional ingredients and bioactive components of the dried skim milk, the sweet buckwheat, the tartary buckwheat, the tea, the linseed, the raffinose and the like, avoids any additive, has health-care functions of invigorating stomach, helping digestion, relaxing bowels, reducing blood fat, reducing blood pressure, reducing blood sugar, losing weight, resisting fatigue and the like, keeps peculiar mellow taste of traditional Mongolian milky tea, also has peculiar fragrance of the buckwheat and further is beneficial to human health.

Owner:INNER MONGOLIA MEDICAL UNIV

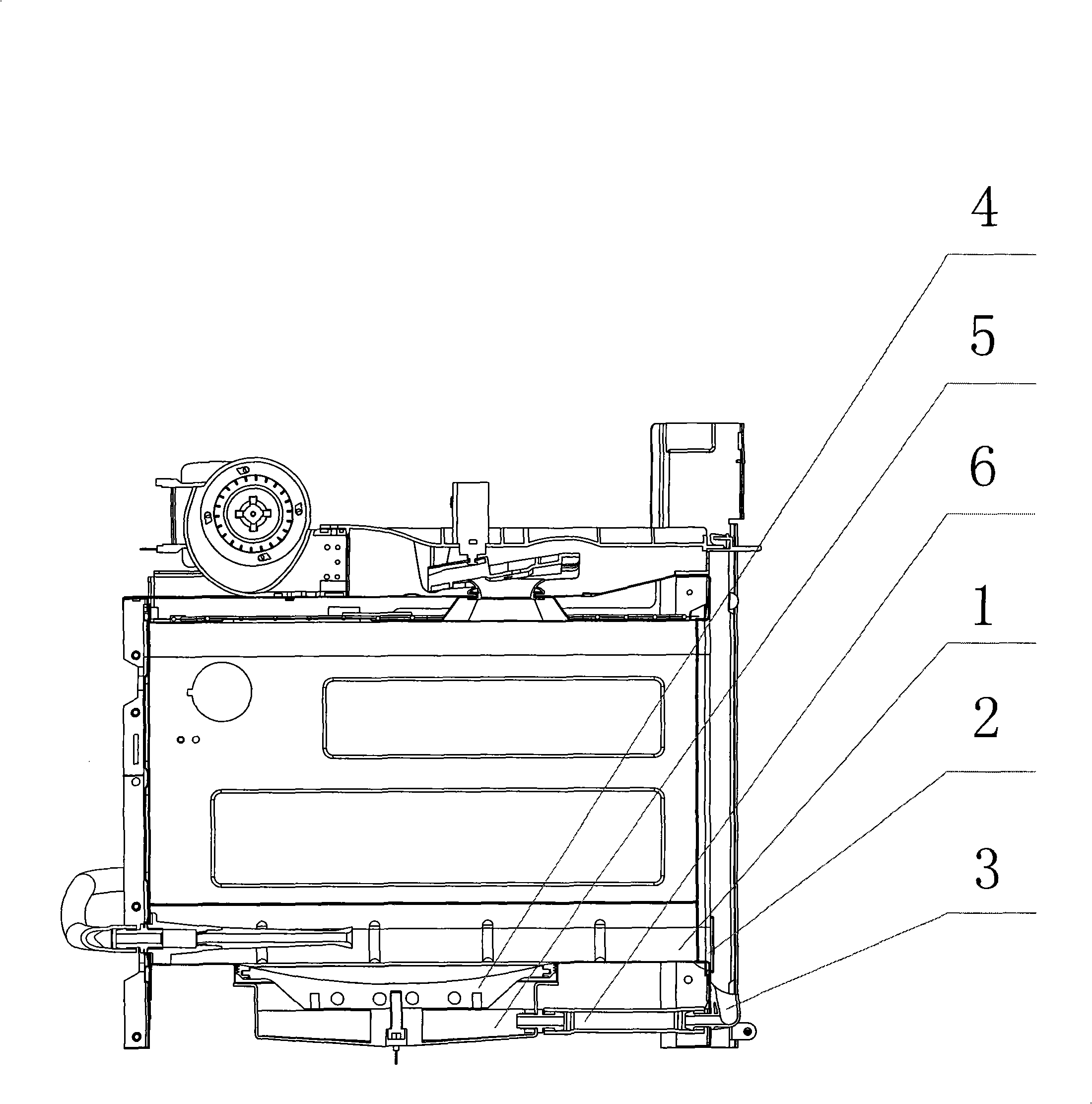

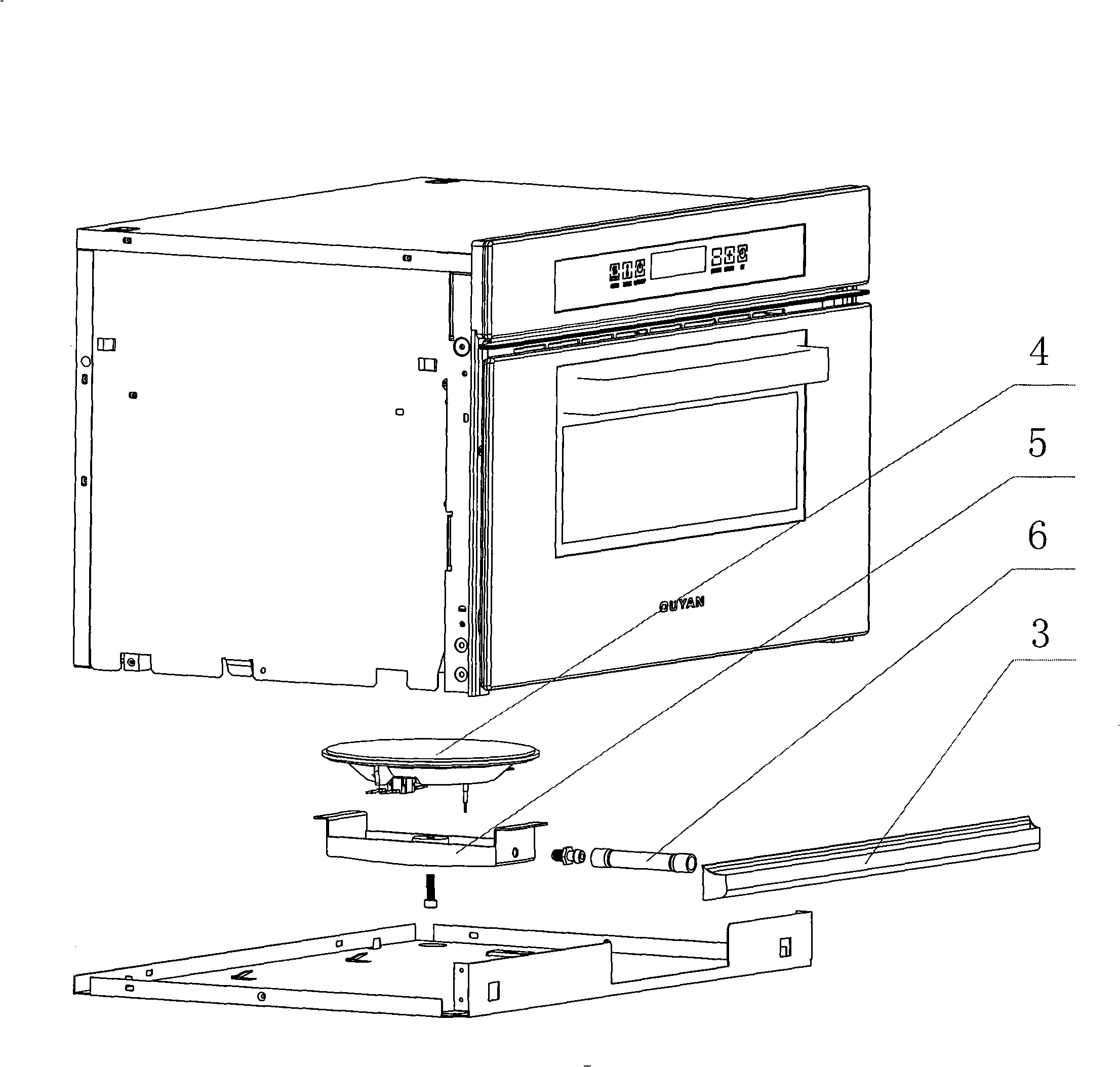

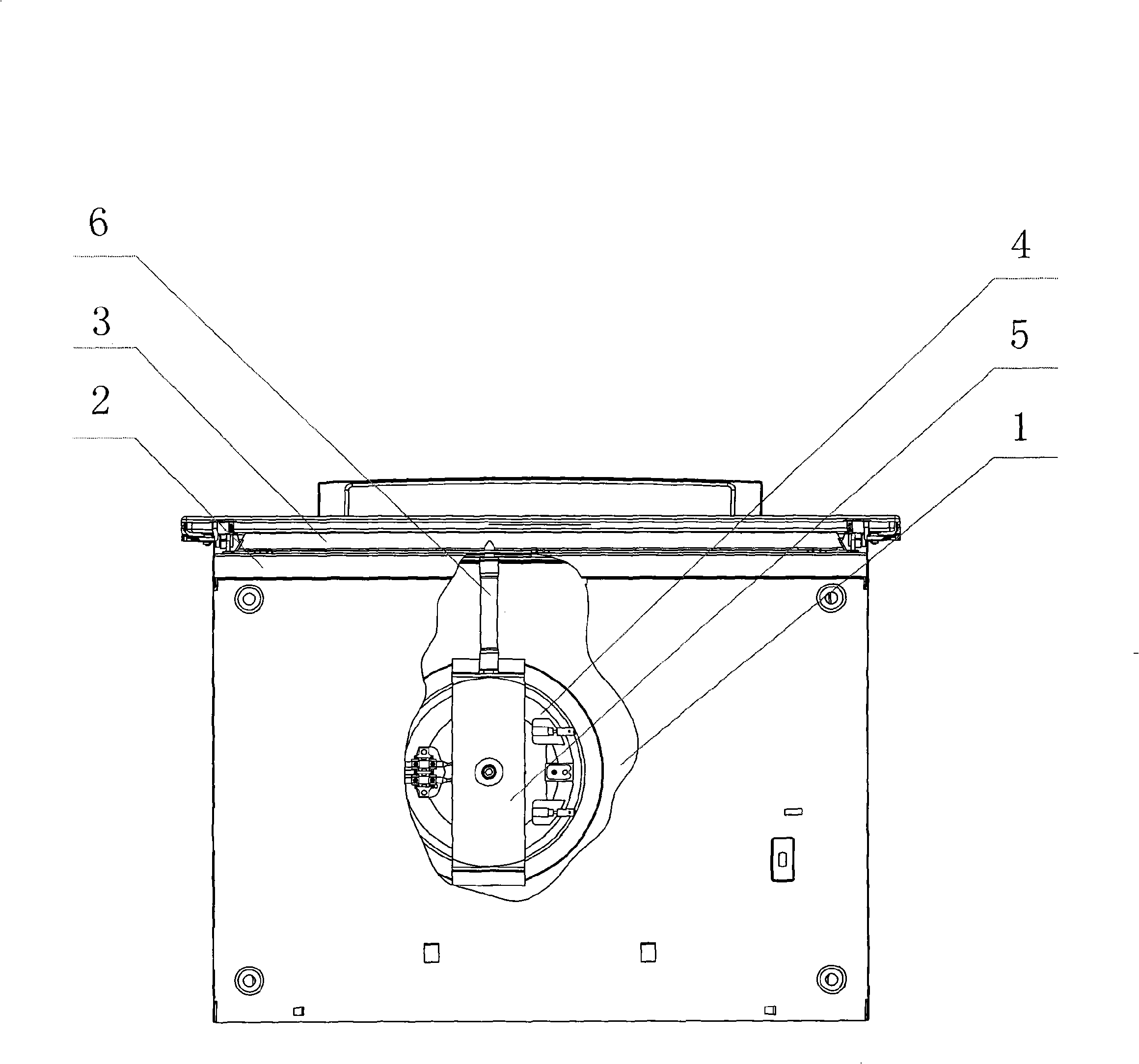

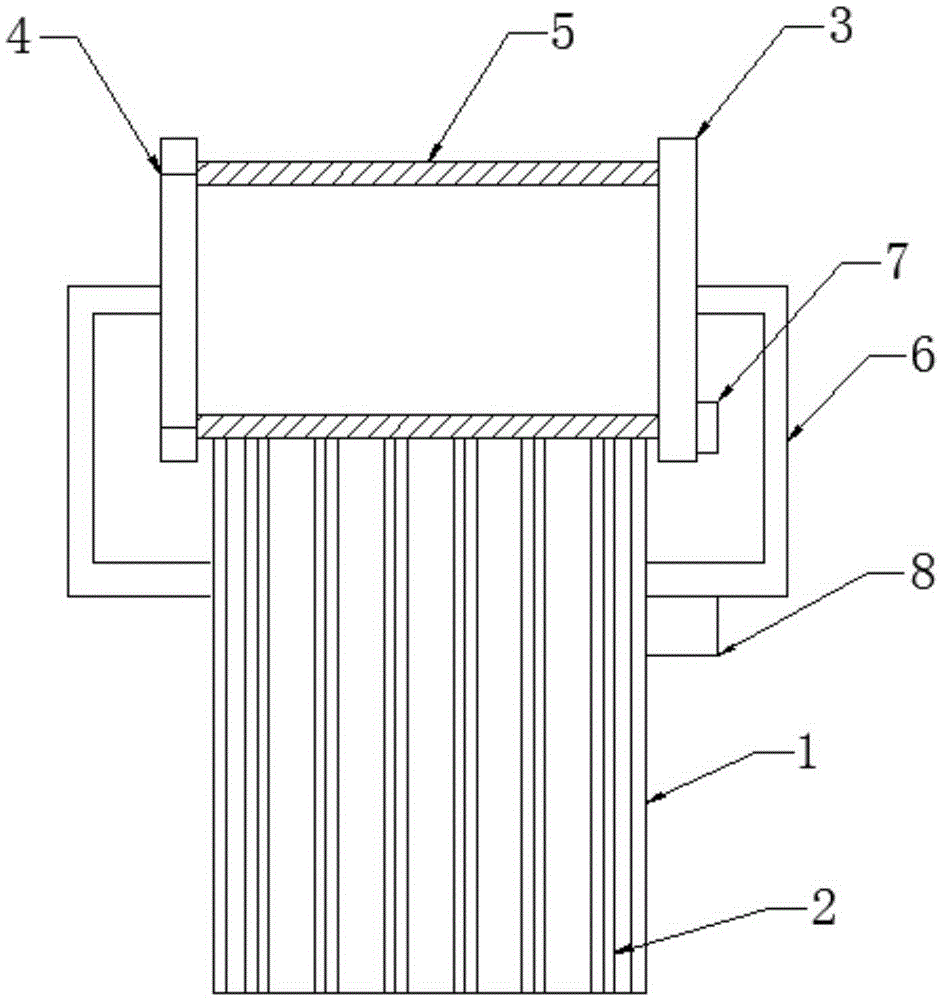

