Lunch box

A technology for lunch boxes and lids, which is applied in the field of vending machines, can solve the problems of wasting energy, increasing heating time, and splashing, and achieve the effects of shortening heating time, saving energy, and avoiding splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

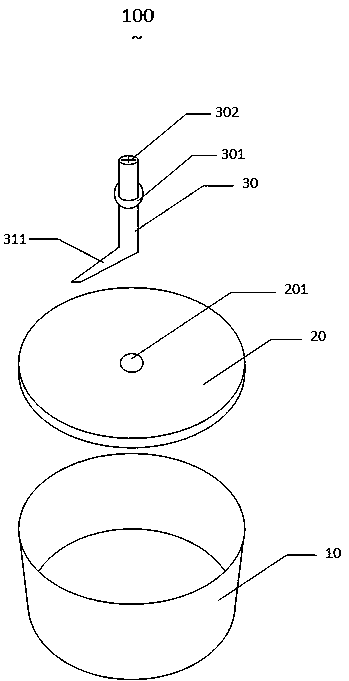

[0039] Please refer to figure 1 , The lunch box 100 provided in this embodiment includes a box body 10 , a box cover 20 and a stirring device 30 .

[0040] The lid has a through hole 201, which can be inserted into the stirring device 30; the stirring device 30 has a stirring claw 311; into the box body 10; the upper end of the stirring device 30 has a transmission mechanism 302, the transmission mechanism 302 of the present embodiment is a cross-shaped groove, and the external manipulator drives the transmission mechanism 302 to rotate the stirring device 30 to work.

[0041] Take heating a lunch box of porridge as an example. When the lunch box is heated externally, the outer / upper food is already very hot due to uneven heating, while the inner / lower food is still cold. In order to ensure that the food is thoroughly heated, the heating time can only be increased, not only Waste of energy, more waste of time, loss of efficiency. Using the lunch box provided by this embodime...

no. 2 example

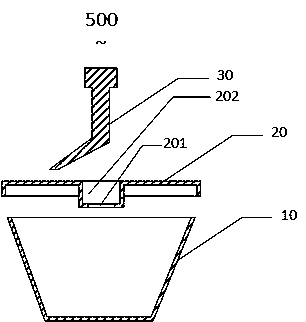

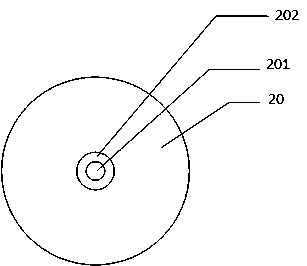

[0043] Please refer to figure 2 and image 3 , the stirring device 30 provided by the present embodiment includes a limit mechanism 301 to ensure that the stirring device 30 is mounted on the lid and will not fall into the box body; the stirring device 30 has a stirring claw 311; the upper end of the stirring device 30 has a transmission mechanism 302, the transmission mechanism 302 of this embodiment is a straight protrusion, and the external manipulator drives the transmission mechanism 302 to rotate the stirring device 30 to work.

no. 3 example

[0045] Please refer to Figure 4 and Figure 5 The stirring device 30 provided in this embodiment is similar to that of the second embodiment, except that a hollow channel 303 is added to inject seasoning into the food at a preset time, making the food more delicious. Of course, it is also possible to inject air flow or liquid, such as air, water vapor, hot air, hot water, or ice water, into the channel 303 . The common situation is that the food in the lunch box is concentrated, or does not include soup, for example: if the processed food is rock sugar porridge, you can inject ice water at this time to dilute and lower the temperature; The food is hot millet porridge. At this time, hot water can be injected to dilute and increase the temperature quickly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com