Patents

Literature

182results about How to "Ensure accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Egr Cooler

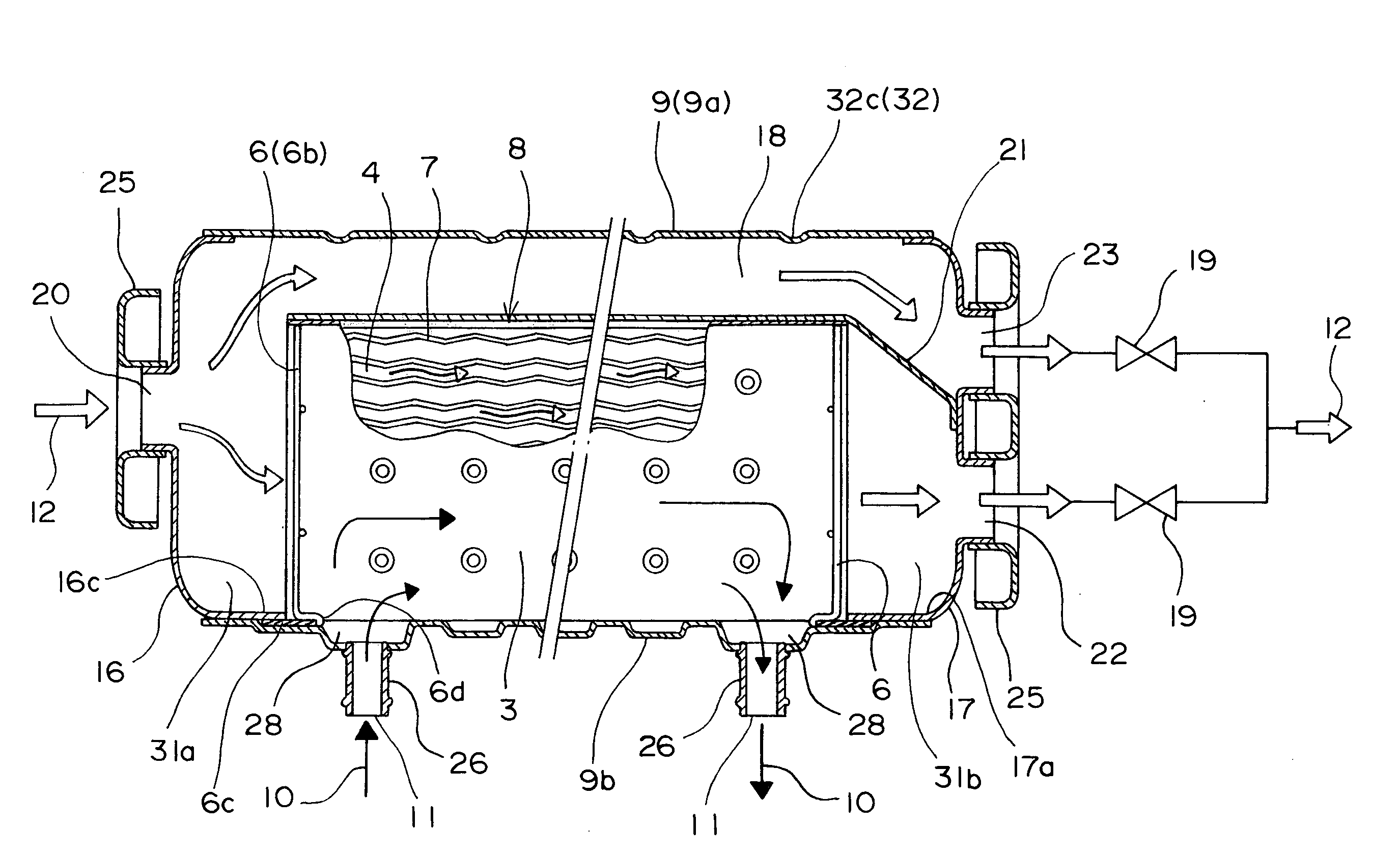

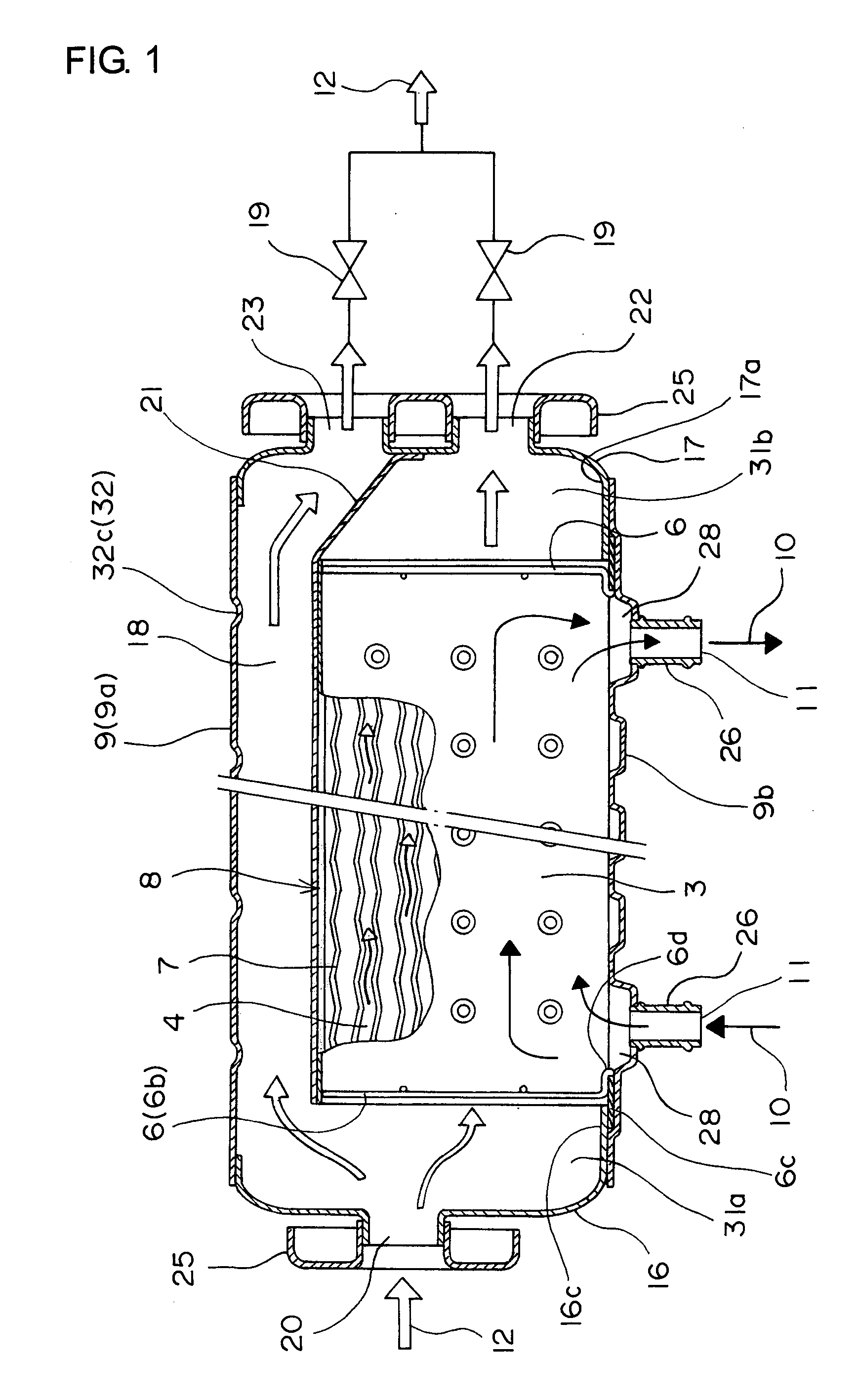

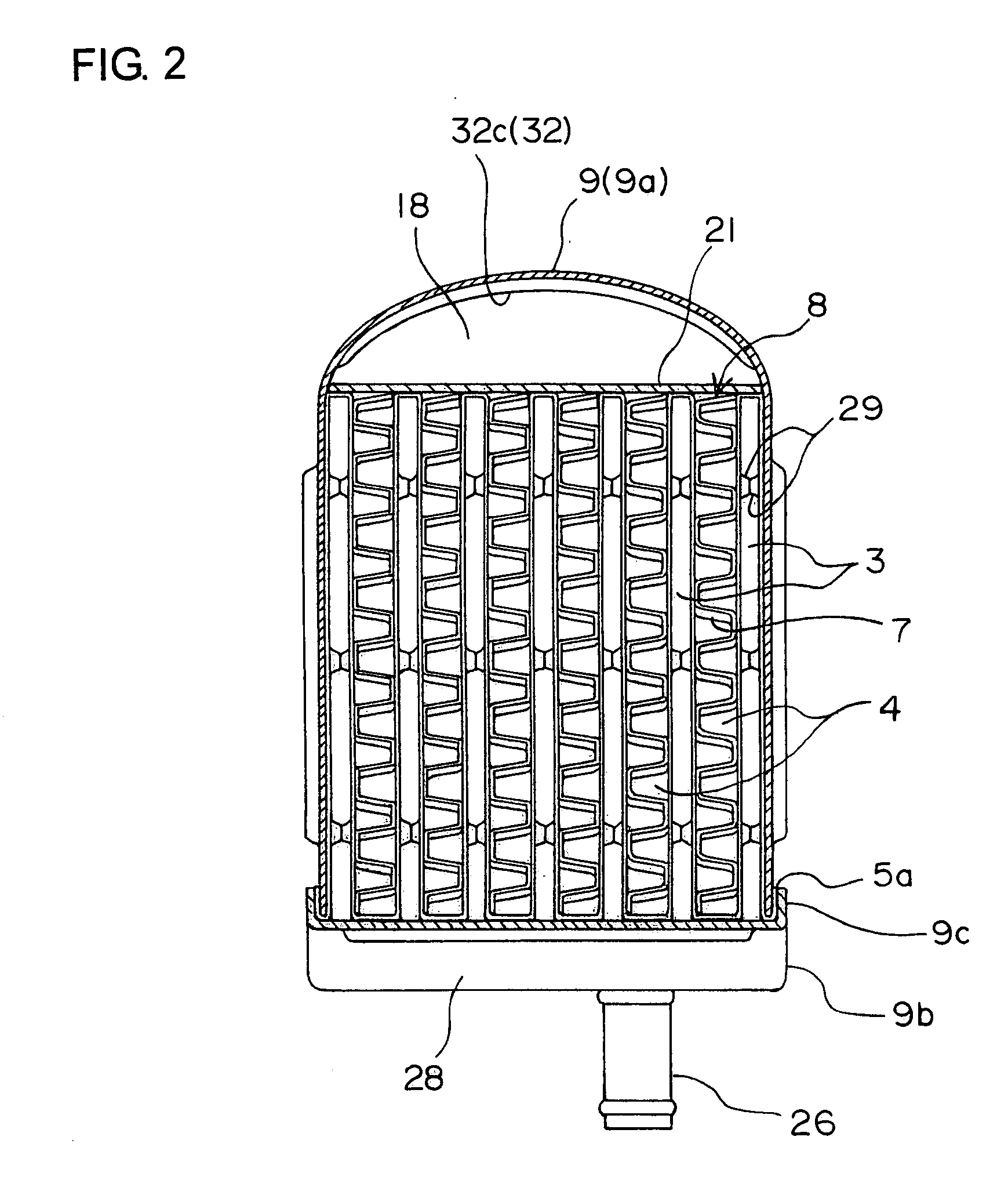

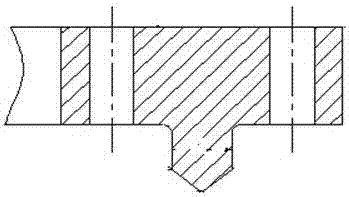

InactiveUS20070289581A1Easy to manufactureAvoid deformationInternal combustion piston enginesNon-fuel substance addition to fuelThin metalEngineering

A bypass duct portion is integrally provided in a casing of an EGR cooler so that heat distortion generated at a part of the casing when bypassing of an exhaust gas is rationally absorbed, and the EGR cooler body and a valve case are brazed / fixed all together so as to improve strength of the valve case, whereby, the bypass duct portion is formed between an inner surface of the casing and the core, a switch is provided for switching and guiding the exhaust gas to either of the core or the bypass duct portion, and a large number of outer ribs formed in the circumferential direction respectively are arranged side by side while being separated from each other in the longitudinal direction in the bypass duct portion of the casing so as to constitute a heat stress absorbing portion. And a cylindrical valve case is integrally formed by deep drawing of a thin metal plate by a press machine, a pair of slits are provided at the rear end of the valve case, both edges of an intra-valve partition plate are inserted into the slits, support projection portions are provided on both faces of the both edge portions of the intra-valve partition plate, and the edge of the slit is supported by the support projection portion. And an opening of the valve case is integrally brazed / fixed to an opening of a header portion of the casing.

Owner:T RAD CO LTD

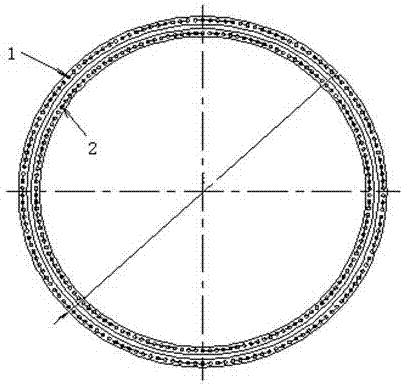

Construction process of wind power tower tube

InactiveCN107876943AGuaranteed accuracyReduce reworkFinal product manufactureWelding accessoriesNumerical controlElectricity

The invention relates to a construction process of a wind power tower tube. The construction process comprises the procedures of sectioned tube section manufacturing, tower tube flange installation, and tower tube assembly; sectioned tube section manufacturing comprises the procedures of factory inspection of raw materials, material reinspection, pretreatment of a steel plate, numerical control cutting blanking, dimensional inspection, groove machining, circle rolling, group-welding of longitudinal joints, circle rectifying, measuring of tube section ovality, 100%UT detection and T-shaped seam100%MT detection; tower tube flange installation is achieved through the procedures of flange detection, tower tube detection, flange fixing, tube body installation, welding measuring, bottom flangeassembly, tube body connection, bolt connection, tube body positioning welding and detection after welding jointly; and tower tube assembly comprises the procedures of grouping of tube sections and flange nipples, inspection, welding, 100% UT detection, inspection, drawing of position lines of inner parts, inspection, group-welding of the inner parts, anticorrosion treatment, assembly of the innerparts, packing and forwarding. The construction process has the advantage of being high in precision.

