Equipment and method of continuously and rapidly preparing graphene under normal pressure

A graphene and atmospheric pressure technology, which is applied in the field of continuous and rapid preparation of graphene, can solve the problems of long graphene preparation cycle, poor economic benefits, and low production efficiency, and achieve the effects of shortening the preparation cycle, convenient operation, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

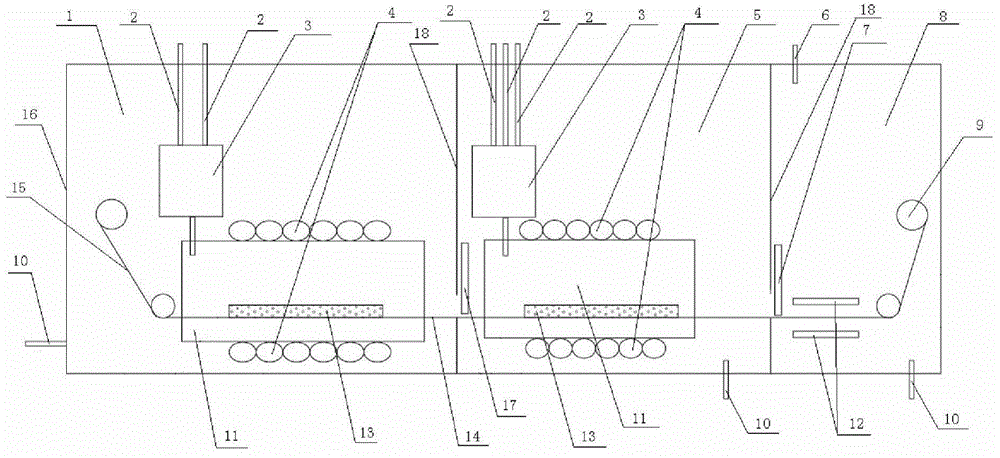

[0035] Adopt the following preparation method to complete the preparation of graphene by the equipment of the present invention, comprise the following steps: 1) metal substrate 13 is sent in the described constant temperature annealing chamber 1 by described feeding device, to the inlet pipe of described constant temperature annealing chamber 1 2. Pass in an inert protective gas and a reducing gas to carry out an annealing reaction. After the annealing reaction is completed, the metal substrate 13 is sent into the cooling growth chamber 5 through the feeding device; 2) the air inlet pipe 2 to the cooling growth chamber 5 Feed the reaction gas, and carry out the cooling reaction, during the cooling reaction process, the graphene on the metal substrate 13 nucleates and grows to film formation, and then the metal substrate 13 is sent into the cooling chamber 8 through the feeding device; 3 ) feed inert gas into the cooling chamber 8, reduce the temperature in the cooling chamber ...

Embodiment 1

[0043] The feeding mechanism 15 sends the metal substrate 13 to the conveyor belt 14, and the conveyor belt 14 sends the metal substrate 13 into the reaction chamber 11 in the constant temperature annealing chamber 1. Ar and H at 1000sccm and 200sccm 2 , the pressure in the constant temperature annealing chamber 1 is adjusted to normal pressure through the pressure release gas pipe, the temperature in the constant temperature annealing chamber 1 is 1000° C., and annealed in the reaction chamber 11 for 30 minutes. Open the first valve 17, send the metal substrate 13 into the reaction chamber 11 in the cooling growth chamber 5, and the three air intake pipes 2 of the cooling growth chamber 5 correspond to Ar and H with flow rates of 500 sccm, 200 sccm, and 10 sccm respectively. 2 、CH 4 , the pressure in the cooling growth chamber 5 is adjusted to normal pressure through the pressure release air pipe, the temperature of the metal substrate 13 copper foil is dropped from 1000°C t...

Embodiment 2

[0045] The feeding mechanism 15 sends the metal substrate 13 to the conveyor belt 14, and the conveyor belt 14 sends the metal substrate 13 into the reaction chamber 11 in the constant temperature annealing chamber 1. Ar and H at 1000sccm and 200sccm 2 , the pressure in the constant temperature annealing chamber 1 is adjusted to normal pressure through the pressure release gas pipe, the temperature in the constant temperature annealing chamber 1 is 900° C., and after annealing in the reaction chamber 11 for 60 minutes. Open the first valve 17, send the metal substrate 13 into the reaction chamber 11 in the cooling growth chamber 5, and the three air intake pipes 2 of the cooling growth chamber 5 correspond to Ar and H with flow rates of 500 sccm, 200 sccm, and 10 sccm respectively. 2 、CH 4 , the pressure in the cooling growth chamber 5 is adjusted to normal pressure through the pressure release air pipe, the copper foil of the metal substrate 13 drops the temperature from 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com