Patents

Literature

220results about How to "Compact and reasonable design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

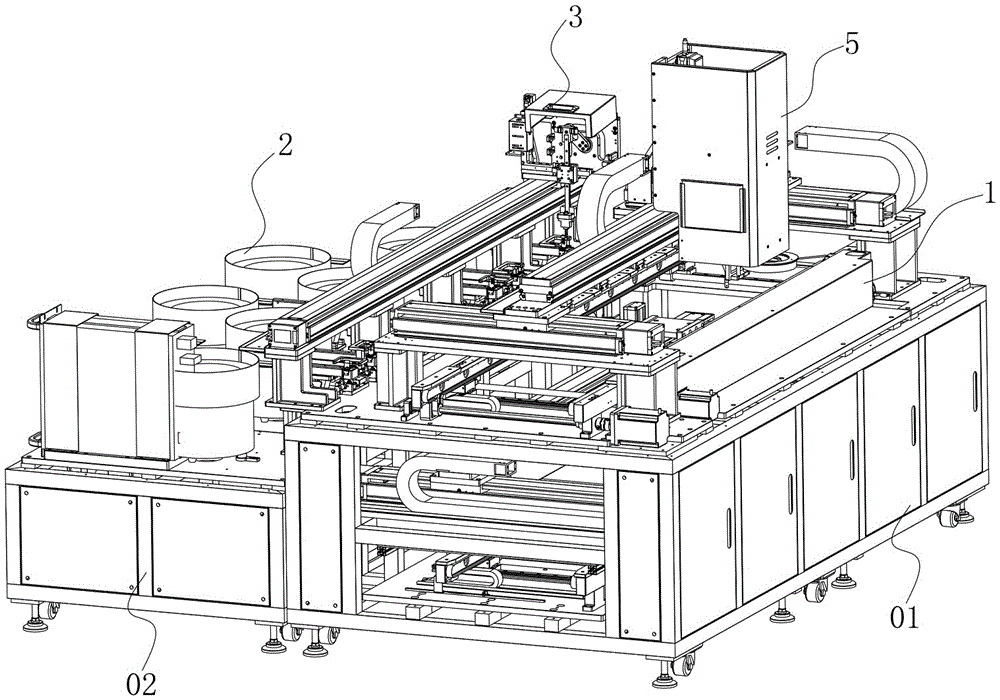

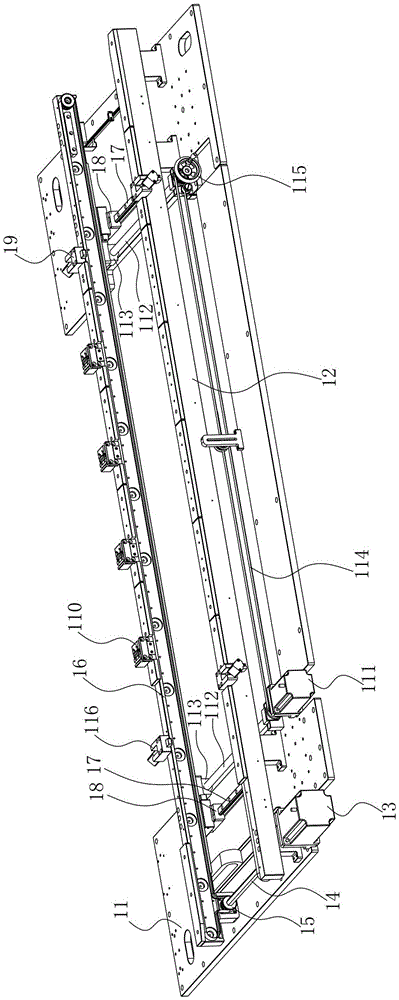

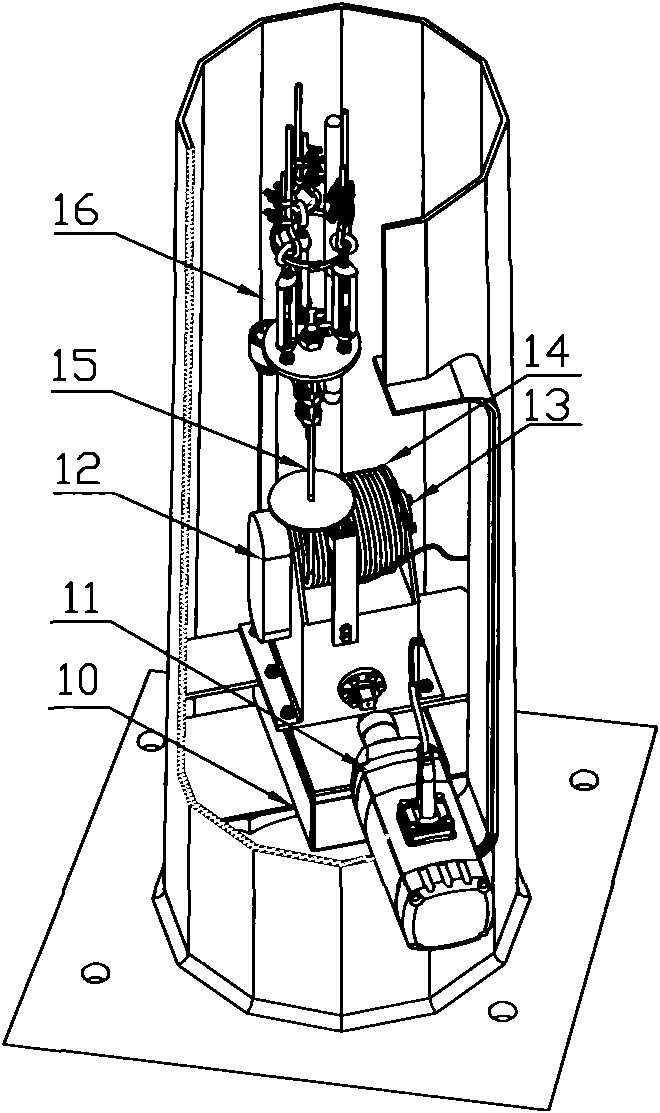

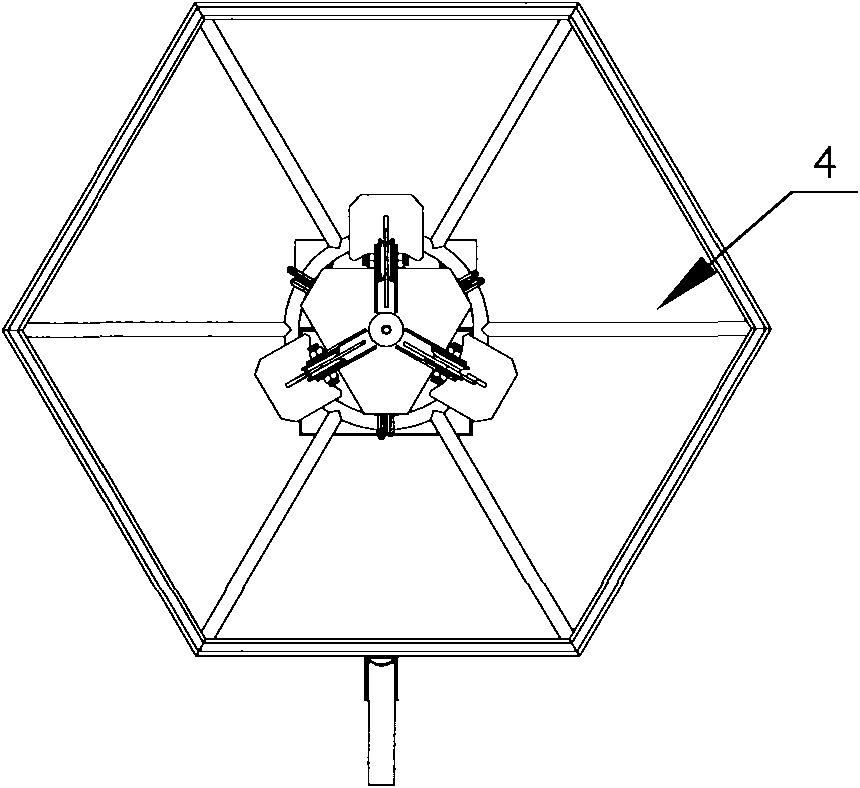

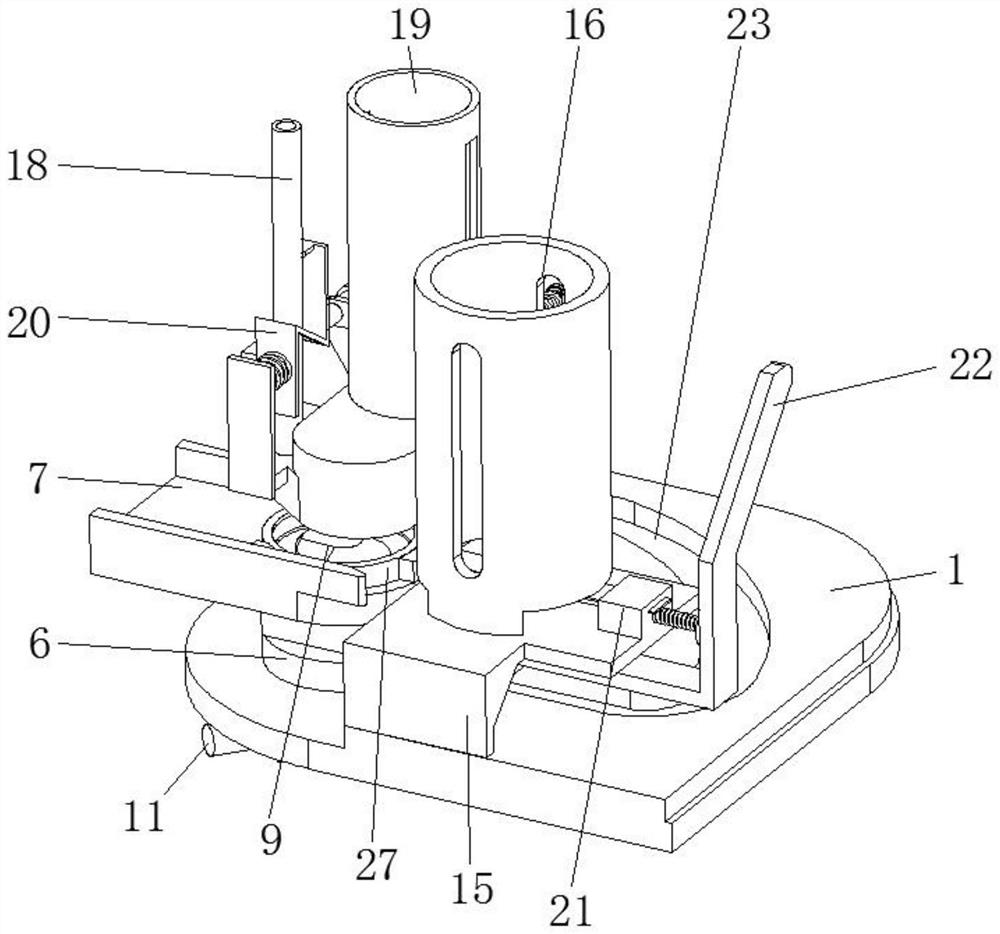

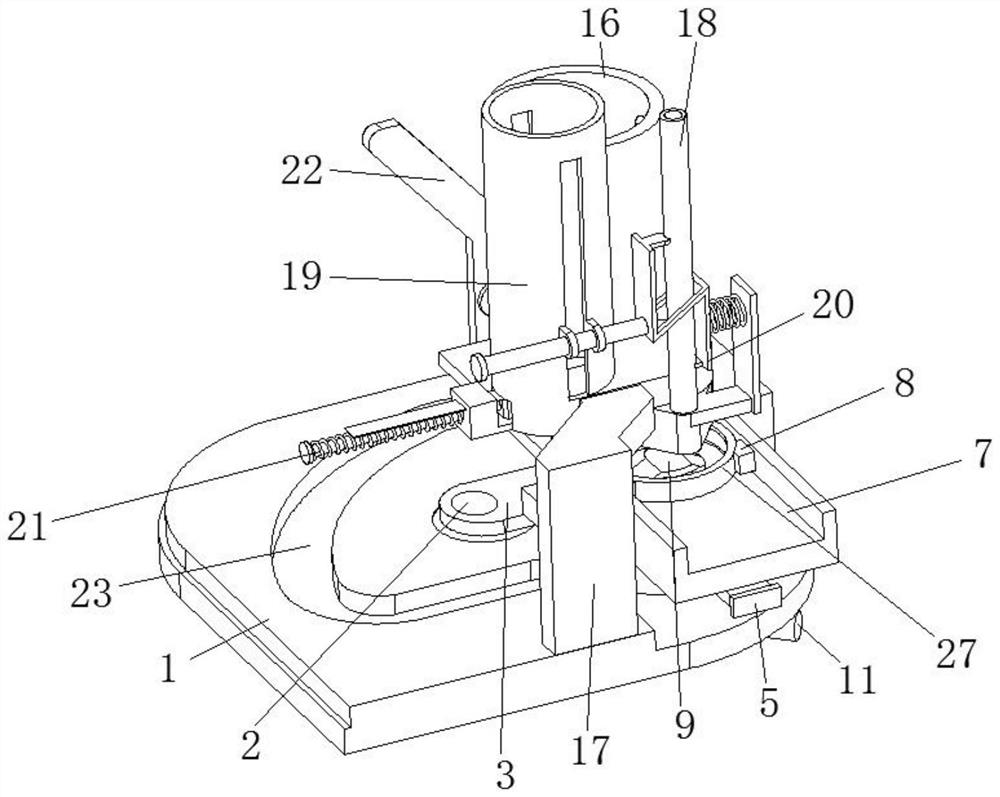

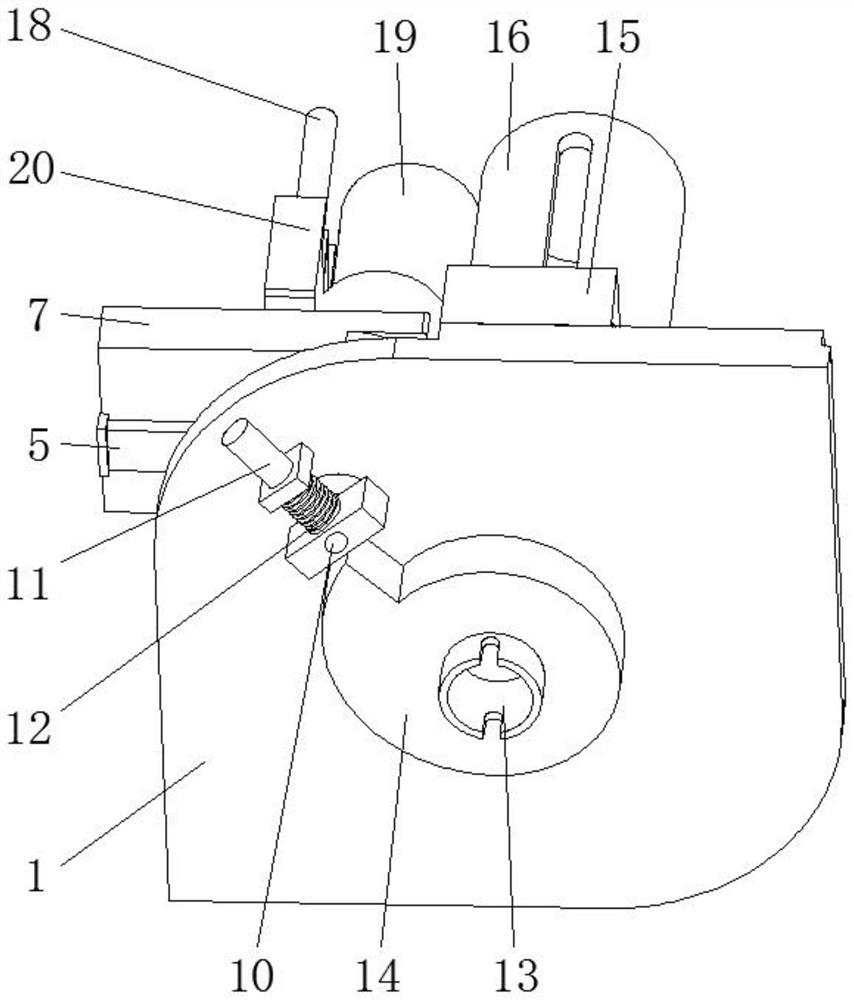

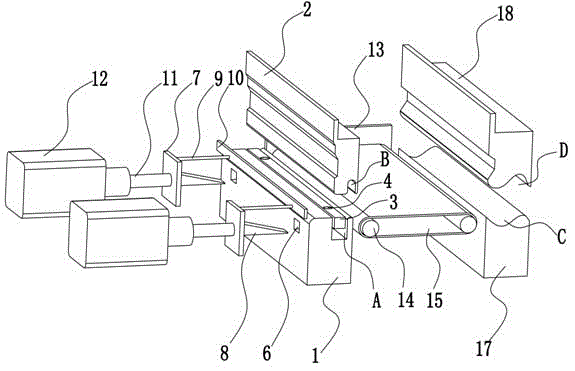

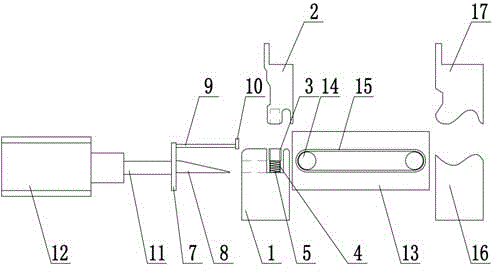

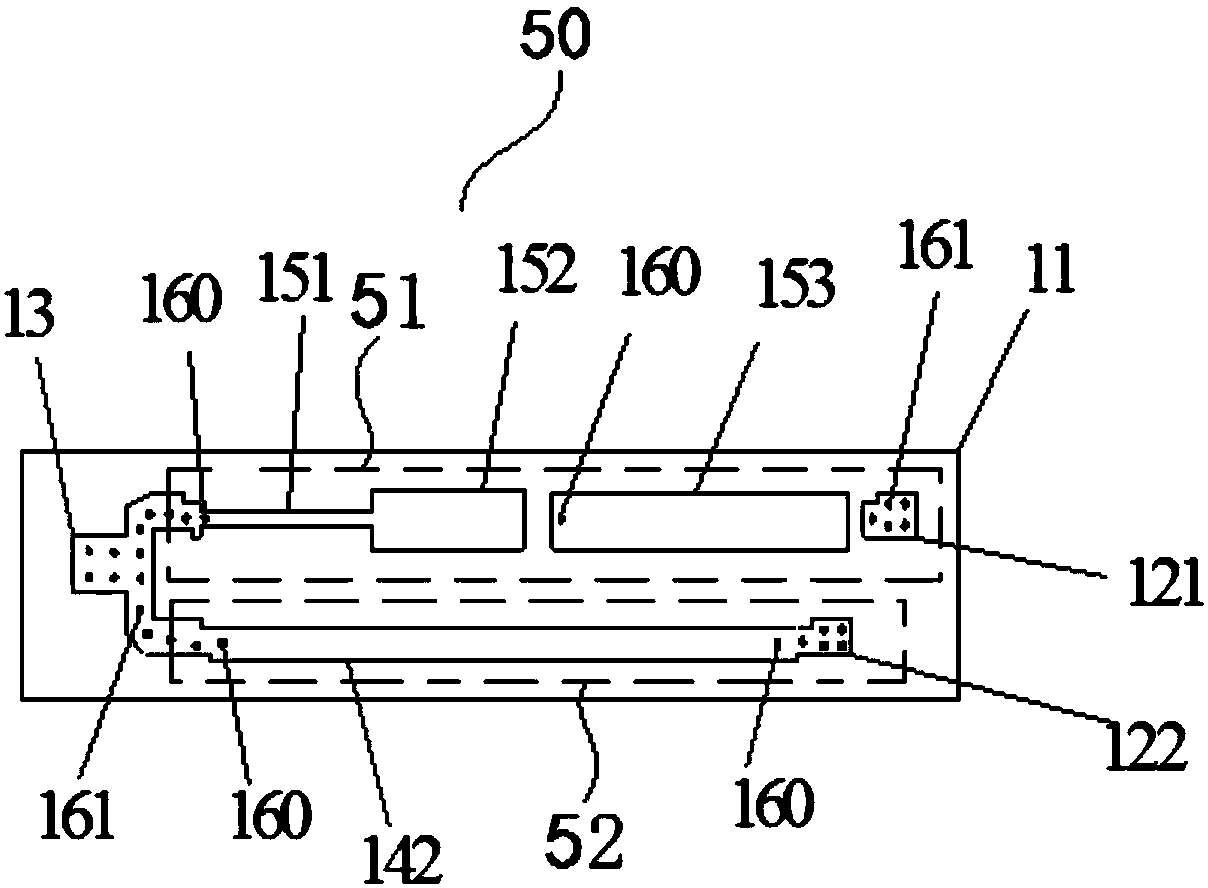

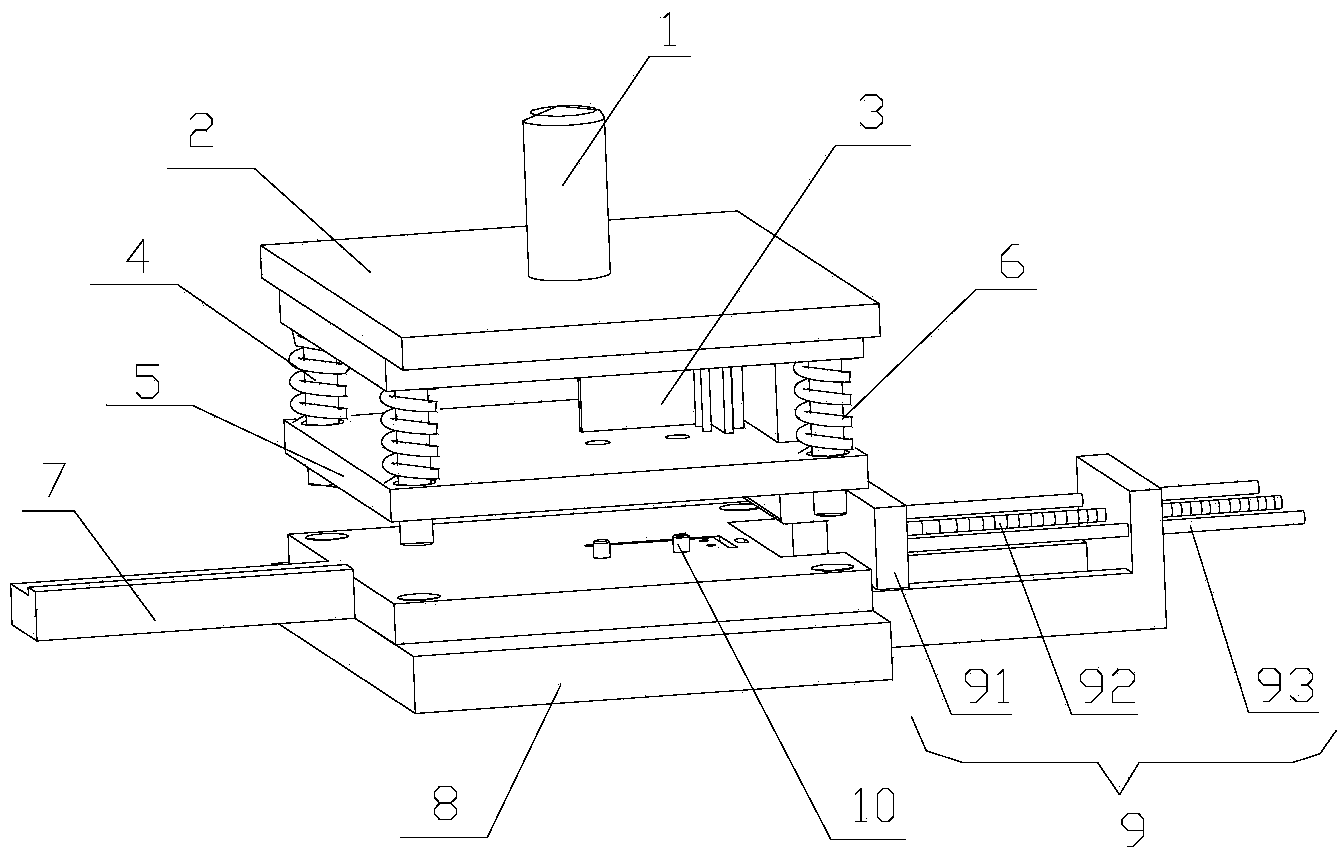

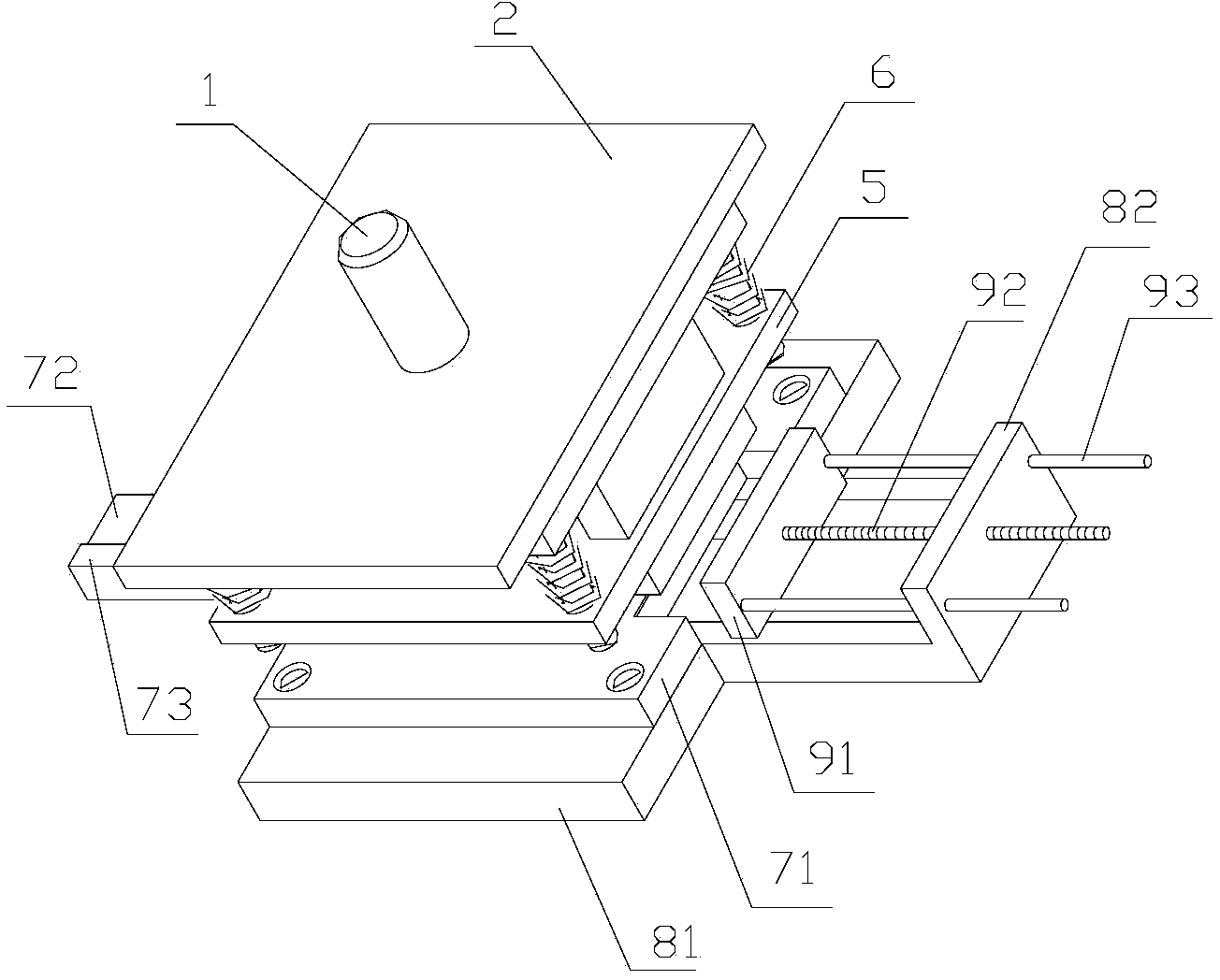

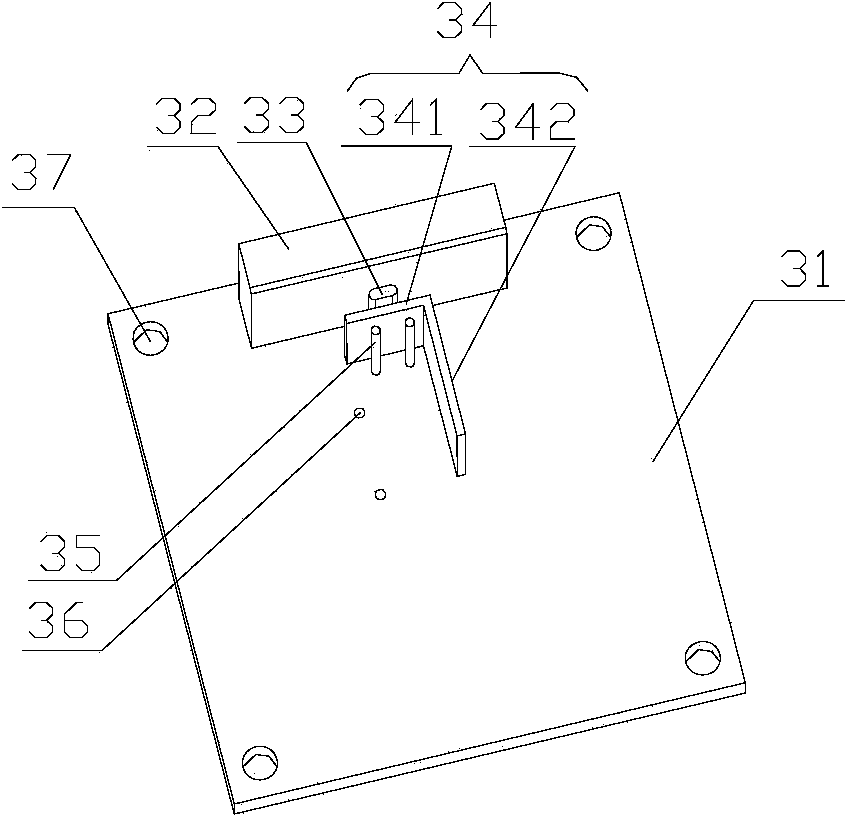

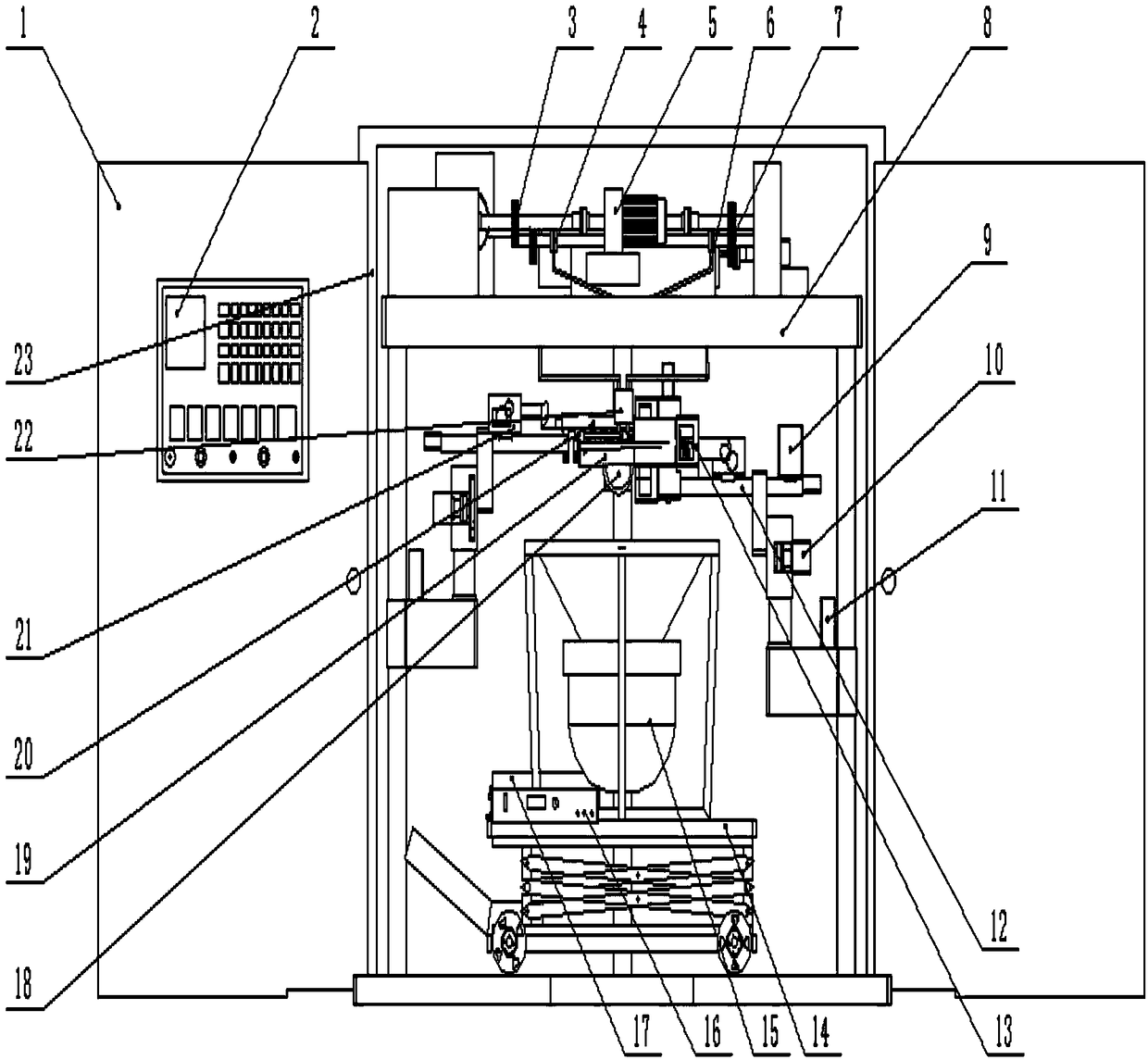

Automatic screw-driving machine

The invention discloses an automatic screw-driving machine which comprises a machine body assembly, a material guide mechanism, a material conveying mechanism, a material grabbing mechanism, a material ejecting mechanism and a screw-driving mechanism. The material guiding mechanism is arranged on a main machine frame of the machine body assembly. The material conveying mechanism is arranged on an auxiliary machine frame on one side of the main machine frame. The material grabbing mechanism is arranged between the material conveying mechanism and the material guide mechanism and conveys guide pins to the material ejecting mechanism. The guide pins are conveyed to the position below PCBs through the material ejecting mechanism. The screw-driving mechanism is arranged above the material guiding mechanism and drives screws into the guide pins. The automatic screw-driving machine is suitable for a PCB automatic machining assembly line, the functions of automatically positioning blocking materials and adjusting the sizes of the conveyed PCBs are achieved through the material guide mechanism, the automatic material feeding or blocking movement is achieved through the material conveying mechanism, the automatic conveying movement of the guide pins is achieved through the material grabbing mechanism, the automatic material ejecting movement is achieved through the material ejecting mechanism, and nuts are automatically locked on the guide pins through the screw-driving mechanism.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