Owner:NANTONG BLUE ISLAND OFFSHORE CO LTD

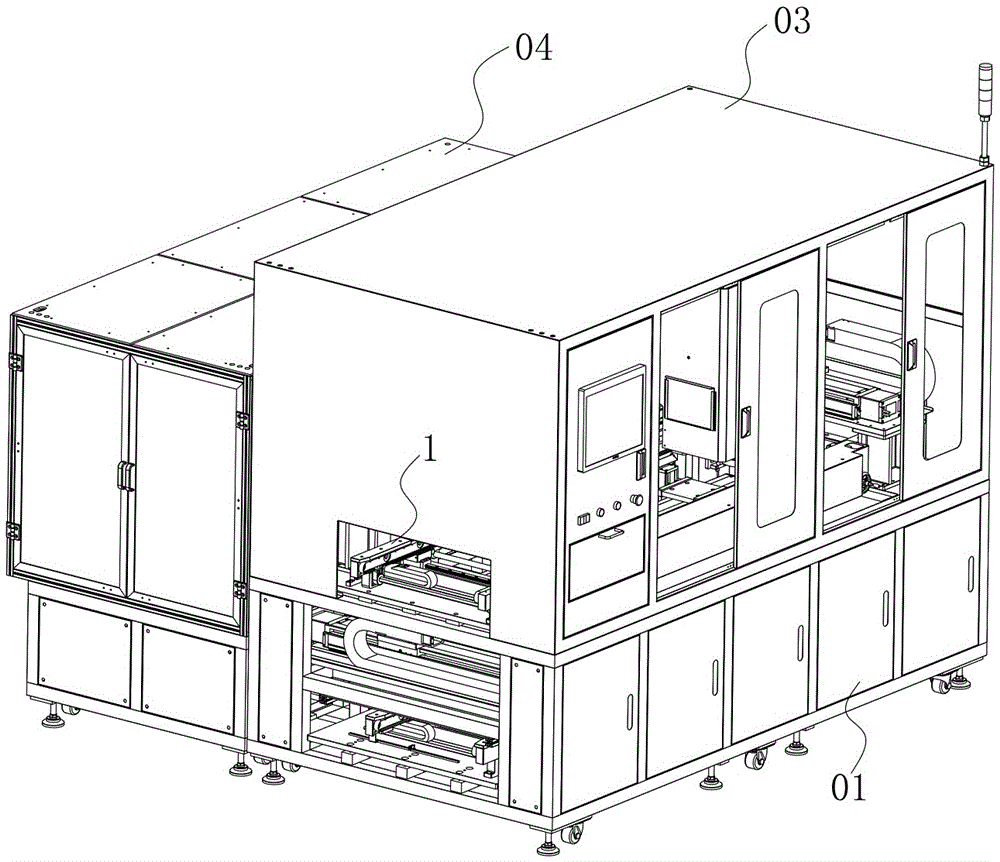

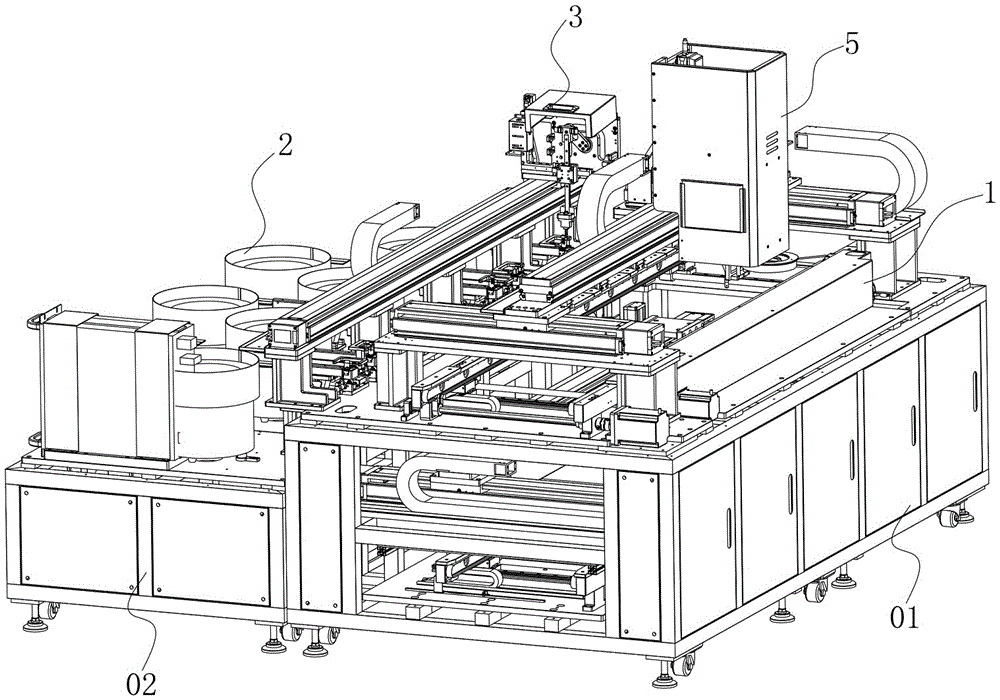

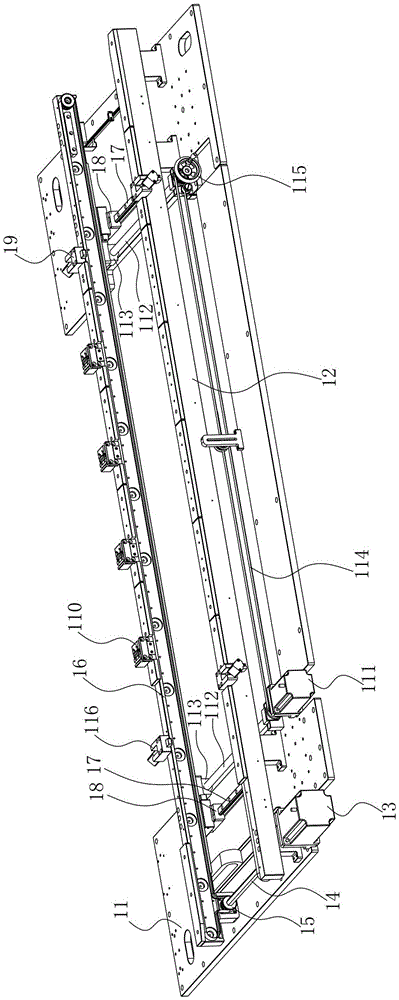

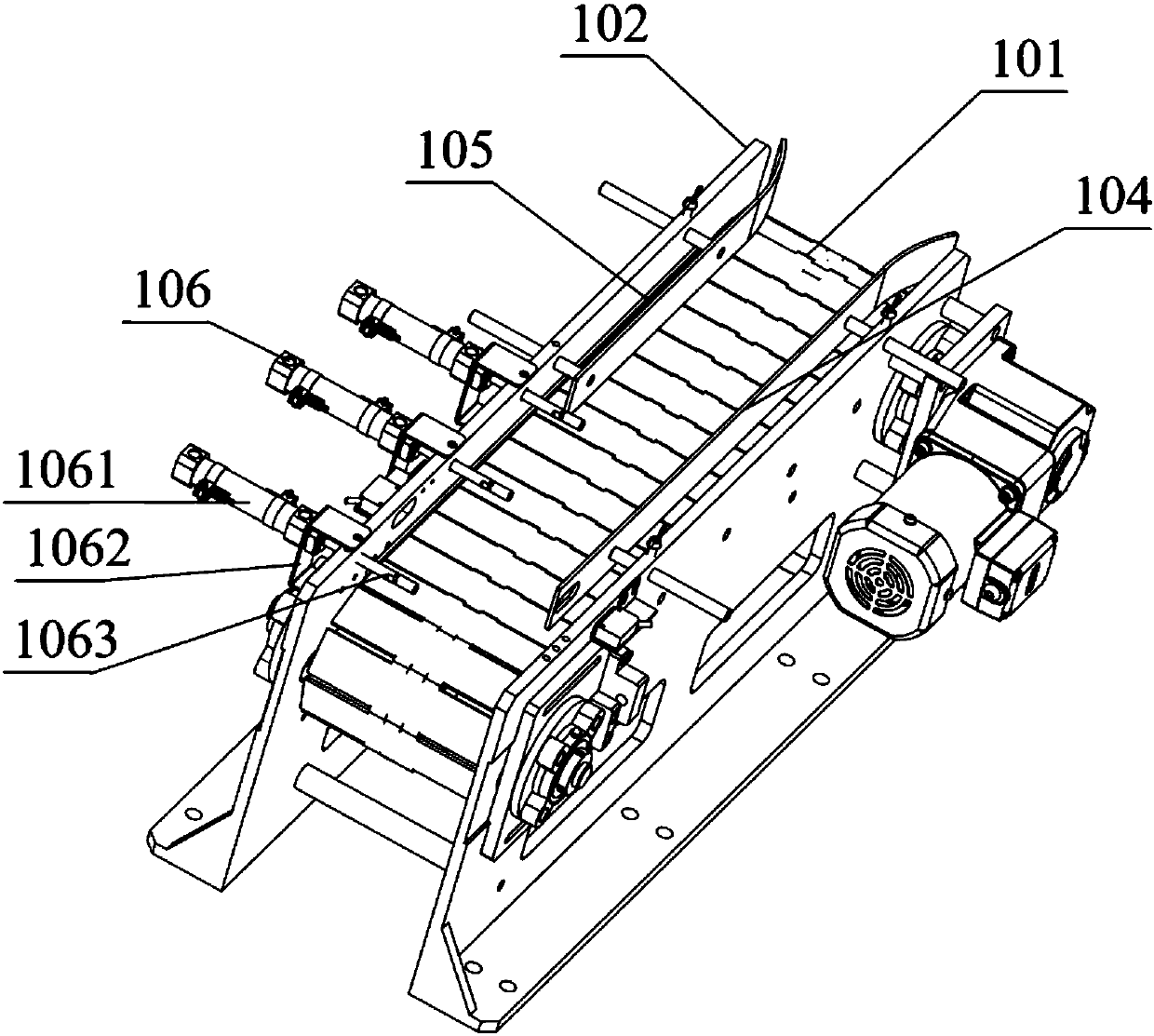

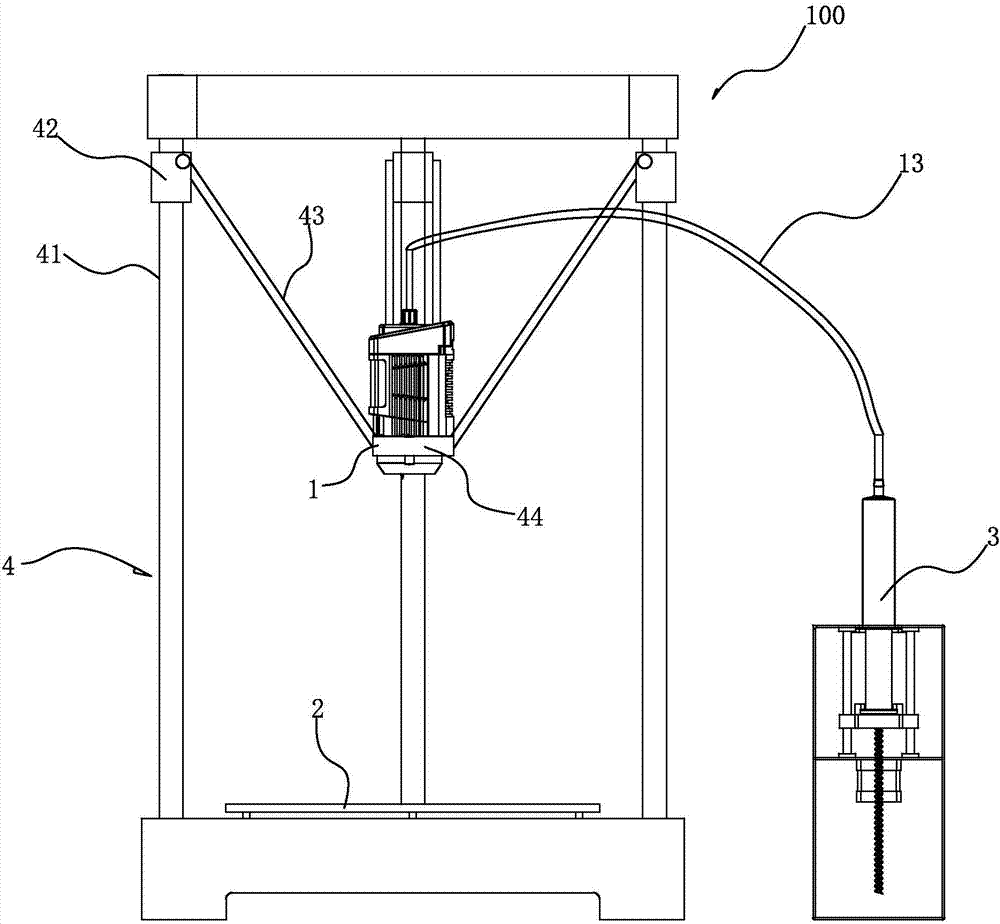

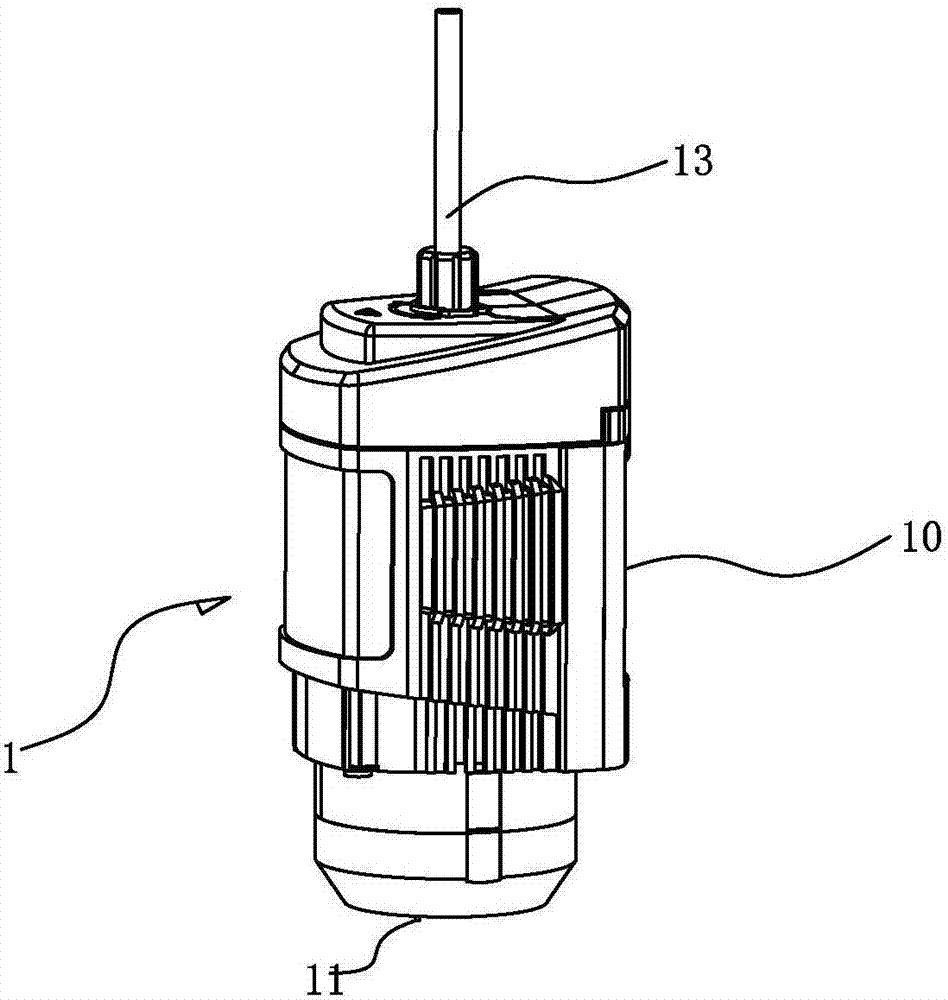

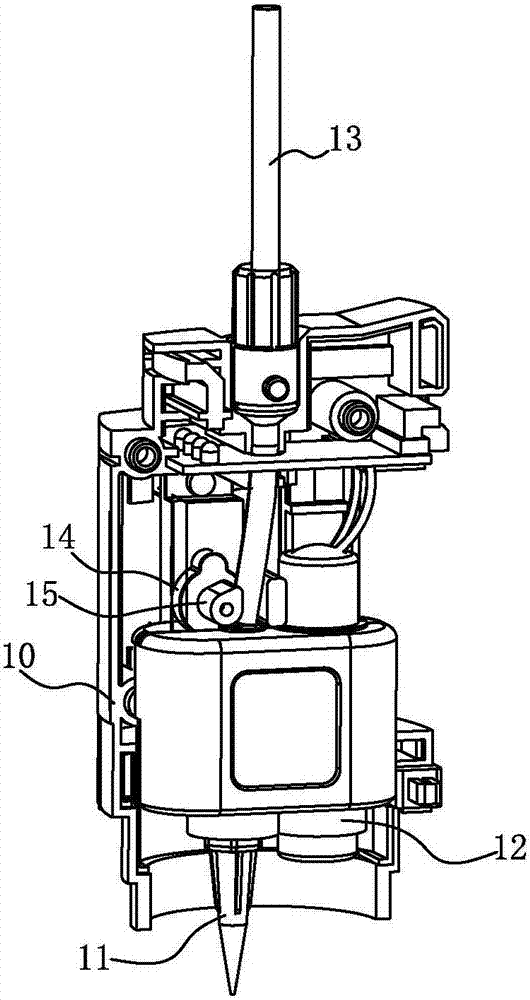

Automatic screw-driving machine

The invention discloses an automatic screw-driving machine which comprises a machine body assembly, a material guide mechanism, a material conveying mechanism, a material grabbing mechanism, a material ejecting mechanism and a screw-driving mechanism. The material guiding mechanism is arranged on a main machine frame of the machine body assembly. The material conveying mechanism is arranged on an auxiliary machine frame on one side of the main machine frame. The material grabbing mechanism is arranged between the material conveying mechanism and the material guide mechanism and conveys guide pins to the material ejecting mechanism. The guide pins are conveyed to the position below PCBs through the material ejecting mechanism. The screw-driving mechanism is arranged above the material guiding mechanism and drives screws into the guide pins. The automatic screw-driving machine is suitable for a PCB automatic machining assembly line, the functions of automatically positioning blocking materials and adjusting the sizes of the conveyed PCBs are achieved through the material guide mechanism, the automatic material feeding or blocking movement is achieved through the material conveying mechanism, the automatic conveying movement of the guide pins is achieved through the material grabbing mechanism, the automatic material ejecting movement is achieved through the material ejecting mechanism, and nuts are automatically locked on the guide pins through the screw-driving mechanism.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

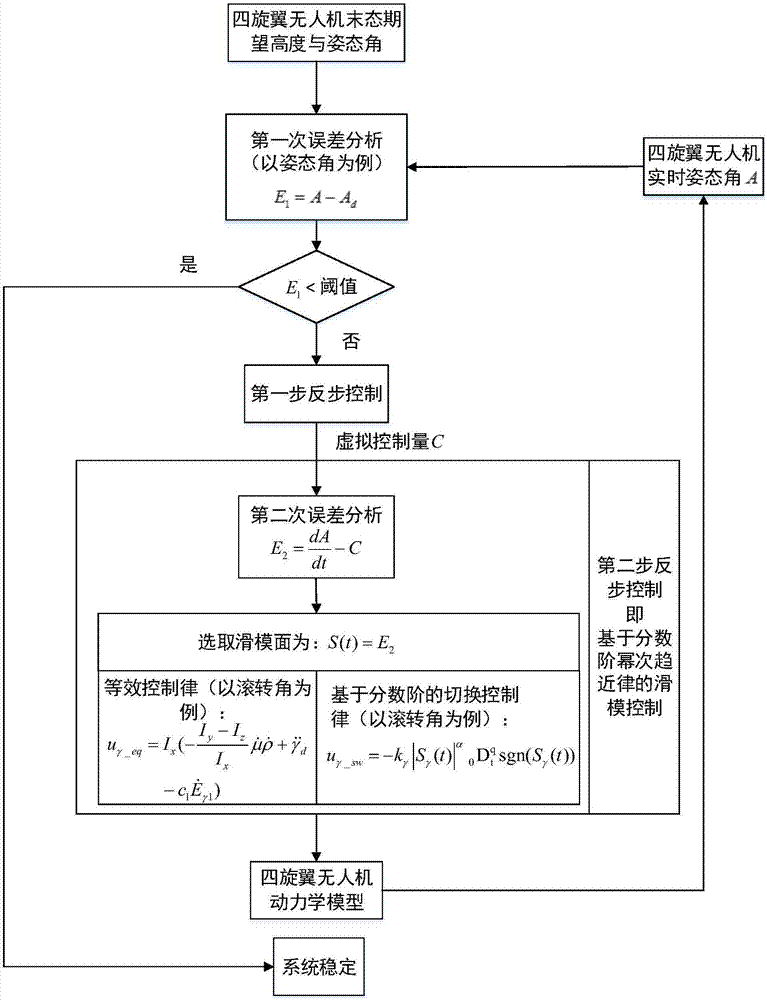

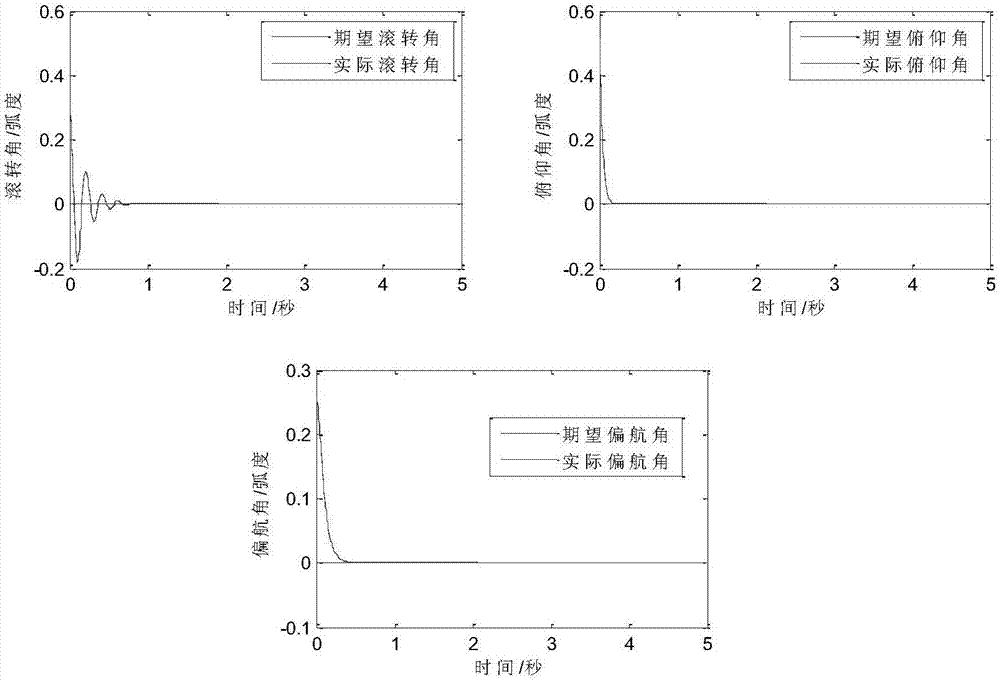

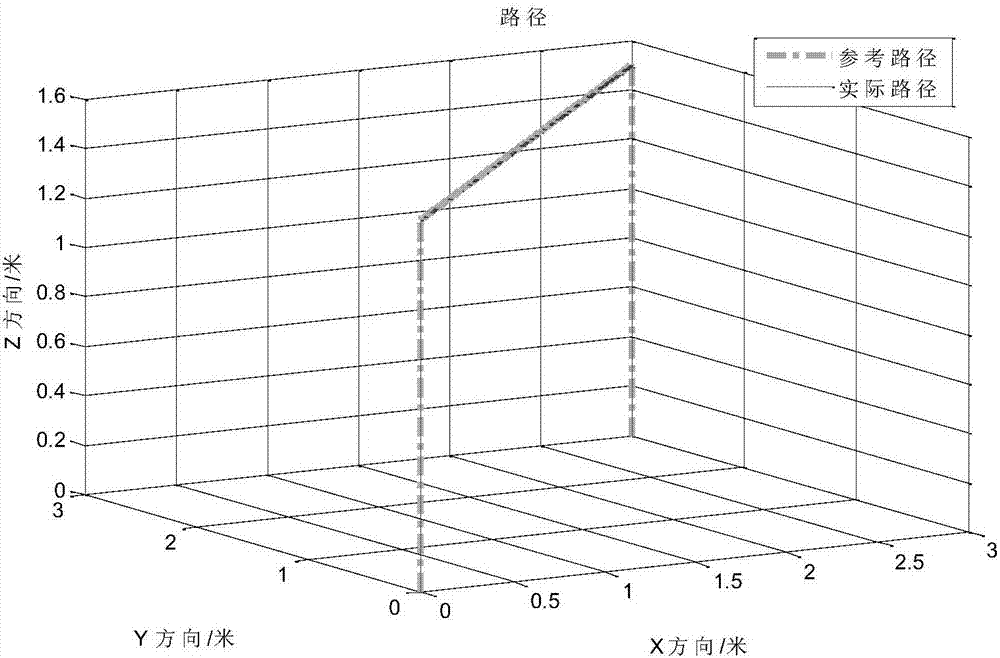

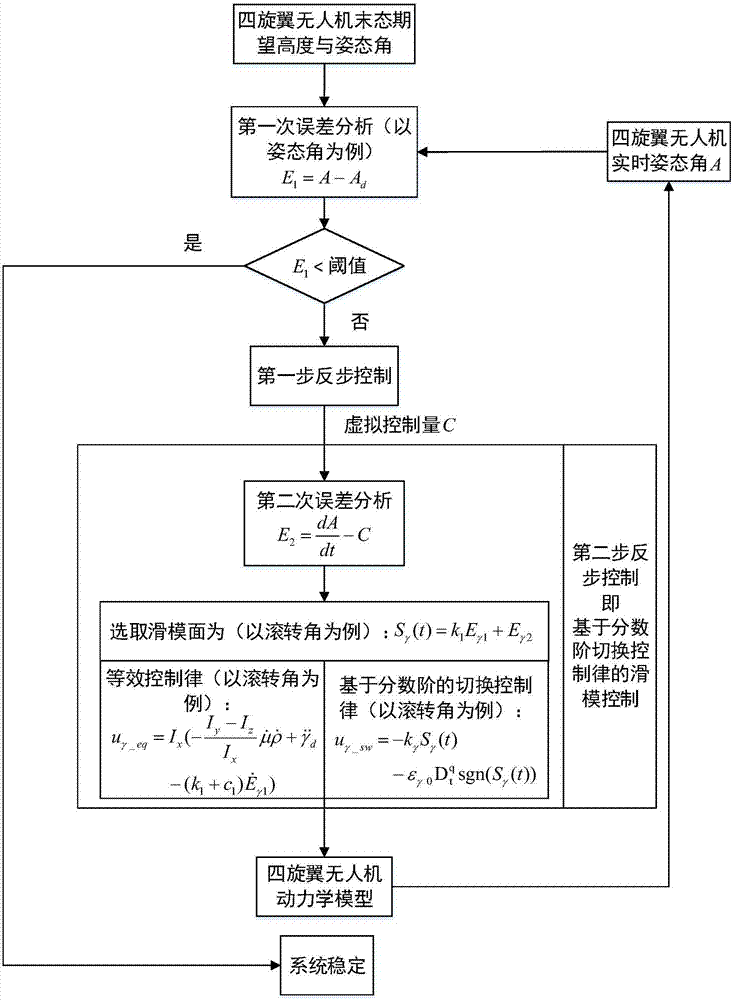

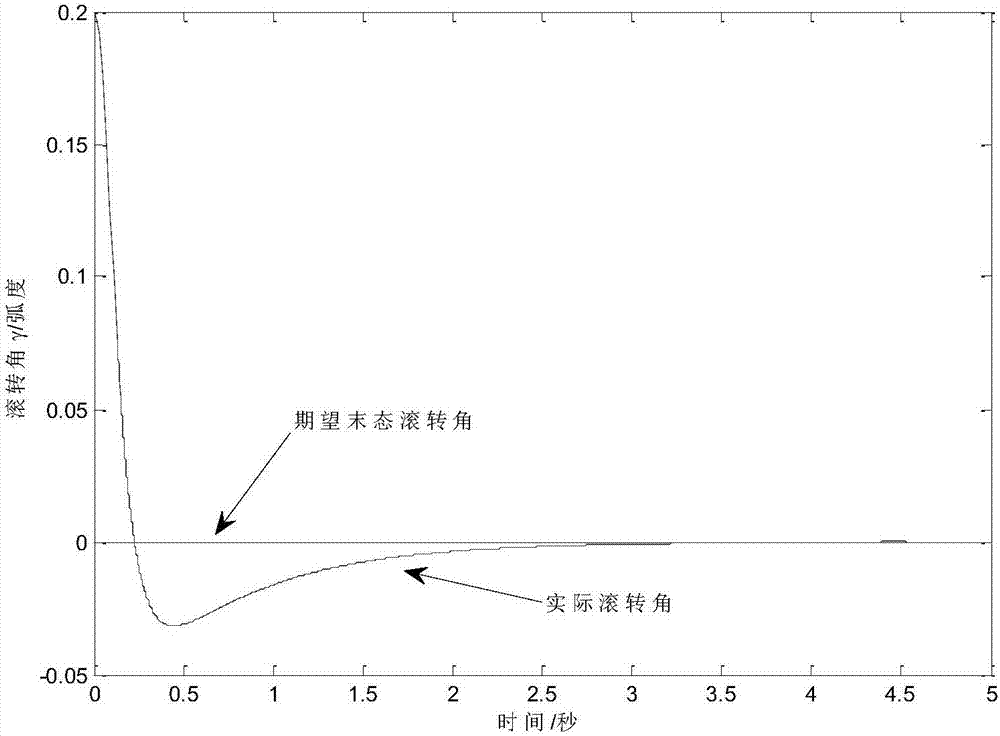

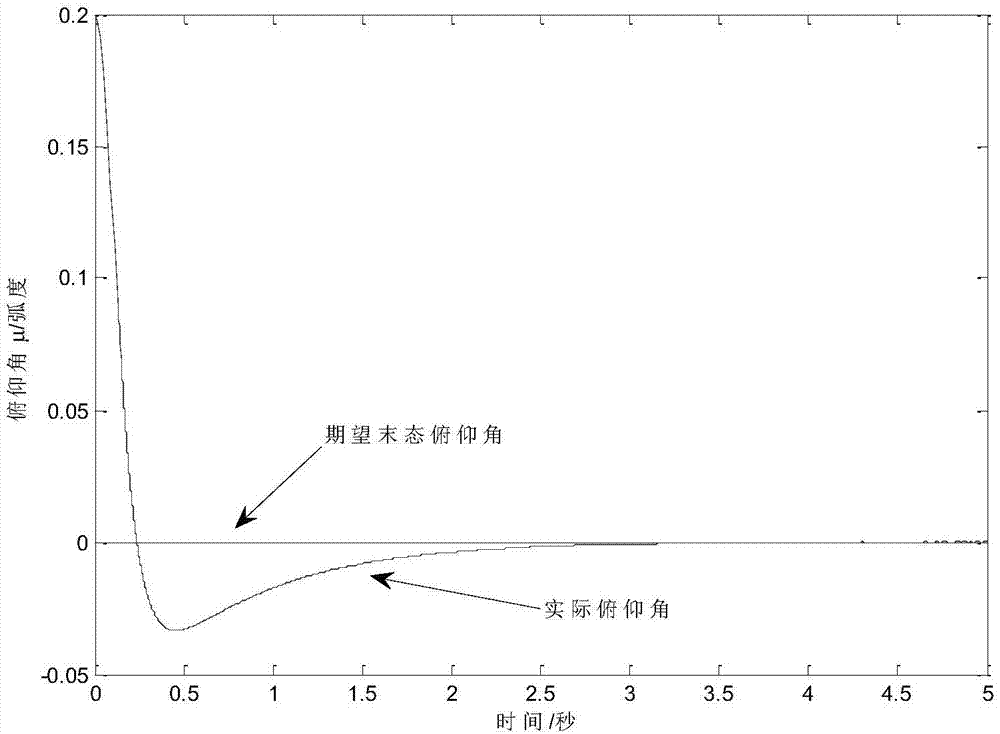

Four-rotor UAV flight control method based on fractional order power switching law

ActiveCN107992082AImprove anti-disturbance abilityImprove robustnessAttitude controlPosition/course control in three dimensionsStability theoryBackstepping

The invention discloses a four-rotor UAV flight control method based on a fractional order power switching law. A whole controller is of a backstepping control structure, a second-order nonlinear system of a quadrotor UAV is split into two subsystems, control laws that satisfy Lyapunov's stability theory are constructed, and the two subsystems are in series connection through a virtual intermediate control variable to form the complete controller, so that the controller can well adapt to the nonlinearity of the system and have good integrity. At the same time, in order to enhance the anti-disturbance capability and robustness of the controller, in the second backstepping design, the controlled variable is subjected to the sliding mode control design, which introduces the high disturbance resistance and high robustness of the sliding mode control. .

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

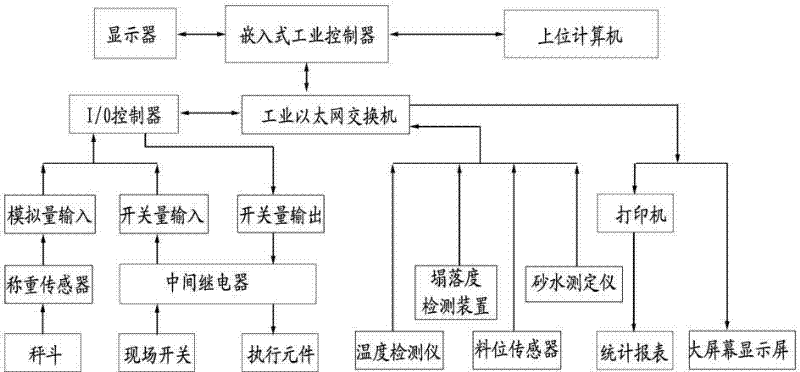

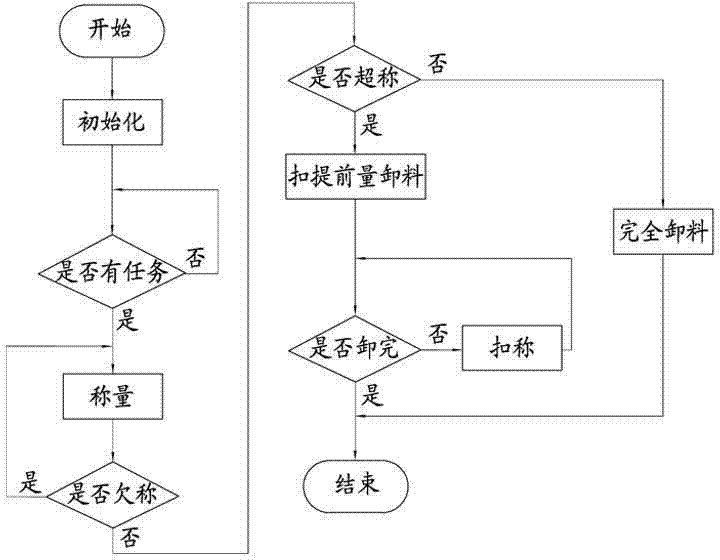

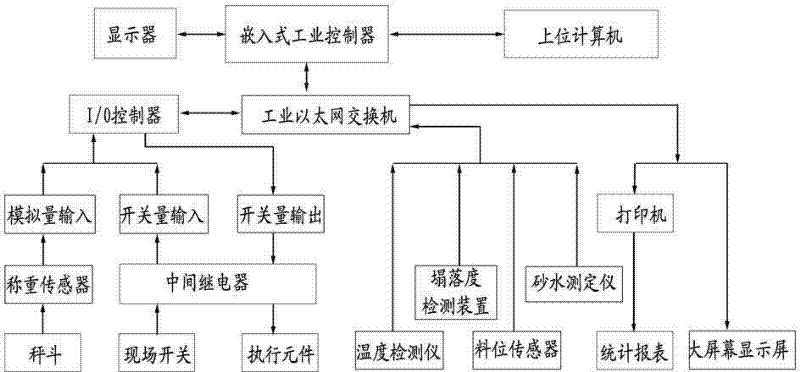

Stirring building or station embedded control system

InactiveCN102350736AGuaranteed accuracyEasy to operateControl apparatusMixing operation plantIndustrial EthernetControl system