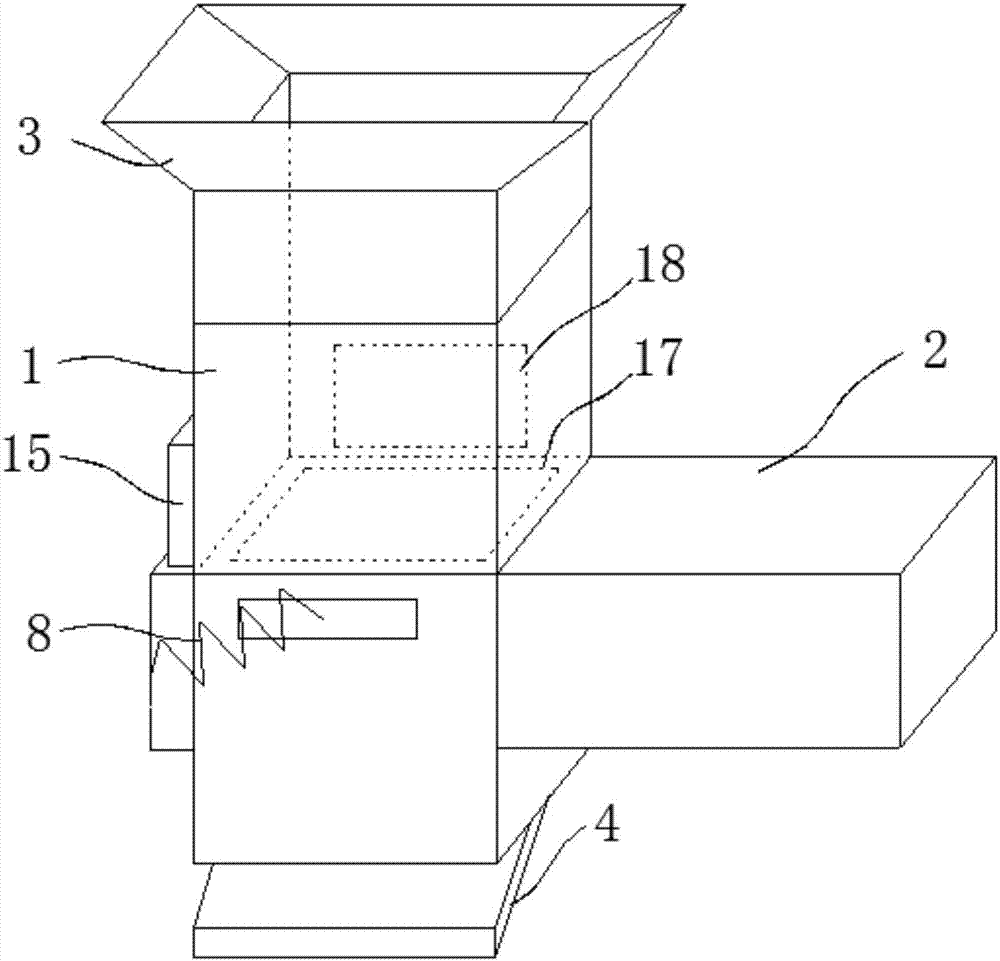

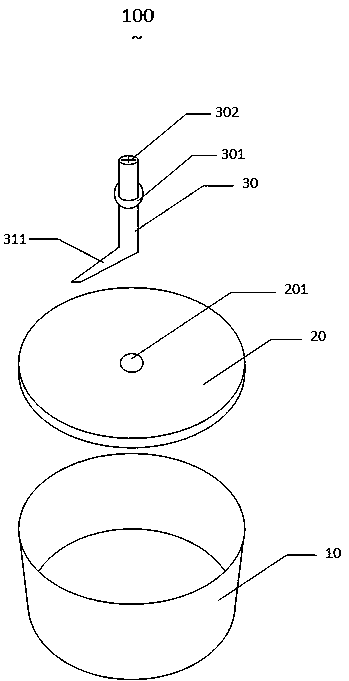

Domestic electric steaming furnace

InactiveCN101536870AThere will be no overflowEnsure food hygieneSteam cooking vesselsHeat conductingEngineering

The invention discloses a domestic electric steaming furnace which can clean water in a water containing tank without the water containing tank being dismounted, ensures the dietetic hygiene of users and successfully protects cupboards while bringing conveniences to the users. The domestic electric steaming furnace comprises a furnace body (1), a furnace body panel (2), the water containing tank (3) and a heating disk (4). The furnace is also provided with an air discharging channel and a heat conducting device (5) used for evaporating water. The heat conducting device (5) is communicated with the water containing tank (3) via a connecting pipe (6) and is also communicated with the air discharging channel. The heat conducting device (5) is arranged under the heating disk (4) and is in contact with the heating disk (4). The inner bottom surface of the heat conducting device (5) is lower than the inner bottom surface of the water containing tank (3). The connecting pipe (6) is arranged in a horizontal or inclined way. The inclined arrangement of the connecting pipe (6) indicates that the higher end of the connecting pipe (6) is connected with the water containing tank (3) and the lower end of the connecting pipe (6) is connected with the heat conducting device (5).

