Patents

Literature

37results about How to "Improve liquid tightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Egr Cooler

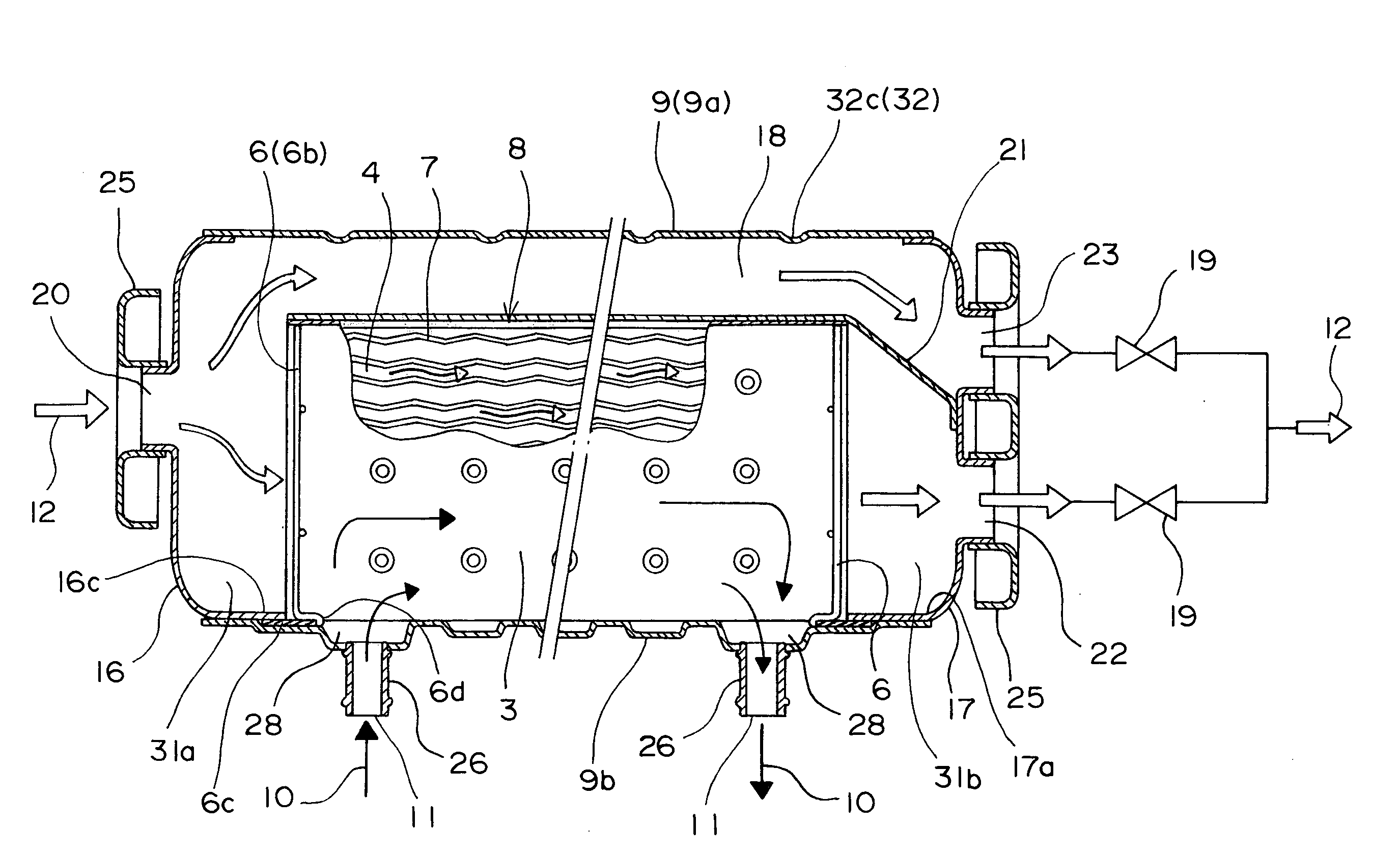

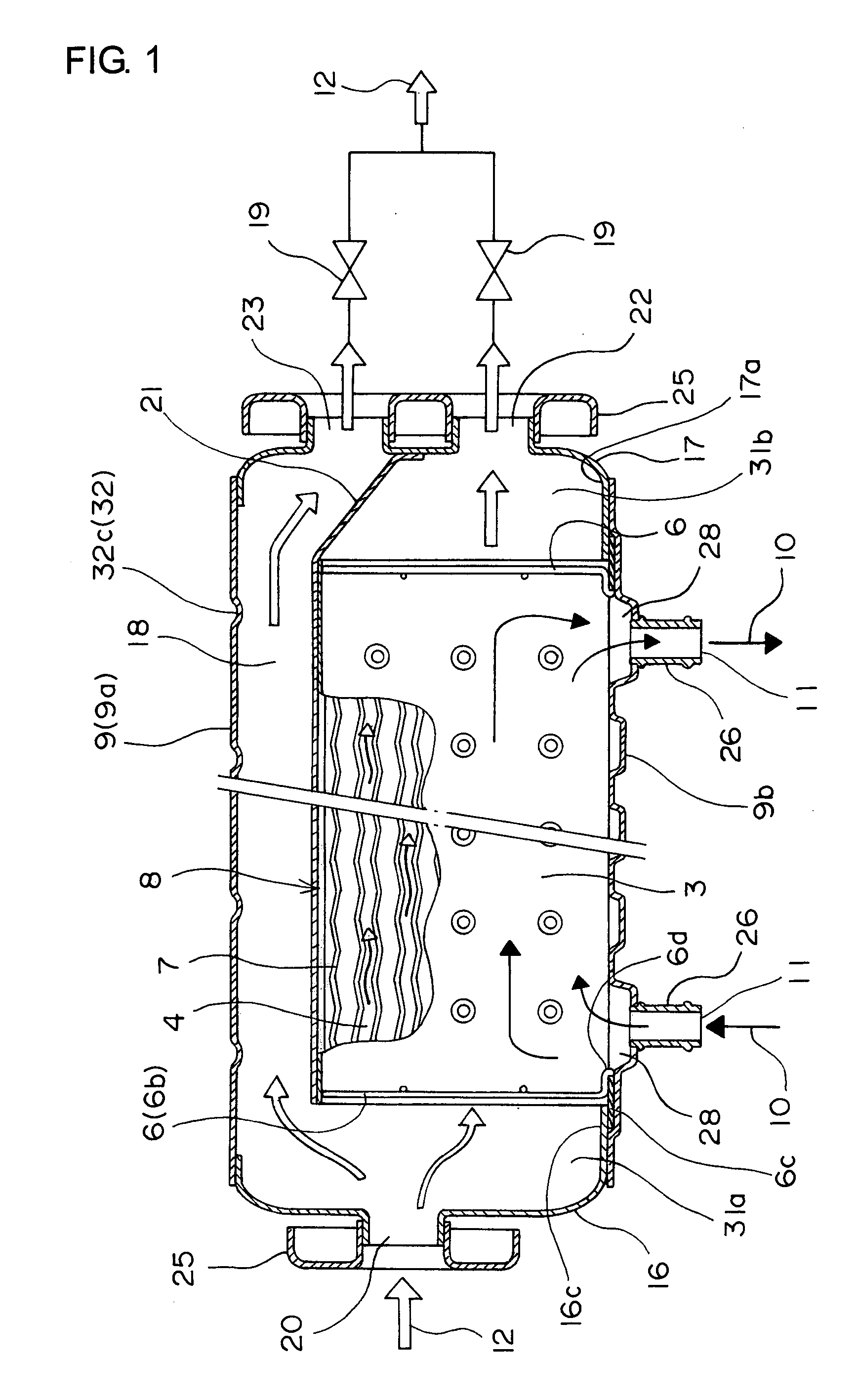

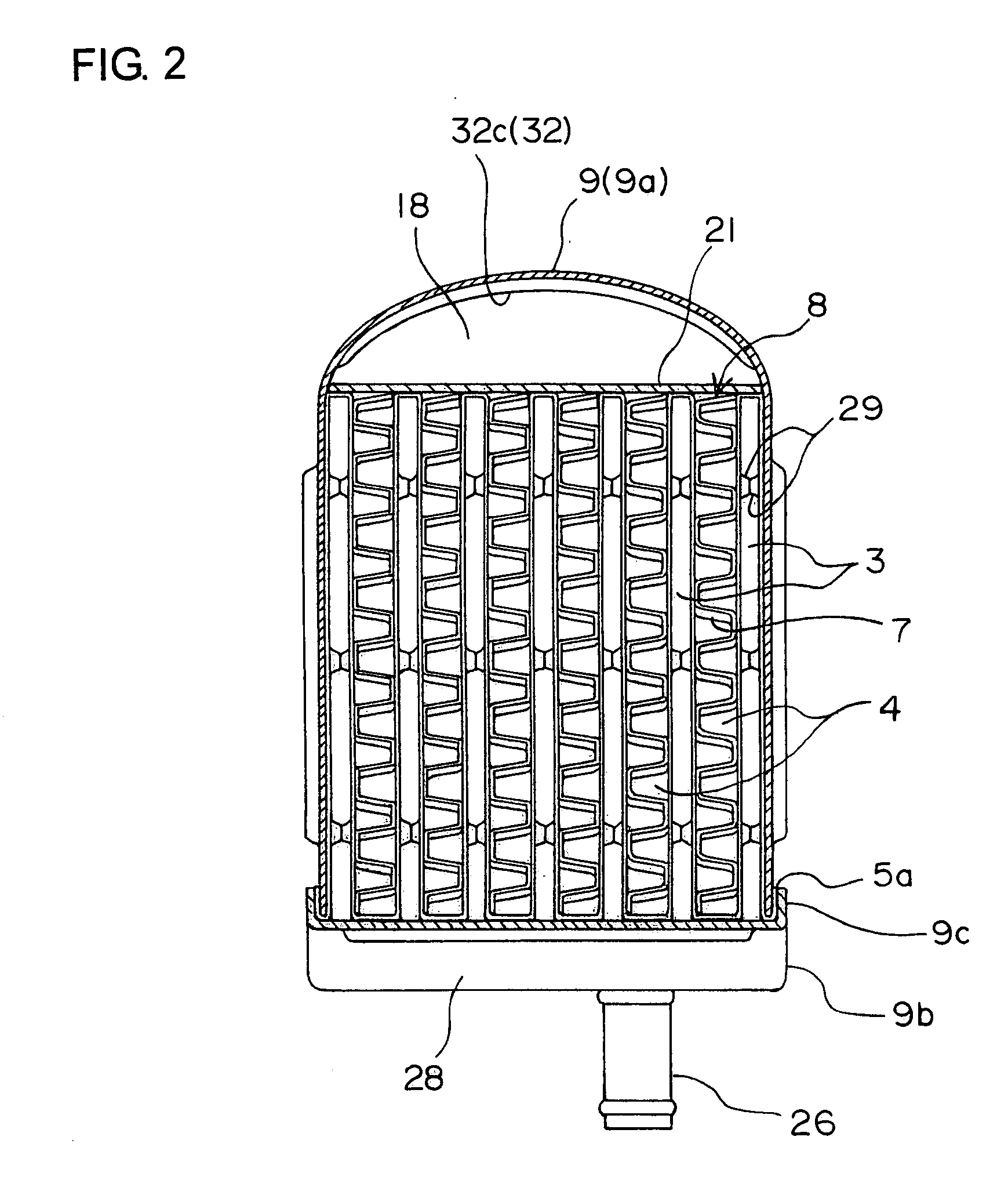

