A fully automatic underground mining transportation system

A transportation system, fully automatic technology, applied in underground transportation, transportation and packaging, earthwork drilling and mining, etc., can solve the problems of easy damage to steering wheels, inconvenient use, scratches and damages on driving wheels, etc. , easy to use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

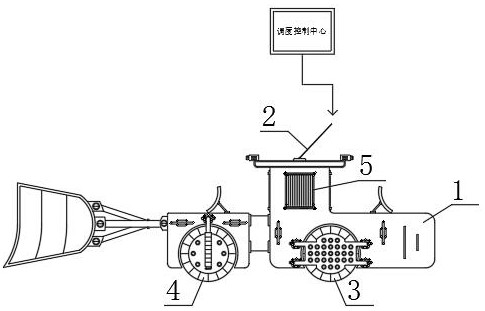

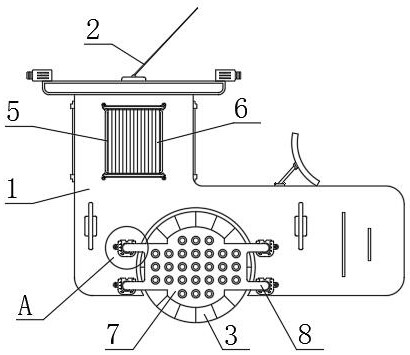

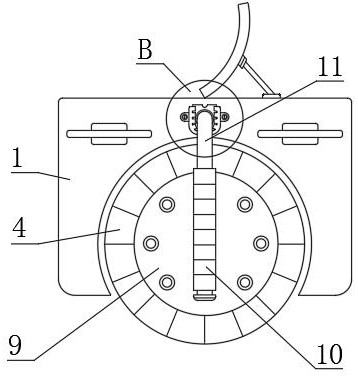

[0025] see Figure 1-7 , the present invention provides the following technical solutions: a fully automatic underground mining transportation system, comprising a scraper 1, a communication antenna 2 is installed on the upper end of the scraper 1, and the communication antenna 2 is wirelessly connected to a dispatch control center, and the scraper 1 The drive wheel 3 is installed on one side of the bottom end, and the outer side of the drive wheel 3 is fitted with a No. 1 wheel guard plate 7. The upper and lower ends of both sides of the No. 1 wheel guard plate 7 are integrally formed with a No. 1 connecting rod 8, and the No. 1 connecting rod One side of 8 is fixedly connected with a No. 1 block 12, and the outer surface of the scraper 1 is located on both sides of the driving wheel 3. The upper and lower ends are provided with a No. 1 magnetic card holder 13, and the other side of the bottom of the scraper 1 is A steering wheel 4 is installed, and the outer side of the stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com