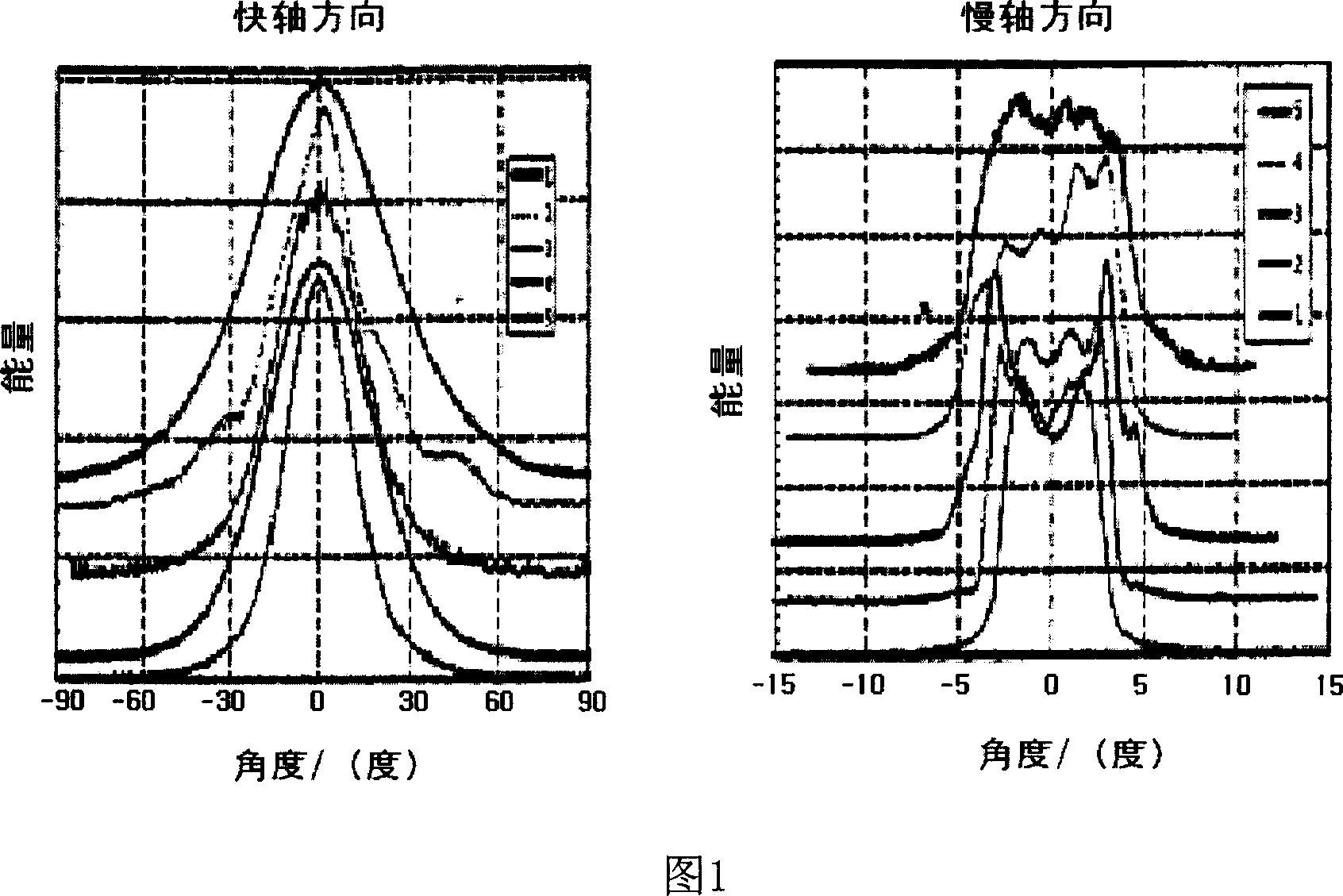

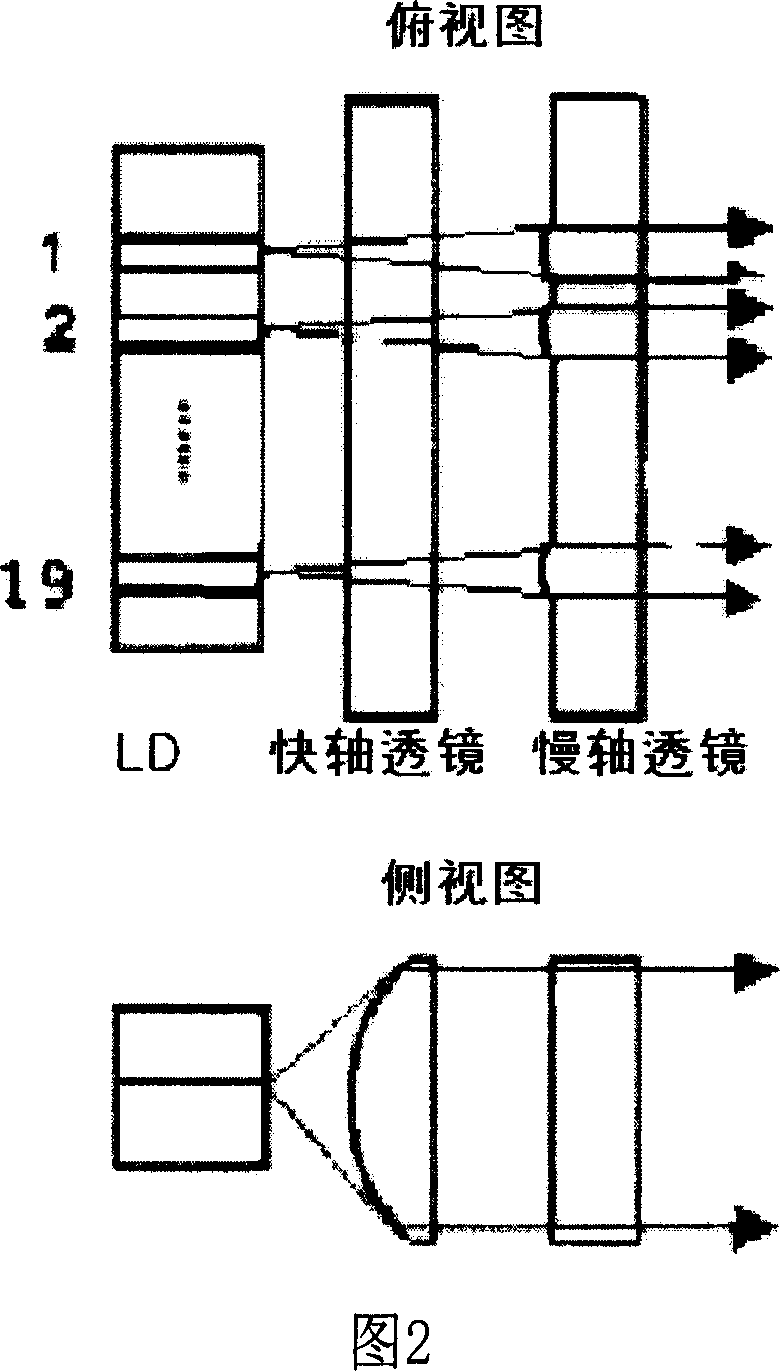

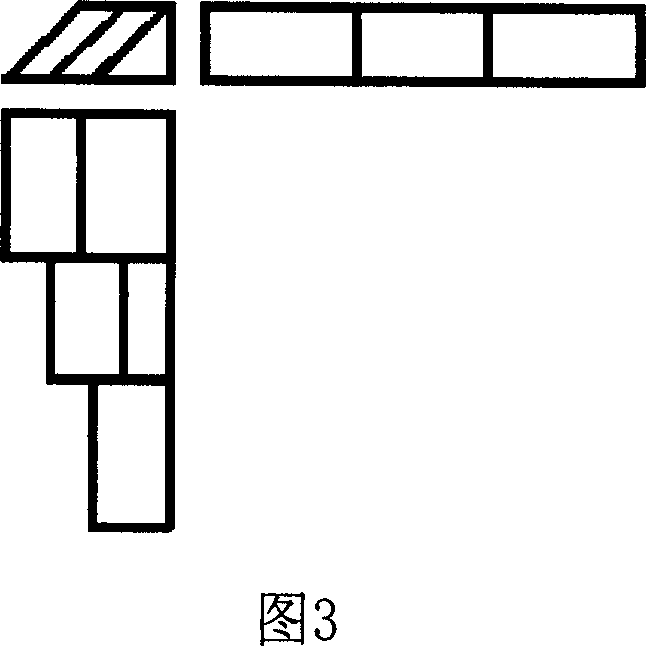

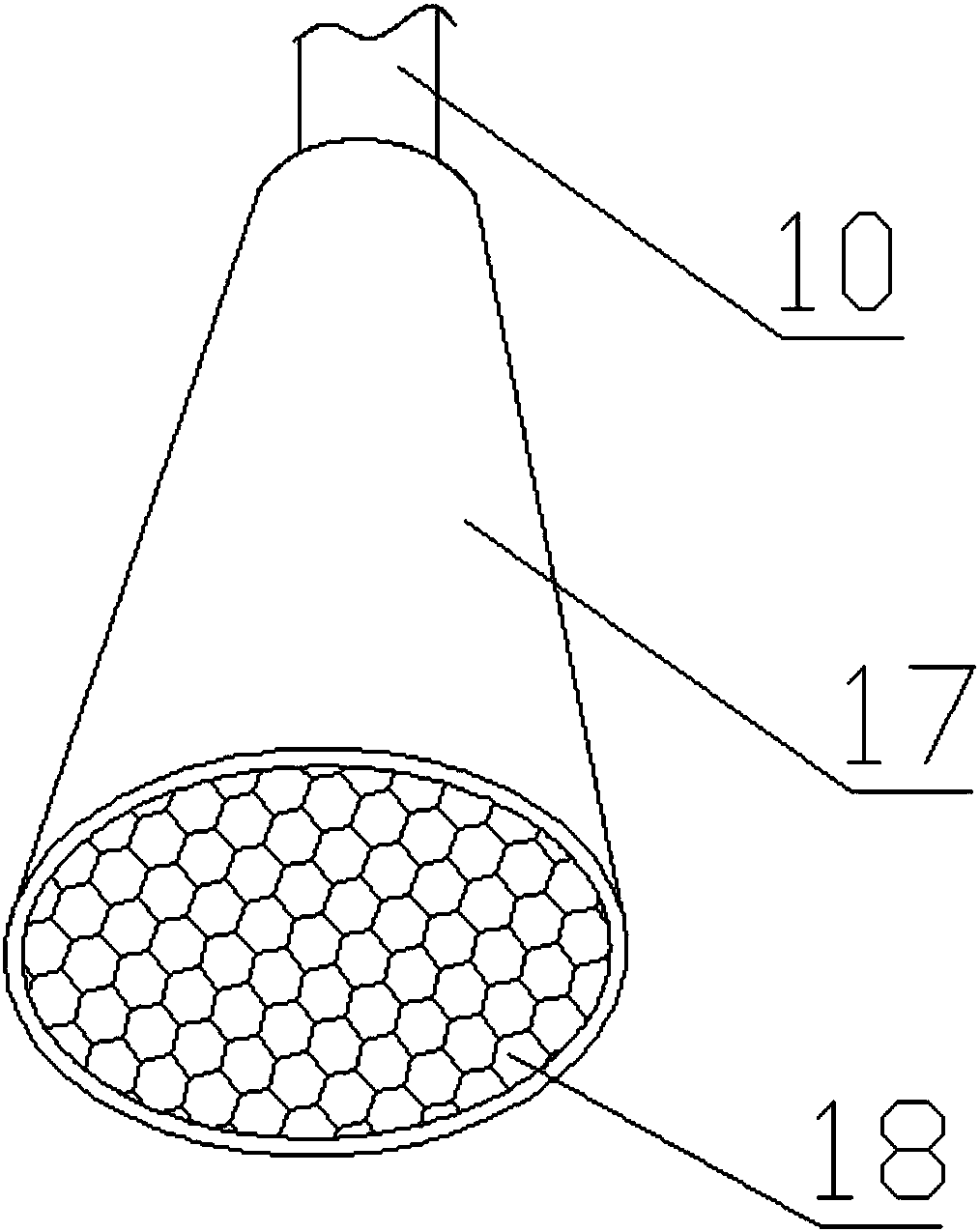

Method for shaping bar array large power semiconductor laser device added with guide light

InactiveCN1975507ACompact and reasonable designGuaranteed stabilityCoupling light guidesHigh power lasersLight beam

Adding guided light strip array high-power semiconductor laser device (High-Power Laser Diode Bar , LD for short) reshaping method: (1) by calculating the product of the optical fiber core radius and half of the angular aperture, and the optical parameter product of the LD light beam in the direction of quick, slow axis, ascertain the number of times which the LD light beam needed to reshaping, to make reshaping implement with high reflecting efficiency; (2) adopting the quick, slow axis collimation lens array to collimates in two direction of the quick, slow axis alignment of LD, getting the strip collimation facula; (3) assembling reshaping implement , realizes reshaping of the light beam; (4) assembling the focusing lens and optical fiber, adjusting the optical fiber to the right location , making the outputting power of LD maximal;(5)entrancing the guided light in proper location of the reshaping implement, adjusting the guided light to appropriate location, makes the luminous power of the guided light which is output from the optical fiber maximum. The light path design is reasonable and compact, has not changed the light path of LD, has avoided leading into new scattering and reflecting loss, guarantee light path stability of LD.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

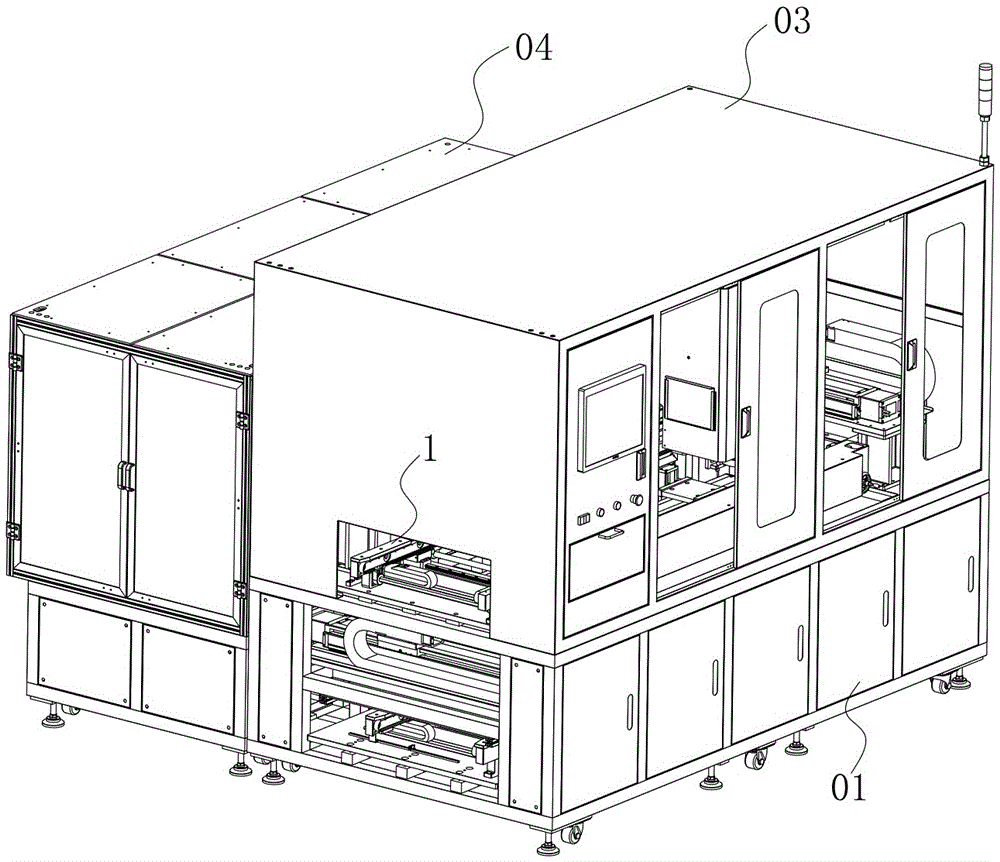

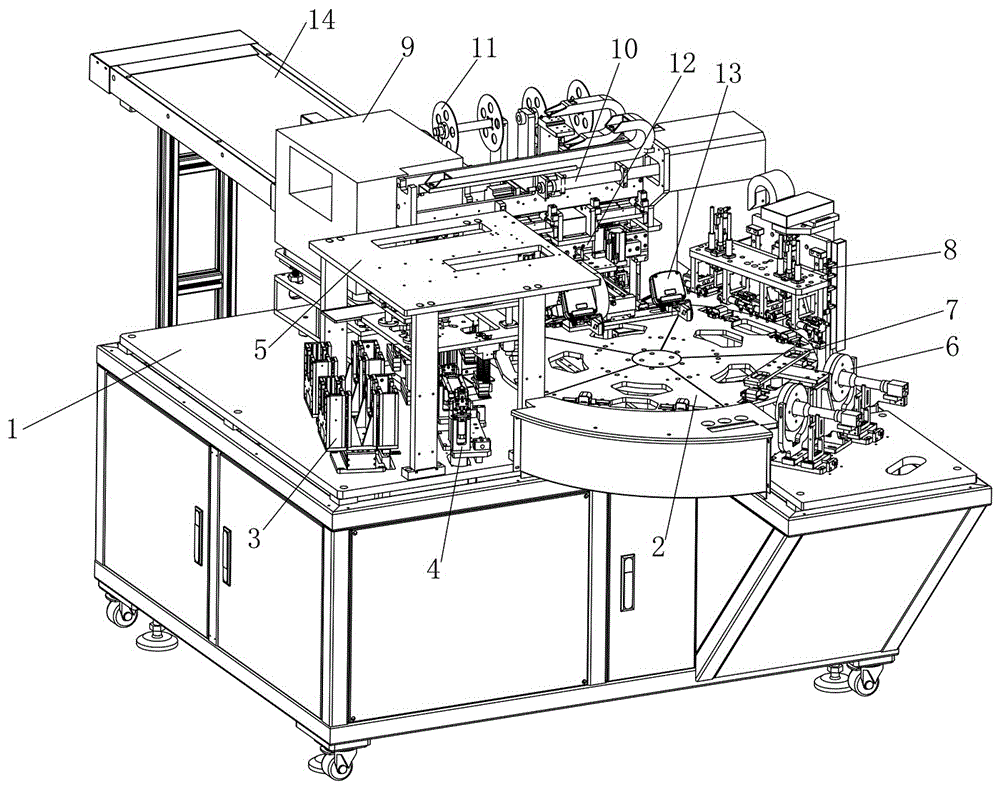

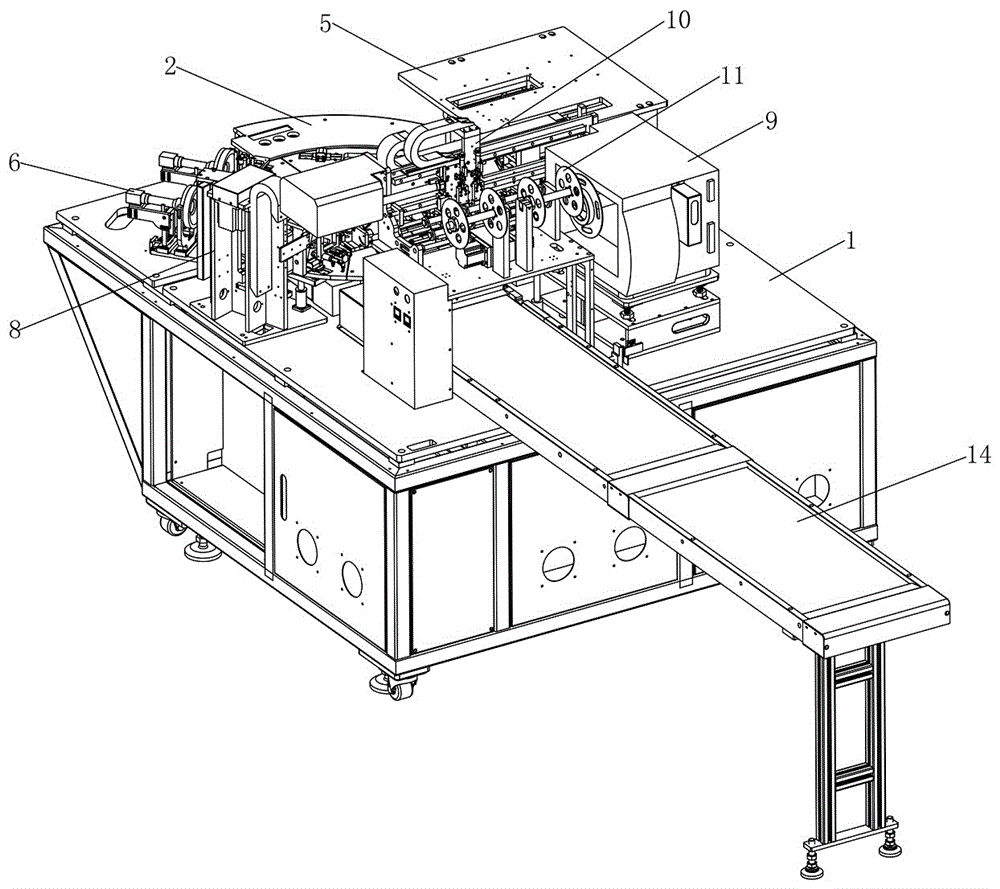

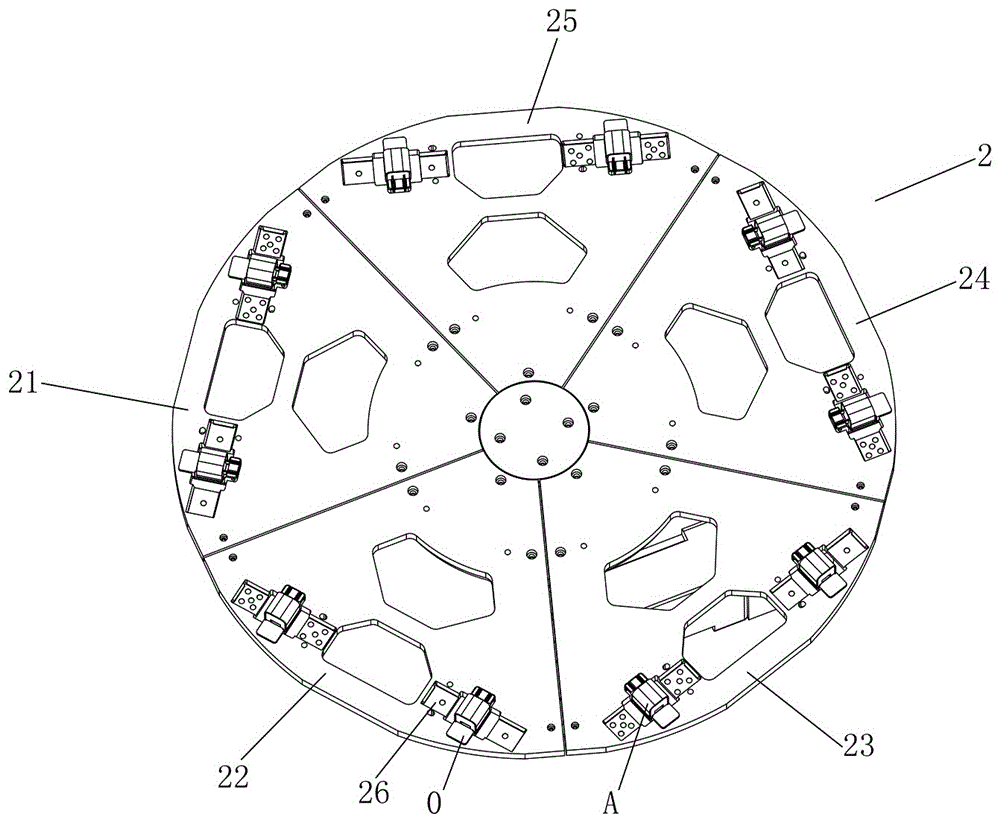

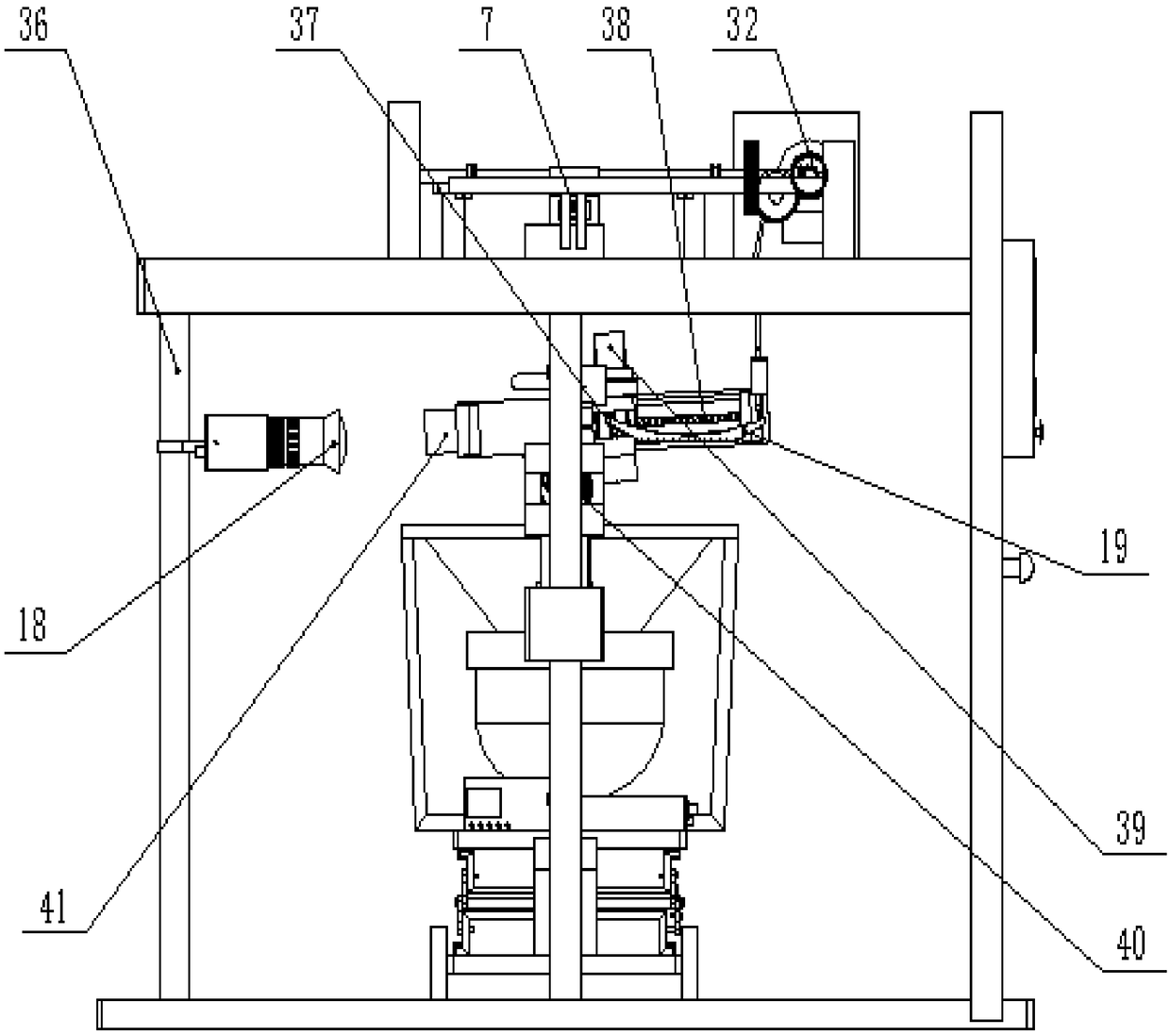

Automatic packaging machine and automatic packaging technology thereof

ActiveCN105799958AIncrease production capacityGuarantee the efficiency of automated packagingWrapper twisting/gatheringSolid materialProduct processingEngineering

