Patents

Literature

79results about How to "Automate transportation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

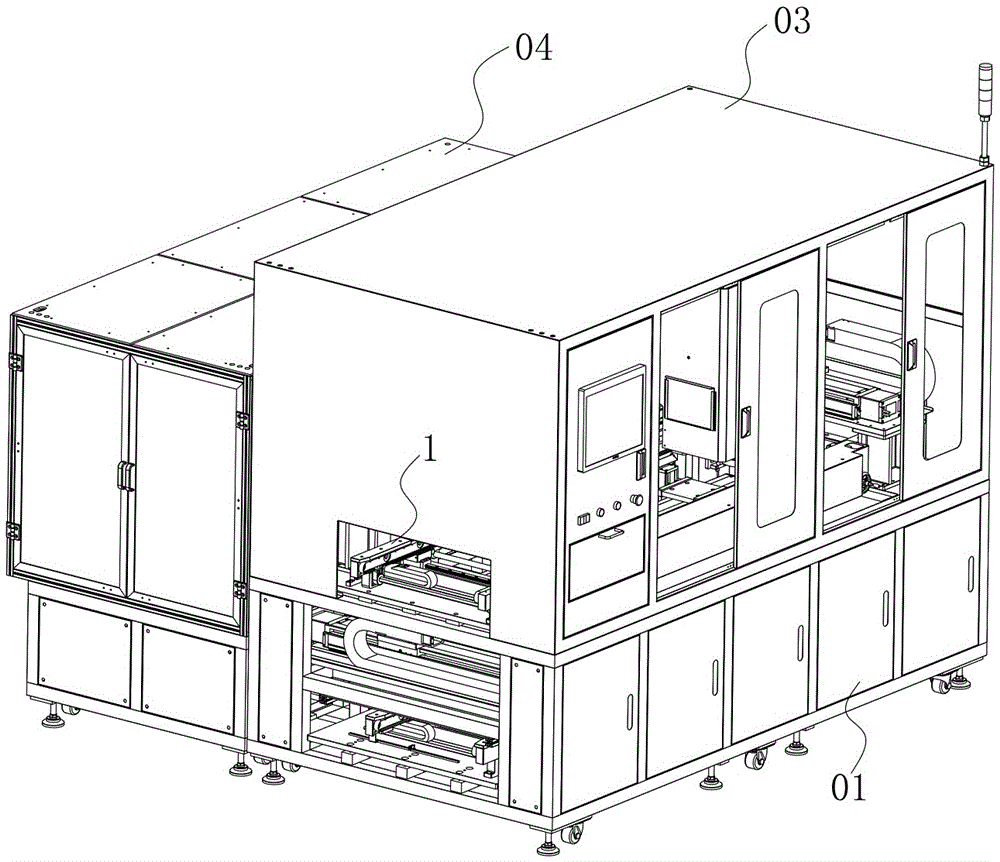

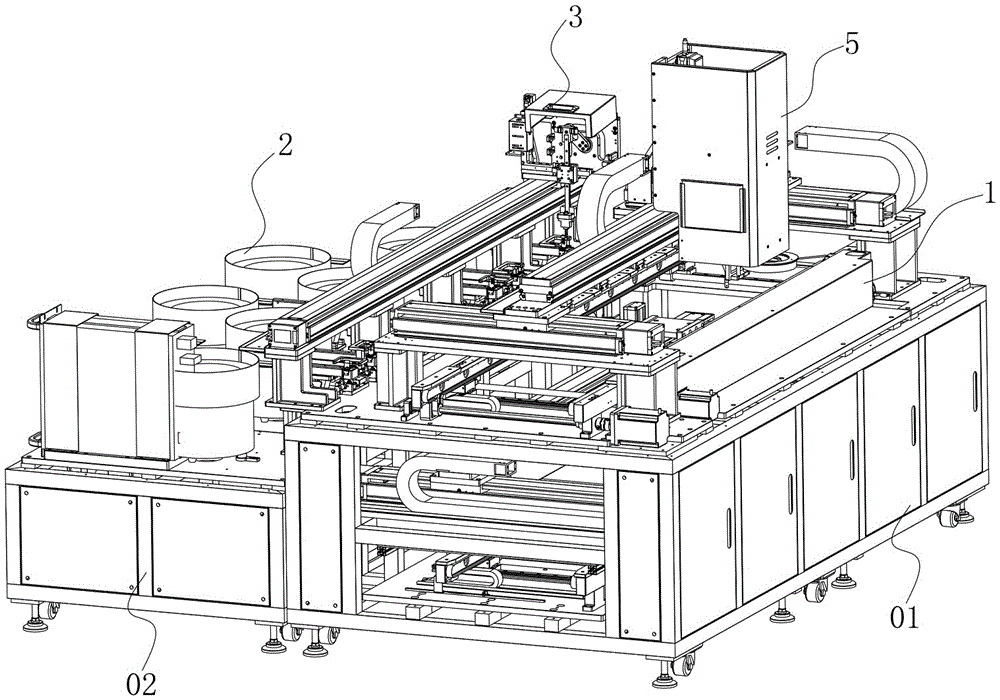

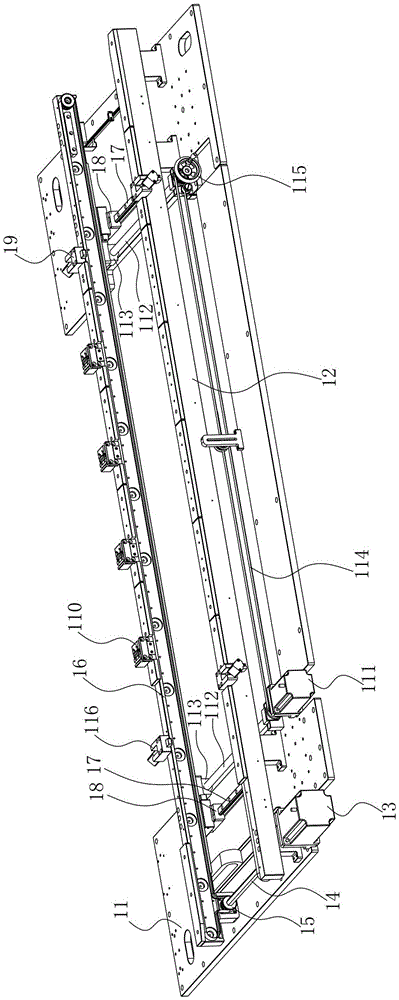

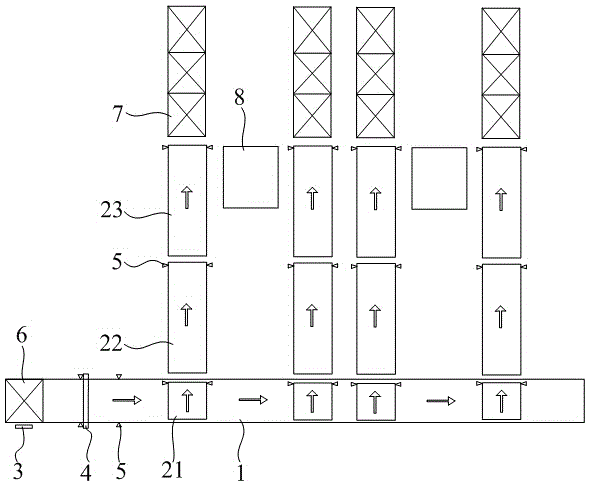

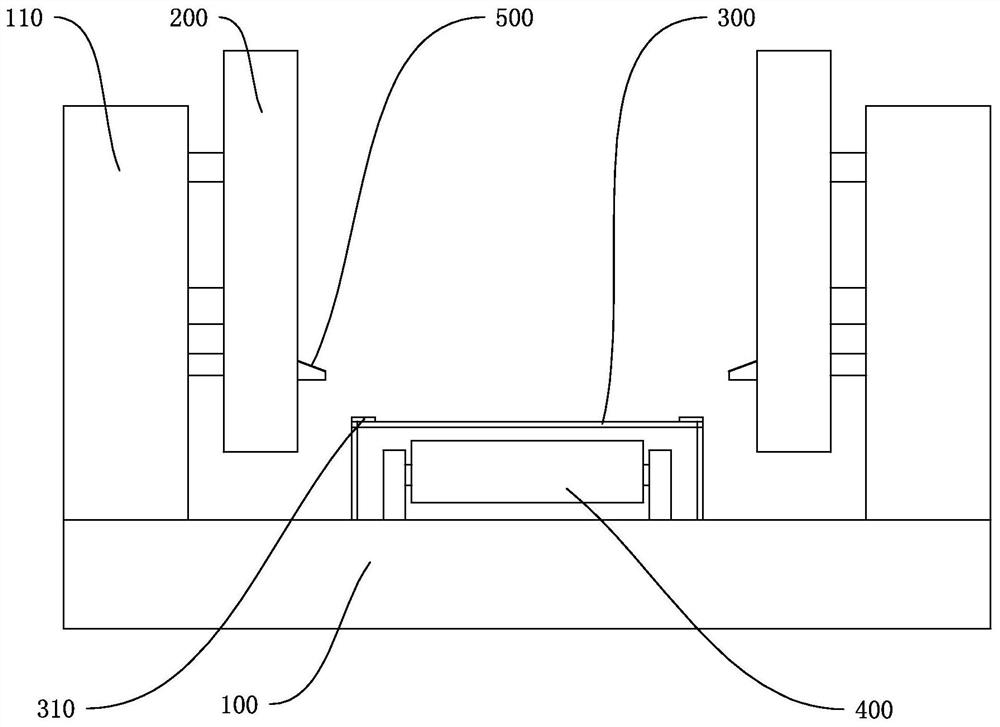

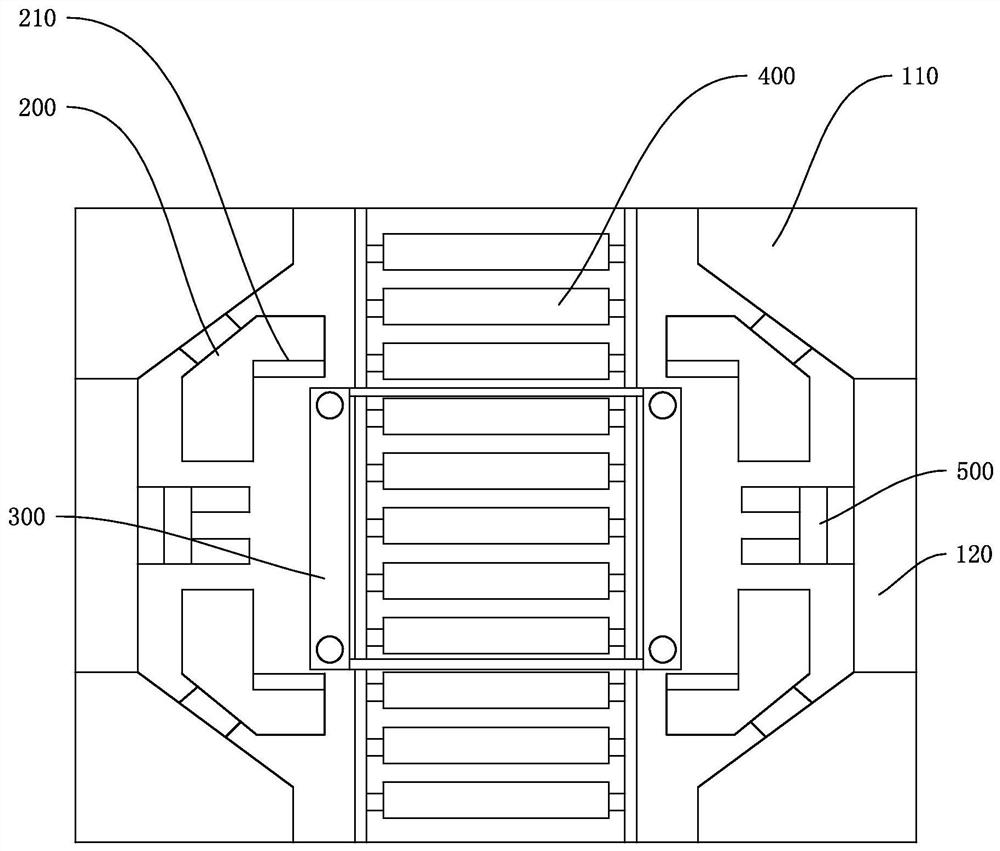

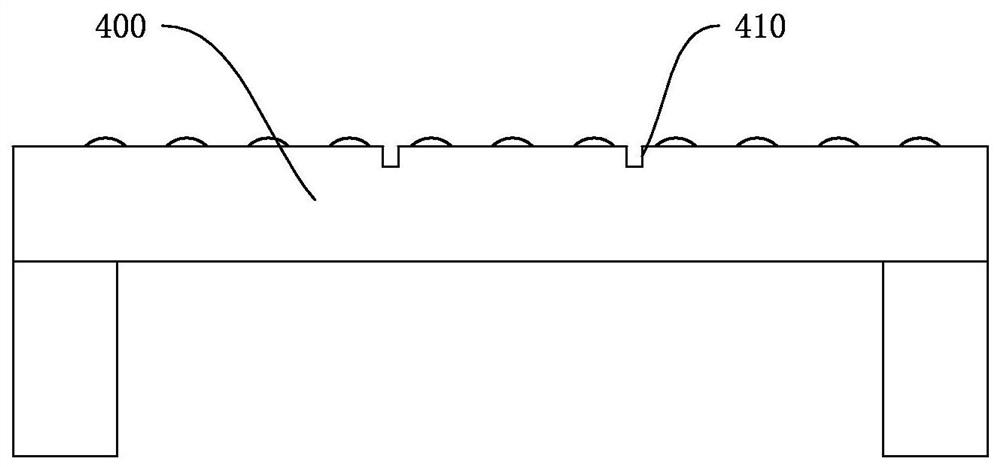

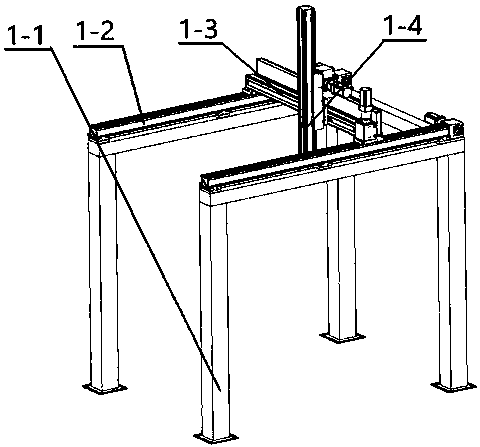

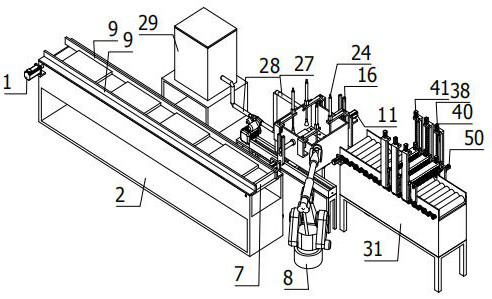

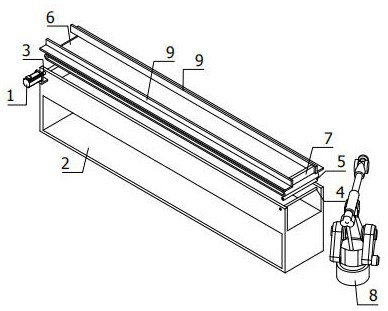

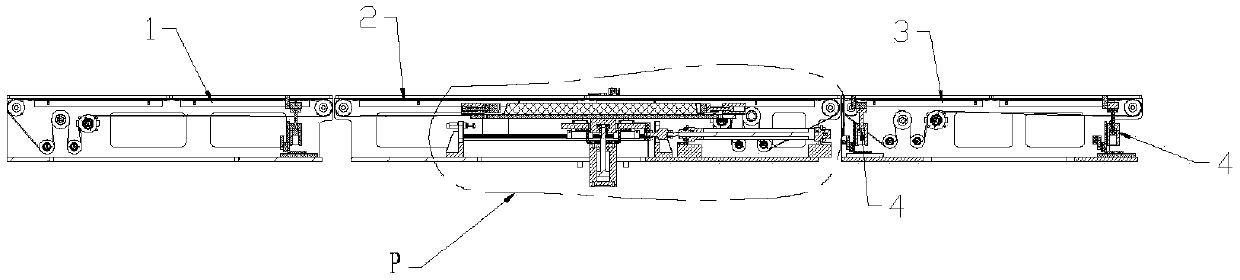

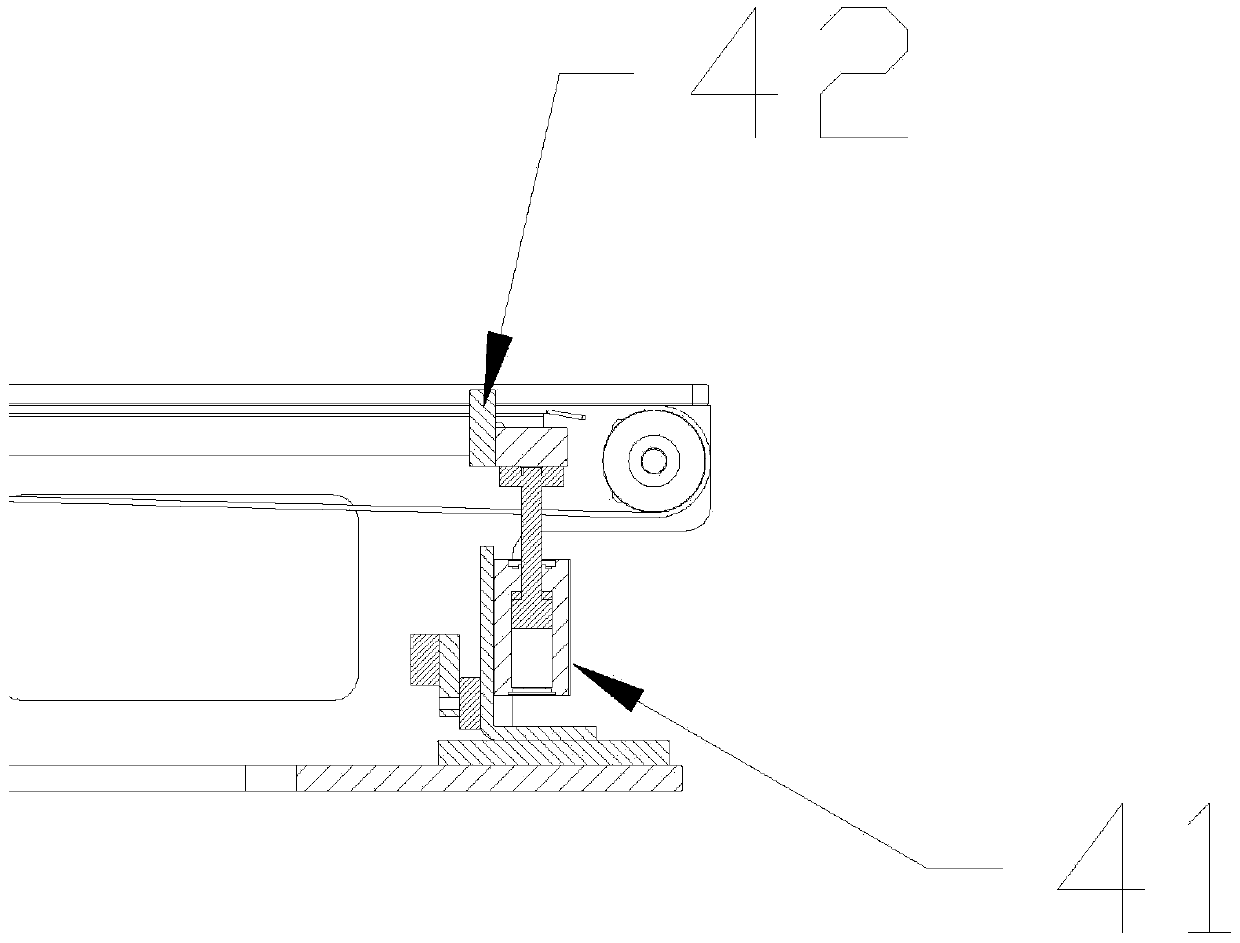

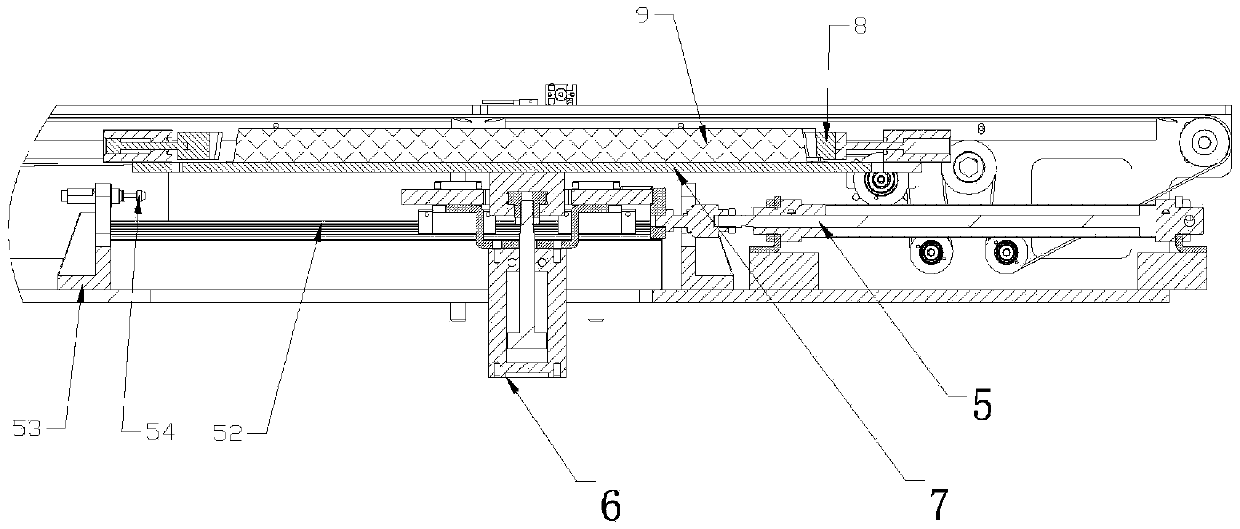

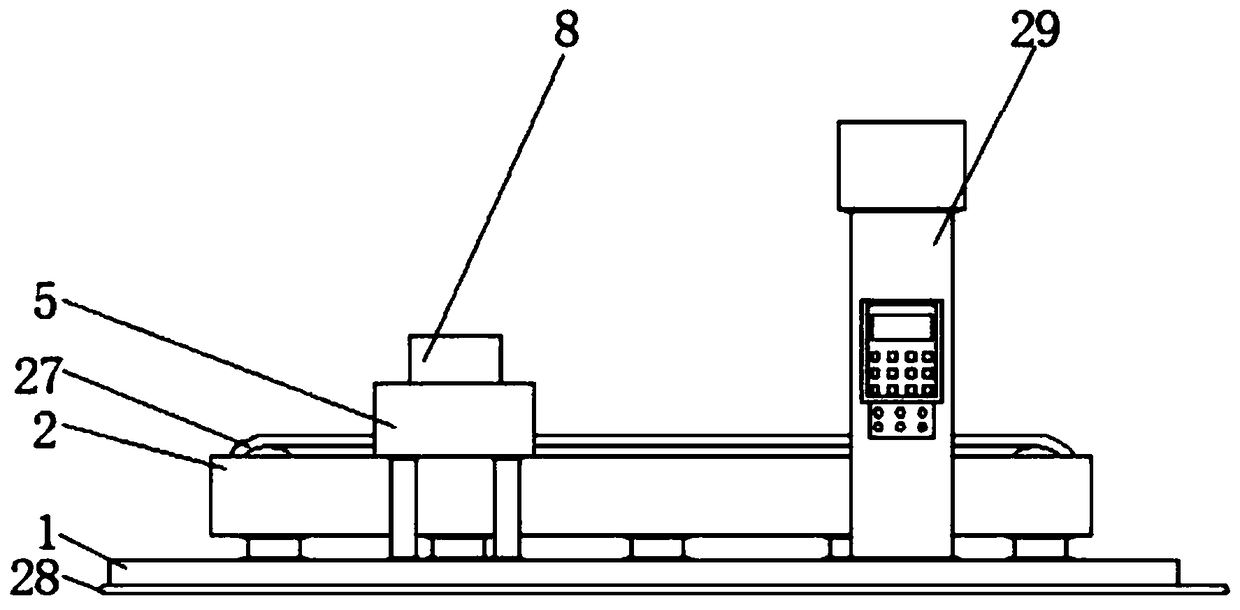

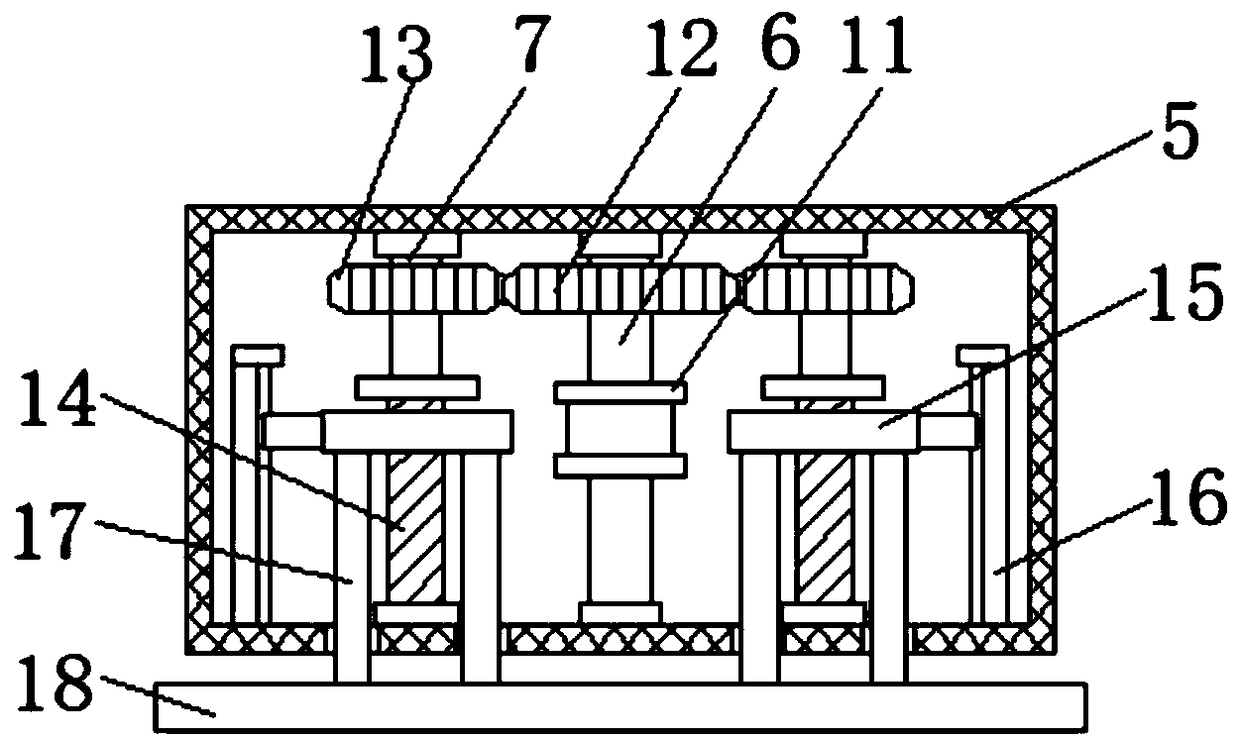

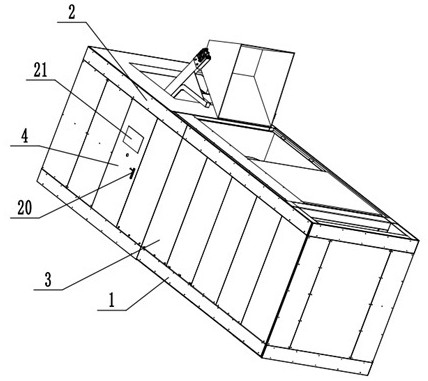

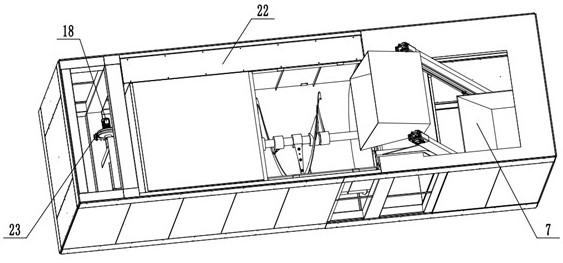

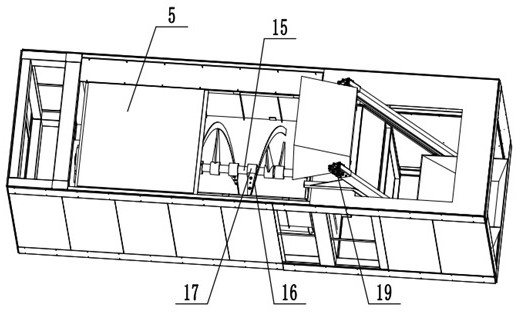

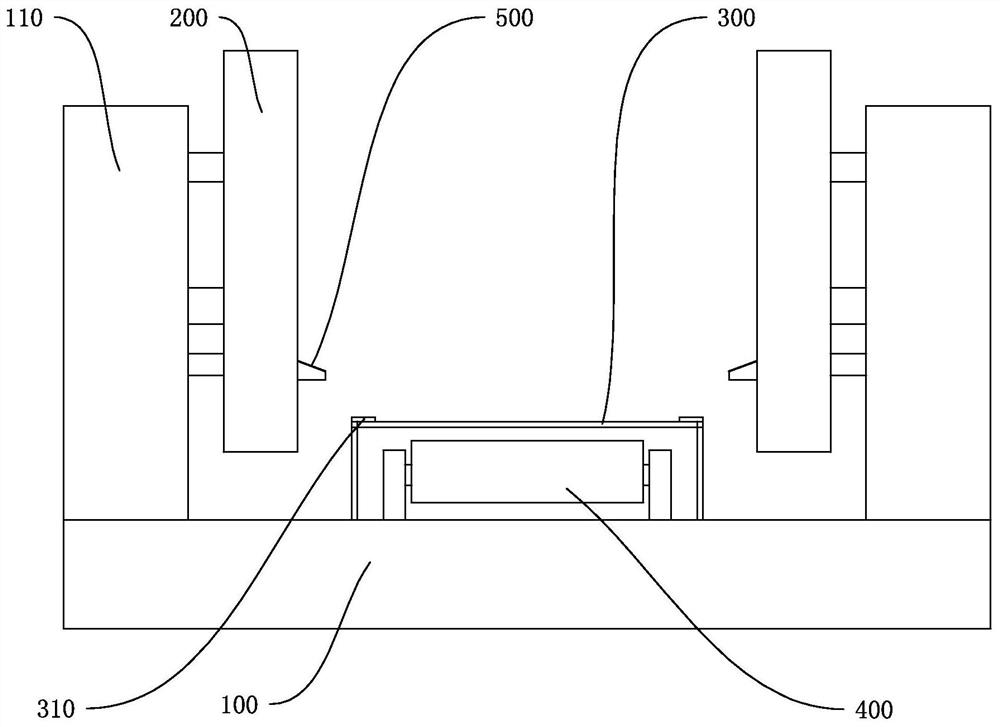

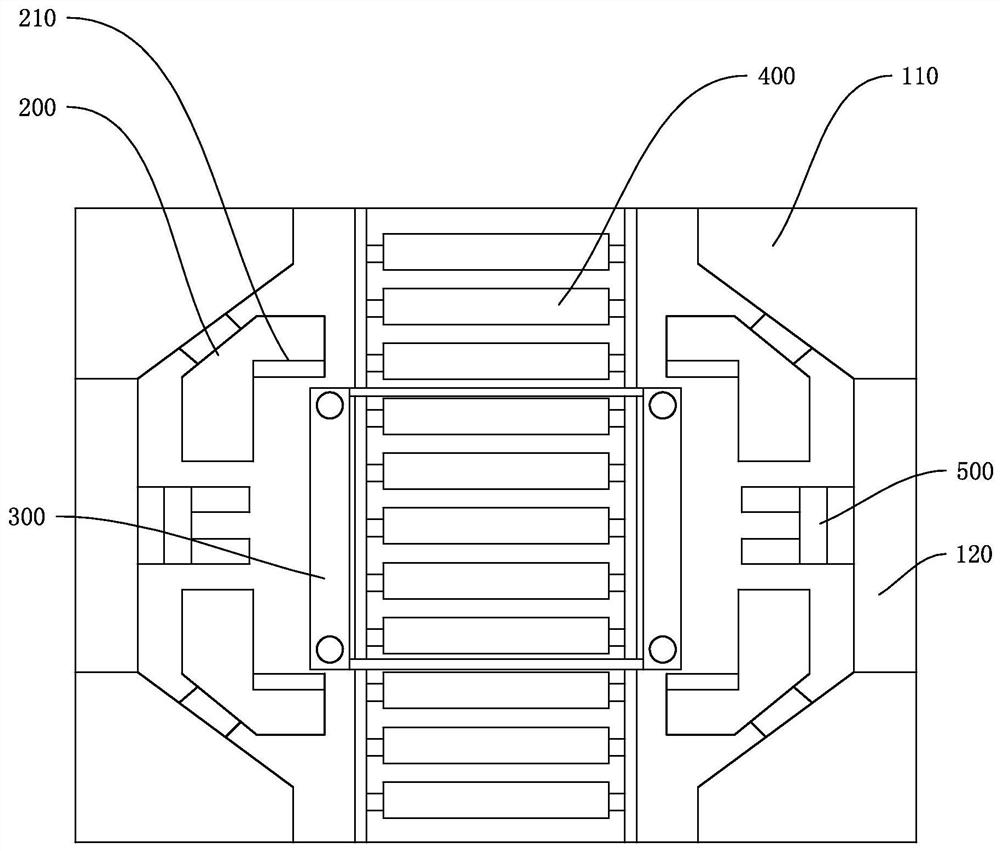

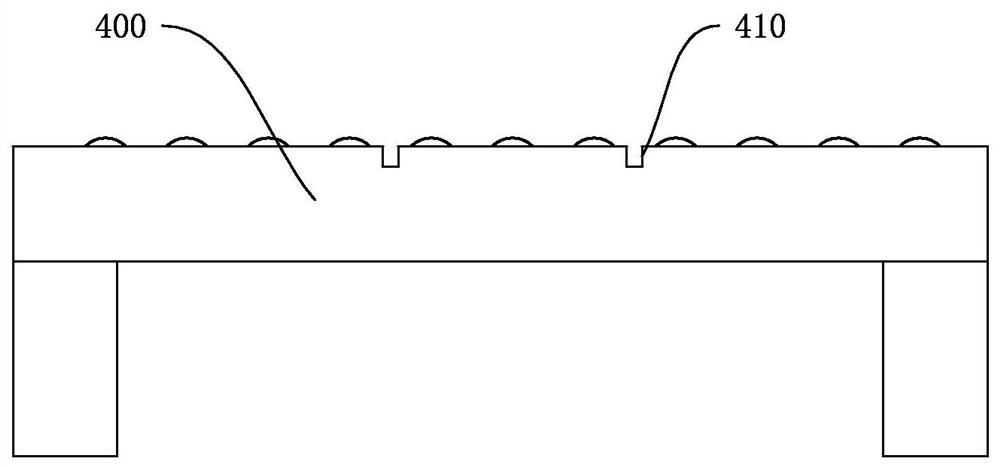

Automatic screw-driving machine

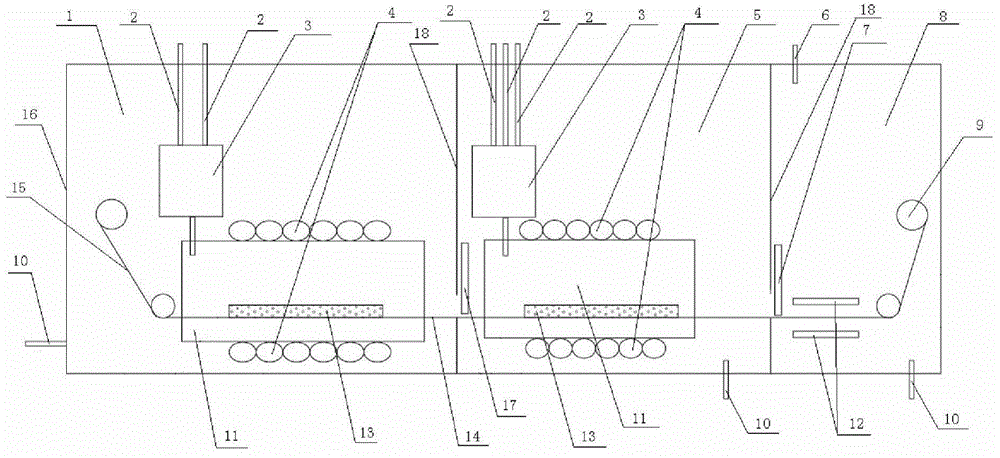

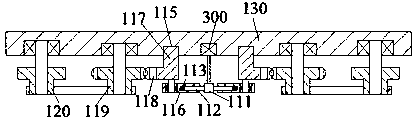

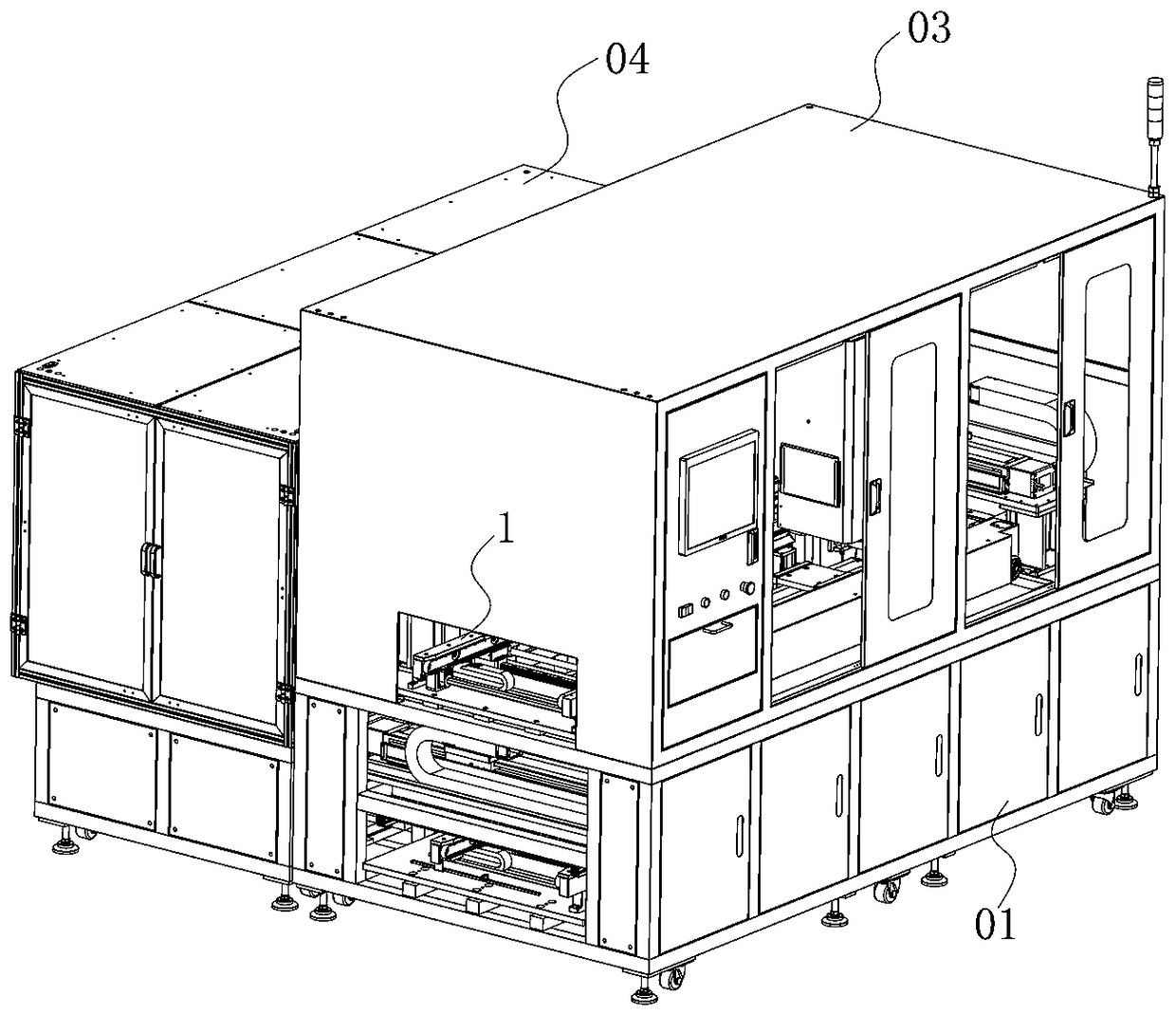

The invention discloses an automatic screw-driving machine which comprises a machine body assembly, a material guide mechanism, a material conveying mechanism, a material grabbing mechanism, a material ejecting mechanism and a screw-driving mechanism. The material guiding mechanism is arranged on a main machine frame of the machine body assembly. The material conveying mechanism is arranged on an auxiliary machine frame on one side of the main machine frame. The material grabbing mechanism is arranged between the material conveying mechanism and the material guide mechanism and conveys guide pins to the material ejecting mechanism. The guide pins are conveyed to the position below PCBs through the material ejecting mechanism. The screw-driving mechanism is arranged above the material guiding mechanism and drives screws into the guide pins. The automatic screw-driving machine is suitable for a PCB automatic machining assembly line, the functions of automatically positioning blocking materials and adjusting the sizes of the conveyed PCBs are achieved through the material guide mechanism, the automatic material feeding or blocking movement is achieved through the material conveying mechanism, the automatic conveying movement of the guide pins is achieved through the material grabbing mechanism, the automatic material ejecting movement is achieved through the material ejecting mechanism, and nuts are automatically locked on the guide pins through the screw-driving mechanism.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