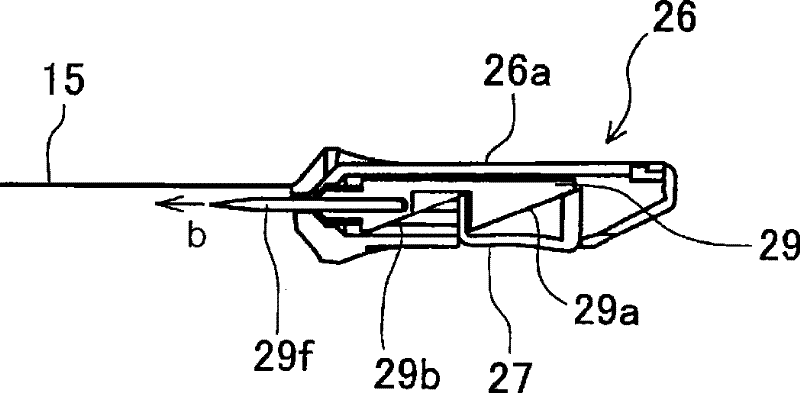

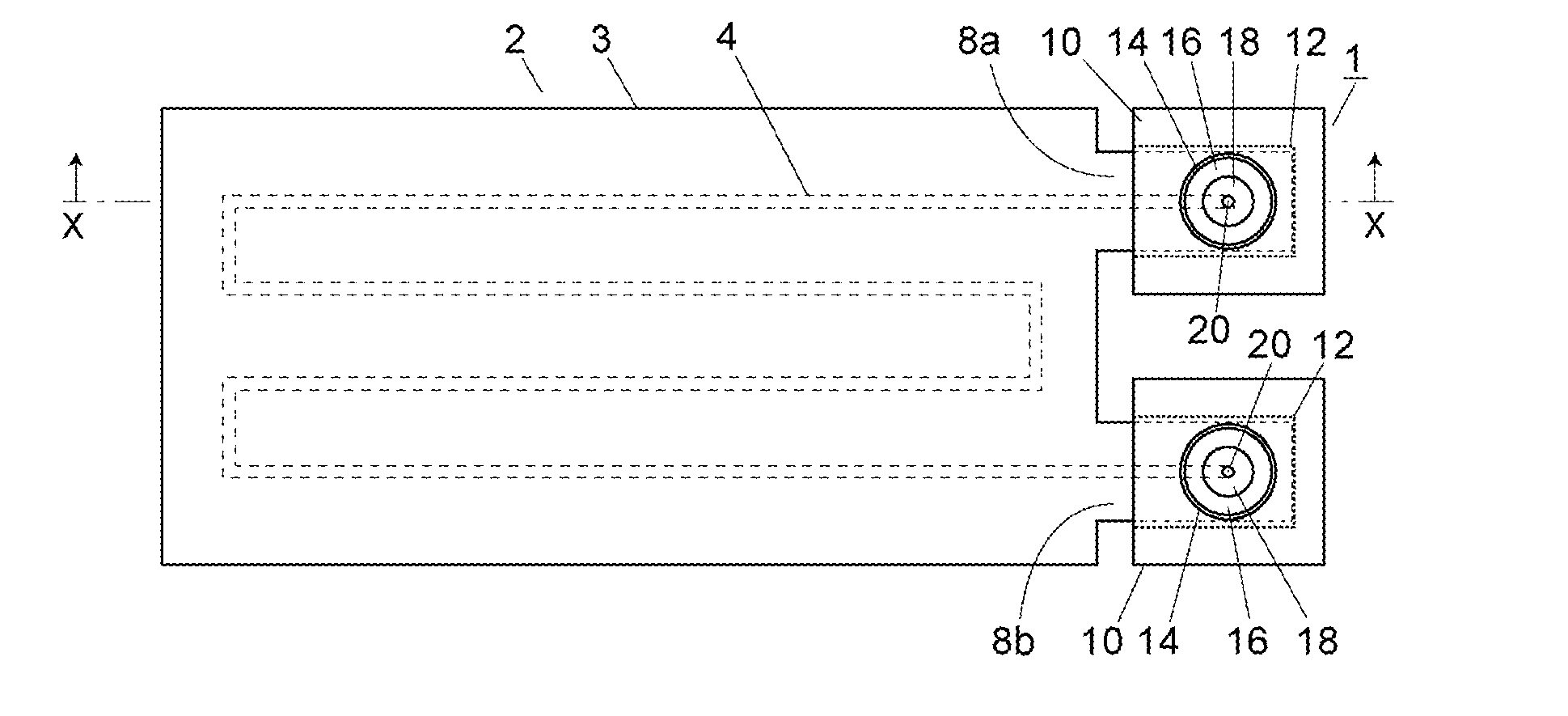

InactiveUS20070289581A1Easy to manufactureAvoid deformationInternal combustion piston enginesNon-fuel substance addition to fuelThin metalEngineering