Owner:ZHENGZHOU HYDRAULIC MACHINERY

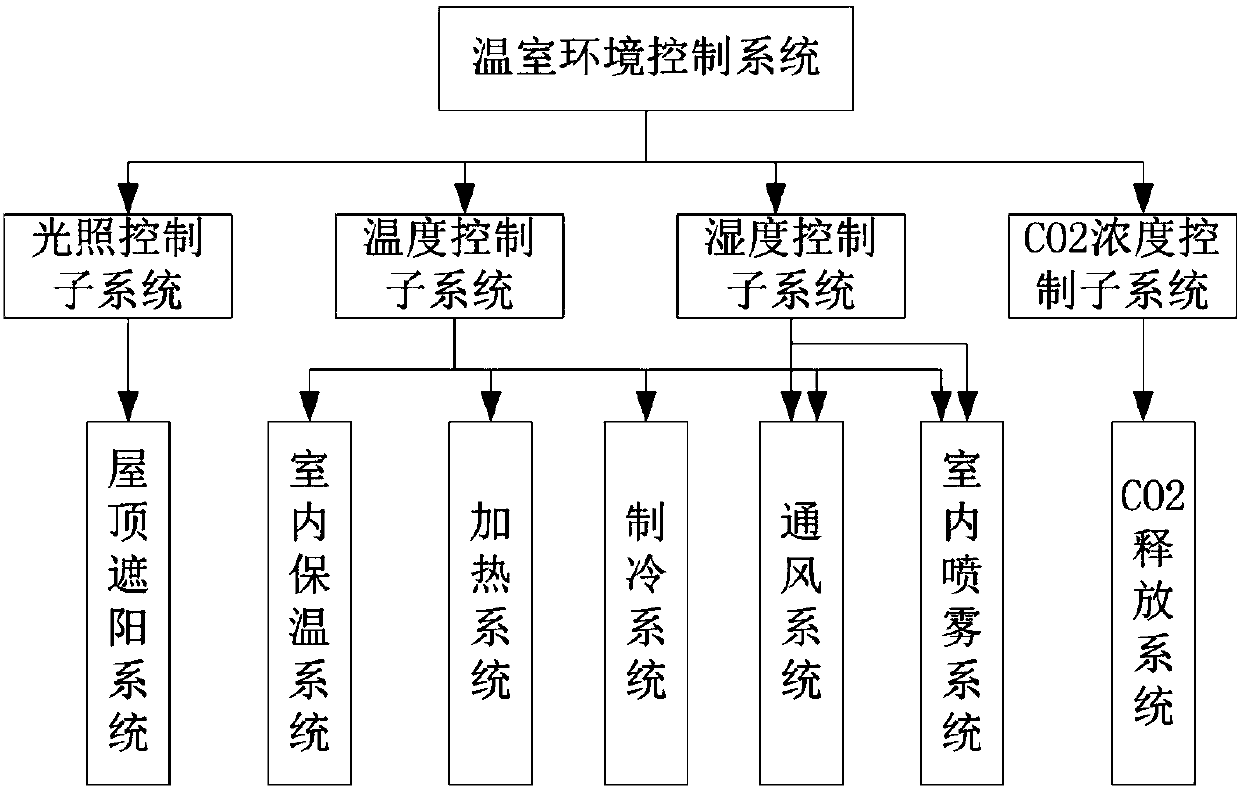

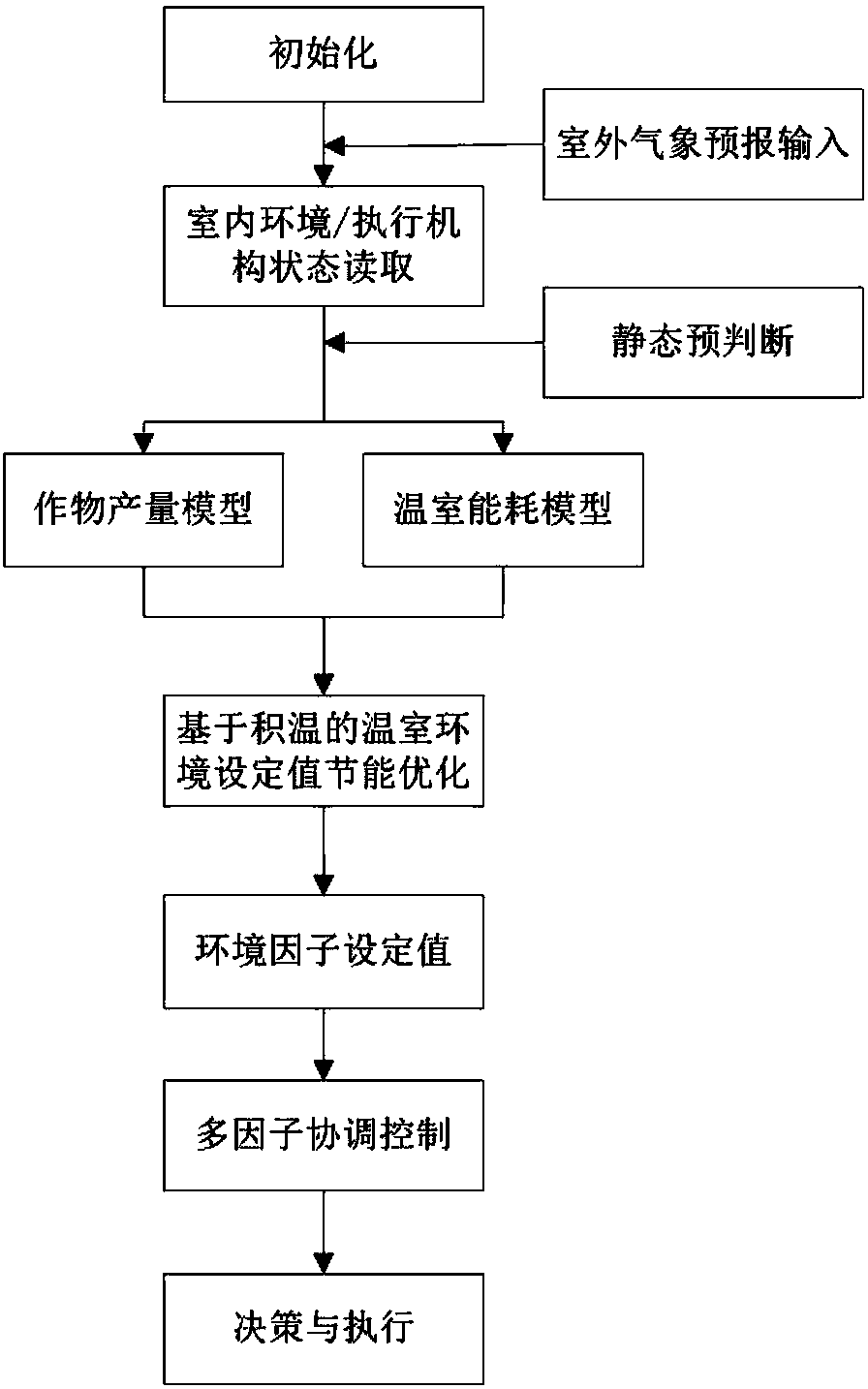

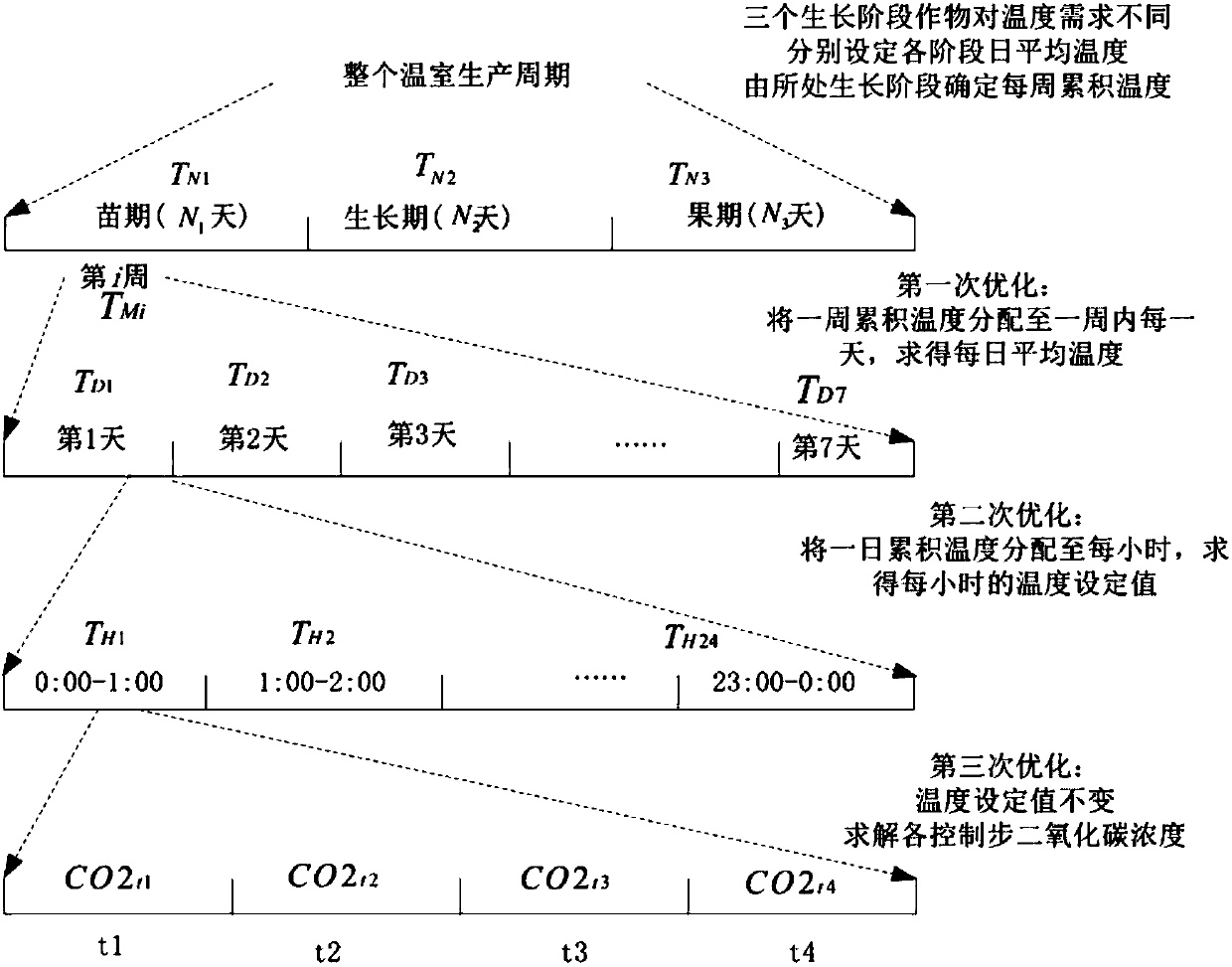

Multi-factor coordinated energy-saving optimization control method of greenhouse environment

ActiveCN107045367AReduce energy consumptionGuaranteed accumulated temperature requirementsSimultaneous control of multiple variablesEnvironmental factorCrop

The invention relates to a multi-factor coordinated energy-saving optimization control method of a greenhouse environment. The method comprises: (1), an expected daily average temperature of the crop in each growth period is set and weather forecast data of next seven days are obtained; (2), a greenhouse ventilation system state is estimated; (3), setting values of all environmental factors in the greenhouse are set by using a multi-factor coordination algorithm according to the steps (1) and (2), wherein the environmental factors include a temperature, humidity, a light radiation intensity and carbon dioxide concentration; and (4), real-time environmental factor values are obtained and corresponding executing mechanisms in the greenhouse are regulated according to the environmental factor setting values. Compared with the prior art, on the basis of crop physiological properties like temperature accumulation, the energy consumption of the greenhouse can be reduced effectively. With corresponding strategies, secondary greenhouse environment factors are coordinated to main temperature factors equivalently, thereby guaranteeing the precision and efficiency of greenhouse regulation, avoiding unnecessary energy wasting, saving the regulation cost, and ensuring the precise and effective controlling.

Owner:TONGJI UNIV

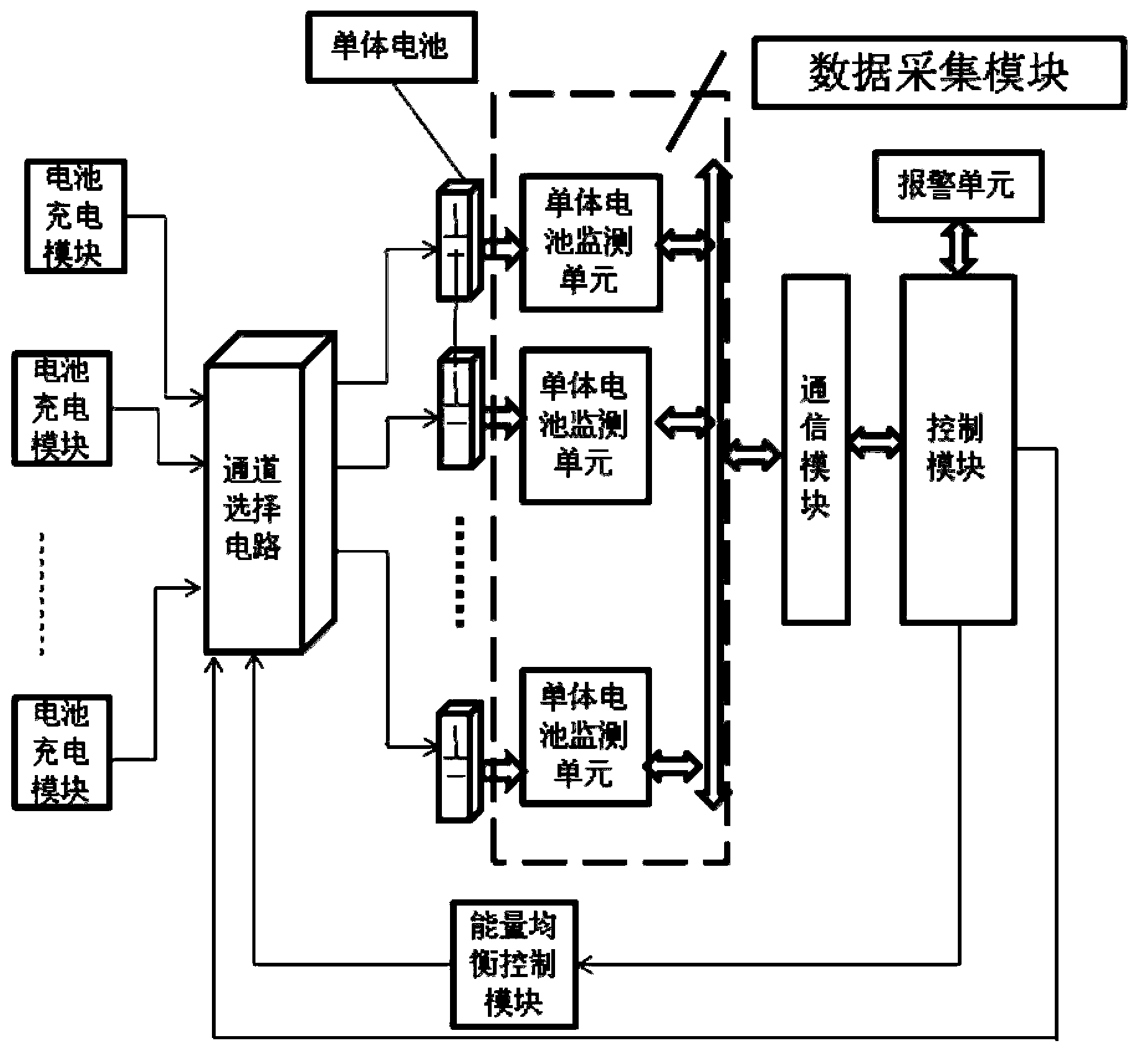

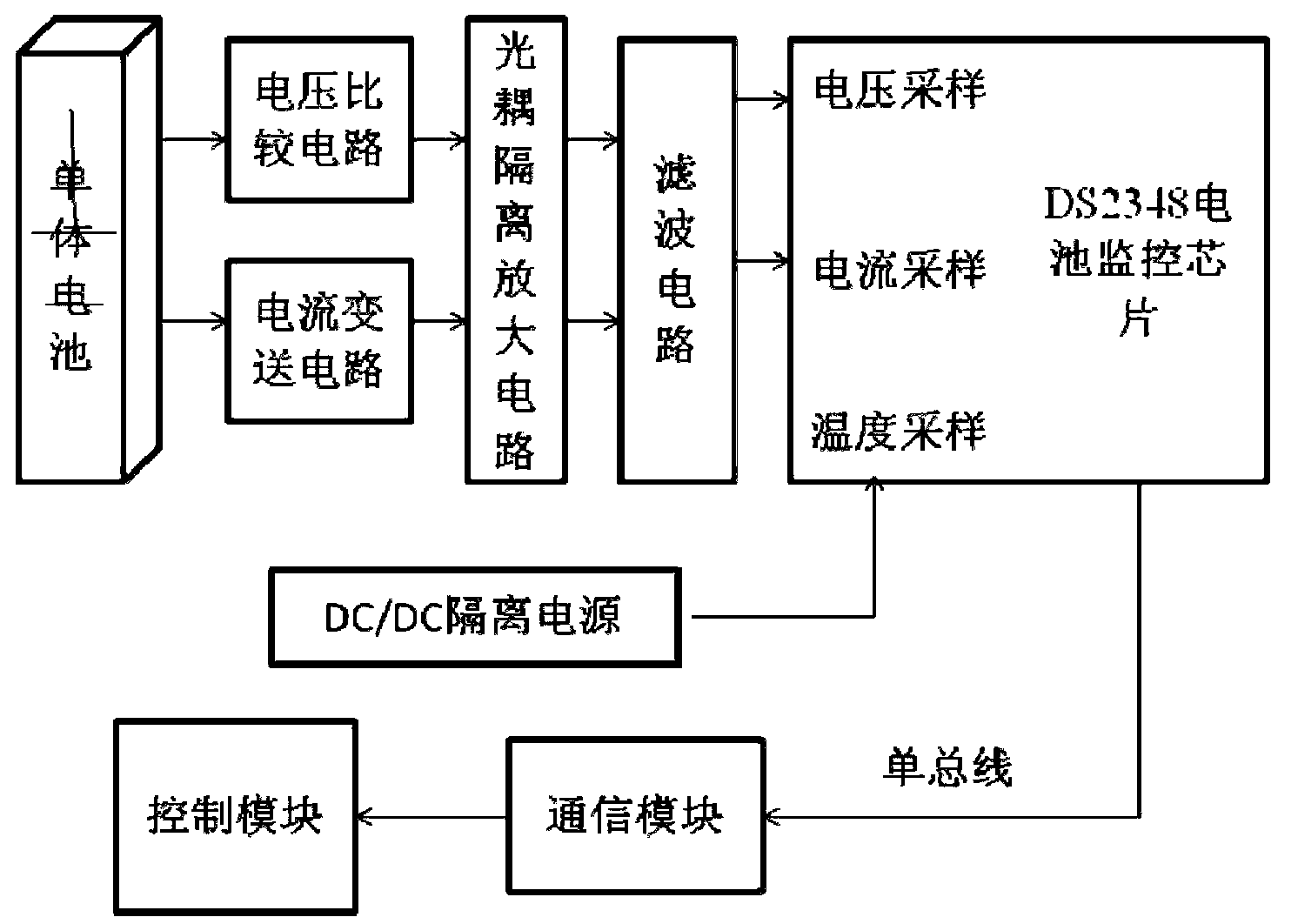

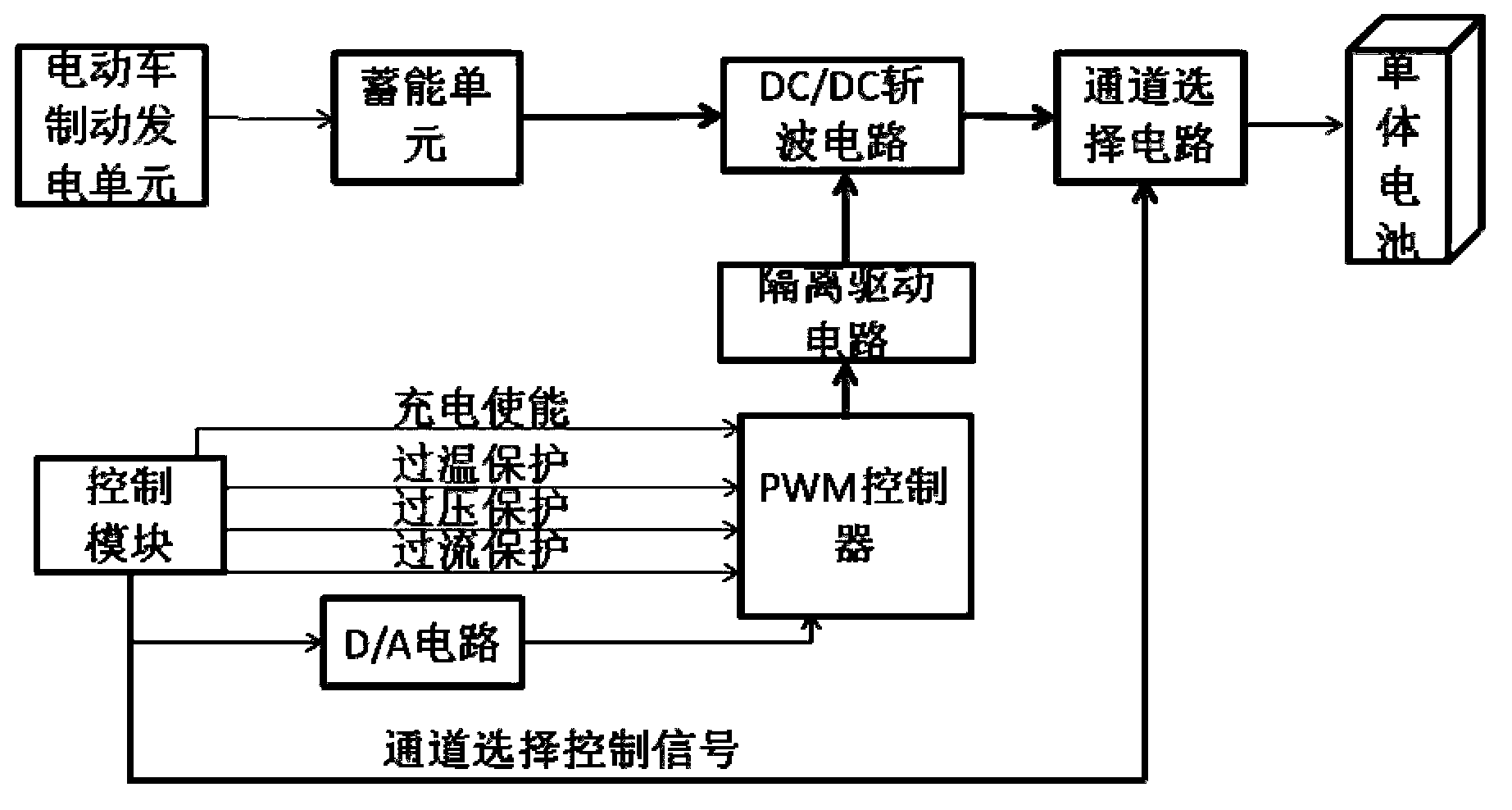

Data collection and energy balance control device and method for lithium battery pack of electromobile

InactiveCN103227491AExtended driving distanceImprove efficiencyBatteries circuit arrangementsEmergency protective circuit arrangementsBattery chargeData acquisition

The invention discloses a data collection and energy balance control device and method for a lithium battery pack of an electromobile. The device comprises a data collection module, an energy balance module, a channel selection circuit, a communication module and a control module, wherein the energy balance module, the channel selection circuit, the lithium battery pack, the data collection module, the communication module and the control module are connected sequentially. A charging mode is selected from battery charge modules or an energy storage unit automatically by the channel selection circuit; working conditions of battery cells are collected in real time by the data collection module; the control module selects corresponding battery cell channels; energy balance control is conducted on the battery cell channels by the energy balance module; a power generation system of the electromobile and the energy storage unit are effectively used for charging the battery cells on line timely during operation of the electromobile; the device generates less heat and is good in balance effect; the service efficiency of the lithium battery pack is improved; and a driving distance of the electromobile is prolonged effectively.

Owner:XIANGTAN UNIV

Optical scanning sensor

InactiveCN107490792AStrong converging effectIncrease the effective light-receiving areaElectromagnetic wave reradiationDriven elementLight source

The invention provides an optical scanning sensor, which comprises a light source, a light casting unit, a light receiving unit, a light receiver, a deflection unit, a curved light transmission cover, a rotation unit, and an angle encoder, wherein the deflection unit comprises a reflector and a reflector support; the rotation unit comprises a hollow part and a driving element; the light casting unit comprises a basic light casting unit, and the basic light casting unit and the light receiving unit are a transmitting-receiving coaxial optical system and are located at the same side of the reflector, and light reflected by a target area and deflected by the reflector enters the light receiver through a through hole in the hollow part; and the reflector is fixed above the rotation unit through the reflector support and rotates for 360 DEG under driving of the driving element.