Owner:宁波欧燕电器有限公司

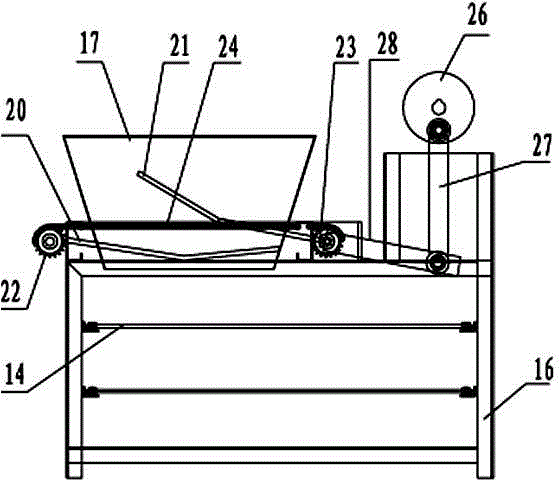

Pancake cooling equipment with automatic feeding-discharging function

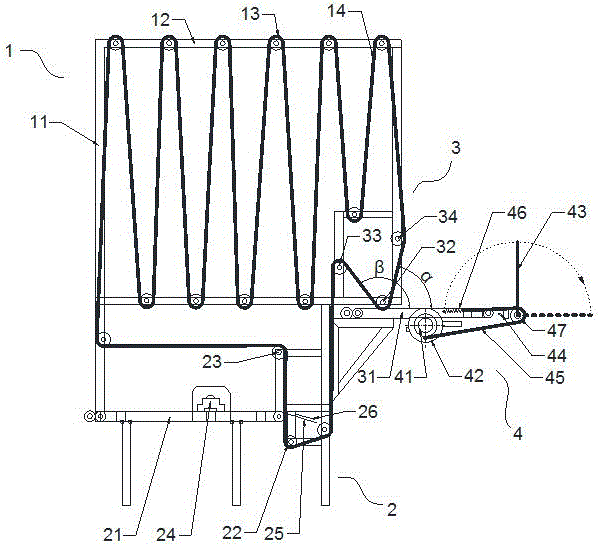

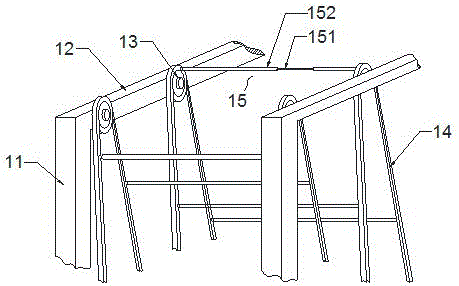

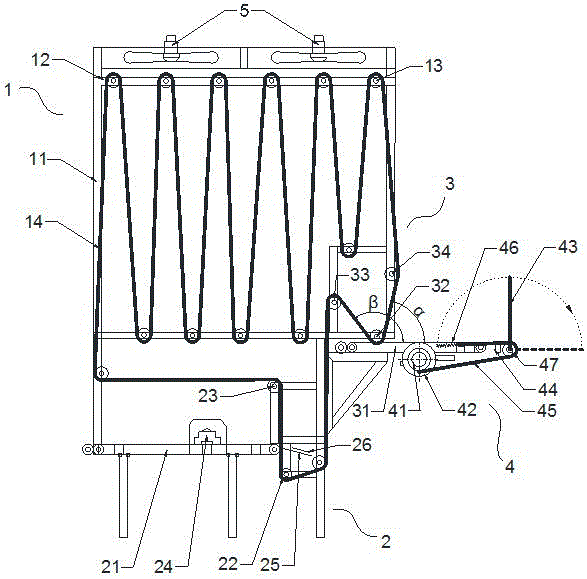

ActiveCN106240967AReduce investmentSave human effortPackagingUltimate tensile strengthMechanical engineering

The invention belongs to the technical field of food processing equipment, and provides pancake cooling equipment with an automatic feeding-discharging function. The pancake cooling equipment comprises a cooling device, an automatic feeding-discharging device, a moisturizing device and a turnover material collecting mechanism which are integrally arranged. The pancake cooling equipment has the advantages that the operation is simple and convenient, the working process can be simplified, the cooling equipment investment can be reduced, the automatic feeding-discharging function can be achieved, the cooling efficiency can be improved by 33-93%, and the occupied plant area can be reduced to be 30% or below of the original basis; and furthermore, the manpower can be saved, the labor intensity can be reduced, the contact between human and food as well as a scald injury can be avoided, pancakes can be prevented from being exposed over a large area in the air, the cooling time and humidity can be controlled conveniently, the excessive loss of water can be prevented, the possibility of secondary pollution can be lowered, and the food quality and hygiene can be guaranteed.

Owner:山东省潍坊市省工食品机械科技有限公司

Automatic noodles winding device

The invention provides an automatic noodles winding device including a conveyor belt, a noodles winding assembly and a motor; a plurality of separation belts are arranged on the conveyor belt; the noodles winding assembly is arranged on the conveyor belt and comprises a noodles winding roller, fixing clamp boards, a noodles winding shaft, a noodles winding frame and a speed reducer; the noodles winding shaft is arranged on the noodles winding roller; the fixing clamp boards are arranged at an upper position and a lower position at one side of the noodles winding roller, the corresponding other side of the noodles winding roller is provided with the speed reducer, and the outer side of the noodles winding roller is provided with the noodles winding frame; the conveyor belt, the noodles winding frame and the speed reducer are connected with the motor through wires. The conveyor belt of the automatic noodles winding device is provided with the separation belts, so as to conveniently quantify and average noodles; with arrangement of the noodles winding shaft and the noodles winding roller, the noodles are effective to wind, and at the same time, unqualified noodles can be screened out.

Owner:宜垦(天津)农业制品有限公司

Continuous production method of hot-dry noodles and special production line

ActiveCN104431781BReduce the number of manpower usedEnsure food hygieneDough processingProduction lineFood sanitation

The invention discloses a continuous production method of hot-and-dry noodles. The continuous production method comprises the following steps: mixing flour, salt and alkali at proper ratio, and then conveying the raw materials in a noodle stirring machine, adding starch, water and the like, mixing into a dough and proofing for certain time, then rolling the dough into noodles, carrying out cooking, cooling, dispersing, oil-spraying and airing, and then packaging to obtain the finished product. The invention further discloses a special production line of the production method. The continuous production method and the special production line disclosed by the invention have the advantages that the industrialized production of hot-and-dry noodles can be realized, and mechanical automation continuous production is realized from all working procedures including stirring, rolling, cutting, cooking, cooling, dispersing and oil-spraying, packaging and the like, thus the use amount of manpower is greatly reduced, and the food sanitation of the products is also ensured. Meanwhile, the quality of the products realizes consistence and stability, and the production efficiency is increased.

Owner:郑州孔河天地食品有限公司

Cucumber cutting device

InactiveCN107088897ASimple structureEasy to useMetal working apparatusOperational ProblemCucumber family

The invention discloses a cucumber cutting device. The cucumber cutting device comprises a main box body, a cutting knife, a push seat and a manual pressing rod. The main box is square, the top is provided with a cutting edge, the front end is provided with a seed clearing port, the rear end is provided with a melon slice opening, the front end of the main box is provided with a baffle plate, and the rear end is provided with a cleaning tank; the cutter Installed on the cutting edge of the main box, the lower end of the center is connected with a seed guide tube, which passes through the nozzle of the baffle and falls on the upper end of the baffle surface; the push seat is installed on the manual pressure rod; the manual pressure The bar is installed on the front part of the cutter and is made up of a base, a rotating disk, a rotating bar, a connecting rod, a screw and a spring. The invention has simple structure, scientific and reasonable design, and solves the problems of low efficiency, long time, cumbersome operation and easy hand injury of traditional cucumber cutting.

