Full-automatic sushi machine

A fully automatic sushi technology, applied in the direction of food science, etc., can solve the problems of high production cost, inseparable labor, and low efficiency of sushi, and achieve the effects of improving production efficiency, preventing dampness and softening, and making production convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

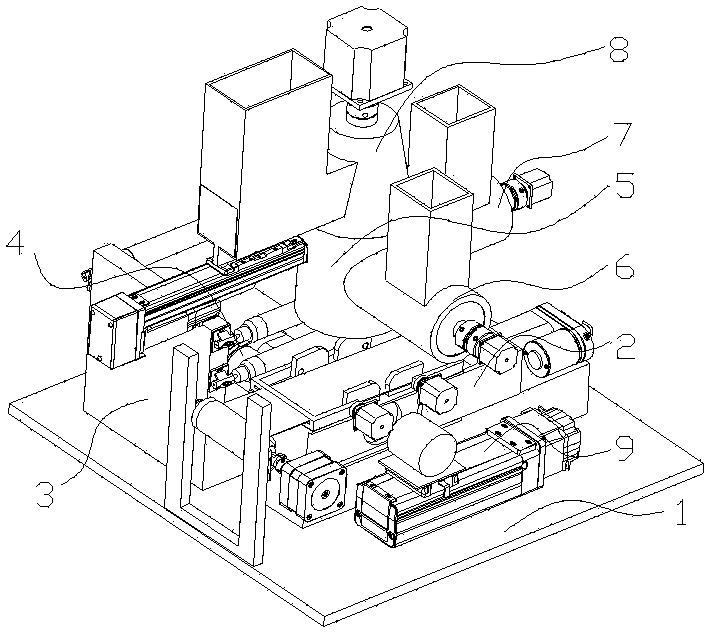

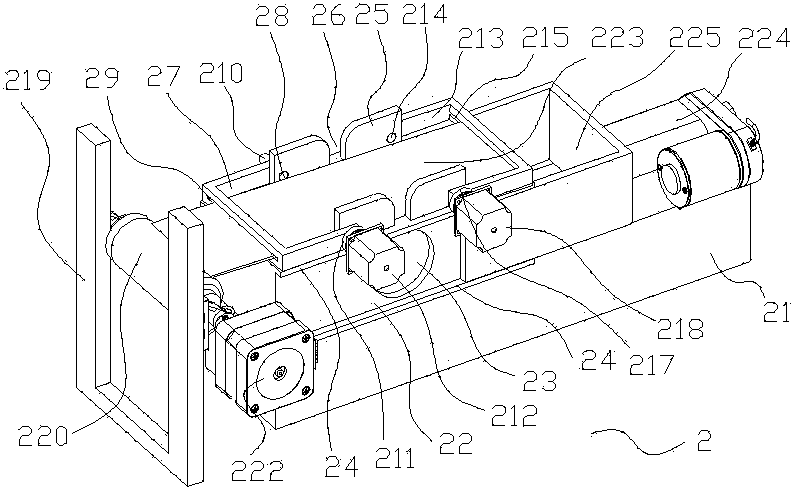

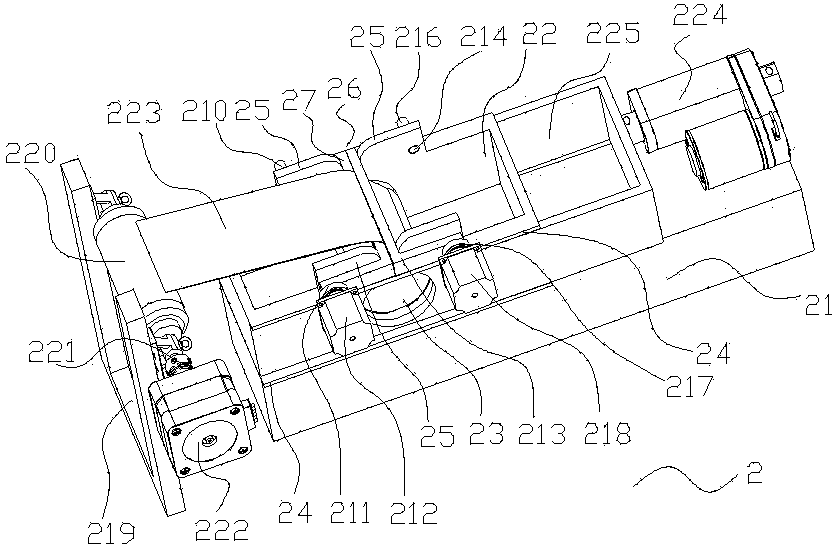

[0043] refer to figure 1 , a kind of fully automatic sushi machine, it is characterized in that: comprise a base plate 1, sushi forming device 2 is fixed on the upper surface of base plate 1, and laver conveying device 3 is fixed on the side close to sushi forming device 2; A sushi pushing device 4 is fixed directly below; a cylindrical connecting cylinder 5 is fixed directly above the sushi forming device 2 and close to the upper surface of the sushi forming device 2, and the axis direction of the connecting cylinder 5 is perpendicular to the upper surface of the sushi forming device 2 Place plane; The discharge port of rice feeding device 6 is connected with opening one 51 on the outer side of connecting tube 5; The meat floss feeding device 7 is connected with opening two 52 on the outer side of connecting tube 5; The discharge port of the shredded cucumber feeding device 8 is connected; the other side of the sushi forming device 2 and the relative position with the seaweed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com