Owner:BEIJING FREEMEASURE OPTOELECTRONICS TECH CO LTD

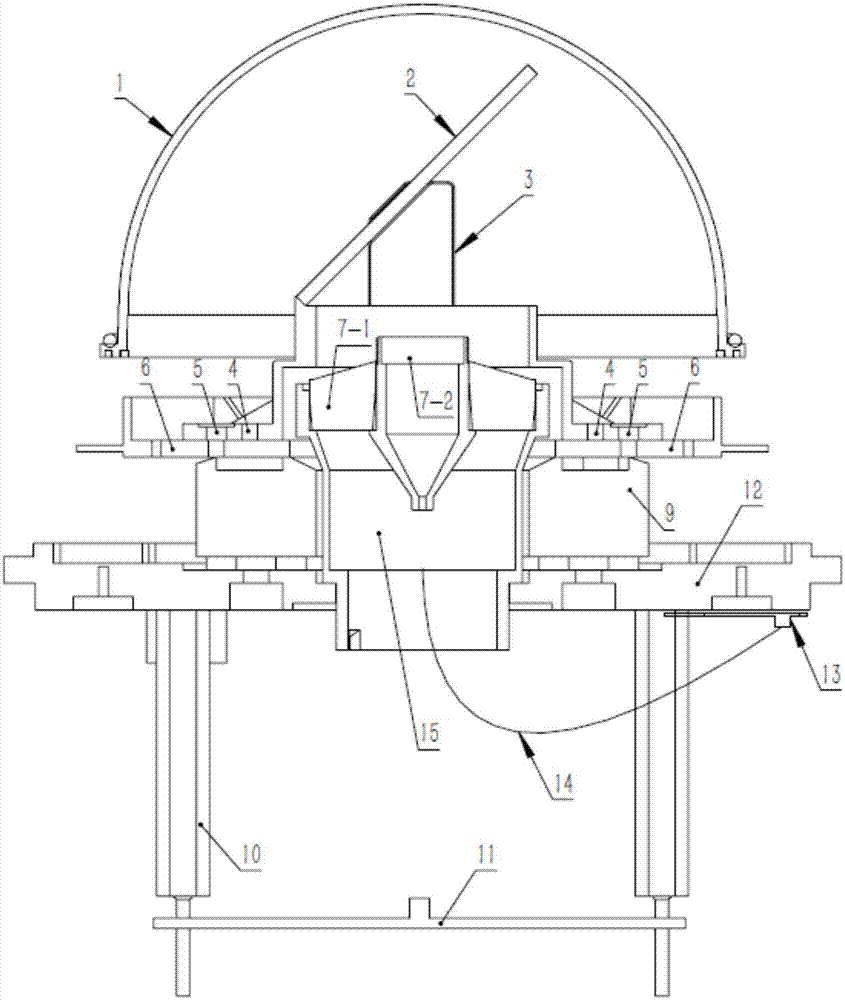

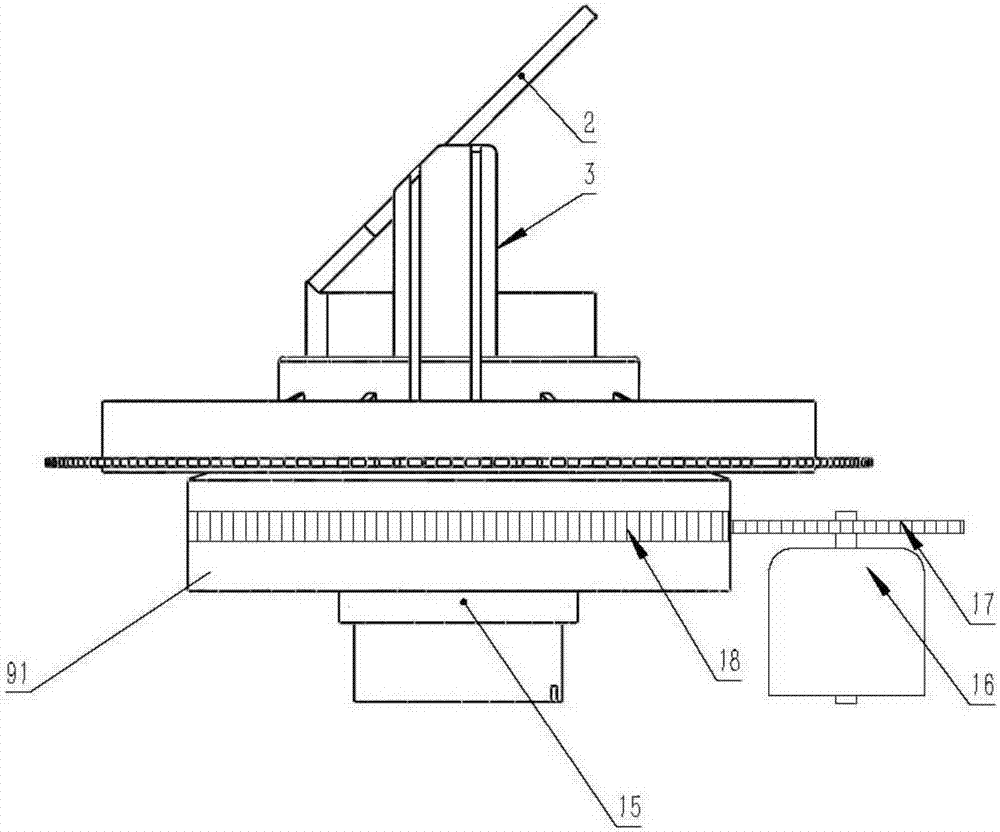

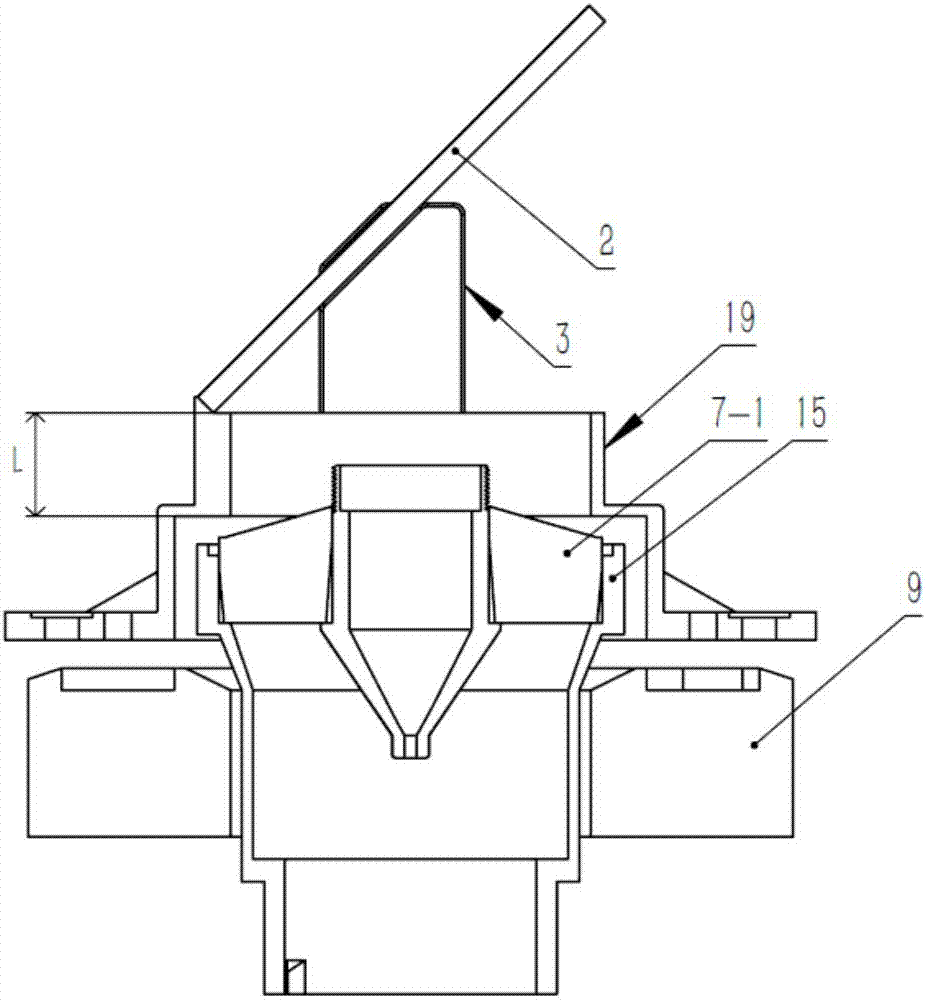

Test device and test method for I-II composite crack fatigue propagation rate

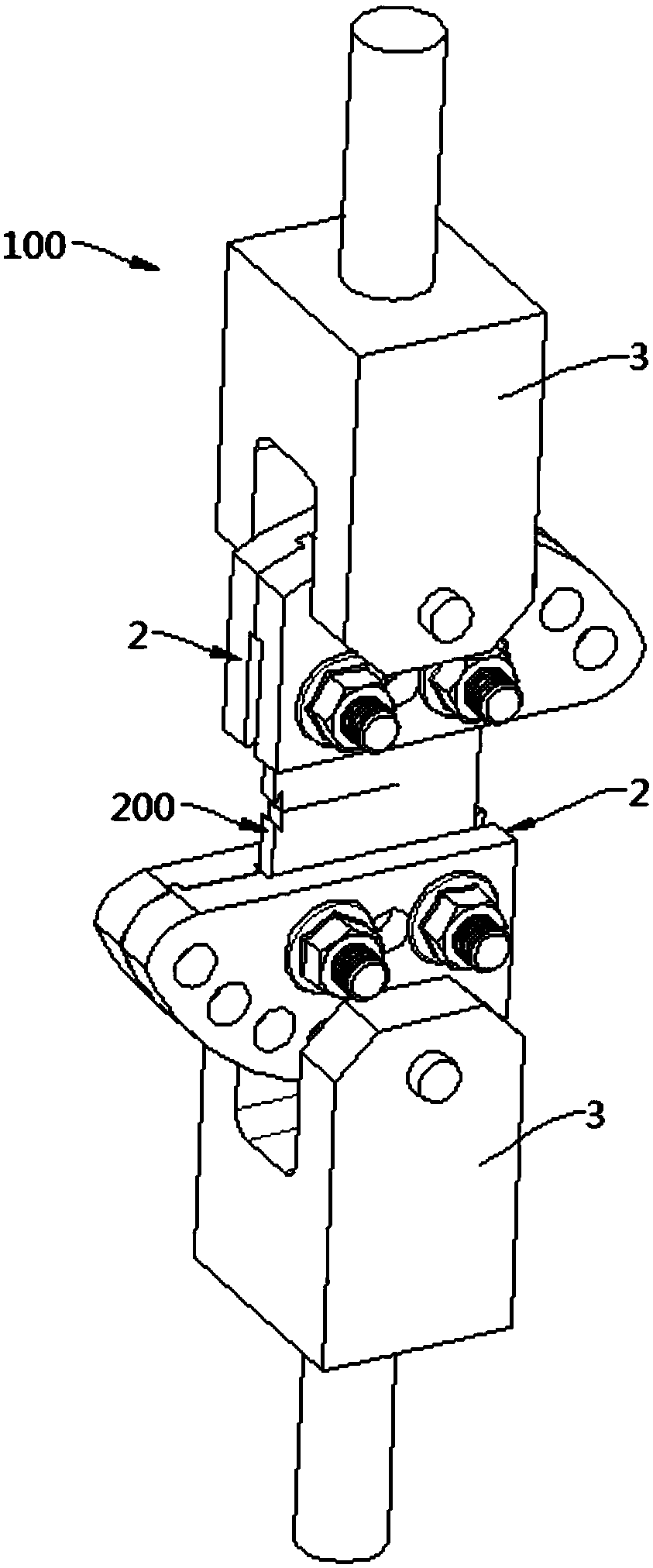

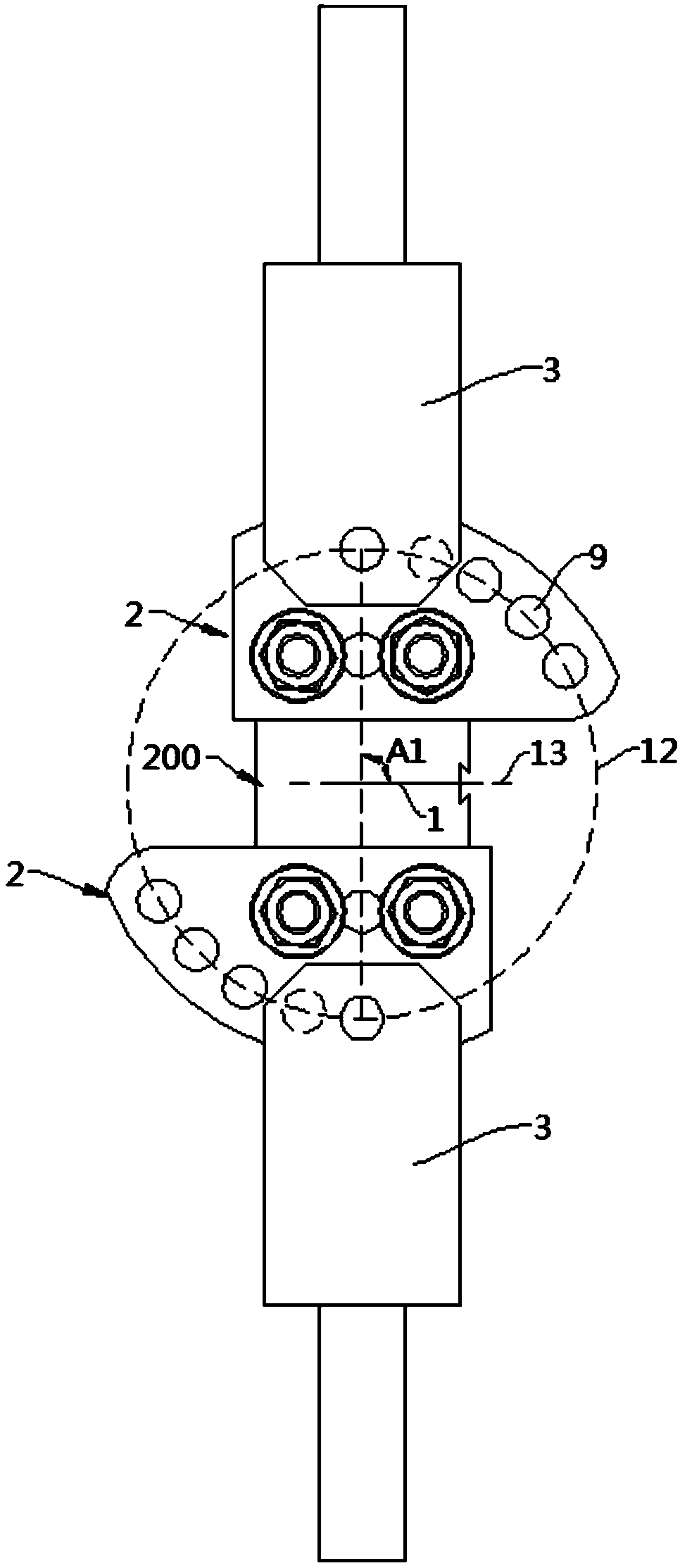

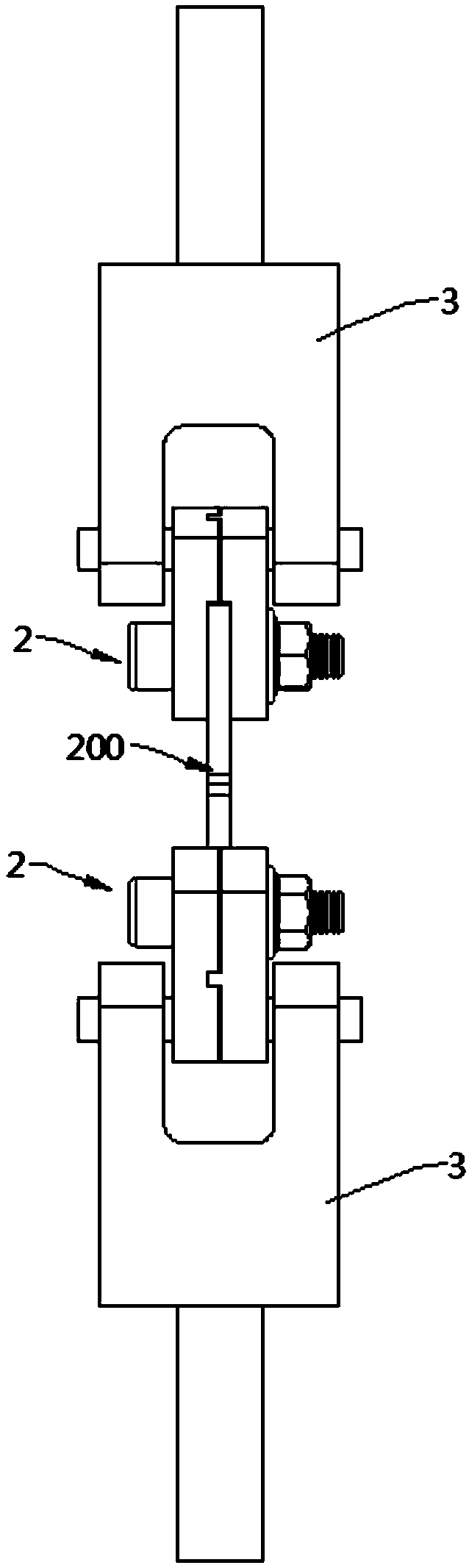

ActiveCN109030248AEnsure accurateEnsure reliabilityMaterial strength using repeated/pulsating forcesPropagation rateMaterials science

The invention relates to the technical field of mechanical experimental devices and testing methods, aims to solve the problems that the test device for crack fatigue propagation rate in the prior artcannot conveniently realize the alignment of samples, and the test precision and reliability are insufficient, and provides a test device and a test method for I-II composite crack fatigue propagation rate. The test device for I-II composite crack fatigue propagation rate comprises two clamps for respectively clamping both ends of a sample, wherein each clamp comprises two clamp plates having opposite surfaces and a locking structure connecting the two clamp plates; the locking structure is configured to lock the two clamp plates to clamp the sample or to loosen the two clamp plates to release the sample; and the clamps are configured to be clamped on the corresponding end of the sample in the form of making the corresponding end of the sample clamped between the two clamp plates and connected onto the locking structure. The test device and test method for I-II composite crack fatigue propagation rate provided by the invention have the beneficial effect of conveniently ensuring that the clamped sample is in the correct, for example, centered posture, thereby ensuring the accuracy and reliability of the implementation.

Owner:SOUTHWEST JIAOTONG UNIV

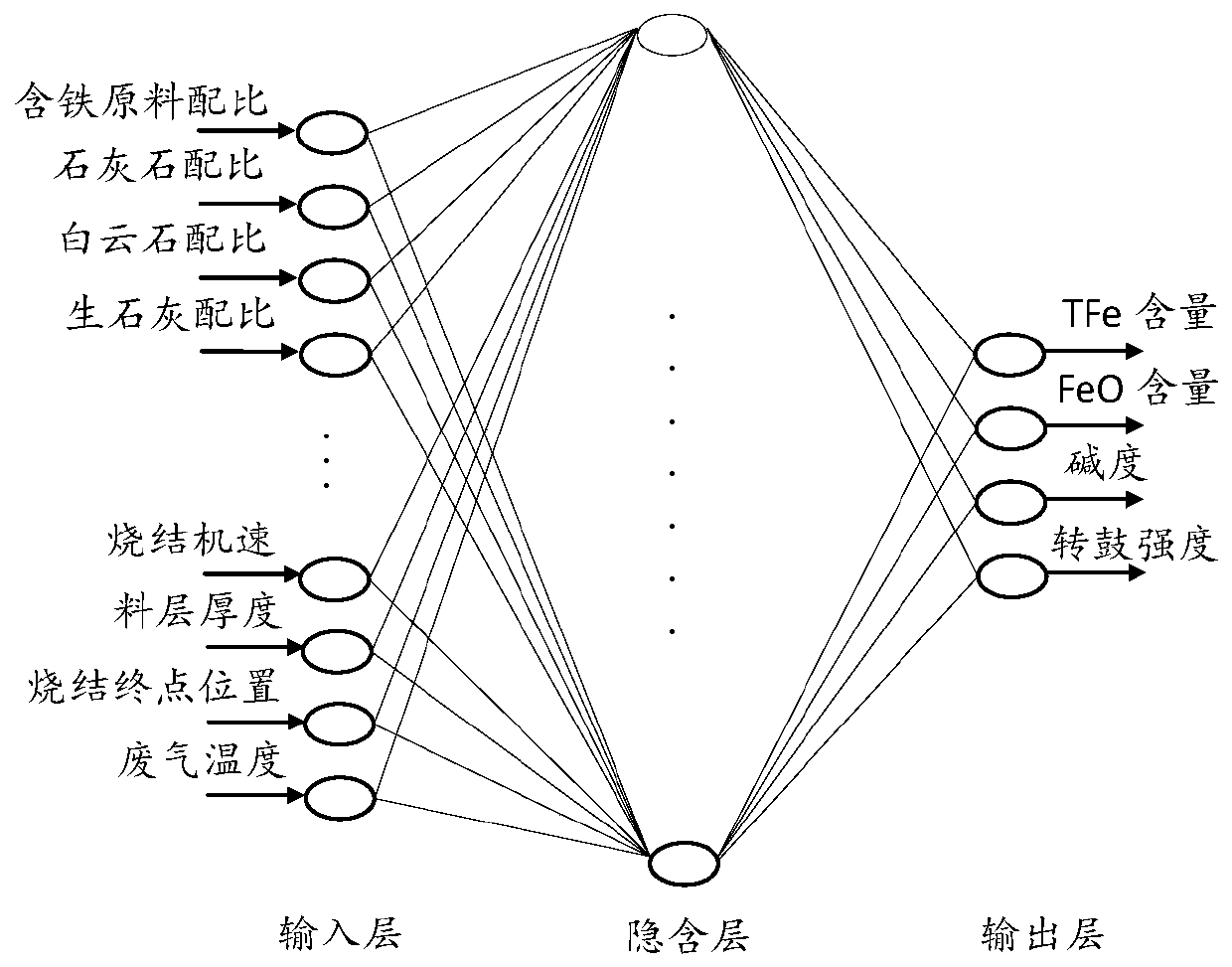

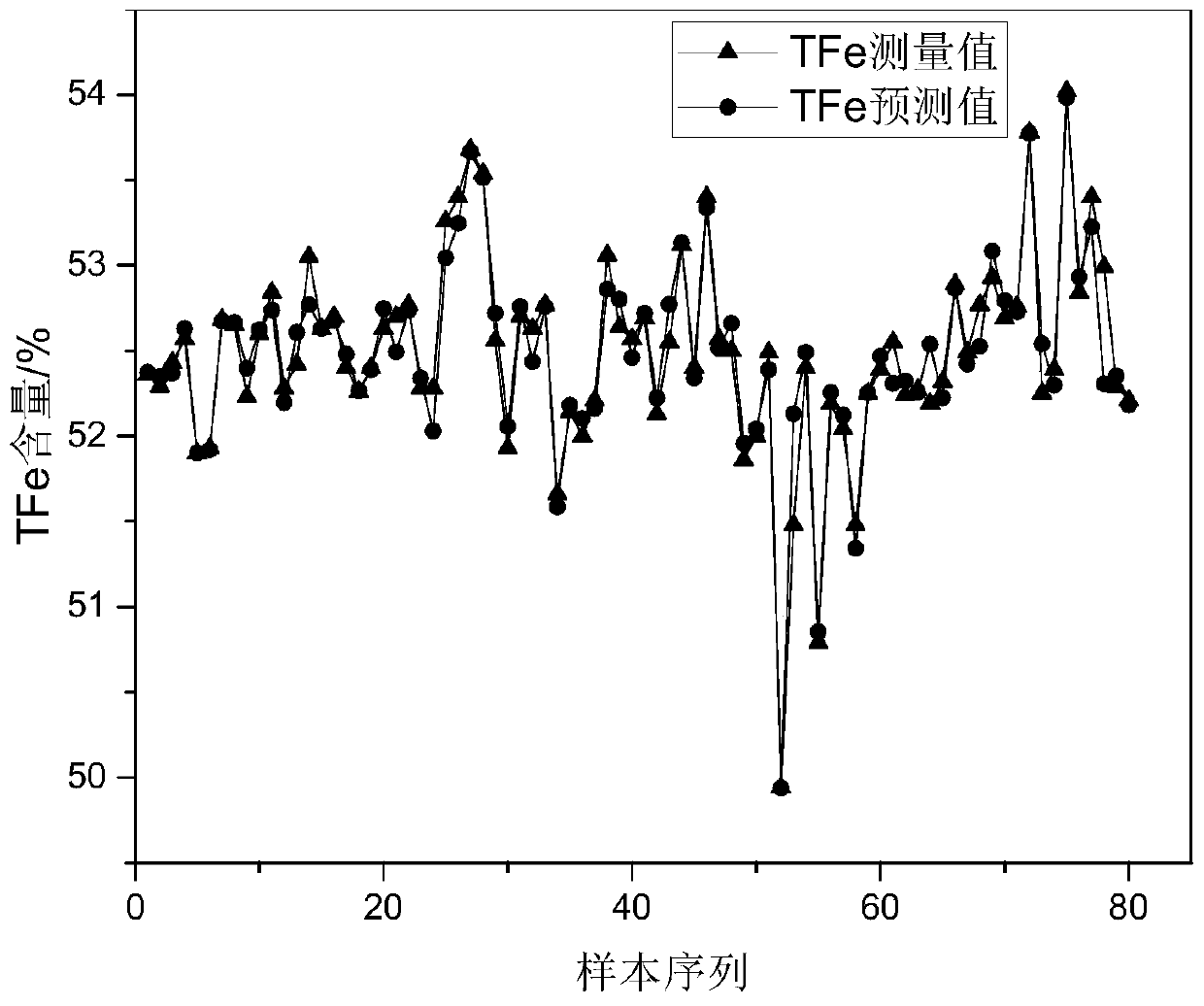

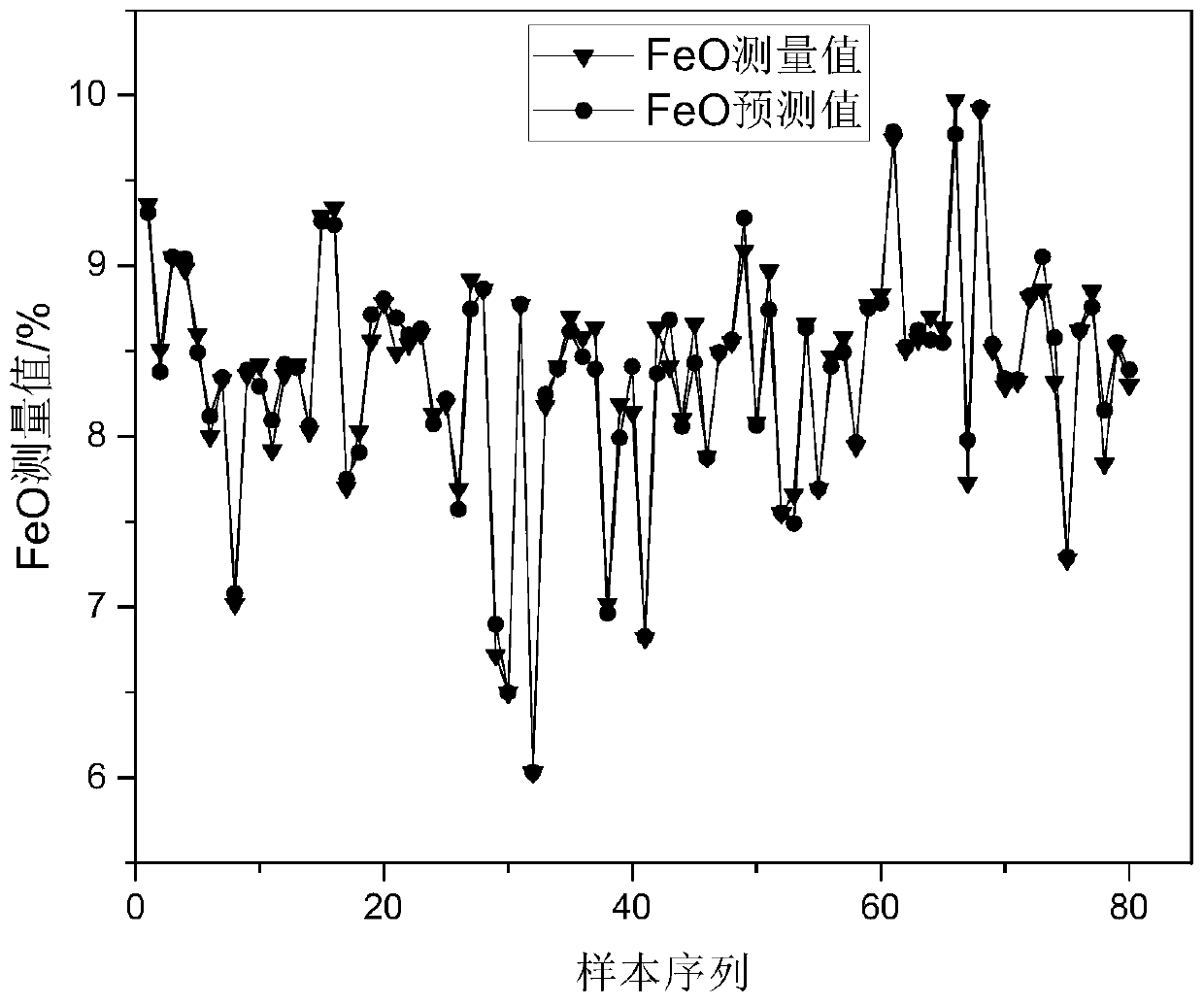

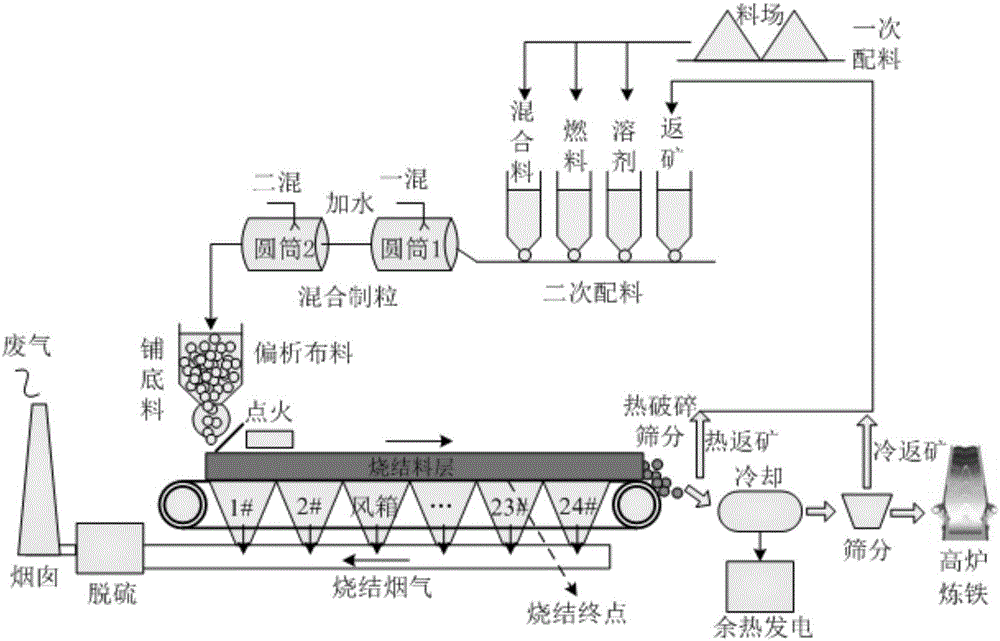

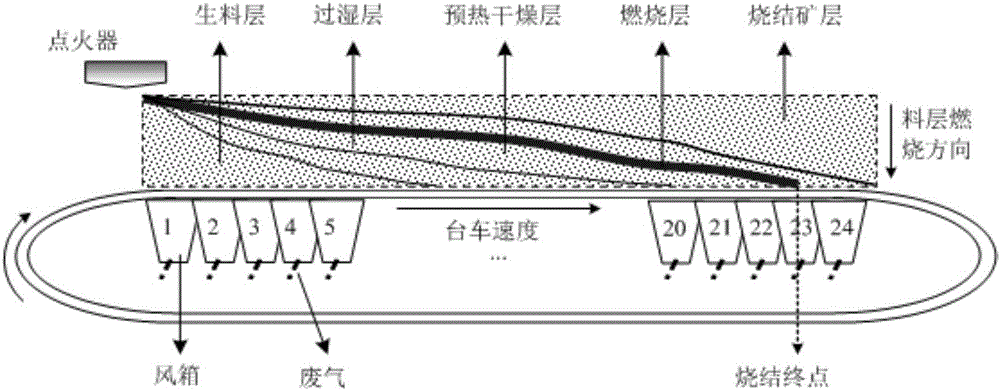

Sinter quality prediction method based on process parameters

InactiveCN110070217AEnsure accurateGuaranteed reasonablenessForecastingResourcesAlgorithmNetwork mapping

The invention relates to a sinter quality prediction method based on process parameters. According to the technical scheme, determining sinter quality parameters and sintering process parameters; establishing a historical production data sample library of sintering process parameters and sinter quality parameters, and performing [0, 1] normalization processing; by taking the normalized sintering process parameters as input variables and the sinter quality parameters as output variables, establishing a sinter quality prediction model based on the process parameters by adopting a BP neural network mapping nonlinear function; and taking the sintering process parameters collected in real time as input variables and inputting into the sinter quality prediction model,wherein the output variables are the predicted sinter quality parameters. The method can predict the sinter quality parameters in advance, and has the characteristics of high prediction precision and high generalization capability.