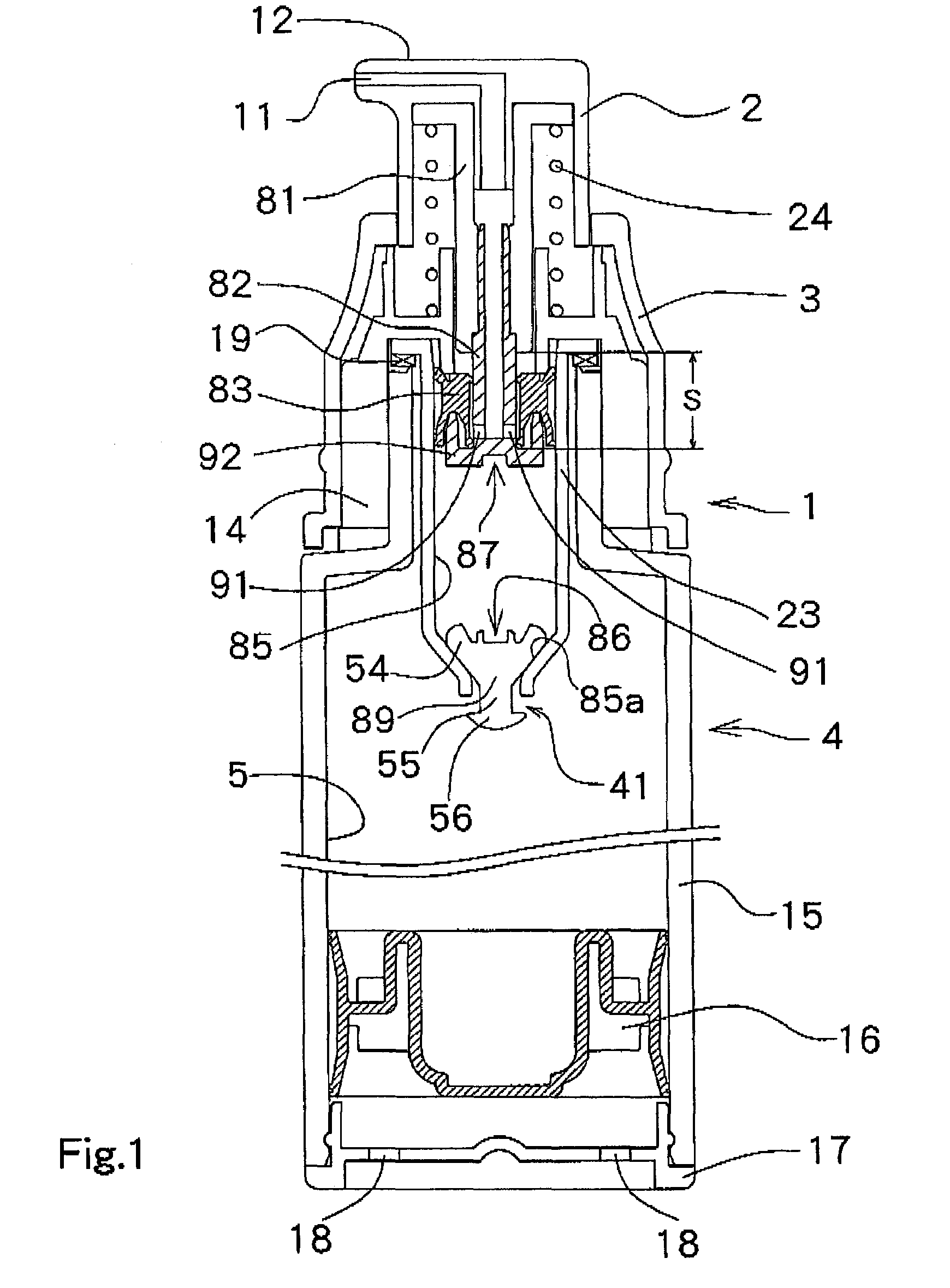

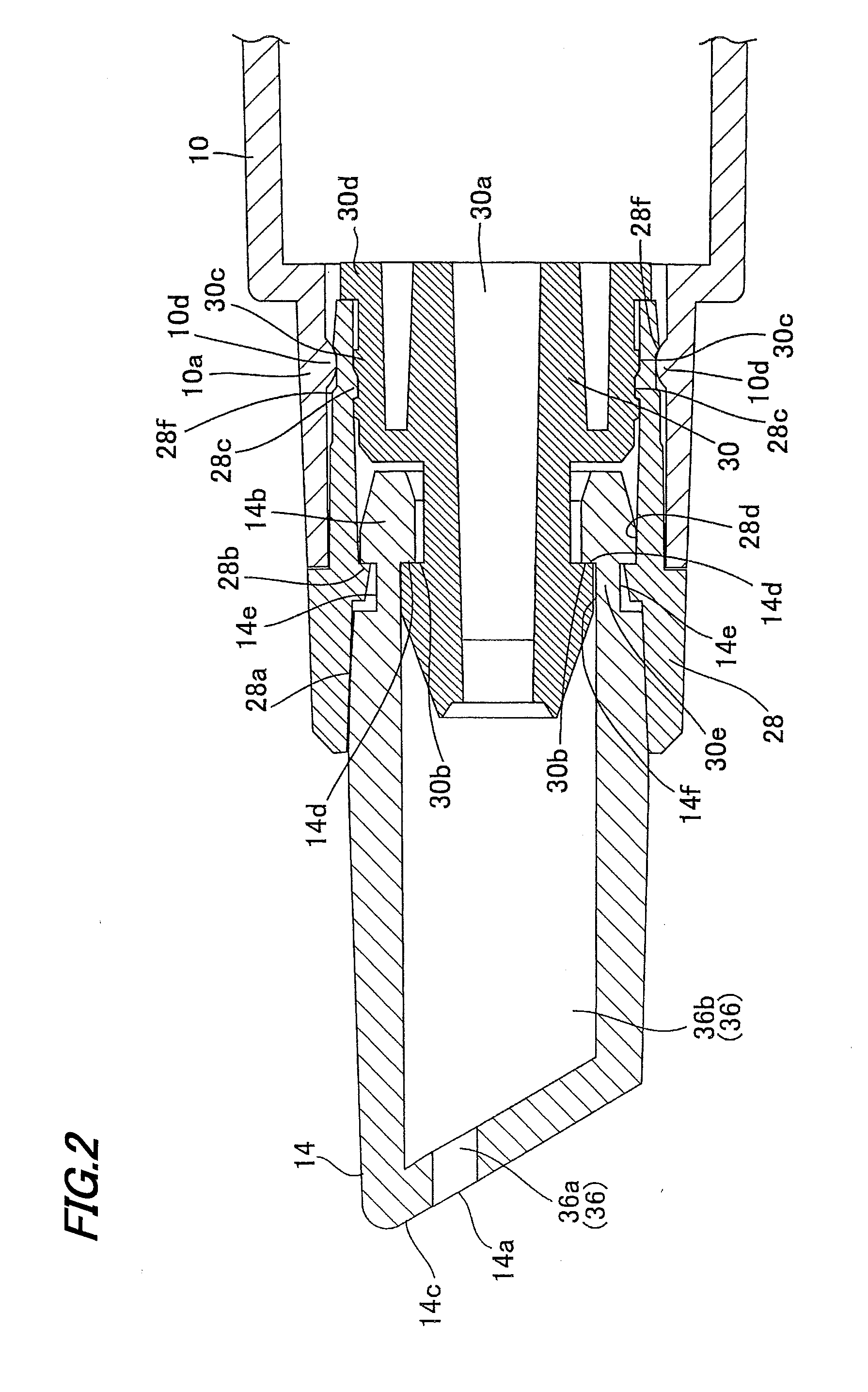

A bypass duct portion is integrally provided in a casing of an EGR cooler so that heat distortion generated at a part of the casing when bypassing of an exhaust gas is rationally absorbed, and the EGR cooler body and a valve case are brazed / fixed all together so as to improve strength of the valve case, whereby, the bypass duct portion is formed between an inner surface of the casing and the core, a switch is provided for switching and guiding the exhaust gas to either of the core or the bypass duct portion, and a large number of outer ribs formed in the circumferential direction respectively are arranged side by side while being separated from each other in the longitudinal direction in the bypass duct portion of the casing so as to constitute a heat stress absorbing portion. And a cylindrical valve case is integrally formed by deep drawing of a thin metal plate by a press machine, a pair of slits are provided at the rear end of the valve case, both edges of an intra-valve partition plate are inserted into the slits, support projection portions are provided on both faces of the both edge portions of the intra-valve partition plate, and the edge of the slit is supported by the support projection portion. And an opening of the valve case is integrally brazed / fixed to an opening of a header portion of the casing.