The invention discloses an automatic packaging machine which comprises a rotary table, material trough mechanisms, a film tearing mechanism, a material feeding mechanism, a bar code scanning mechanism, a film coating mechanism, a labeling mechanism, a bag discharging mechanism, a bag tearing mechanism and a bagging mechanism, wherein the material trough mechanisms, the film tearing mechanism, the material feeding mechanism, the bar code scanning mechanism, the film coating mechanism, the labeling mechanism, the bag discharging mechanism, the bag tearing mechanism and the bagging mechanism are arranged outside the rotary table in the anticlockwise rotation direction of the rotary table; and a film feeding station, a material feeding station, a bar code scanning station, a film coating station and a bagging station are arranged on the rotary table in the circumferential direction of the rotary table in sequence so as to finish working procedures such as film releasing and tearing, film feeding, material feeding, bar code scanning, film coating, bag discharging, labeling, bag tearing, bag opening, bagging and discharging. The automatic packaging machine integrates various working procedures, realizes automatic film coating, bar code sticking and bagging, is compact in connection of the working procedures, high in production stability and high in degree of automation, adopts a double-product processing mode and has high productivity.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

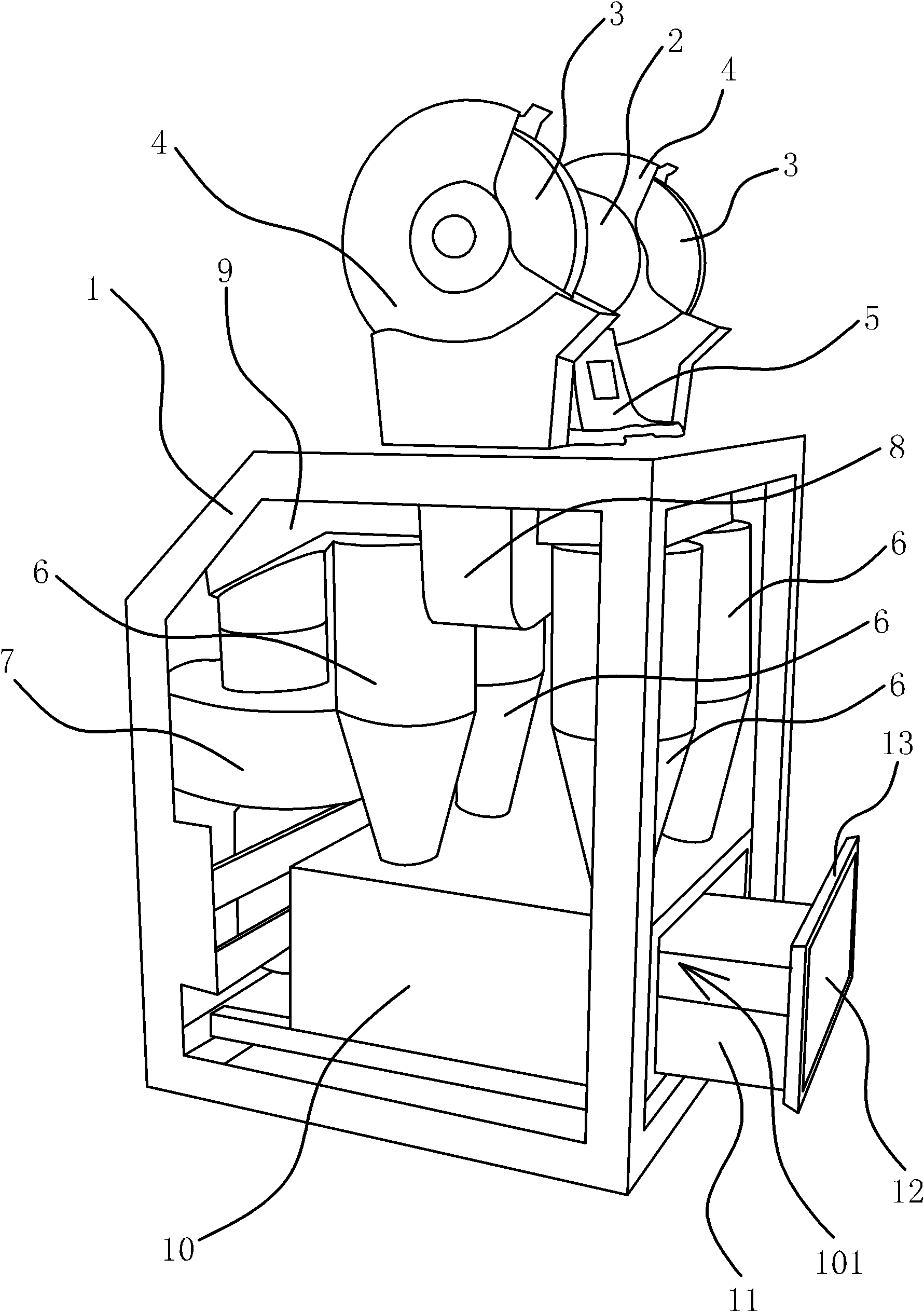

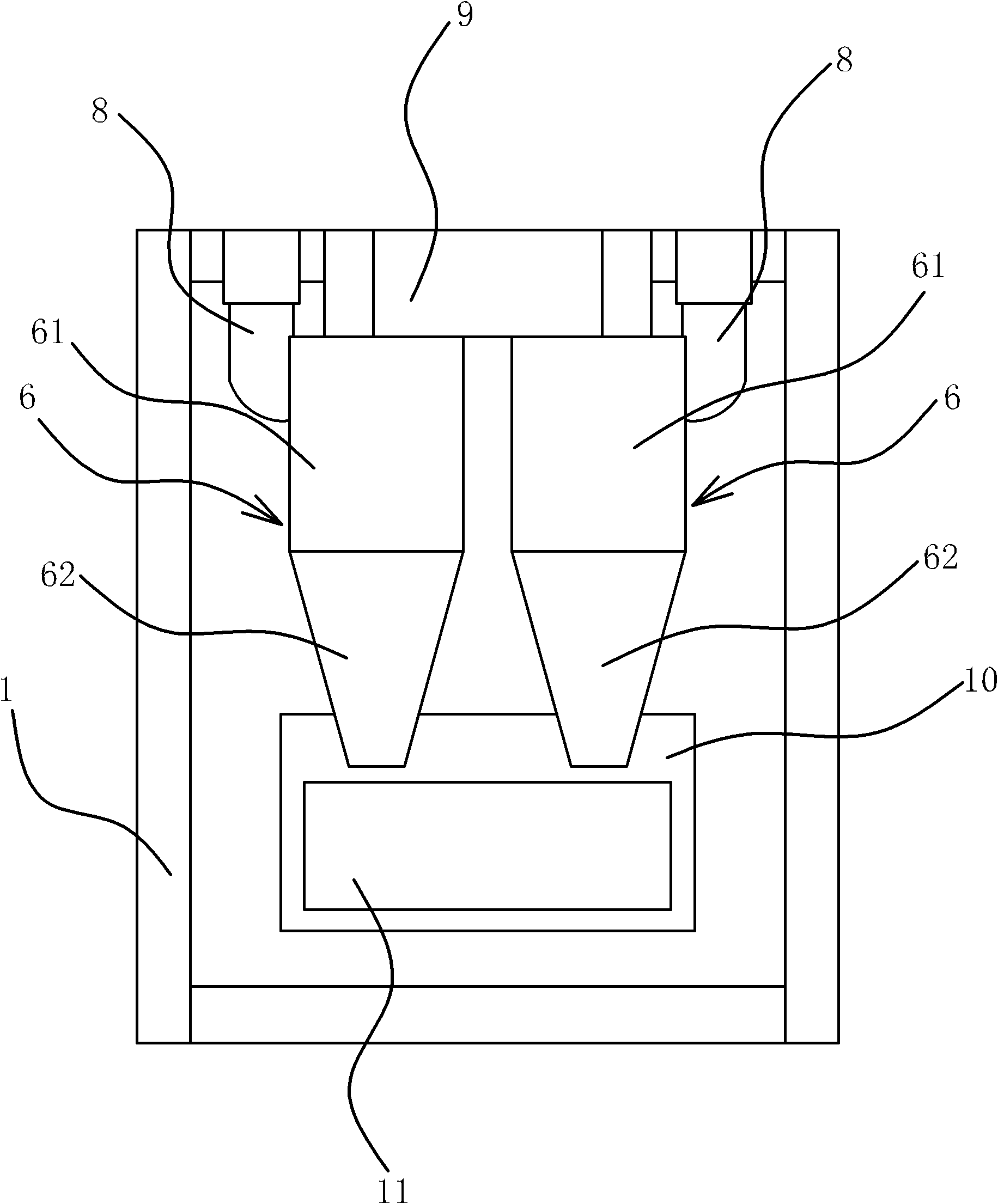

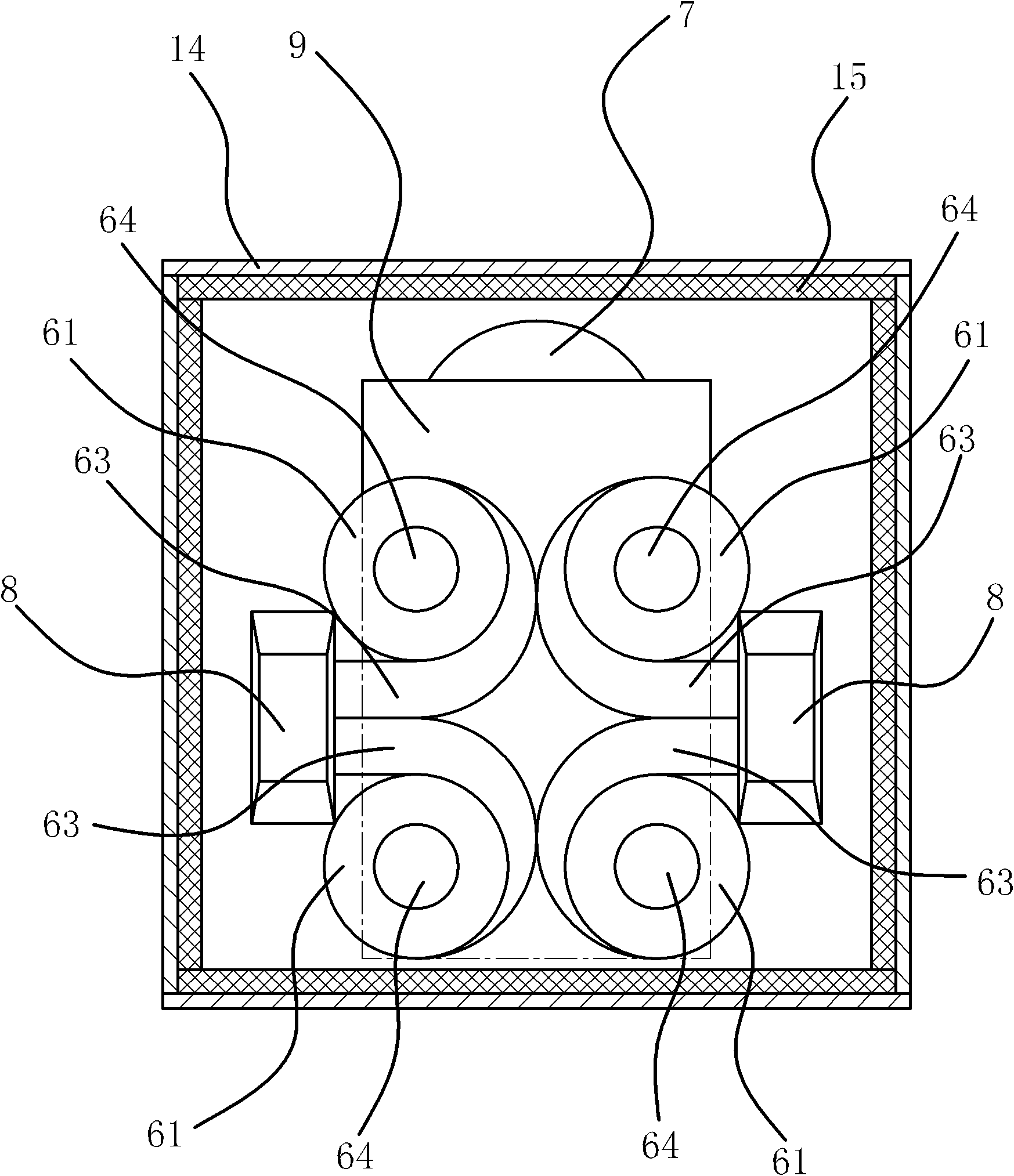

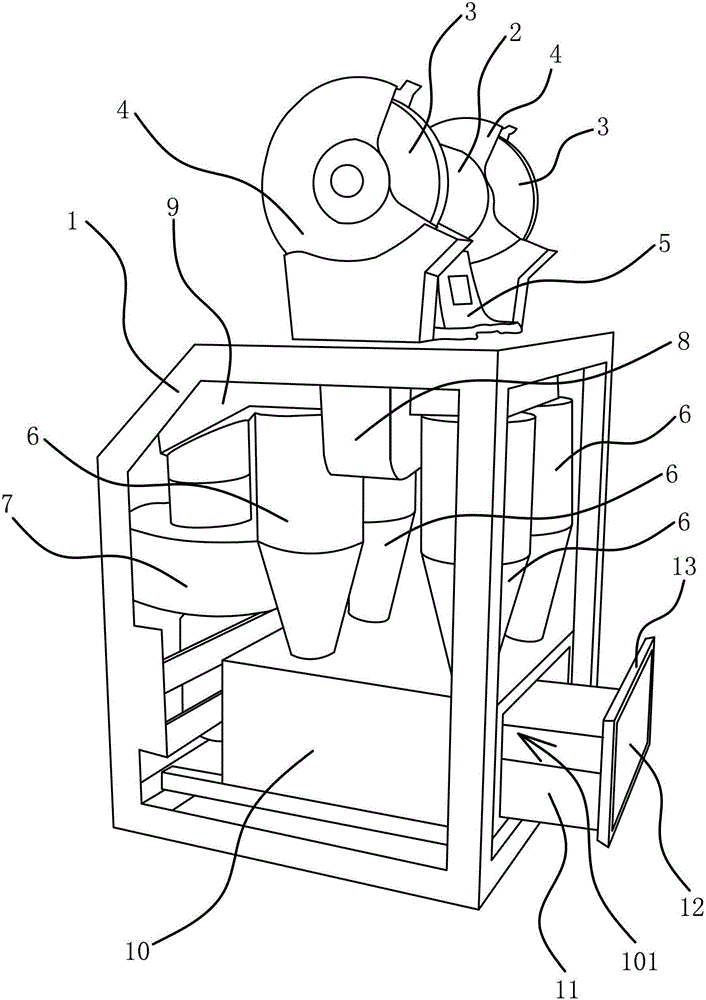

Dust removal grinding wheel machine

ActiveCN101966665ASimple structureCompact and reasonable designOther manufacturing equipments/toolsGrinding/polishing safety devicesEngineeringNoise reduction

The invention provides a dust removal grinding wheel machine which belongs to the technical field of operation. The invention solves the problems of easy breakage of a cloth bag, short service life and troublesome use in the traditional dust removal grinding wheel machine. The dust removal grinding wheel machine comprises a working platform, a motor, a dust hood and a grinding wheel, wherein a fan which is positioned under a platform plate is fixed on the working platform; a cyclone dust removal mechanism which is provided with an air inlet pipe, an exhaust pipe and a dust discharging opening and can be used for separating dust from dust-contained gas and discharging the dust from the dust discharging opening is arranged between the fan and the dust hood; the air inlet pipe is communicated with the dust hood; the exhaust pipe is communicated with an air inlet of the fan; and a dust collecting mechanism which is communicated with the dust discharging opening and can ensure that the dust discharging opening is sealed and can be used for collecting dust falling off the dust discharging opening is fixed on the working platform. The dust removal grinding wheel machine has the advantages of simple structure, reasonable and compact design, low manufacture cost, good dust removal and noise reduction effect and convenient dust particle cleaning.

Owner:陈美青

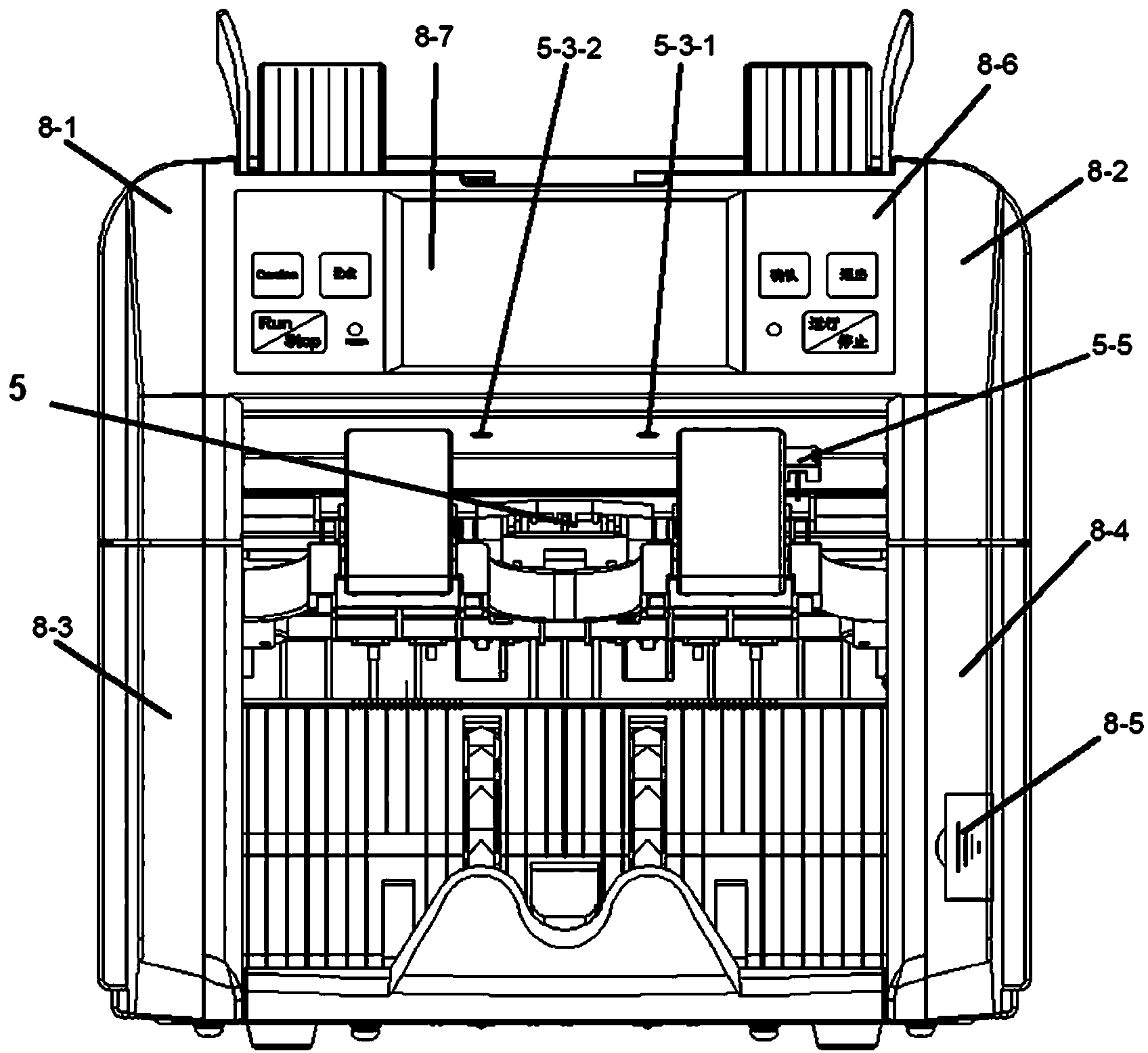

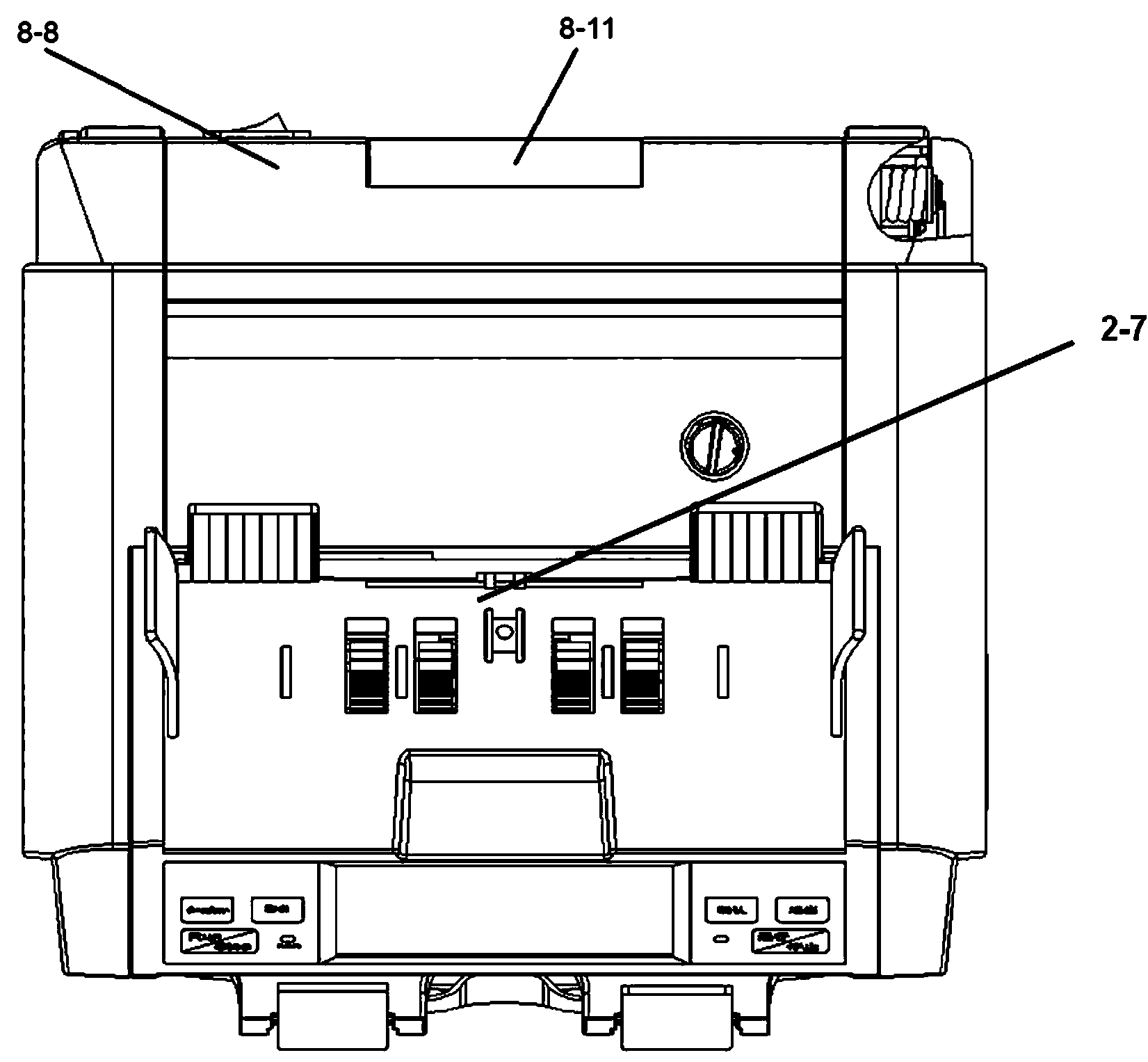

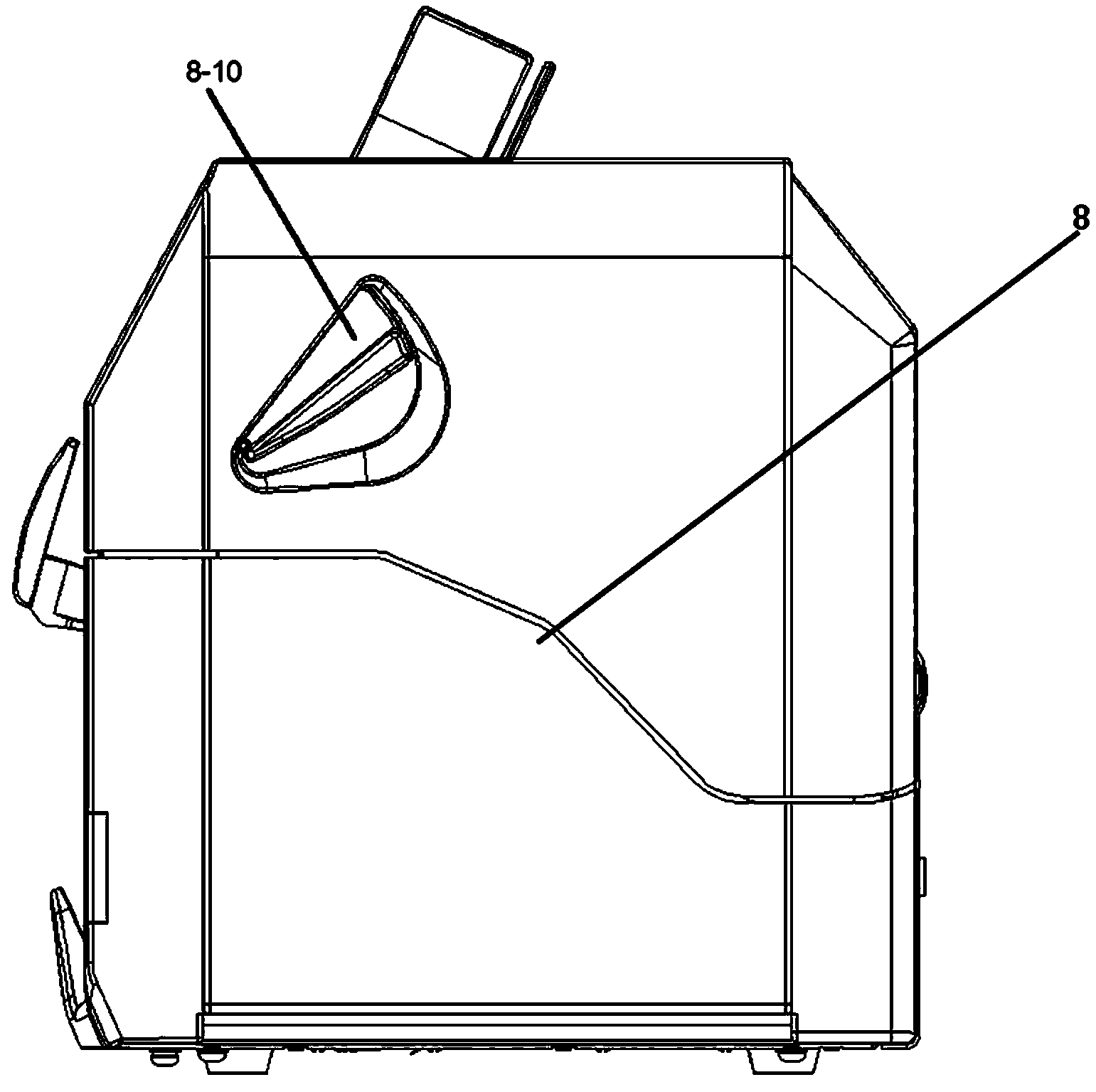

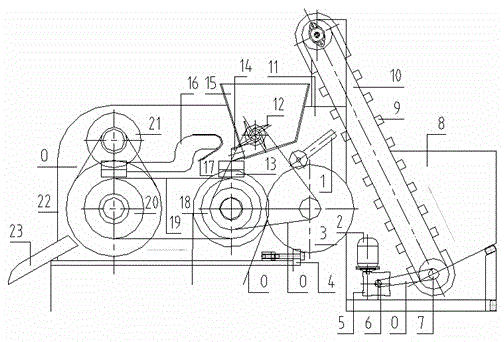

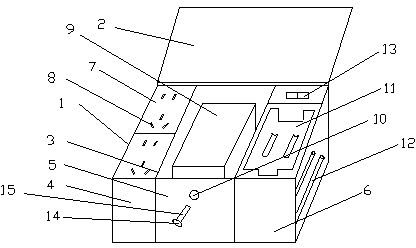

Small paper money processing machine

The invention discloses a small paper money processing machine and relates to a two-channel paper money counting machine and a sorter used for meeting various paper processing requirements of paper money identification, especially used for counting paper money in the financial system commercial disappearance field and paper such as checks, government bonds and the like similar to the paper money, sorting paper money face value, sorting old and new degree of the paper money, identifying authenticity of the paper money, recognizing paper money number and the like. The small paper money processing machine comprises a base mechanism, an upper mechanism, a back turning mechanism, a detection mechanism, a conveying mechanism, an upper money receiving mechanism, a transmission mechanism and a shell, wherein the base mechanism, the upper mechanism and the back turning mechanism are movably connected through a rotation shaft; the upper mechanism and the base mechanism are located and locked through a left locking hook and a right locking hook; a money distribution mechanism comprises a lower money discharging pinch roller, a lower money discharging wheel, a money distributing stirring fork, a money distributing electromagnetic switch and a money distributing sensor; the lower money receiving mechanism comprises a money receiving wheel, a money receiving motor, a wheel receiving frame, a small motor speed measuring plate, a small motor speed measuring sensor, a lower money receiving baffle, a destaticizing sheet and a money receiving sensor.