Owner:WUHAN UNIV OF SCI & TECH

Pneumatic grinding equipment for automobile universal joint

InactiveCN107838778ARealize all-round angle grindingReduced impact on grinding and grinding efficiencyGrinding carriagesGrinding drivesUniversal jointEngineering

The invention provides a pneumatic grinding device for automobile universal joints, which includes a feeding device, a grinding device and a discharging device. The grinding device includes a biaxial drive mechanism, a positioning grinding mechanism and a grinding rotation mechanism. The grinding rotation mechanism is arranged between the feeding device and the grinding rotation mechanism. Between the discharge devices, the dual-axis drive mechanism includes an X-axis drive mechanism and a Y-axis drive mechanism. The Y-axis drive mechanism is connected to the X-axis drive mechanism. The positioning and grinding mechanism is set on the Y-axis drive mechanism, and the X-axis drive mechanism drives the Y-axis The driving mechanism moves back and forth, and the Y-axis driving mechanism drives the positioning and grinding mechanism to move left and right. Under the control of the control system, the present invention performs precise grinding in a three-in-one manner. With the progress of the grinding process, the surface area and angle of the workpiece will also change, and the angle of the grinding tool is continuously adjusted through rotation, lifting and translation to better It adapts to the entire grinding process of the workpiece to adapt to different curved surface structures, ensuring the accuracy of the grinding angle and product quality.

Owner:杭州同筹网络科技有限公司

Equipment and method for automatically obtaining five-dimensional information of pulse condition based on three-dimensional laser scanning

ActiveCN108784654AFull accessGet the implementation synchronouslyDiagnostic recording/measuringSensorsCamera lensThree-dimensional space

The invention discloses equipment and method for automatically obtaining five-dimensional information of a pulse condition based on three-dimensional laser scanning. The equipment comprises a full-automatic pulse diagnostic locator, a pulse instrument and a computer, wherein the pulse instrument comprises a pulse sensor, a finger pressure controller, a laser generator, a laser receiver, a centralcontroller and the like; the pulse sensor comprises a flexible pulse diagnostic membrane, a pressure sensor, laser emitting lenses and laser receiving lenses, wherein the laser emitting lenses and thelaser receiving lenses all face the inner wall of the flexible pulse diagnostic membrane; an air pressure sensor is located in an airtight cabin; scanning lasers generated by the laser generator aresynchronously transmitted to the three laser emitting lenses, and the three laser receiving lenses receive the reflected lasers and transmit the lasers to a laser receiver; an air pressure and fingerpressure control mechanism, the laser generator and the laser receiver are all connected to a central controller; the central controller is connected to a computer system. The equipment and method forautomatically obtaining the five-dimensional information of the pulse condition based on three-dimensional laser scanning can quickly obtain the accurate five-dimensional (three-dimensional space + time + mechanical characteristics) information of the pulse condition.

Owner:广州中康资讯股份有限公司

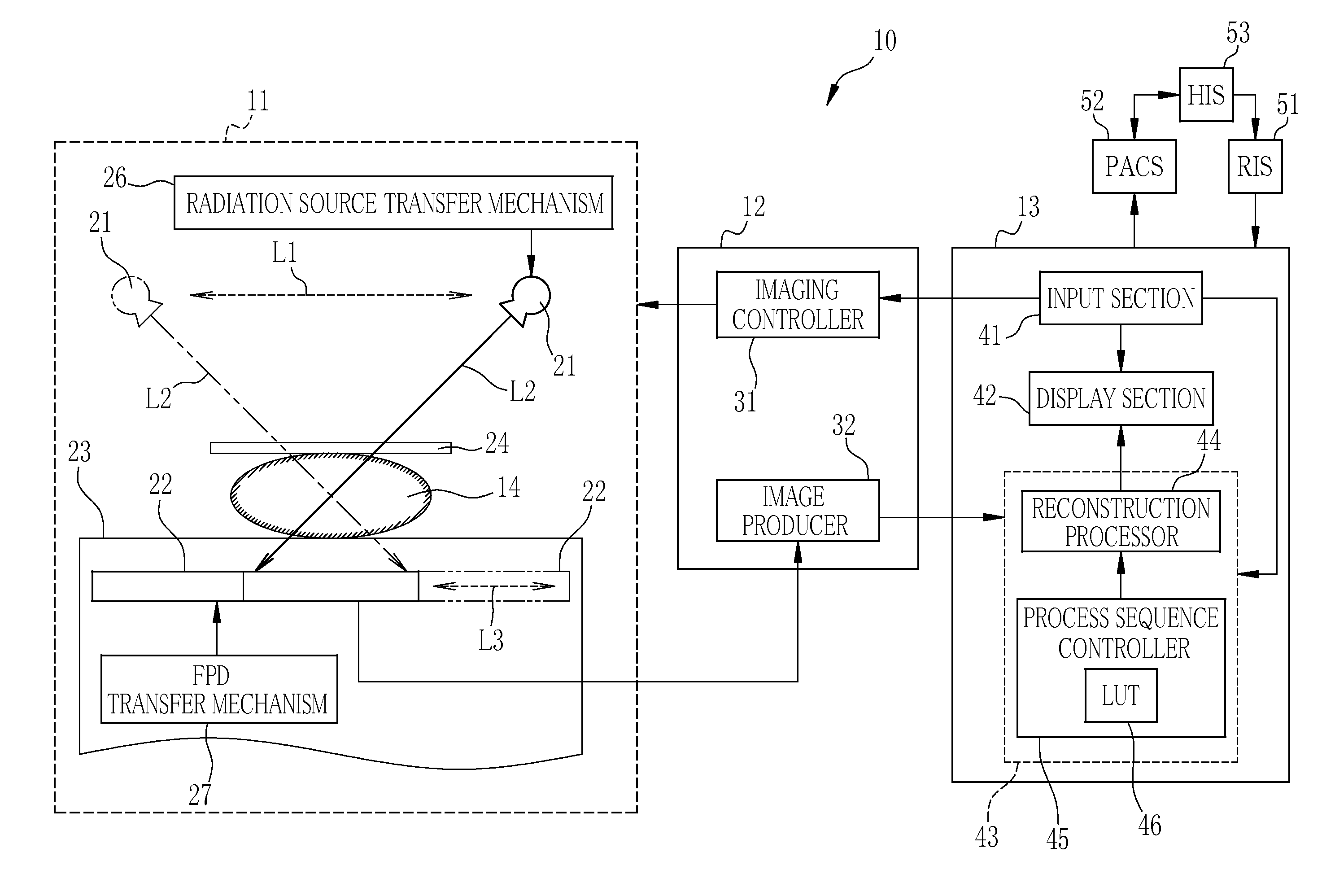

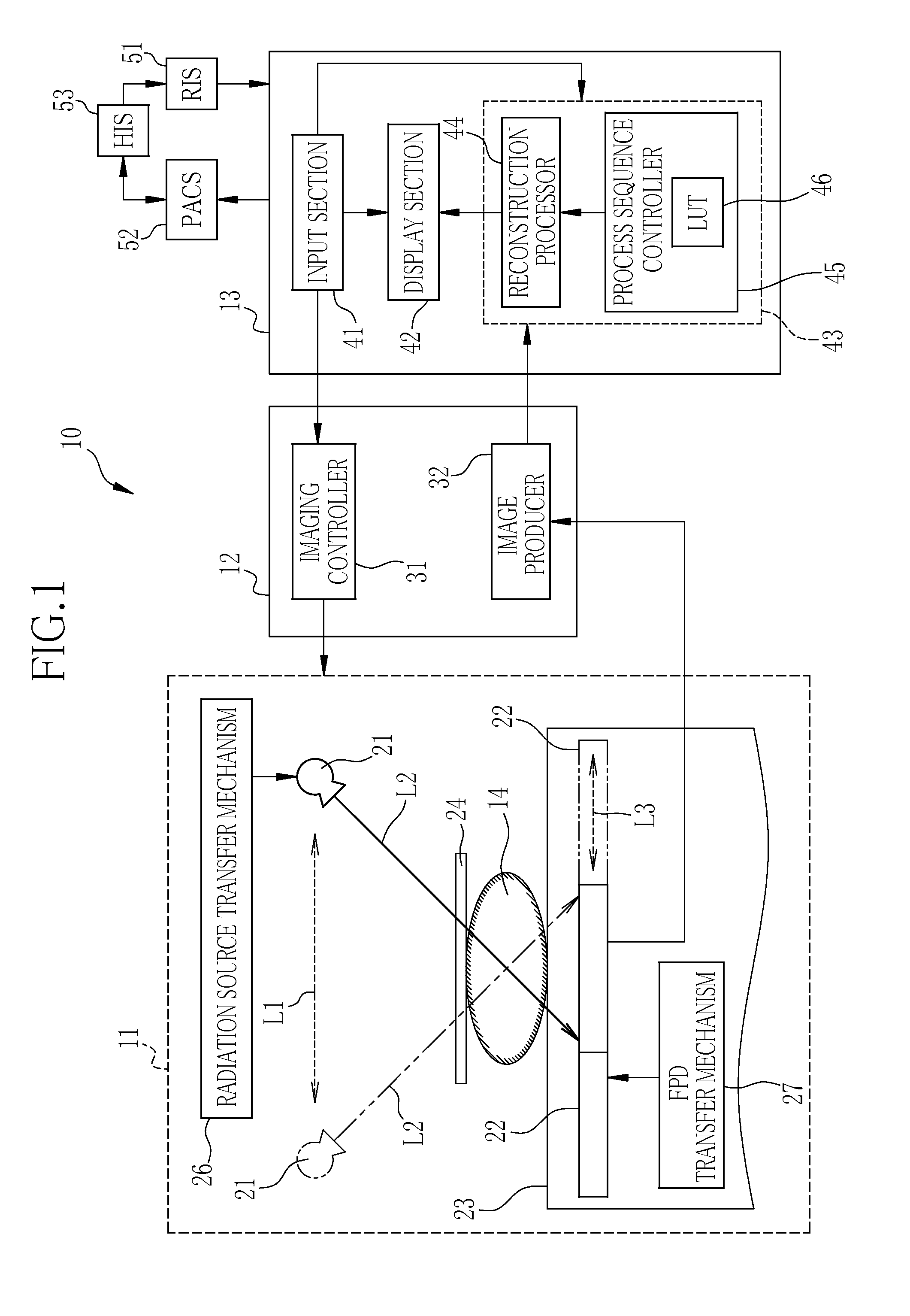

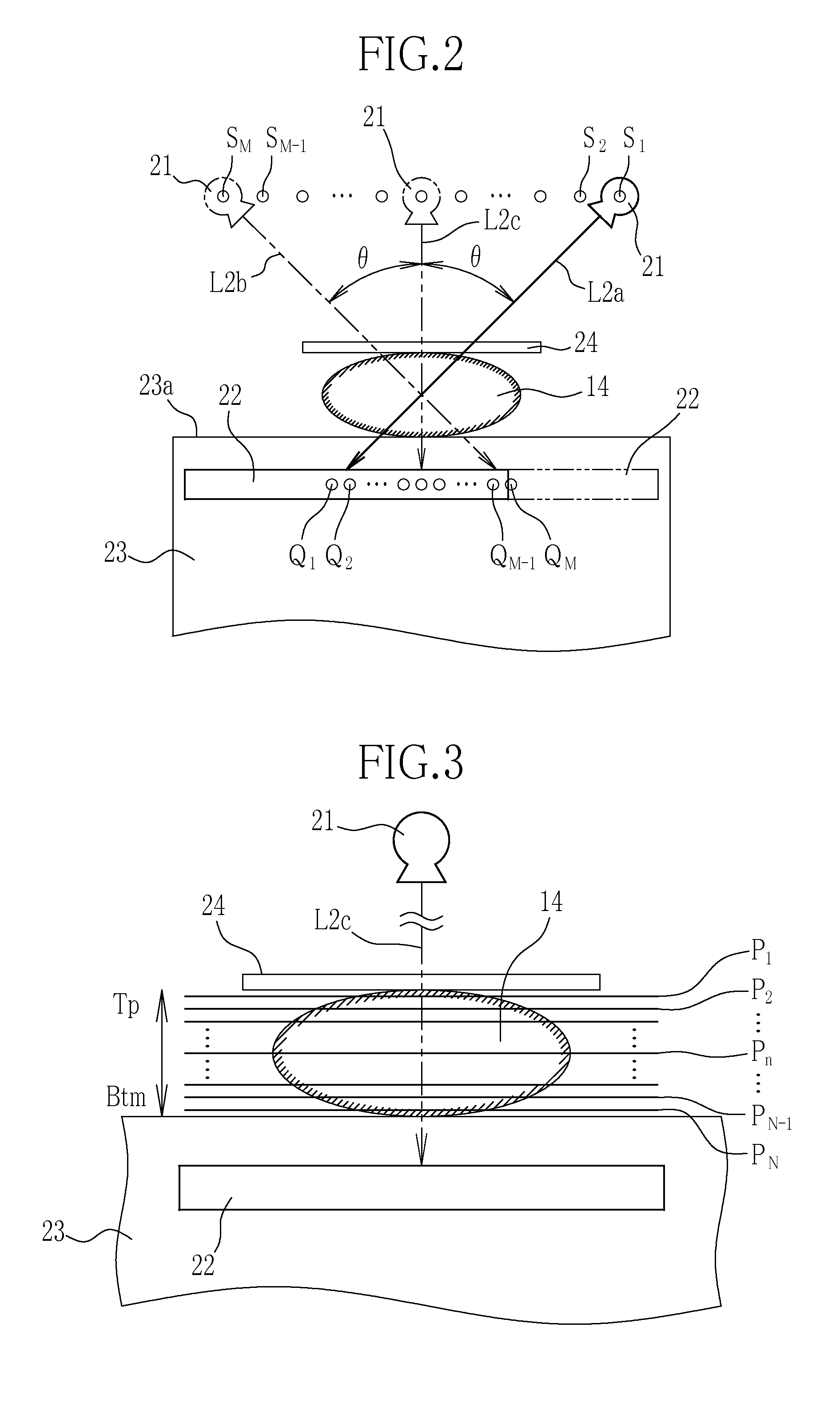

Radiography system and radiography method

ActiveUS20160015333A1Shorten the timeShort imageMaterial analysis using wave/particle radiationRadiation/particle handlingFlat panel detectorProjection image

A radiography system includes an imaging controller, a reconstruction processor, a process sequence controller and a display section. The imaging controller controls a radiation source to move in a range of a designated sweep angle and project X-rays at different angles to an imaging subject, while controlling a flat panel detector to acquire a set of projection images. The reconstruction processor uses the set of projection images to produce a plurality of tomographic images for use in diagnosis. The process sequence controller determines a parameter for sorting the plurality of tomographic images into first and second groups according to the sweep angle of the radiation source so as the first group of tomographic images to be produced prior to the second group of tomographic images. The display section displays at least the first group of tomographic images.

Owner:FUJIFILM CORP

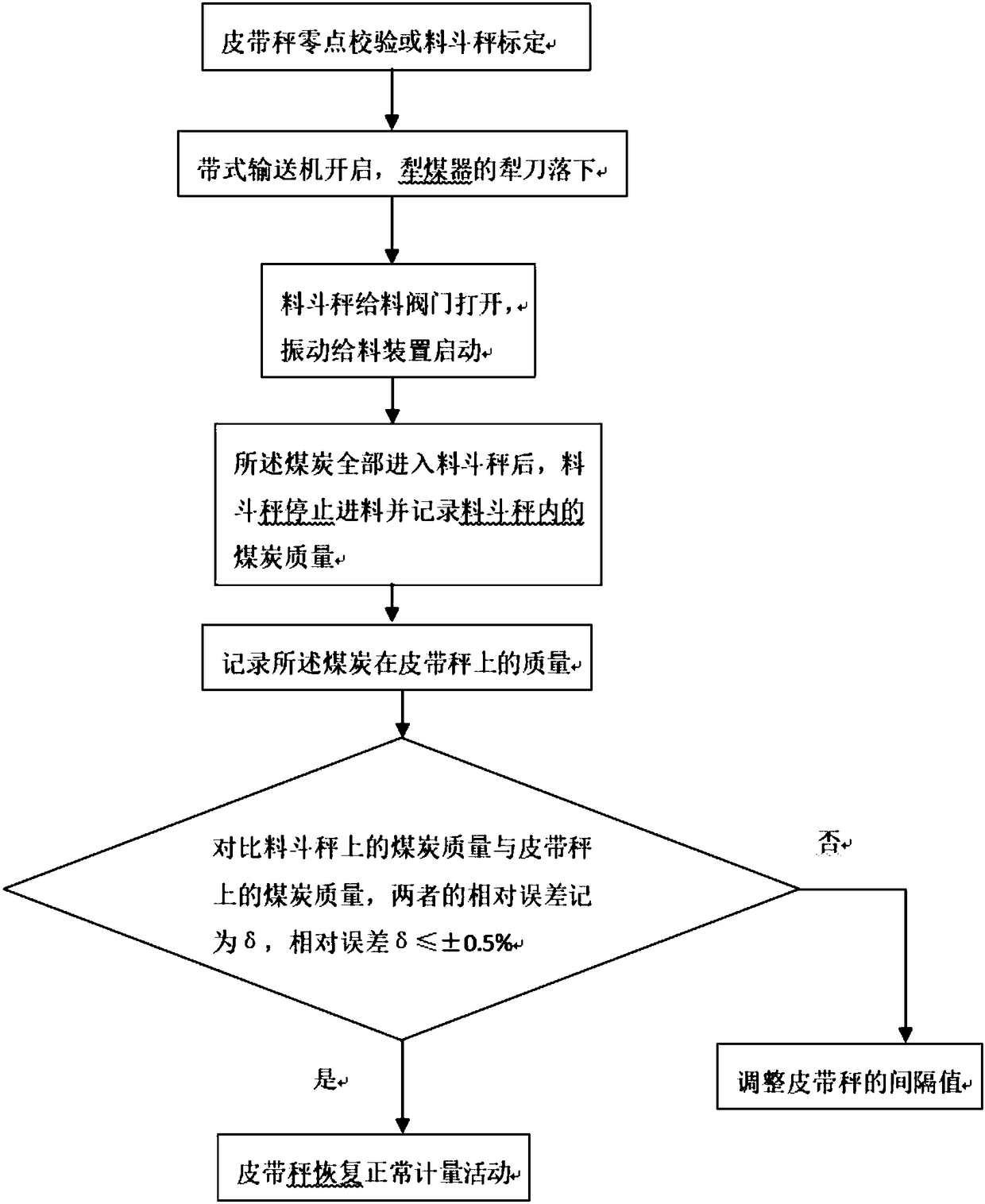

Weighing check method for belt weighers

InactiveCN108225533AHigh measurement accuracyImprove stabilityWeighing apparatus testing/calibrationEngineeringBelt conveyor

The invention discloses a weighing check method for belt weighers, which comprises the following steps: the zero point check of a belt weigher or the calibration of a hopper weigher is carried out; abelt conveyer is switched on, and the coulter of a coal plough drops; after coal completely gets into the hopper weigher, the hopper weigher stops feeding and records the weight of the coal in the hopper weigher; the feed valve of the hopper weigher is opened, and a vibrating feeder is started; the weight of the coal on the belt weigher is recorded; the weight of the coal on the hopper weigher iscompared with the weight of the coal on the belt weigher, the relative error between both is recorded as delta, delta is equal to (M1-M2) / M1*100 percent, wherein M1 is the coal weight recorded by thehopper weigher, and M2 is the coal weight recorded by the belt weigher; if the relative error delta is less than or equal to plus or minus 0.5 percent, then the normal weighing activity of the belt weigher is resumed; and if the relative error Delta is greater than plus or minus 0.5 percent, then the interval value of the belt weigher is adjusted. The advantage of the technical solution is that the weighing check method can quickly switch production and check and can check the belt weigher at any time.

Owner:GUANGZHOU DEV GRP CO LTD +3

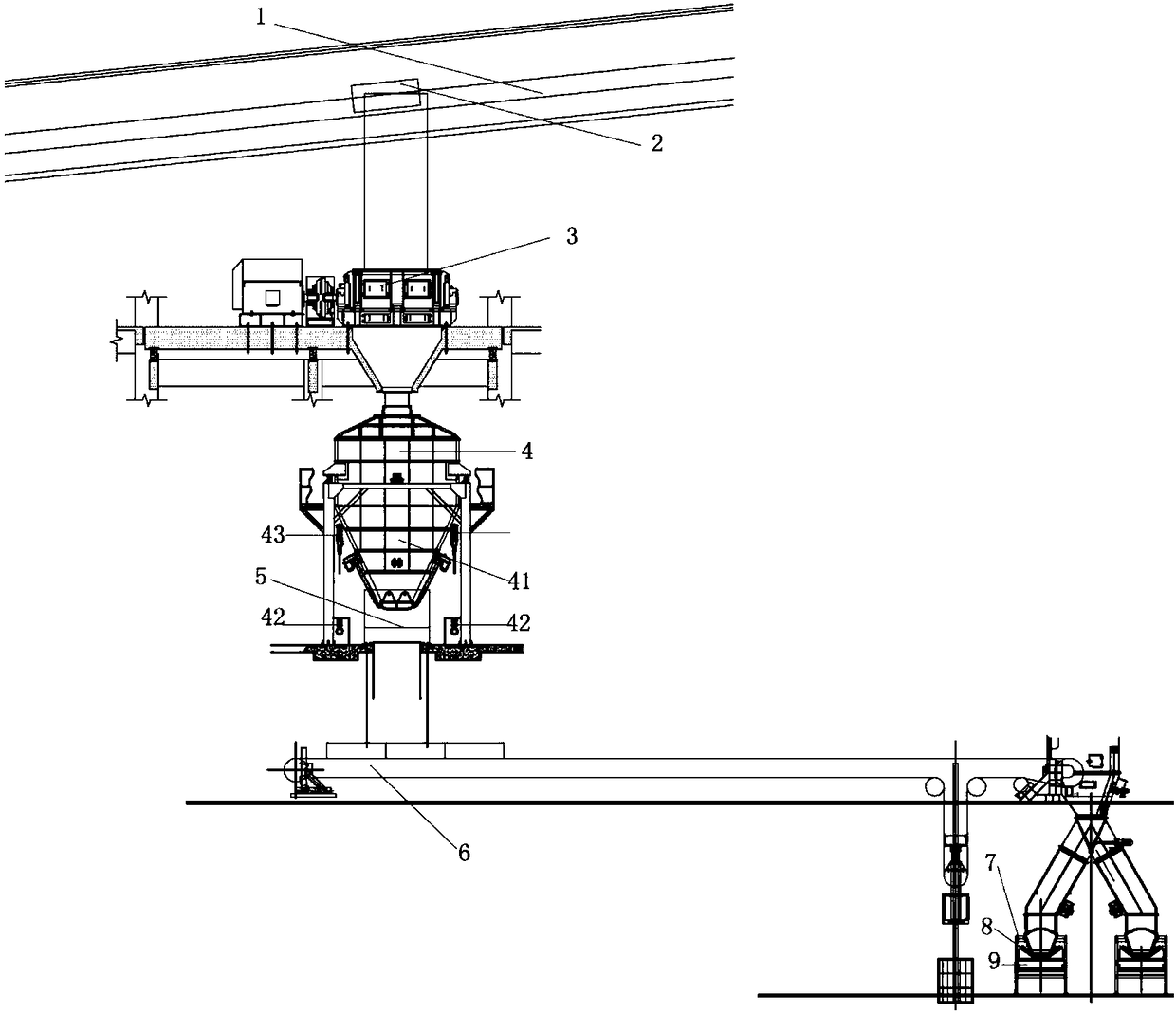

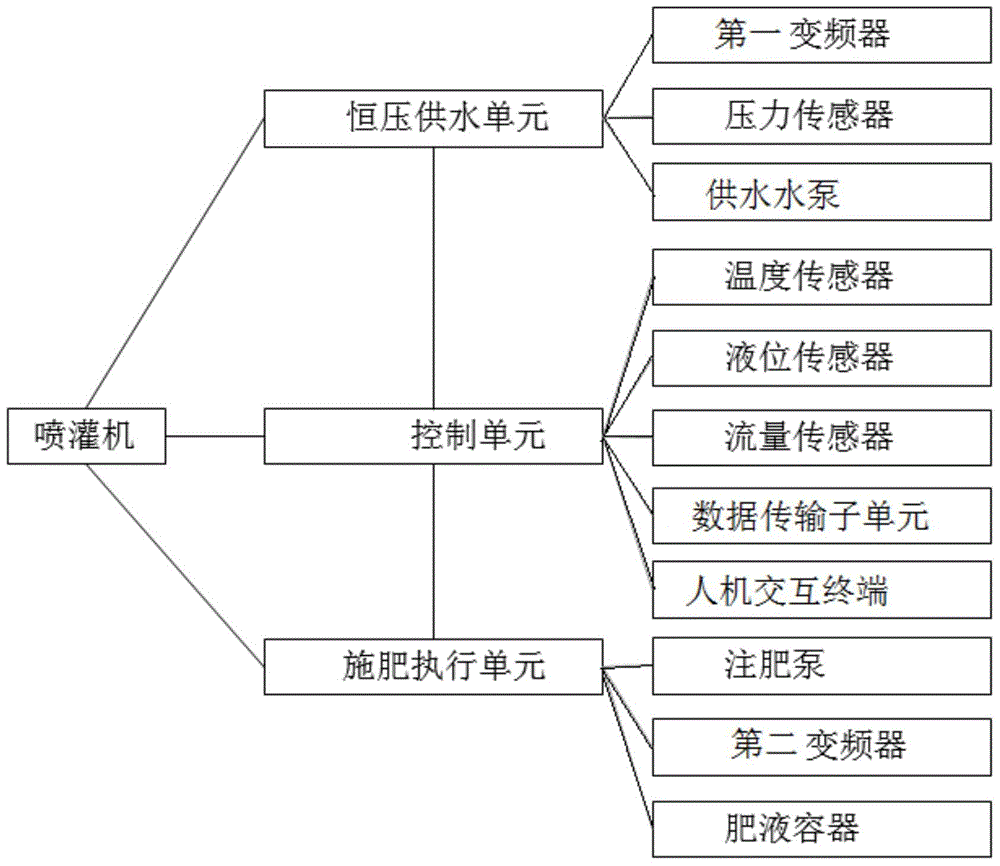

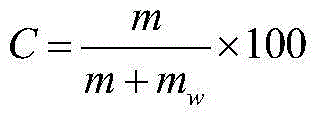

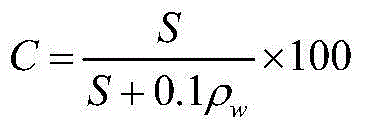

Fertilization control system for circular and translational motion type sprinkling irrigation machine

ActiveCN104938131AImprove operational reliabilityImprove spray uniformityPressurised distribution of liquid fertiliserAgriculture gas emission reductionControl systemSpray nozzle

The invention relates to a fertilization control system for a circular and translational motion type sprinkling irrigation machine. In the fertilization control system, a constant pressure water supply unit is equipped to solve the hydraulic pressure fluctuation caused by switching of spray nozzle and other reasons, so that the operational reliability and spraying uniformity of the fertilization control system are improved; a control unit is adopted to adjust the variation of the pumping flow of fertilization injection along with the water supply flow of the constant pressure water supply unit, so that the precise and constant fertilization concentration and fertilizing amount within the whole sprinkling irrigation range are guaranteed, and especially, the precise and constant fertilization concentration and fertilizing amount are guaranteed in the situation of large flow variation amplitude of a circular and translational motion type sprinkling irrigation machine provided with a tail gun within the opening and closing time period of the tail gun.

