Hinge assembling equipment

A hinge and assembly mechanism technology, applied in the field of hinge processing, can solve problems such as slow efficiency, complex structure, and large space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

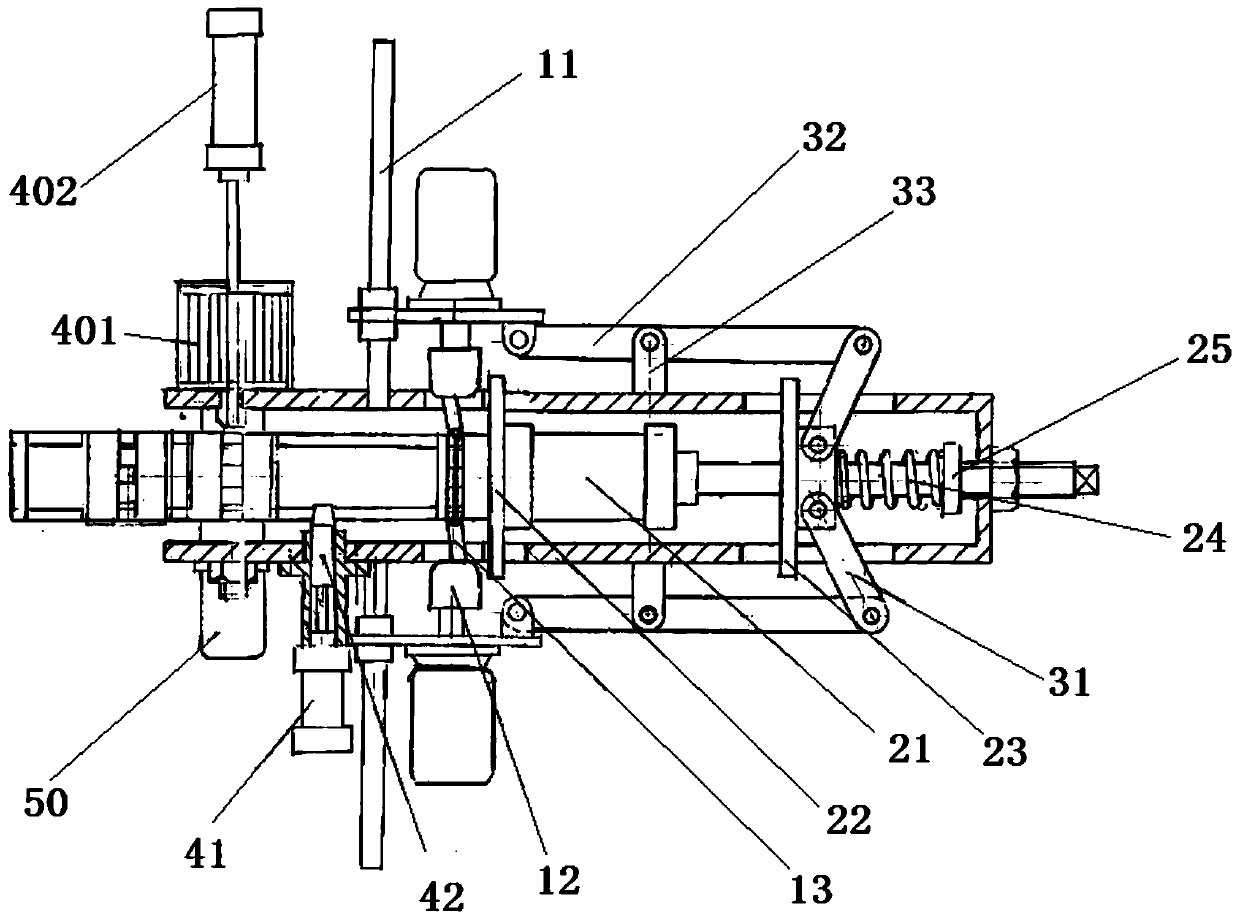

[0072] Embodiment one, such as Figure 8 As shown, the driving mechanism includes a driving cylinder, a push plate, an elastic device 24 and a pawl capable of unidirectionally limiting the positioning column. The end is arranged outside the groove, the ratchet is connected with the groove through the elastic device 24, the elastic device 24 is arranged directly below the ratchet, the push plate is connected with the driving cylinder, the ratchet is facing the positioning column arranged at the bottom of the feeding wheel structure, The rotation direction of the ratchet is opposite to that of the feeding wheel structure, and the driving cylinder is connected with the control mechanism.

Embodiment 2

[0073] Embodiment 2, the driving mechanism is a servo motor 50, the servo motor 50 is connected to the rotating shaft, and the servo motor 50 is connected to the control mechanism.

[0074] The feeding wheel structure and the support structure are all arranged on the right left of the pressing block. The feeding wheel structure is rotationally connected with the support structure through the rotating shaft. The support structure includes a first support plate and two second support plates arranged side by side. The two second support plates are symmetrically arranged on the front and rear sides of the first support plate, and the two second support plates The support plates are all fixedly connected to the first support plate, the feeding wheel structure and the driving cylinder are arranged between the two second support plates, the feeding wheel structure is connected to the two second support plates through the rotating shaft, and the driving cylinder is connected to the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com