Owner:NANJING EBDEL TECHCAL DEV

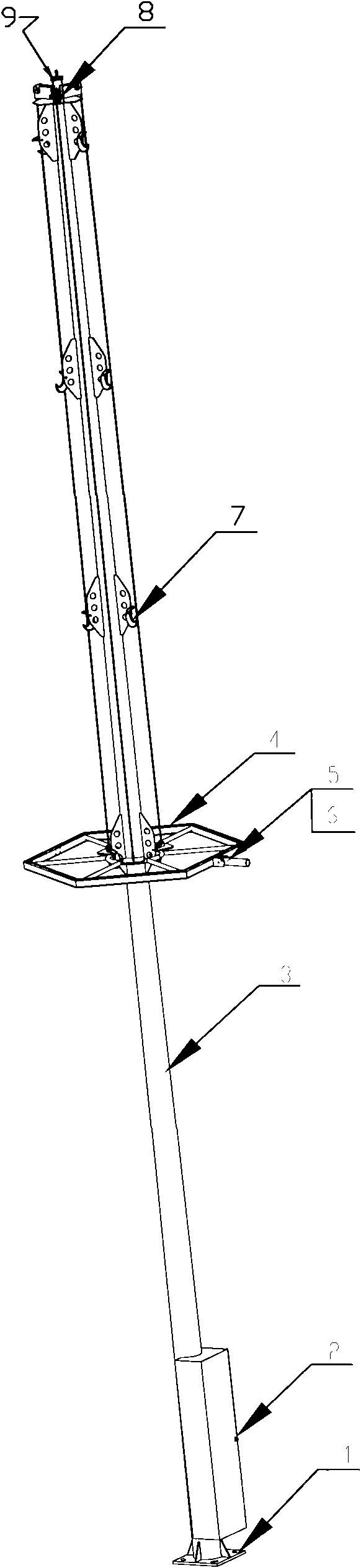

Lifting street lamp post

InactiveCN101846294ACompact and reasonable designWide range of power sourcesLighting support devicesPoint-like light sourceLow noiseEngineering

The invention discloses a lifting street lamp post, which comprises a base, a base post arranged on the base, and a lamp disc sleeved on the base post, wherein a lamp is arranged on a branched post of the lamp disc. The lifting street lamp post is characterized in that: the base post is a hollow post body which is provided with a lifting mechanism inside; a pulley is arranged on the top of the post body; the lifting mechanism comprises a shaft seat, a motor, a rotating shaft, a steel wire rope and a guide rail; and one end of the steel wire rope passes through the pulley to connect the lamp disc, and the other end of the steel wire is connected with the rotating shaft and linked with the motor for revolution. The lifting street lamp post has the advantages of compact and reasonable design, wide power source, low noise, convenient installation, flexible use, multiple functions, multiple matching forms, high reliability, long service life, and the like, and is suitable for illumination of various roads.

Owner:NANJING HANDSON SCI & TECH CORP

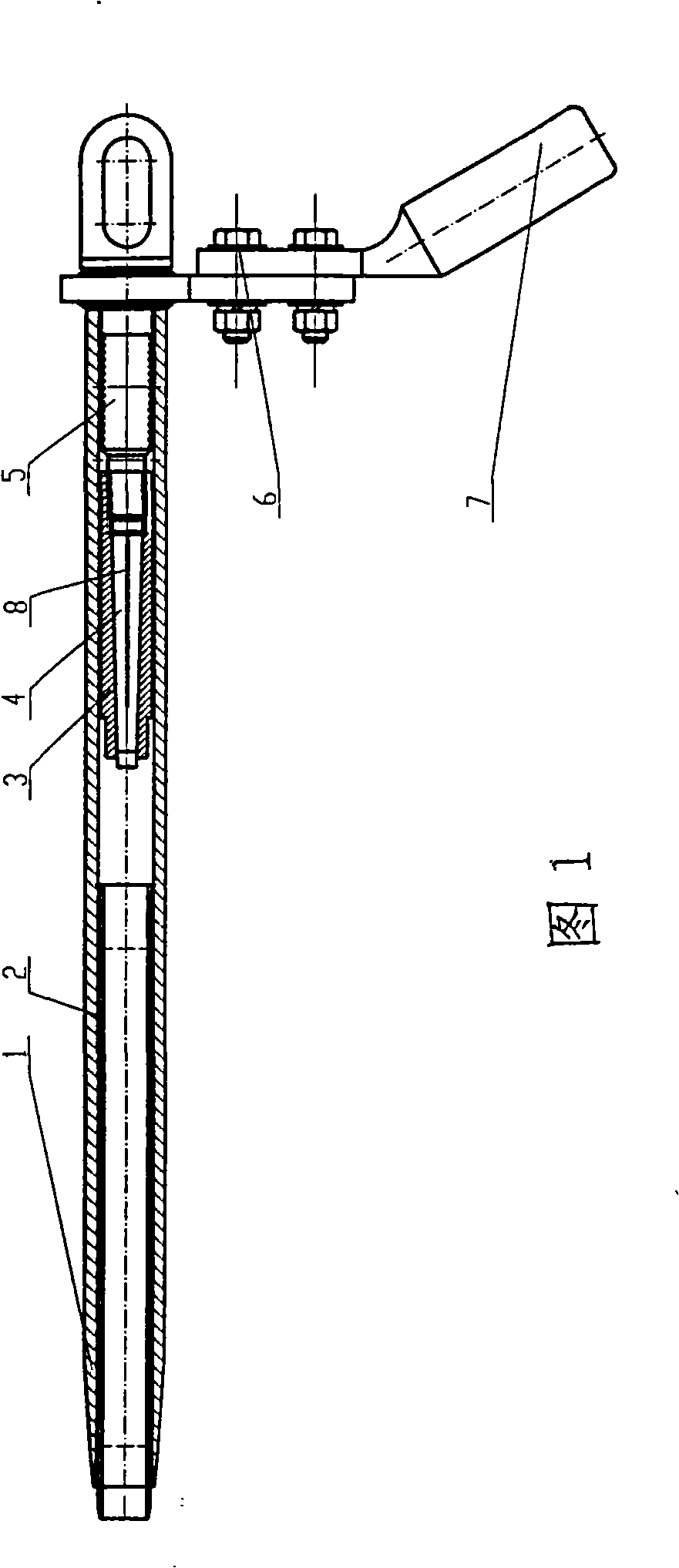

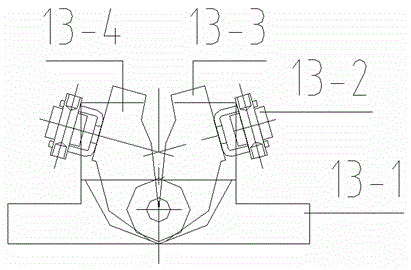

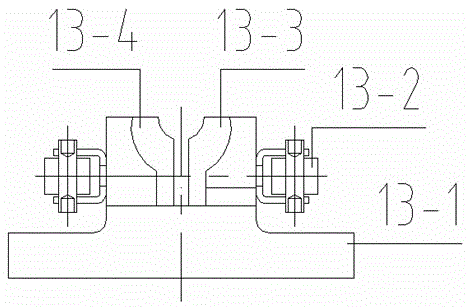

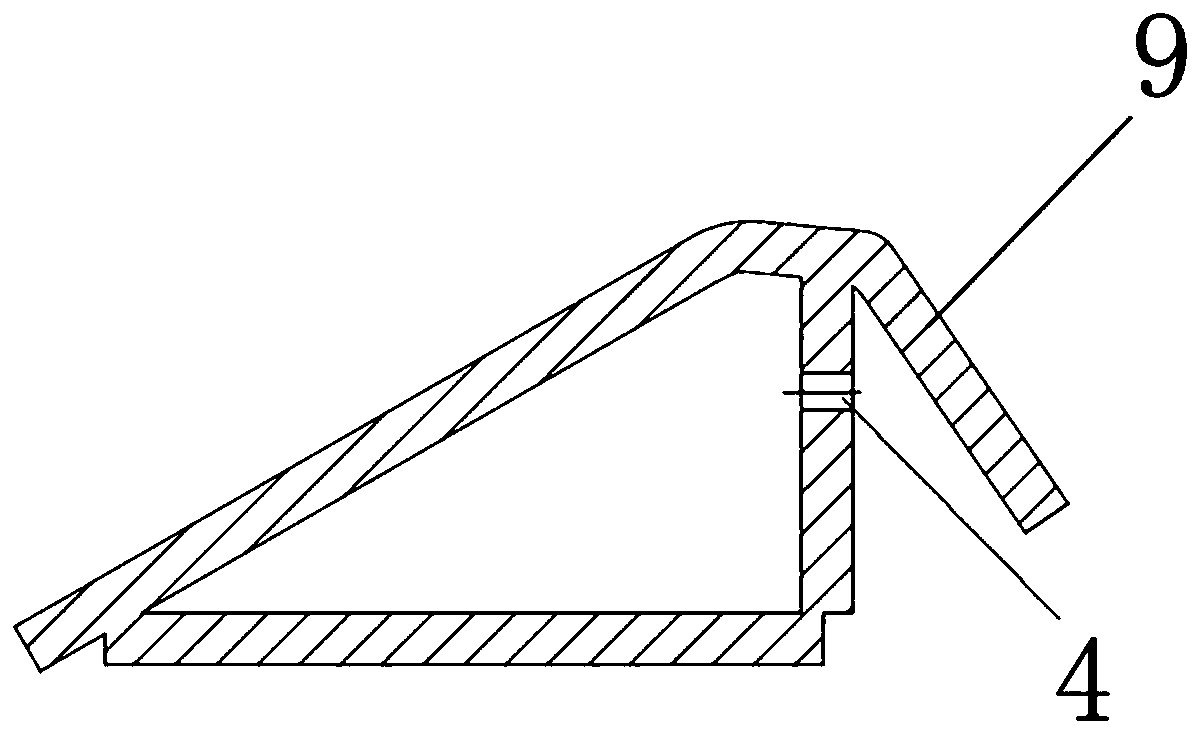

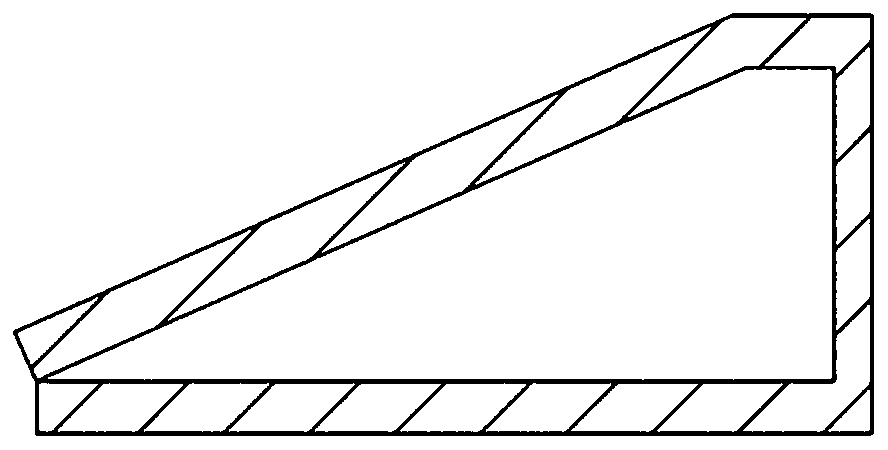

Tension resisting clip for carbon fiber composite core conductive wire

InactiveCN101335444ANo damagePlay a protective effectAdjusting/maintaining mechanical tensionFiberElectrical conductor

The invention discloses a strain clamp used by a carbon fiber composite core lead for fixing carbon fiber composite core aluminum strands on overhead power lines and strain poles and towers of a substation in the electric power system. The clamp of the invention is composed of a sphenoid clip holder provided in a wire clamp body, a sphenoid clip in the clip holder with a shape matching the shape of inner holes of the sphenoid clip holder and an internal liner pipe provided additionally. The wire clamp of the invention fully utilizes the feature that the sphenoid clip moves inside of the clip holder to clamp the carbon fiber composite core reliably under the change of temperature, forms a conductor by the crimp connection of the internal liner pipe with the wire clamp body and the aluminum strands, and imposes no damage to the carbon fiber composite core. The wire clamp of the invention has the advantages of compact and reasonable design, novel and ingenious construction, small impact from temperature, strong shock and endurance resistance, even grip distribution, strong bearing grip strength and effective avoidance of grip looseness. Furthermore, the wire clamp of the invention, in the situation that a system increases capacity, needs not to replace an iron tower, imposes no damage to green land and reduces economic loss, thus being economical and practical. The development prospect thereof is broad and an extensive application is available.

Owner:中国电建集团四平线路器材有限公司 +1

Automatic positioning holding device and automatic splitting machine for areca nuts

The invention discloses an automatic positioning holding device for processing areca nuts and an automatic splitting machine for the areca nuts, and belongs to the technical field of food processing devices. A holder fixed to a conveying chain and an elastic clamping device fixed to a machine frame are designed to be matched, and the process that the areca nuts are clamped and fed into a cutter to be split is completed during the relative movement. Two hoppers are arranged on the automatic splitting machine for the areca nuts, the two hoppers are connected through a conveying chain with a stopping block, and the feeding height is reduced; a distributing wheel is installed in a conveying hopper to replace manual conveying. By means of the automatic positioning holding device and the automatic splitting machine for the areca nuts, labor is replaced with a machine, and workers are liberated from complicated labor. The number of the workers is decreased, cost is reduced, floor space is reduced, production efficiency is improved, safety is improved, and food hygiene is guaranteed. The machine is compact and reasonable in design and convenient to operate and maintain. Parts in contact with food are manufactured through food-grade materials, and safe and sanitary effects are achieved.

Owner:所广博

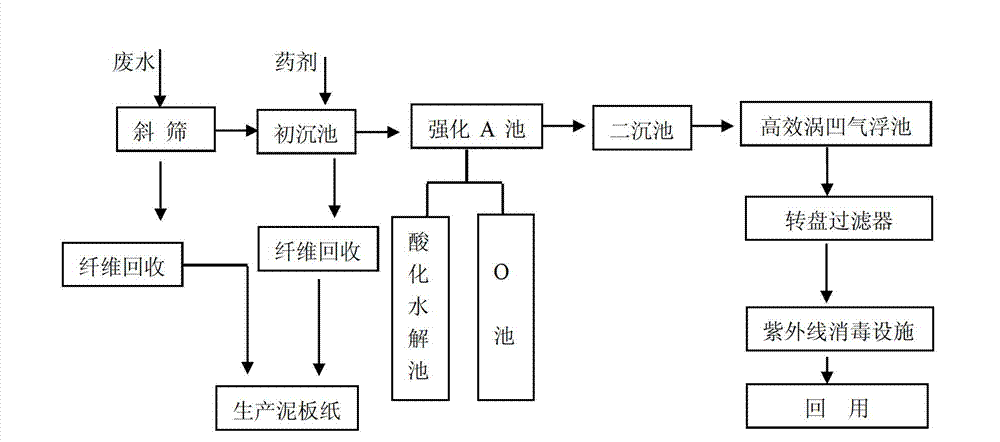

Novel waste paper papermaking waste water comprehensive treatment method and system

InactiveCN102964030AImprove biodegradabilityCompact and reasonable designWater/sewage treatment by irradiationMultistage water/sewage treatmentFiberCavitation

The invention relates to the technical field of waste paper papermaking waste water comprehensive treatment methods. The waste paper papermaking waste water comprehensive treatment method provided by the invention comprises the following steps of: recycling fibers by filtering waste water with an inclined screen of 80-100 meshes; introducing the waste water filtered by the inclined screen into a primary sedimentation tank, sequentially adding flocculant and coagulant aid, introducing waste water at the upper part into a condensation tank A, and sedimenting the waste water at the lower part and recycling the fibers, wherein the condensation tank A comprises an acidification hydrolysis tank and a tank O; according to waste water treatment requirements and the condition of meeting the standard or not, introducing the waste water, which flows out from the tank O and stays for 1-3 hours in a secondary sedimentation tank, into a high-efficiency cavitation air floatation tank, and then filtering by virtue of a rotary table filter; and disinfecting clear liquid after filtering by ultraviolet light and then introducing the disinfected clear liquid into a papermaking workshop to be recycled. The waste paper papermaking waste water comprehensive treatment method provided by the invention can carry out deep treatment on dissolvable substances, suspension solid matters and bacterial population in waste water, the purified waste water can be directly recycled, part of the waste water can be directly discharged, and fine fibers obtained during treatment can be utilized, so that resource is really recycled and energy-saving effect is good.

Owner:杭州富阳春江污水回用处理有限公司 +1

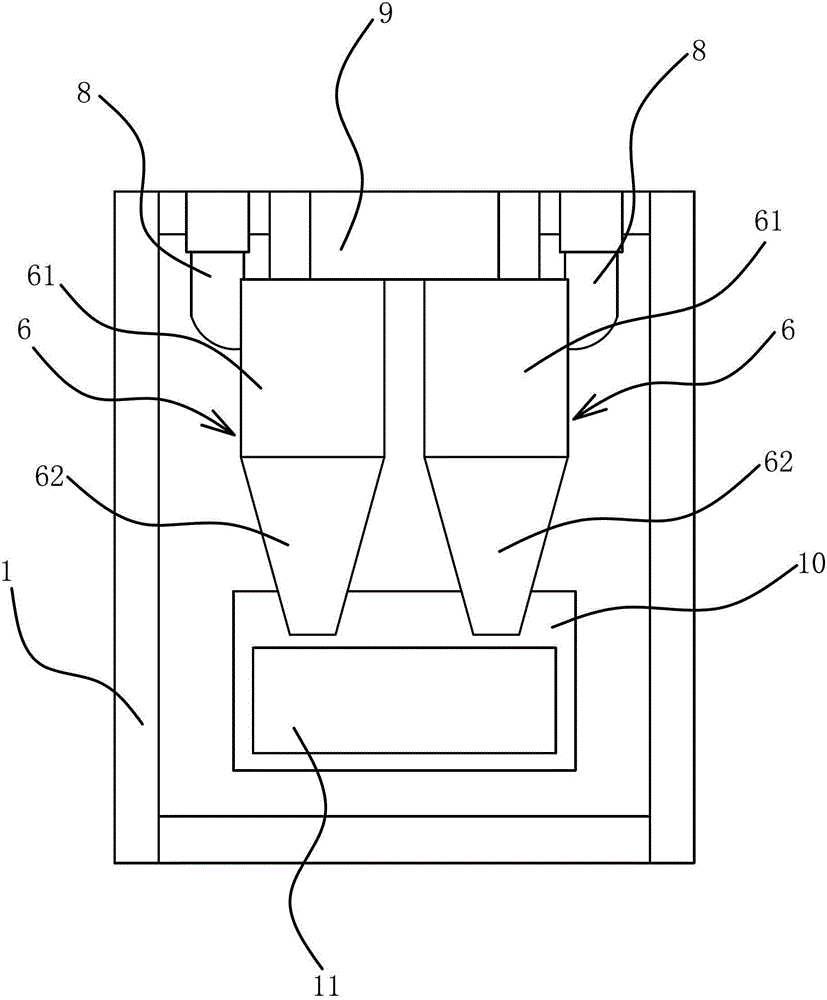

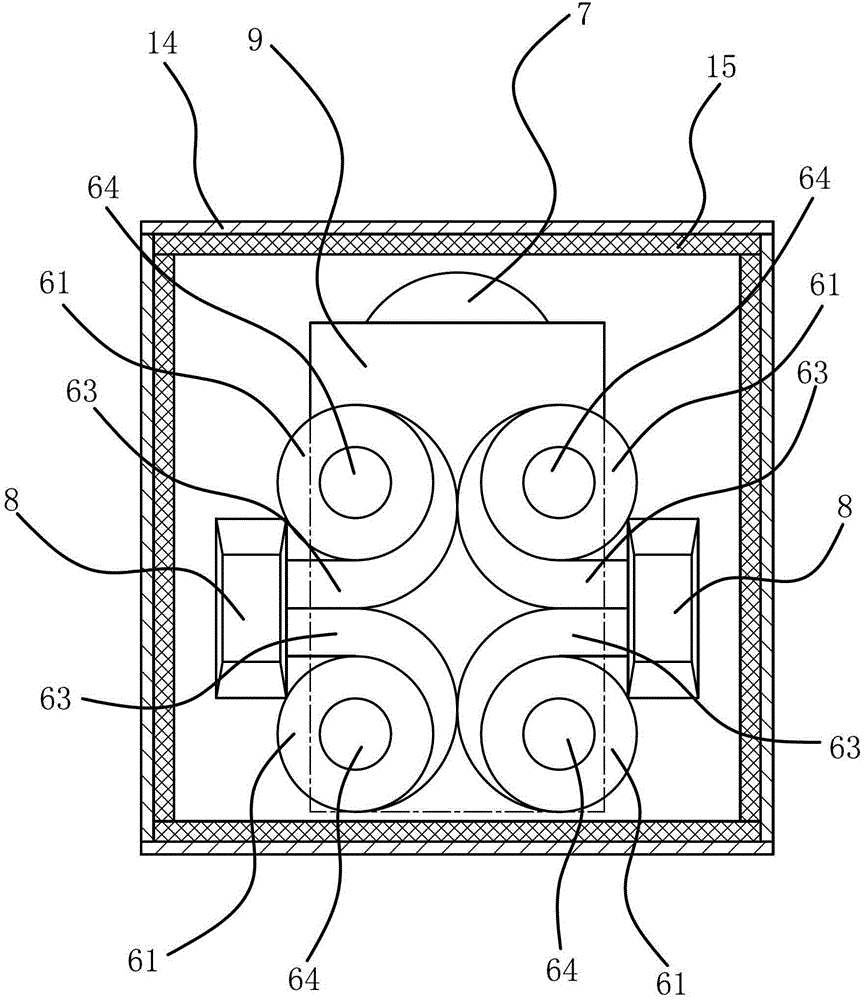

Bearing assembling equipment

InactiveCN111828489ACompact and reasonable designFor processing and productionBearing componentsProduction lineDrive shaft

The invention discloses bearing assembling equipment. The bearing assembling equipment comprises a base. A driving shaft is rotationally connected to the center of the base, a rotating frame is fixedly connected to the top of the driving shaft, and a movable column is movably connected to the inner wall of the rotating frame. A movable plate is fixedly connected to the top of the movable column, and a rotary table is slidably connected to the outer side of the movable plate. An assembling table is fixedly connected to the top of the rotary table, and limiting devices are arranged on the two opposite sides of the inner wall of the assembling table. A limiting block is connected to the side, close to the inner wall of the movable column, of the assembling table through a buckle, a shifting rod is fixedly connected to the bottom of the limiting block, and a top frame is slidably connected to the bottom of the shifting rod. The invention relates to the technical field of bearings. The bearing assembling equipment solves the problems that most existing bearing production is achieved through a production line, the machining stroke is long, the production efficiency is low, the size is large, the occupied area is large, electrical control is adopted, the equipment cost is high, and maintenance and repair are not easy.

Owner:张建波

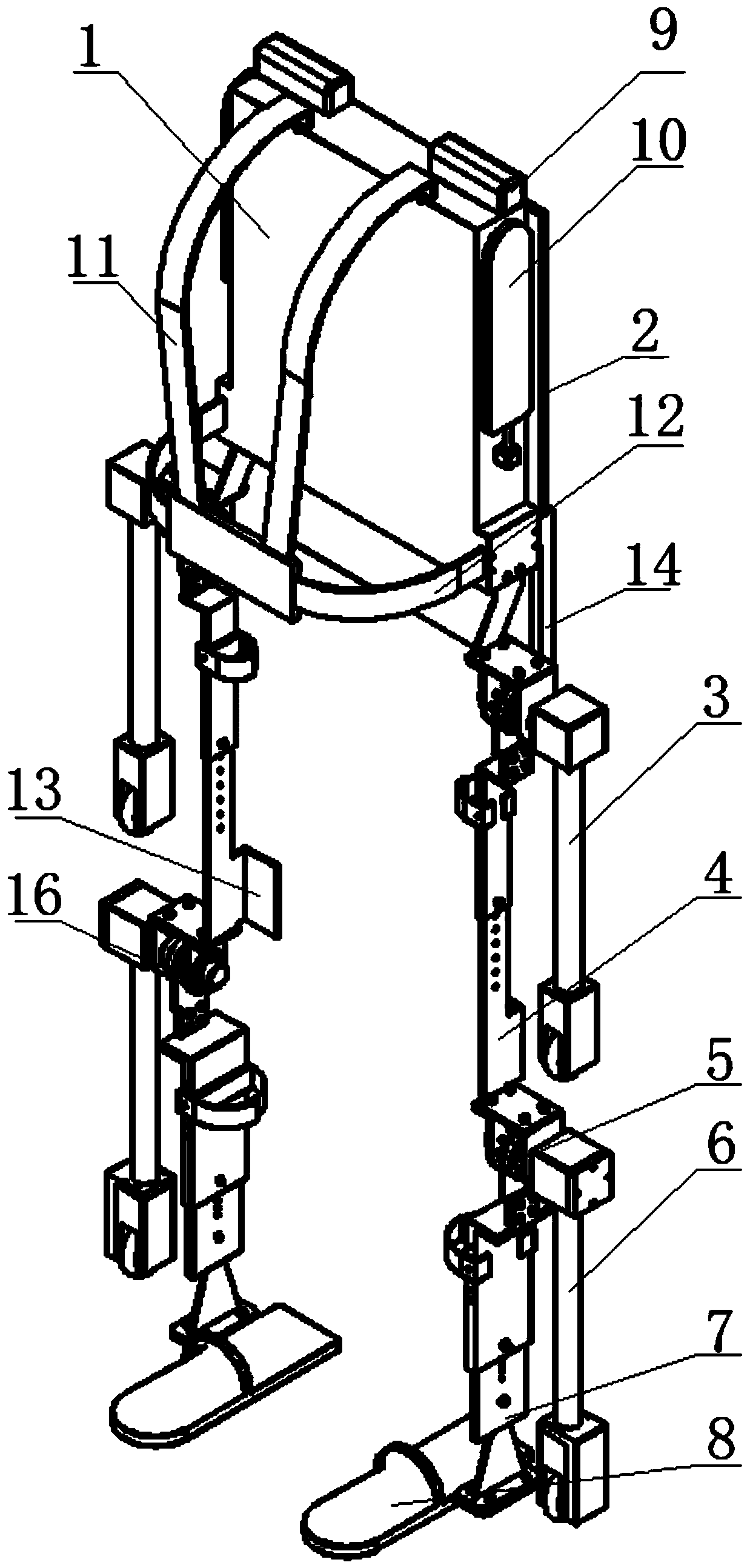

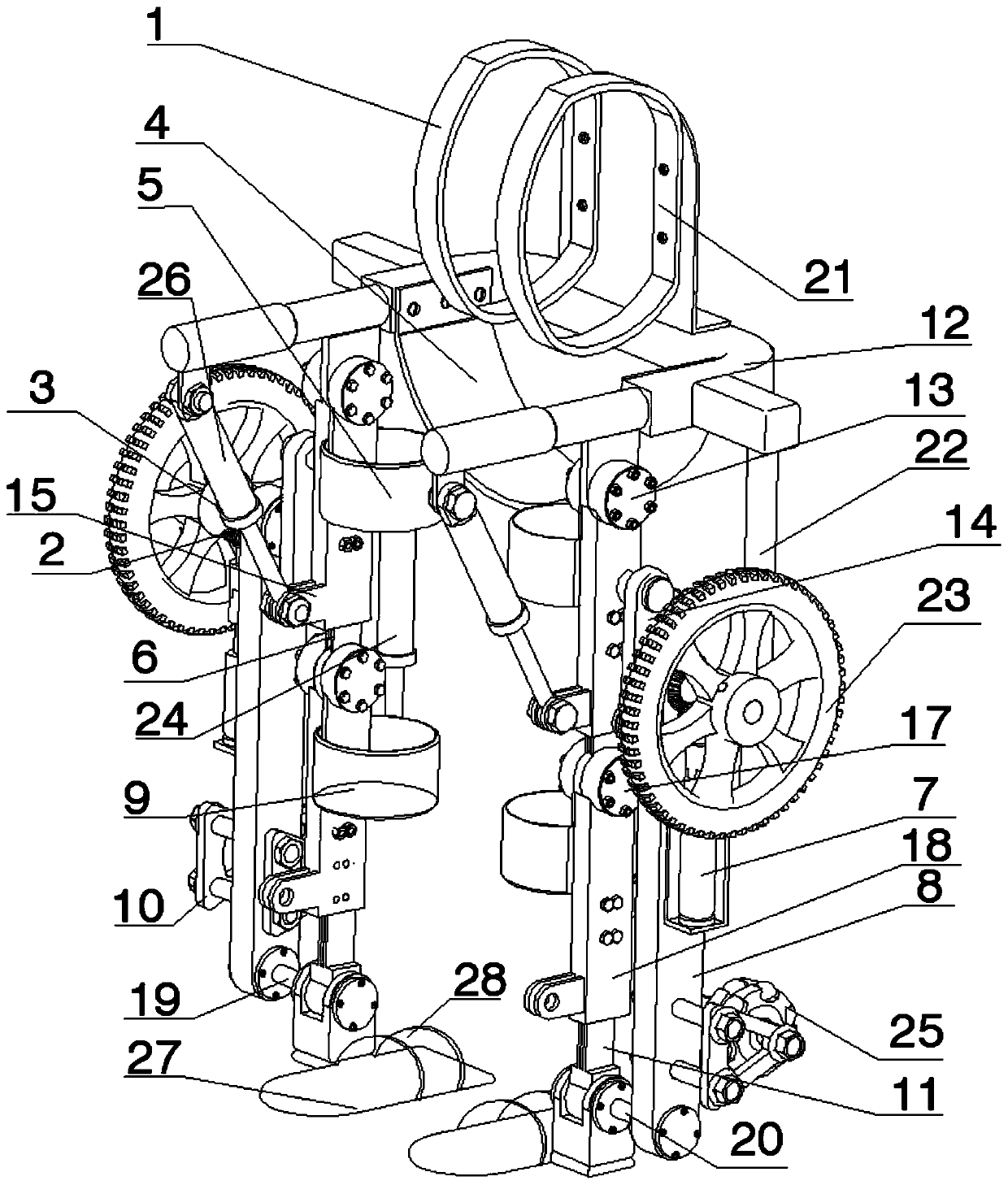

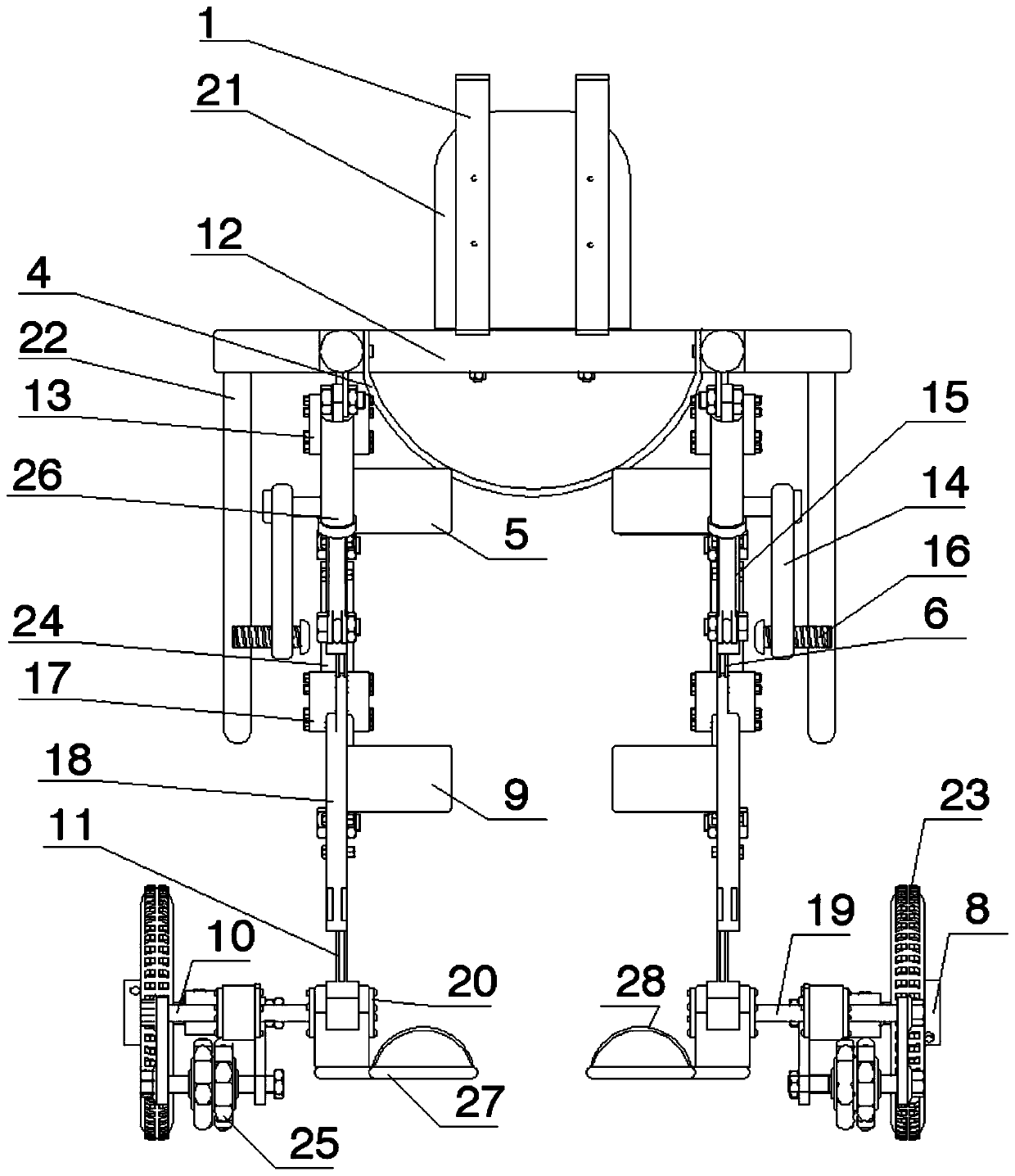

Composite exoskeleton walking assisting equipment

PendingCN109846681ARealize integrationMeet the needs of useWheelchairs/patient conveyanceWalking aidsThighHuman body

The invention discloses composite exoskeleton walking assisting equipment. The composite exoskeleton walking assisting equipment comprises back supporting plates, seat plates, shoulder puttees, waistputtees, seat plate brackets, a left part and a right part, wherein each of the seat plate brackets is fixed to the corresponding back support plate, and each seat plate is placed in the correspondingseat plate bracket; each shoulder puttee and each waist puttee are fixed to the corresponding back support plate; the structure of the left part is the same as that of the right part, and the left part and the right part are symmetrically mounted at the lower part of each of the back supporting plates; and the left part comprises a rear wheel module, a thigh module, a hip joint driving module, afront wheel module, a calf module, a foot module, a seat support and a knee joint driving module. Exoskeleton is used as a mother body, and the rear wheel module and the front wheel module are arranged on the hip joint and the knee joint of the exoskeleton, through mechanism deformation, the walking assisting equipment which is dressed on human bodies, can enable the people to climb stairs, can complete daily simple motion and can recover exoskeleton are deformed to obtain the wheelchair capable of rapid walking forwards, the integration of the auxiliary walking and the wheelchair can be realized, and the using requirements of people inconvenient to walk can be met.

