Special steel rod surface defect local polishing robot system

A robot system and robot technology, applied in the direction of grinding racks, grinding machines, abrasive belt grinders, etc., can solve problems such as product backlog, low efficiency, and affecting the operation of special steel bars, and achieve the effect of ensuring stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] combined with Figure 1-6 Describe the content and operation of the present invention.

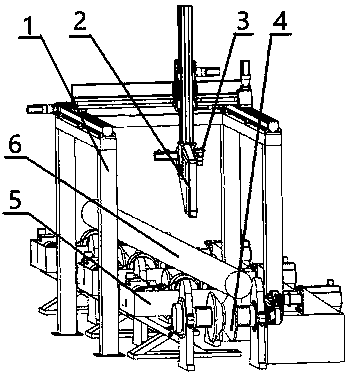

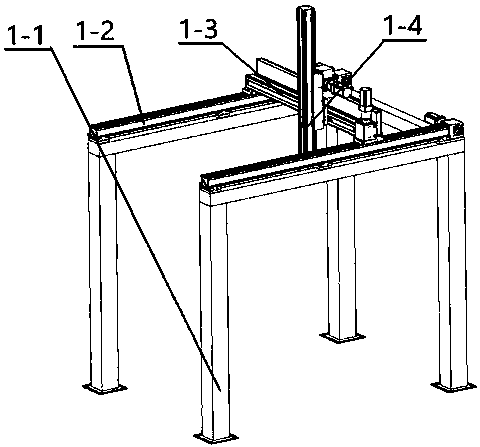

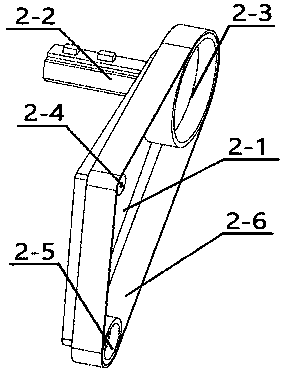

[0018] The robot system for local grinding of surface defects of special steel bars in the present invention includes a Cartesian coordinate robot 1 , a grinding device 2 , an industrial camera 3 , a bar transmission device 4 and a bar lifting and rotating device 5 .

[0019] A grinding device 2 and an industrial camera 3 are fixedly installed at the end of the Cartesian coordinate robot 1 , and the grinding device 2 and the industrial camera 3 move synchronously with the Cartesian coordinate robot 1 . The industrial camera 3 is arranged vertically downward on one side of the grinding device 2 to realize visual identification of surface defects of the special steel bar 6 . Cartesian coordinate robot 1, bar transmission device 4 and bar lifting and rotating device 5 are all fixedly installed on the workshop floor. Cartesian coordinate robot 1, grinding device 2, and industrial came...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com