Owner:T RAD CO LTD

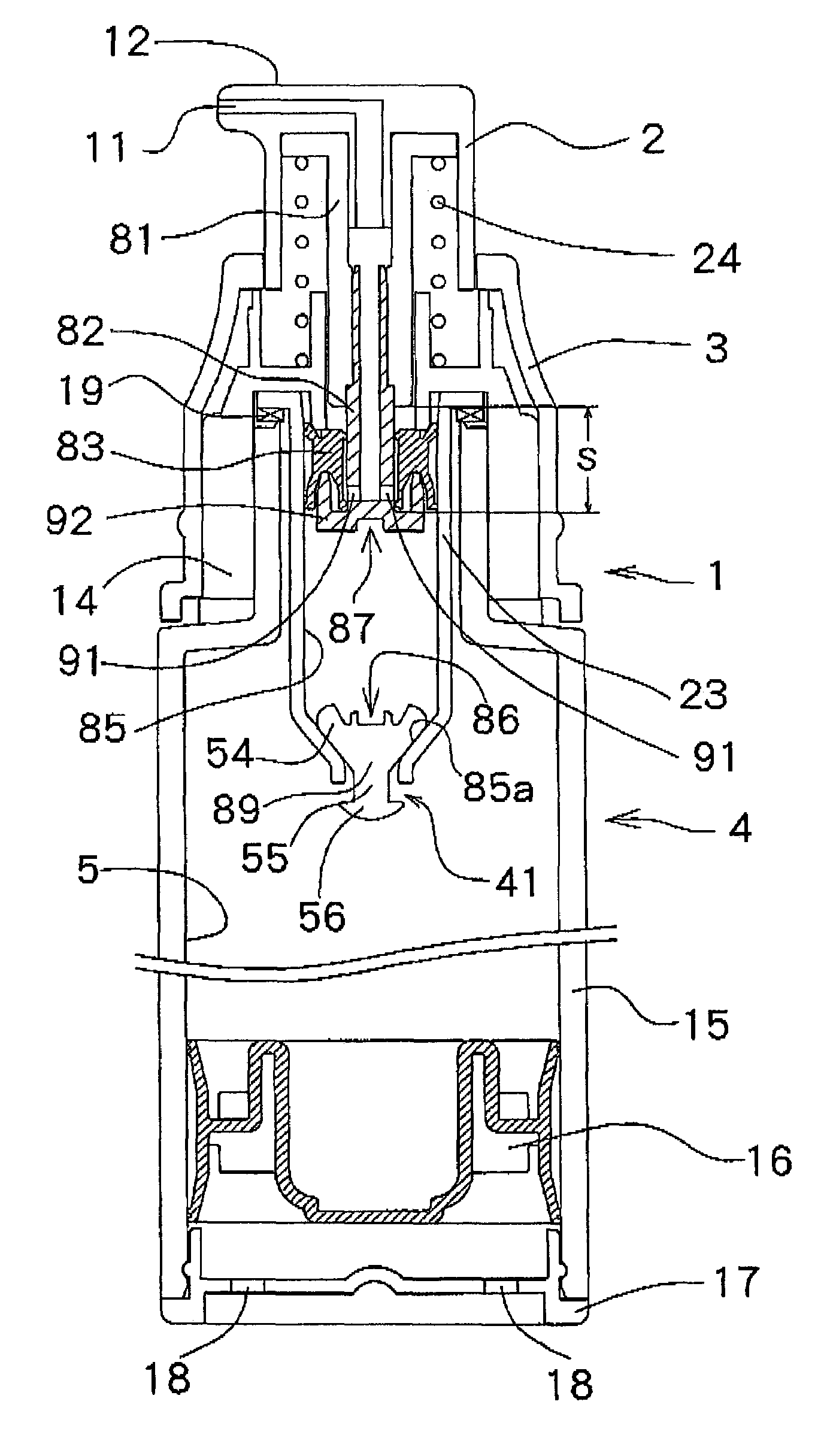

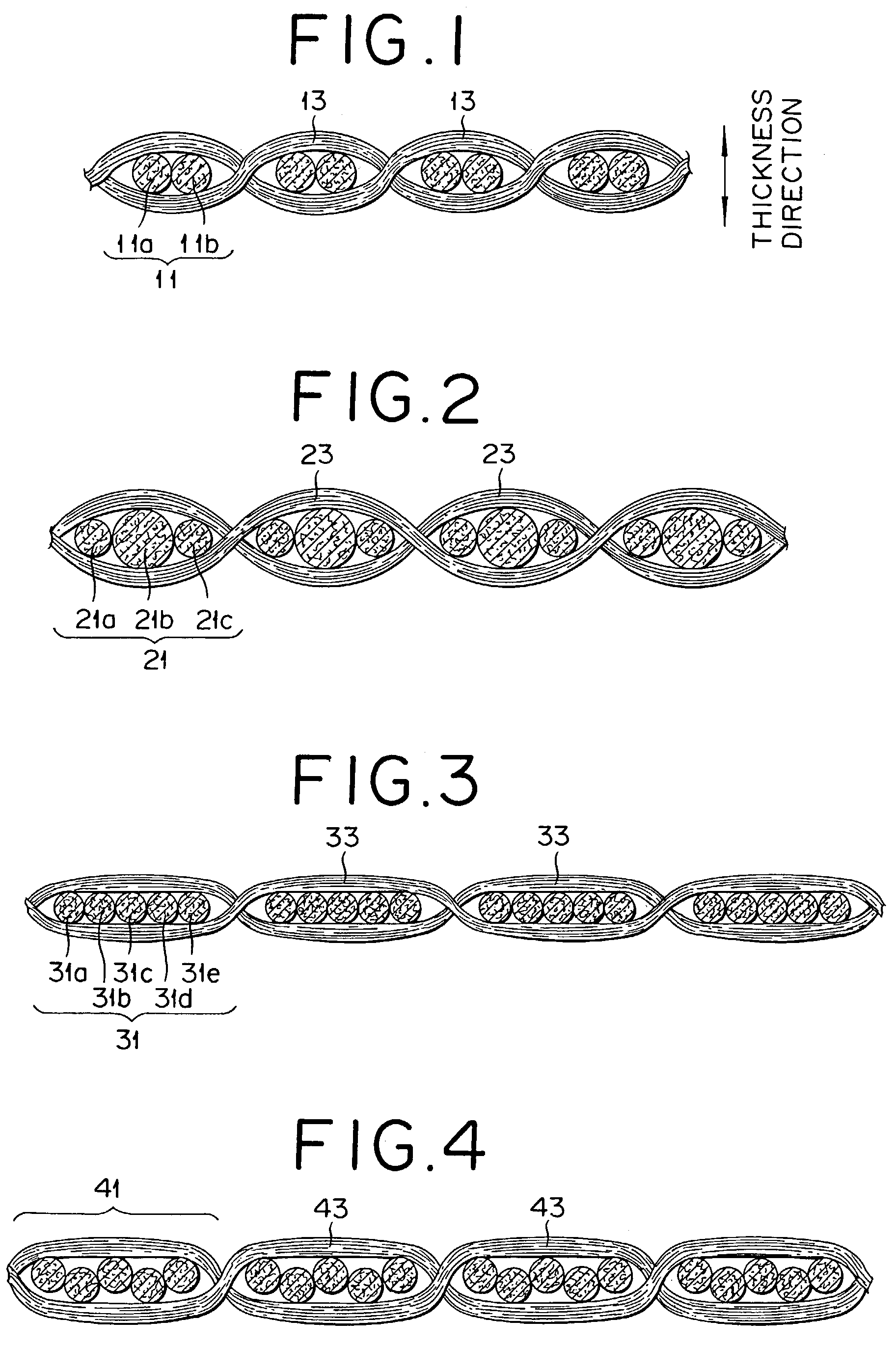

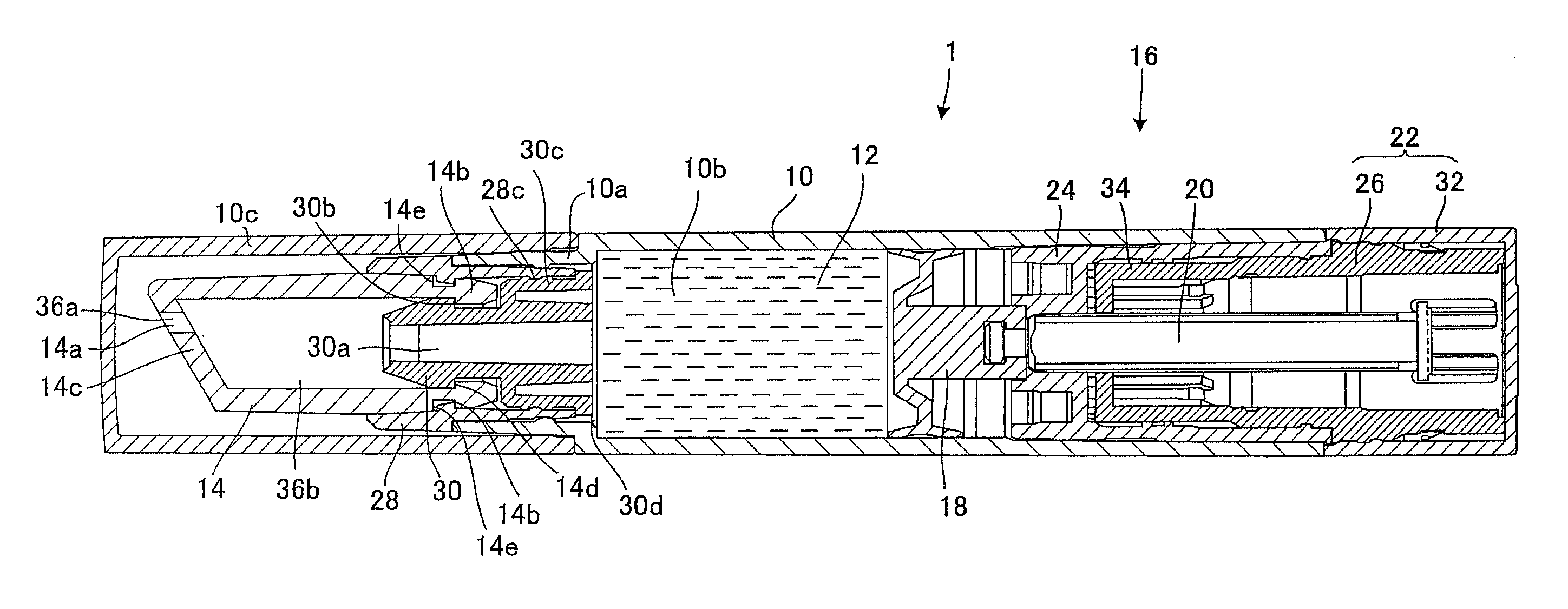

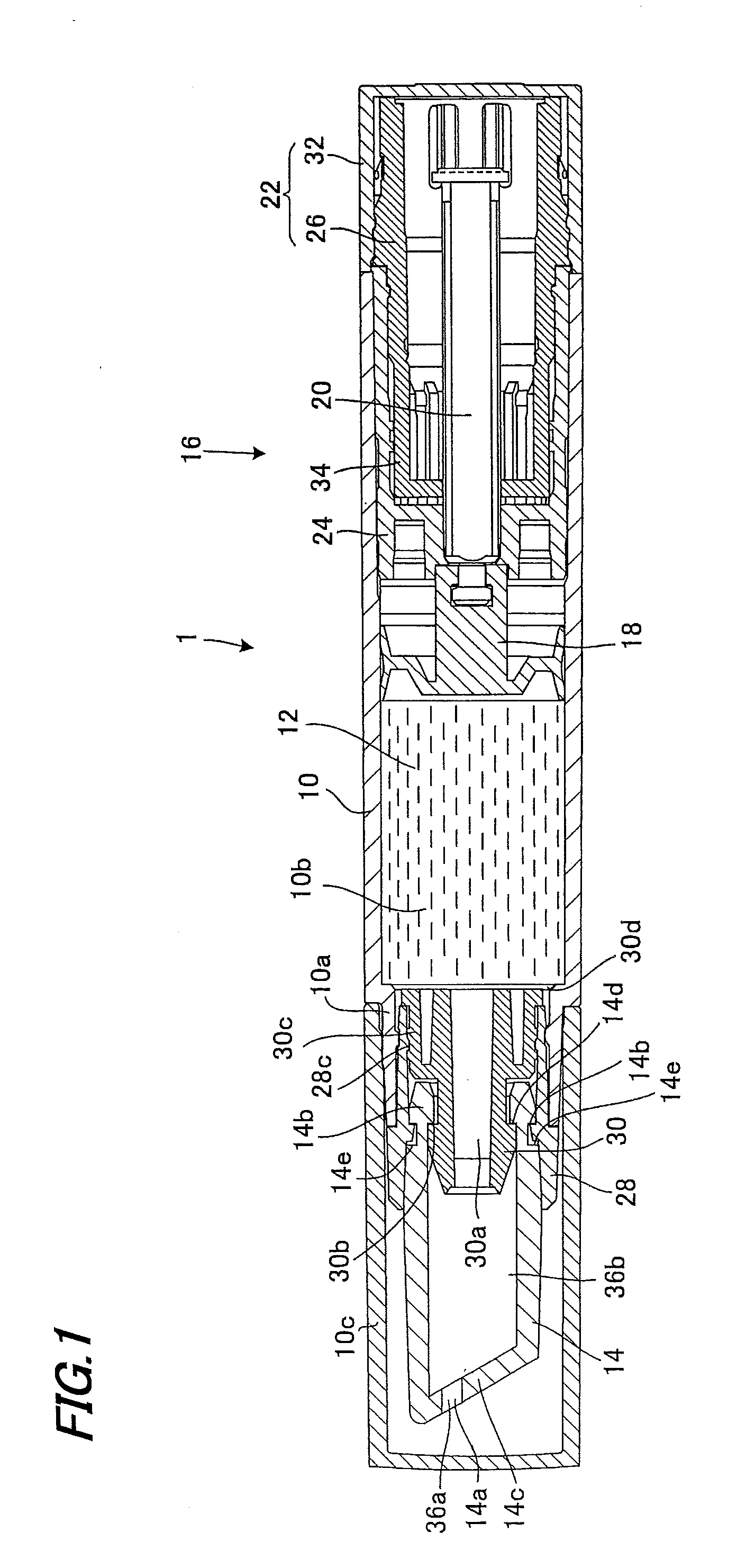

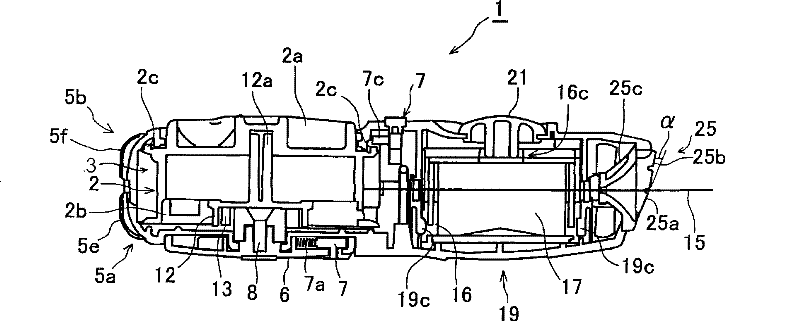

Cylinder and valve structures for liquid-dispensing containers

A liquid-dispensing structure includes: an outer cylinder with a one-way valve at its lower end to allow a liquid to flow into the outer cylinder; a hollow piston being slidable inside the outer cylinder and having a pair of liquid-tight portions formed with circular convex portions around its outer circumferential surface in positions apart in an axial direction; and an inner cylinder for dispensing a liquid, which reciprocates inside the outer cylinder so that the piston moves in a piston-sliding area of the inner cylinder having an opening through which the liquid flows. The opening is closed when the piston is at a lower position and is opened when the piston is at an upper position.