Owner:HEBEI UNIV OF TECH

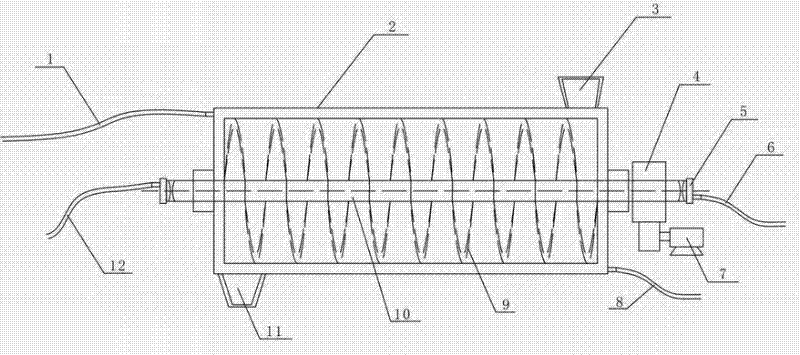

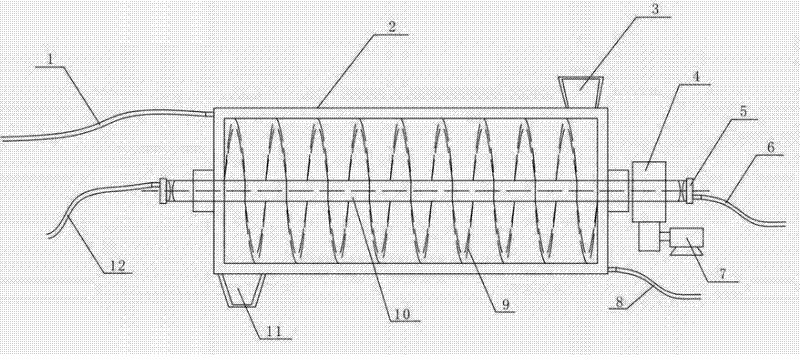

High-temperature spiral conveyor

InactiveCN102514895ASimple structureCompact and reasonable designPackagingSpiral bladeElectric machinery

The invention discloses a high-temperature spiral conveyor. The high-temperature spiral conveyor comprises a motor, a speed reducer, a shell and a spiral conveying shaft, wherein the spiral conveying shaft is arranged in the shell; the motor is connected with the spiral conveying shaft through the speed reducer; spiral blades are arranged on the outer side of the spiral conveying shaft uniformly; the spiral conveying shaft is a hollow shaft; two ends of the spiral conveying shaft are connected with a first water inlet pipe and a first water outlet pipe respectively through rotating joints; the shell has a double-layer structure comprising an inner layer and an outer layer; a cavity is formed between the inner layer and the outer layer; two ends of the shell are connected with a second water inlet pipe and a second water outlet pipe; and the second water inlet pipe and the second water outlet pipe are communicated with the cavity of the shell. The high-temperature spiral conveyor has a simple structure and reduces the temperature of main parts of the spiral conveyor by a spiral conveying shaft and shell double water-cooled method so as to reduce damage to the spiral conveyor and guarantee normal transportation of the materials at a high temperature of between 800 and 1,000 DEG C, and has good economic benefits and social benefits.

Owner:洛阳绿之海环保工程有限公司

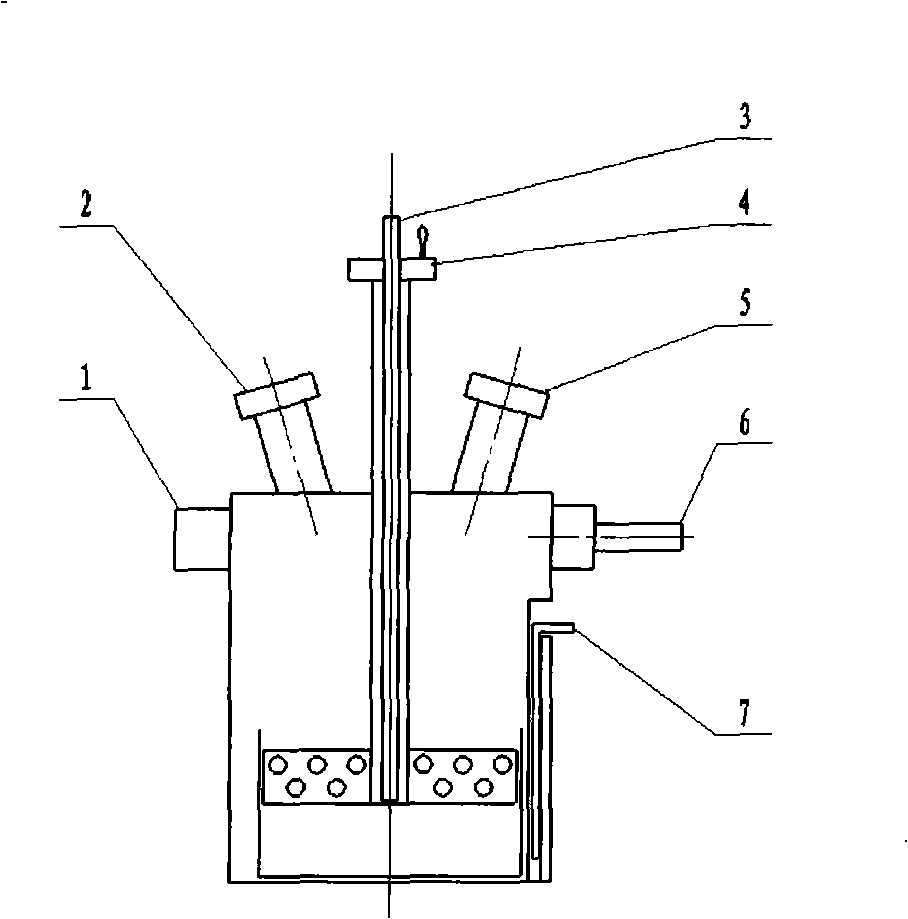

Method and apparatus for preparing Li-B alloy by vacuum smelting

InactiveCN101353734AReduce performanceFlat surfaceCrucible furnacesTemperature controlVacuum pumping

The invention discloses a method and a device for preparing Li-B alloy by vacuum smelting, pertaining to the metallurgy technology field. The device is a vacuum smelting furnace, a temperature-control thermocouple is arranged at the outer side of a crucible, a stirring paddle is arranged at the central position of the smelting furnace, a temperature thermocouple is arranged at the bottom end of the stirring paddle, an incident light port and an observation port are arranged on the upper surface of the furnace cover, a vacuum-pumping and argon channel is arranged at the upper end of the side of the furnace body, and an air-cooling device is arranged at the corresponding position of the argon channel. Li and B powder are put into the iron crucible, protected in high vacuum atmosphere, heated to 400 DEG C and then kept for 10min to 2h, the B powder is introduced with Ar gas to carry out protection when being fully dissolved in the melting of the Li; temperature rise is continued and stirring is reinforced, melt is solidified at the temperature of 530 DEG C, and after the alloy is fully solidified, the temperature rises to 650 DEG C, and the alloy is cooled with the furnace and treated with air-cooling after the temperature of 400 DEG C. The method and the device of the invention have compact and reasonable structure, simple technology, safe use, convenient operation and high-efficient production, thus having generalization and application value.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

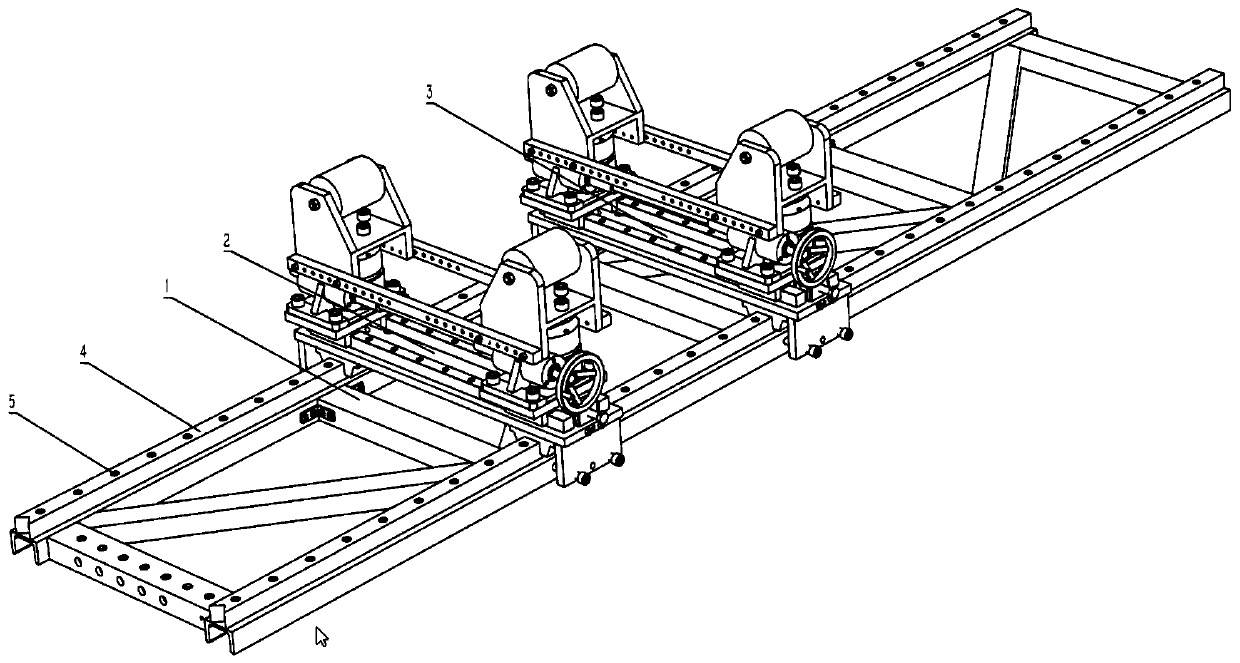

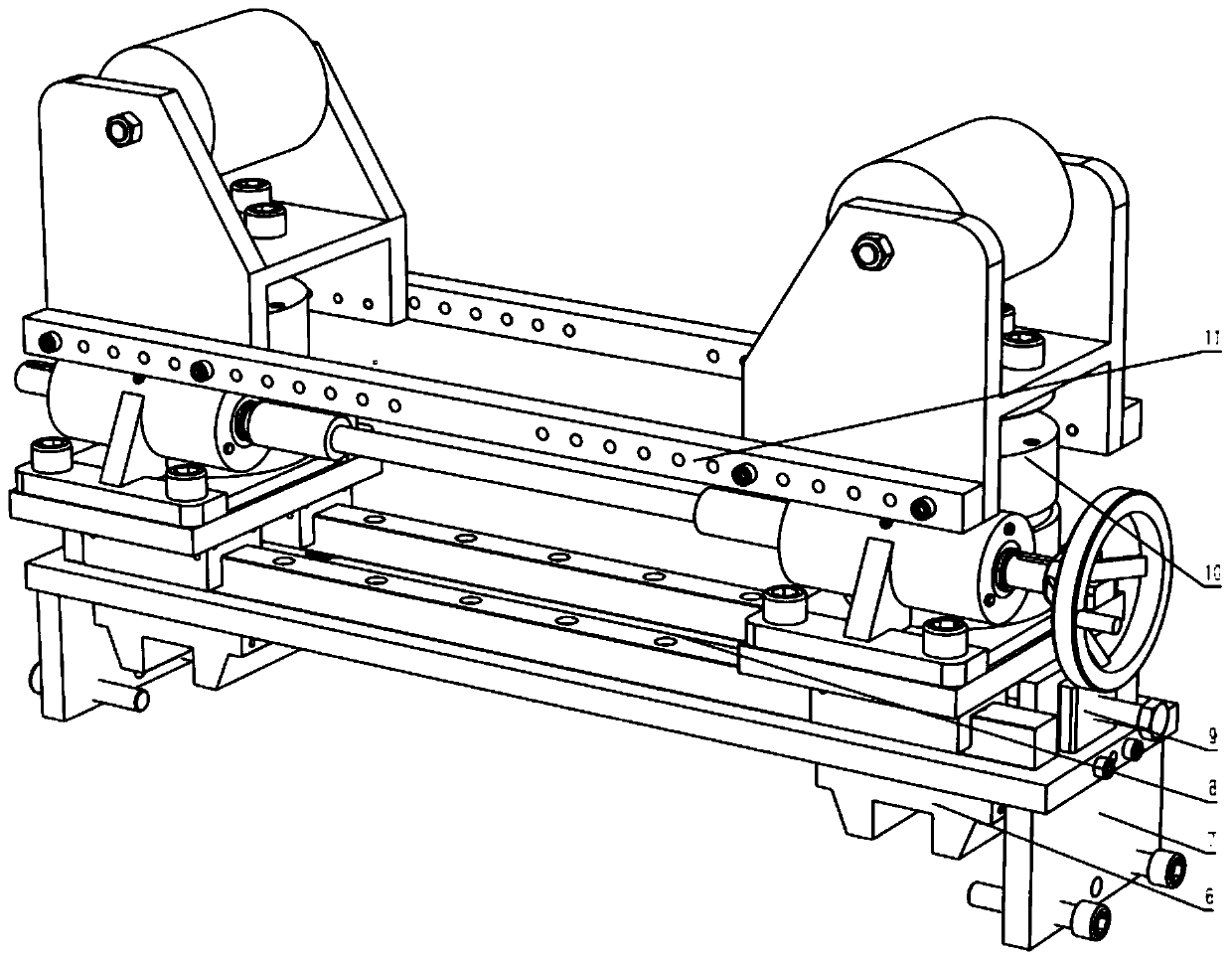

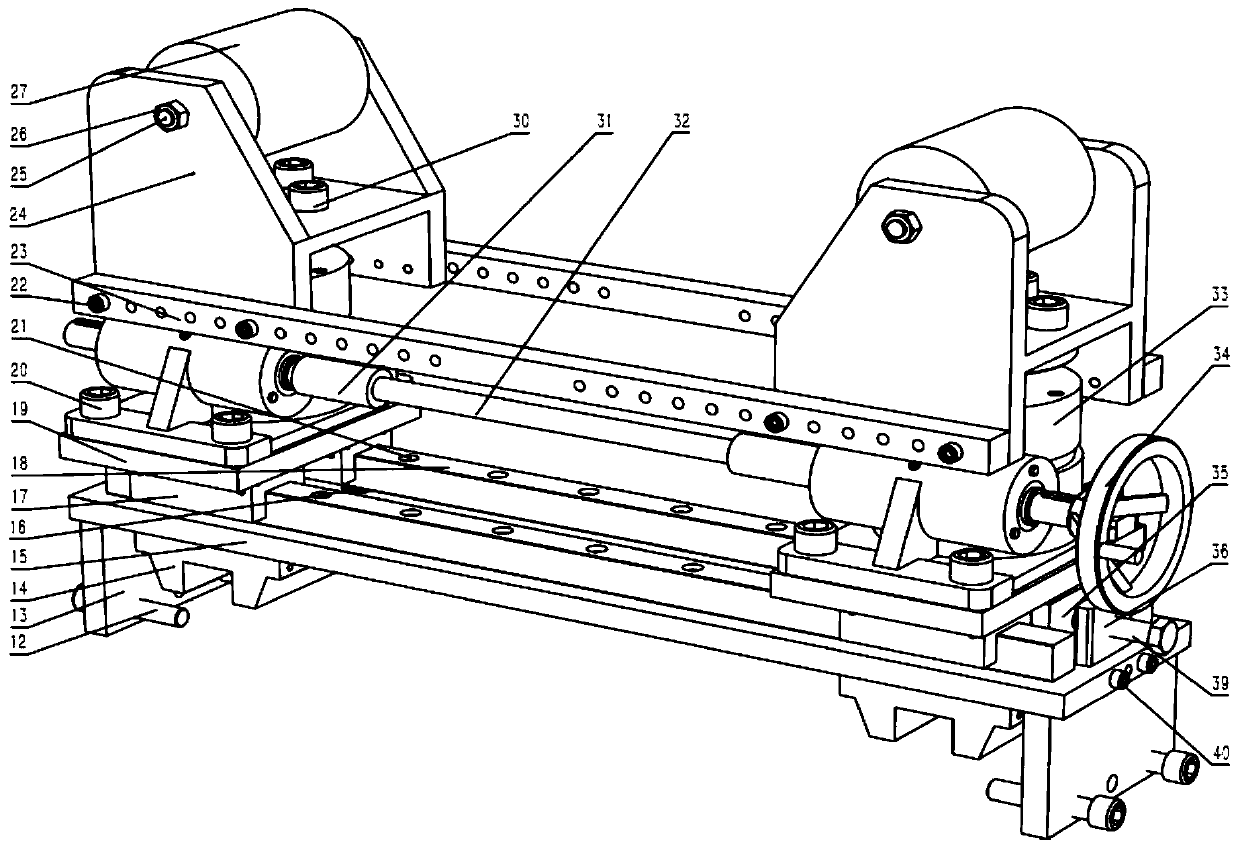

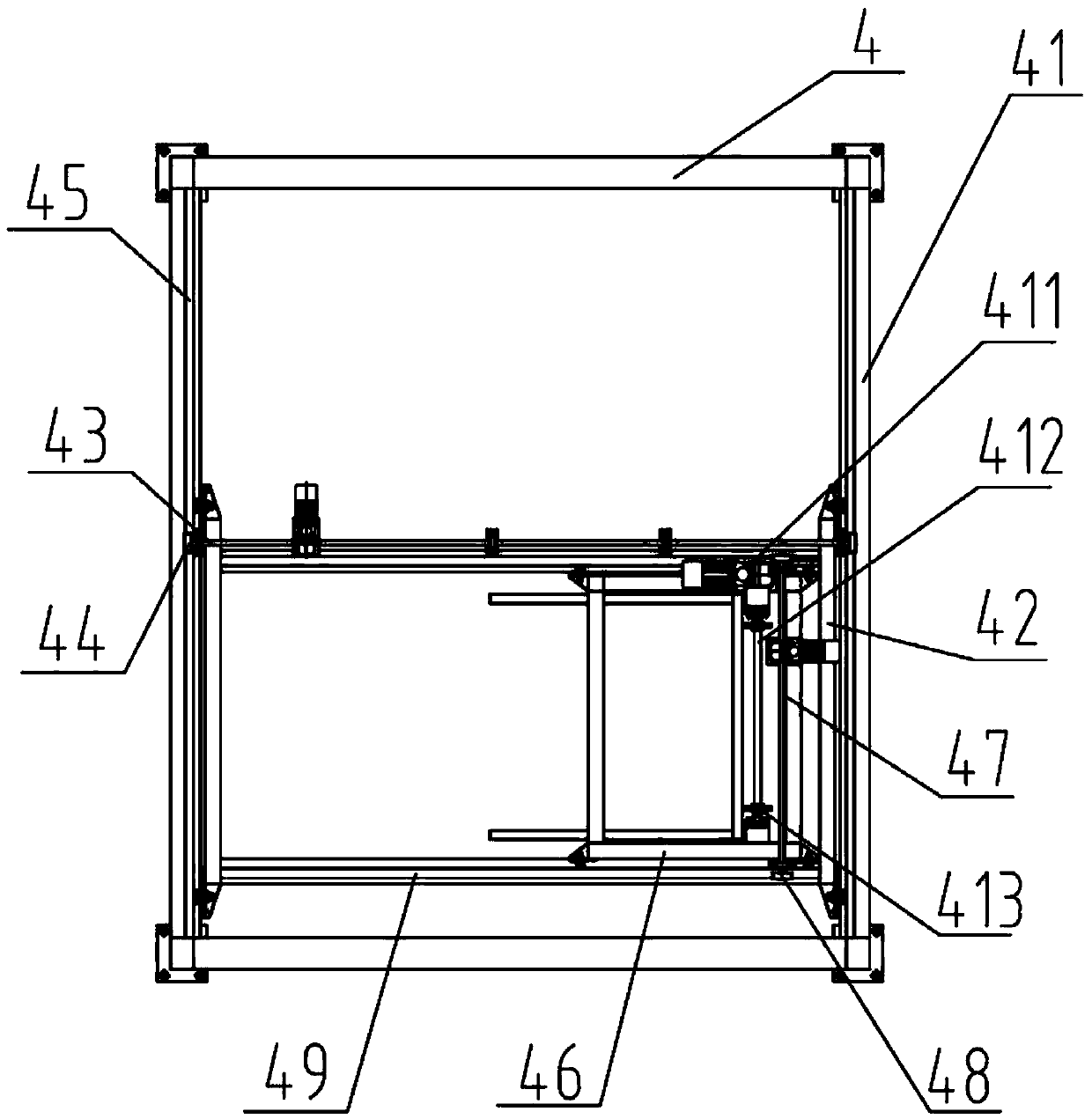

Cabin assembling and docking platform for autonomous underwater vehicle

The invention provides a cabin assembling and docking platform for an autonomous underwater vehicle, and belongs to the field of underground robots. The cabin assembling and docking platform comprisesa first-stage platform, a posture adjusting mechanism a, a posture adjusting mechanism b, a linear guide rail a and a linear guide rail b, wherein the posture adjusting mechanism a and the posture adjusting mechanism b are arranged on a sliding block a of the linear guide rail a. The cabin assembling and docking platform is fixedly arranged on an experiment table, and the platform can be docked and lengthened at a preserved port according to the actual length of the autonomous underwater vehicle (AUV); the posture adjusting mechanism a comprises a front-back moving mechanism, a lifting mechanism, a left-right translation mechanism, a front-back locking tool, a left-right locking tool and a diameter adjusting tool; and the front-back moving mechanism comprises the linear guide rail a, thesliding block a and a secondary platform, and manual fine adjustment is adopted during assembling and docking of cabins.

Owner:CHINA JILIANG UNIV

Grinding machine with a dust removal function

ActiveCN103331700AImprove Noise CancellationImprove sound insulationGrinding/polishing safety devicesEngineeringNoise reduction

The invention provides a grinding machine with a dust removal function, belonging to the technical field of operation. The grinding machine with the dust removal function solves the problems that a cloth bag in the existing grinding machine with the dust removal function is apt to rupture, the service life is short and the existing grinding machine with the dust removal function is troublesome to use. The grinding machine with the dust removal function comprises a worktable, a motor, a dust suction hood and a grinding wheel. A fan below a table board is fixedly arranged on the worktable. An air inlet pipe, an air exhaust pipe, a dust discharge port and a cyclone dust removal mechanism which can separate out dust in dust-containing air and discharge the dust from the dust discharge port are arranged between the fan and the dust suction hood. The air inlet pipe is communicated with the dust suction hood. The air exhaust pipe is communicated with the air inlet of the fan. A dust collection mechanism which is communicated with the dust discharge port, can enable the dust discharge port to be closed and can collect the dust which falls down from the dust discharge port is fixedly arranged on the worktable. The grinding machine with the dust removal function has the advantages of simple structure, reasonable and compact design, low manufacturing cost, good dust removal and noise reduction effect and convenience in dust particle cleaning.

Owner:陈美青

Mold pressing production technology for polytetrafluoroethylene plates

The invention discloses a mold pressing production technology for polytetrafluoroethylene plates. The mold pressing production technology for the polytetrafluoroethylene plates comprises the following steps of preparing materials, sieving the raw materials, selecting a pressing mold, arranging dustproof operation during mold pressing, detecting semi-finished products, conducting sintering treatment, eliminating stress, conducting extension treatment, conducting trimming and shearing, conducting press fit treatment, conducting extension treatment for the second time, conducting surface treatment on the plates, conducting cooling, cutting the plates, detecting the finished products and conducting packaging treatment on the finished products. By the adoption of the mold pressing production technology for the polytetrafluoroethylene plates, the density of the processed plates is 2.2 gram per cubic centimeter, the tensile strength of the processed plates is larger than 15 MPA, the processed products meet the national industrial standard specifications, and the production technological process is reasonable in design and compact.

Owner:SUZHOU JIENING MOLDING CO LTD

Portable hydraulic power water elevator

InactiveCN108105052ARealize irrigationSave energyPositive displacement pump componentsHydro energy generationWater dischargeWater wheel

The invention belongs to the technical field of water elevating equipment, and particularly relates to a portable hydraulic power water elevator. The portable hydraulic power water elevator comprisesa water wheel power device, a pumping device and a transmission mechanism. The water wheel power device transmits power to the pumping device through the transmission mechanism. The pumping device carries out water pumping and water discharging under the action of the power and comprises a piston rod, a piston, a pressure cylinder, a water inlet pipeline and a water outlet pipeline. Through the reciprocating of the piston in the pressure cylinder, water pumping and water discharging are carried out, the structure is simple, and practicability is high. The portable hydraulic power water elevator is applicable in a remote mountainous region, and can carry out water pumping through the mobility of river water without other power, and energy is saved. In the use process, no pollutants are discharged, and the characteristics of environment protection and energy saving are achieved. In addition, the portable hydraulic power water elevator is simple in structure, convenient to convey and capable of realizing irrigation of nearby farm land.