Tobacco stereoscopic warehouse conveyor and conveying method thereof

InactiveCN105173500AAutomate transportationStoring evenlyStorage devicesEngineeringMechanical engineering

The invention provides a tobacco stereoscopic warehouse conveyor. The conveyor comprises a transverse conveyor, a vertical conveyor and a control center, wherein the transverse conveyor and the vertical conveyor are provided with photoelectric switches for detecting the positions of tobacco stacks; a code scanner is arranged on the inlet of the transverse conveyor, an appearance detection device is arranged on the downstream of the code scanner; the vertical conveyor is divided into a first section, a second section and a third section which are mutually independent; and the transverse conveyor, the vertical conveyor, the code scanner, the appearance detection device, a lifting device, the photoelectric switches are in electric signal control connection with a control center. The PLC control center performs the unified control, and the tobacco stacks can be automatically conveyed into a stereoscopic warehouse. The vertical conveyor is arranged in sections, independent control of each section of the conveyor is performed, the conveyor stops operating when there is no conveying task, and the energy consumption is reduced. The whole system is reasonable in structure and highly efficiently operates, and the conveying efficiency of the stereoscopic warehouse is increased.

Owner:SHANDONG QINGDAO TOBACCO

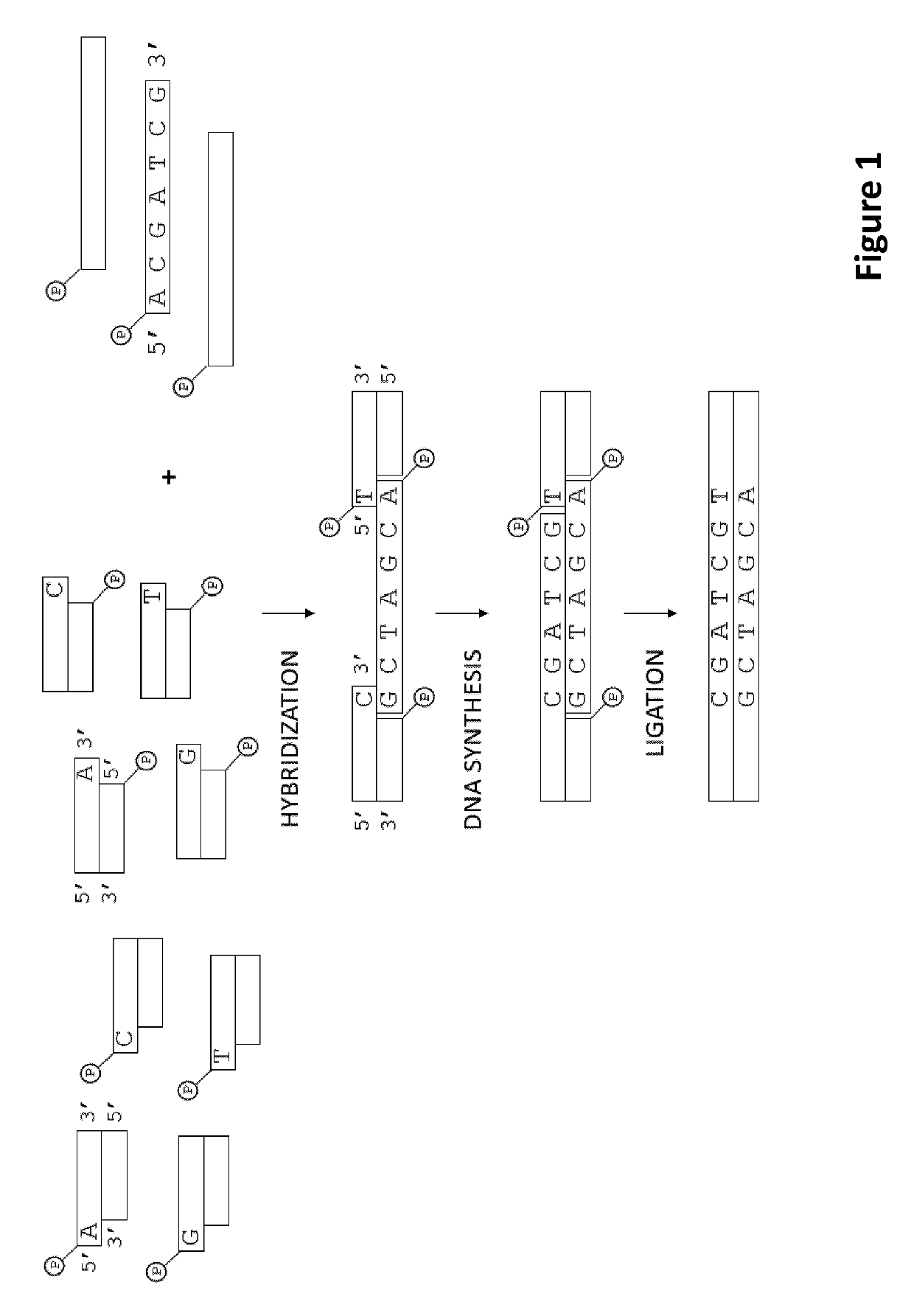

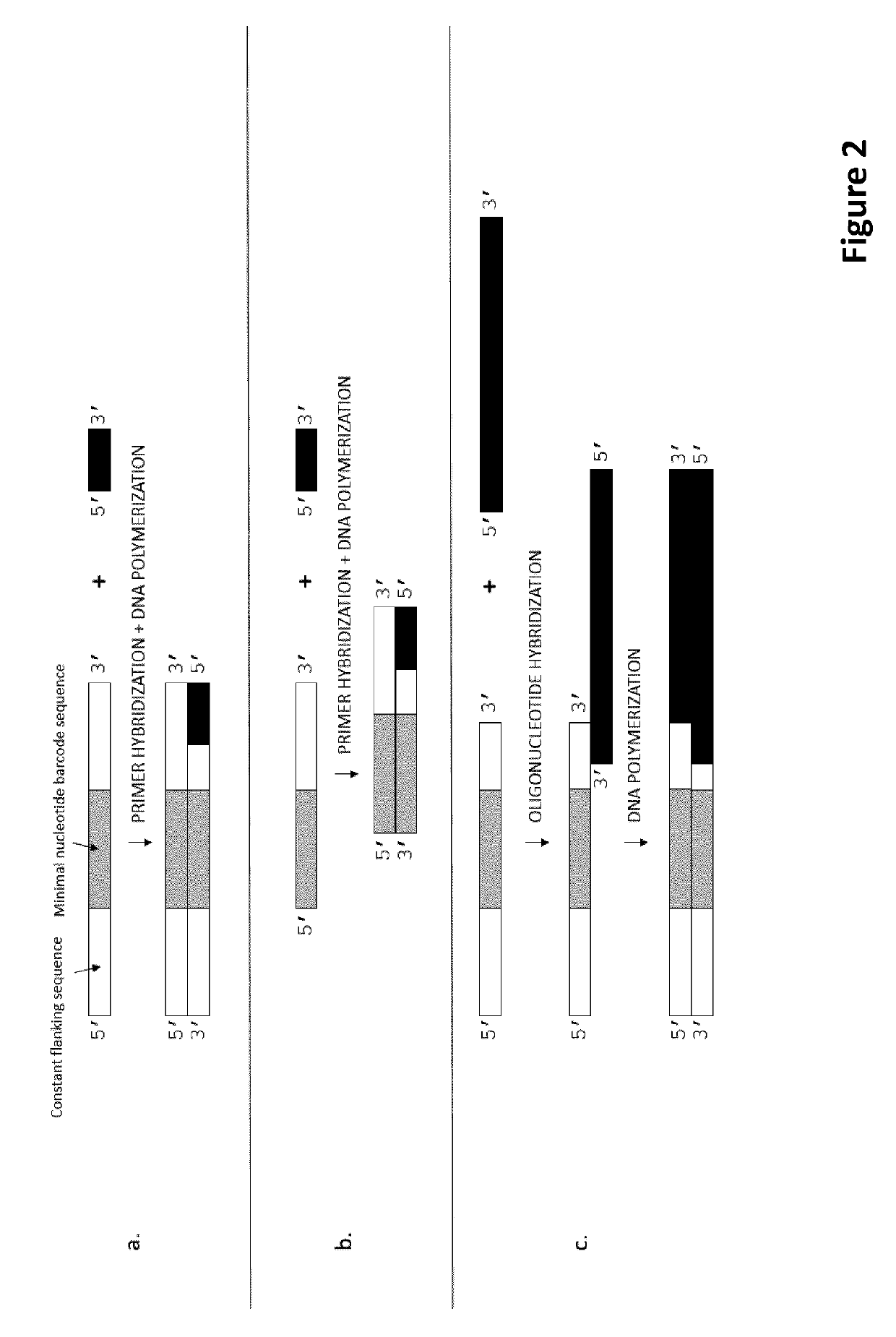

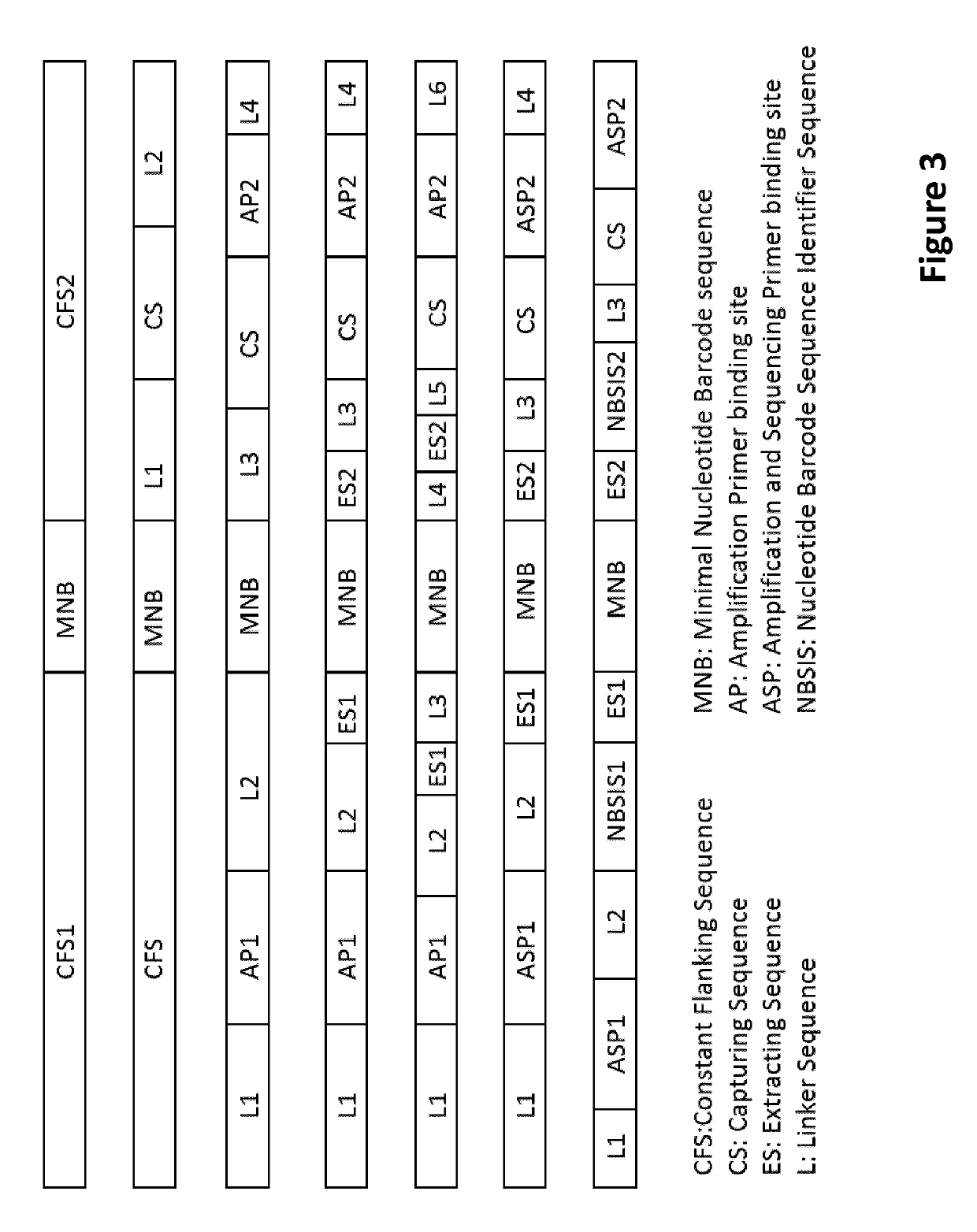

Methods for identification of samples

PendingUS20190300948A1Automate transportationCheap productionMicrobiological testing/measurementLaboratory glasswaresMolecular identificationBarcode

The present invention describes methods, carriers, and vectors relating to nucleic acids for labelling an item, wherein each carrier comprises at least 2 nucleotide barcode nucleic acids, other than sample nucleic acid, for labelling, wherein each nucleotide barcode nucleic acid comprises a different minimal nucleotide barcode sequence with a length of at least 4 nucleotides, where at least two of said different nucleotide barcode nucleic acids have a minimal nucleotide barcode sequence of the same length, wherein the combination of these different nucleotide barcode nucleic acids generates a transferable molecular identification barcode, whereby each such transferable molecular identification barcode is different for each of the carriers in the collection.