Owner:MASUDA MASATOSHI

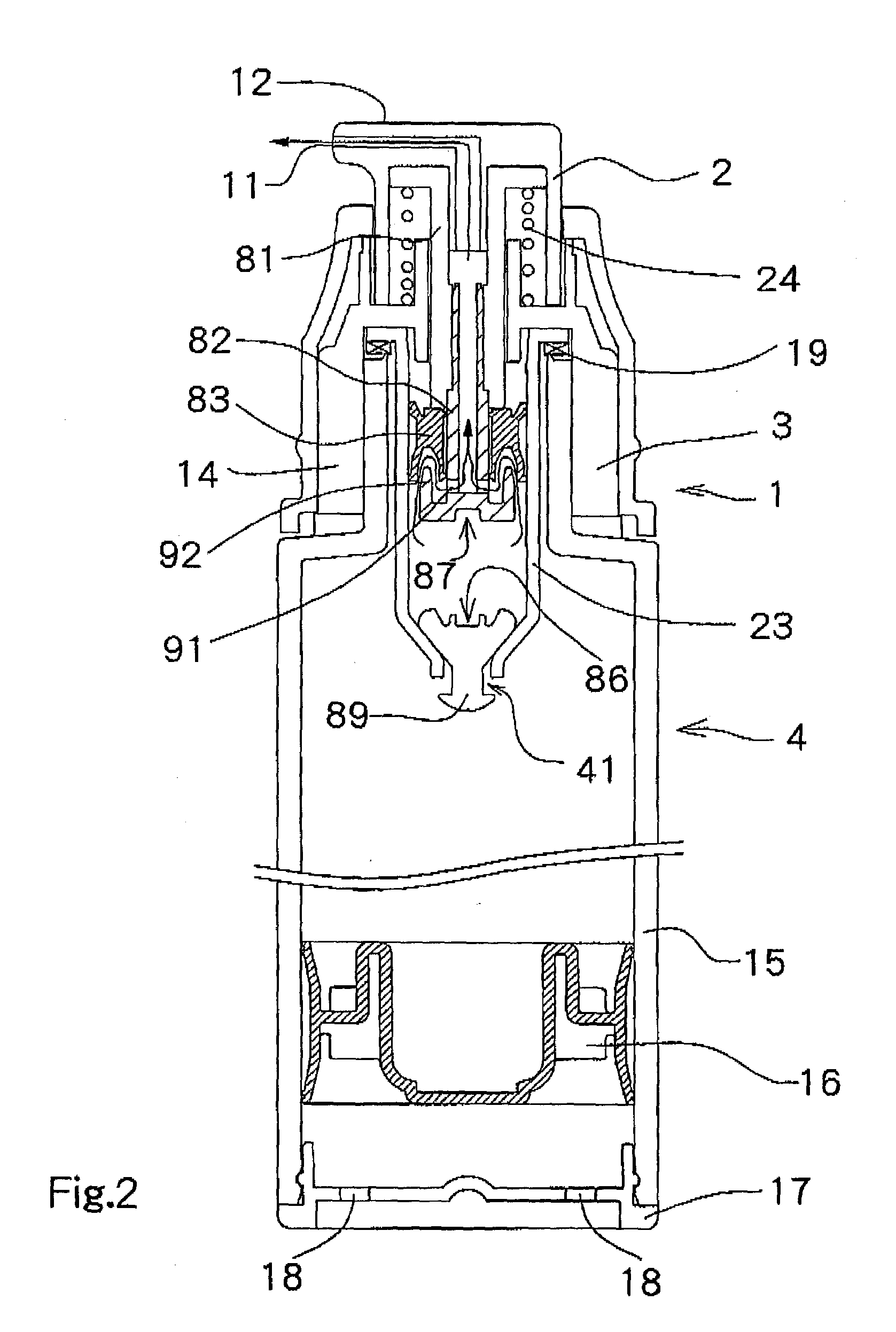

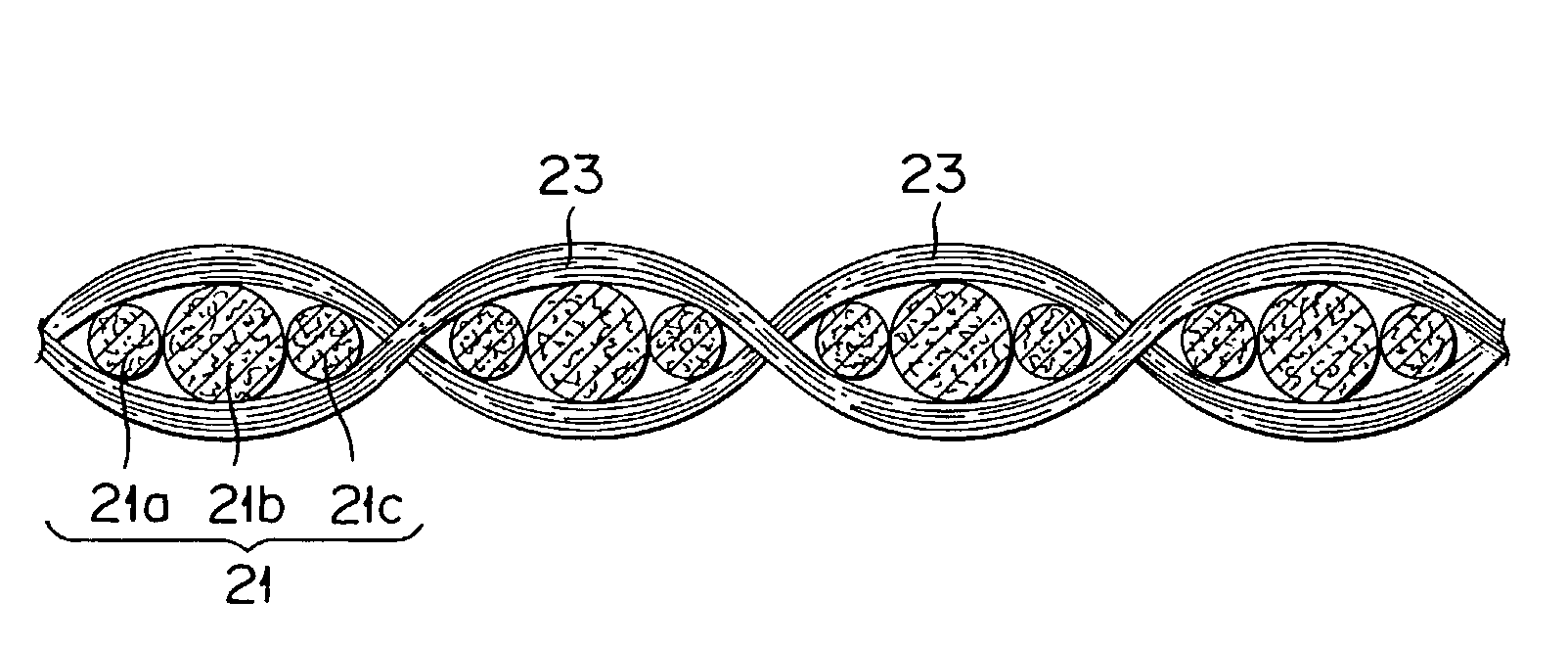