Owner:HEZHOU SITONG INFORMATION TECH CO LTD

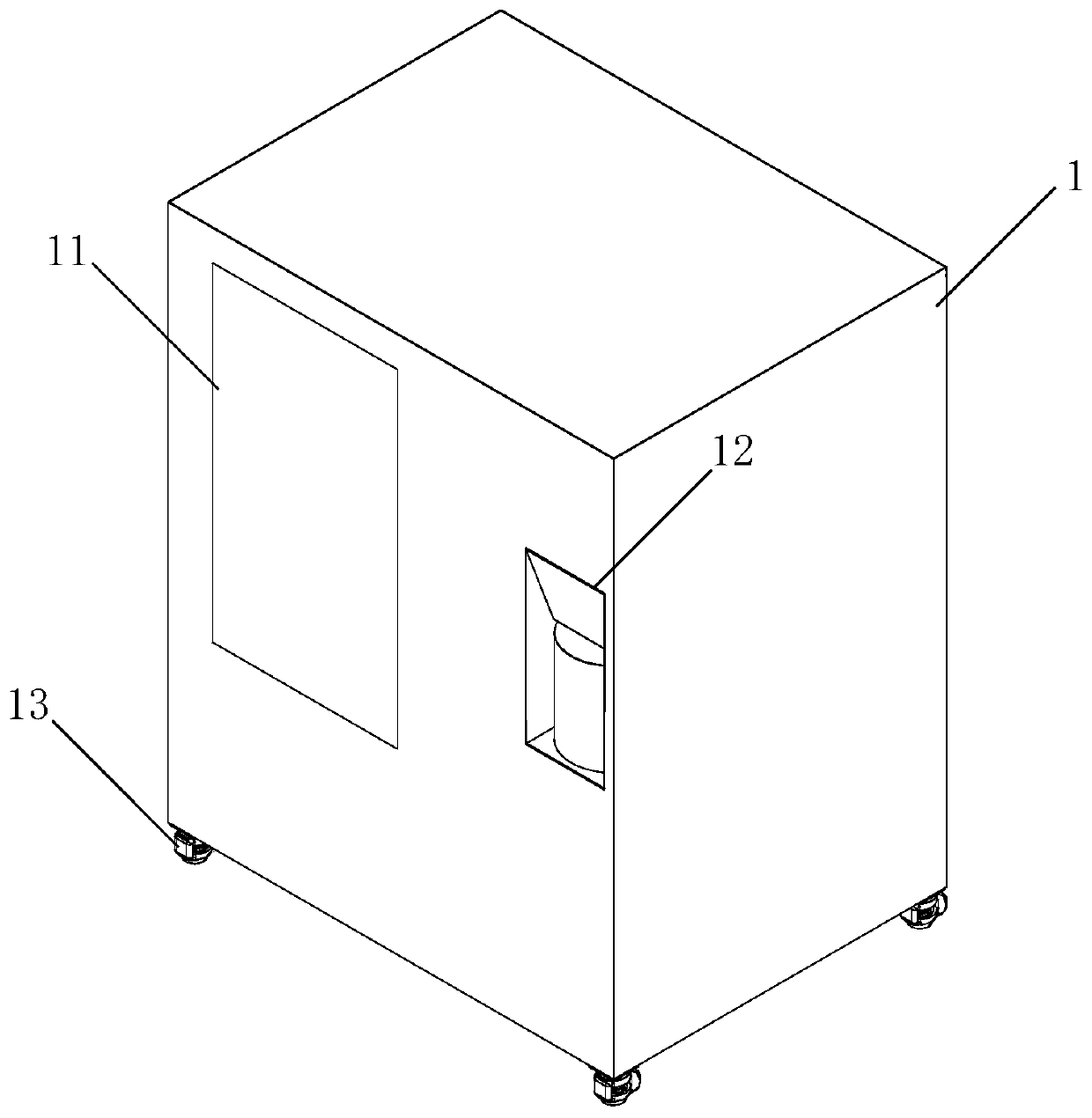

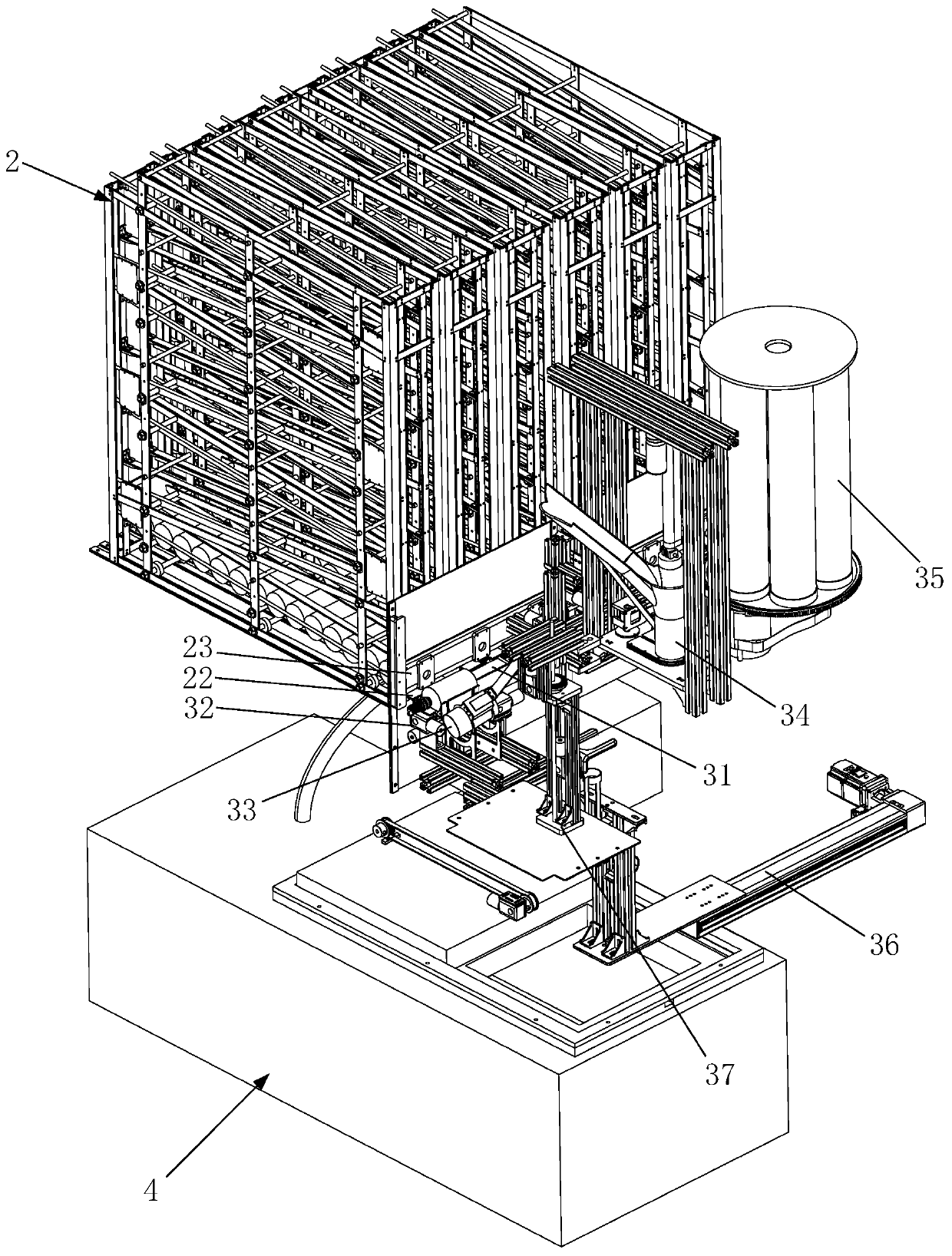

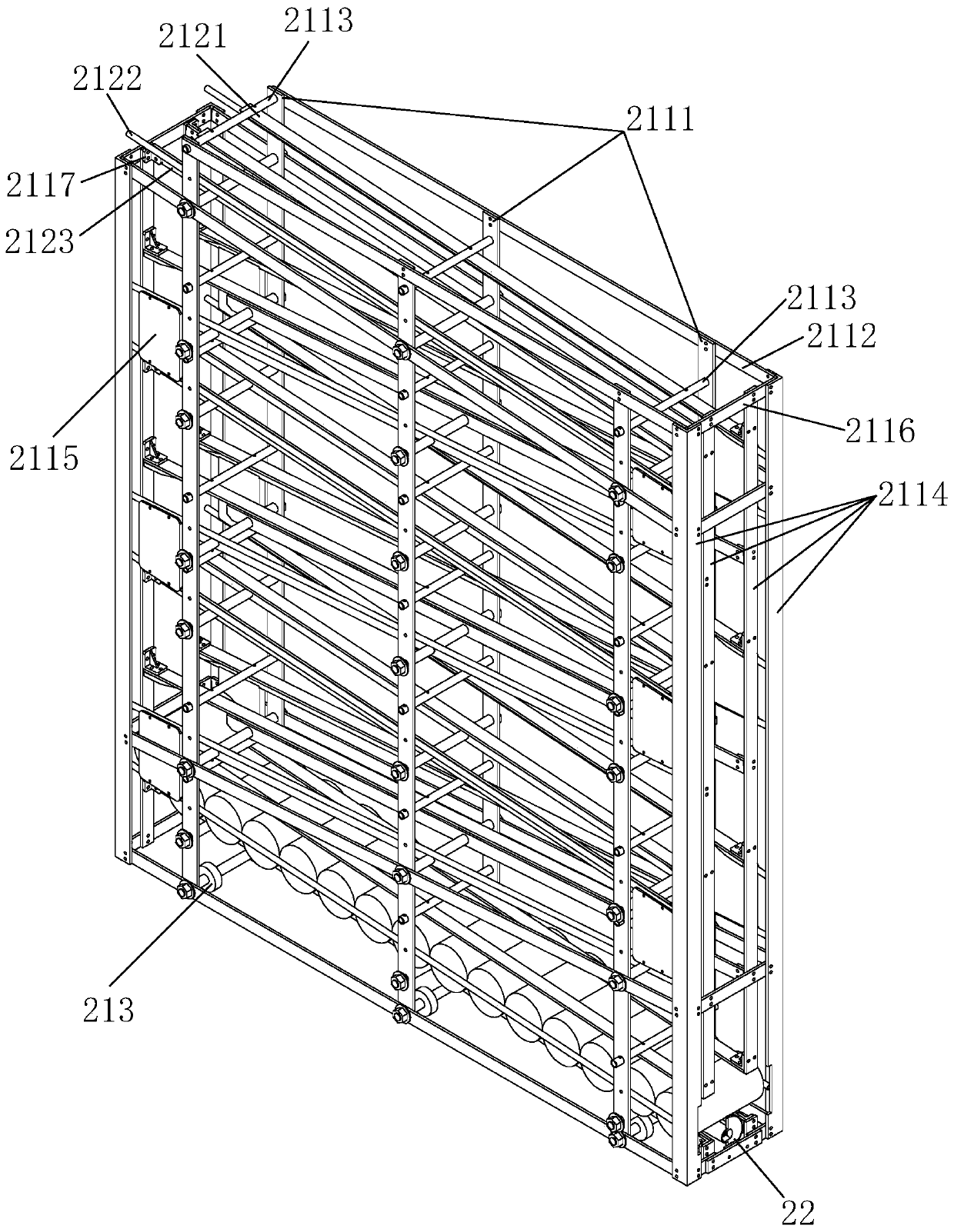

Intelligent dish vending machine

InactiveCN107161368AEnsure hygieneHigh speedCoin-freed apparatus detailsPayment architectureEngineeringCam

The invention relates to an intelligent dish vending machine comprising a vending machine body, a discharging control box, a cam and a decelerator. The vending machine body is vertical and hollow, the discharging control box crossing the middle of the vending machine body is arranged in the middle of the vending machine body, a charging box is arranged at the upper end of the vending machine body, and a tray for containing bowls is arranged at the lower end or the side face of the vending machine body; a feeding inlet is formed in an upper plate of the discharging control box, and a discharging outlet is formed in a lower plate of the discharging control box; one side wall of the discharging control box is movably connected with the cam through a driving rod, and the other side wall of the discharging control box is connected with the vending machine through a spring; the cam is connected with an output shaft of the decelerator through a driving belt; the input end of the decelerator is connected with an output shaft of a motor; and the motor is connected with an intelligent square card reader through a circuit. Compared with the prior art, the intelligent dish vending machine operates automatically and is high in speed, time is saved in the vending process, and efficiency is improved; intelligent and automatic vending is achieved, and manpower is not needed, so that the operating cost is reduced by a large margin; and the steps where people participate in are reduced, and guaranteeing of dish sanitation is facilitated.