Owner:DNAME IT NV

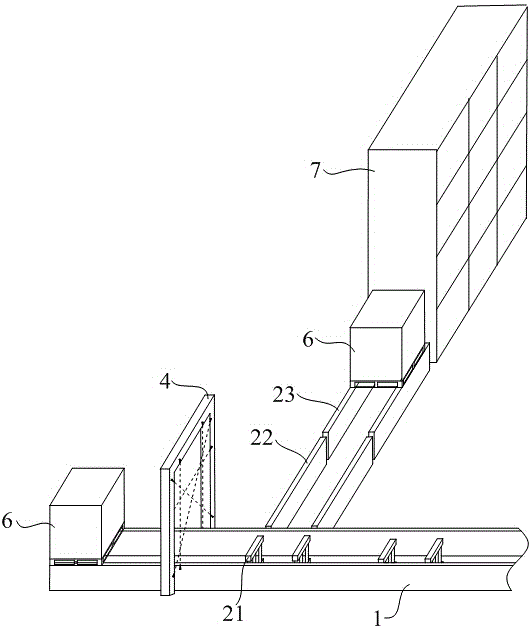

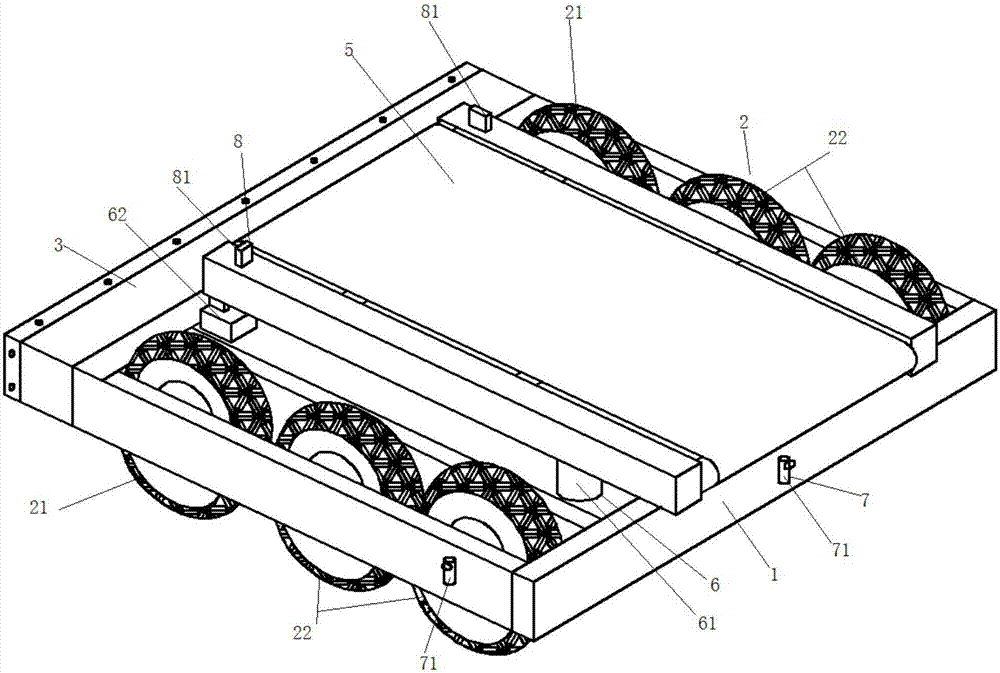

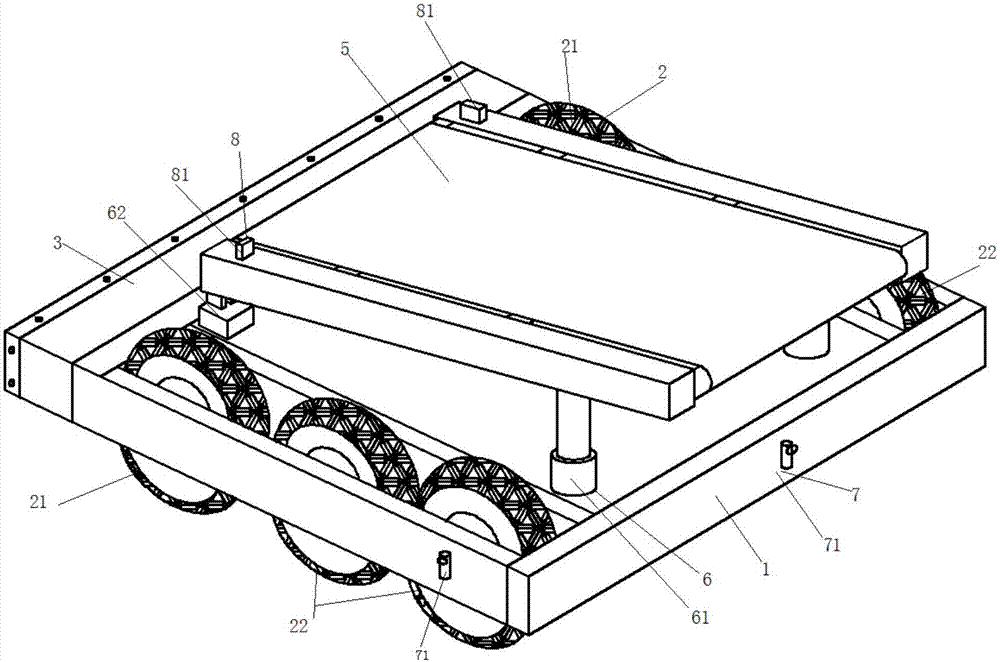

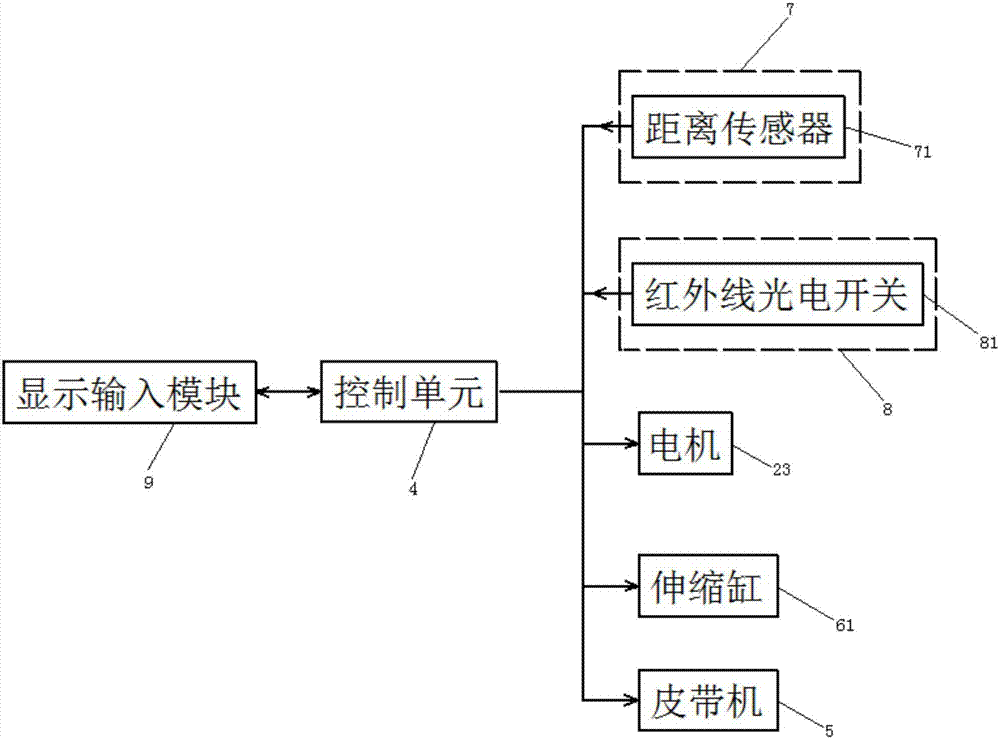

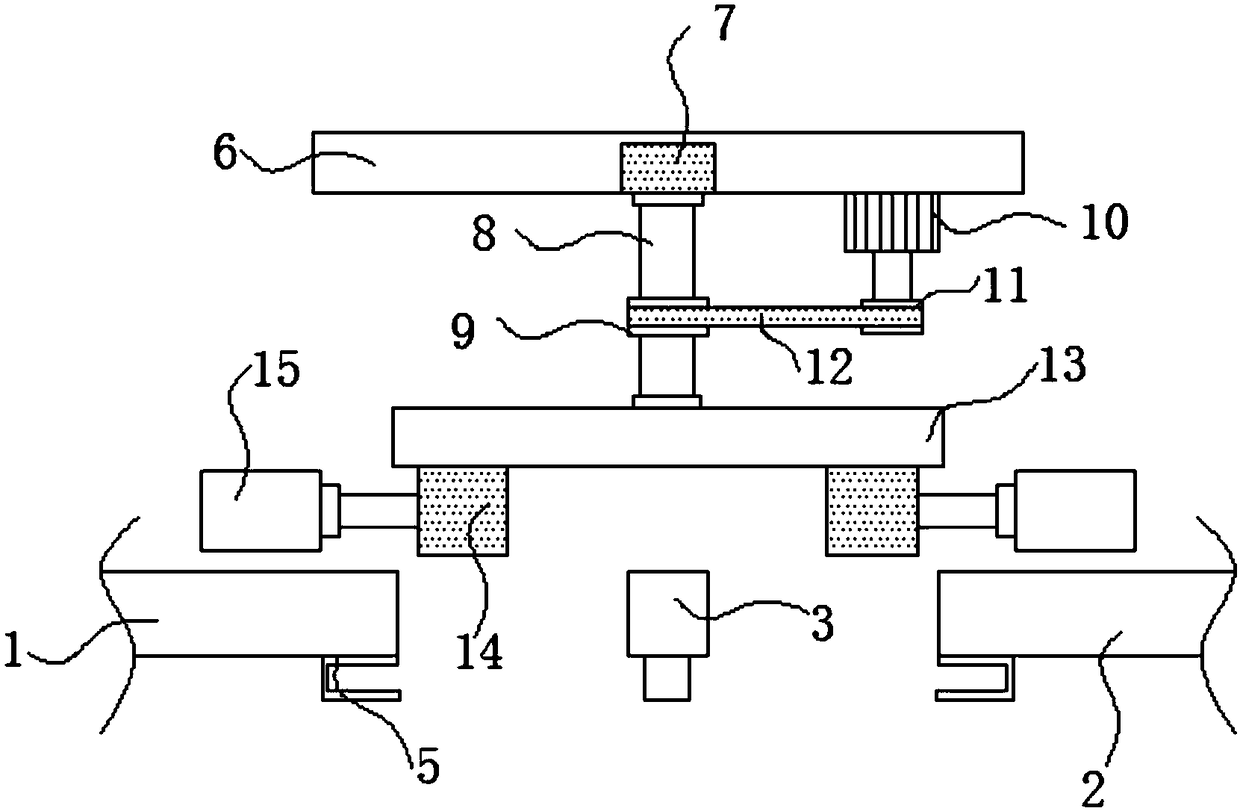

Conveying angle adjustable intelligent conveying robot

InactiveCN107364698ARealize intelligent transportationThe phenomenon of transport without manual operationConveyorsControl devices for conveyorsEngineeringWorkload

An intelligent transportation robot with adjustable transportation angle is provided. The vehicle frame is provided with a walking device in contact with the ground, and the walking device is connected with a control unit located in the box body at the left end of the vehicle frame to realize that the control unit controls the walking device to drive the vehicle frame to move. The middle part of the vehicle frame is provided with a belt conveyor in the length direction, and the belt conveyor is connected through a lifting device located below the belt conveyor to adjust the transport angle of the belt conveyor. The obstacle detection unit and the display input module mounted on the outer wall of the box are all connected with the control unit connection. In the present invention, the belt conveyor used for transporting items on the transport robot is designed as a structure with an adjustable transport angle, so that the items above the ground can be transported to the warehouse or outside the workshop through the belt conveyor and the transport robot. There is no need for manual transportation, which reduces the difficulty of the operator's work, reduces the workload of the operator, and realizes the automatic transportation of items. The structure is simple, the operation is convenient, and it has high use value.

Owner:SHAANXI LAIFU TECH DEV CO LTD

Equipment and method of continuously and rapidly preparing graphene under normal pressure

The invention relates to equipment and a method of continuously and rapidly preparing graphene under a normal pressure. The equipment comprises a box, a constant-temperature annealing cavity, a cooling growth cavity and a cooling cavity, wherein the box is separated into the constant-temperature annealing cavity, the cooling growth cavity and the cooling cavity; a gas intake tube, a gas mixing chamber and a reaction cavity are arranged in the constant-temperature annealing cavity and the cooling growth cavity respectively; the gas intake tube stretches in the gas mixing chamber; the gas mixing chamber is communicated with the reaction cavity; a cooling device is arranged in the cooling cavity; a feeding device and a cold gas tube are further arranged in the box; the feeding device penetrates through the reaction cavities and the cooling devices of the constant-temperature annealing cavity and the cooling growth cavity; the constant-temperature annealing cavity, the cooling growth cavity and the cooling cavity are provided with pressure release tubes. The method comprises the following steps: conveying a metal substrate in the constant-temperature annealing cavity and annealing at first; then conveying the metal substrate in the cooling growth cavity and reacting to grow graphene; finally conveying graphene in the cooling cavity and cooling. The equipment and method have the beneficial effects that preparation cycle is short, the equipment is simple in structure and convenient in operation, production efficiency is increased, and high economic benefits are achieved.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI +1

Small-sized soaking etching machine for laboratory

The invention relates to a small-sized soaking etching machine for a laboratory. The small-sized soaking etching machine comprises a rack body, wherein a conveying table board is arranged on the rack body; a plurality of conveying rollers are arranged on the conveying table board; the rack body includes a spraying soaking part and a washing spraying part; a soaking pool is arranged at the conveying rollers of the spraying soaking part; a slot for allowing a workpiece to enter is respectively formed in each of two end parts of the soaking pool; a baffle plate capable of rising and falling and sealing each slot is arranged at the outer side of the corresponding slot; a corrosive liquid spraying pipeline is arranged at the upper side of the spraying soaking part; and a washing spraying pipeline is arranged at the upper side of the washing spraying part. By the adoption of the abovementioned structure, automatic transportation can be realized, and spraying and soaking are combined; and the small-sized soaking etching machine is small in size, and is suitable for laboratory use, and occurrence of a phenomenon of corroding an operator is prevented.

Owner:SUZHOU WAYTHTEC ELECTRONICS TECH

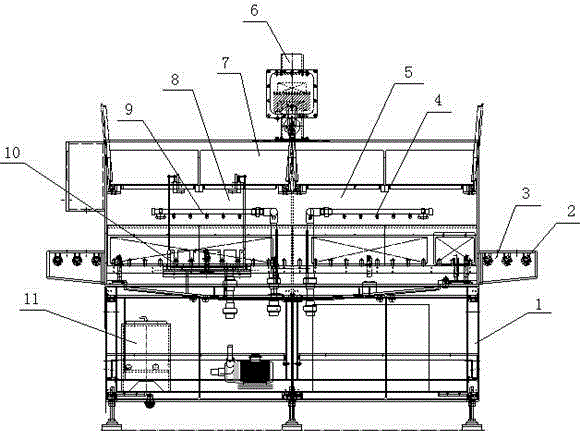

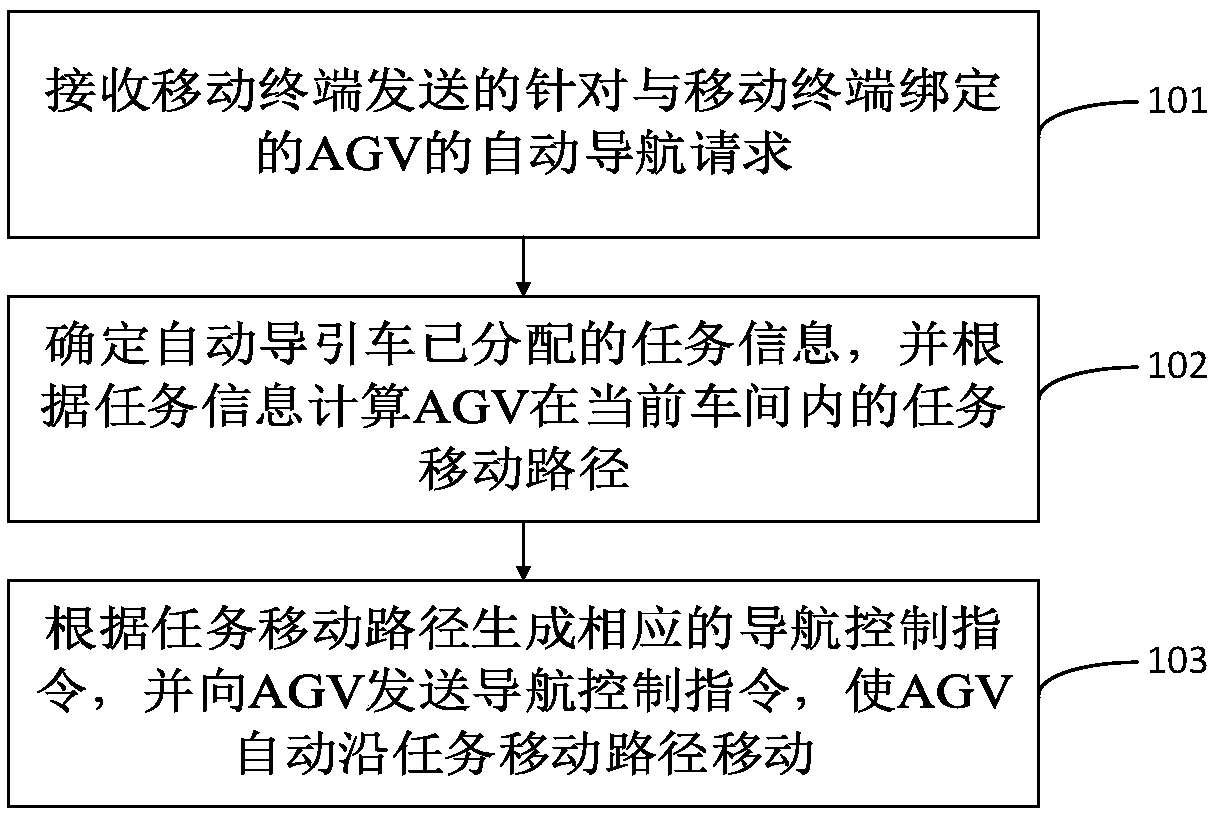

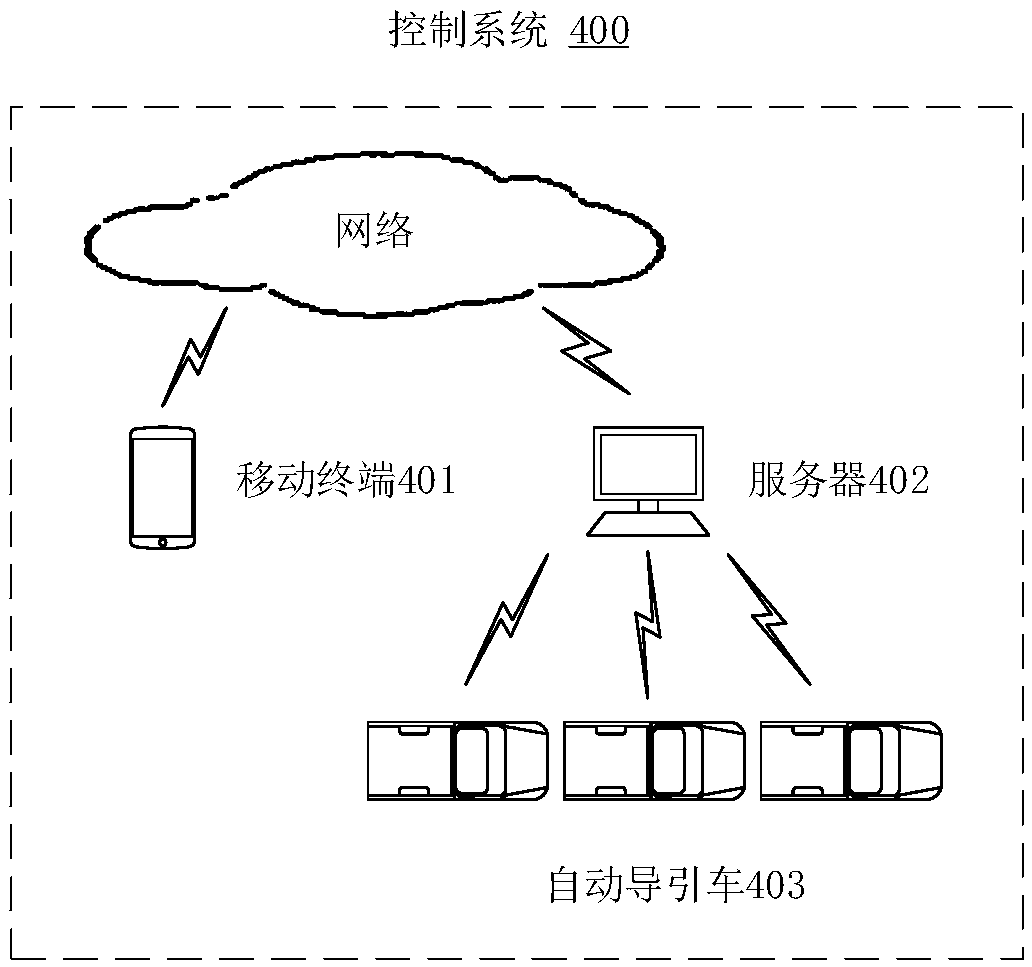

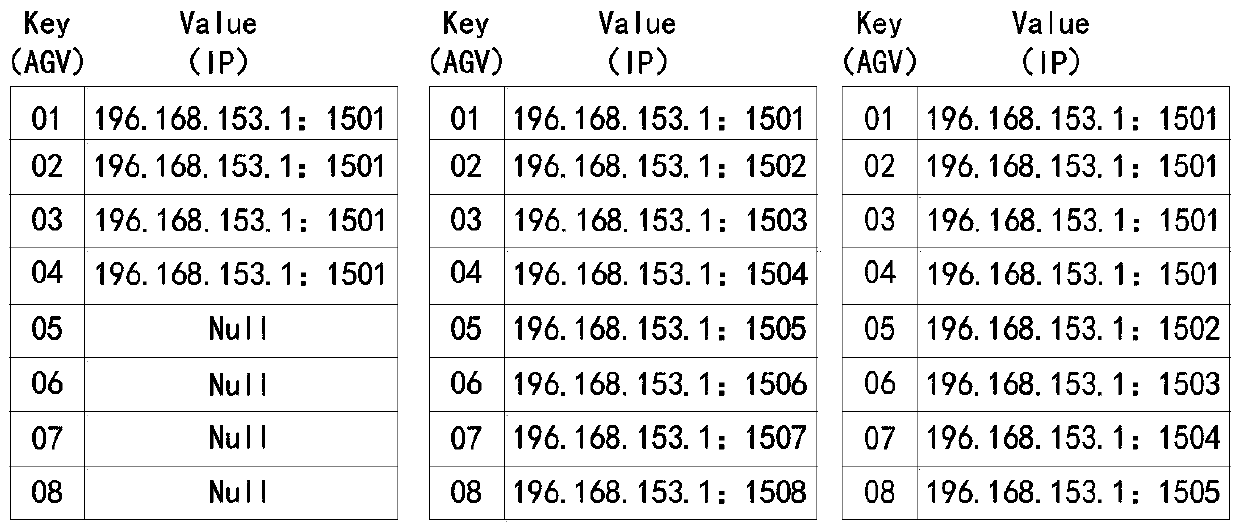

Method, device, and system for controlling automated guided vehicle

InactiveCN109612480AAutomate transportationObvious and understandable technical solutionInstruments for road network navigationPath generationAutomated guided vehicle

The invention discloses a method, a device, and a system for controlling an automated guided vehicle. The method is applied to a server. The server is separately in communication connection with a mobile terminal and the automated guided vehicle. The method comprises: receiving an automatic navigation request sent by the mobile terminal for the automated guided vehicle bound with the mobile terminal; determining the assigned task information of the automated guided vehicle, and calculating a task movement path of the automated guided vehicle in the current workshop according to the task information, wherein the task information comprises a starting task node and a terminating task node of the automated guided vehicle; and generating a corresponding navigation control instruction accordingto the task movement path, and sending the navigation control instruction to the automated guided vehicle, so that the automated guided vehicle automatically moves from the starting task node to the terminating task node according to the navigation control instruction. According to the method, the server performs path planning and navigation on the task assigned by the mobile terminal to the automated guided vehicle, so that the automated guided vehicle can perform automatic transportation according to the control of the mobile terminal.

