Automatic grading potato peeler

A potato peeling machine and automatic grading technology, which is applied in the peeling of vegetables or fruits, solid separation, filtering and sieving, etc. It can solve the problems such as the mismatch between the diameter of the drum and the size of potatoes, low efficiency of potato peeling, food hygiene problems, etc. , to achieve the effect of increasing the potato peeling rate, improving the peeling efficiency and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

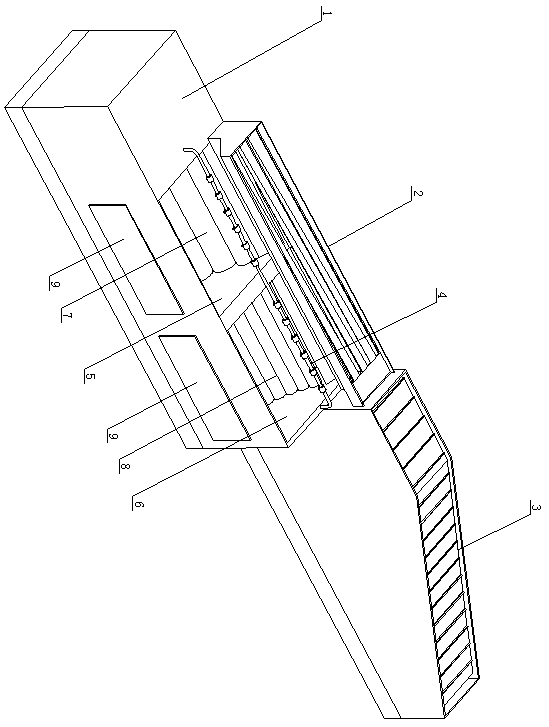

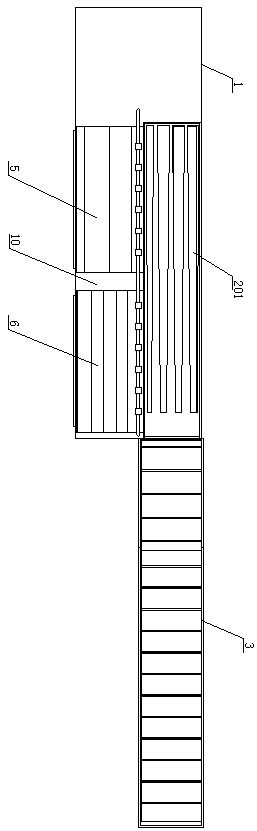

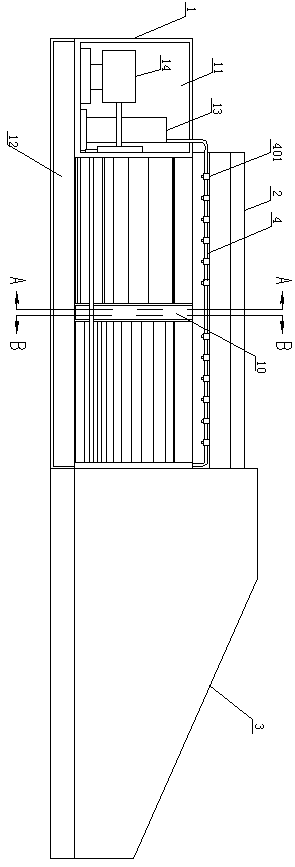

[0023] Such as figure 1 , 2An automatic grading potato peeling machine shown in and 3 includes a body 1. The body 1 is a cubic structure spliced by steel profiles and stainless steel sheets. The lower part of the body 1 is a recovery chamber 12, and the upper part of the body 1 is from left to right. The equipment chamber 11, the first-level peeling chamber 5 and the second-level peeling chamber 6 are in sequence. There is a transmission chamber 10 between them, the bottom of the primary peeling chamber 5 and the secondary peeling chamber 6 are steel wire mesh, the bottom of the equipment chamber 11 is a steel plate, the top of the equipment chamber 11 is an openab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com