Owner:莫专文

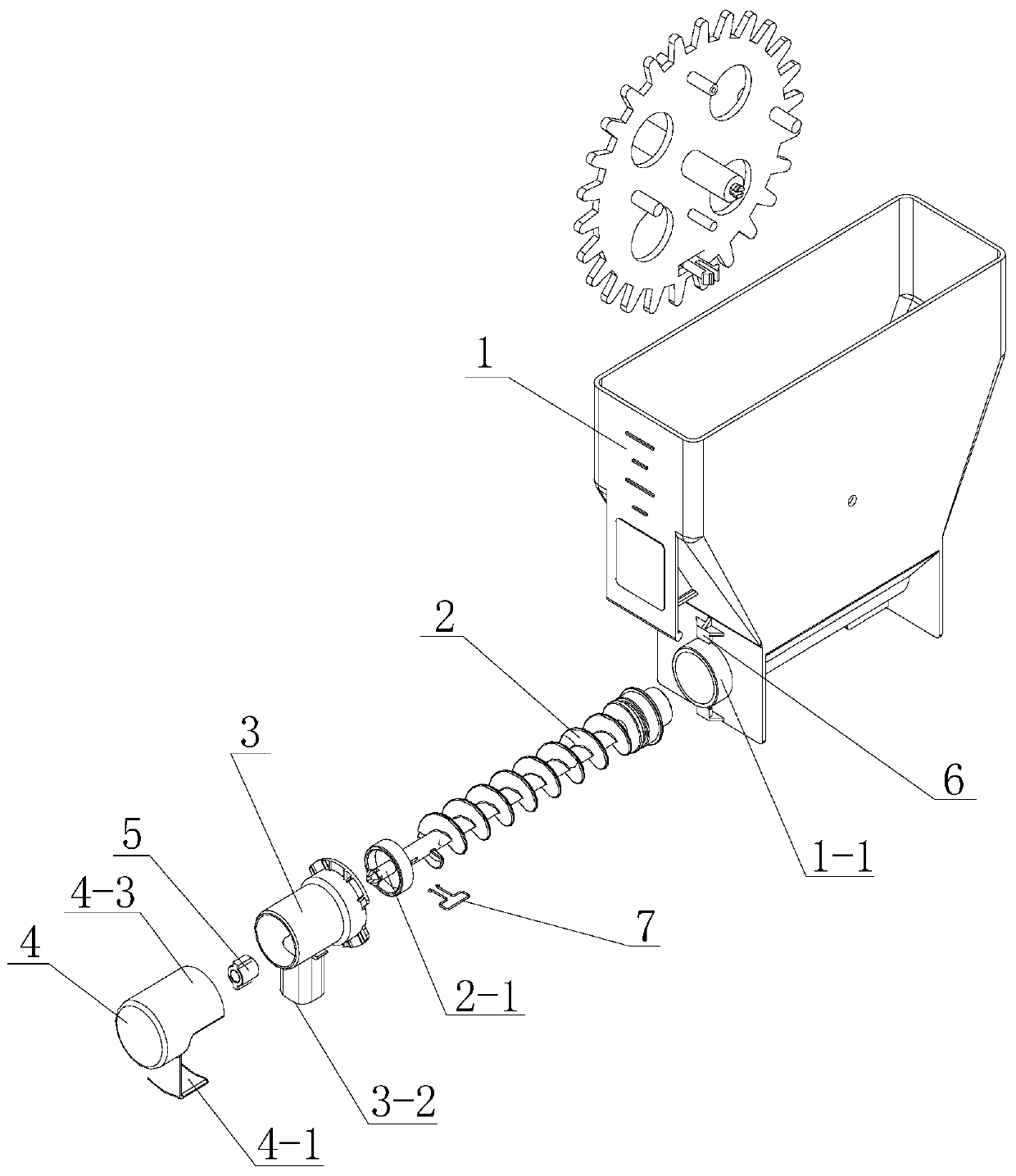

High-efficiency fattening and breeding device for rabbits and breeding method thereof

ActiveCN111887162ARealize automatic supplyGrowth and fattening guaranteeSievingFeeding-stuffAnimal scienceEuropean rabbit

The invention provides a high-efficiency fattening and breeding device for rabbits and a breeding method thereof. The device comprise a storage bin, a feeding trough, a feed conveying mechanism and arabbit cage, wherein the feed conveying mechanism is used for conveying feed in the storage bin into the feeding trough, one end of the feed conveying mechanism is connected with the storage bin, thefeeding trough comprises a feeding barrel and a trough plate, an upper end of the feeding barrel is connected with the feed conveying mechanism, a lower end of the feeding barrel is connected with thetrough plate, and the trough plate is arranged beside the rabbit cage. According to the device, a spiral conveyor, the feeding barrel and the trough plate are matched, so that automatic feed supply is realized, when the feed in the trough plate is reduced by consumption, the feed in the feeding barrel automatically falls into the trough plate by gravity, and the spiral conveyor continuously conveys the feed into the feeding barrel, so as to ensure that there is always feed in the trough for the rabbits to eat, and the rabbits continue to eat the feed to ensure growth and fattening.