Owner:NANCHANG UNIV

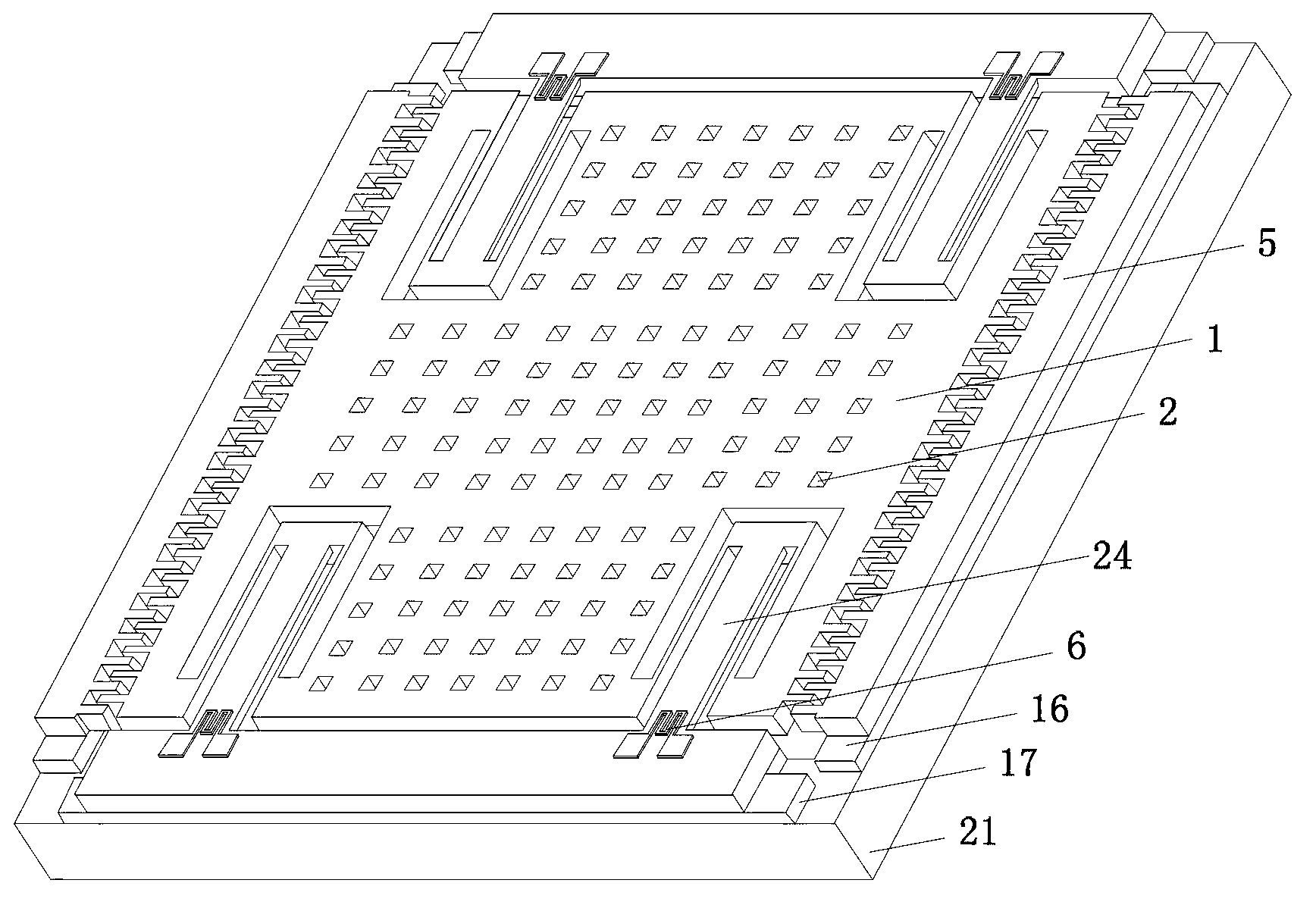

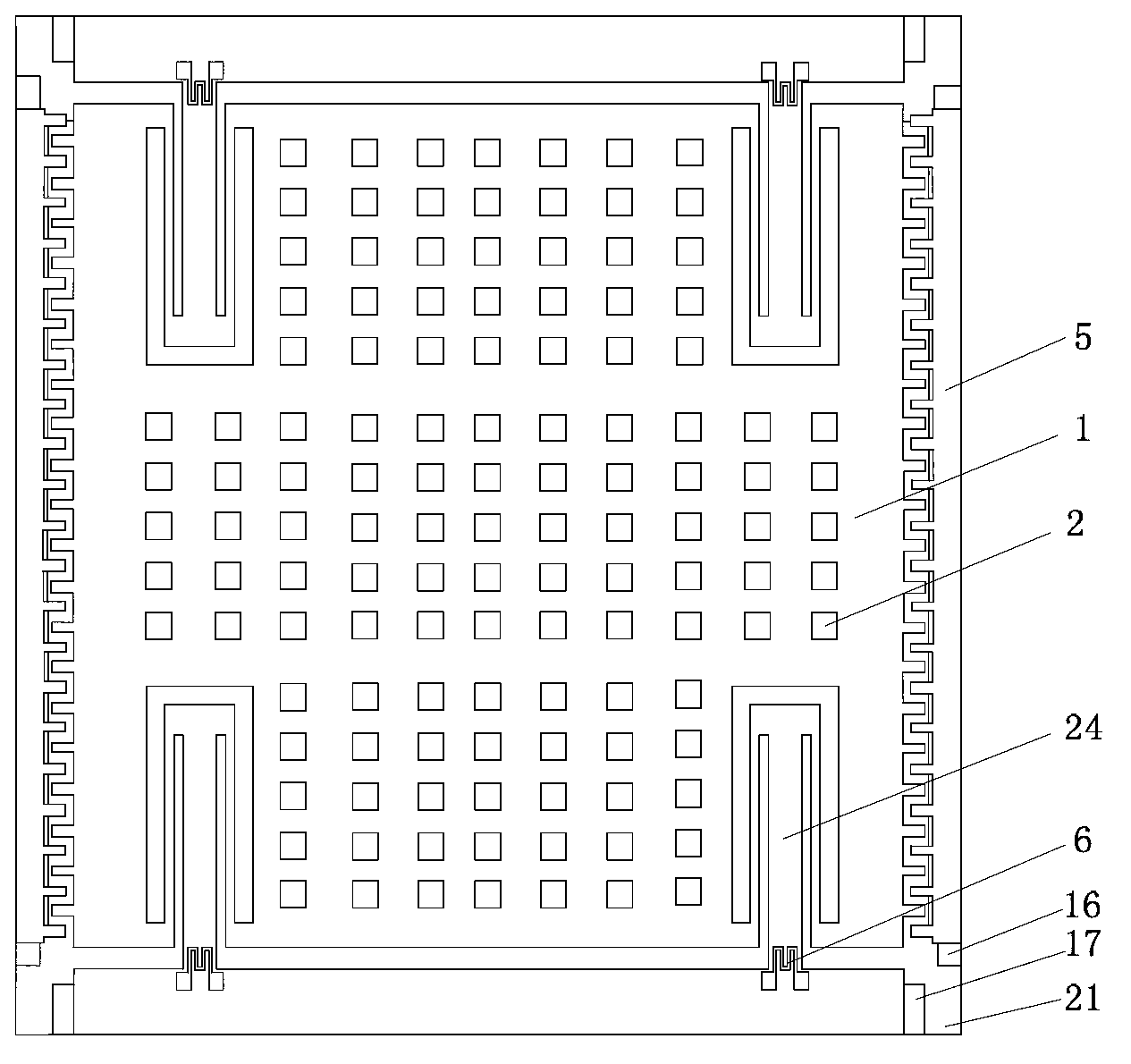

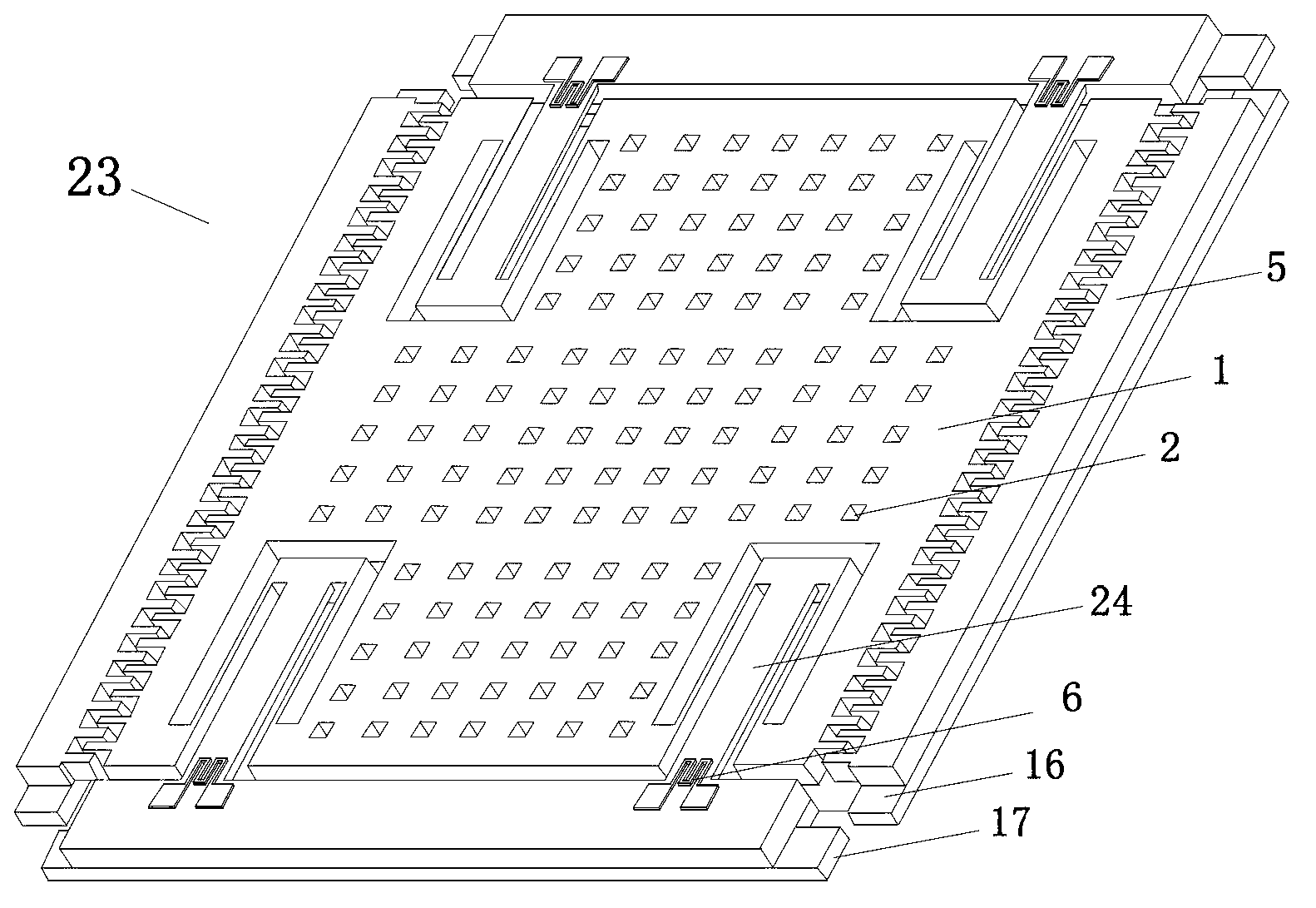

SOI (Silicon-On-Insulator) based giant-piezoresistive-effect micro gyroscope

ActiveCN102798387ACompact and reasonable designTake advantage ofSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesElectrical resistance and conductanceGyroscope

The invention discloses an SOI (Silicon-On-Insulator) based giant-piezoresistive-effect micro gyroscope. The main structure comprises a bonding base plate and a micro gyroscope angular speed sensitive body, wherein a rectangular bottom slot is etched in a middle position of the upper surface of the bonding base plate; and the micro gyroscope angular speed sensitive body is arranged on the upper surface of the bonding base plate and is connected with the bonding base plate. The micro gyroscope angular speed sensitive body further comprises a fixed comb tooth electrode anodes distributed on the supper surface at the left and right sides of the bonding base plate, comb tooth electrode cathodes distributed on the upper surface at the front and rear sides, fixed comb tooth structures arranged on the upper surfaces of the fixed comb tooth electrode anodes, fixed seats arranged on the upper surfaces of the comb tooth electrode cathodes and a sensitive mass block correspondingly arranged above the bottom slot, and damping holes are evenly distributed on the upper surface of the sensitive mass block; the sensitive mass block is connected with the fixed seats through combination beams; and the detection beam roots of the combination beams are provided with silicon nanowire resistors as sensitive mechanisms. The micro gyroscope according to the embodiment of the invention adopts the overall structure design, has reasonable and compact structure, simple detection circuit, convenience for use and good reliability and is applicable to miniaturization.

Owner:ZHONGBEI UNIV

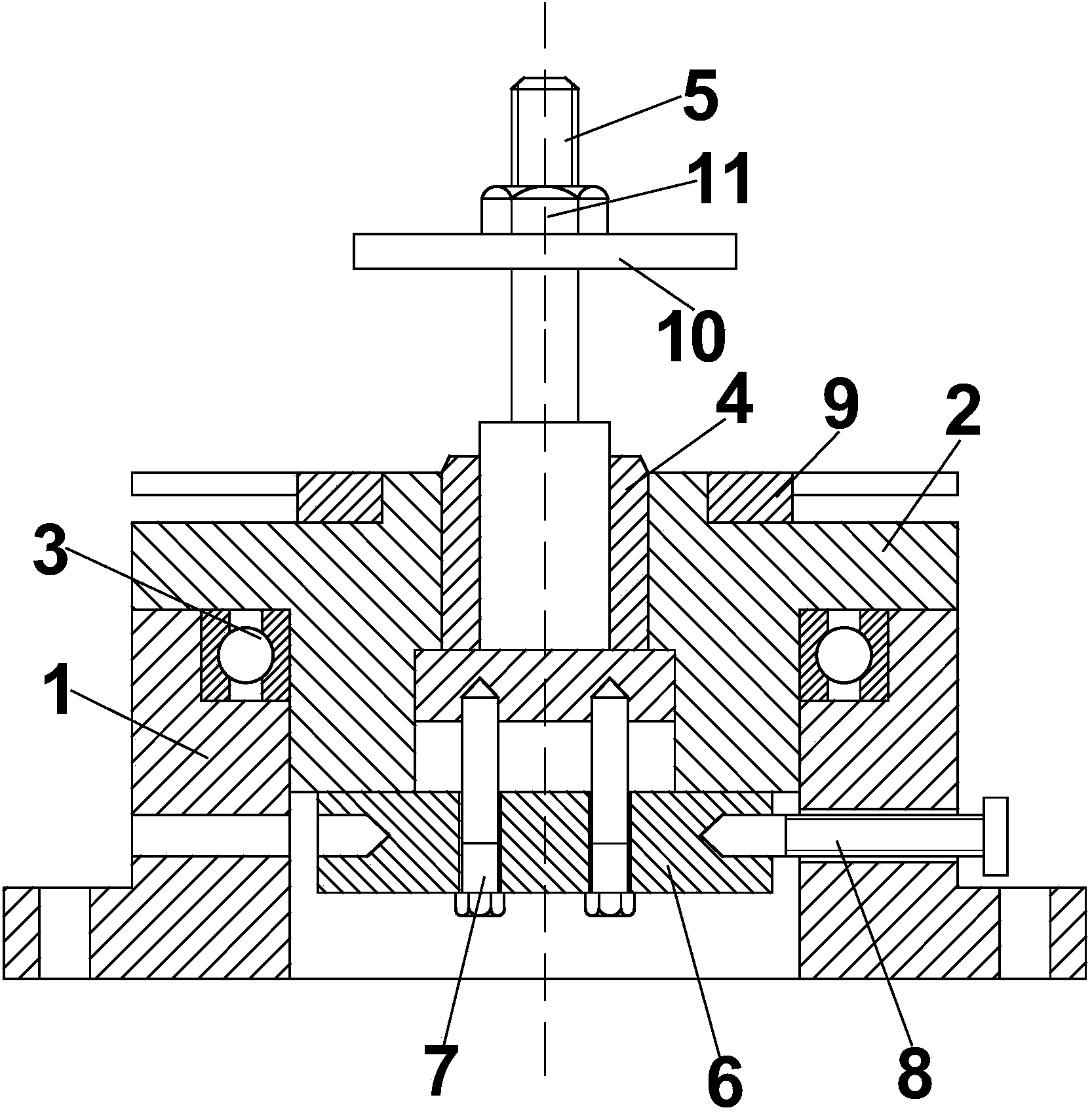

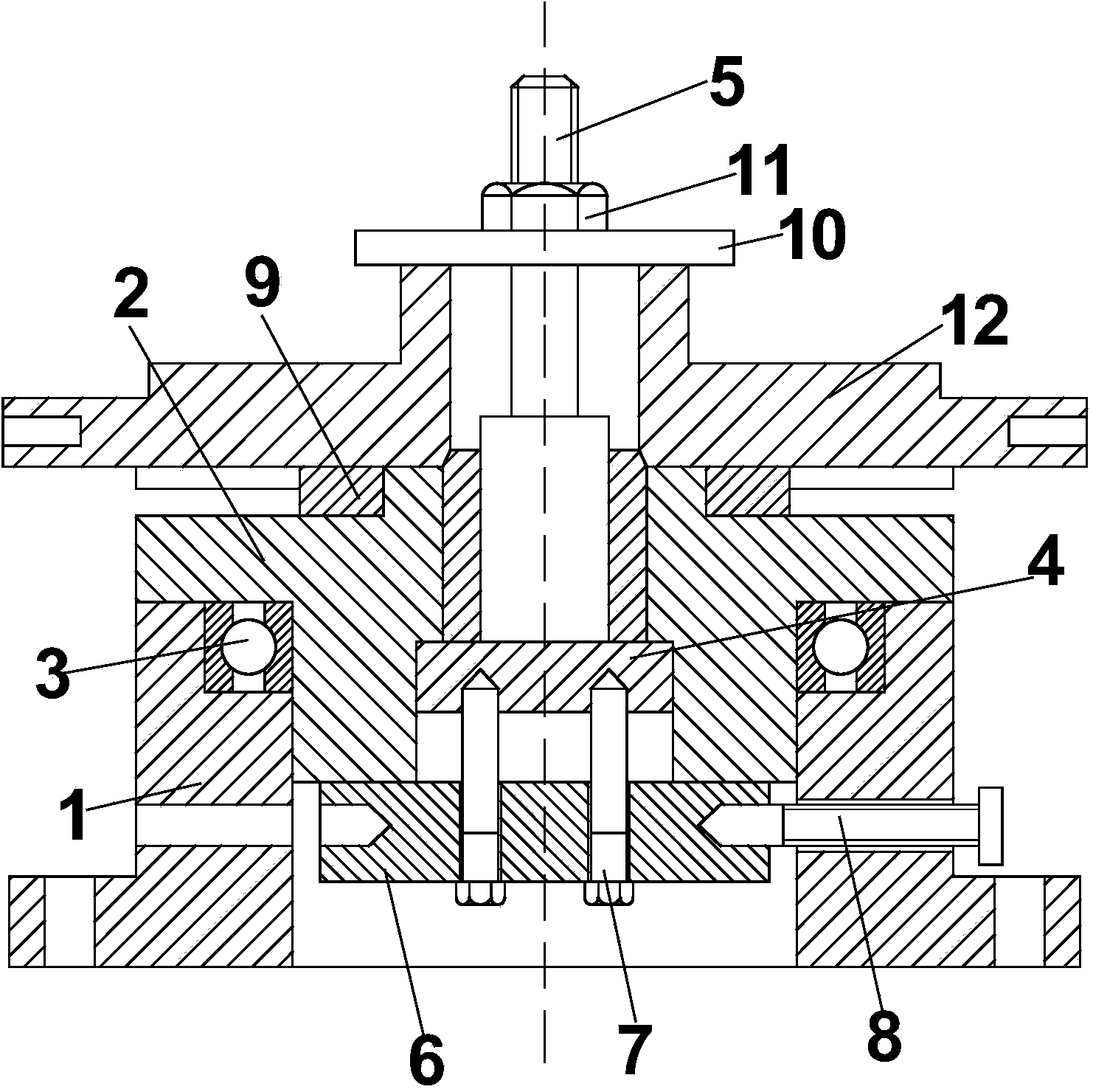

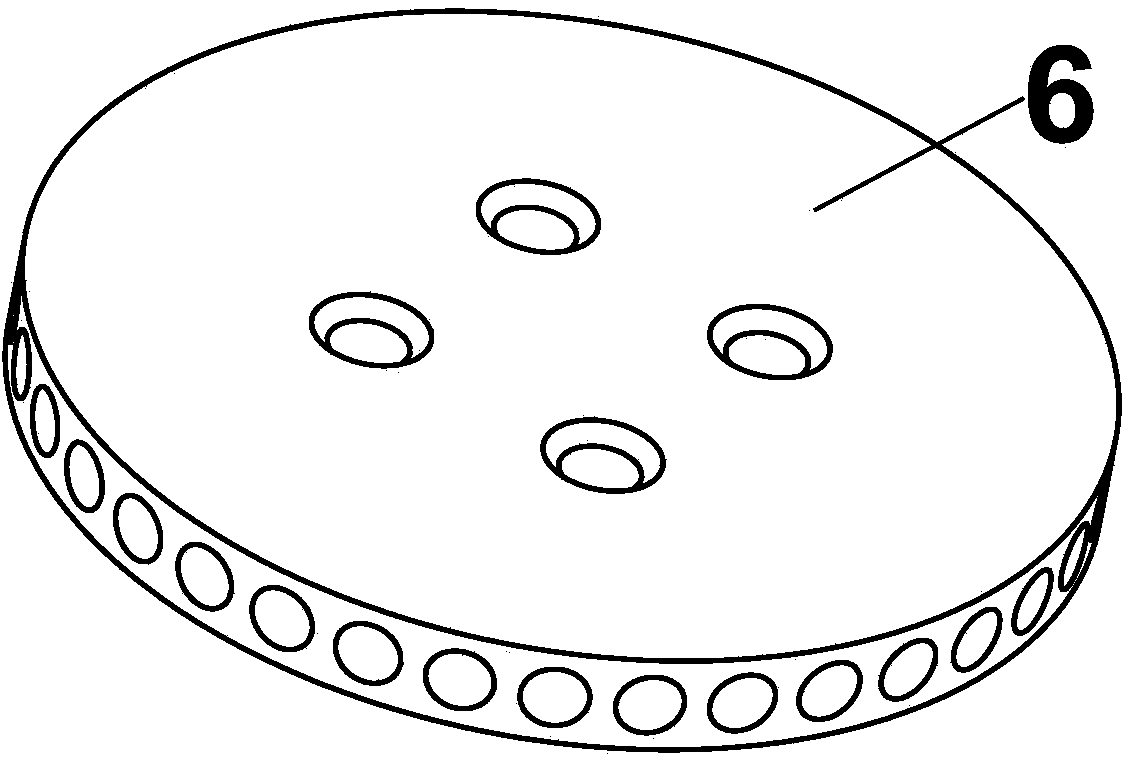

Rotary positioning drilling clamp

ActiveCN104384562ASimple structureEasy to operatePrecision positioning equipmentLarge fixed membersEngineeringMechanical engineering

The invention relates to a rotary positioning drilling clamp, which comprises a bottom seat, a base, rolling bearings, a sleeve cylinder, a movable core shaft, an indexing disc, axial locking nuts, radial locking pins, a chip removal disc, a press plate and a locking bolt, wherein the base is arranged in a fixing seat on the bottom seat through the rolling bearings, a boss is arranged at the upper end of the base, the sleeve cylinder is fixedly arranged in the base, the movable core shaft is arranged in an opening at the upper end of the sleeve cylinder, the indexing disc is fixedly arranged at the sealing part of the lower end of the sleeve cylinder by the axial locking screws, the radial locking pins penetrate through the through hole in the fixing seat and are arranged on the indexing disc, the chip removal disc sleeves the boss on the base, the press plate is arranged on the movable core shaft, and the locking bolt is positioned at the upper end of the movable core shaft. The rotary positioning drilling clamp has the advantages that when a belt disc is drilled, the axial and radial locking functions of the belt disc are realized, and the circumferential equal dividing and drilling position determining effects of the belt disc are realized.