Owner:HUBEI UNIV OF ARTS & SCI +1

An automatic medical logistics carrying system and a control method thereof

InactiveCN109685441AWill not affect normal orderImprove management levelLogisticsLogistics managementAutomatic control

The invention discloses an automatic medical logistics carrying system and a control method thereof. the system comprises a carrying robot which is used for carrying materials, and is provided with awireless communication module; The receiving and dispatching station is used for receiving and dispatching materials; The robot automatic control longitudinal conveying device is a conveying device which is arranged in a hospital building and is not loaded with non-medical staff, and is used for conveying the carrying robot to different floors; The horizontal logistics channel special for the robot is arranged in the top space of at least one floor of a hospital building; And the control center communicates with the carrying robot and is used for controlling the system. The horizontal logistics channel special for the robot is arranged in the top space of the storey of the hospital building, so that the carrying robot can walk; The medical material transportation efficiency is effectivelyimproved, time is won for medical work, the occupied space is small, the normal order of a hospital is not affected, and the management level and the modernization level of the hospital are effectively improved.

Owner:江苏振邦医用智能装备有限公司

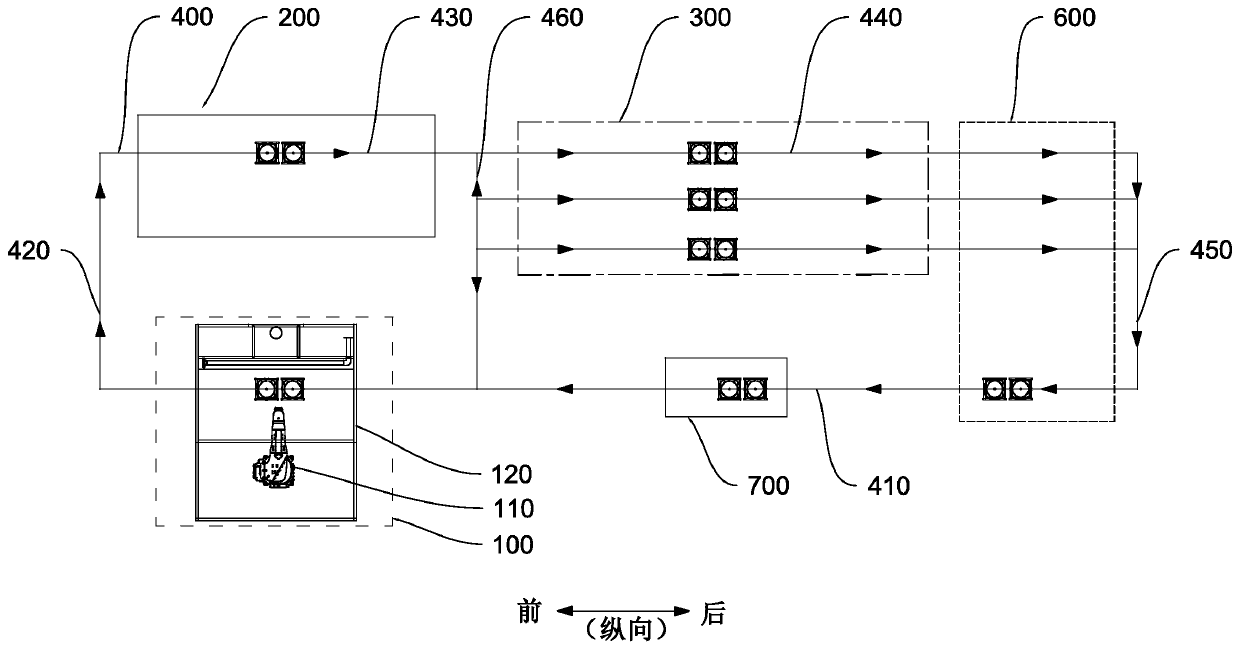

Intelligent spraying production system

PendingCN110665723AIncrease productivityRealize automatic spraying productionPretreated surfacesCoatingsProcess engineeringIndustrial engineering

The invention discloses an intelligent spraying production system. The intelligent spraying production system comprises a leveling area, a drying furnace, a paint spraying area, circulating transmission lines and a control module. The drying furnace is arranged adjacent to the leveling area. The paint spraying area comprises a spraying assembly used for automatically spraying a jig and a workpiece. The circulating transmission lines comprise a feeding conveying line, a second automatic conveying line, a leveling line, a drying line and a third automatic conveying line, wherein the feeding conveying line, the second automatic conveying line, the leveling line, the drying line and the third automatic conveying line are sequentially connected end to end. The feeding conveying line passes through the paint spraying area, the leveling line passes through the leveling area, and the drying line passes through the drying furnace. The circulating transmission lines further comprise a first automatic conveying line located between the leveling line and the drying line. The control module is electrically connected with the first automatic conveying line and is used for controlling the first automatic conveying line to select to transfer the workpiece and the jig from the leveling line to the feeding conveying line or the drying line. According to the technical scheme of the intelligent spraying production system, automatic spraying production can be achieved, the working efficiency is improved, and the intelligent spraying production system can be suitable for a plurality of productsand spraying processes.

Owner:东莞市深川工业设备有限公司

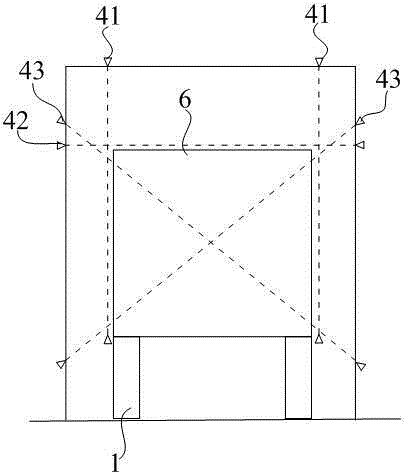

Stacking plate warehouse and automatic conveying system with same

ActiveCN111674941AImprove stacking capacitySolve the inconvenience of dischargingDe-stacking articlesStructural engineeringMechanical engineering

The invention discloses a stacking plate warehouse and an automatic conveying system with the same. The stacking plate warehouse comprises a rack, a lifting frame and a clamping assembly, wherein stacking piles are arranged at four corners of the rack, telescopic clamping pieces are arranged on one sides, facing the central axis of the rack, of the stacking piles, L-shaped groove faces are vertically arranged on the clamping pieces, and a cuboid stacking space is formed by the L-shaped groove faces at the four corners of the rack; the lifting frame is arranged at the bottom of the rack; the clamping assembly comprises two clamping pieces which are arranged on two sides of the rack respectively and a first driving mechanism connected with and drives the clamping pieces to move transversely.The problem of inconvenient discharging at the top is solved, the stacking capacity of stacking plates is incrased, stacked piles are adjusted in order by the clamping pieces and are convenient to arrange, and one-by-one orderly discharging is achieved.

Owner:珠海市长陆工业自动控制系统股份有限公司

Sorting system

PendingCN111842174ASmall pitchSave transportation resourcesConveyorsPackagingControl systemControl engineering

The invention discloses a sorting system. The sorting system comprises a conveying mechanism and a control system. The conveying mechanism comprises a rack, two rollers, a chain and multiple trolleys,wherein the two rollers are arranged on the rack at intervals in the first horizontal direction, the chain is wound on the two rollers, and the multiple trolleys are connected to the chain and sequentially arranged in the first horizontal direction; and each trolley comprises a trolley body and a sorting and conveying mechanism arranged on the trolley body, the bottom of each trolley body is connected to the chain, and the sorting and conveying mechanisms are configured to bear and convey packages in the second horizontal direction perpendicular to the first horizontal direction. The controlsystem comprises a controller connected to the conveying mechanism, and the controller is configured to control the conveying mechanism to convey the packages in the first horizontal direction and isconfigured to independently control the sorting and conveying mechanisms of the trolleys to convey the packages in the second horizontal direction. According to the sorting system, the pitch of the trolleys can be reduced, transportation resources are saved, and parcels can be thrown more accurately and adjusted in position.

Owner:BEIJING JINGDONG QIANSHITECHNOLOGY CO LTD

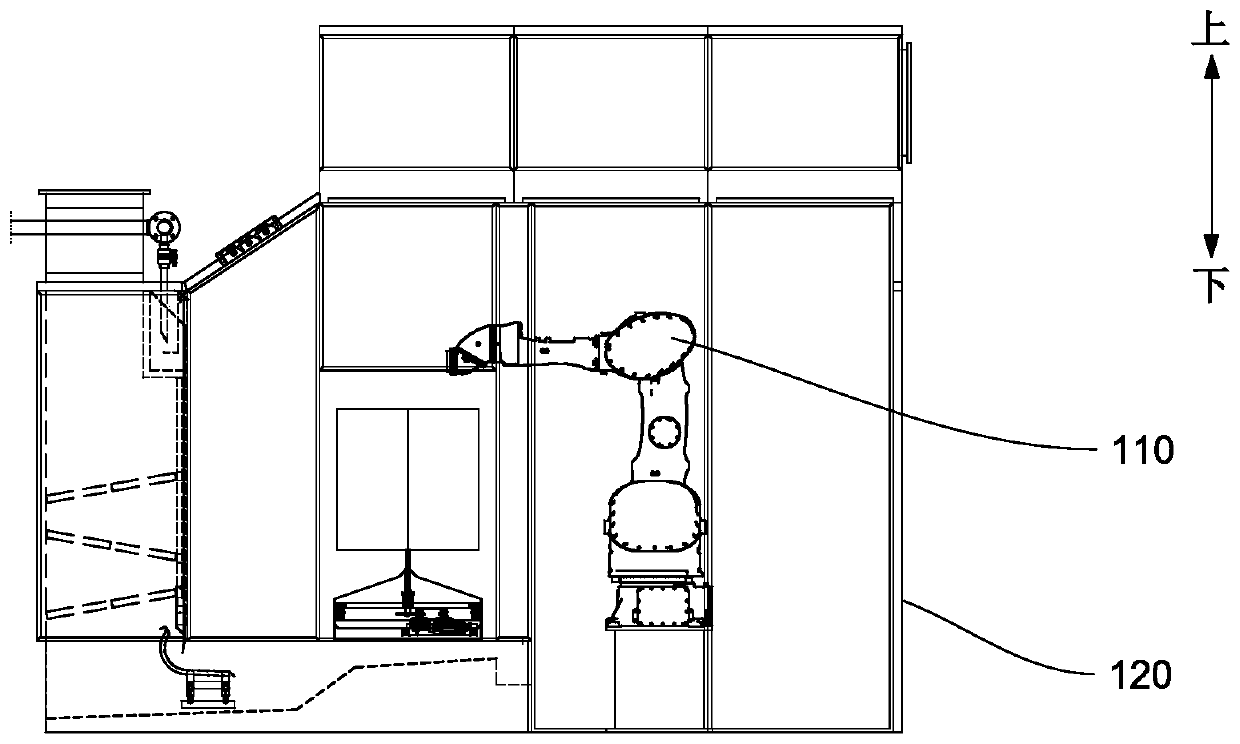

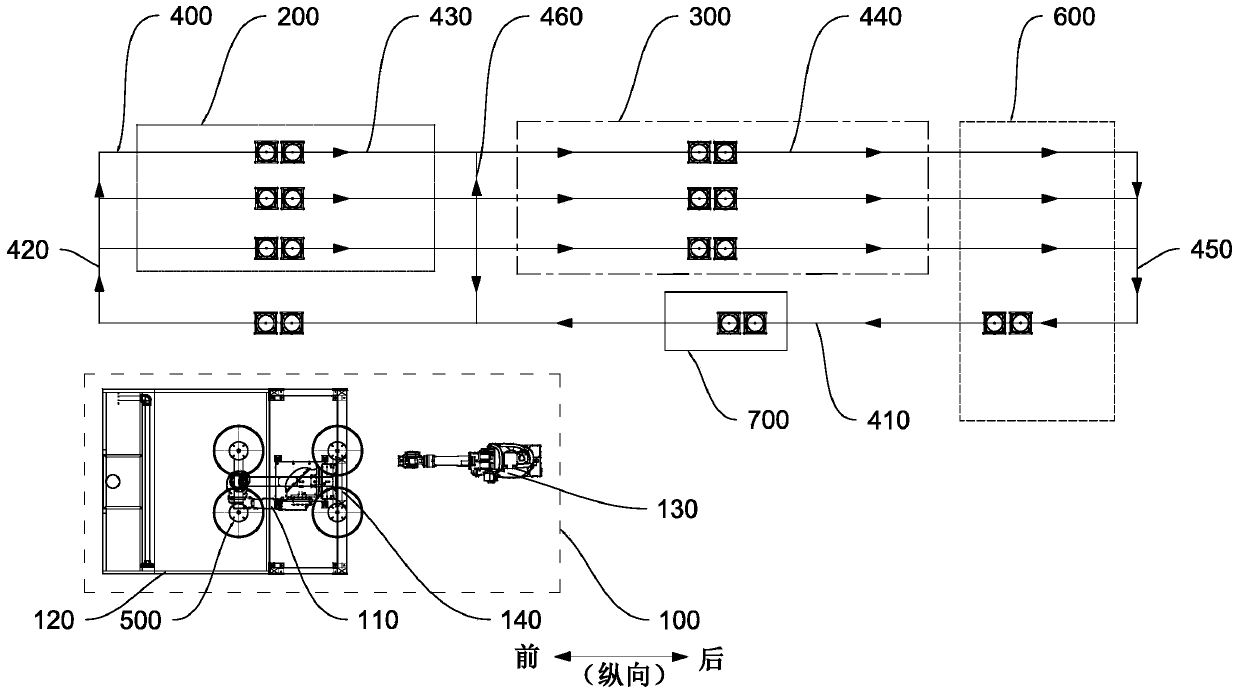

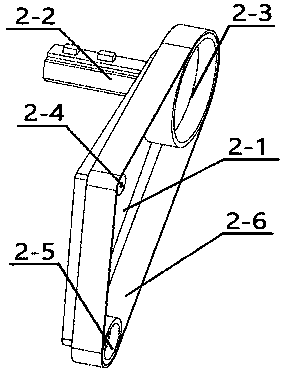

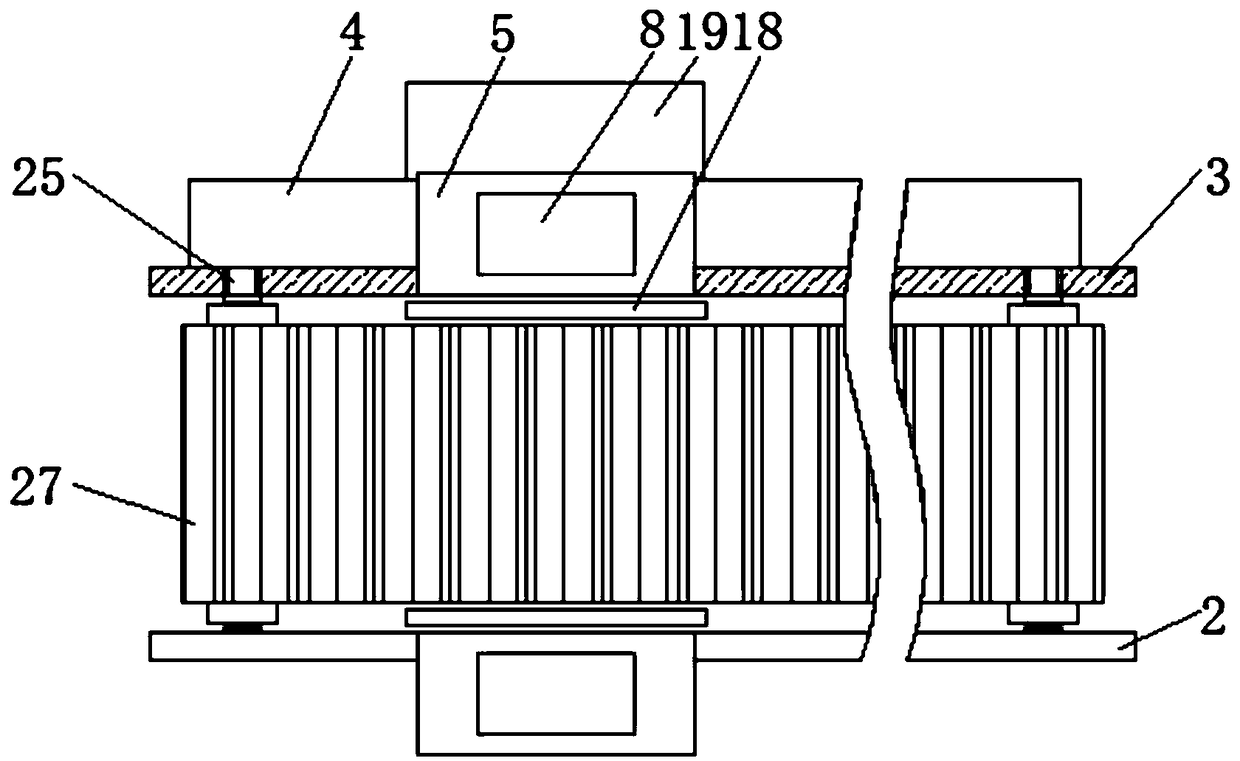

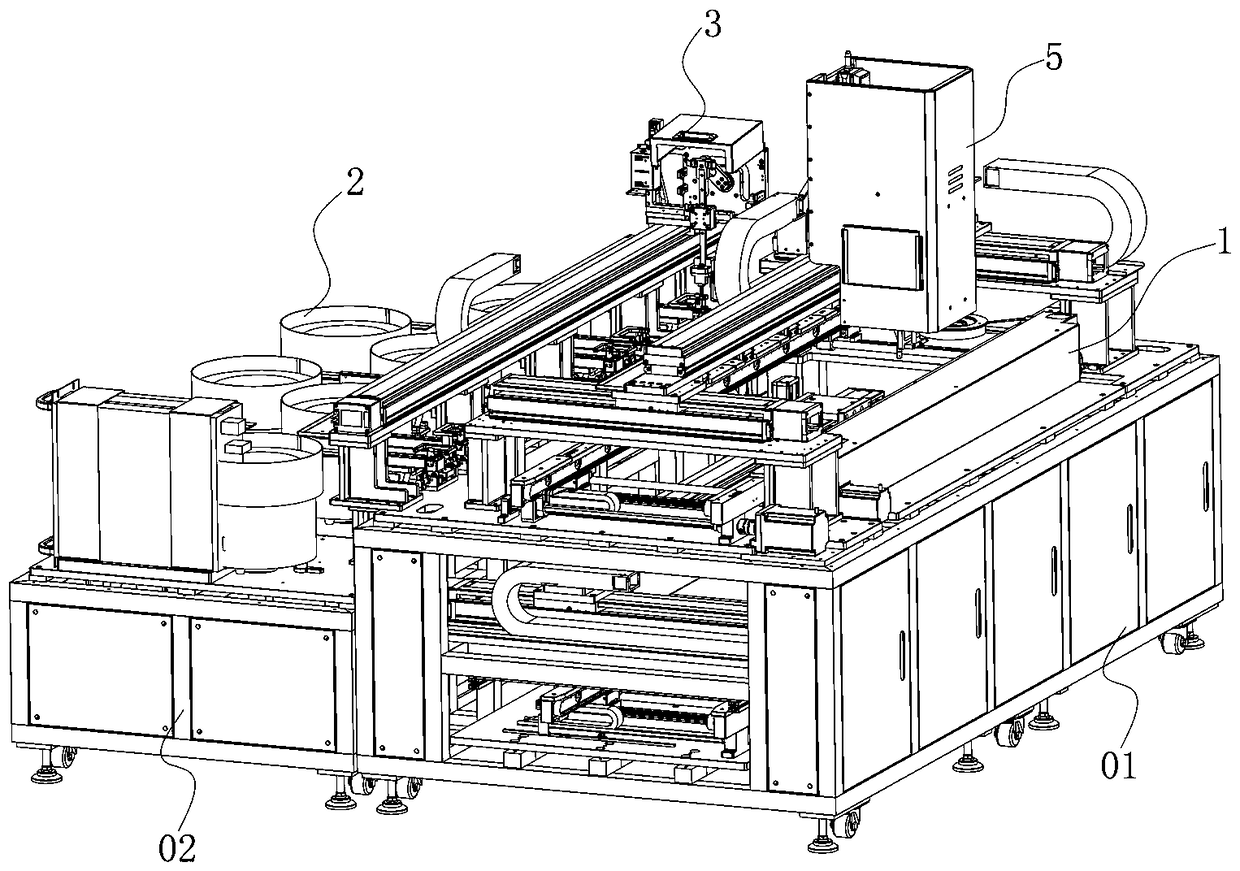

Special steel rod surface defect local polishing robot system

InactiveCN110587435AAutomate transportationMeet transportationGrinding carriagesGrinding drivesRobotic systemsEngineering

The invention discloses a special steel rod surface defect local polishing robot system. The system comprises a right-angled coordinate robot (1), a polishing device (2), an industrial camera (3), a rod transmission device (4) and a rod jacking and rotating device (5). The right-angled coordinate robot is connected with the polishing device to provide a platform for polishing; the rod jacking androtating device can guarantee the polishing stability and reliability; the rod transmission device can realize automatic transportation; and through the number change of the rod transmission device and the rod jacking and rotating device, the transportation and the rotation of special steel rods with different specifications can be met without consuming a lot of manpower, material resources and financial resources, and the online polishing operation of the special steel rod surface defect local polishing robot system is met.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

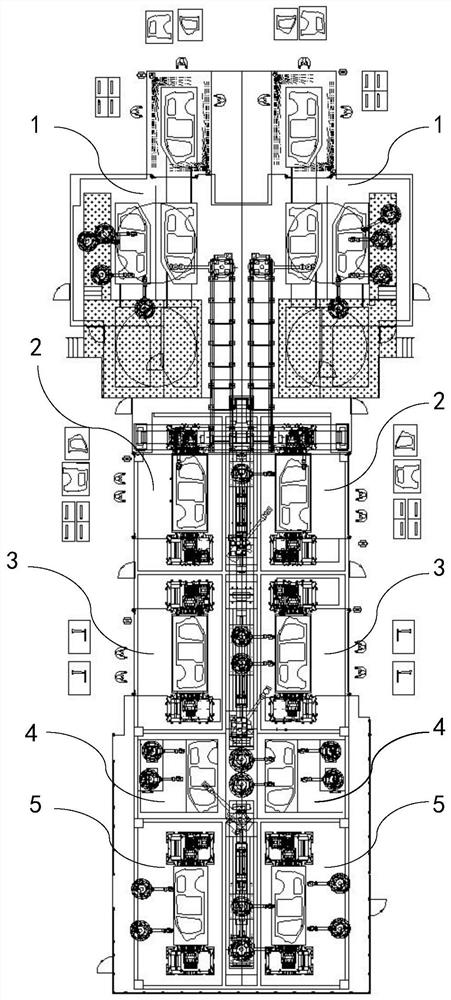

Side wall welding flexible production line

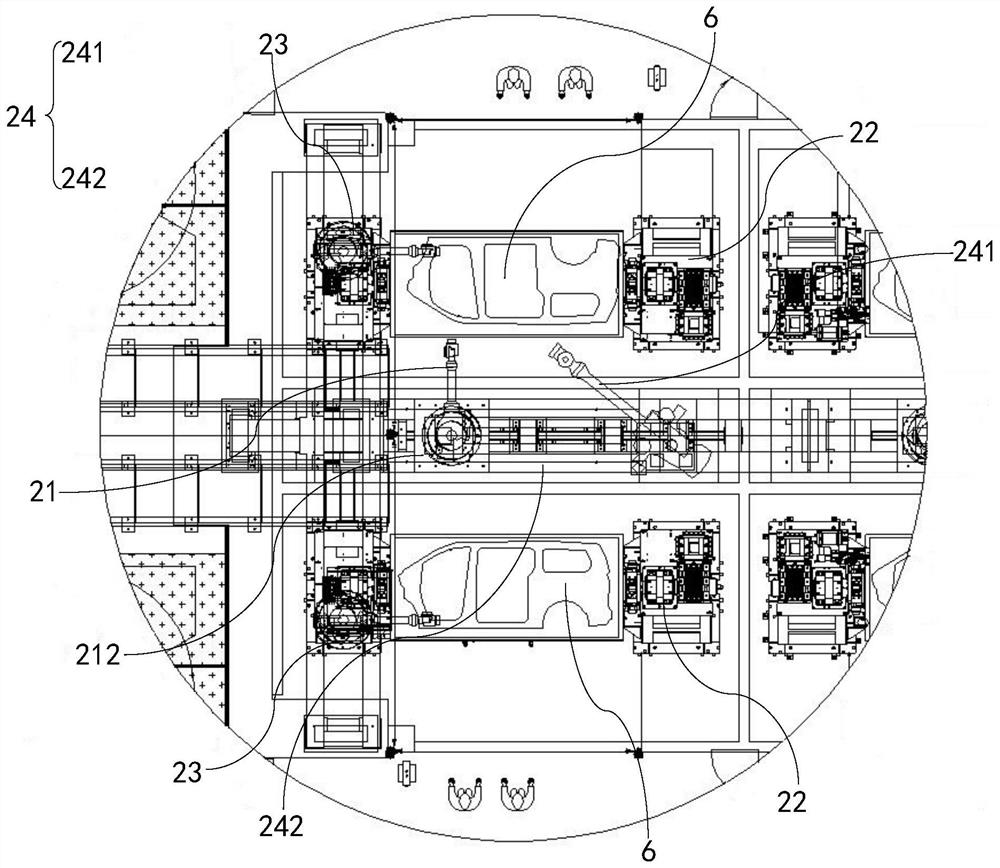

ActiveCN111774746AReasonable space layoutImprove applicabilityWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringWeld line

The invention relates to the technical field of vehicle production and manufacturing, and discloses a side wall welding flexible production line. The side wall welding flexible production line comprises two welding line bodies used for welding a vehicle left side wall assembly and a vehicle right side wall assembly, the two welding line bodies are symmetrically arranged, each welding line body comprises a first side wall outer plate assembly welding station, a second side wall outer plate assembly welding station, a side wall assembly welding station, a first side wall assembly repair weldingstation and a second side wall assembly repair welding station which are sequentially arranged, and the side wall outer plate assembly or the side wall assembly is conveyed between two adjacent welding stations through a corresponding conveying device. The side wall welding production line can solve the problems that in the prior art, a side wall welding production line is poor in flexibility andlow in conveying efficiency, a side wall assembly is difficult to carry in the welding process, and the appearance of the side wall assembly is prone to being scratched.