Owner:龙岩市万家兔业发展有限公司

Ice cream vending machine

ActiveCN111383384AExtended shelf lifeNo need for manual cleaningApparatus for meter-controlled dispensingCool storageIce Creams

The invention relates to an ice cream vending machine, and the vending machine comprises a case; a display screen and a goods taking opening which are installed outside the machine box; and Foma wheels which are installed at the bottom of the machine box. The vending machine is characterized in that an embossing tank refrigeration storage device and an ice cream subpackaging device are arranged atthe upper part in the case in parallel; the ice cream vending machine further comprises a control circuit, the embossing tank is taken out of the embossing tank refrigeration storage device, finishedice cream cones are manufactured in the ice cream split charging device and then sent out, and the embossing tank and waste finished ice cream are recycled at the same time through the recycling device. According to the invention, various ice creams with different tastes can be stored in the cold storage device of the cold storage embossing tank through the embossing tank, and the ice creams withdifferent tastes can be prepared through the ice cream subpackaging device according to the selection of customers. Meanwhile, the ice cream is stored in the embossing tank, and no stirring device isarranged in the equipment, so workers do not need to frequently clean, and the maintenance cost is reduced.

Owner:深圳市新创造科技有限公司

Automatic grading potato peeler

Owner:李曼瑶

Lunch box

The invention discloses a lunch box. The lunch box comprises a box body and a box lid, the box lid is provided with a through hole, and a stirring device is inserted into the through hole; the stirring device is provided with at least one stirring claw; and a transmission mechanism is arranged at the upper end of the stirring device, and an external manipulator drives the transmission mechanism torotate the stirring device. The lunch box has the following advantages: a food can be evenly heated while being heated, so the heating time is shortened, and the energy is saved; and it is ensured that the sputtering phenomenon cased by fatty food pressure accumulation during heating of oil hardened and solidified vegetables is avoided.

Owner:SUZHOU GUYUEFENG INFORMATION TECH CO LTD

Automatic energy-saving type rabbit feeding and breeding device and breeding method

The invention provides an automatic energy-saving type rabbit feeding and breeding device and breeding method. The feeding and breeding device includes a feed cabin, a circulating feed conveying mechanism and feeding troughs; the circulating feed conveying mechanism is provided with discharging ports for conveying feed in the feeding troughs; the circulating feed conveying mechanism includes a first screw conveyor assembly and a second screw conveyor assembly; the feed cabin is connected to the inlet end of the circulating feed conveying mechanism; the outlet end of the first screw conveyor assembly is connected to the inlet end of the second screw conveyor assembly; and the outlet end of the second screw conveyor assembly is connected to the feed cabin so as to form a closed circulation conveying circuit. The head and tail of the feed conveying circuit are connected to each other, so that feed can always be at a circulating feed supply state, and the accumulation of the feed can be effectively prevented; and as the feed is in the circulating feed supply state, the feed can be continuously supplied to the feeding troughs, so that rabbits can be always fed with the feed, and the nutrition required by the growth of the rabbits can be guaranteed.

Owner:龙岩市万家兔业发展有限公司

Instant noodle device in normal-temperature water

InactiveCN101449758AAchieve the purpose of brewing instant noodlesSimple and fast operationFood preparationInstant noodleThermal water

The invention discloses a device for normal temperature water instant noodle, which includes a reaction bottom warehouse an a detachable food warehouse. Quicklime is stored in the reaction bottom warehouse, after adding normal temperature water, the water temperature of the reaction bottom warehouse is raised, thereby heating the food warehouse and reaching purposes that normal temperature water is automatically heated and heats instant noodle. The invention solves disadvantage that the instant noodle is soaked only by hot water, and provides a device for normal temperature water instant noodle with advantages of easy operation, low production cost, safety and sanitary.

Owner:莫丽梅

Powder box of beverage machine

PendingCN111387822AAvoid enteringEnsure food hygieneBeverage vesselsEngineeringStructural engineering

The invention relates to the technical field of beverage machines, in particular to a powder box of a beverage machine. The problem that an existing powder box is prone to damp is mainly solved. According to the scheme, the powder box comprises a box body and a spiral powder pushing rod, a powder outlet cabin is arranged on the outer wall of the box body at the extending part of the front end of the spiral powder pushing rod; the front end of the spiral powder pushing rod is supported on the powder outlet cabin; the spiral powder pushing rod is also provided with an extension section extendingout of the powder outlet cabin; a cabin door is arranged on the extending section, the powder outlet bin is provided with a material channel extending downwards and a material opening in the lowermost end of the material channel. The cabin door is provided with a cabin cover for opening the material opening when the cabin door forwards rotates along with the spiral powder pushing rod and blockingthe material opening when the cabin door reversely rotates along with the spiral powder pushing rod; and a structure for stopping the cabin door from rotating even after the cabin door forwards rotates to open the material opening and the cabin door reversely rotates to close the material opening is arranged between the cabin door and the powder outlet cabin.

Owner:CHANGZHOU PILOT ELECTRONICS

Material dividing and conveying device

PendingCN110482191AImprove sorting efficiencyImprove delivery efficiencyConveyorsPackagingEngineeringMechanical engineering

The invention discloses a material dividing and conveying device arranged on a material slicer. The material slicer comprises a rack. A material feeding device is arranged on one side of the rack. A conveying frame arranged on the other side of the rack is included and provided with a conveying belt for conveying materials and a plurality of material dividing grooves formed in the conveying frame.The end, away from the rack, of each material dividing groove is provided with an overturning mechanism for material overturning and a pushing mechanism for pushing overturned materials out of the overturning mechanism. The conveying belt is used for conveying the materials, the material dividing grooves conduct material dividing on the materials, the problem about pollution in the manual sortingprocess is effectively solved, the material sorting and conveying efficiency is improved, and food sanitation is guaranteed.