Owner:CHINA AGRI UNIV +1

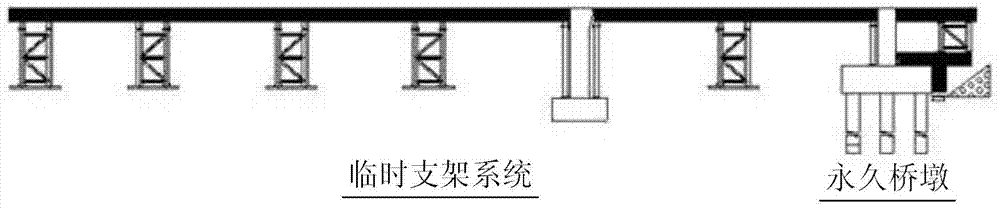

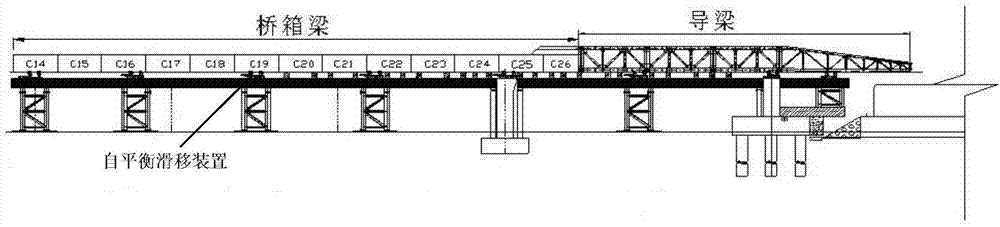

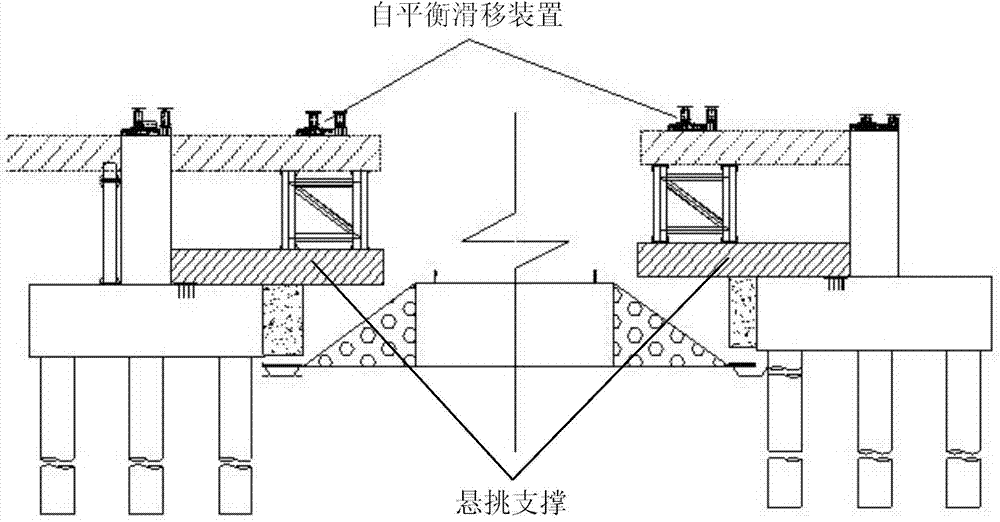

Overall long-distance pushing slippage construction method for large-span bridge box girder structure of large-span bridge

The invention provides an overall long-distance pushing slippage construction method for a large-span bridge box girder structure. Under the conditions that terrain conditions of a construction site are special, and construction operation cannot be performed below a span of the large-span bridge box girder structure, a bridge box birder is jacked up by using a pushing unit and a jacking unit in a self-balancing slippage device and moves, when the self-balancing slippage device is used, horizontal thrust cannot be applied to a permanent bridge pier, pushing stability and pushing safety on the bridge box girder are ensured, influences of special terrain conditions of a span portion of the bridge box girder structure are effectively avoided, particularly, under the conditions that important traffic main lines such as an expressway and a railway are arranged below the bridge box girder structure, and road closure construction cannot be realized, by using the pushing slippage construction method, road closure is not required, smooth traffic is guaranteed, and the accuracy and the safety of long-distance pushing construction on the large-span bridge box girder are ensured.

Owner:SHANGHAI MECHANIZED CONSTR GRP

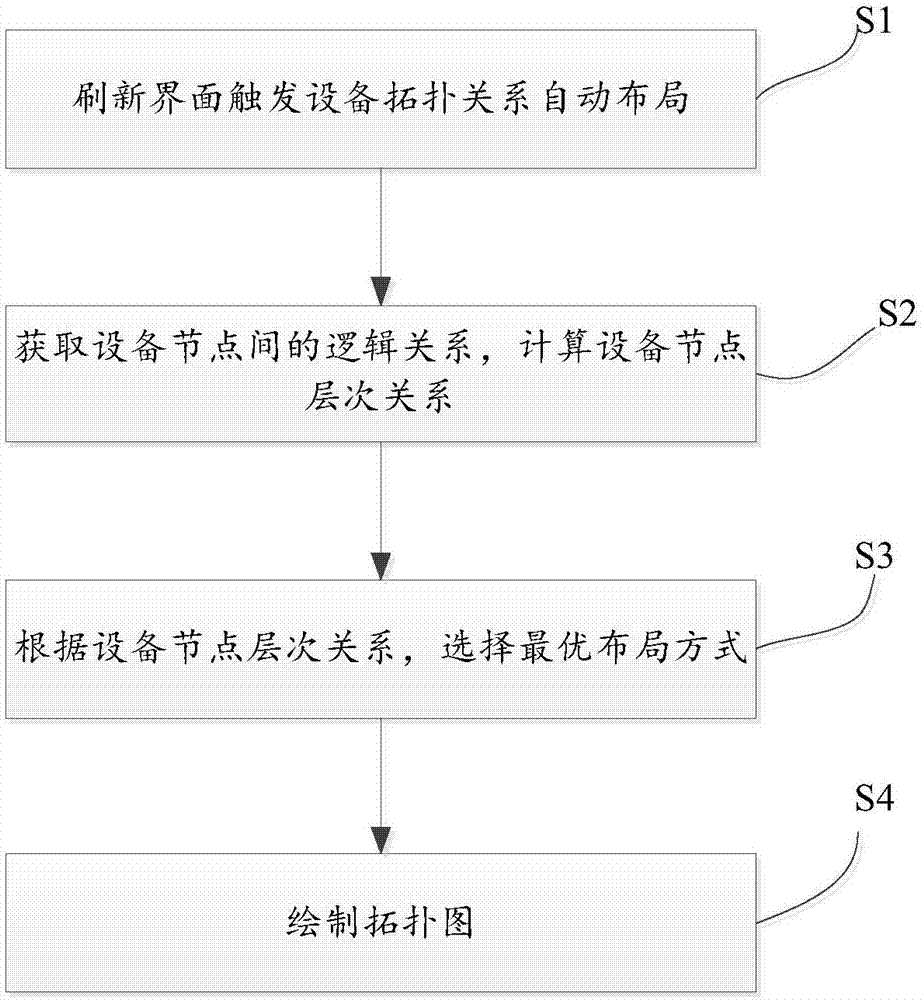

Automatic topology arrangement method

InactiveCN107453911AEfficient layoutImprove efficiencyData switching networksNetwork managementTopological graph

The invention belongs to the technical field of network communication, and particularly relates to an automatic topology arrangement method. The automatic topology arrangement method comprises the steps of refreshing an interface to trigger automatic layout of a topological relationship of equipment; acquiring a logic relationship between equipment nodes, and calculating a hierarchical relationship of the equipment nodes; selecting an optimal layout mode according to the hierarchical relationship of the equipment nodes; and drawing a topological diagram. The automatic topology arrangement method can effectively solve confused and complicated conditions of manually moving the position of each node, realizes reasonable layout of the topological diagram quickly and effectively, and ensures the layout to be accurate and visual. When certain equipment breaks down, a network manager can locate quickly after checking and maintains timely, thereby enabling the equipment to operate normally, and improving the problem solving efficiency of the network manager.

Owner:武汉微创光电股份有限公司

Printing method of 3D product, and 3D printer used in method

ActiveCN107009614AAccurately control the dosageEasy to controlManufacturing enclosures3D object support structuresEngineeringLight head

The invention discloses a printing method of a 3D product, a 3D printer used in the method, and a printer head of the 3D printer. The printing method of the 3D product comprises the following steps of: spraying material layers layer by layer through the printer head of the 3D printer; after finishing spraying of each of the material layers, performing light curing on a specified region on each of printing material layers through curing light heads arranged on the printer head; performing continuous stacking; and finally dissolving uncured regions of all material layers through a solvent to obtain a cured substance, namely the required 3D product. According to the printing method of the 3D product, which is disclosed by the invention, the flowability of gel type resins is utilized, heating set is not needed, and heating for melting does not need to be performed on raw materials; and besides, in order to overcome the flowability of the raw materials, a frame for assisting in printing operation is arranged to limit the raw materials to make sure that a height value is accurate when each material is sprayed. Compared with a conventional printing manner of a hot melt adhesive, the printing method disclosed by the invention is lower in manufacture cost and higher in precision.

Owner:DONGGUAN RUIDI THREE DIMENSIONAL ELECTRONICS TECH

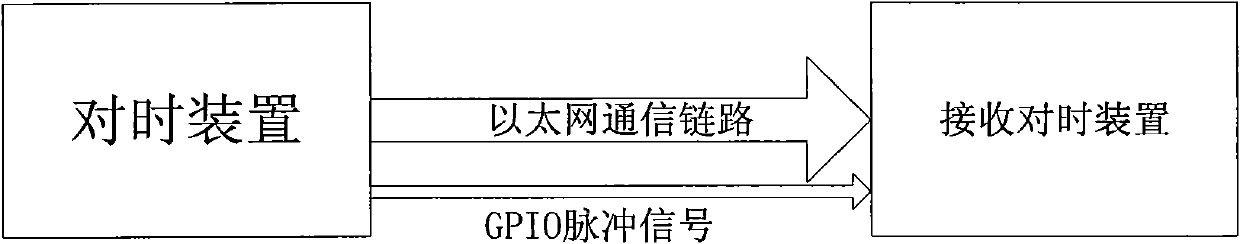

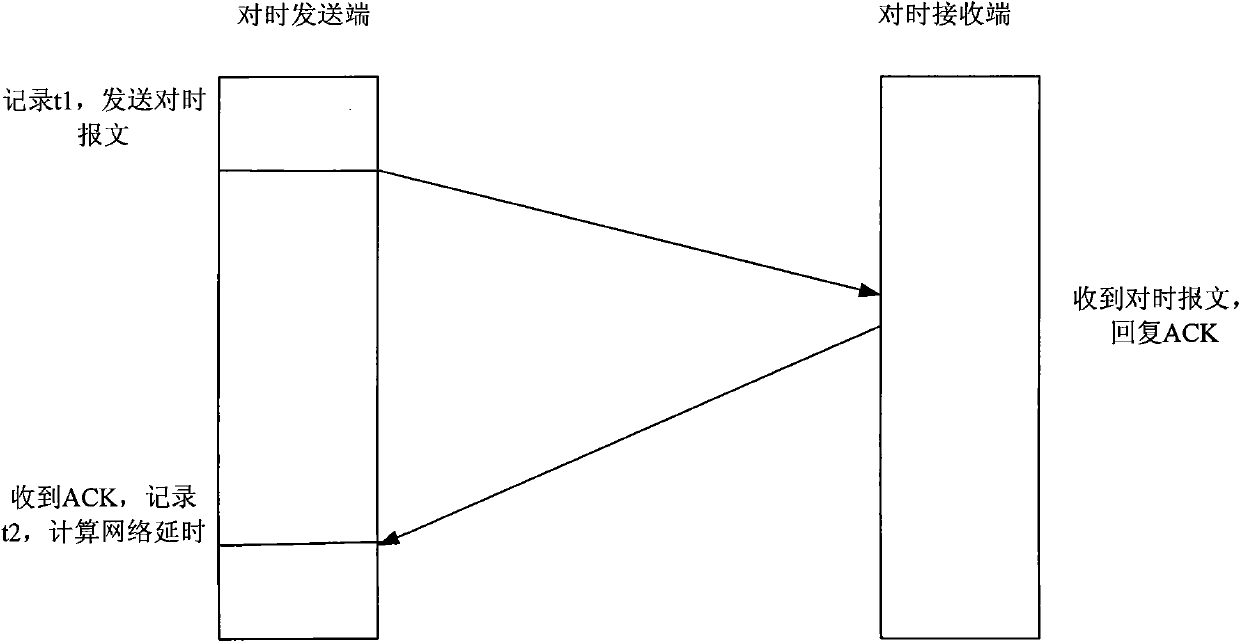

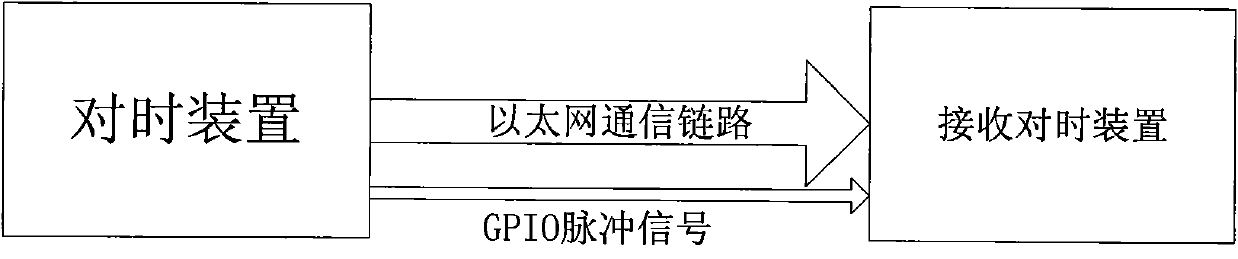

Method for realizing accurate time tick of Ethernet

ActiveCN101951300AEnsure accurateGuaranteed synchronizationTime-division multiplexTemporal informationReal-time clock

The invention discloses a method for realizing the accurate time tick of an Ethernet. The method comprises the following steps that: a central processing unit (CPU) of a time tick device D1 immediately sends an auxiliary time tick signal through a general purpose input / output (GPIO) after reading a real-time clock t1 and the level is changed only once; then the read clock information is assembled to be a network message and the network message is sent to a reception time tick device through a physical layer interface; the reception time tick device D2 also receives the signal change through a GPIO signal, records the time and marks the time as t2; the reception time tick device receives a network time tick message and sends the network time tick message to the CPU of the reception time tick device D2 for processing; and the CPU of the reception time tick device D2 analyzes the message and then exacts time information, records the time before writing into the chip of the real-time clock and marks the time as t3, wherein the period from t3 to t2 is used as network delay and the delay of message processing of the CPU of the reception time tick device D2 and is used for correcting time information. The method has the advantage that the device is easy to implement and convenient to install.

Owner:STATE GRID ELECTRIC POWER RES INST

Four-rotor unmanned aerial vehicle flight control method based on fractional-order control algorithm

ActiveCN107977011AImprove integrityImprove anti-disturbance abilityAttitude controlPosition/course control in three dimensionsLyapunov stabilityFractional-order control

The invention discloses a four-rotor unmanned aerial vehicle flight control method based on a fractional-order control algorithm. According to the method, a controller is of a back-stepping control structure on the whole, a second-order nonlinear system of a four-rotor unmanned aerial vehicle is divided into two subsystems, control laws meeting Lyapunov stability theories are built, and the two subsystems are serially connected into a complete controller through virtual intermediate control variables, so that the controller can effectively adapt to nonlinearity of a system and has good integrity. Besides, in order to enhance the anti-disturbance capability and robustness of the controller, sliding mode control design of controlled variables is performed in second back-stepping design, andhigh anti-interference capability and high robustness of sliding mode control are introduced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

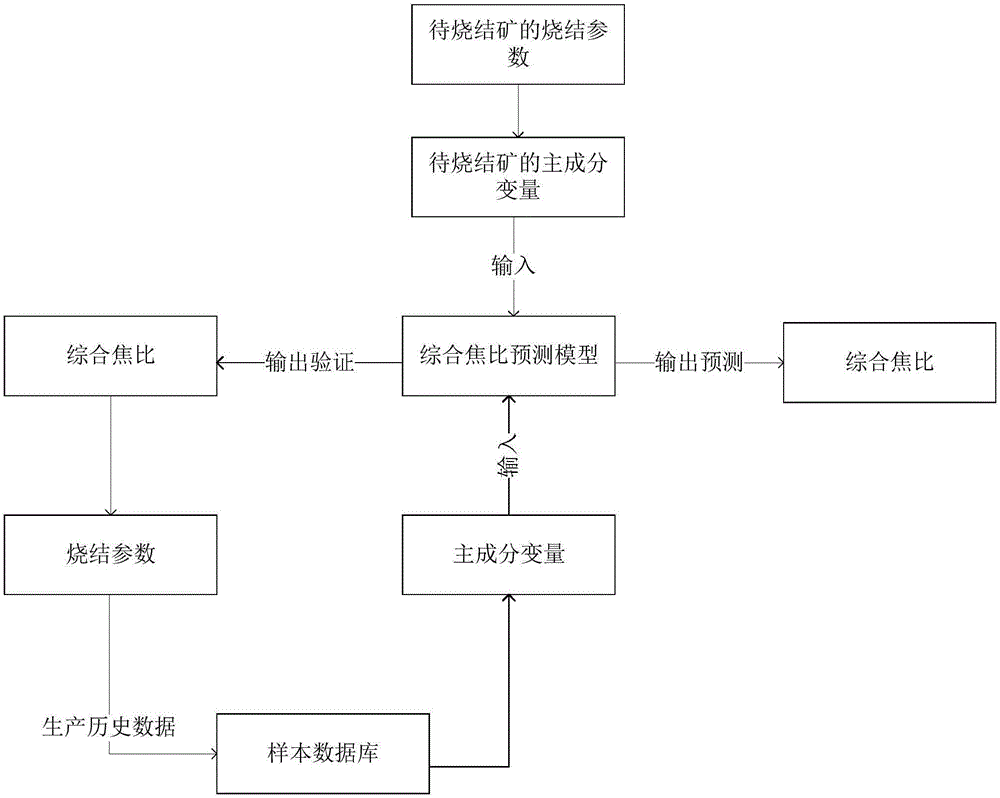

Method for building comprehensive coke ratio predicting model and predicting comprehensive coke ratio

ActiveCN106777684ASolve the coupling problemEnsure accurateDesign optimisation/simulationSpecial data processing applicationsMetallurgyDimensionality reduction

The invention discloses a method for building a comprehensive coke ratio predicting model and predicting a comprehensive coke ratio. The method includes: selecting the comprehensive coke ratio to serve as the index for measuring the carbon efficiency of a sintering process; determining sintering parameters affecting the comprehensive coke ratio through the mechanism analysis of the sintering process, using a main component analysis method to perform data dimension reduction and recombination on the sintering parameters to obtain a main component variable, building the comprehensive coke ratio predicting model on the basis of the main component variable, analyzing the sintering parameters of to-be-sintered ore, converting the sintering parameters into the a main component variable, and inputting the main component variable of the to-be-sintered ore into the comprehensive coke ratio predicting model to obtain an output variable, namely the comprehensive coke ratio. The method has the advantages that the coupling problems among the sintering parameters can be solved, a foundation is laid for the carbon efficiency optimization of the sintering process, the comprehensive coke ratio of the sintering process can be precisely predicted, and the production requirements of an actual sintering process are satisfied.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

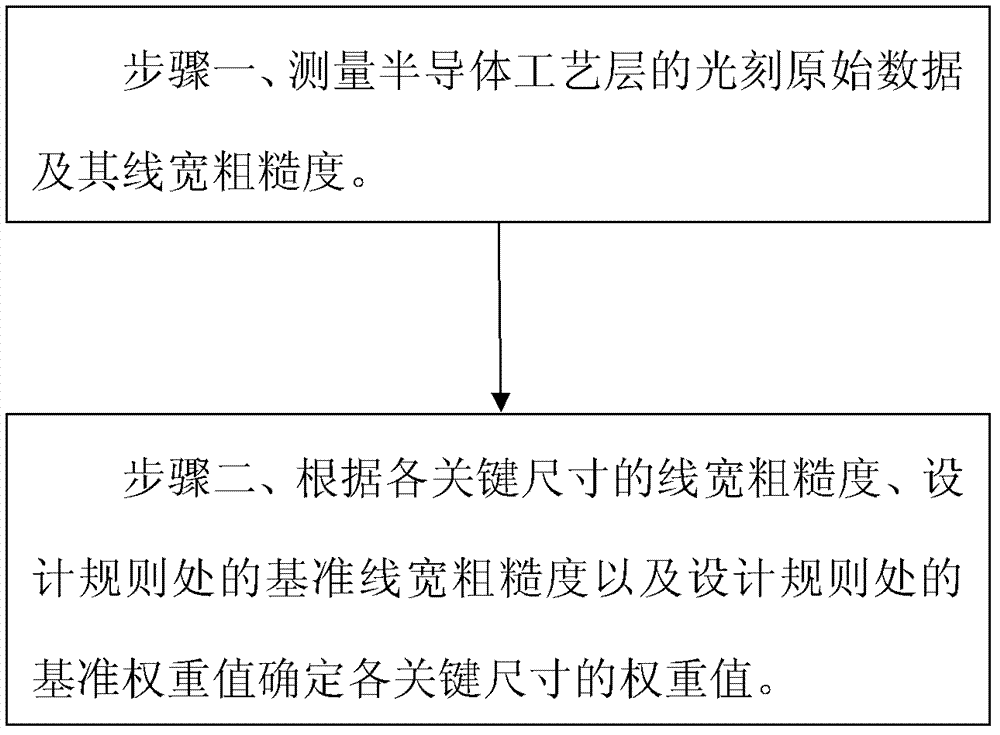

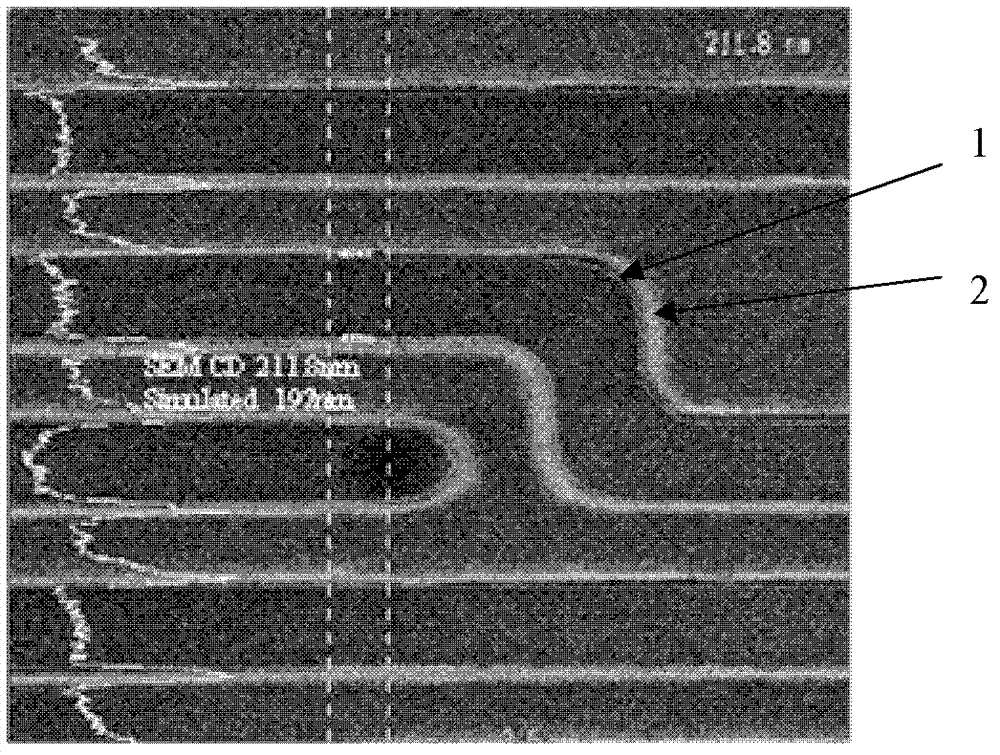

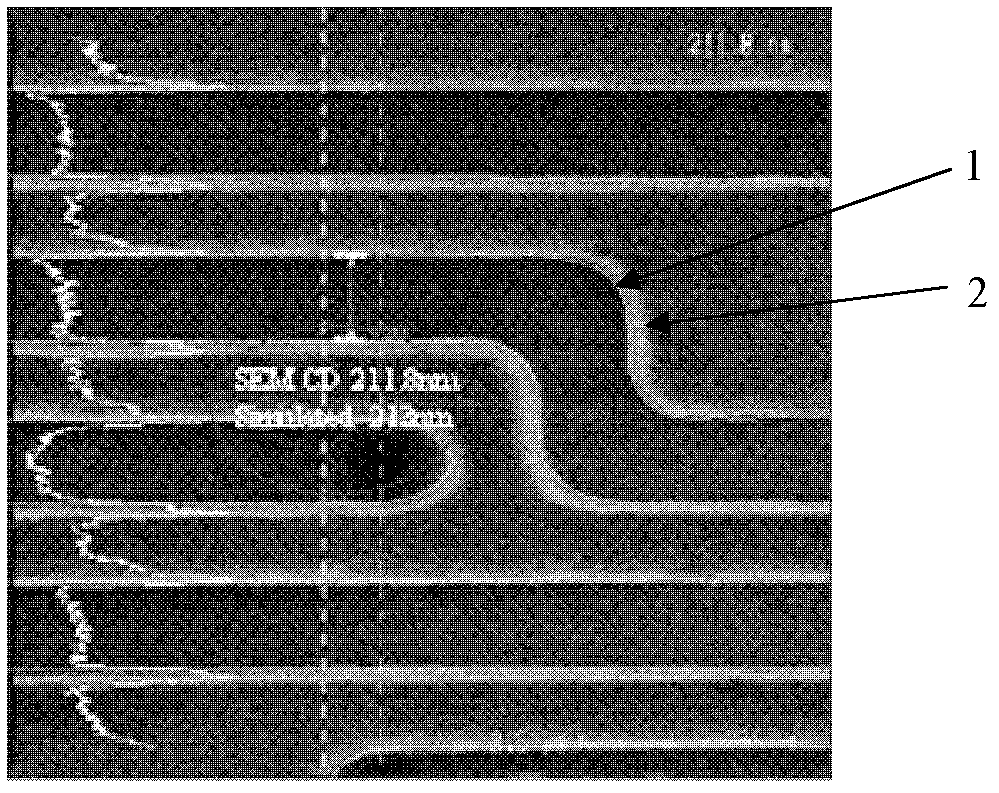

Modeling method for optical proximity correction process model

InactiveCN102902154AReduce the amount of measurement dataFaster fitting and convergence timesOriginals for photomechanical treatmentWeight valueLine width