Owner:DONGFENG LIUZHOU MOTOR

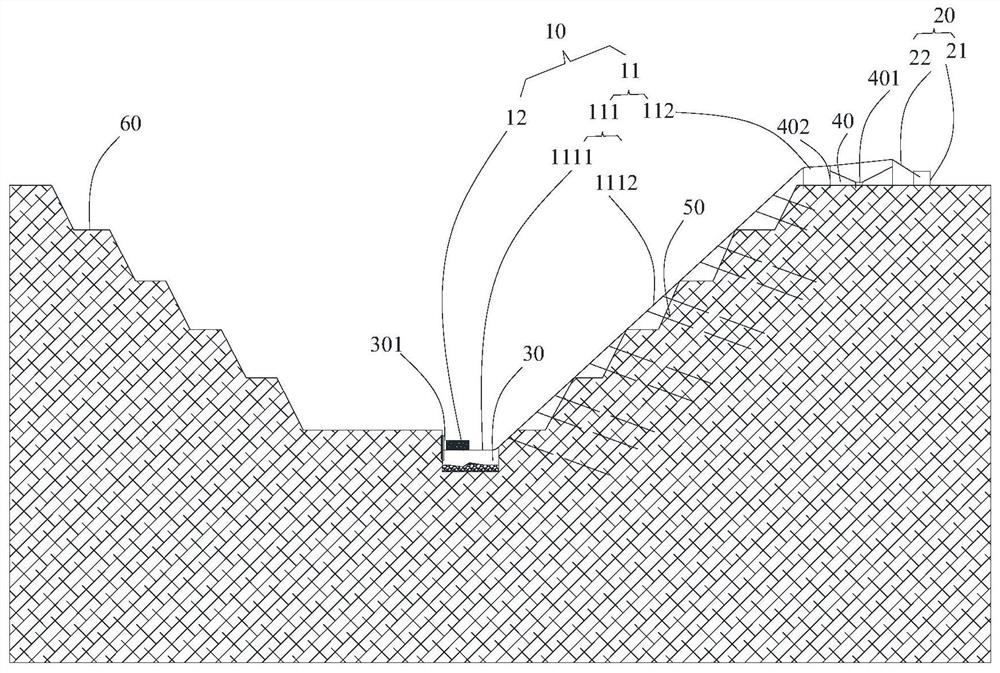

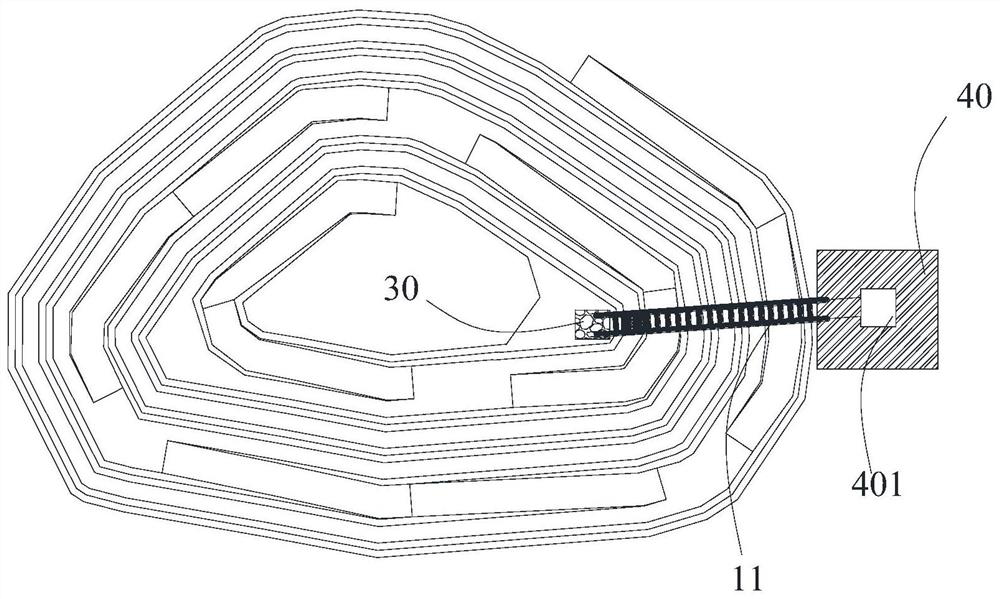

Transportation system and transportation method for open-pit mining of ore rocks

PendingCN113738372AAutomate transportationImprove transportation efficiencyOpen-pit miningOpen-pit miningTransit system

Owner:CHINA MINMETALS CHANGSHA MINING RES INST +1

Board cleaning device in building field

InactiveCN112775086AReduce investmentEasy to flow awayCleaning using toolsCleaning using liquidsArchitectural engineeringWater flow

The invention relates to the field of building board processing, in particular to a board cleaning device in the building field. The board cleaning device comprises a feeding mechanism, a liquid conveying mechanism, a soaking assembly, a rolling mechanism and three sets of cleaning assemblies, the feeding mechanism is vertically arranged, and the soaking assembly comprises a moving mechanism, a stabilizing mechanism and a shifting mechanism; the rolling mechanism is arranged on the side, away from the liquid conveying mechanism, of the soaking assembly, each set of cleaning assembly comprises a rolling brush mechanism, a lifting mechanism and a spraying mechanism, and through cooperative operation of the feeding mechanism and a driving mechanism, automatic conveying is achieved, and input of the labor amount is reduced; through the arrangement of the soaking assembly, boards are soaked firstly, so that the fitting degree of dust and impurities on the surfaces of the boards and the boards is reduced, follow-up cleaning is facilitated, the height between the rolling brush mechanism and the boards can be adjusted through the lifting mechanism, and therefore the board cleaning device adapts to cleaning of the plates of different sizes; and the spraying mechanism sprays when the rolling brush mechanism performs rolling brushing, and washed impurities can conveniently flow away through sprayed water flow.

Owner:冯祥

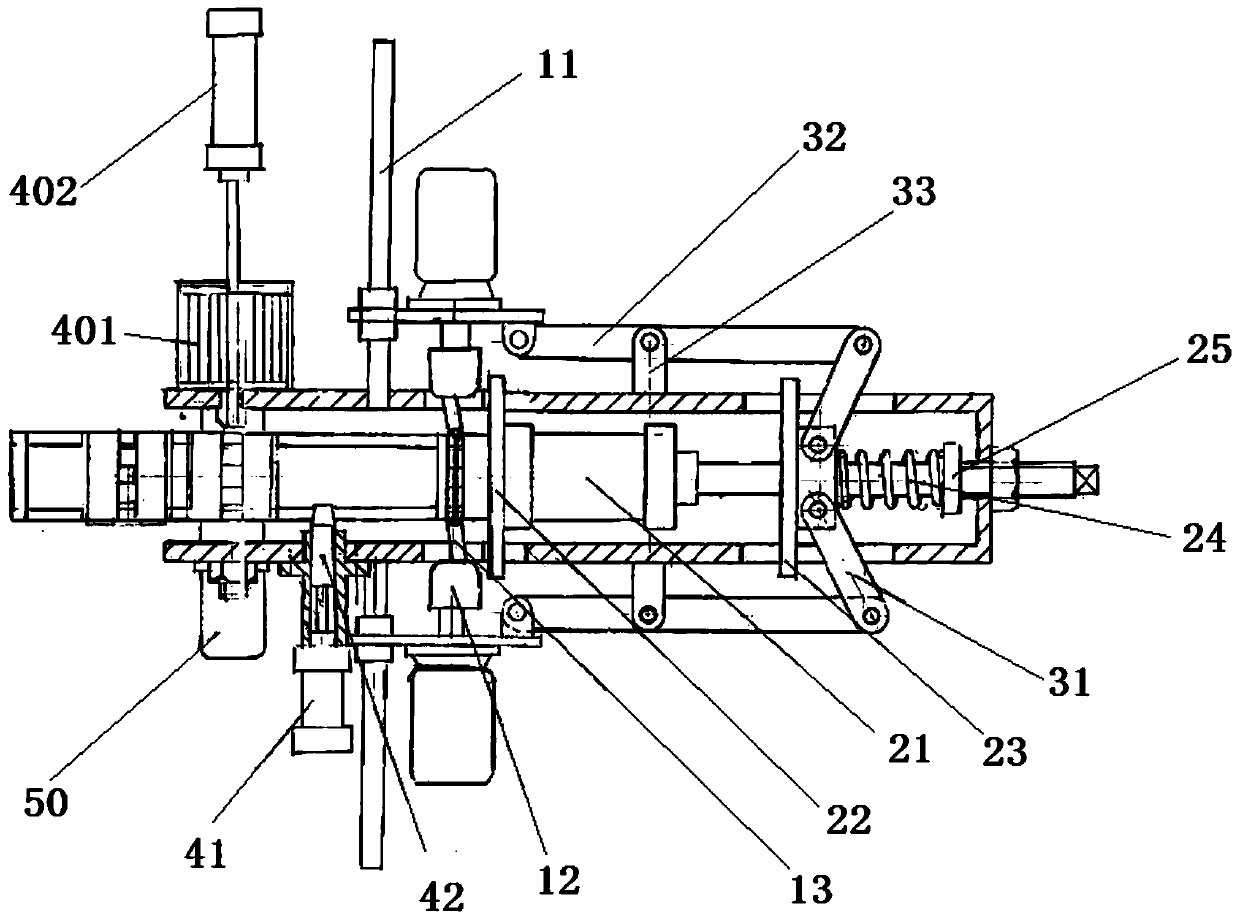

Hinge assembling equipment

PendingCN110421347APrecise positioningEasy to installAssembly machinesMetal working apparatusEngineeringMechanical engineering

The invention provides hinge assembling equipment. The equipment comprises a control mechanism, a hinge bearing assembling mechanism, a hinge shaft assembling mechanism and a hinge assembling mechanism; the hinge assembling mechanism comprises a wheel type hinge feeding device and a hinge grinding riveting mechanism; and the wheel type hinge feeding device comprises a plurality of hinge positioning mechanisms and a wheel type feeding device. According to the hinge assembling equipment, the technical problems that traditional large-batch hinge assembling equipment is large in occupied space, complex in structure and not prone to install and maintain are solved.

Owner:TIANJIN BOLIXIN HARDWARE PROD

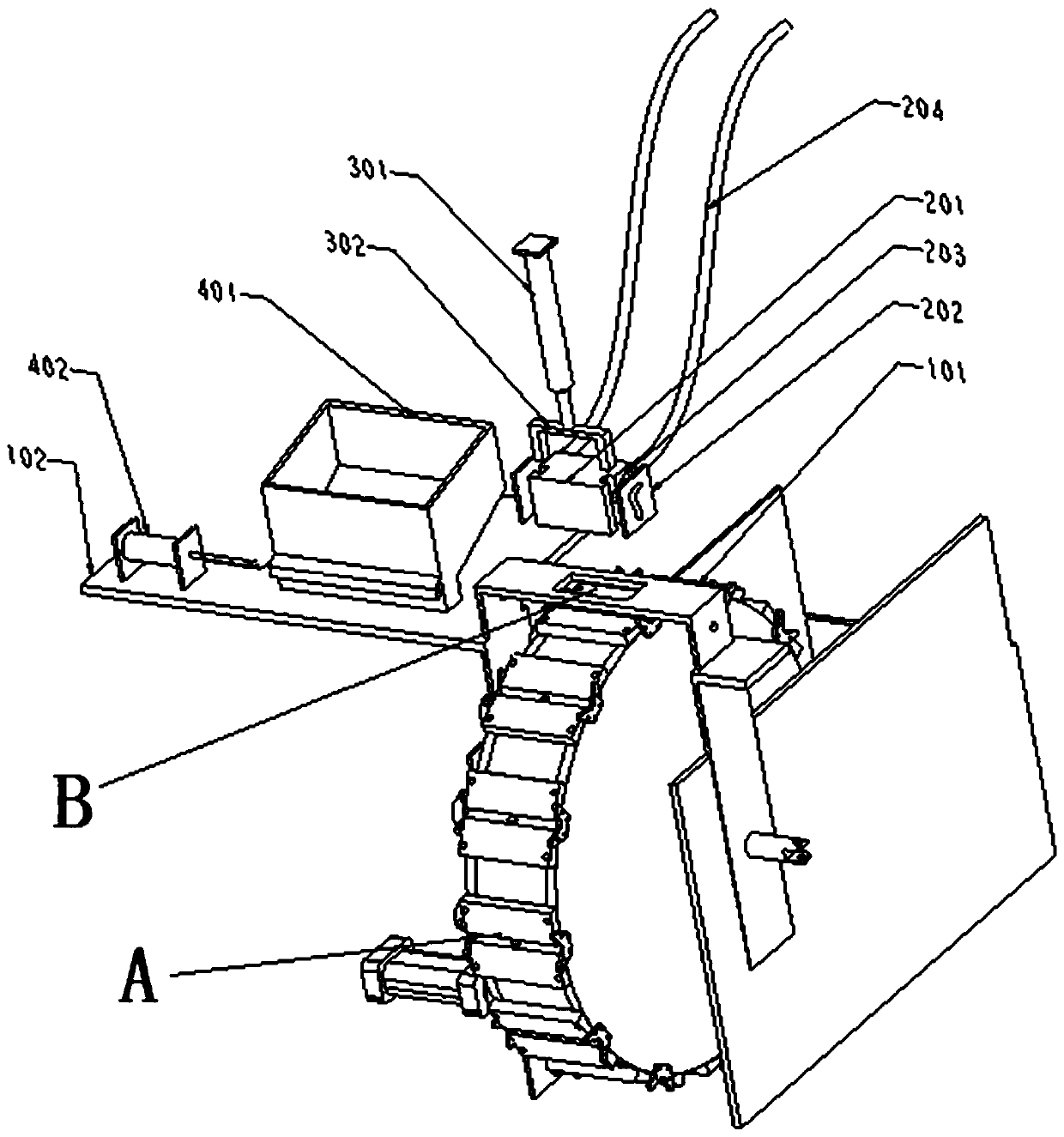

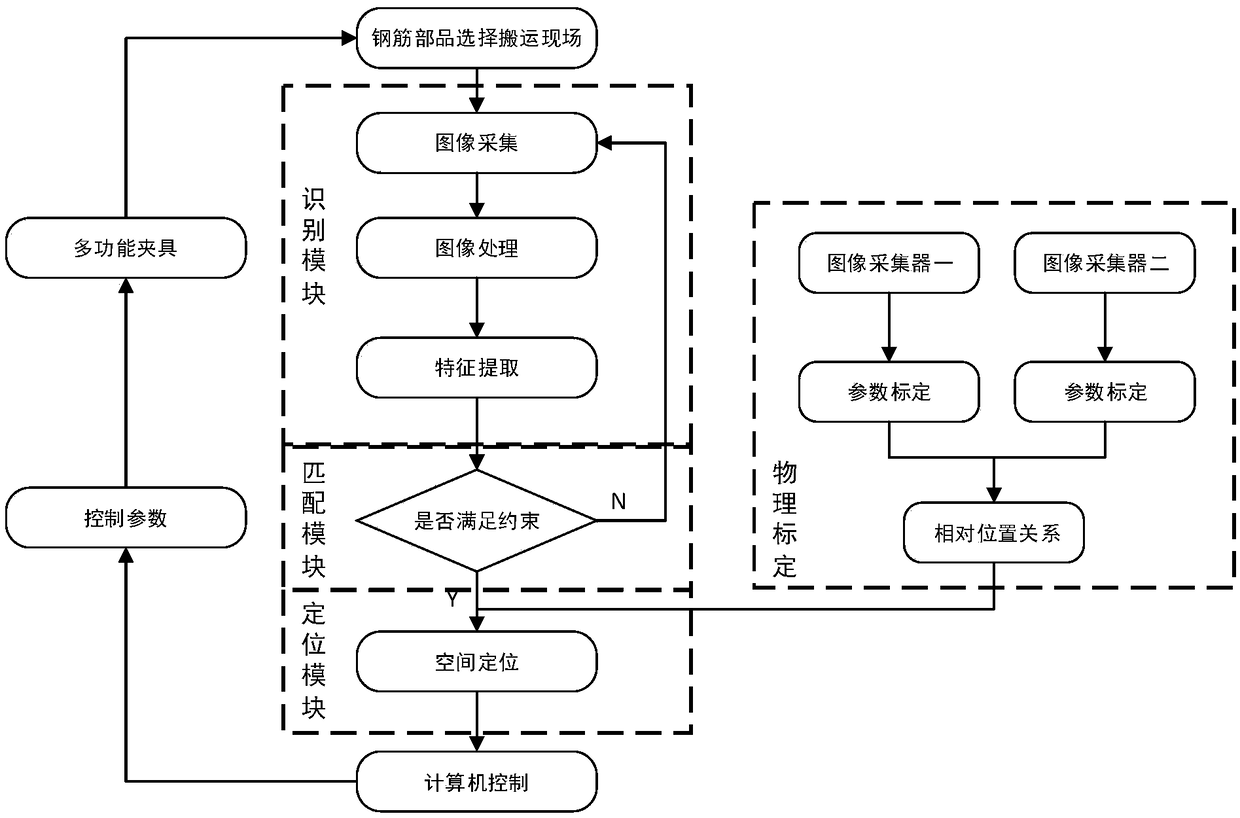

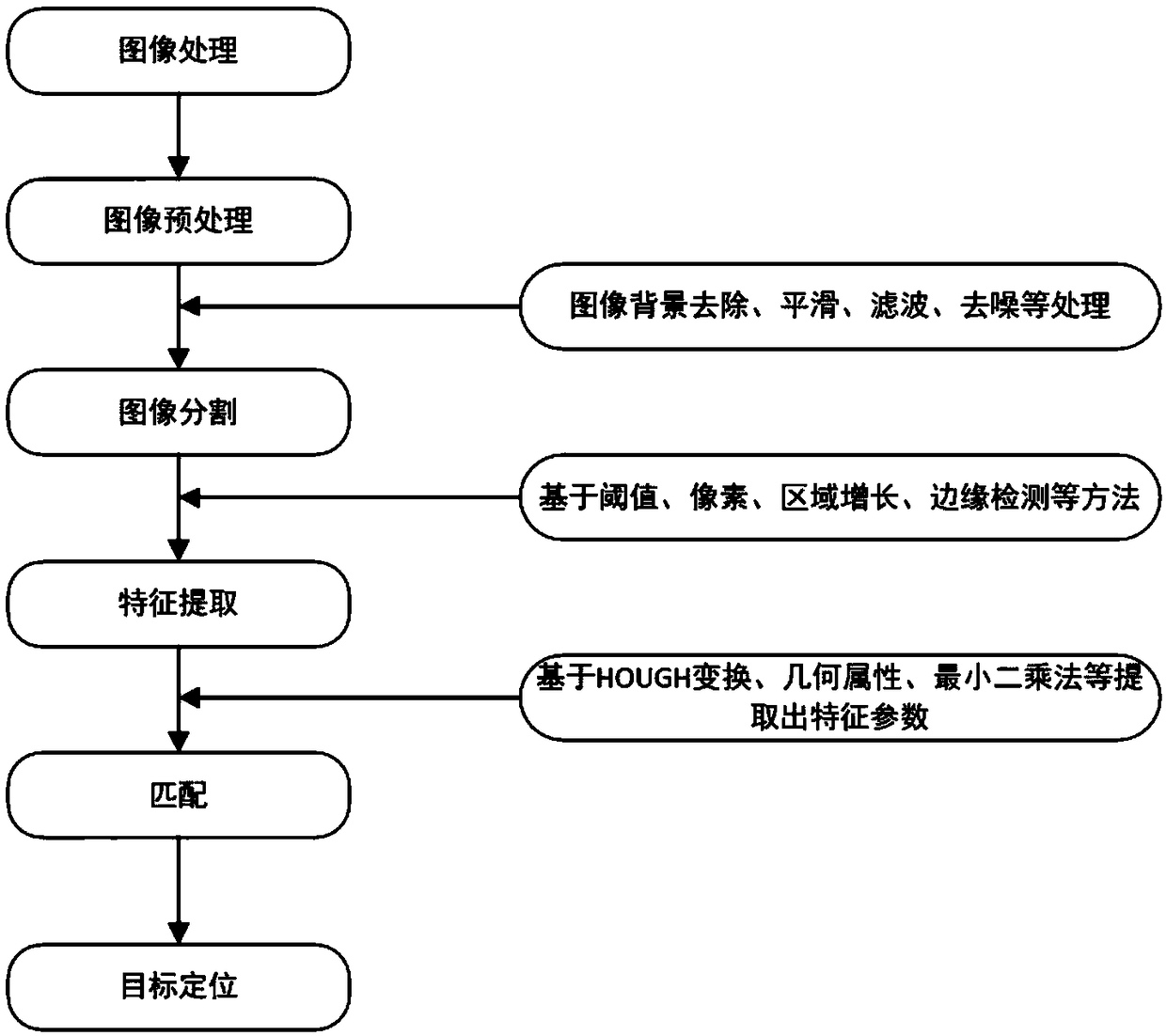

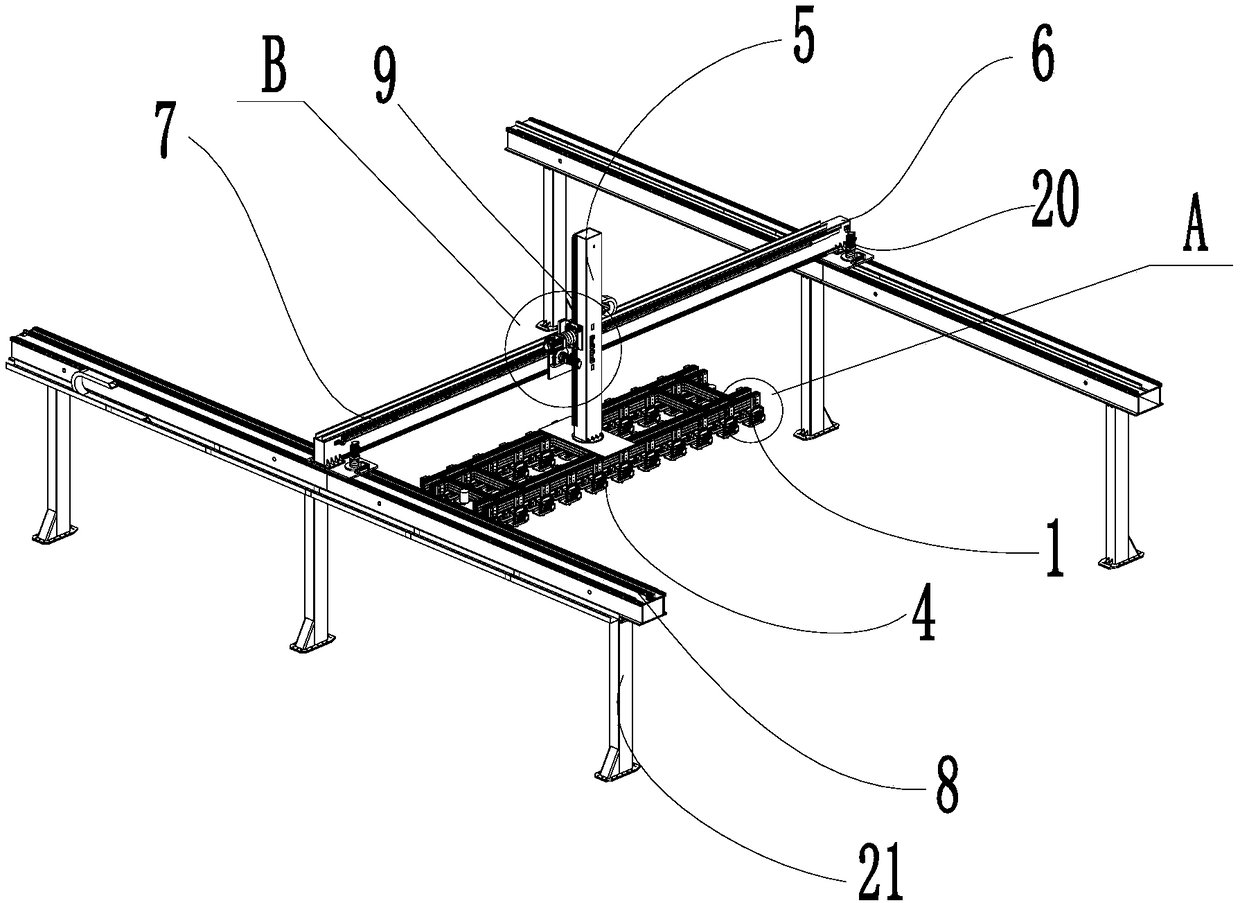

Reinforcement mesh grabbing control method based on visual recognition

ActiveCN109108966AIntelligent transferSmart onlineProgramme-controlled manipulatorSpatial positioningImaging processing

The invention relates to a reinforcement mesh grabbing control method based on visual recognition. The reinforcement mesh grabbing control method comprises the following steps that (1) image acquisition and image processing are carried out; (2) extraction of material features is carried out, wherein the material features including the reinforcement mesh overall size, the grid size, the hole forming condition, the hole size if holes are formed and the reinforcement thickness are extracted from material images collected from the step (1) and subjected to image processing; (3) feature matching iscarried out; (4) spatial positioning is carried out; and (5) movement of a grabbing mechanism and grabbing of the reinforcement mesh are carried out. According to the reinforcement mesh grabbing control method, visual identity is carried out on the reinforcement mesh to be grabbed, feature analysis is performed on the collected images, corresponding clamping, handling and releasing are carried out according to analyzed instructions, intelligent and automatic transferring and putting online of the reinforcement mesh can be achieved, the transfer time of the reinforcement mesh is saved, some uncertain damage during handling is reduced, labor cost is saved, and the production efficiency is improved.

