Automatic packaging machine and automatic packaging technology thereof

An automatic packaging machine and packaging bag technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve problems such as high labor costs, poor production stability, and uncompact connection of processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be further described below in conjunction with accompanying drawing:

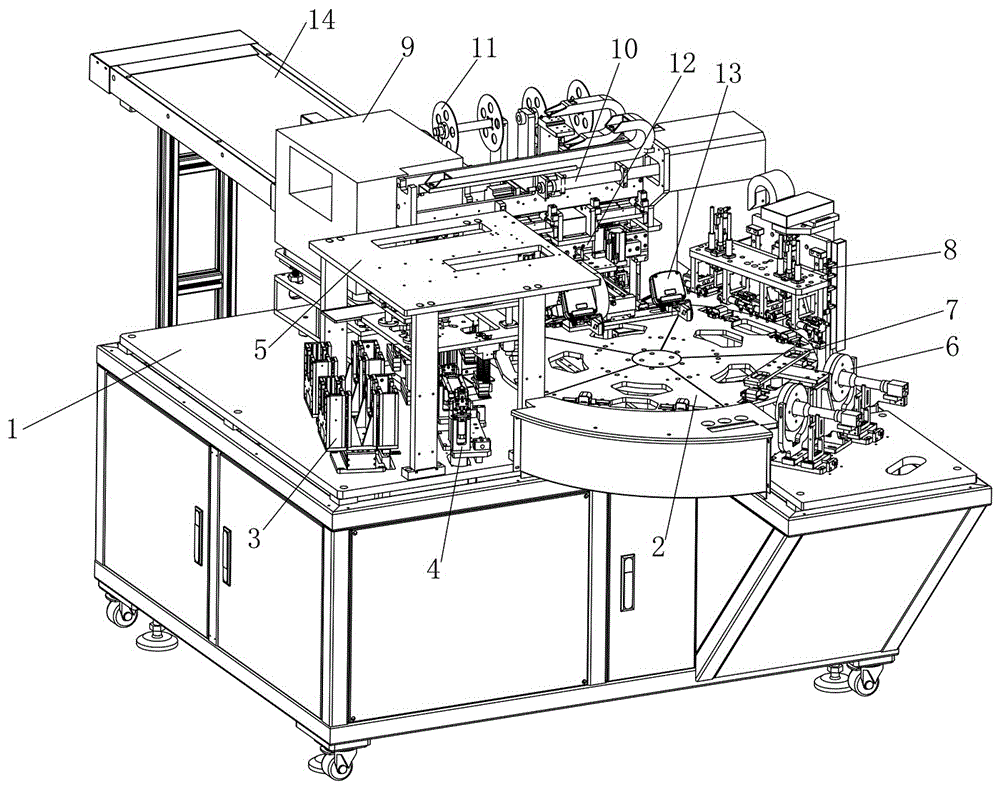

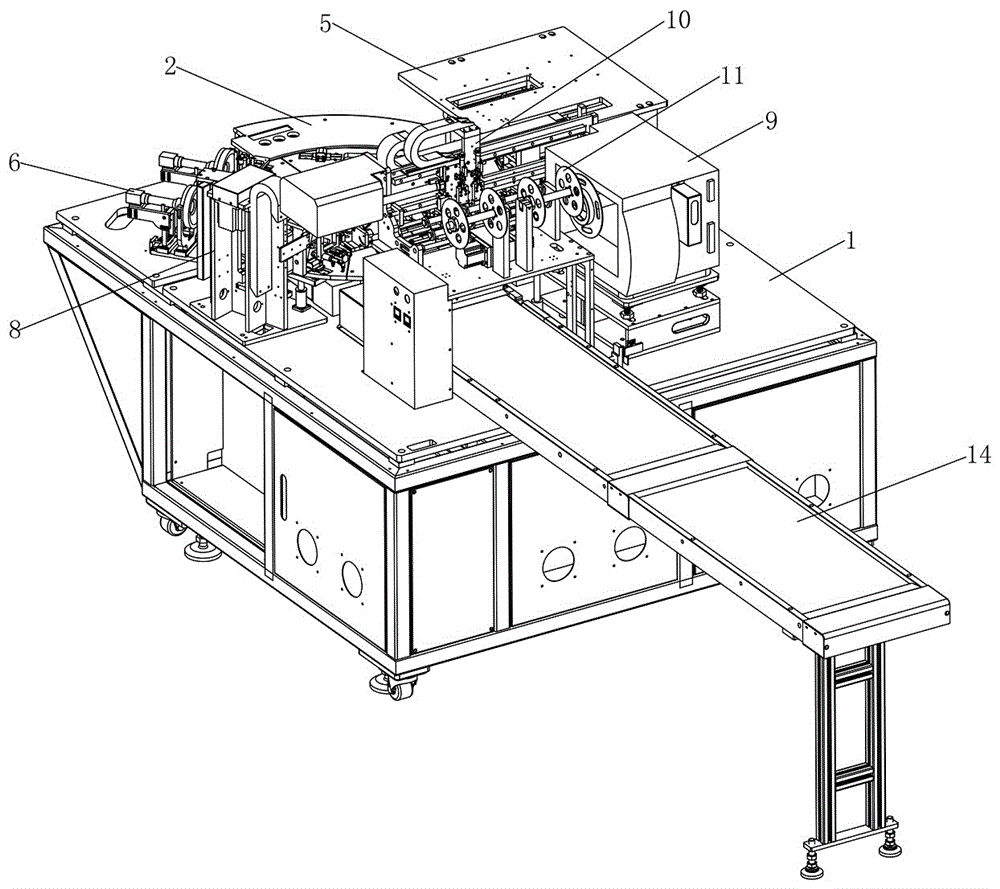

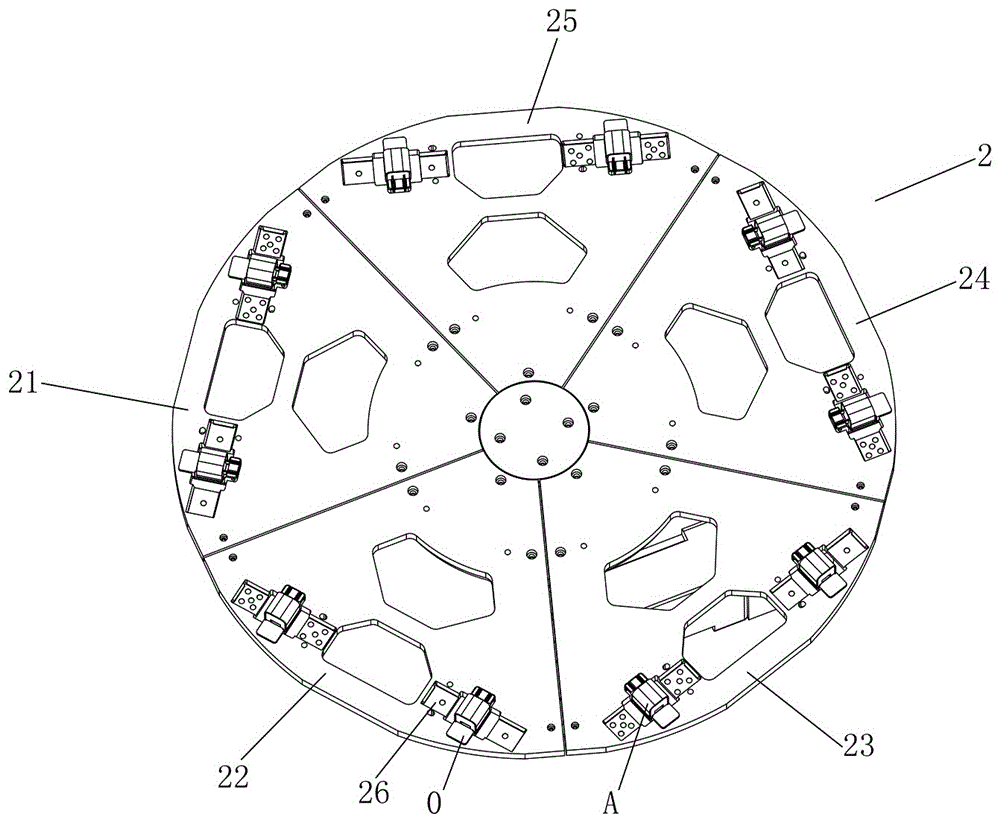

[0077] like Figure 1 to Figure 24 As shown, the technical solution adopted by the present invention is as follows: an automatic packaging machine, comprising a turntable 2, a trough mechanism 3 arranged on the outside of the turntable 2 in a clockwise direction around the turntable 2, a film tearing mechanism 4, a feeding mechanism 5, a sweeping Barcode mechanism 6, coating mechanism 8, labeling mechanism 10, bag-out mechanism 11, tearing bag mechanism 12 and bagging mechanism 13, wherein, above-mentioned rotating disk 2 is arranged on the frame 1, and rotates on frame 1, so that Switch stations; the turntable 2 is sequentially provided with a filming station 21, a feeding station 22, a barcode scanning station 23, a filming station 24 and a bagging station 25 along its circumferential direction. Jig 0, the product A to be packaged is placed on jig 0 through the loading s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com