Rotary positioning drilling clamp

A drilling jig and indexing technology, which is applied in the field of mechanical processing jigs, can solve problems such as complicated marking work, imprecise production efficiency, and affecting production quality and efficiency, and achieve the effects of compact and reasonable design structure, convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

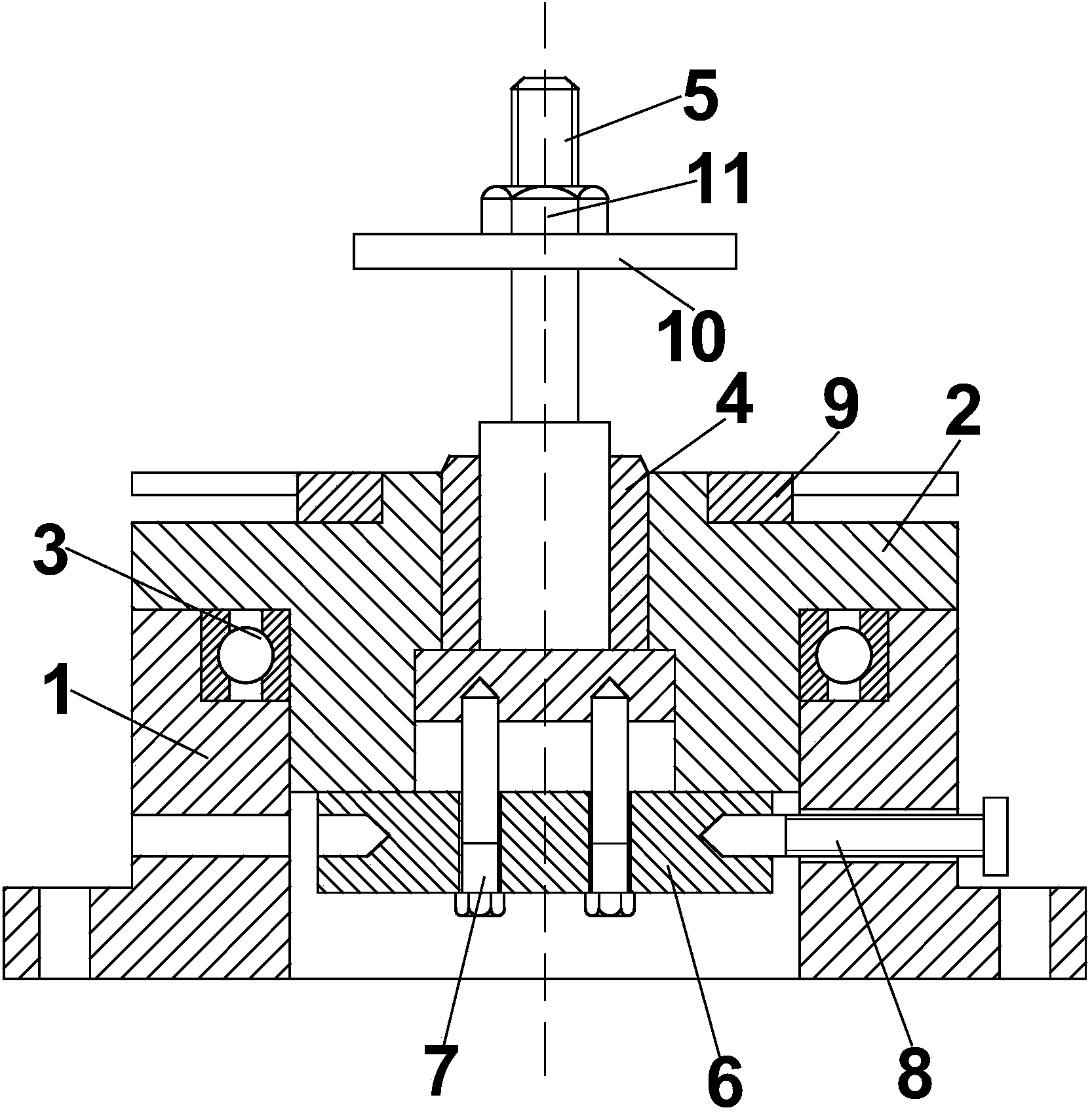

