Cabin assembling and docking platform for autonomous underwater vehicle

An underwater vehicle and docking platform technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of unguaranteed assembly accuracy, uncompact device design, low structural reliability, etc., to save manpower and structure. Simple and stable, high assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

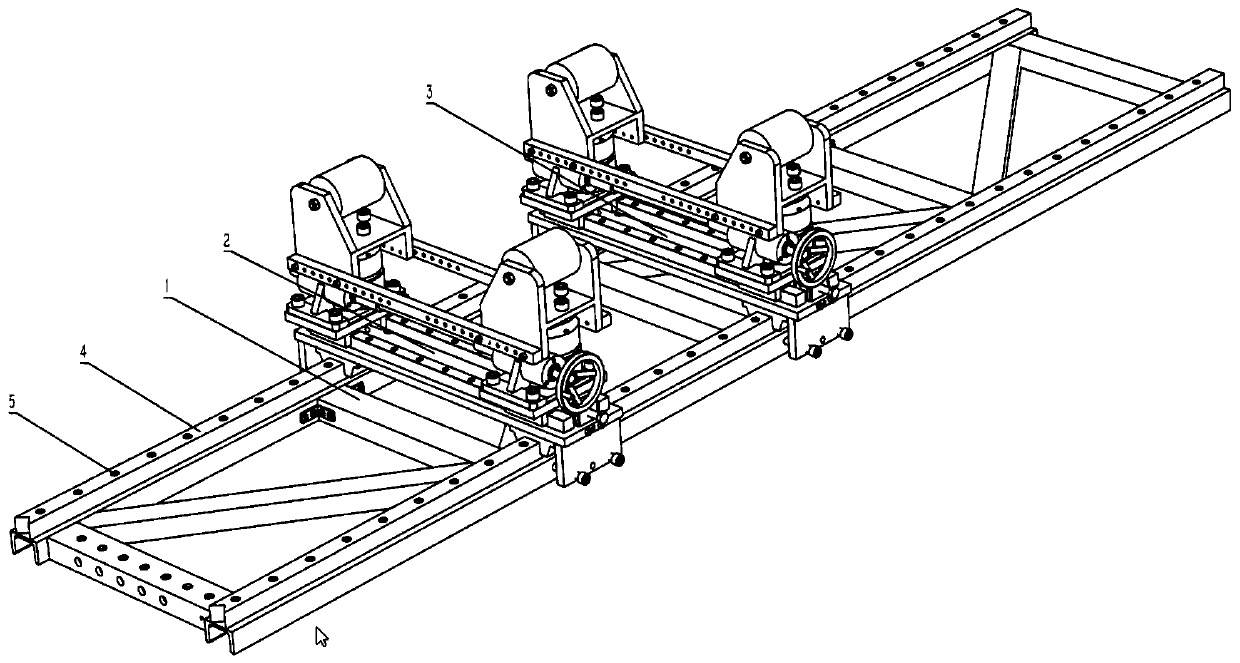

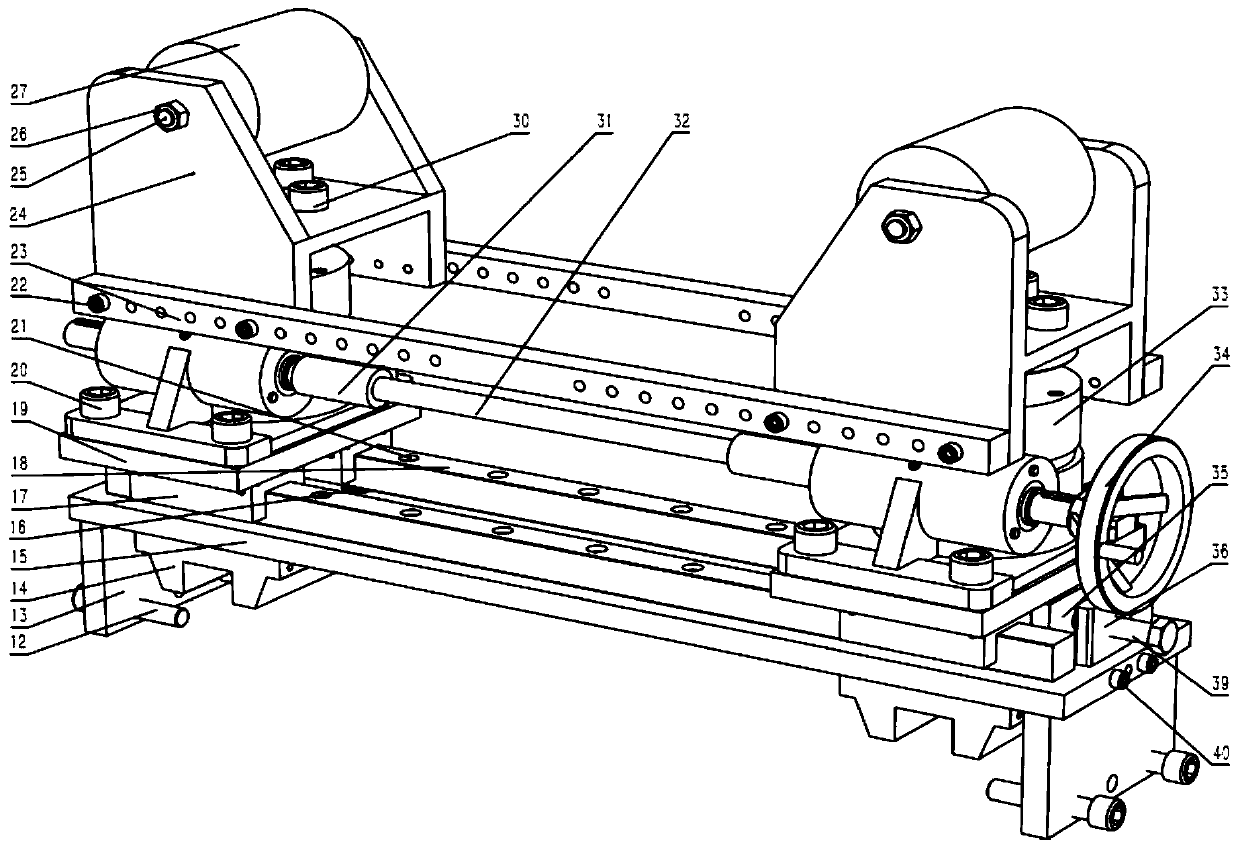

[0023] A cabin assembly and docking platform for an autonomous underwater vehicle, including a first-level platform 1, an attitude adjustment mechanism a2, an attitude adjustment mechanism b3, and a linear guide rail a4. The two linear guide rails a4 are parallel and symmetrically installed on the first-level