Owner:CHINA MINGSHENG DRAWIN TECH INVESTMENT CO LTD

Conveying device for glass cover boards and detection equipment with same

PendingCN109941755AAutomate transportationControl devices for conveyorsCharge manipulationGlass coverButt joint

Owner:HUIZHOU LIANSHUO TECH

Packing machine based on multilayer diaper production

InactiveCN109178389AAvoid skewReduce the efficiency of packaging workBundling machine detailsComputer engineering

The invention discloses a packing machine based on multilayer diaper production and relates to the technical field of article packing. The packing machine comprises a bottom plate; the front surface and the back surface of the top of the bottom plate are fixedly connected with a first supporting plate and a second supporting plate through supporting legs correspondingly; the back surface of the second supporting plate is fixedly connected with a rectangular box; one sides of the tops of the first supporting plate and the second supporting plate are fixedly connected with fixing boxes; the front surface and the back surface of the inner wall of each of the two fixing boxes are rotatably connected with movable rods through bearings; the opposite sides of the inner wall of each of the two fixing boxes, located on the two sides of the surfaces of the movable rods, are rotatably connected with rotating rods through bearings; the tops of the fixing boxes are fixedly connected with protectivecovers. The packing machine based on the multilayer diaper production can prevent the situation that an outer packing bag containing diapers is aslant in the transport process, causing a loosening phenomenon after packing, which affects the packing aesthetics and practicability and greatly reduces the packing efficiency.

Owner:宜城成雄织造有限公司

Transportation device for electronic product automatic production

InactiveCN108163530AEasy to get close to each otherClose to each other to achieveConveyor partsProduction lineThird platform

The invention discloses a transportation device for electronic product automatic production. The transportation device comprises a first platform, a second platform, a third platform and a fourth platform; the first platform is parallel to the second platform; the third platform is parallel to the fourth platform; through arrangement of the first platform, the second platform, the third platform and the fourth platform representing four different production lines, electronic products are placed at the upper ends of the first platform, the second platform, the third platform and the fourth platform; through arrangement of a first cylinder on the left side of a rotating plate, the positions of the electronic products are conveniently adjusted through left-right extension; and through arrangement of a seventh cylinder at the front end of the rotating plate, the positions of the electronic products are conveniently adjusted through front-back extension. The transportation device for electronic product automatic production is simple in structure and convenient to use, realizes automatic transportation, is higher in practicability, greatly improves the use functionality, guarantees the use effect and the use benefit, and is suitable for wide popularization.

Owner:YUEQING ZOII ELECTRIC

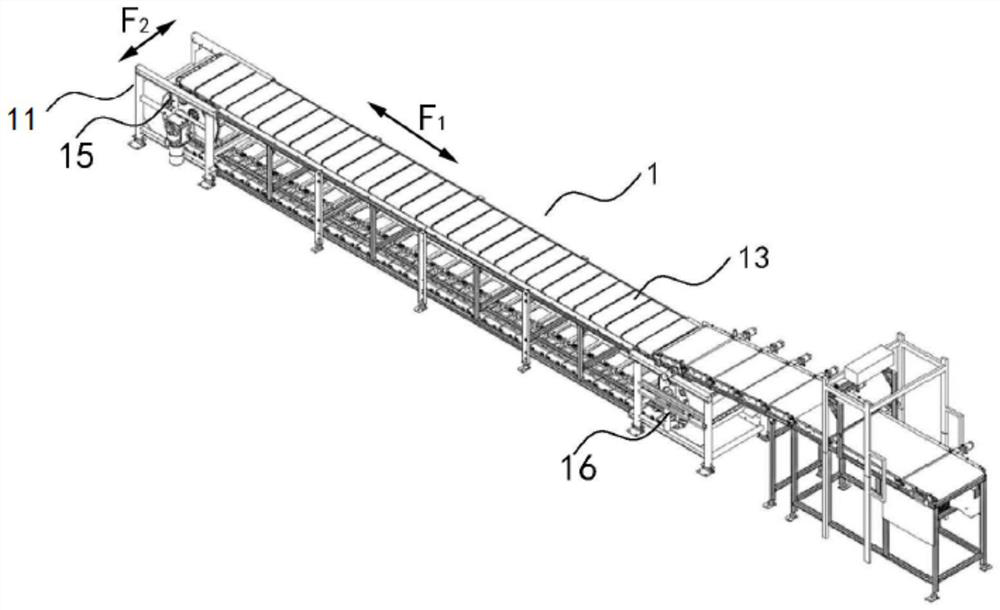

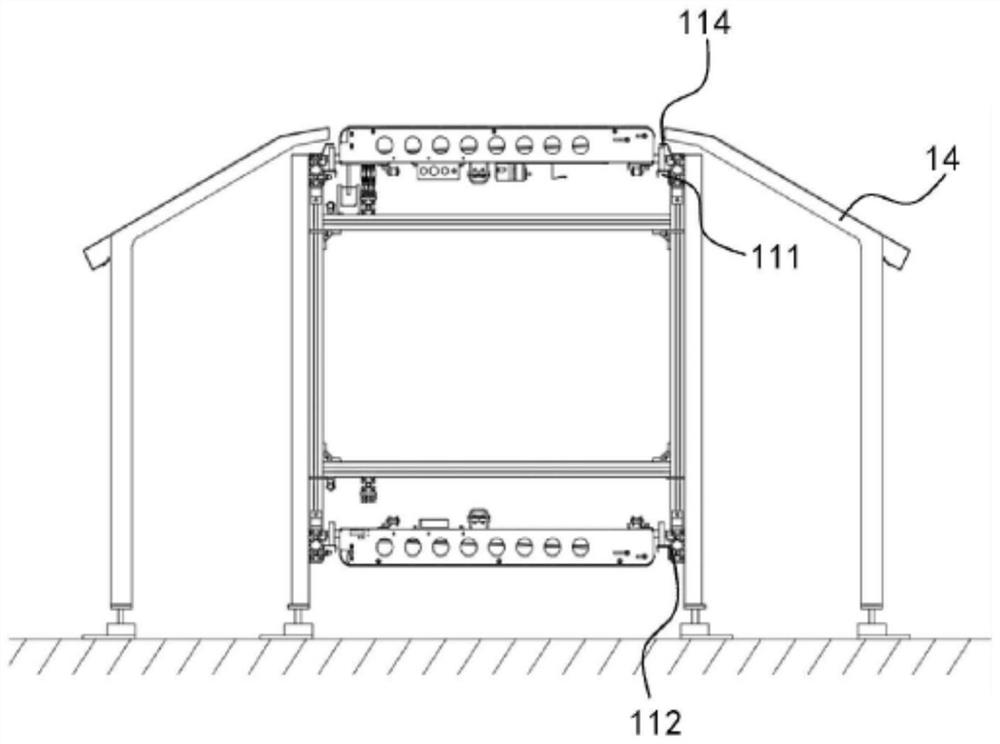

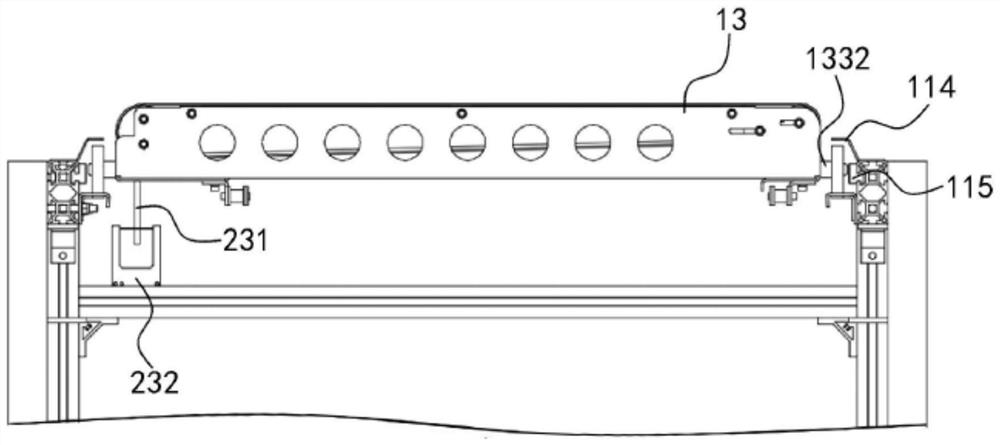

Linear conveying device

PendingCN113460598AWeight increaseStable deliveryCleaningSupporting framesEngineeringMechanical engineering

The invention discloses a linear conveying device which comprises a base assembly, a conveying assembly and a driving assembly. The base assembly is provided with at least two base units which are sequentially distributed at intervals in the first direction, and each base unit is provided with a supporting base arranged in the second direction; the conveying assembly is provided with conveying seats and a plurality of conveying rails, the conveying seats are movably mounted on the conveying rails, and the plurality of conveying rails are mounted on the corresponding supporting seats respectively; and the driving assembly is provided with at least two driving parts, and the driving parts are used for driving the conveying seats to move along the conveying rails. The linear conveying device can convey heavy and large-size workpieces, conveying is more stable, meanwhile, the conveying seats are driven by the multiple driving parts, the driving force is larger, high-speed conveying of the heavy and large-size workpieces can be achieved, automatic conveying of the large-size workpieces is achieved, and the production efficiency can be better improved.

Owner:GUANGZHOU MINO AUTOMOTIVE EQUIP CO LTD

Automatic fermentation machine for distillery

PendingCN111793537AFully fermentedAutomate transportationAlcoholic beverage preparationBulk conveyorsEngineeringProcess engineering

The invention relates to an automatic fermentation machine for a distillery. The automatic fermentation machine for the distillery comprises a supporting mechanism, a stirring mechanism, a feeding mechanism, a heating mechanism, a heat preservation mechanism and a discharging mechanism; the stirring mechanism and the feeding mechanism are fixedly installed on the upper end face of an underframe; the stirring mechanism can automatically stir currently fermented grains, so that more uniform fermentation of the grains can be facilitated; the feeding mechanism feeds the grains into a fermentationtank to ferment; the heating mechanism is fixedly installed on the side end face of a bracket on the underframe; the heating mechanism is used for promoting fermentation of the grains; the heat preservation mechanism is fixedly installed on the side end face of the supporting mechanism; the heat preservation mechanism can shorten the fermentation period of the grains by saving the heat; and the discharging mechanism is fixedly installed on the fermentation tank, and used for conveying the fermented grains into a vessel for distilling liquor.

Owner:刘兴娥

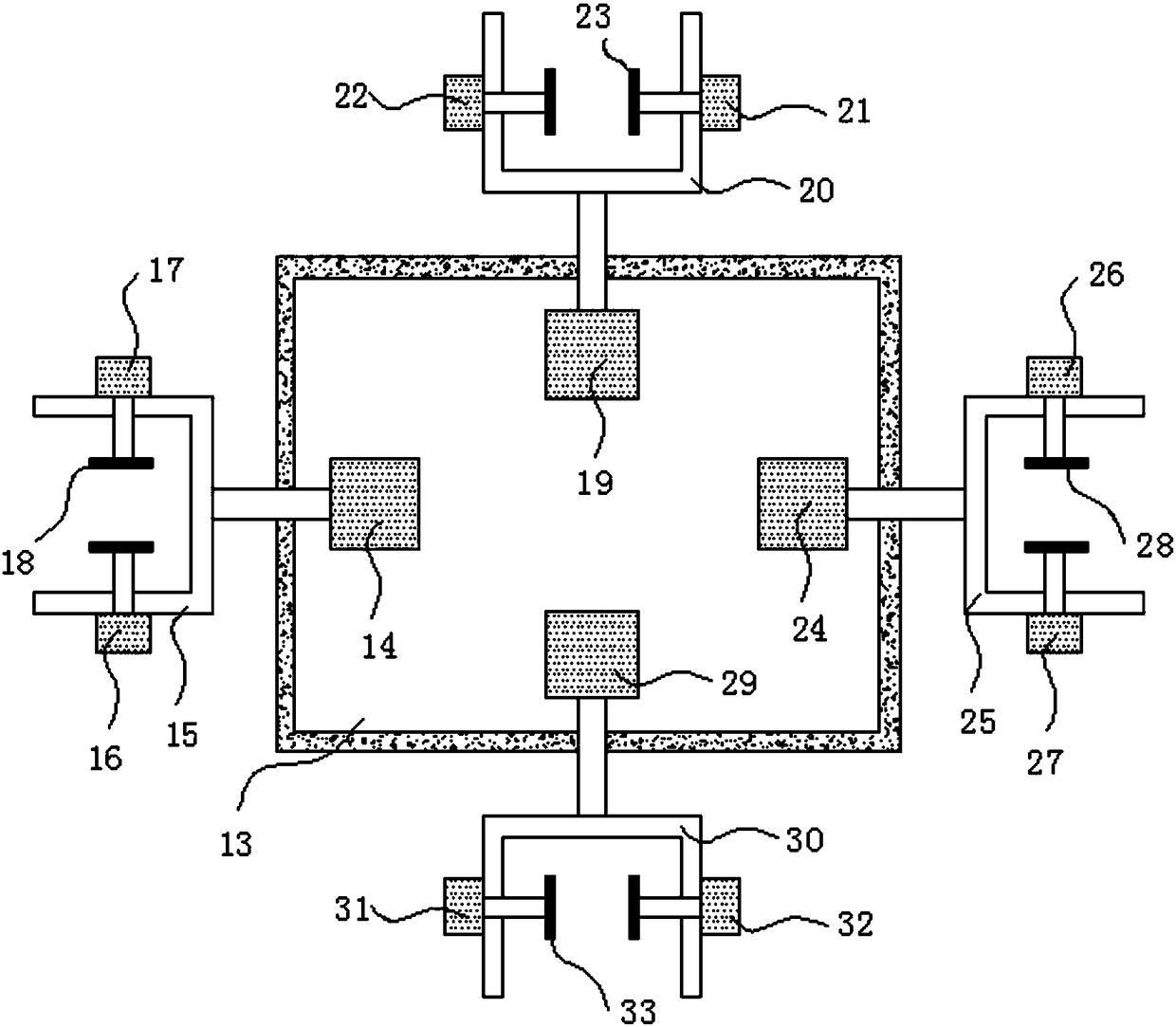

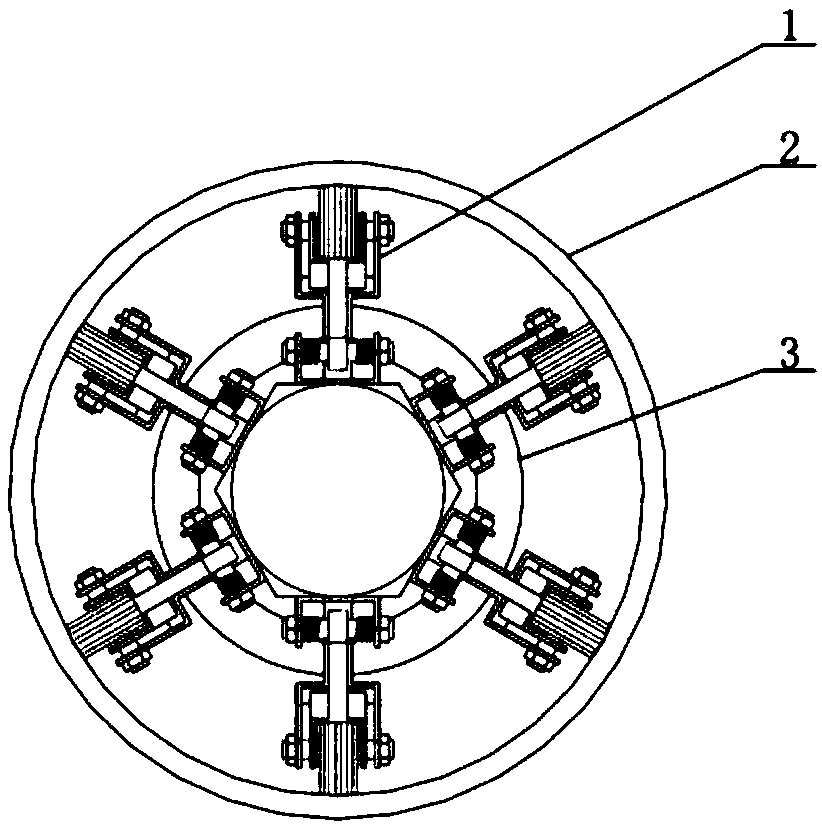

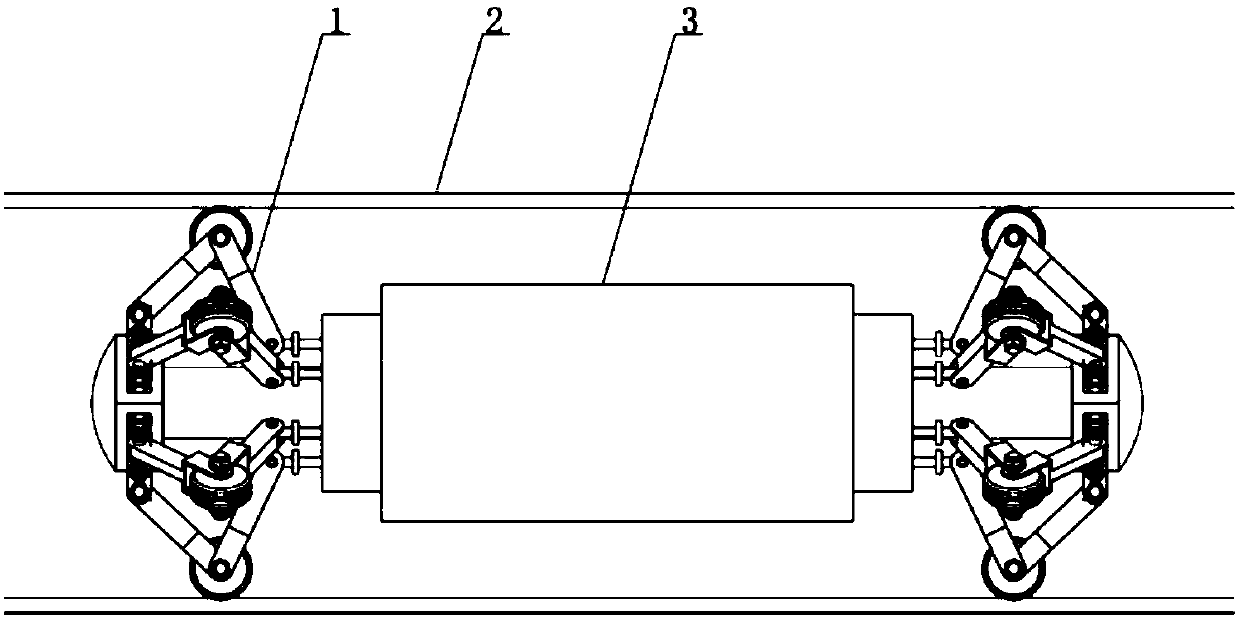

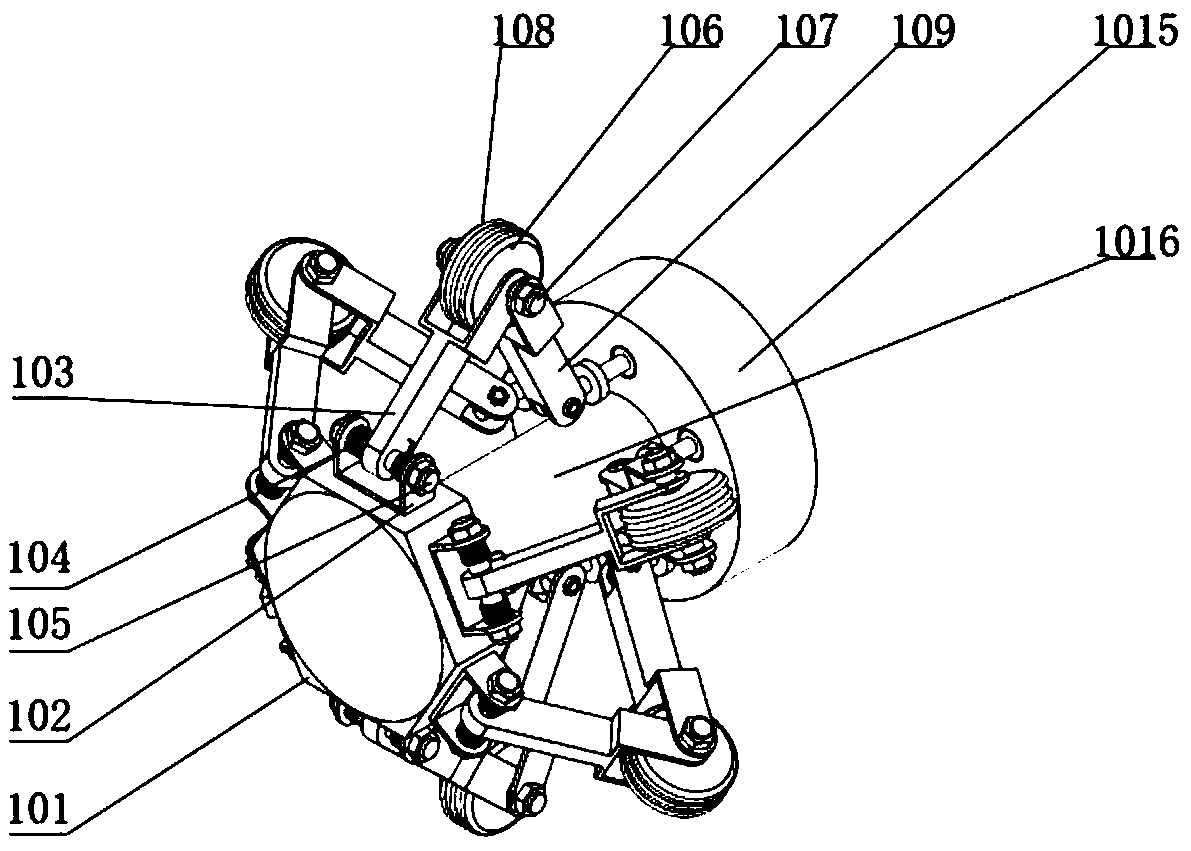

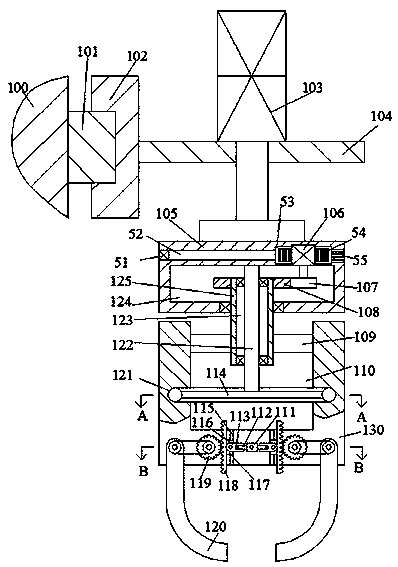

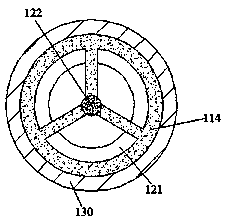

Flexible self-adaptive device of cold chain logistics pipeline unit load device and pipeline system

PendingCN109625821ASolve the last mile problemRealize flexible self-adaptationMechanical conveyorsCold chainUnit load device

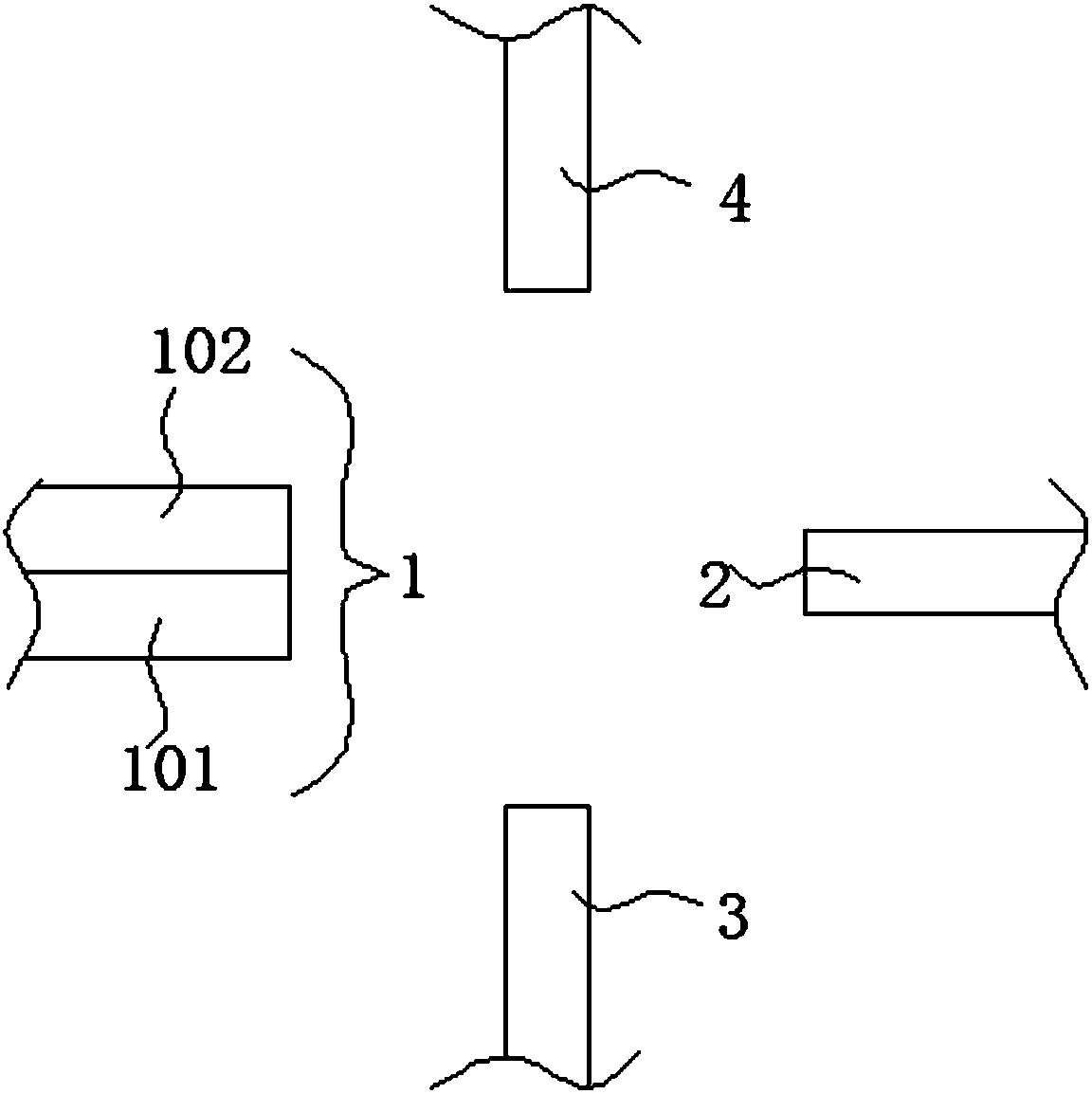

The invention discloses a flexible self-adaptive device of a cold chain logistics pipeline unit load device. A cold chain unit load device (3) runs in a cold chain transmission pipeline (2), a cold chain cargo compartment is arranged in the cold chain unit load device (3), the cold chain cargo is loaded in the cold chain cargo compartment, and flexible self-adaptive devices (1) are mounted in thecold chain unit load device (3) in the back and forth direction; and each flexible self-adaptive device (1) comprises a plurality of sets of multi-linkage mechanisms distributed in the circumferentialdirection of the cold chain transmission pipeline (2), an elastic mechanism and rollers (106), and the elastic mechanism at least drives the multi-linkage mechanisms to make the rollers (106) closelybe attached to the inner pipe wall of the cold chain transmission pipe (2). The flexible self-adaptive device breaks through the limitation of the fluid pipeline, realizes the pipeline transmission of the cold chain cargoes, further realizes the flexible self-adaption of the cold chain unit load device in the pipeline transportation process, and improves the transportation stability, safety and reliability.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

An automatic pharmaceutical robot device

ActiveCN108483026BImprove work coordinationAutomate transportationConveyor partsPhysical medicine and rehabilitationGear wheel

The invention discloses an automatic pharmaceutical robot device. The automatic pharmaceutical robot device comprises a wall, wherein the wall is fixedly arranged on a support; a track is fixedly arranged on the right end surface of the wall; a sliding block is slidably arranged on the right end surface of the track; a backing plate is fixedly arranged on the right end surface of the sliding block; a pushing cylinder is fixedly arranged on the upper end surface of the backing plate; a push rod of the pushing cylinder telescopically penetrates through the backing plate and downwards extends; afixing block is fixedly arranged on the lower end surface of the push rod of the pushing cylinder; a power cavity is fixedly formed in the fixing block; the pushing cylinder is fixedly arranged in theupper end wall of the power cavity; a driving gear is fixedly arranged on the lower end surface of an outputting shaft of a driving motor; the left side of the driving gear is engaged with a driven gear; and a rotating body is fixedly arranged in the driven gear, rotatably penetrates through the lower end wall of the power cavity and downwards extends out of external space. The automatic pharmaceutical robot device is simple in structure and convenient to use, a low-cost structure is adopted in the device, gripper type structures are used, articles in a pharmaceutical process are carried effectively, and the production cost is reduced effectively.