Owner:浙江德弘机电科技股份有限公司

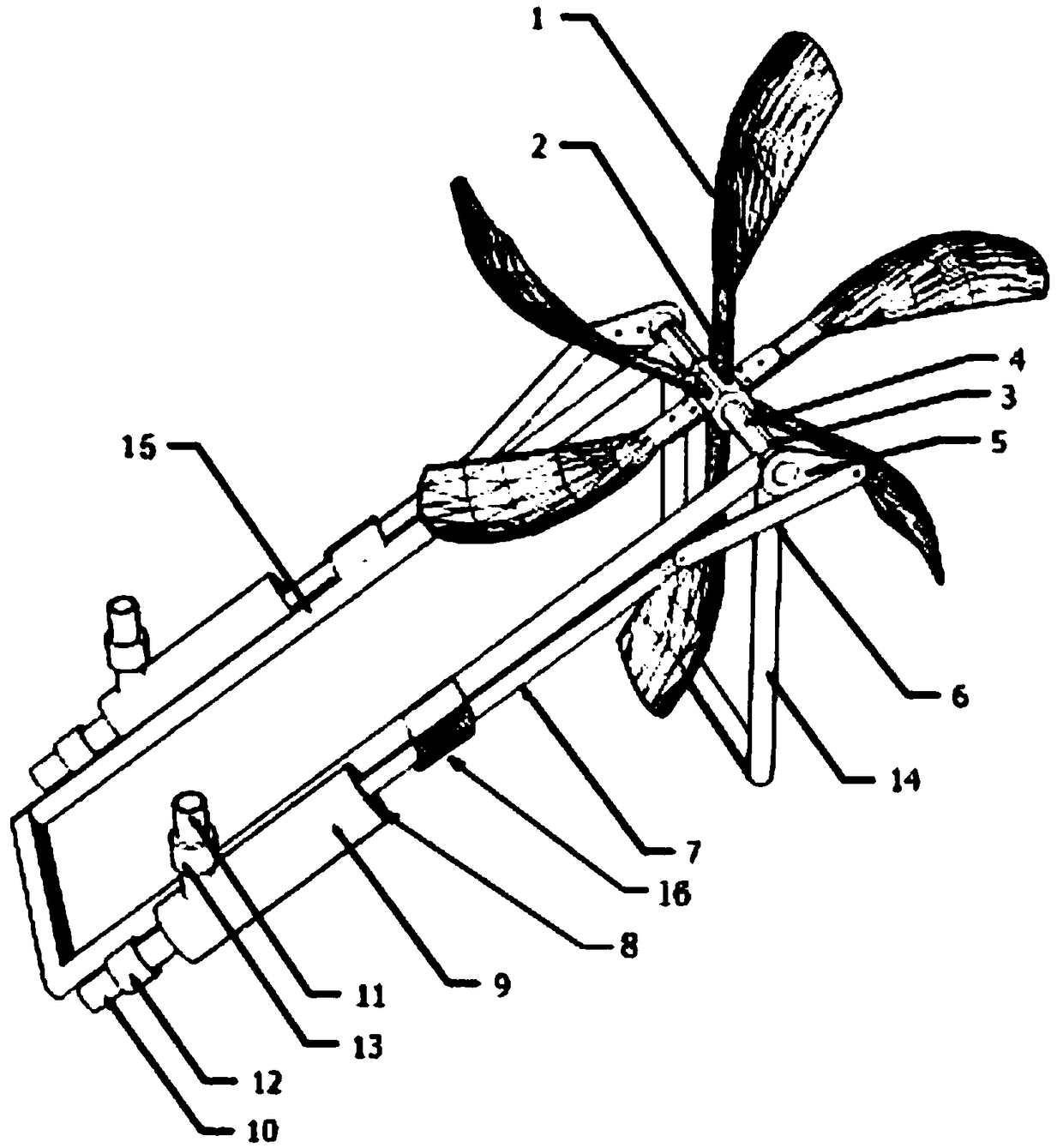

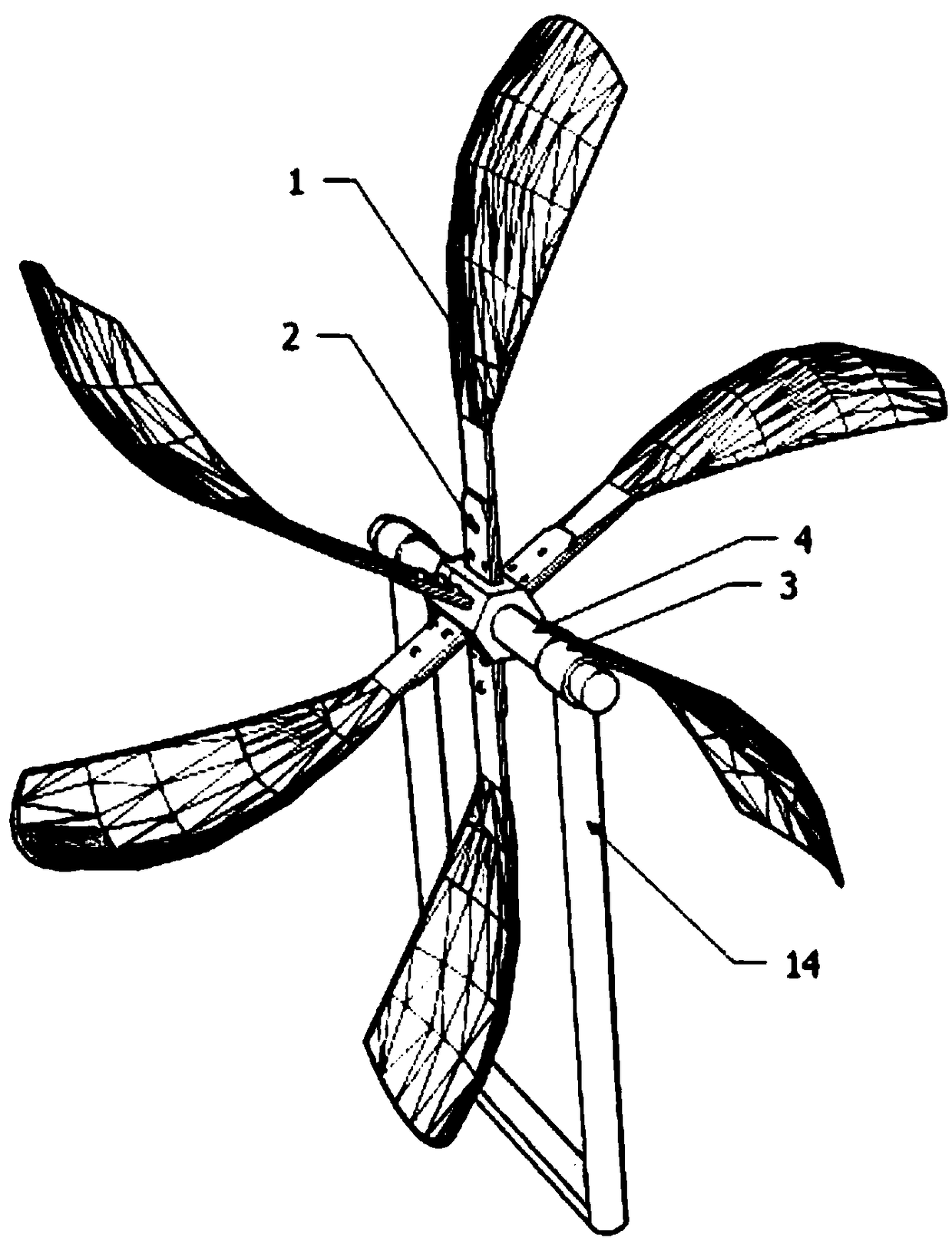

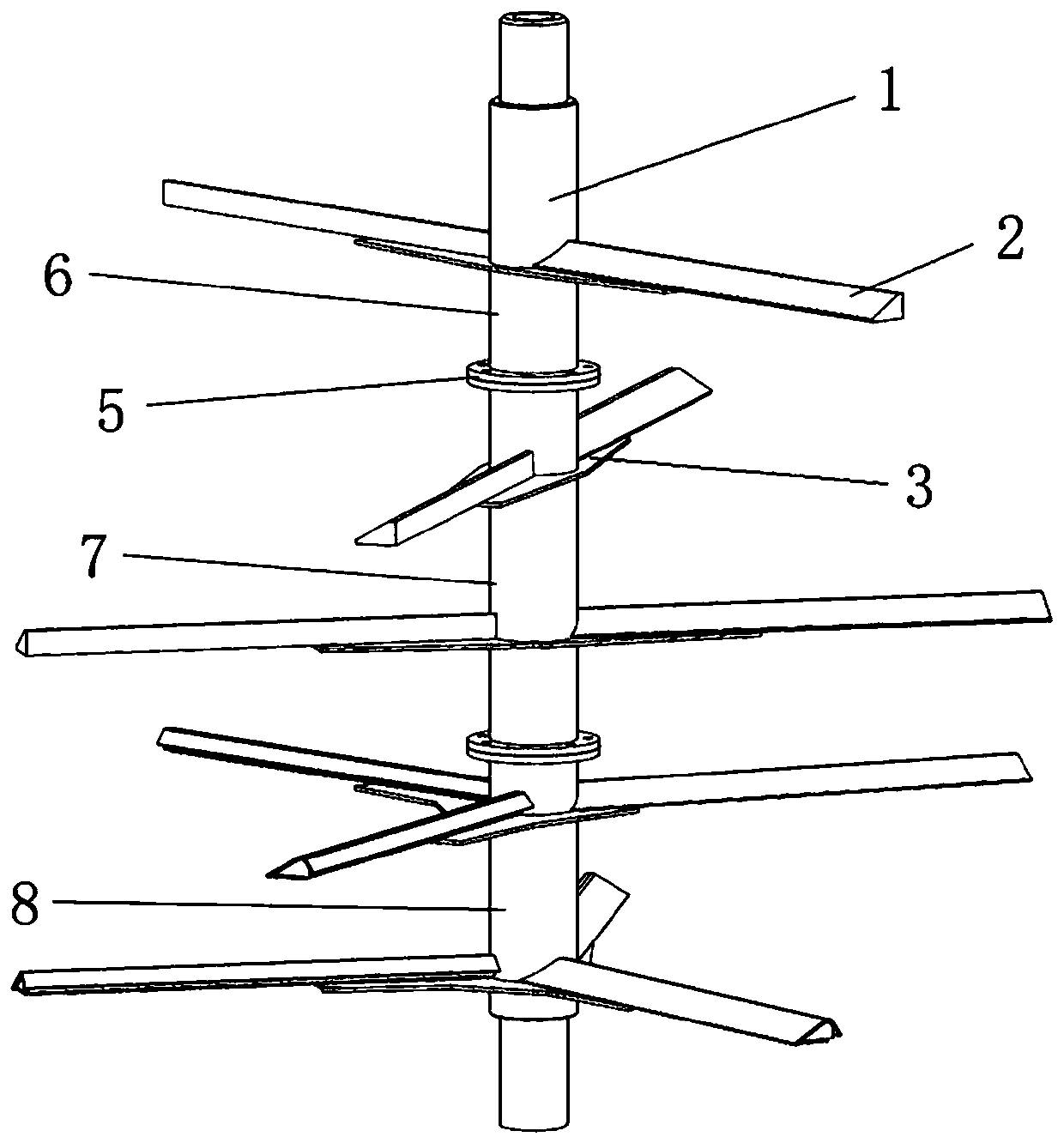

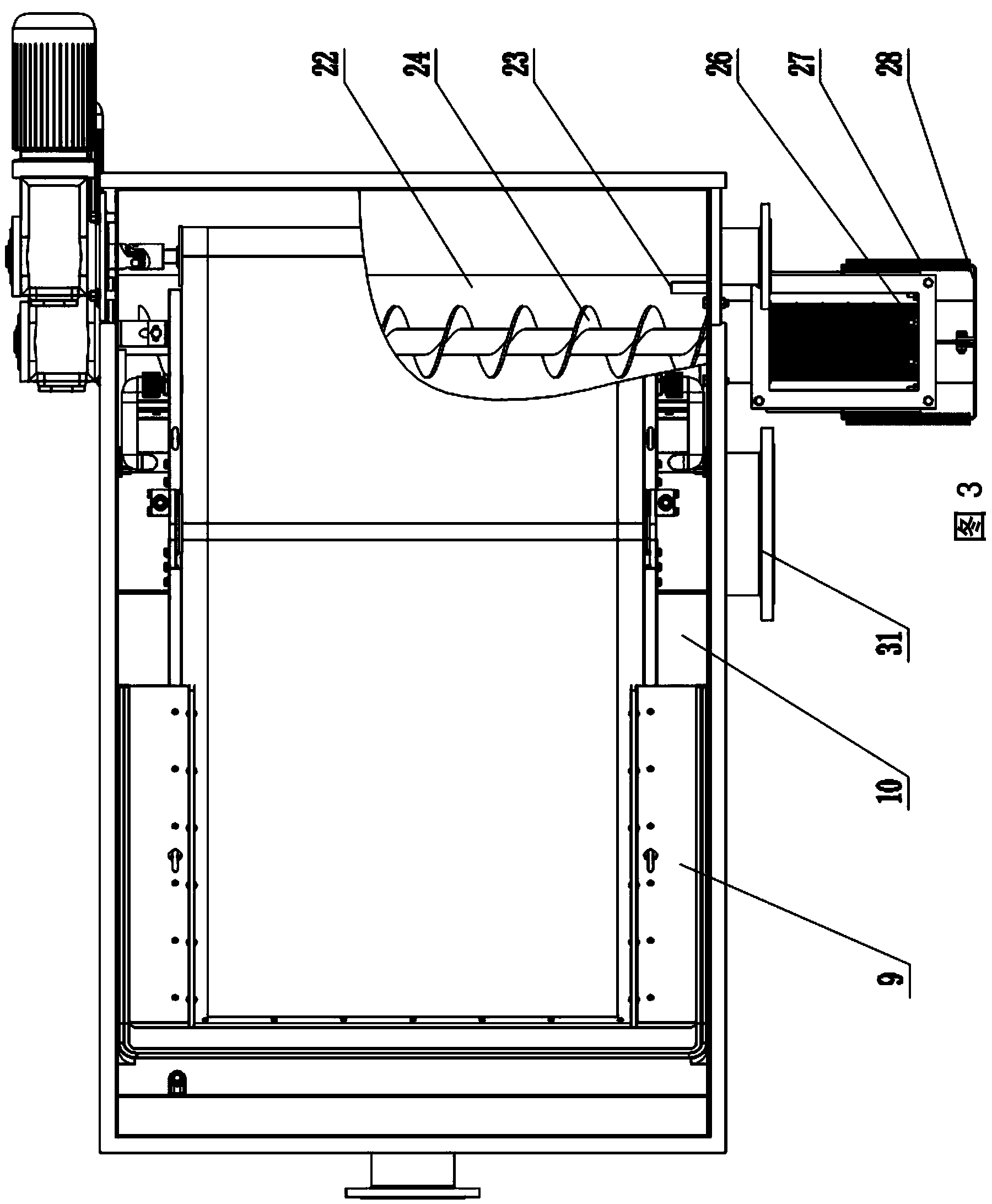

Stirring device for livestock and poultry excrement aerobic fermentation tank

PendingCN111116246ASave spaceCompact and reasonable designClimate change adaptationExcrement fertilisersLivestockAgricultural science

The invention discloses a stirring device for livestock and poultry excrement aerobic fermentation tank. The stirring device comprises a main shaft, stirring blades and stirring blade supporting plates; the main shaft is of a tubular structure, and a cavity longitudinally penetrating through a tube body is formed in the main shaft; the stirring blade supporting plates are arranged on the pipe wallof the main shaft and are divided into five layers from bottom to top along the pipe wall; the stirring blades are arranged on the stirring blade supporting plates, the number of the blades on each layer is sequentially 3, 3, 2, 2 and 2 from bottom to top, and the stirring blades on each layer are evenly distributed and welded to the main shaft. According to the device, livestock and poultry excrement can be fully stirred in the fermentation tank, the fermentation reaction efficiency is improved, stable and reliable operation of a stirring device and a stirring shaft of the fermentation tankis guaranteed, operation is easy, the service life is long, the equipment failure rate and the manufacturing cost are low, installation is rapid, maintenance is convenient, and application and popularization are facilitated.

Owner:YANCHENG INST OF IND TECH +1

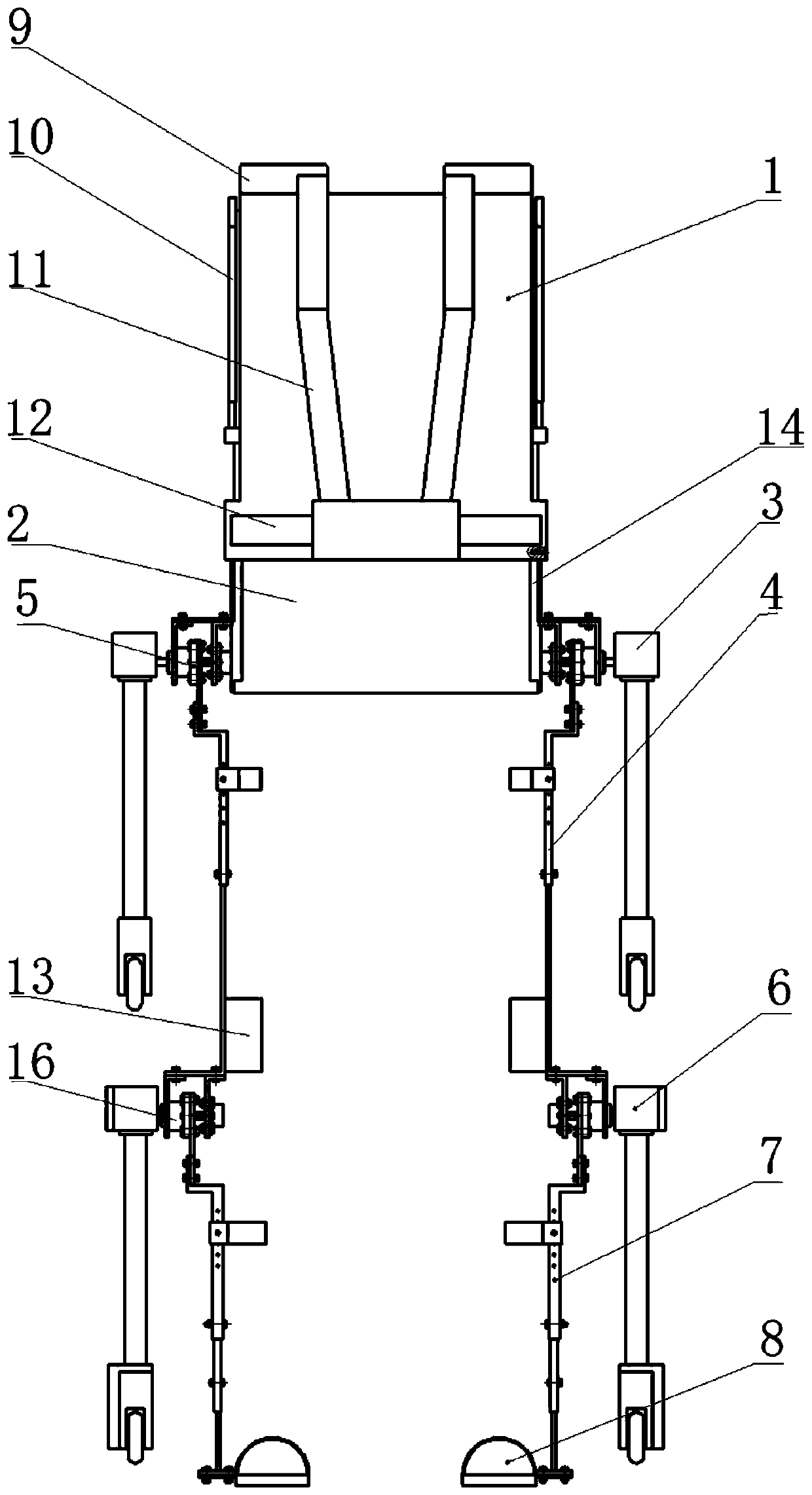

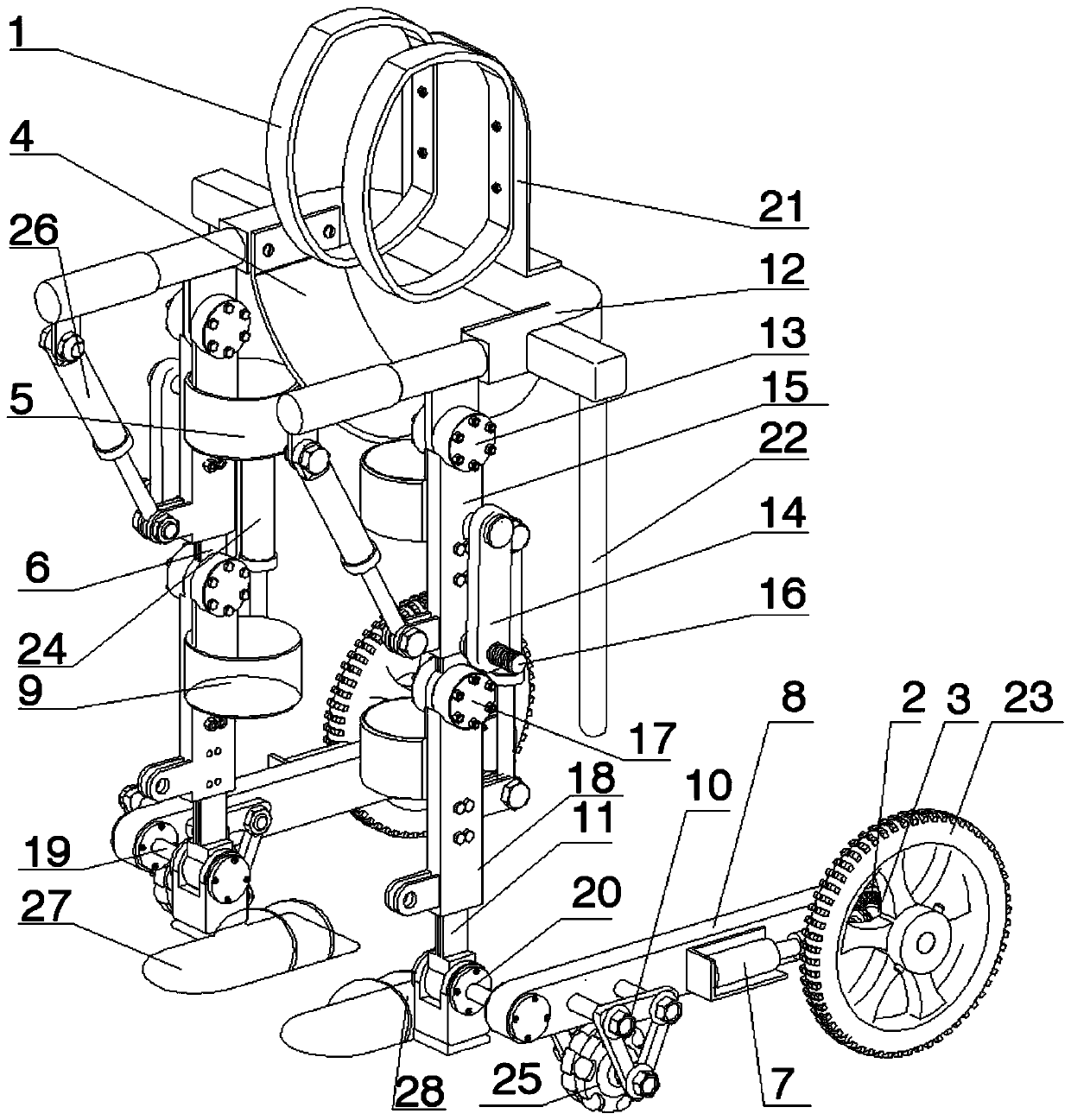

Composite type exoskeleton robot

PendingCN109846682ARealize integrationMeet the needs of useWheelchairs/patient conveyanceWalking aidsExoskeleton robotStub axle

The present invention discloses a composite type exoskeleton robot. The composite type exoskeleton robot comprises a waist balance frame, a back support plate, two shoulder bandages, a hip support belt, a left part and a right part; the back support plate is fixed on the waist balance frame; the shoulder bandages are fixed on the back support plate; both ends of the hip support belt are fixed on the waist balance frame; the left and right parts are identical in structure and symmetrically arranged on a lower part of the waist balance frame; the left part comprises a thigh module, a calf module, a wheelchair module, a foot module, an insert pin, a short shaft, a retractable wheelchair support rod, a first hydraulic cylinder and a second hydraulic cylinder; and the wheelchair module comprises a wheelchair bracket, a rear wheel drive shaft, a wheelchair rear wheel and a wheelchair front wheel. Through deformation and reorganization of the robot, people can wear the robot to climb stairs and complete auxiliary walking and rehabilitation of daily simple movement, the exoskeleton is transformed into a rapid advancing wheelchair, and the exoskeleton robot realizes integration of the auxiliary walking and the wheelchair and satisfies use needs of the people having difficulty in moving.

Owner:HEBEI UNIV OF TECH

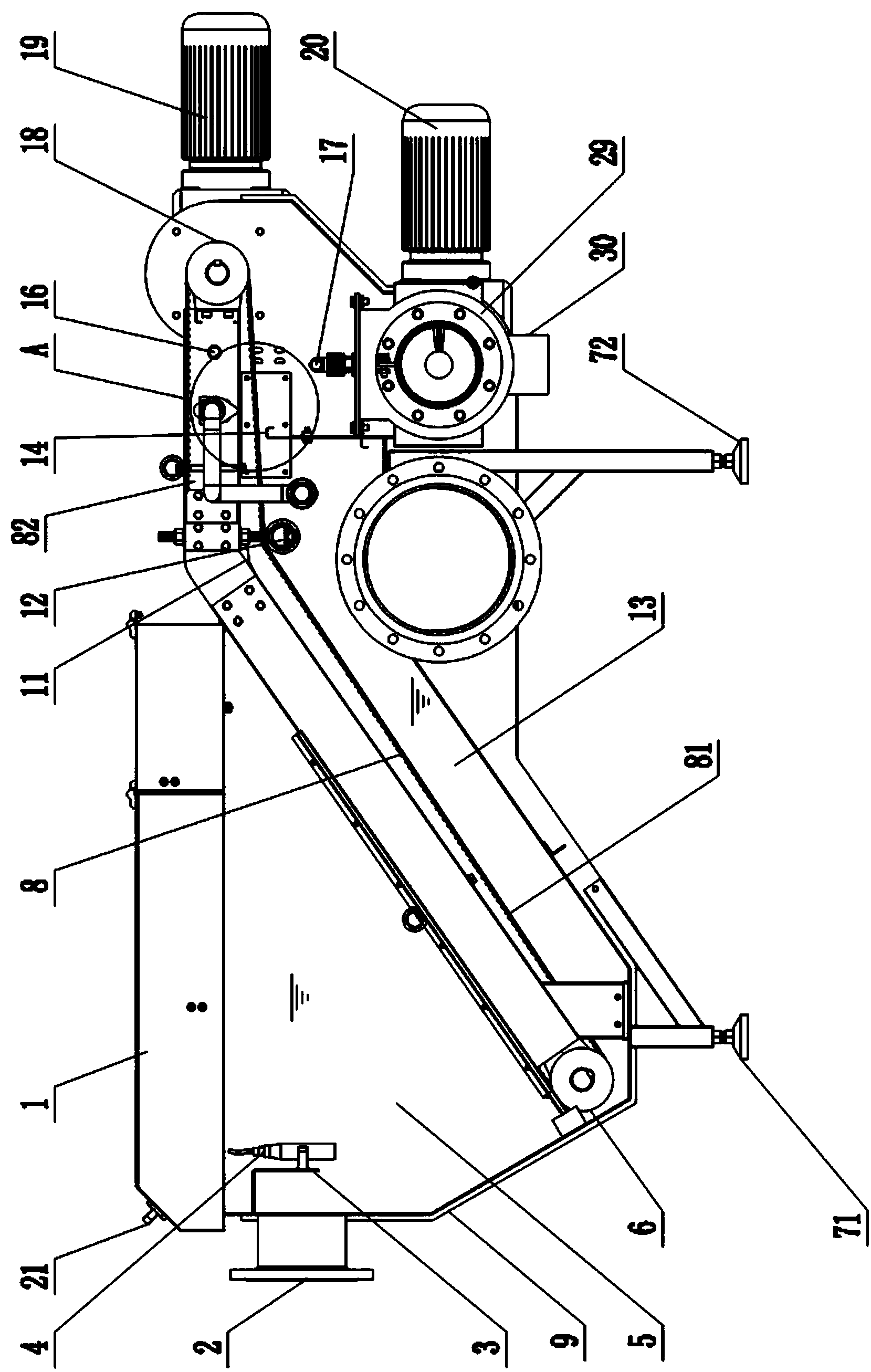

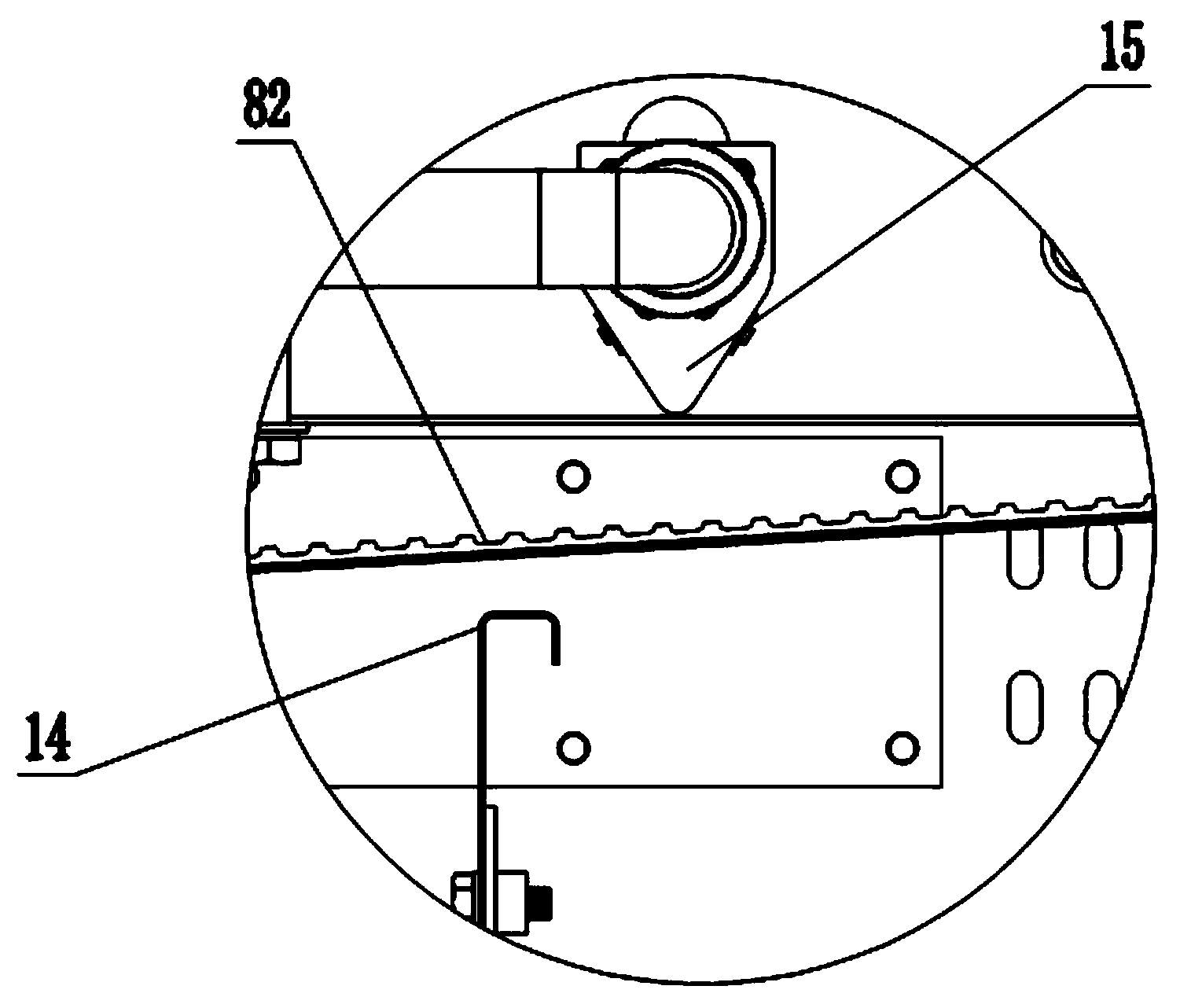

All-in-one machine for sewage sludge treatment

ActiveCN104069679ACompact and reasonable designReduce volumeFiltration circuitsSewageSewage sludge treatment

The invention relates to an all-in-one machine for sewage sludge treatment, and belongs to the technical field of environmental protection. The all-in-one machine comprises a sewage filtering tank, a clear water tank, a micro filter screen and a sludge pressing tank, wherein the sewage filtering tank is used for being communicated with the outside to store sewage; the clear water tank is arranged below the sewage filtering tank; the micro filter screen is arranged between the sewage filtering tank and the clear water tank, and used for filtering the suspended solids and the flocculating constituents in the sewage; the sludge pressing tank is arranged at one end of the micro filter screen to collect the suspended solids and the flocculating constituents on the micro filter screen; the micro filter screen is arranged on a transmission mechanism, and pushed to move circularly by the transmission mechanism; a pushing device used for pushing the suspended solids and the flocculating constituents in the sludge pressing tank to move is arranged in the sludge pressing tank; a concentrated liquid storing tank positioned at one end of the pushing device is arranged in the sludge pressing tank; a filter cylinder and a pressing plate arranged at the opening end of the filter cylinder are arranged in the concentrated liquid storing tank; the filter cylinder is connected with the pushing device; the suspended solids and the flocculating constituents in the sludge pressing tank are pushed into the filter cylinder by the pushing device.

Owner:CAPITAL GREINWORTH ENVIRONMENTAL CORP

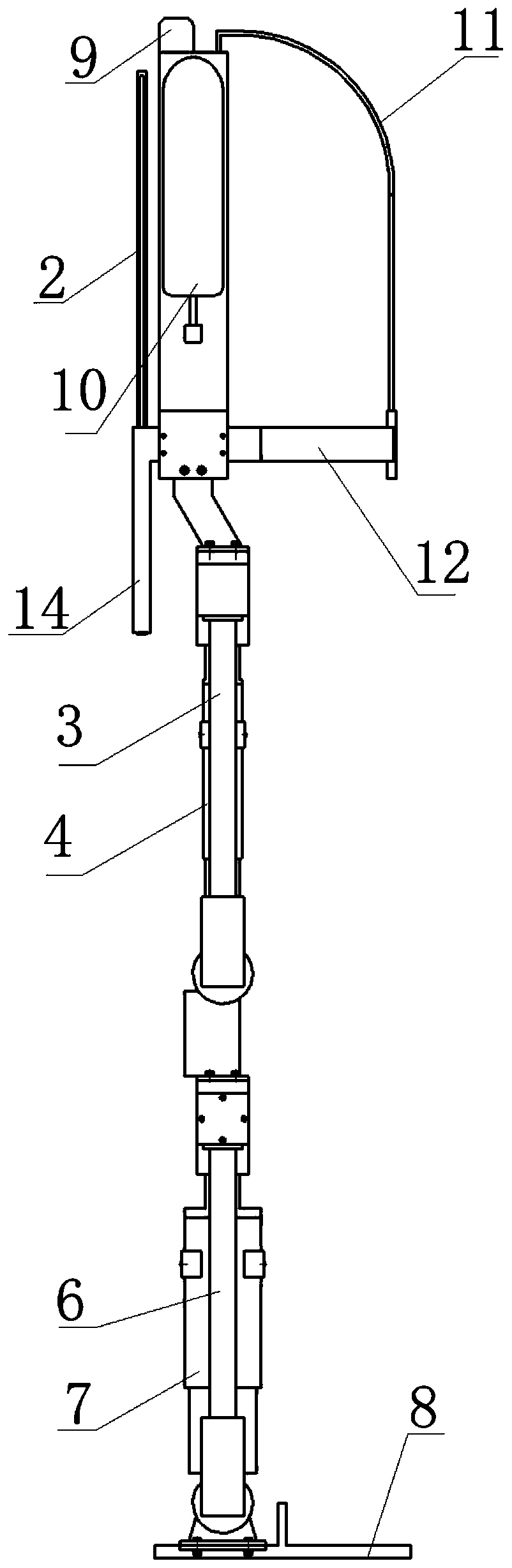

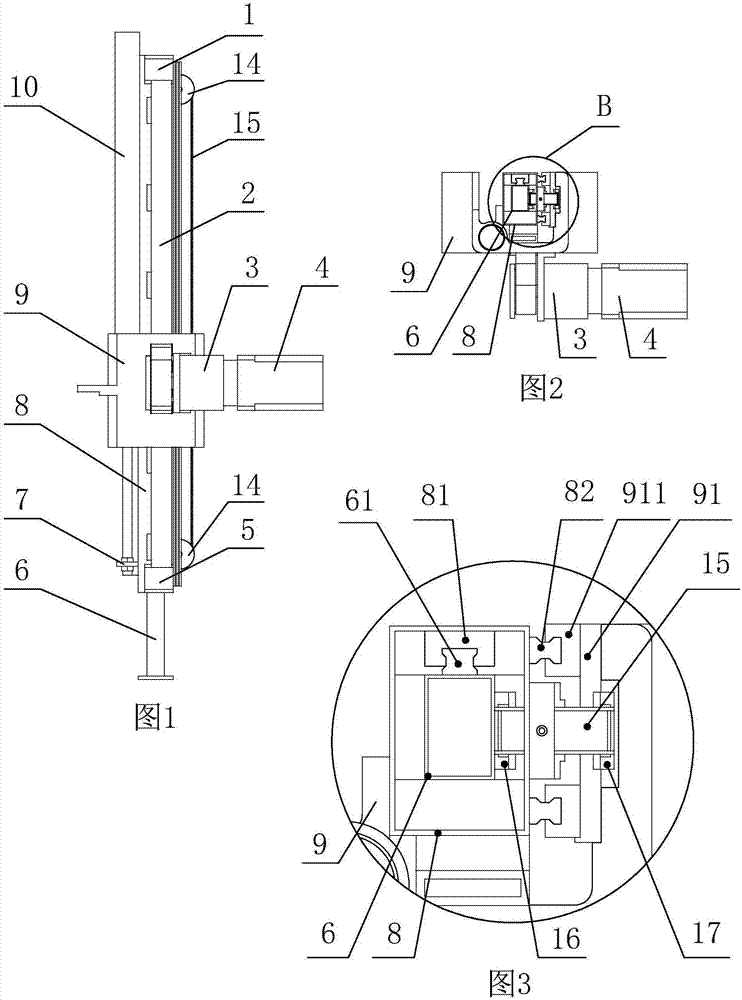

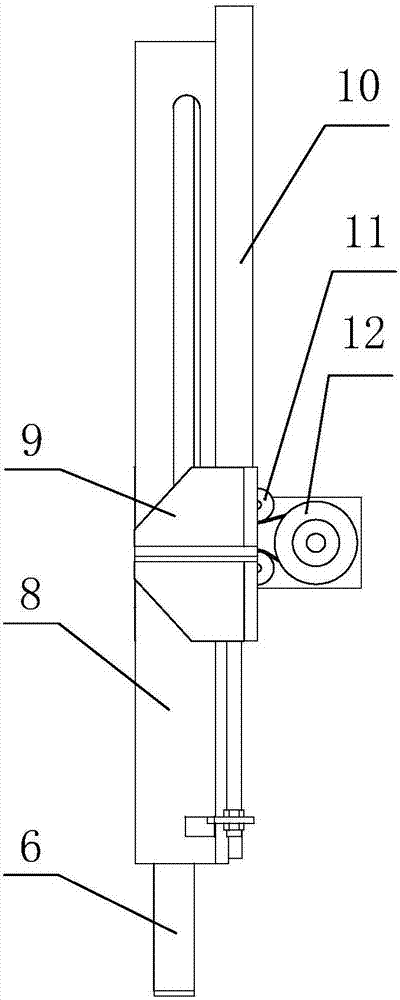

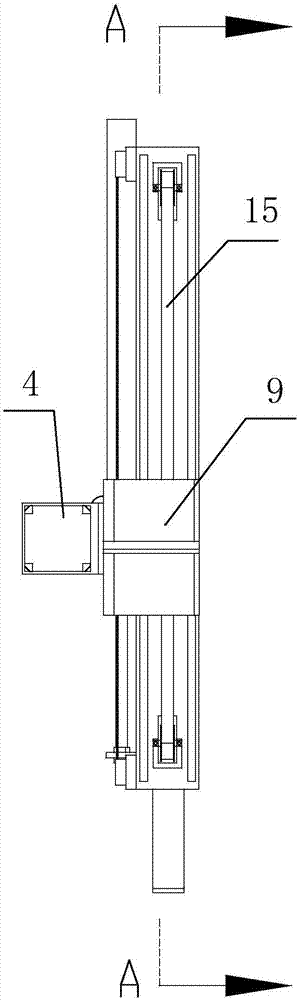

Mechanical arm driven in compound manner

PendingCN107030685ALarge travel rangeSave spaceProgramme-controlled manipulatorArmsRobotic armReduction drive

A mechanical arm driven in a compound manner comprises double slide arms and drive devices. The double slide arms include the outer slide arm and the inner slide arm embedded in the outer slide arm and connected with the outer slide arm in a sliding manner. The outer slide arm is connected with a slide rail base through slide rails in a sliding manner. The drive devices are installed on the slide rail base and include the first drive device and the second drive device. The first drive device comprises a servo motor, a speed reducer and a belt wheel I. The servo motor drives a conveyor belt I through the speed reducer and the belt wheel I so that an outer profile can be driven to slide up and down. The second drive device comprises a cylinder. A piston rod of the cylinder is connected with the outer profile and pushes the outer profile to slide. Two belt wheels II are arranged on the outer profile. A conveyor belt II is assembled between the belt wheels II. The inner side of the conveyor belt II is fixed to an inner profile, and the outer side of the conveyor belt II is fixed to the slide rail base. The outer profile moves up and down so as to drive the inner profile to move up and down at a double speed relative to the outer profile. By means of the mechanical arm, the stroke is increased, space is saved, the operation precision and efficiency are improved, the material mass range is widened, and safety is high.