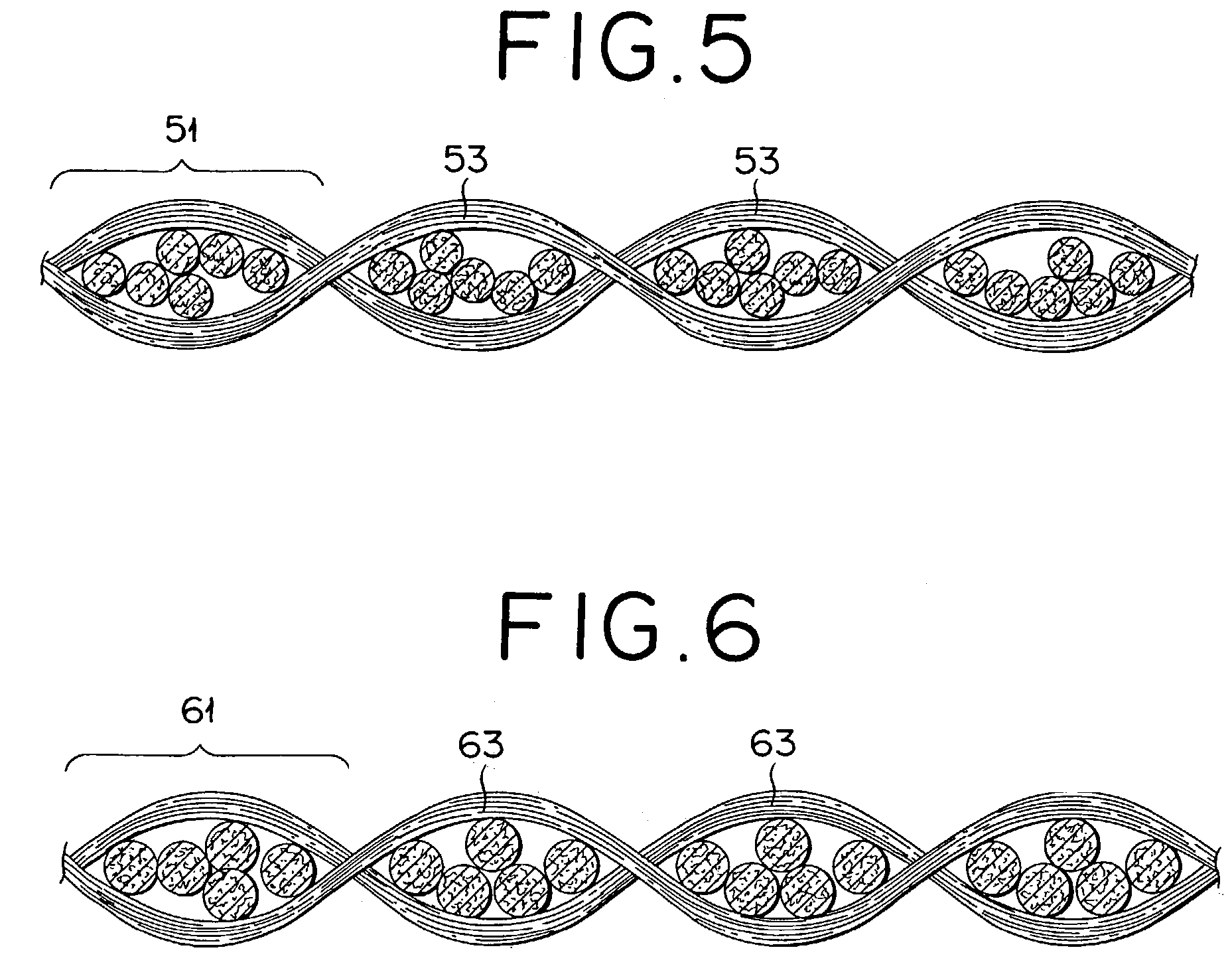

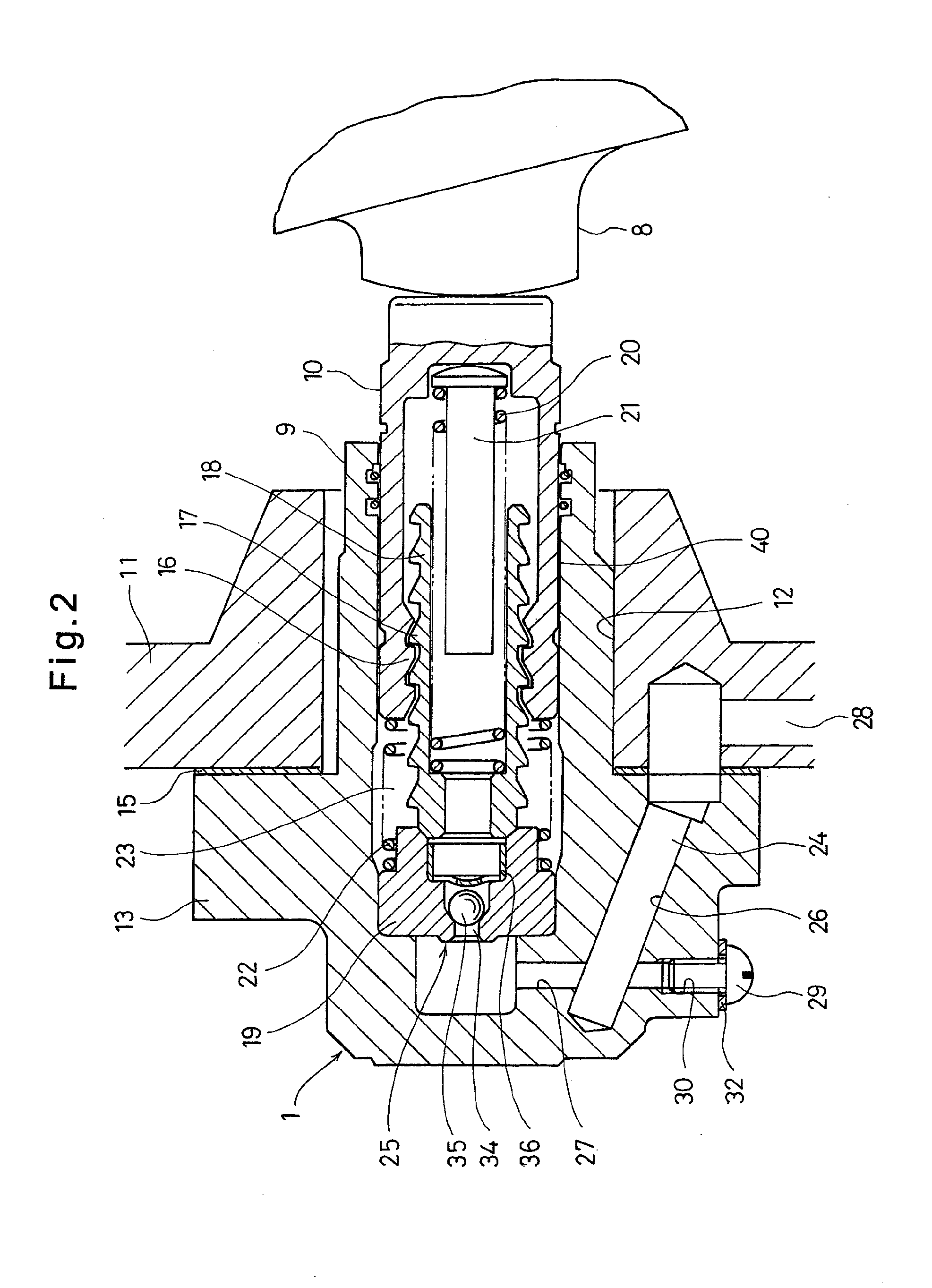