Owner:曹玉春

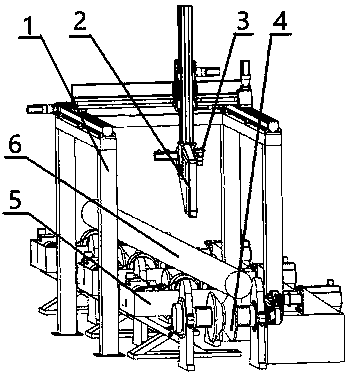

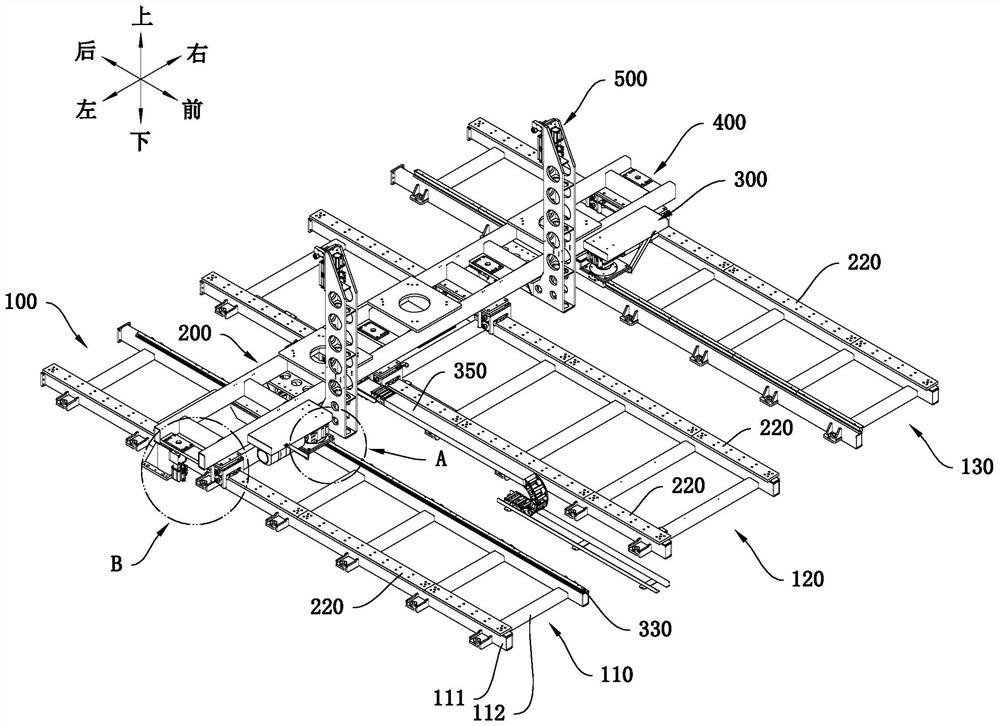

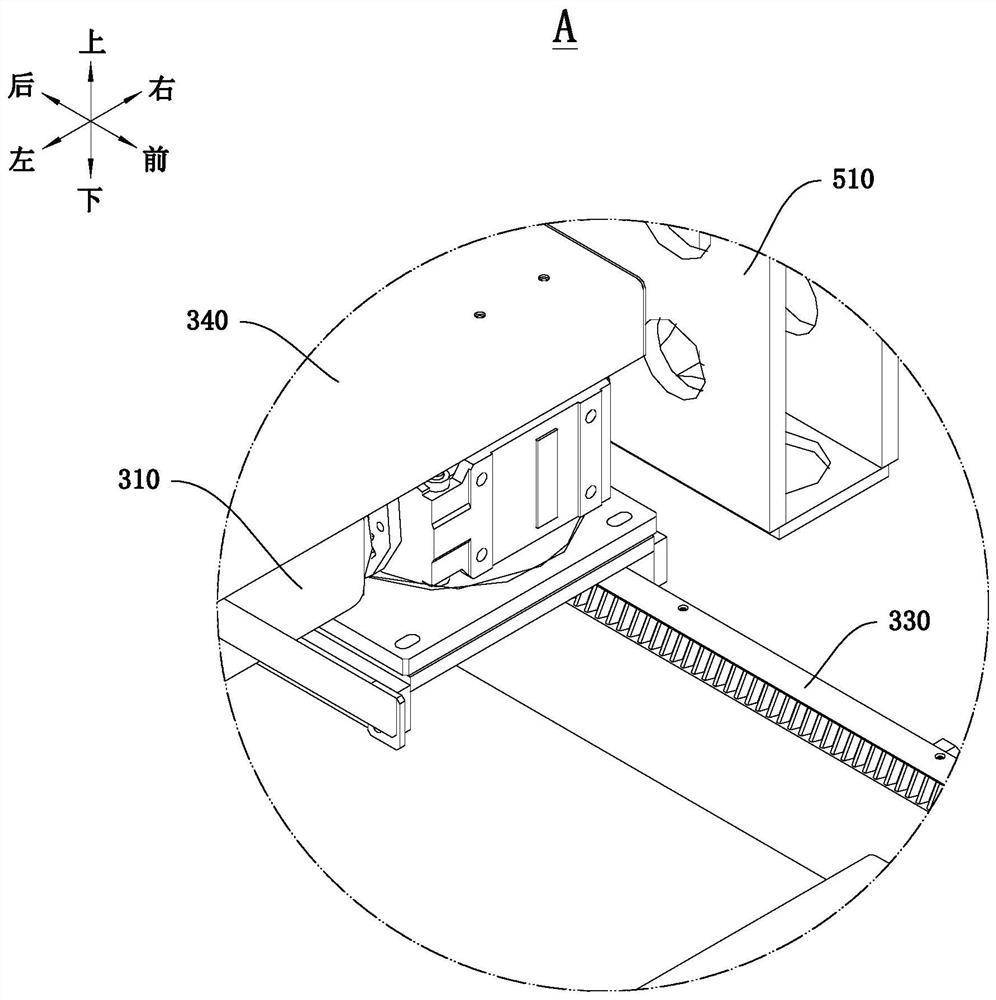

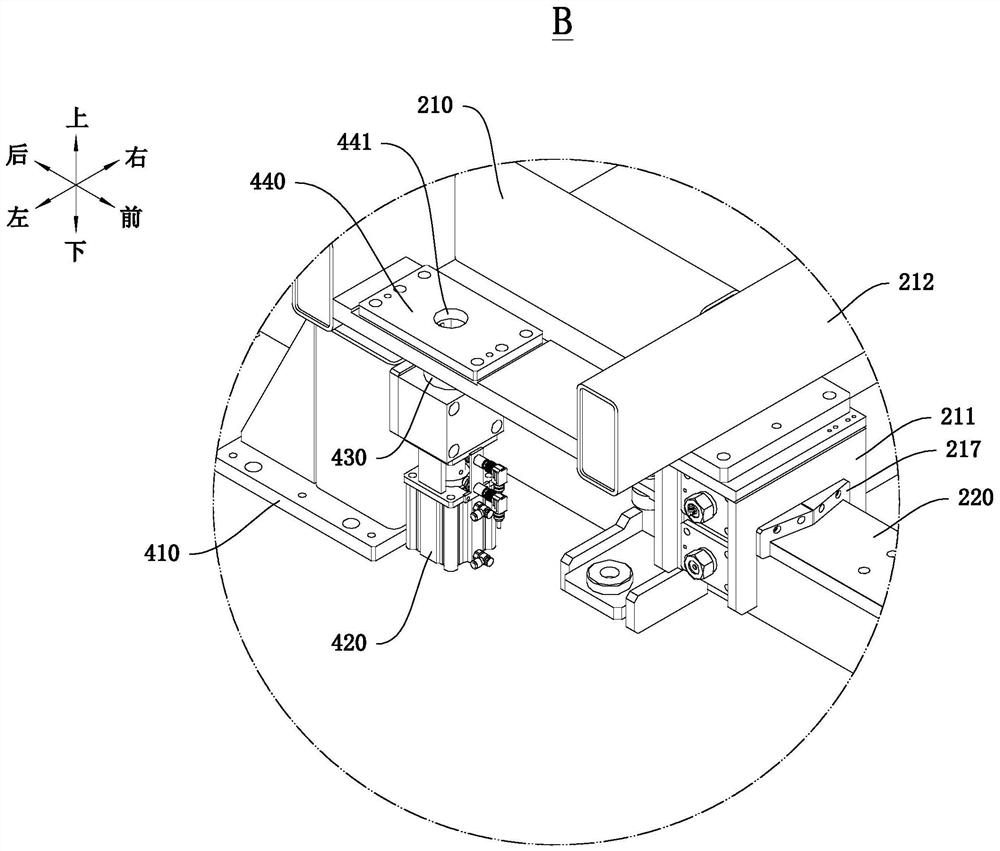

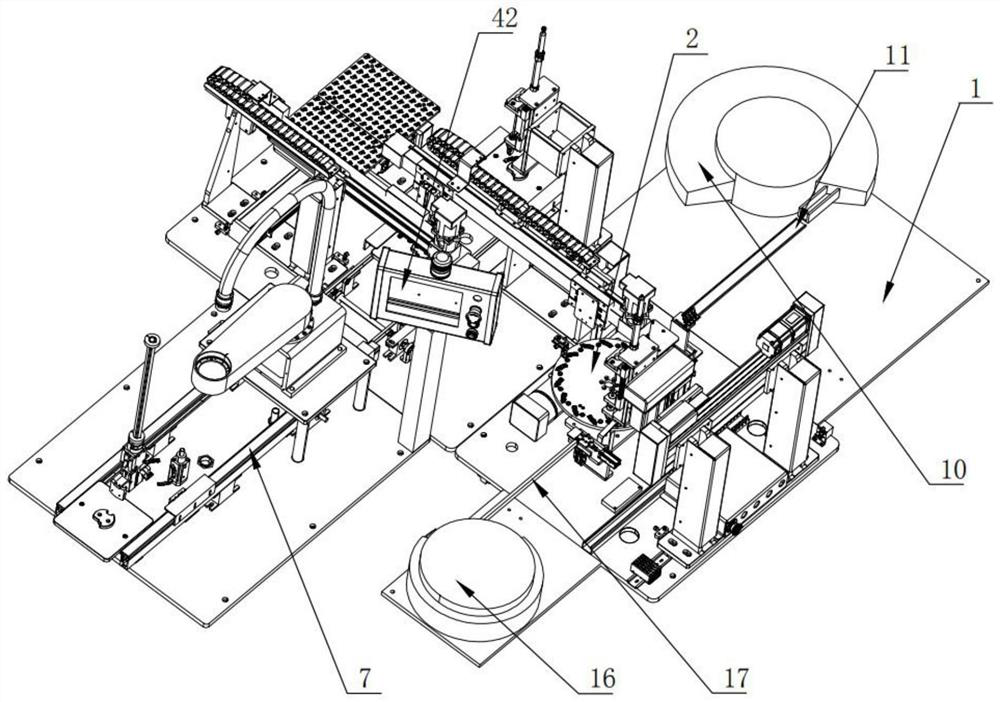

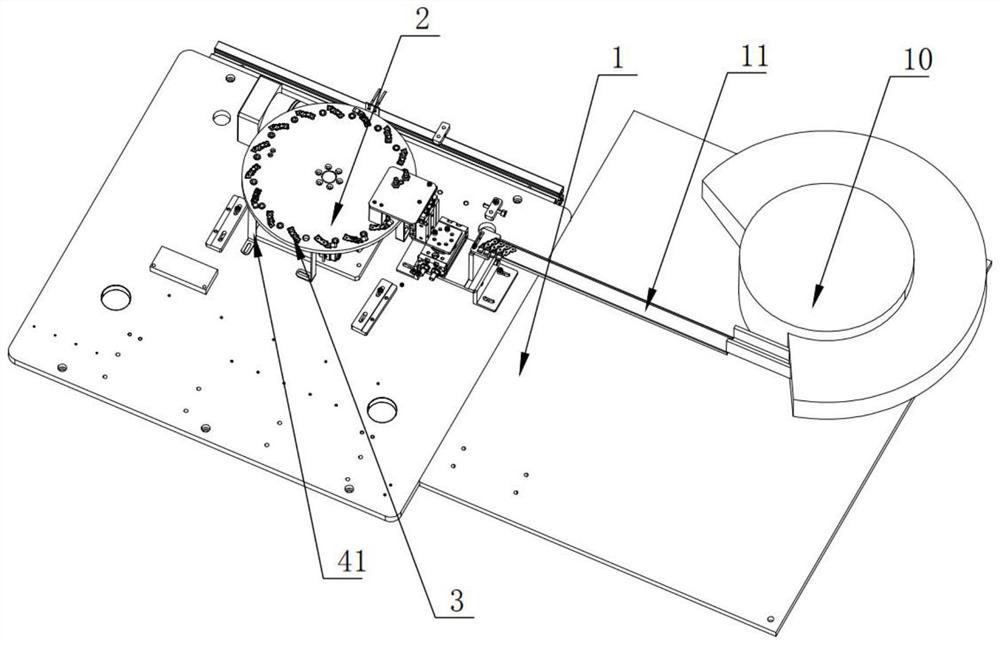

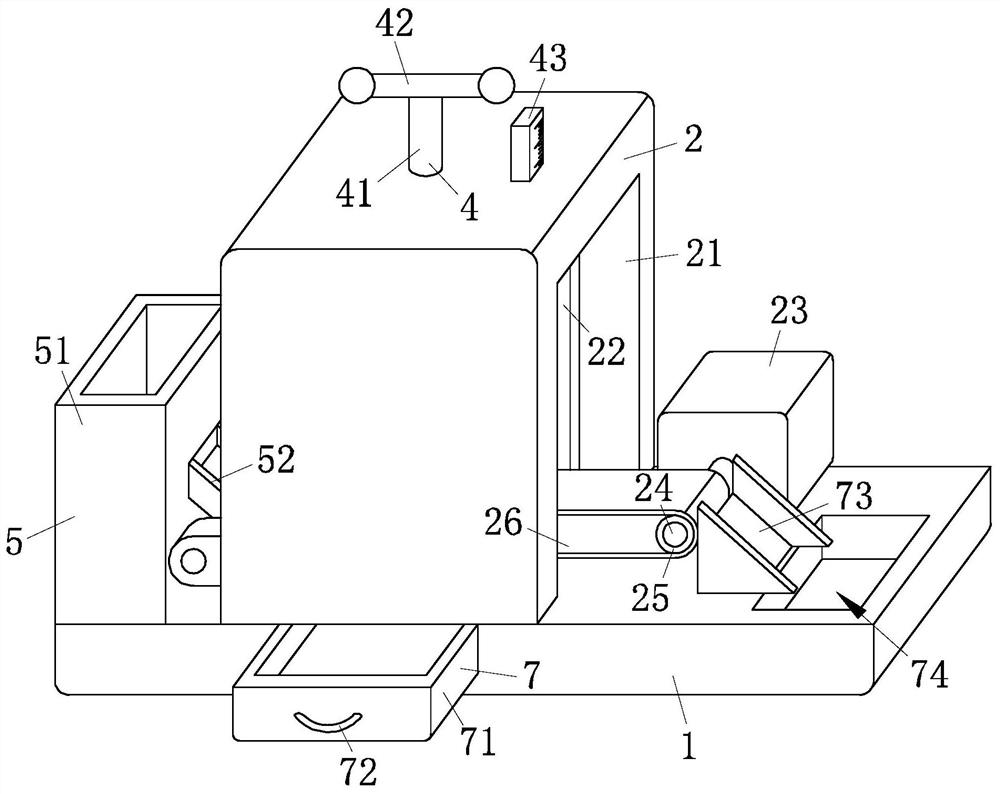

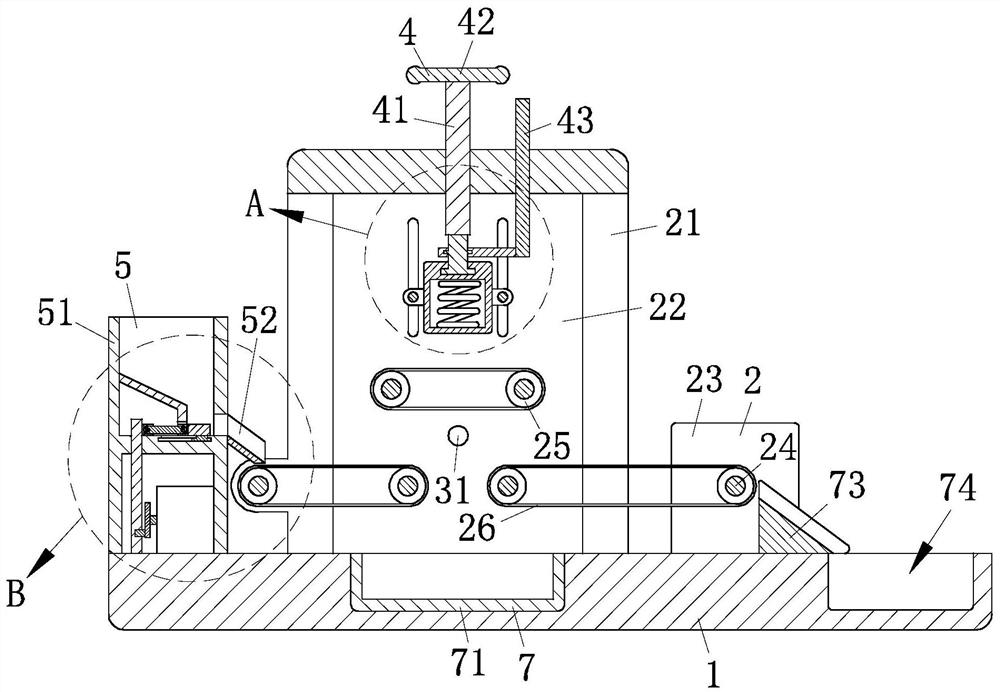

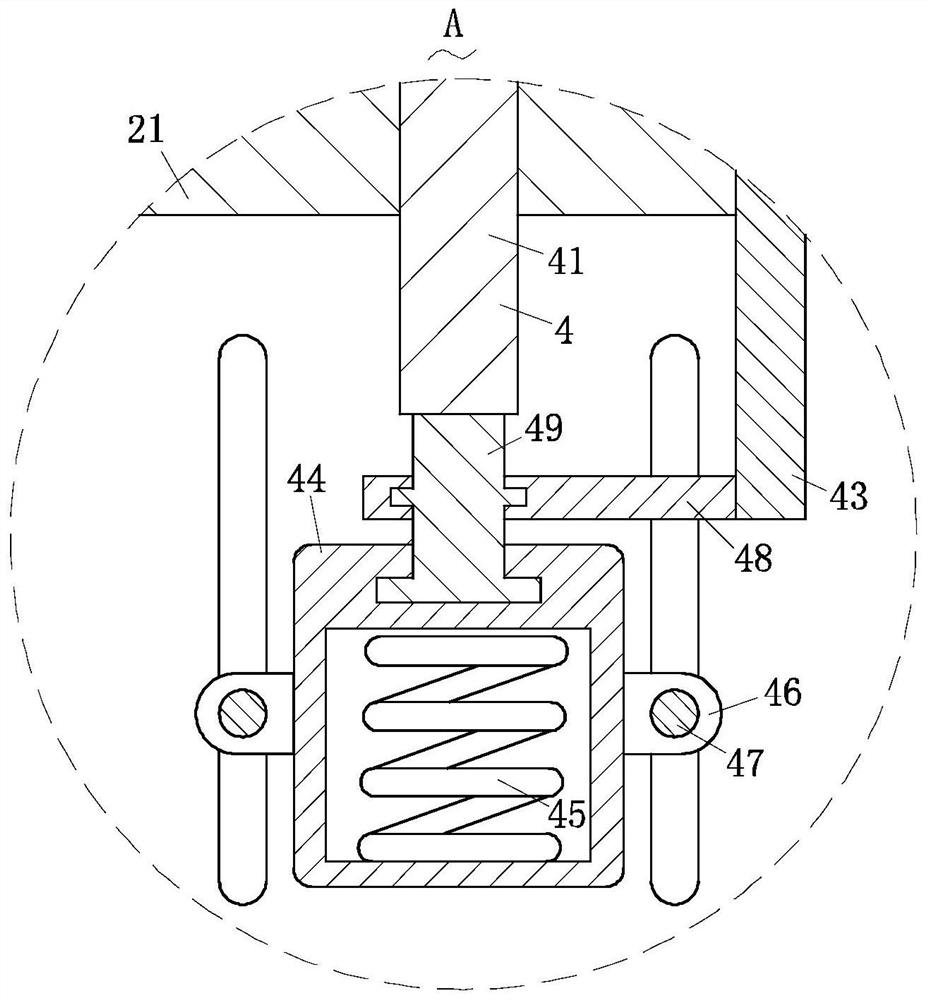

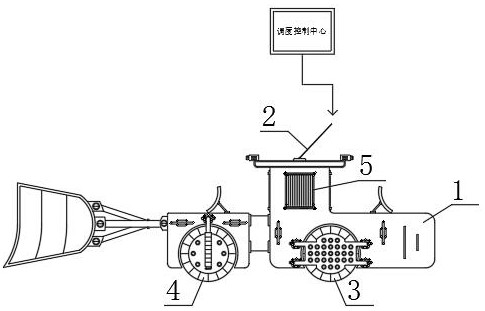

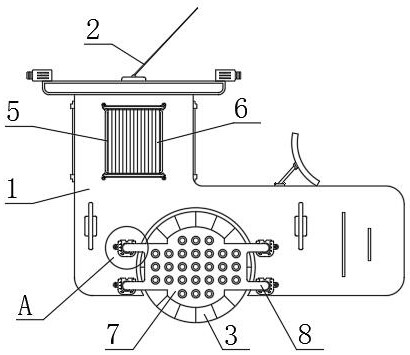

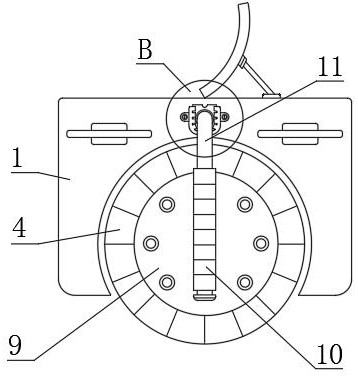

An automatic locking screw machine

The invention discloses an automatic screw-driving machine which comprises a machine body assembly, a material guide mechanism, a material conveying mechanism, a material grabbing mechanism, a material ejecting mechanism and a screw-driving mechanism. The material guiding mechanism is arranged on a main machine frame of the machine body assembly. The material conveying mechanism is arranged on an auxiliary machine frame on one side of the main machine frame. The material grabbing mechanism is arranged between the material conveying mechanism and the material guide mechanism and conveys guide pins to the material ejecting mechanism. The guide pins are conveyed to the position below PCBs through the material ejecting mechanism. The screw-driving mechanism is arranged above the material guiding mechanism and drives screws into the guide pins. The automatic screw-driving machine is suitable for a PCB automatic machining assembly line, the functions of automatically positioning blocking materials and adjusting the sizes of the conveyed PCBs are achieved through the material guide mechanism, the automatic material feeding or blocking movement is achieved through the material conveying mechanism, the automatic conveying movement of the guide pins is achieved through the material grabbing mechanism, the automatic material ejecting movement is achieved through the material ejecting mechanism, and nuts are automatically locked on the guide pins through the screw-driving mechanism.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

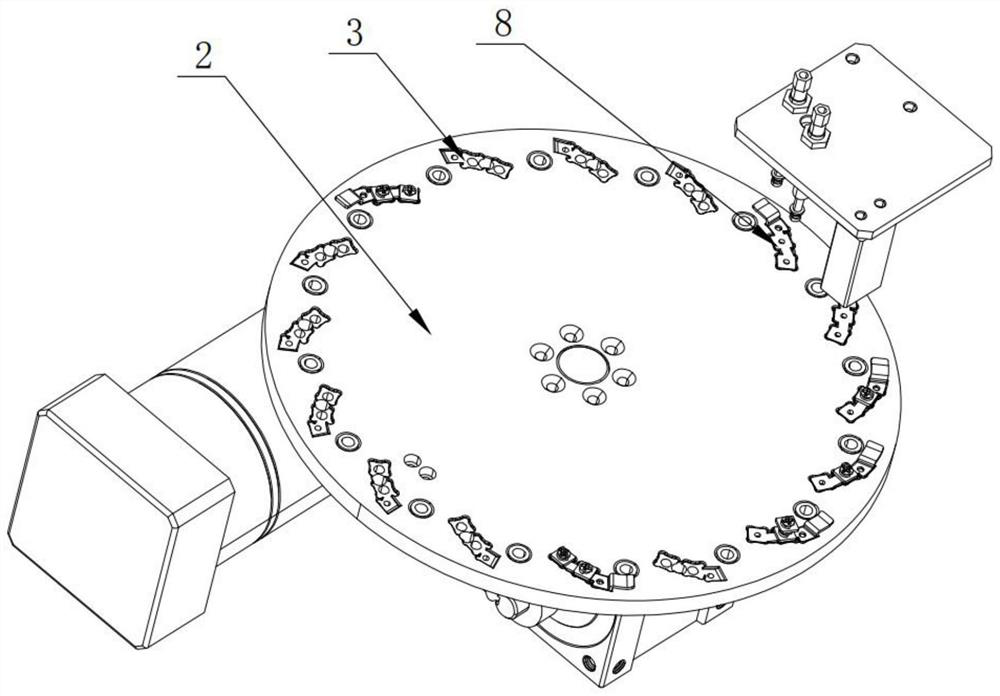

Automatic base assembling equipment

ActiveCN111890023AAutomate transportationAchieve positioningMetal working apparatusEngineeringAutomatic processing

The invention provides automatic base assembling equipment which comprises an elastic piece loading mechanism, a square screw loading mechanism, a tray conveying mechanism and an elastic piece conveying and assembling mechanism. A turnplate is further arranged on a worktable, a plurality of processing stations are arranged on the turnplate, a magnetic suction block is arranged above the tray, anda conveying table is arranged on the tray conveying mechanism. During work, a first taking table conveys elastic pieces to the processing stations, a second taking table conveys square screws to one side of the turnplate, the magnetic suction block sucks the square screws to the elastic sheets, the conveying table conveys trays to to-be-processed stations, and the elastic piece conveying and assembling mechanism conveys and mounts the elastic pieces to the trays. The automatic base assembling equipment transports, positions and assembles the elastic pieces and the square screws automatically,and the elastic pieces can be assembled and fixed automatically in the trays, so that integrated automatic processing of a whole flow of base assembling is achieved, and the work efficiency is higherand the manpower is saved.