Owner:柳州科瑞科技有限公司 +1

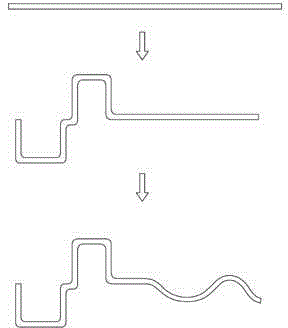

Refrigerator handle bending device

InactiveCN104942101ACompact and reasonable designHigh degree of automationMetal-working feeding devicesStripping-off devicesEngineeringRefrigerated temperature

The invention discloses a refrigerator handle bending device. The refrigerator handle bending device comprises a primary bending component, a feeding component, a conveying component and a secondary bending component, wherein the primary bending component comprises a lower bending die, an upper bending die and a buffering plate, and the lower bending die and the upper bending die are arranged in a vertical corresponding manner; the buffering plate is arranged inside the lower bending die, a to-be-machined workpiece is placed between the lower bending die and the upper bending die, and the upper bending die is pressed downwardly into the lower bending die to finish primary bending of the to-be-machined workpiece; the feeding component is arranged on the lateral portion of the lower bending die and used for upwardly ejecting the bent to-be-machined workpiece out and pushing the same to the conveying component; the conveying component is arranged at the tail end of the lower bending die and used for conveying the to-be-machined workpiece to the secondary bending component for secondary bending. The refrigerator handle bending device is simple in structure, compact in design, small in occupied space, convenient and quick to operate and low in production cost.

Owner:德清一洲制冷科技有限公司

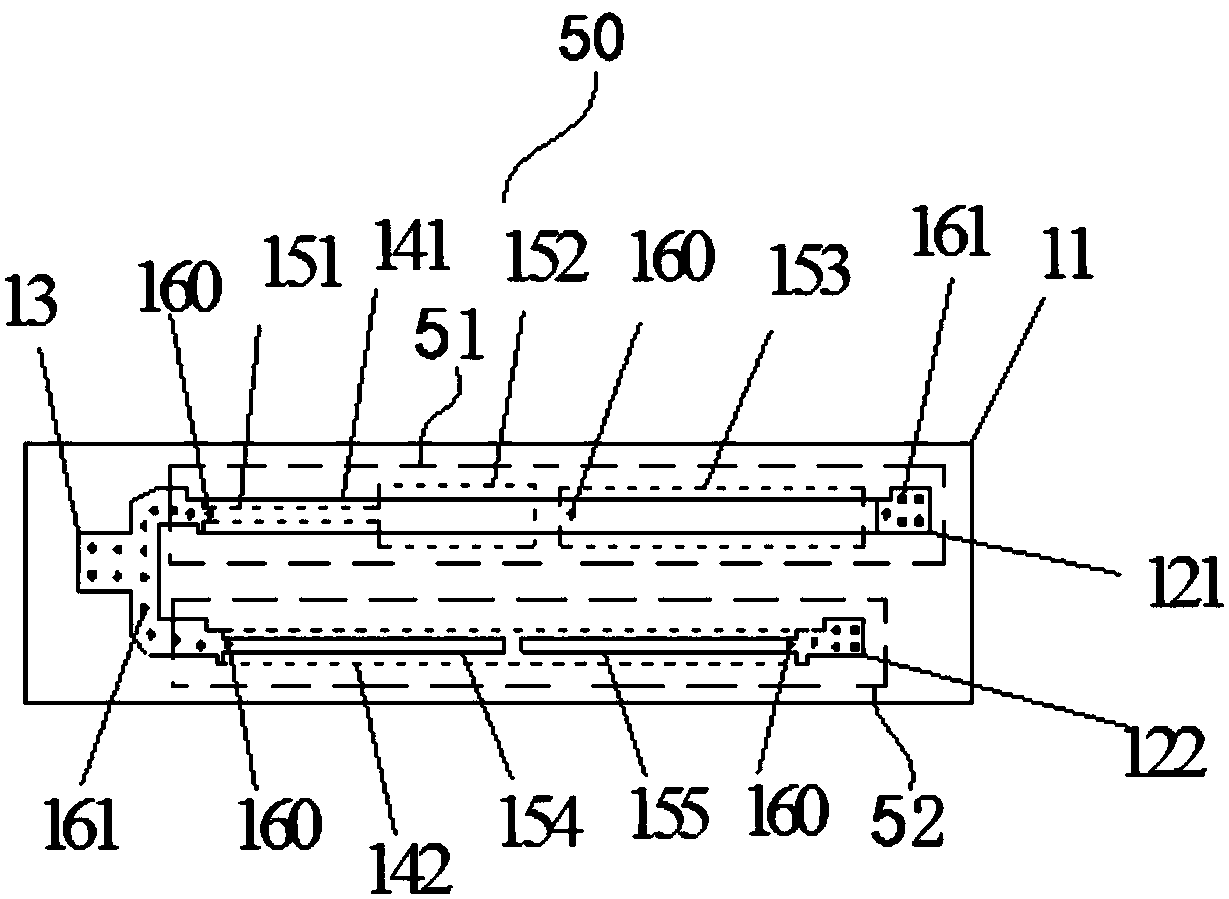

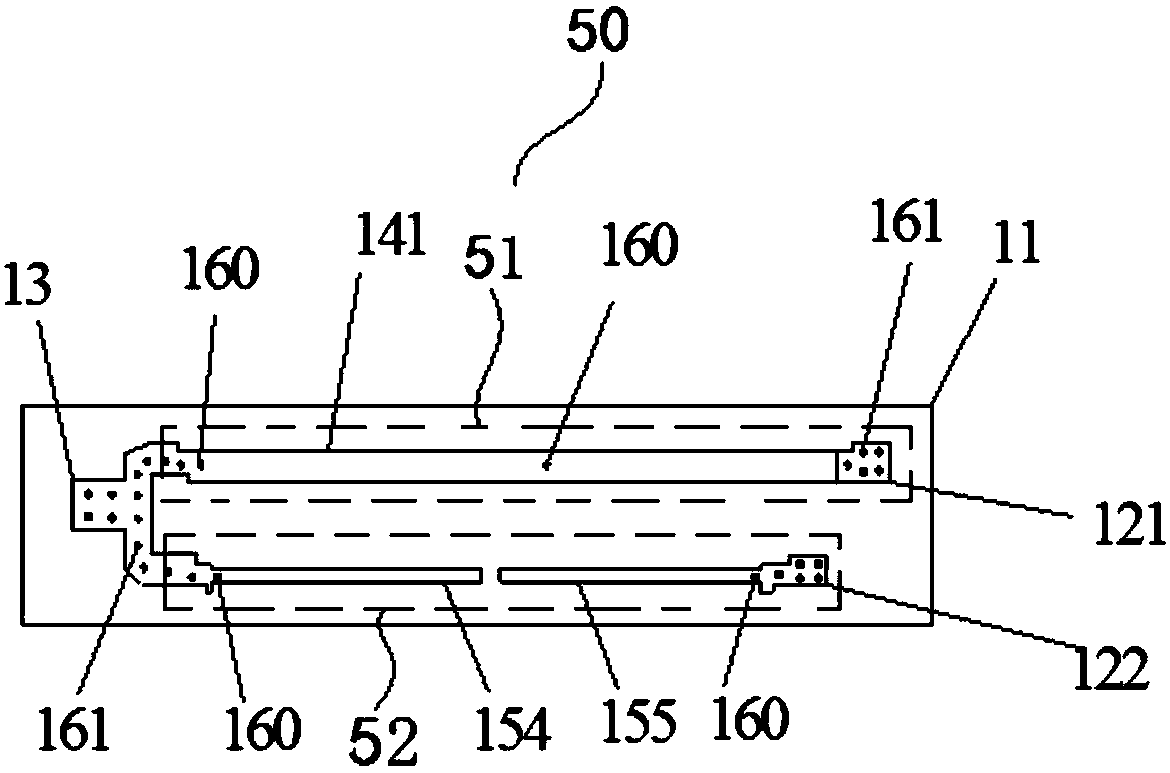

Path combiner, phase shifter assembly and antenna

PendingCN108023147ACompact and reasonable designEasy to processWaveguide type devicesAntennasTransmission lineEngineering

An embodiment of the invention provides a path combiner comprising a medium substrate and at least two wave filters arranged on the medium substrate; each wave filter comprises an input end, an outputend, a main transmission line and a parallel connection stub line; each of input ends of all wave filters is used as an input end for the path combiner, output ends of all the wave filters are connected to form an output end of the path combiner, the main transmission line is electrically connected with the input ends of the wave filter and the output end of the wave filter, one end of the parallel connection stub line is electrically connected with the main transmission line while the other end is open, the main transmission line of each wave filter and the parallel connection stub line matched with the same in use are distributed on different circuit layers, path combiner miniaturization is realized, and requirements for integration of the path combiner with other communication parts can be met. The embodiment of the invention also provides a phase shifter assembly and an antenna; when the path combiner is applied to the parts, the parts can be greatly downsized.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD

Machining device of installation corner connector

InactiveCN103769481ACompact and reasonable designReduce occupancyShaping toolsPerforating toolsEngineering

The invention discloses a machining device of an installation corner connector. The machining device comprises an upper mold and a lower mold, wherein the upper mold comprises an installation handle and an upper fixed plate which is connected to the installation handle, the upper fixed plate is connected with an upper mold plate, the upper mold plate is connected with a blanking plate through a guide column, and a spring is sleeved on the guide column; the lower mold comprises a lower mold plate which is matched with the upper mold plate, the lower mold plate is installed on a soleplate, the upper mold plate comprises a plate-like base part, the plate-like base part sequentially vertically extends upwards to form a cutting mold, a kidney-shaped porous mold, a bending mold and two circular hole molds from outside to inside. By designing a composite continuous stamping mold, the cutting mold, the kidney-shaped porous mold, the bending forming mold and the circular hole molds are sequentially distributed on the continuous stamping mold, and the traditional independent four continuous stamping molds are integrated together, so that a product can be continuously machined; the mold is compact and reasonable in design and durable; the consumption of machines, production fields and operation personnel is only two thirds of the traditional equipment, and not only can the product quality be improved, but also the operation and production cost can be saved.

Owner:潼南华轩绿色建材有限公司

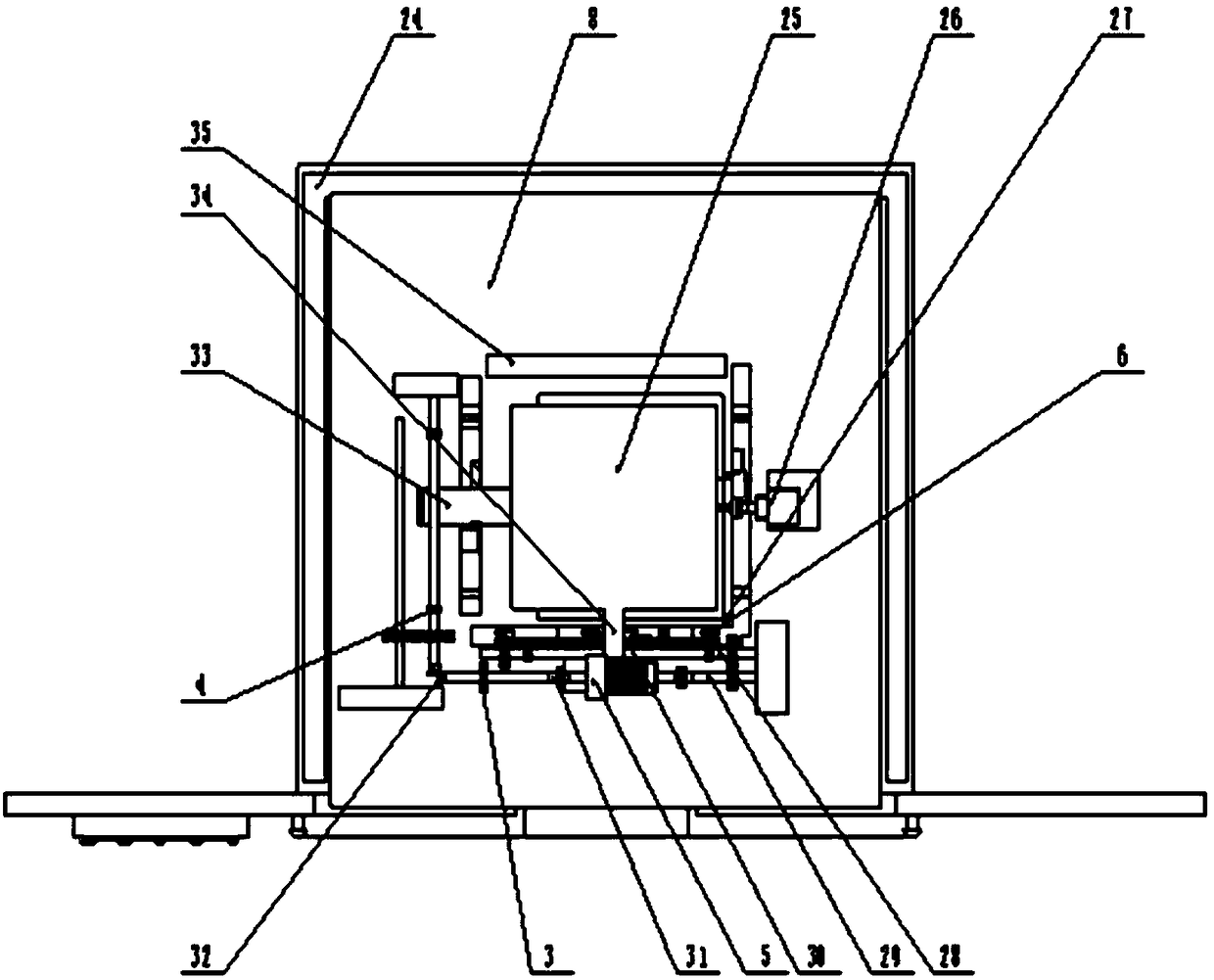

Aircraft panel vibration device under free boundary excited by aircraft sound waves and application method thereof

The invention belongs to the vibration test technology field and particularly relates to an aircraft panel vibration device under the free boundary excited by aircraft sound waves and an application method thereof. The device comprises an auxiliary positioning device, an omnidirectional measuring device, an automatic adjusting suspension device, a movable sound wave excitation device and an auxiliary tool device, wherein the auxiliary tool device is used for supporting other four devices and providing the auxiliary function of a test device, the automatic adjusting suspension device is used for suspending aircraft panels before a vibration test and adjusting height of the aircraft panels, the movable sound wave excitation device is a vibration source of the vibration test device, the omnidirectional measuring device is used for measuring and collecting vibration data of the aircraft panels, and the auxiliary tool device ensures that the aircraft panels can return to a measuring originafter each vibration process. The device is suitable for measuring dynamic characteristics of various aircraft panels, the relevant vibration data of the aircraft panels can be directly obtained through aircraft sound wave excitation, the data can be then analyzed through computer software, the device is simple and efficient, and the data is accurate.

Owner:NORTHEASTERN UNIV

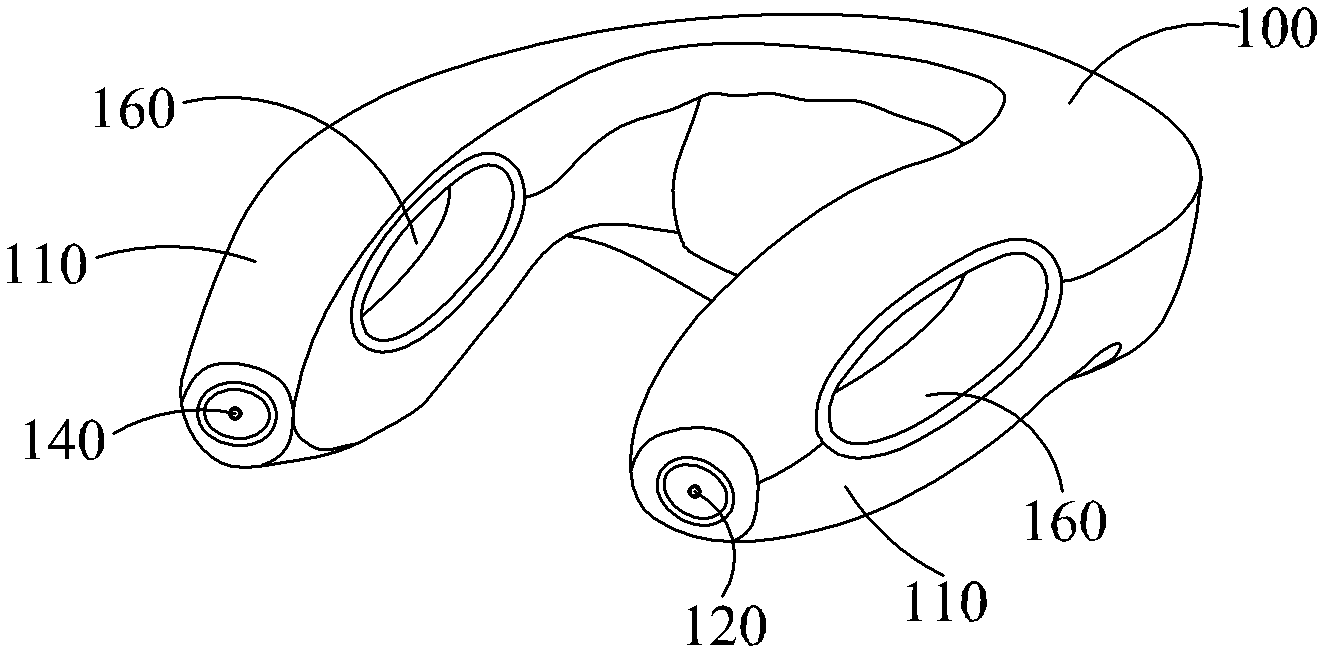

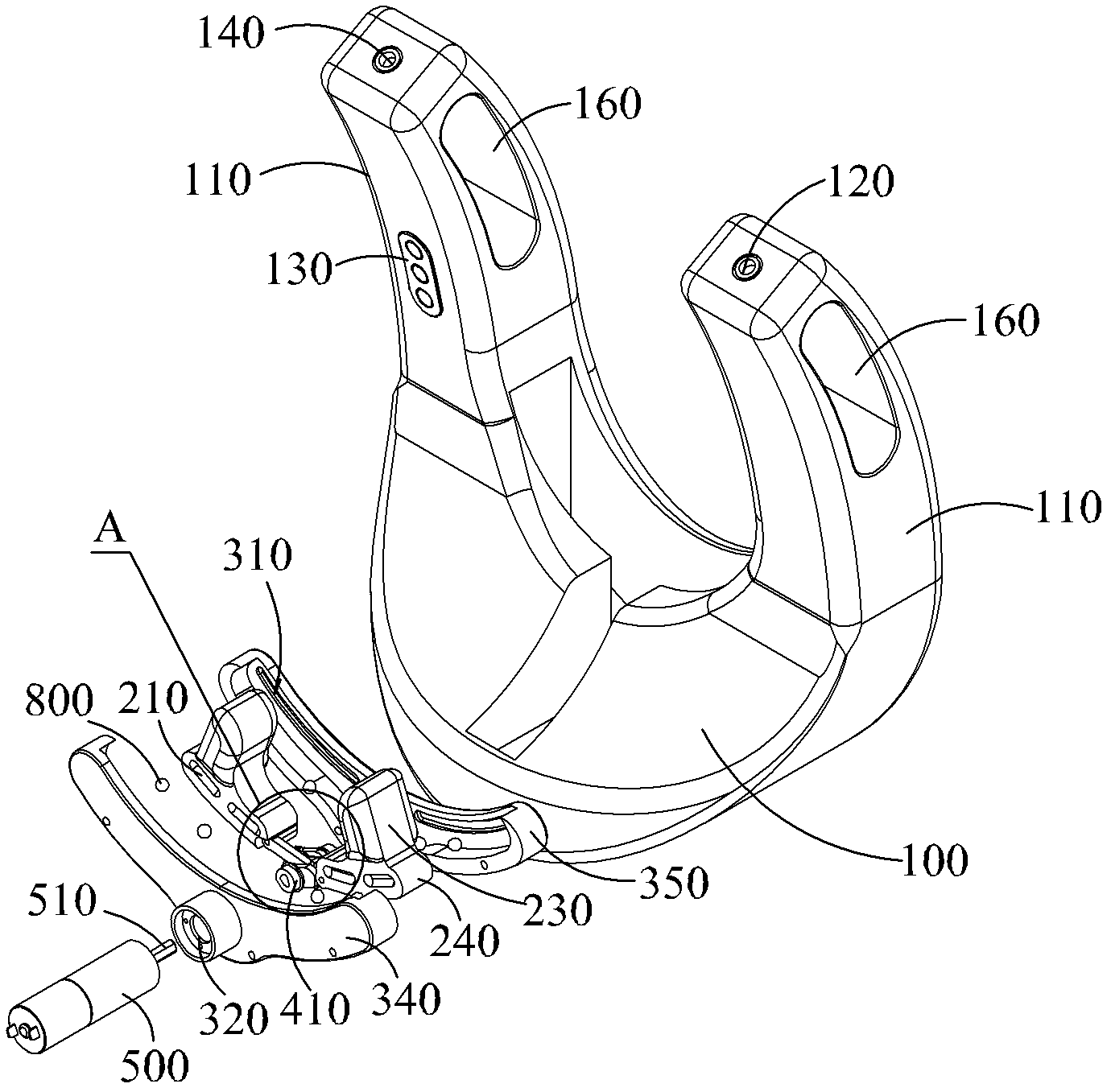

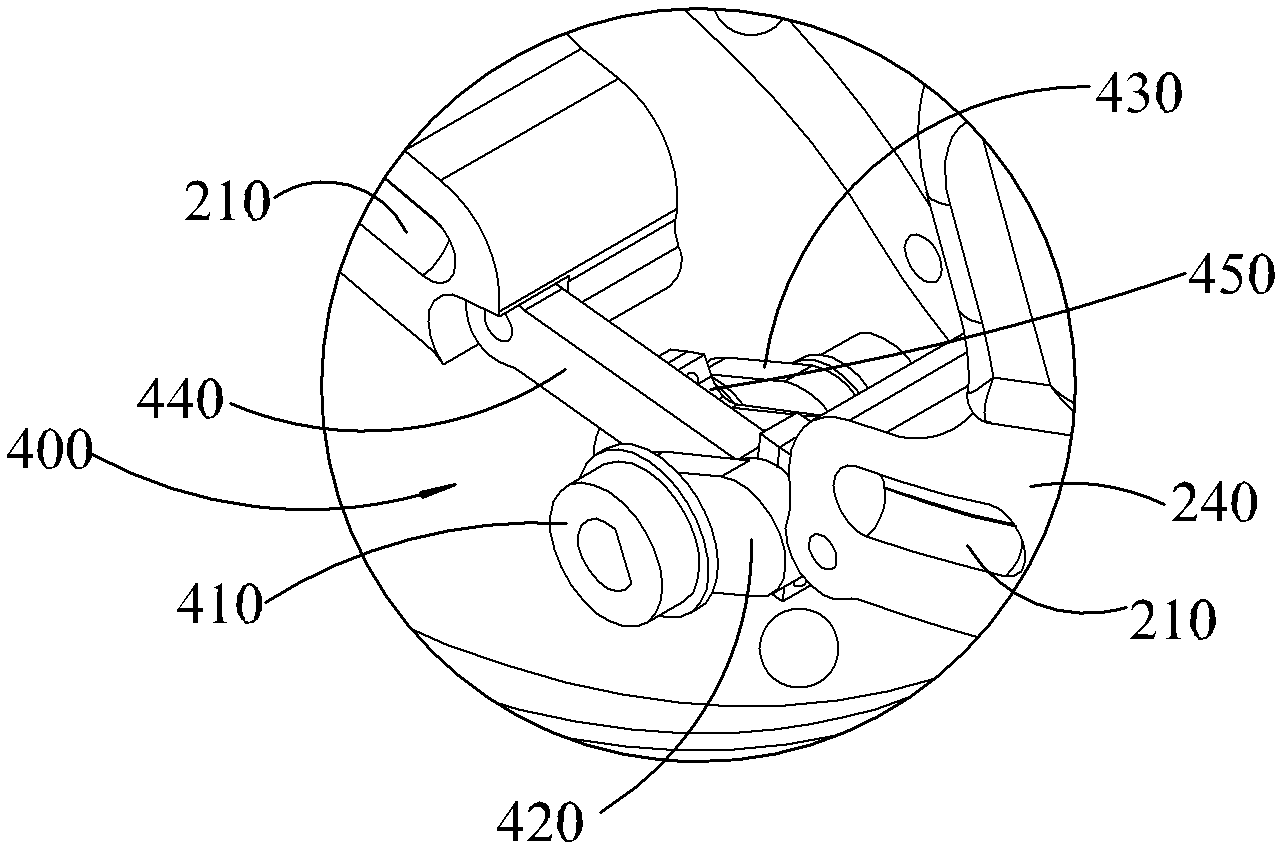

Kneading-type neck massager

ActiveCN102600033ASimple structureCompact and reasonable designSuction-kneading massageMedicineMassage

The invention relates to a massaging appliance, and provides a kneading-type neck massager. The kneading-type neck massager comprises a U-shaped neck pillow which can be suspended on the neck of a human body, wherein two massaging contacts are symmetrically arranged at the inner side of the U-shaped neck pillow, corresponding to the position of a cervical vertebra of the human body; a sliding chute is arranged inside the U-shaped neck pillow, a crank-link mechanism capable of driving the two massaging contacts to slide on the sliding chute so as to knead and massage, a power element connectedto the crank-link mechanism and a control circuit for controlling movement of the power element. In the invention, two massaging contacts are symmetrically distributed to simulate hands of a person and can achieve the kneading and massaging effects as those of the hands of the person. Simultaneously, the crank-link mechanism is adopted to drive the massaging contacts to move. The crank-link mechanism is simple in structure, rational and compact in design and small in occupied space. The power element is adopted to drive, so that a manual operation is avoided, and the output power is strong, so that the massaging effect is effectively achieved and the use is convenient.

Owner:SHENZHEN BREO TECH CO LTD

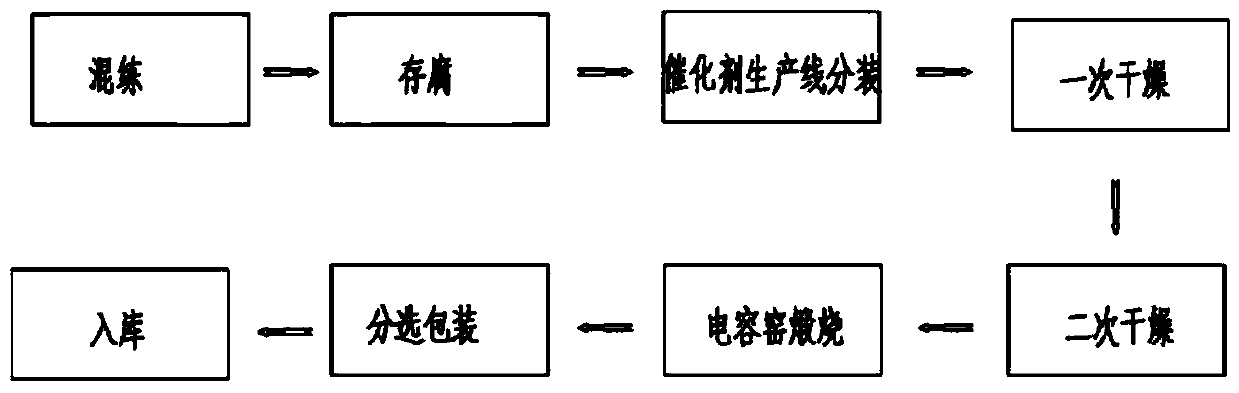

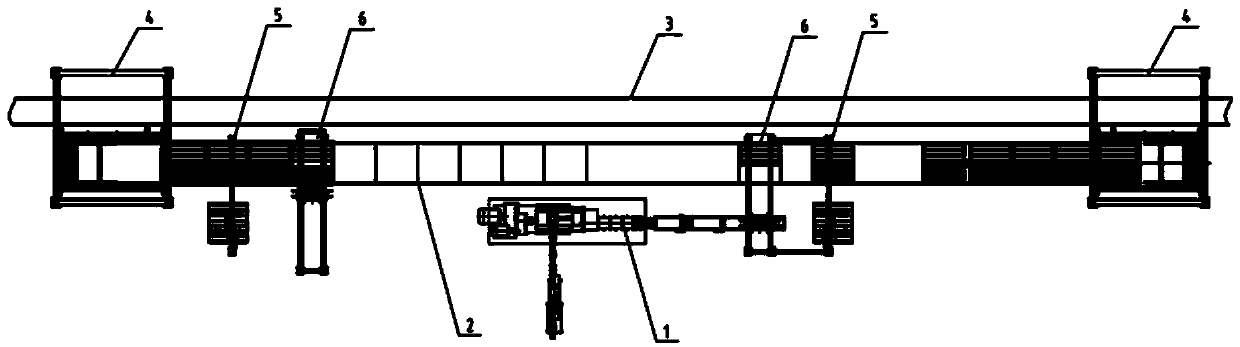

SCR catalyst production system

InactiveCN104190476AImprove automation production efficiencySmall amount of deformationDrying gas arrangementsCatalyst activation/preparationCapacitanceConveyor belt

The invention discloses an SCR catalyst production system which comprises a mixer, a storage room, an automatic production line, a primary drying kiln, a secondary drying kiln, a capacitance kiln and the like, wherein the production line mainly comprises a product conveying line, a tray loading and unloading system, an upper cover loading and unloading system and a catalyst loading and unloading system; the primary drying kiln comprises a primary drying kiln body, a product conveying system, a gas circulation control system, a temperature control system and a humidity control system; the secondary drying kiln comprises a kiln body, a steam pipeline, a frequency conversion control axial flow fan, a humidity control system and a kiln vehicle guide rail; and the capacitance kiln comprises a kiln body, a conveyor belt and a moisture removal system. A catalyst blank production line is automatically assembled, and the automatic production efficiency is greatly improved. According to the production process generated by the unique structure of the drying kilns, the product deformation is reduced, and the rejection rate is reduced. The products are conveyed in the capacitance kiln by adopting ceramic roller rods, the production system is stable in structure, difficult to deform and high in firing yield and achieves heating of heating wires.

Owner:江苏宇达环保科技股份有限公司

Tool box with power socket

InactiveCN103612250ACompact and reasonable designEasy to carryWork tools storageElectric powerEngineering

Owner:无锡市华昊热能设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com