platform 1. The attitude adjustment mechanism a2 and the attitude adjustment mechanism b3 are installed on the slider a14 of the linear guide rail 4, wherein the first-level platform 1 is processed after welding, and the flatness is guaranteed during welding, and the mounting holes of the two linear guide rails a4 are parallel and aligned during processing. unanimous.

[0024] The first-level platform 1 is fixedly placed on the test bench, and the first-level platform 1 can be docked and extended at the reserved interface according to the actual length of the autonomous underwater vehicle (AUV).

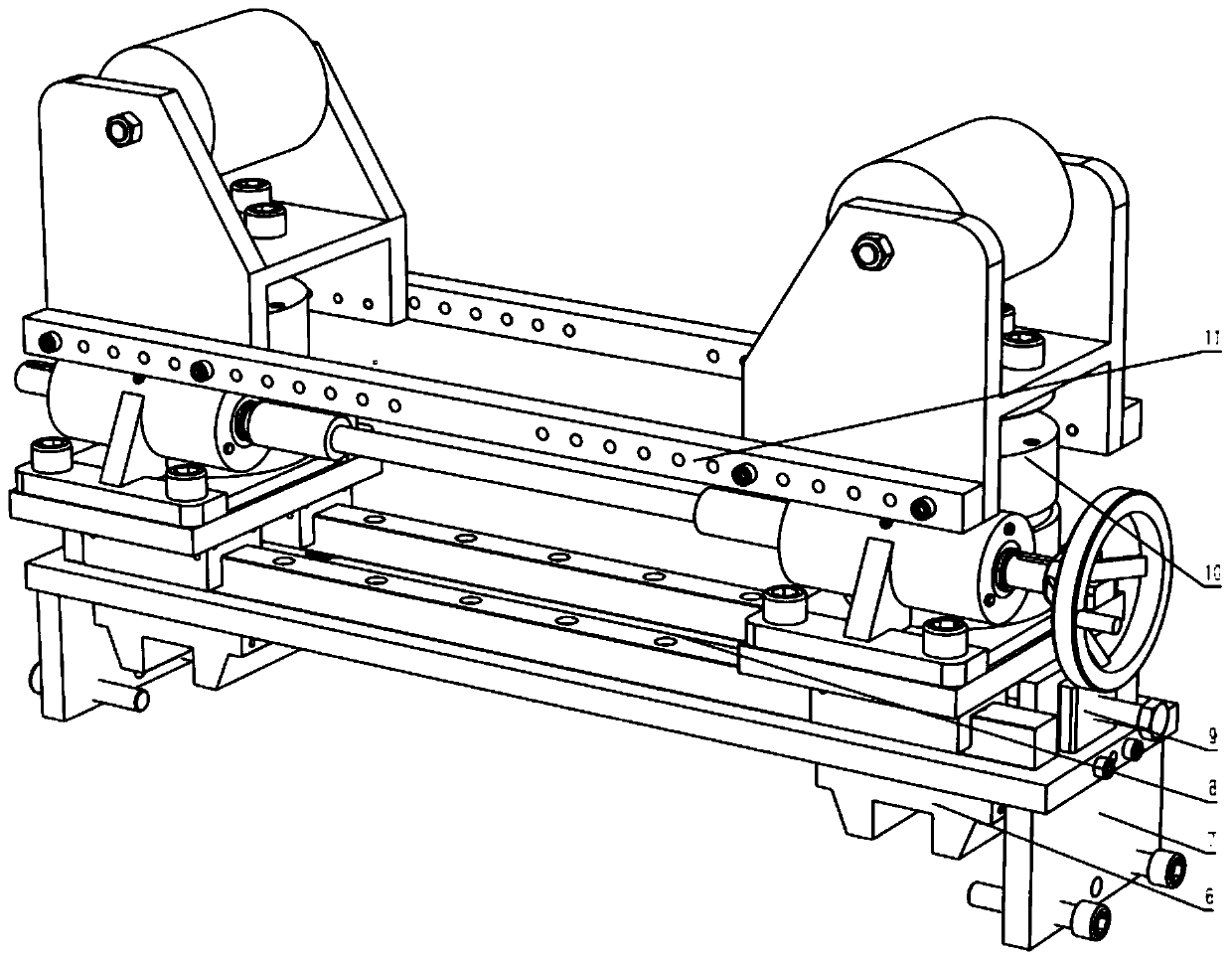

[0025] The attitude adjustment mechanism a2 includes a front and rear movem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com