Owner:宁波威兹马特电子有限公司

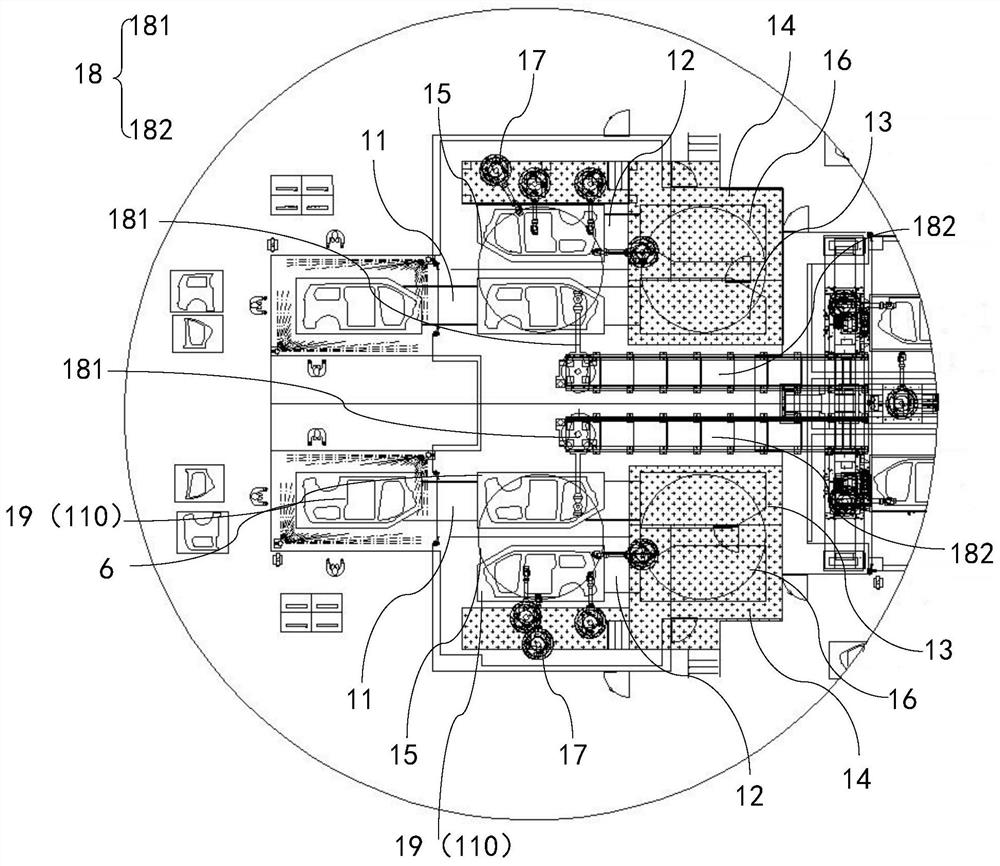

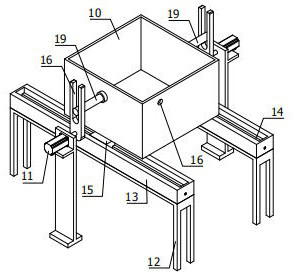

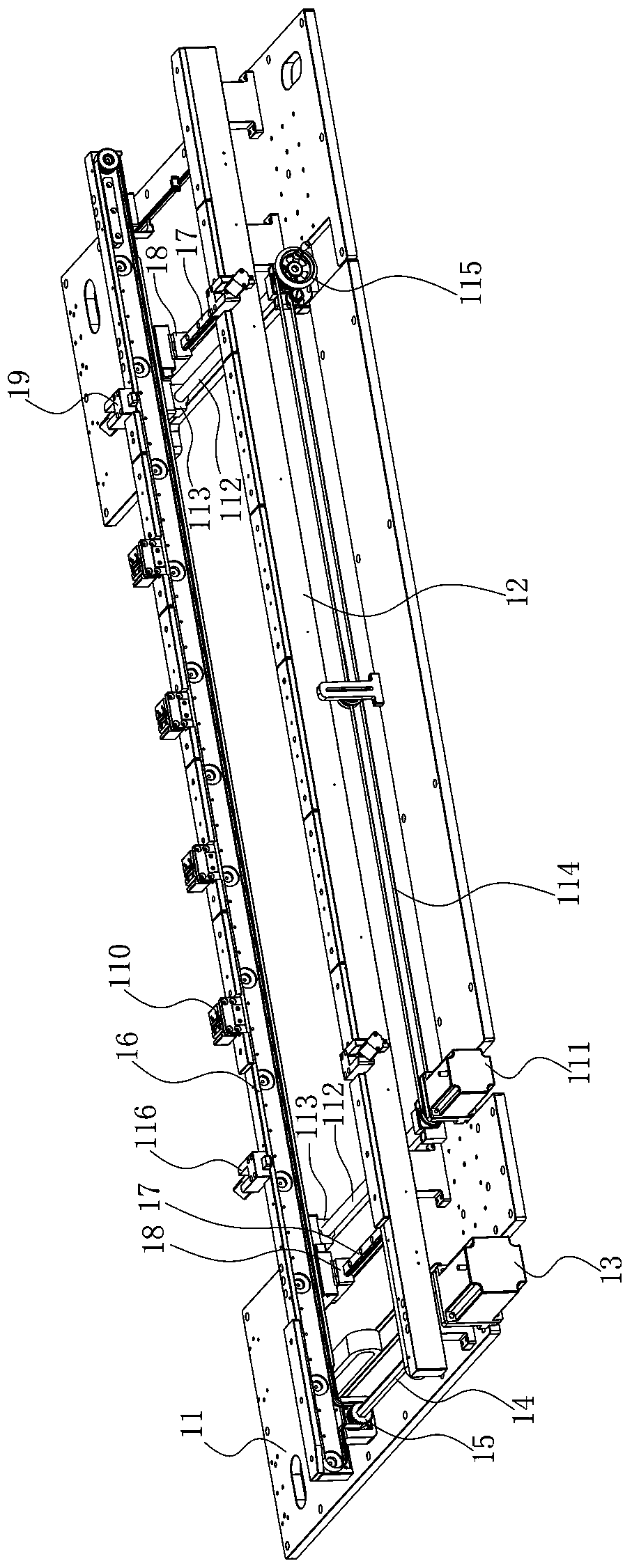

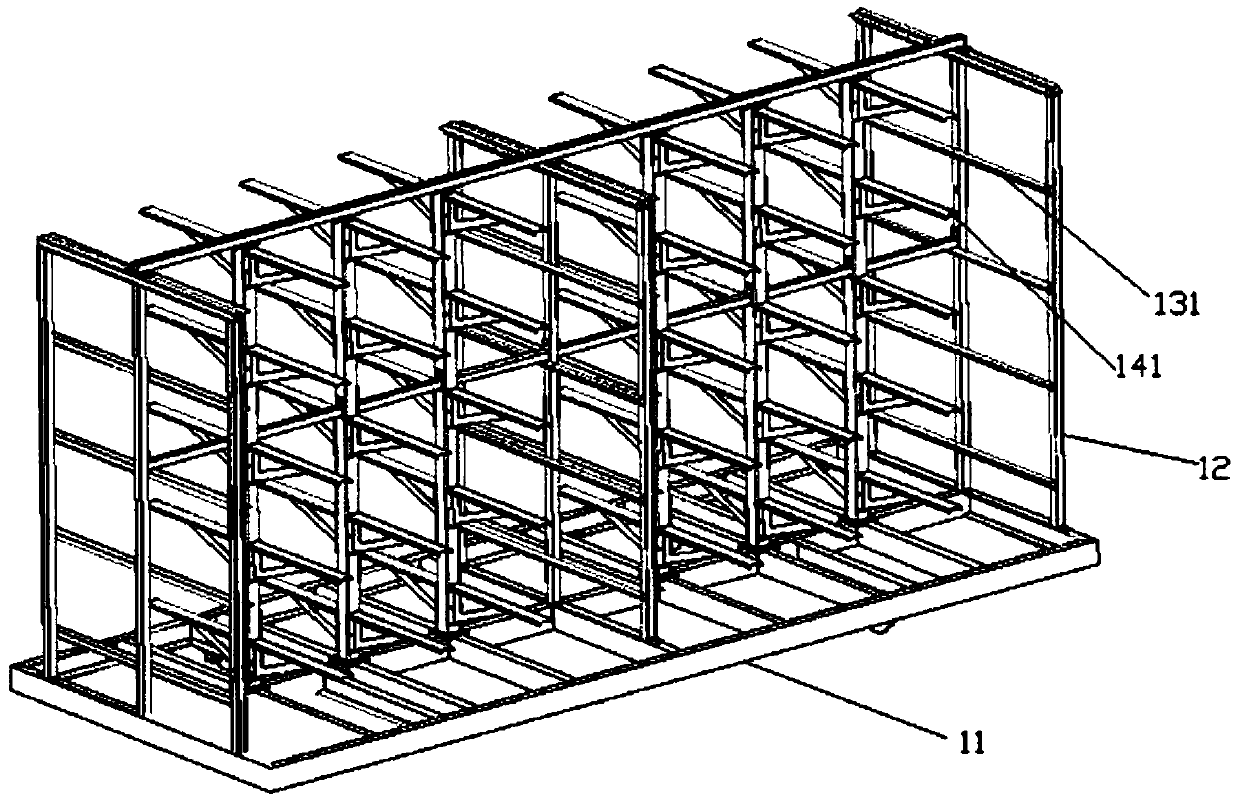

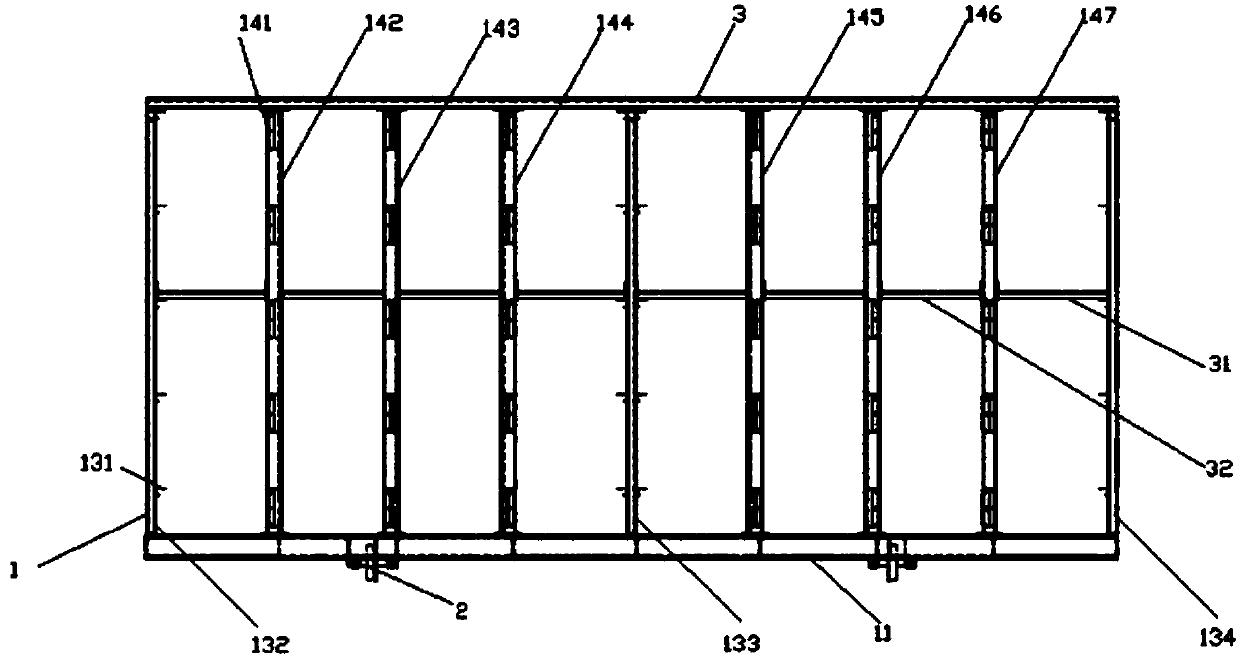

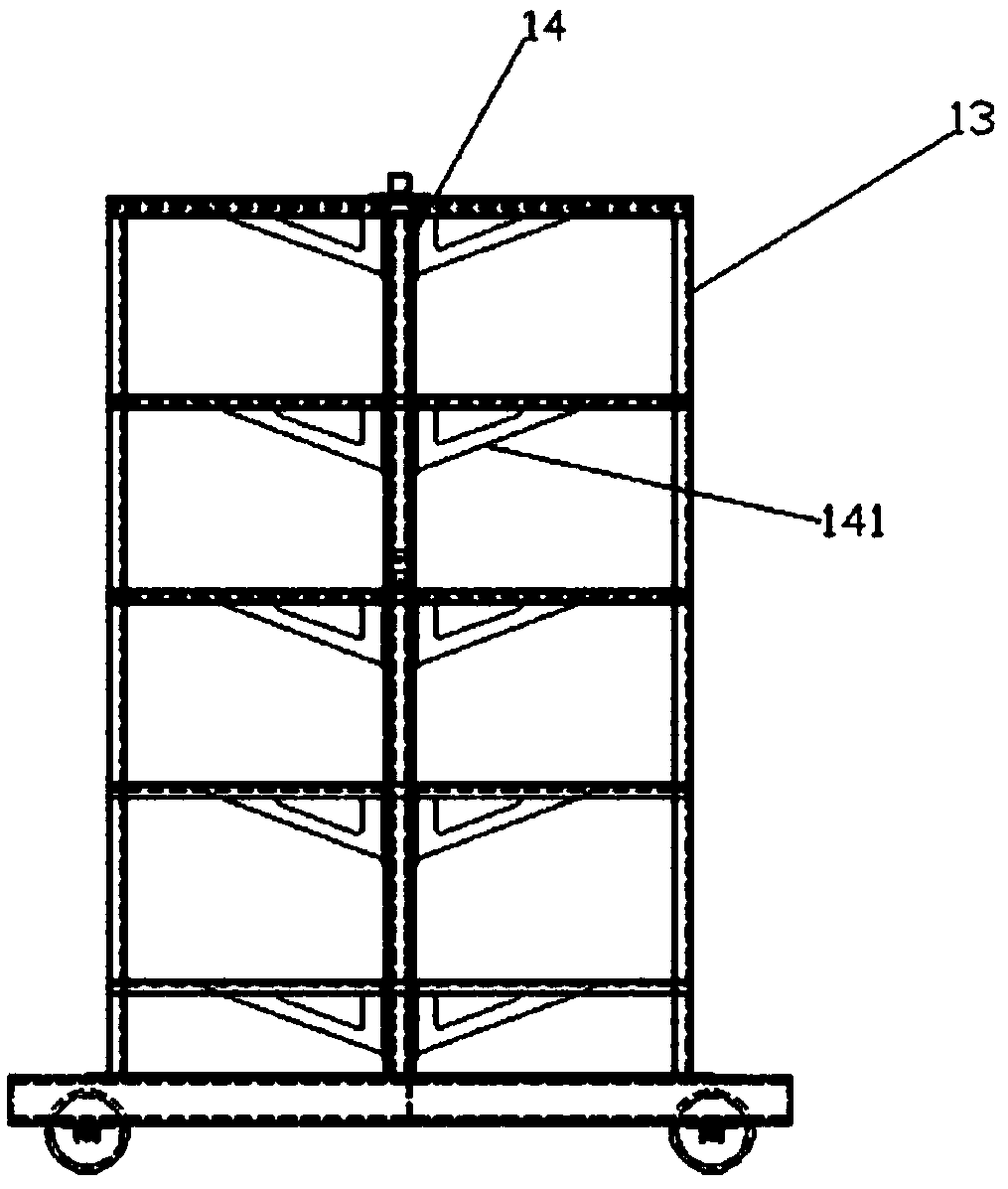

Ceramic blank conveying, storing and drying system

ActiveCN107672005AAutomate transportationSave human effortAuxillary shaping apparatusVehicle frameAssembly line

The embodiment of the invention discloses a ceramic blank conveying, storing and drying system. The ceramic blank conveying, storing and drying system comprises a loading and unloading mechanism, a kiln car and a drying room. The loading and unloading mechanism comprises a support, a rolling mechanism, a drive mechanism and a support plate. The support comprises stand columns, a first side beam and a second side beam. The kiln car comprises a frame and a wheel set. The frame comprises a bottom frame and shelves. The shelves are arranged above the bottom frame. The drying room comprises a drying line, a hot air system and a heat exchange system. By adoption of the ceramic blank conveying, storing and drying system, loading and unloading equipment is matched with the ceramic blank drying kiln car, ceramic blanks are automatically loaded and unloaded to the ceramic blank drying kiln car, automatic loading and loading are achieved accordingly, the ceramic blank drying kiln car slides alonga kiln car guide rail, automatic transportation is achieved, manpower is saved, and unmanned automatic assembly line work is finally achieved.

Owner:GUANGDONG LEHUA HOME FURNISHING CO LTD

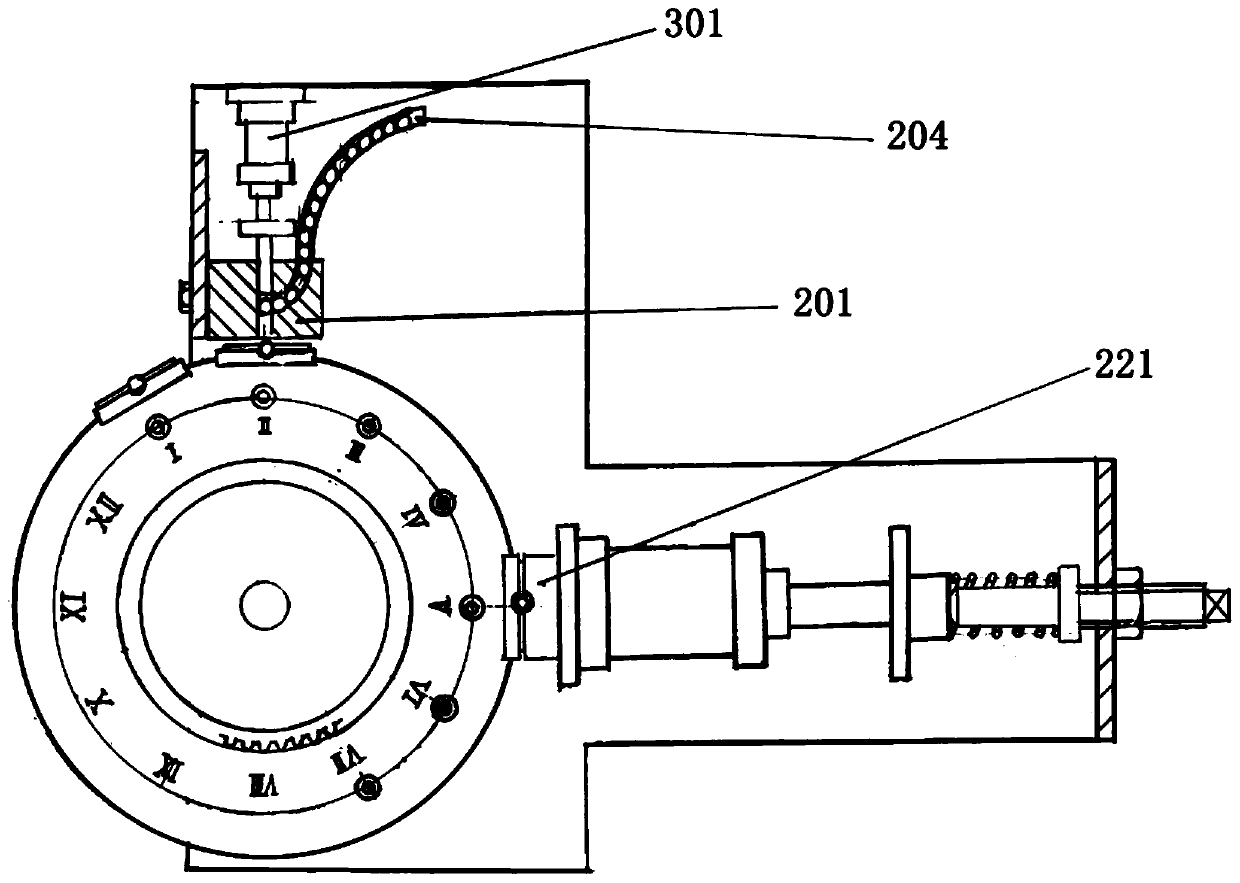

Magnetic force intensity detector for magnetic material part

The invention relates to the field of magnetoelectric equipment, in particular to a magnetic force intensity detector for a magnetic material part. The magnetic force intensity detector comprises a base, a conveying structure, a driving structure, an adjusting structure, a feeding structure, a reciprocating structure and a receiving structure. Through the arrangement of the conveying structure, automatic conveying of magnetic materials can be achieved, . Through the arrangement of the adjusting structure, magnetic intensity detection can be conducted on the magnetic materials in cooperation with the conveying structure. Through the arrangement of the driving structure, the conveying structure can rotate in a proper direction according to needs. Through the arrangement of the receiving structure, the magnetic materials which are conveyed differently can be eventually collected to different sites. Through the arrangement of the feeding structure, the magnetic materials can be automatically fed, and automatic conveying and detection are completed in cooperation with the conveying structure and the adjusting structure. Through the arrangement of the driving structure, the conveying structure can rotate in the proper direction according to needs, and therefore, the magnetic materials are conveyed according to needs.

Owner:惠州市旭展磁性材料有限公司

A fully automatic underground mining transportation system

InactiveCN111441415BImprove the protective effectAutomate transportationSoil-shifting machines/dredgersEarth drilling and miningSteering wheelDrive wheel

The invention belongs to the technical field of mining, in particular to a fully automatic underground mining transportation system, comprising a scraper, a communication antenna is installed on the upper end of the scraper, the communication antenna is wirelessly connected to a dispatch control center, and the bottom side of the scraper is The drive wheel is installed, and the outer side of the drive wheel is fitted with a No. 1 wheel guard plate. The upper and lower ends of both sides of the No. 1 wheel guard plate are integrally formed with a No. 1 connecting rod, and one side of the No. 1 connecting rod is fixedly connected with a No. 1 card. The outer surface of the scraper is located on both sides of the driving wheel, and the upper and lower ends are equipped with a No. 1 magnetic suction seat. The other side of the bottom of the scraper is equipped with a steering wheel. Wheel guard, one side surface of the No. 2 wheel guard is fixedly connected with the drum, and the inner part of the drum is connected with the No. 2 connecting rod, and the upper end of the No. 2 connecting rod is fixedly connected with the No. 2 block. The outer surface of the vehicle is located above the steering wheel and is equipped with a No. 2 magnetic suction seat, which makes the operation of the LHD safer and facilitates the safe transportation of minerals.

Owner:杨辉

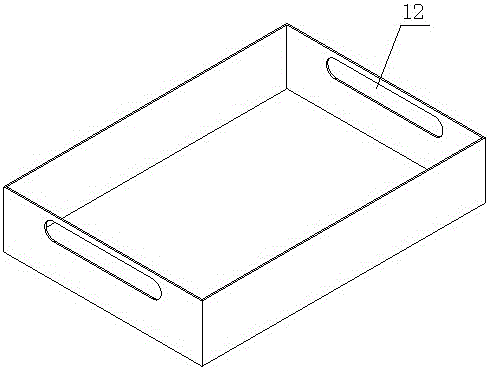

A pallet warehouse and automatic conveying system

ActiveCN111674941BImprove stacking capacitySolve the inconvenience of dischargingDe-stacking articlesEngineeringStructural engineering

The invention discloses a pallet warehouse, and discloses an automatic conveying system with a pallet warehouse, wherein the pallet warehouse includes: a frame, stacking piles are arranged at four corners of the frame, and the The side of the stacking pile facing the central axis of the frame is provided with a telescopic clamping part, and an L-shaped groove surface is vertically arranged on the clamping part, and the L-shaped grooves at the four corners of the frame The groove surface forms a stacking space in the shape of a cuboid; the lifting frame is arranged at the bottom of the frame; the clamping assembly includes two clamping parts respectively arranged on both sides of the frame and connecting and driving the clamping parts. Primary drive mechanism for lateral movement of fasteners. The invention solves the problem of inconvenient discharge at the top, improves the stacking capacity of the pallets, and uses the clamping parts to adjust the stacking, facilitates stacking, and realizes the method of neatly unloading one by one.

Owner:珠海市长陆工业自动控制系统股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com