Owner:WUYI UNIV

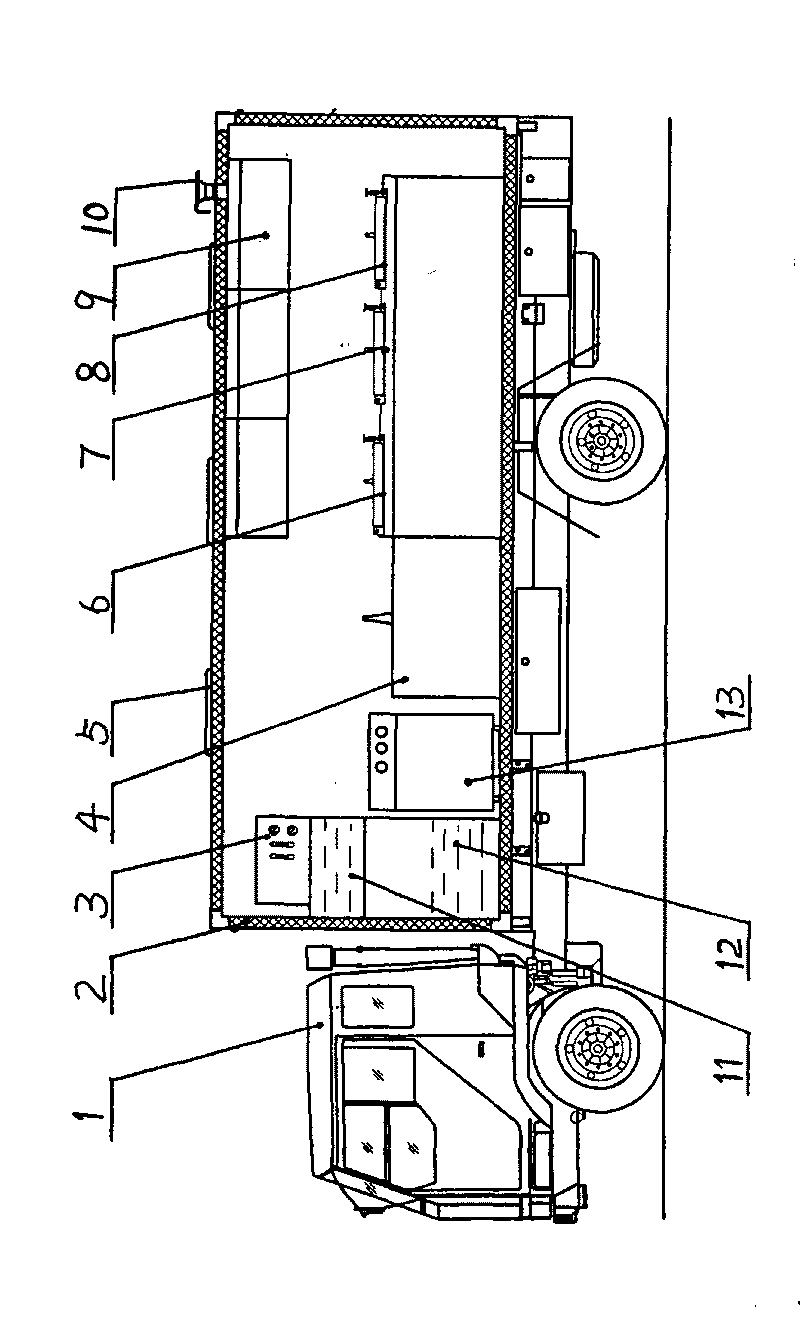

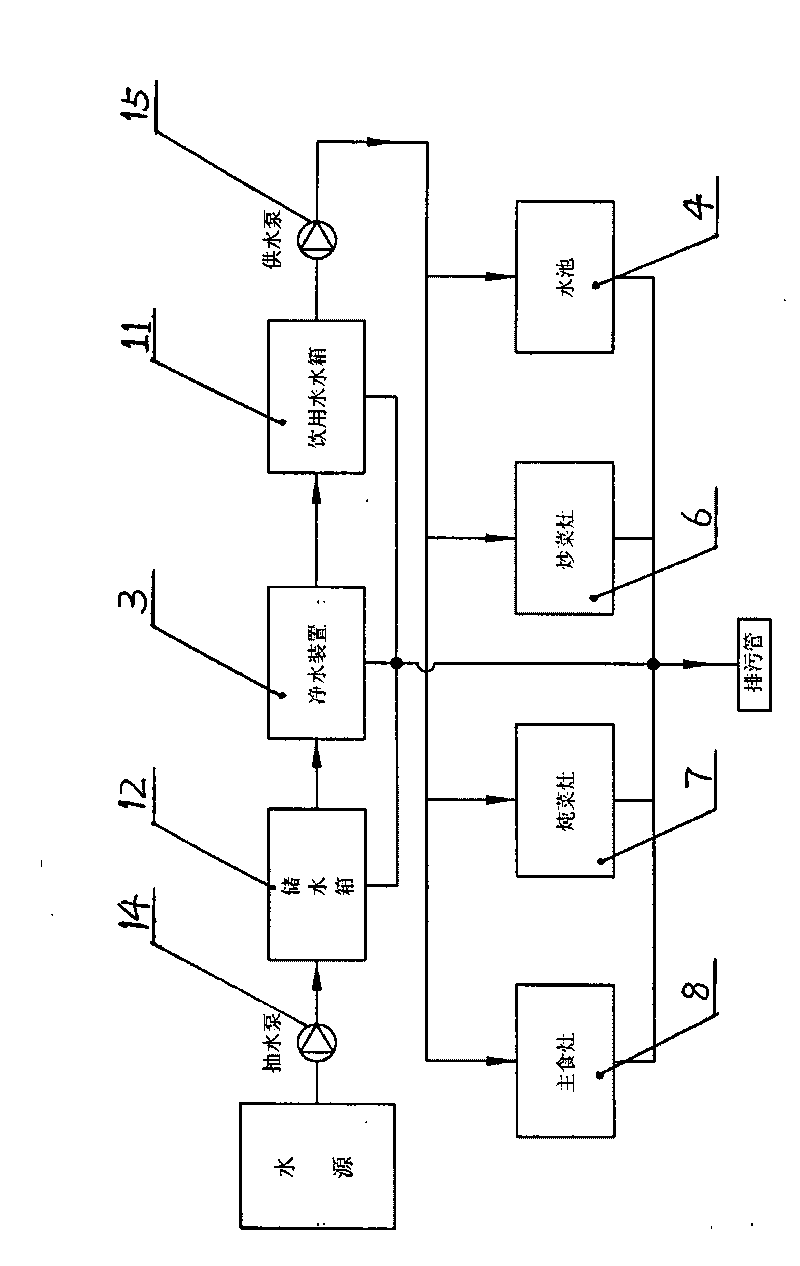

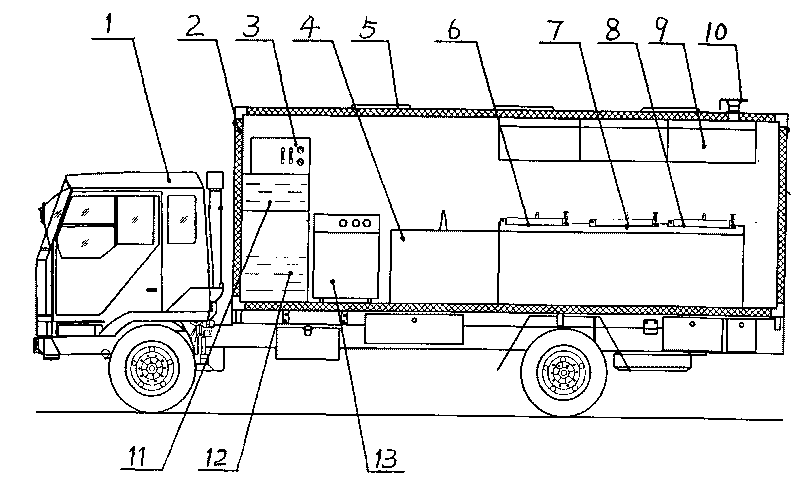

Multiple-safeguard type kitchen vehicle

InactiveCN101734191ARich food patternsGuarantee the quality of drinking waterWorkshop/display transportationEngineeringHearth

The invention belongs to the field of cooking equipment and provides a multiple-safeguard type kitchen vehicle which is improved from the current kitchen vehicle. The multiple-safeguard type kitchen vehicle comprises a vehicle, a kitchen shelter, a principal food oven on one inner side of the kitchen shelter and a fried dish oven. A stewing oven, a water tank, a freezer, a disinfection cabinet, a flour-mixing machine, a food cutter and a platform are parallel arranged on a same side or the other side of the kitchen shelter. The kitchen vehicle is also provided with a water-storing device of a water system, a food resource storage chamber, a washing machine, and the like. The kitchen vehicle not only can provide daily basic food to the field operating personnel in plateau area and flat area but also can ensure the quality of drinking water, the sanitation of food and the rich resources of food and can meet the urgency requirement of the field operating personnel.

Owner:河南华阳装备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com