The invention discloses a modeling method for an optical proximity correction process model. The method comprises the steps of measuring original data and line width roughness of a semiconductor process layer; and determining weighted values of all critical sizes according to the line width roughness of the measured value of each critical size, a datum line width roughness at design rule checking position of the semiconductor process layer and a datum weighted value at the design rule checking position of the semiconductor process layer. By introducing the line width roughness to determine the weighted values of all the critical sizes, to-be-measured data can be reduced; some unstable factors and random factors of process, measuring machines and measuring processes can be filtered; fitting time and convergence time of the process model establishment can be shortened; and simultaneously accuracy and reliable stability of the process model can be guaranteed.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

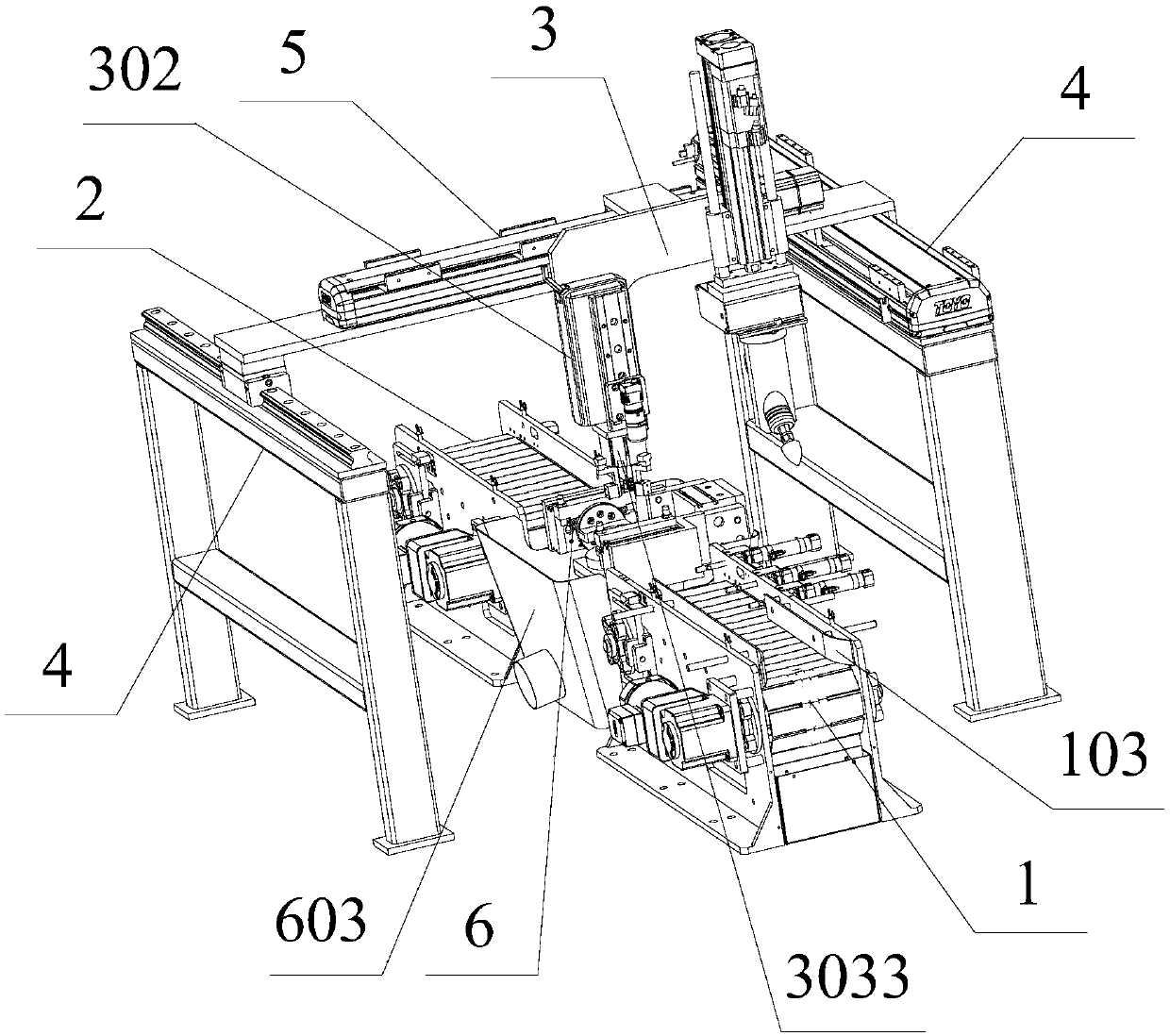

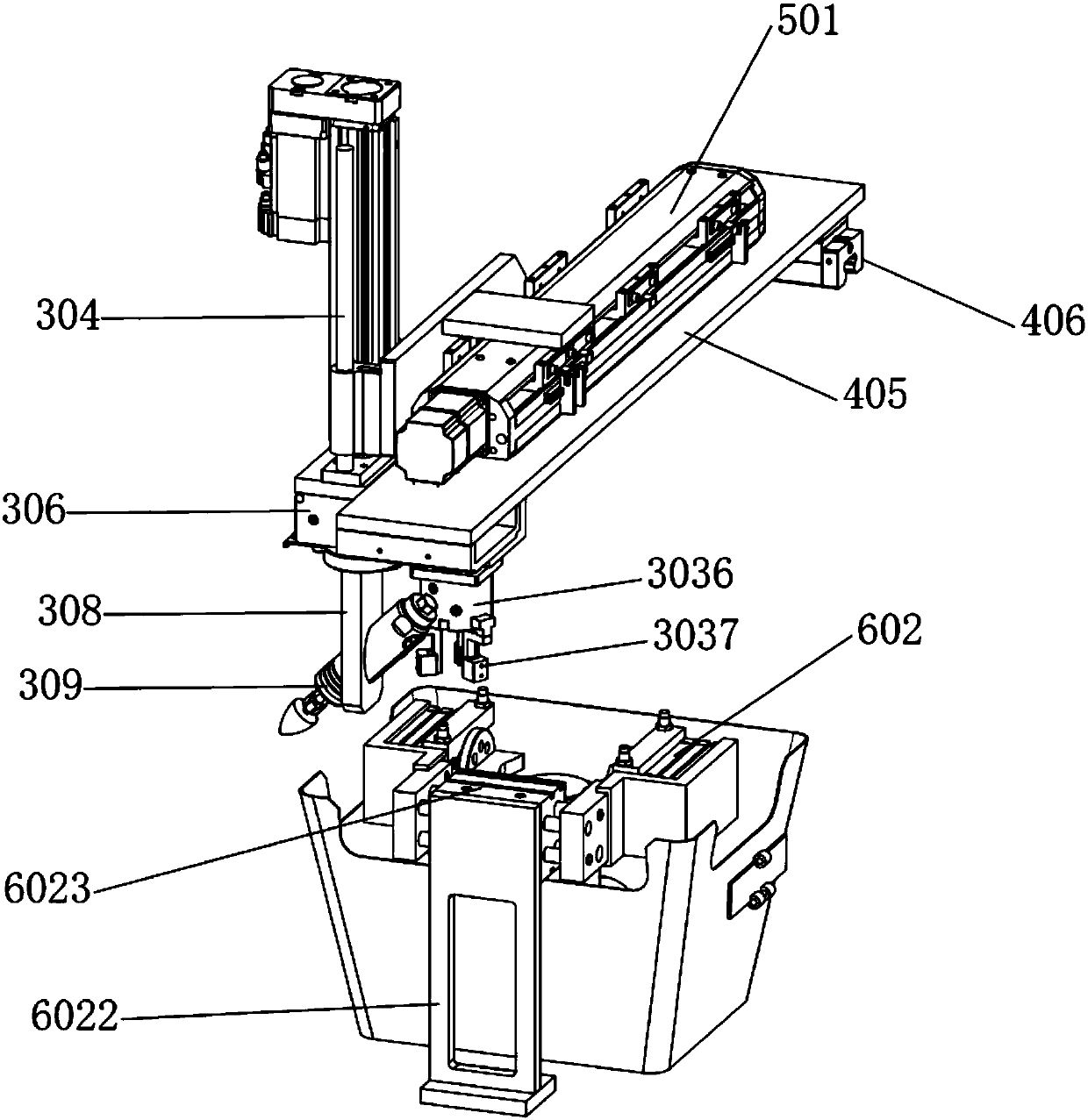

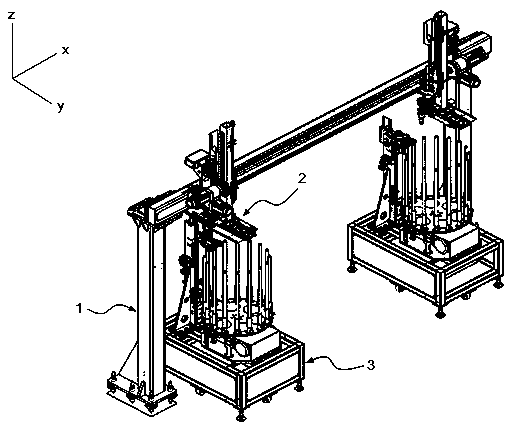

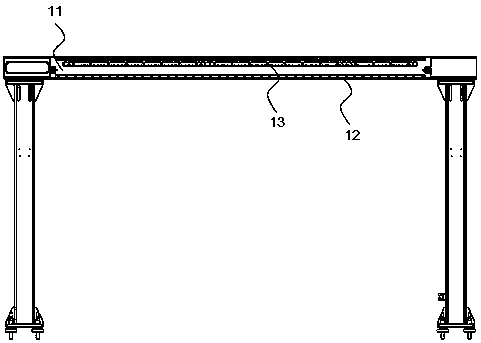

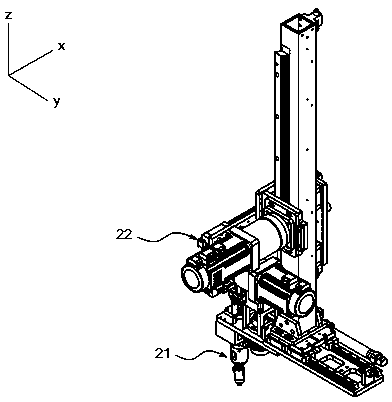

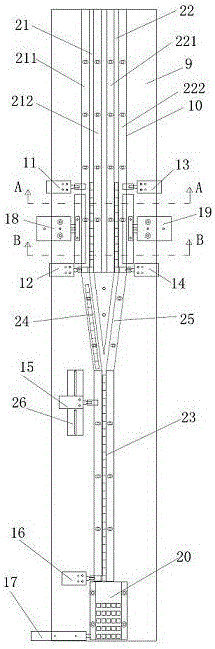

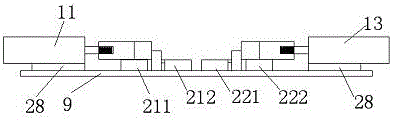

Loading and unloading mechanism for small-module bevel gears

PendingCN111439574ARealize loading and unloadingSmooth feedingDe-stacking articlesGear-cutting machinesGear wheelBevel gear

The invention belongs to the field of gear machining, and discloses a loading and unloading mechanism for small-module bevel gears. The loading and unloading mechanism comprises a portal truss, a feeding mechanism and a storing mechanism; the portal truss comprises a cross beam; double guiding rails A are fixed to one side of the cross beam; a rack is arranged between the double guiding rails A; the feeding mechanism is arranged on the cross beam and comprises internal expansion fixtures, the internal expansion fixtures realize three-dimensional actions of the space through driving mechanisms,and the driving mechanisms are connected onto the double guiding rails A; the storing mechanism is arranged below the cross beam and comprises a group of bases used for loading and unloading respectively, rotating disk mechanisms are arranged above the bases, and clamping mechanisms A are arranged beside the rotating disk mechanisms. By the aid of the loading and unloading mechanism, the problemsof difficulty in clamping, relatively slow loading and unloading of products and the like during machining of the small-module bevel gears are solved.

Owner:江苏双环齿轮有限公司

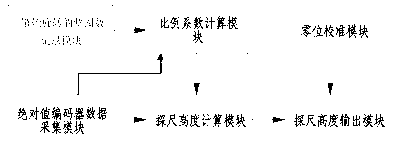

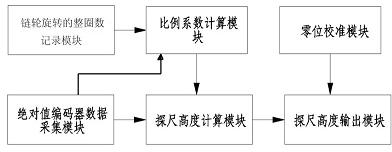

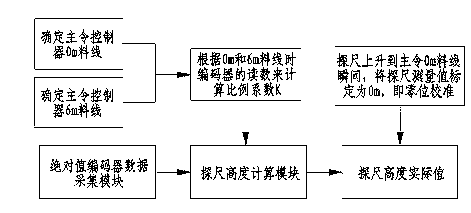

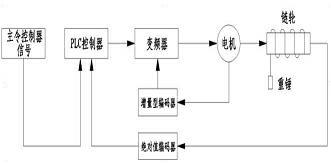

Furnace top stock-level detection system for blast furnace

InactiveCN102703633ASimplified commissioning stepsSave manpower and material costsBlast furnace detailsChecking devicesData acquisition moduleMechanical engineering

The invention discloses a furnace top stock-level detection system for a blast furnace, which includes an absolute value coder data acquisition module, a chain wheel complete rotation round record module, a scale factor K computation module, a stock rod height calculation module and a stock height output module. When a stock rod designed range stockline and a 0 meter stockline of the master controller are determined, the absolute value coder data acquisition module respectively records readings on absolute value coders at that time, and the chain wheel complete rotation round record module records the complete rotation round number of a chain wheel during the descending process of a counter weight; then the scale factor is calculated; and finally, the actual height values of the stock rod can be calculated and output in real time in every period. The system disclosed by the invention solves the problems that the present blast furnace stock rod system is complicated and time-consuming in the zero calibration process and further affects the production.

Owner:WISDRI ENG & RES INC LTD

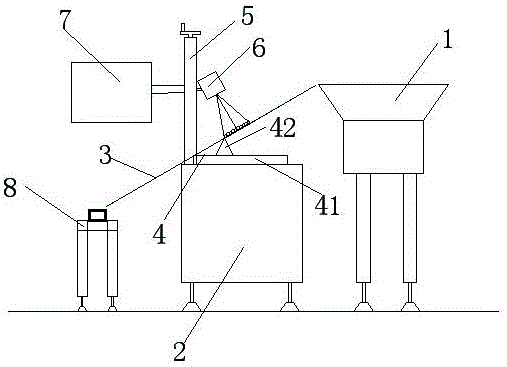

Automatic equipment and method for achieving high-speed laser marking and discharging packaging

ActiveCN105691769AMarking speed is fastImprove counting accuracyPackagingAutomatic test equipmentDisplay device

The invention discloses automatic equipment and method for achieving high-speed laser marking and discharging packaging. The automatic equipment comprises a vibration disc, a control cabinet, a discharging sliding rail, a height adjusting mechanism, a mounting column, a laser marking head, a displayer and a conveying mechanism. The discharging sliding rail is obliquely mounted above the control cabinet through the height adjusting mechanism. The mounting column is mounted on the control cabinet. The laser marking head and the displayer are mounted on the mounting column. The vibration disc is arranged at the high end of the discharging sliding rail. The conveying mechanism is mounted at the lower end of the discharging sliding rail. According to the automatic equipment for achieving high-speed laser marking and discharging packaging, automatic feeding, automatic marking, automatic counting and discharging packaging of nuts are combined together, meanwhile marking is conducted in a double-row manner, and high-speed marking can be achieved effectively.

Owner:EC PRECISION TECHJIANGSUCORP

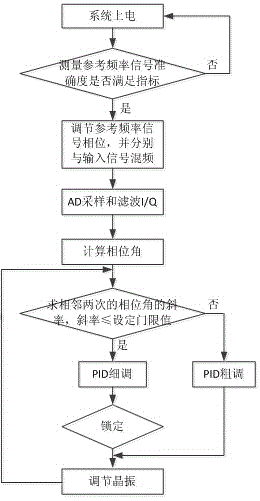

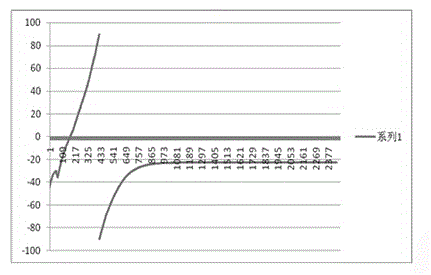

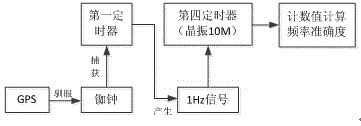

Self-adaptive rapid crystal locking method based on Clean-up digital phase-locked loop

ActiveCN104467825ASmall amount of calculationShorten lock timePulse automatic controlPhase locked loop circuitPhase difference

The invention discloses a self-adaptive rapid crystal locking method based on a Clean-up digital phase-locked loop. The method mainly solves the problems that an existing phase-locked loop is complex in circuit and can not meet a higher application requirement. The method is based on the phase-locked principle of the Clean-up digital phase-locked loop, firstly, the phase difference between a reference signal and a tested signal is worked out through frequency-inspected and phase-inspected calculation, the phase lock adaptively changes in the phase difference processing process of the software, the frequency difference and the phase difference are adjusted at the same time through a software algorithm, and then a high-precision analog-digital converter is controlled to output voltage controlled voltage to control crystal oscillation. The method is simple and can rapidly lock the phase, and meanwhile when the reference signal is affected by interference, the software can adjust coefficients in a self-adaptive mode, and smooth transition of output is achieved. The software processing mode is simple and effective, and the locking time is greatly shortened.

Owner:CHENGDUSCEON ELECTRONICS

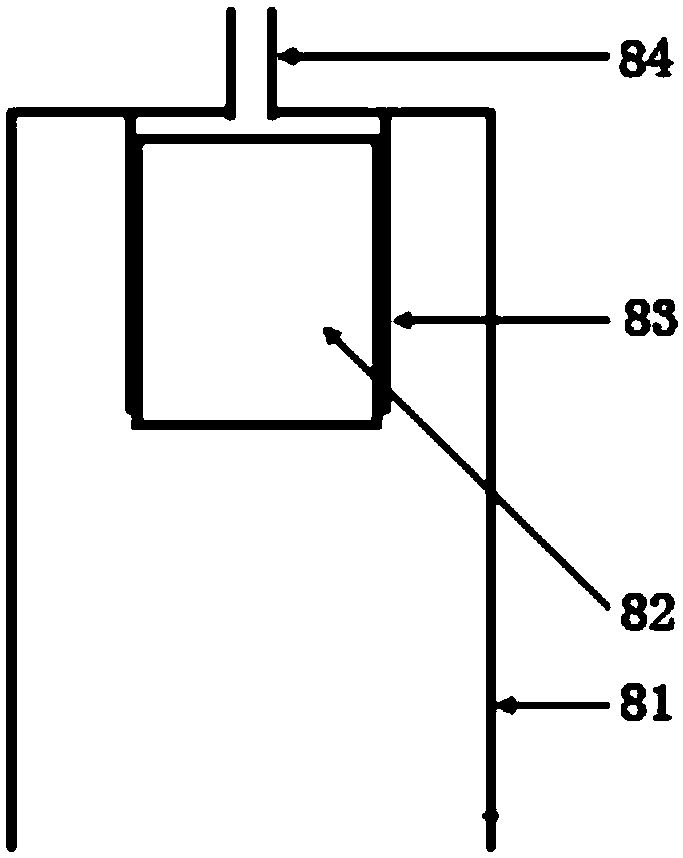

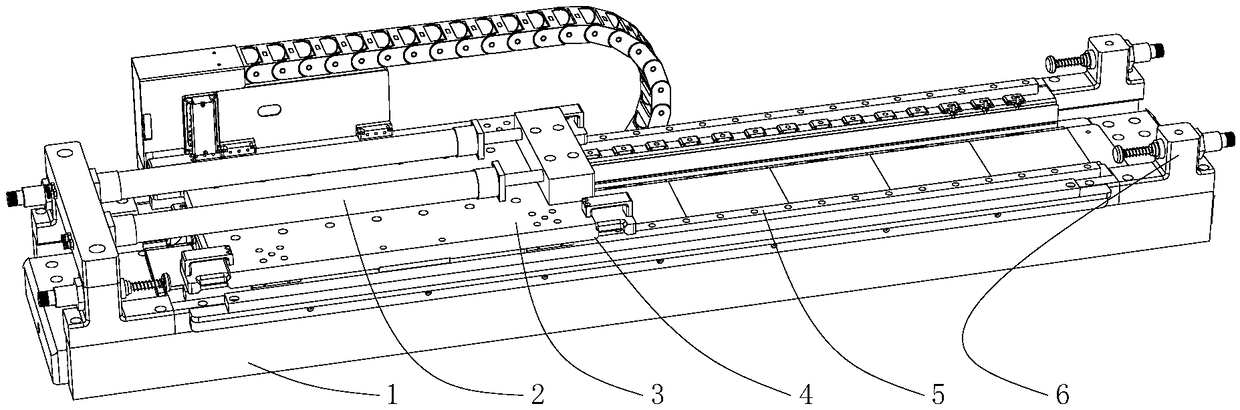

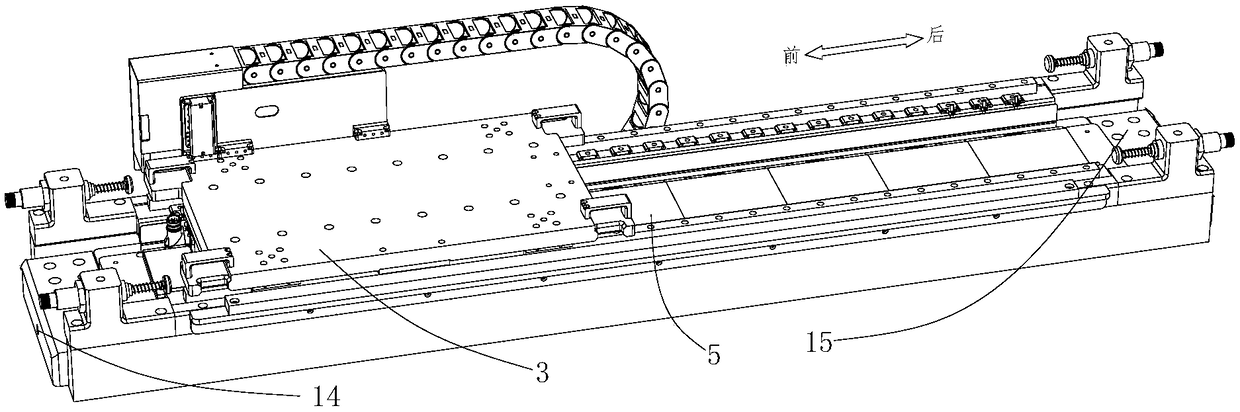

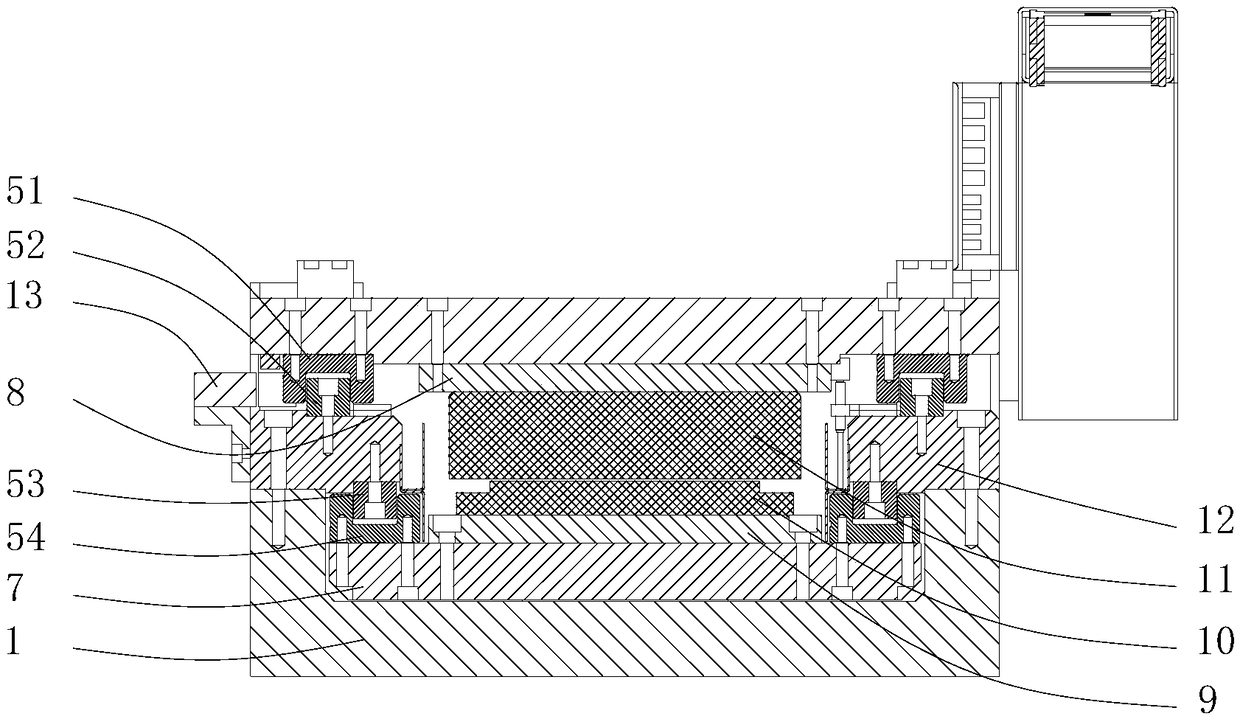

Linear motor test platform

ActiveCN108957321AEnsure accurateAvoid speed out of control phenomenonApparatus for force/torque/work measurementDynamo-electric machine testingGratingEngineering