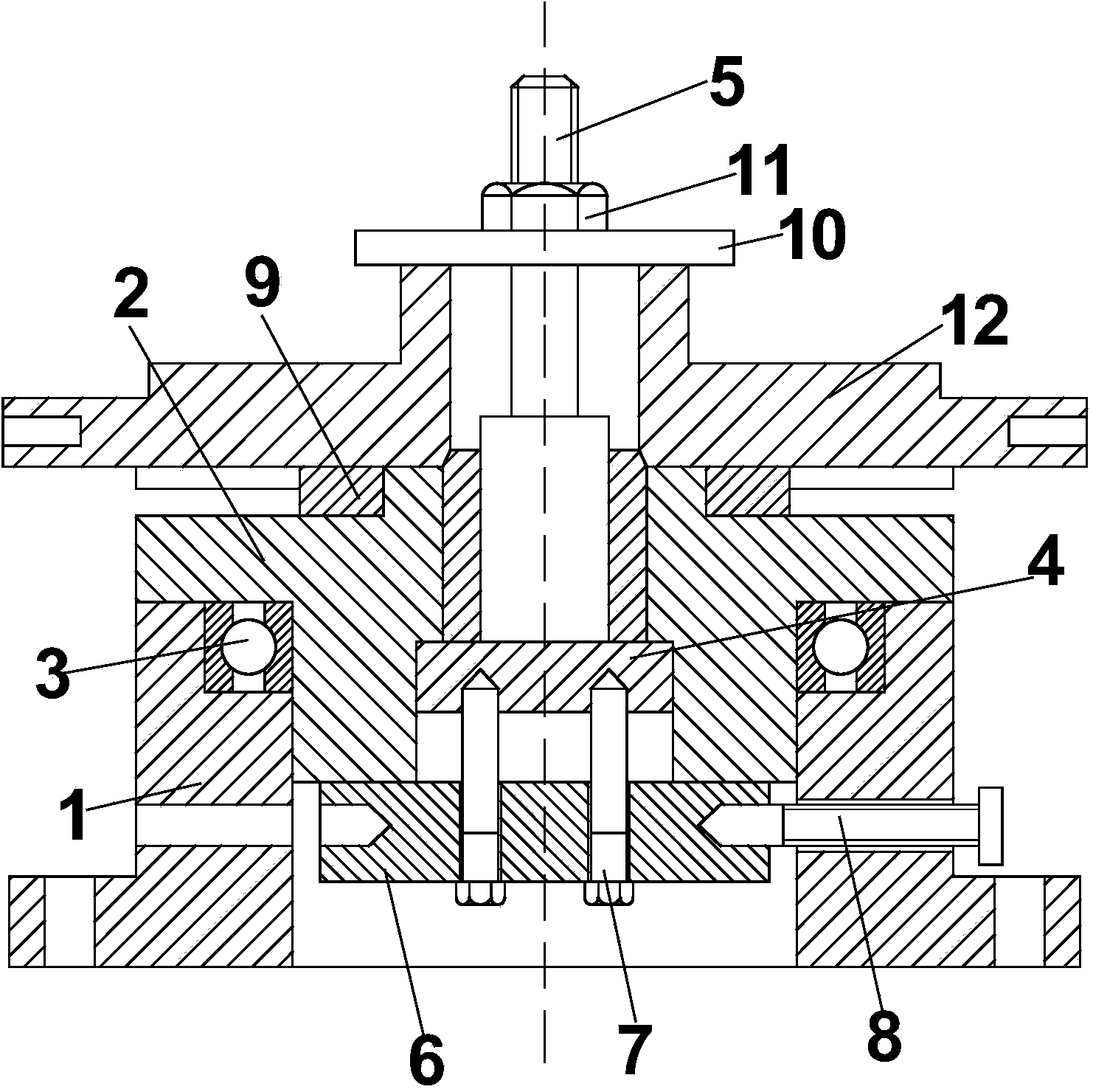

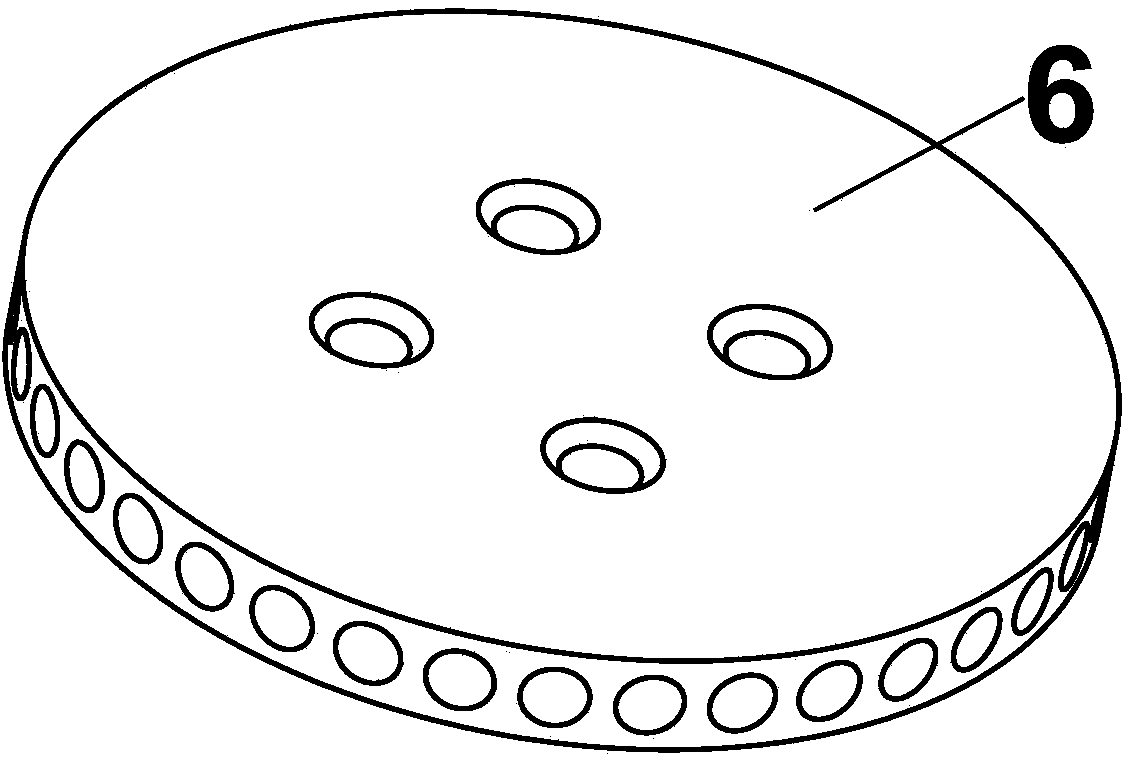

[0025] Such as figure 1 with figure 2 As shown, the above-mentioned indexable positioning drilling jig includes a base 1, a base 2, a rolling bearing 3, a sleeve 4, a movable mandrel 5, an indexing plate 6, an axial locking screw 7, a radial The locking pin 8, the chip removal disc 9, the pressure plate 10 and the locking bolt 11, a mounting plate is arranged under the base 1, and a mounting through hole is evenly opened in the radial direction of the mounting plate, and the mounting through hole is used in the present invention For grounding installation or fixed installation when used in conjunction with other parts, a fixing seat is provided above the base 1, and through holes are symmetrically opened at the lower end of the fixing seat, and the fixing seat is a hollow cylinder str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com