The invention discloses a linear motor test platform which comprises a bed body, a linear track, a test platform, a grating ruler, a pre-tightening mechanism and a force measuring mechanism. The linear track is arranged on the bed body, the test platform and the linear track are connected in a movable manner, a receiving chamber is formed on the test platform, the test platform is connected to a linear motor to be tested, the test platform is driven by the linear motor to be tested to move on the linear track, the grating ruler is positioned on one side of the test platform, the grating ruleris connected with the bed body, the pre-tightening mechanism and the force measuring force mechanism are respectively positioned on two ends of the bed body, the pre-tightening mechanism and the forcemeasuring mechanism are connected with the test platform, the pre-tightening mechanism is used for reducing frictional interference that the testing platform suffers from, and the force measuring mechanism is used for measuring thrust force of the linear motor to be tested. The linear motor test platform is concise in structure and high in compatibility with different types of linear motors; testsafety is improved, a phenomenon that the speed of the linear motor is out of control can be prevented, a situation of collision can be prevented, and test accuracy can be improved.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

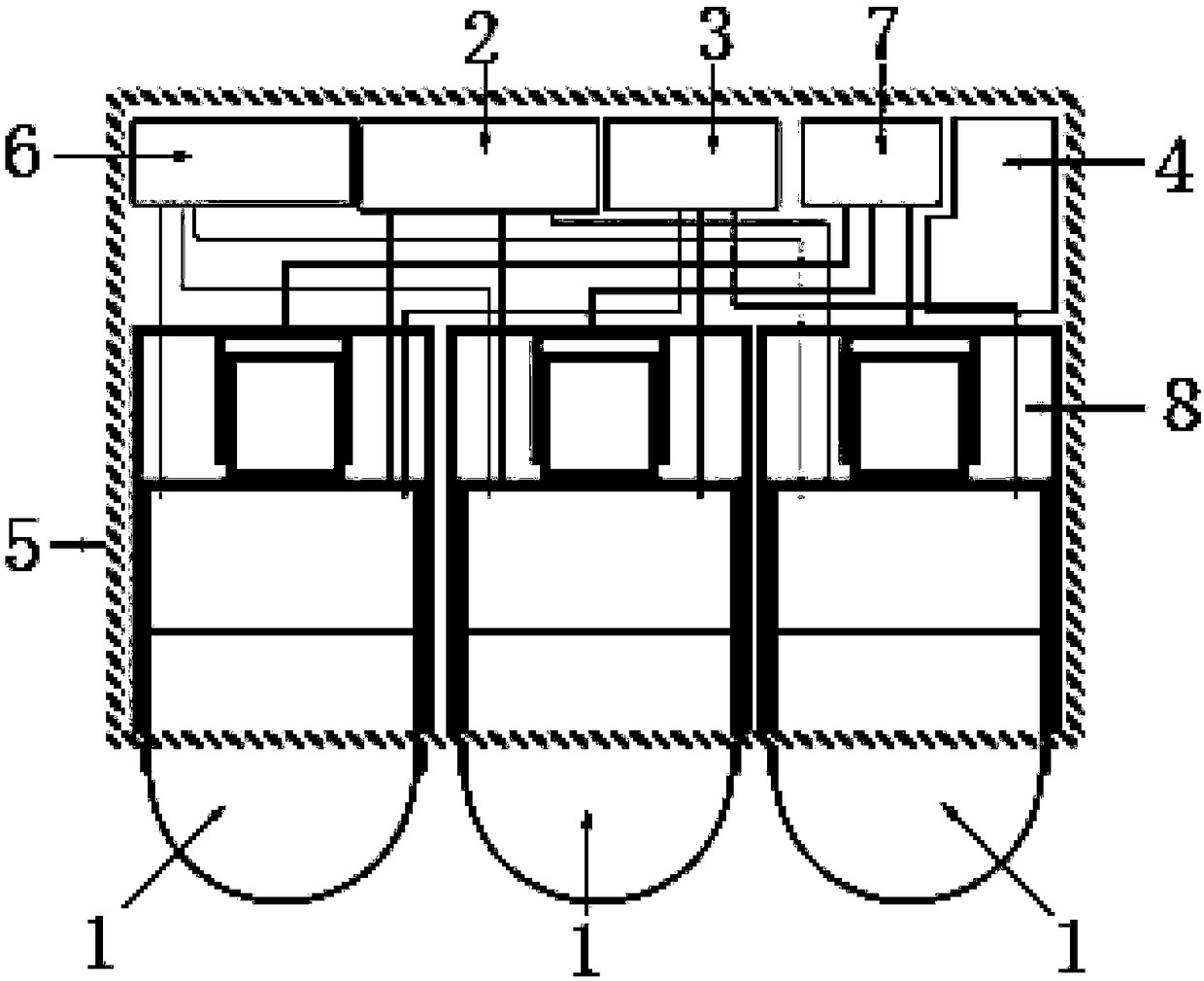

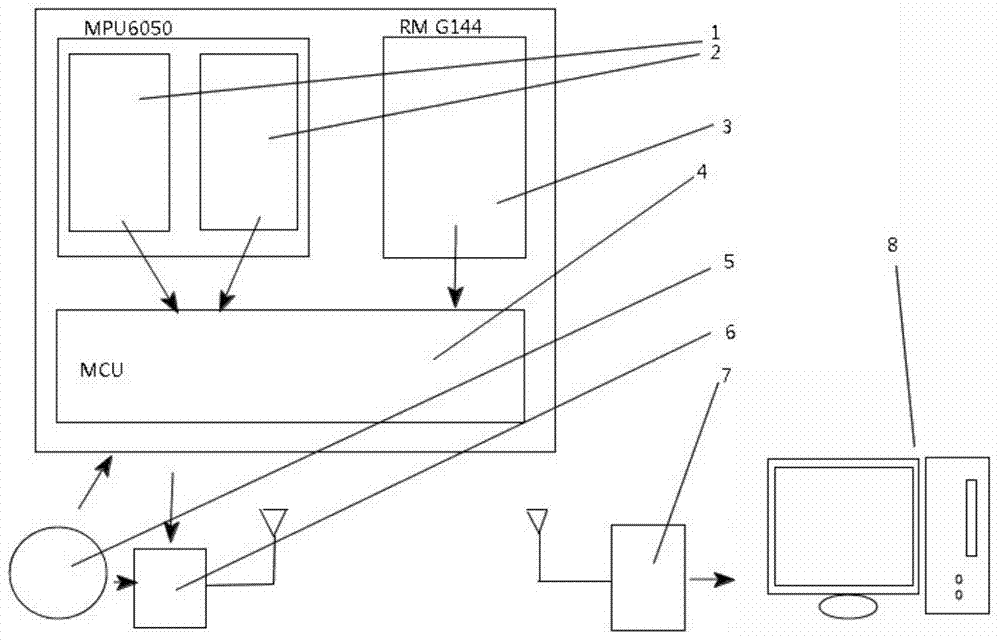

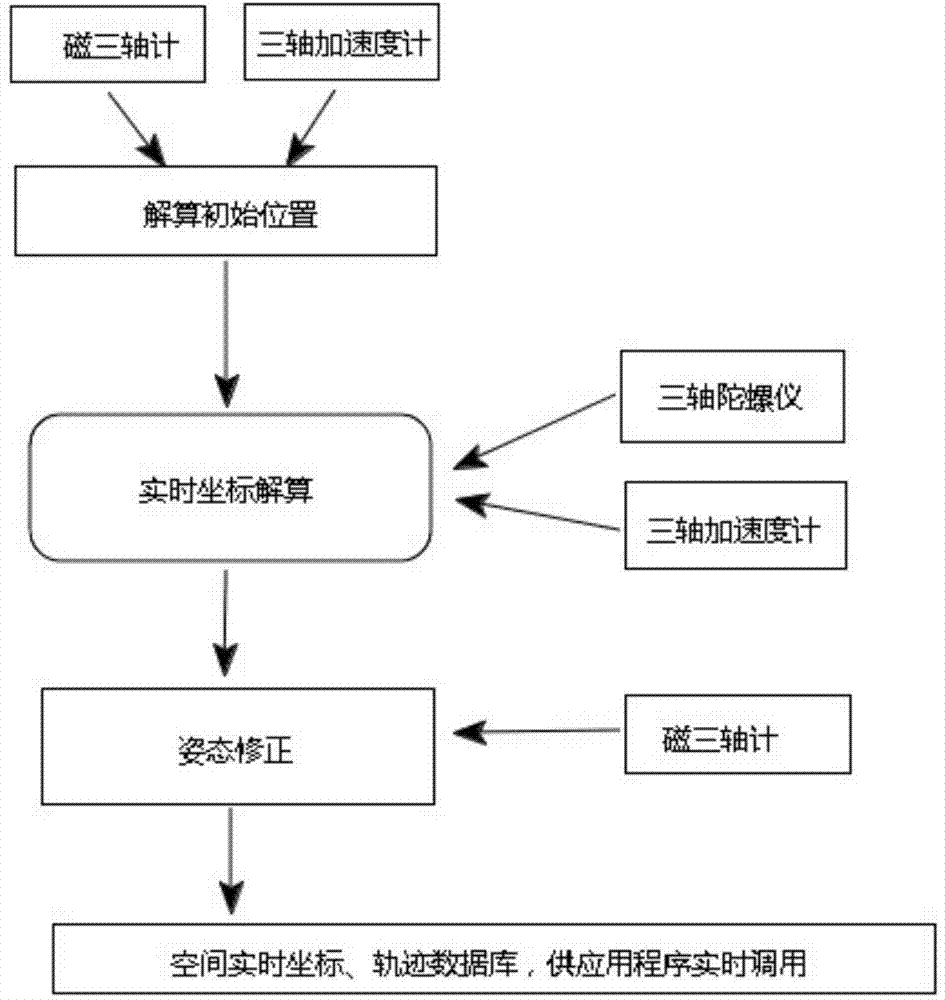

Underwater magnetic field and six-axis inertia combined positioning system

InactiveCN104515522AReal-time perturbation correctionGuaranteed smooth progressNavigation by speed/acceleration measurementsGyroscopeWireless transmission

The invention relates to an underwater magnetic field and six-axis inertia combined positioning system. The system includes the following parts: (1) and (2) are respectively a sensing chip MPU6050 composed of a three-axis acceleration sensor and a triaxial gyroscope, (3) is a triaxial magnetometer RMG144, the two sensing chips send sensed each axis acceleration, acceleration and magnetic field intensity to a host processor (4) through an I2C bus, the host processor (4) finishes preliminary calculation of attitude and determines an absolute underwater space coordinate system, then attitude calculus and action signal discrimination are completed, the absolute position of the current underwater space and the button, function and the like needing control are output to a wireless transmission module (6), a power module (5) is responsible for power supply of the whole system, a receiving module (7) is responsible for receiving and decoding previous data and converts the data into a computer identifiable signal, and a computer (8) subjects the received data to processing and modeling, thus finishing the task of establishing an underwater space trajectory description system.

Owner:NANJING ZHUANCHUANG INTPROP SERVICES

Detection method for blast furnace top material level

InactiveCN102703632AFast and accurate commissioningEnsure accurateChecking devicesEngineeringMaster controller

The invention discloses a detection method for a blast furnace top material level. After a stock rod design range stockline level and a 0m stockline level of a master controller are determined, the current indication of an absolute coder and the whole rotating circle number of a chain wheel in a heavy punch lowering process are respectively recorded, a proportionality factor is calculated according to a formula, and then the practical value of the stock rod height is calculated in real time within each period. According to the detection method for the blast furnace top material level, which is disclosed by the invention, the problem that production is affected due to complex and time-wasting zero calibration process of the traditional blast furnace stock rod system is solved.

Owner:WISDRI ENG & RES INC LTD

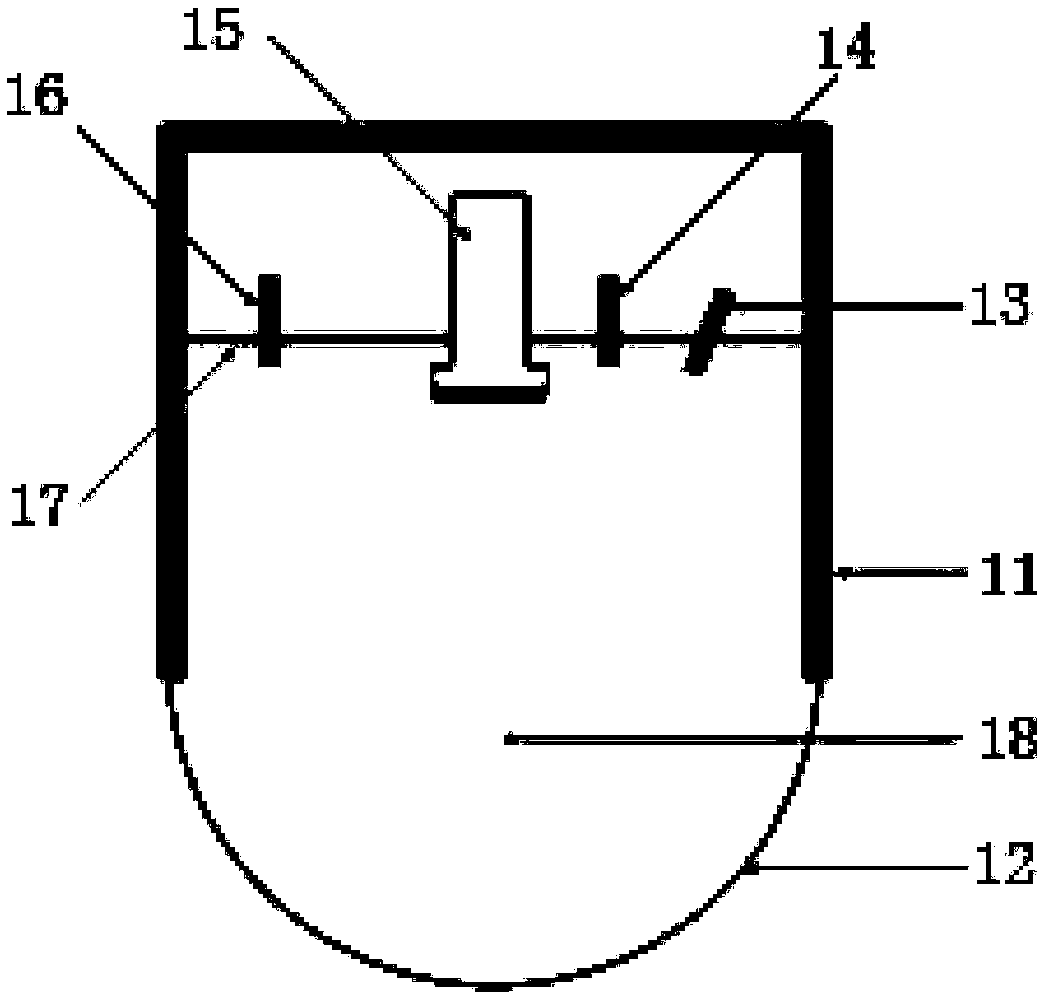

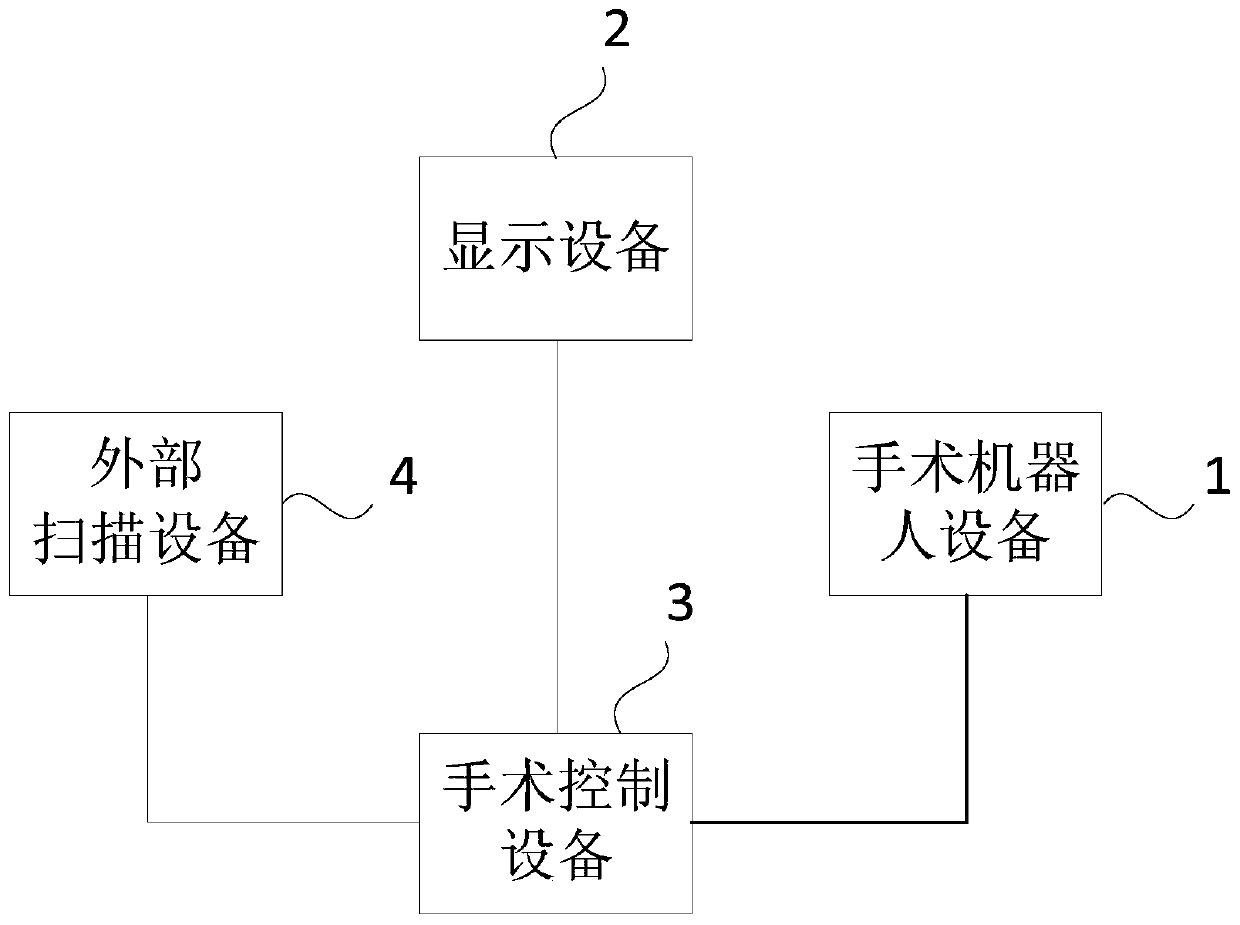

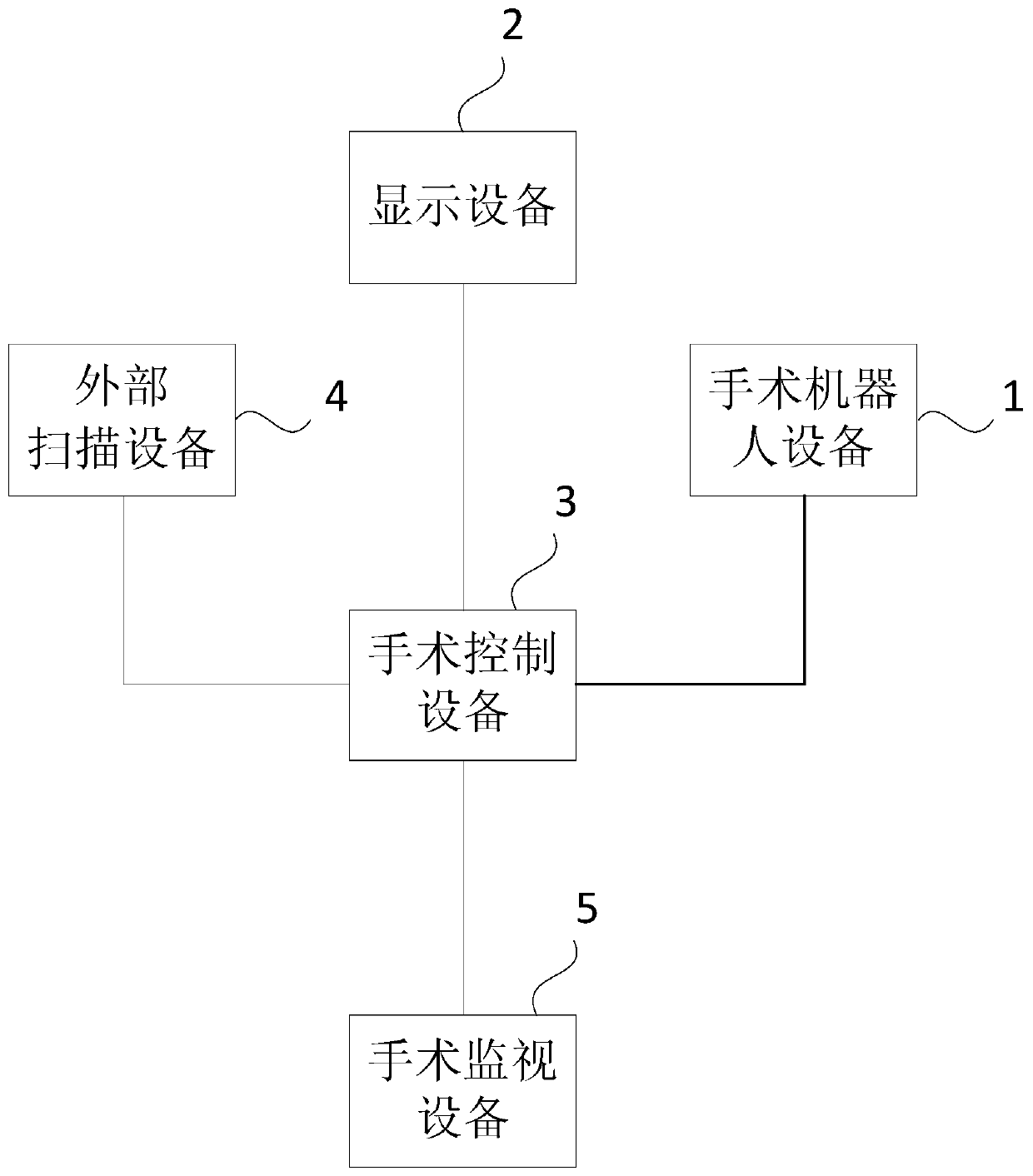

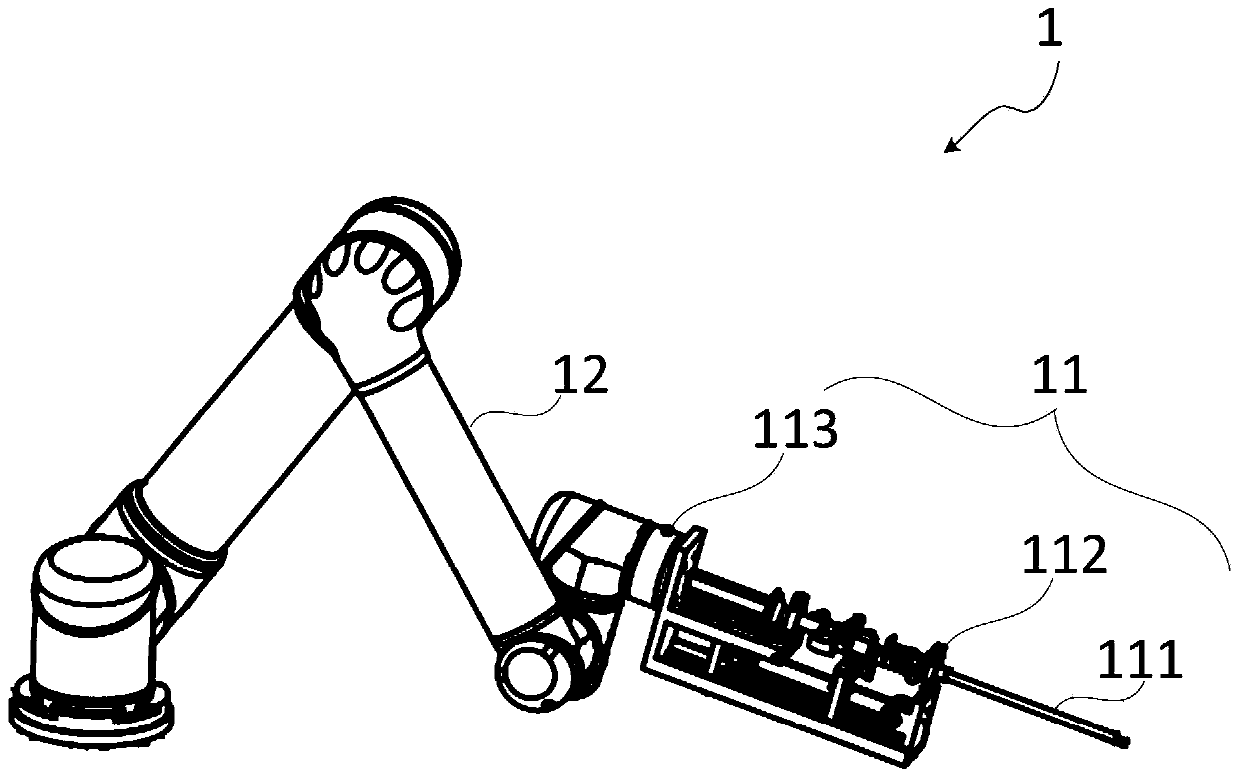

Transurethral prostate surgical robot resection system

PendingCN110051435AEnsure accurateEnsure safetySurgical navigation systemsComputer-aided planning/modellingThree dimensional modelProstate

An embodiment of the invention discloses a transurethral prostate surgical robot resection system comprising a surgical robot device for performing a surgical operation on a predetermined resection range of the prostate of a patient according to a surgical control instruction sent by a surgical control device and sending surgical image information to the surgical control device; a display device for displaying an image to a surgical operator according to display data sent by the surgical control device; the surgical control device for acquiring prostate scan data from an external scanning device and establishing a three-dimensional model of the prostate. A surgical resection path and a surgical resection range are determined according to the three-dimensional model and a preset model to generate the surgical control instruction and send the surgical control instruction to a surgical robot apparatus. The system ensures surgical accuracy and safety by means of the three-dimensional modeling and resection path presetting, improves the resection efficiency, and avoids tissue residue and damage caused by improper human operation and unskilled technology.

Owner:北京科迈启元科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com