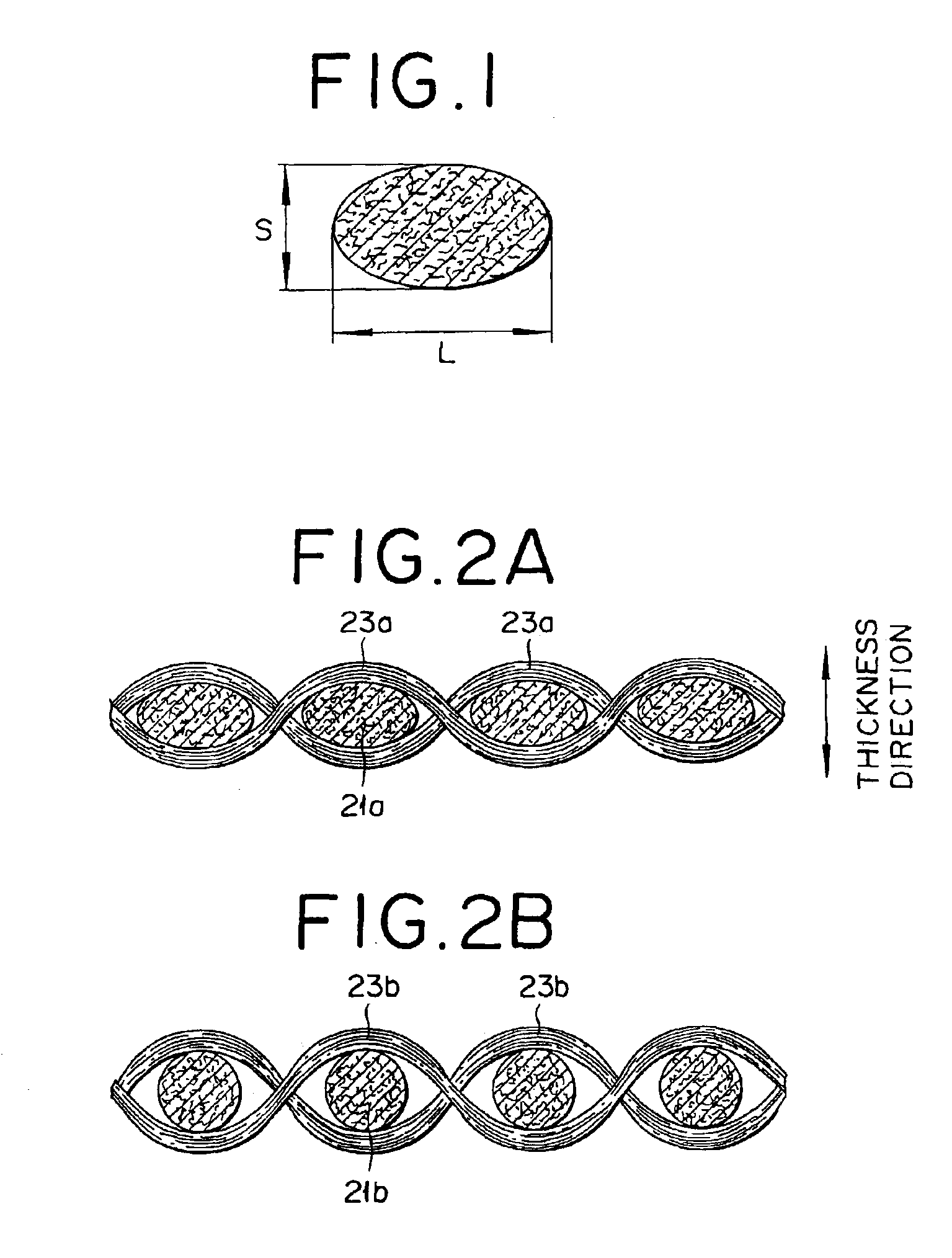

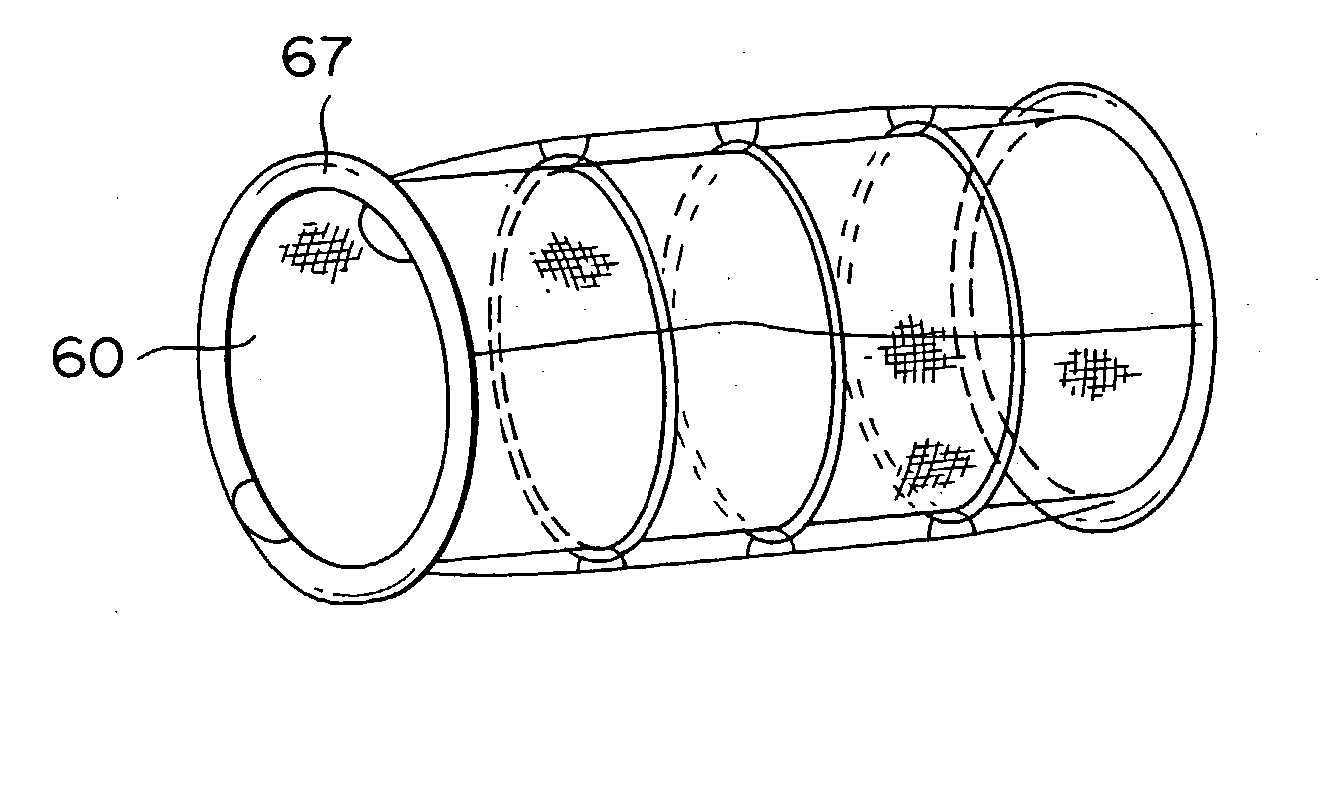

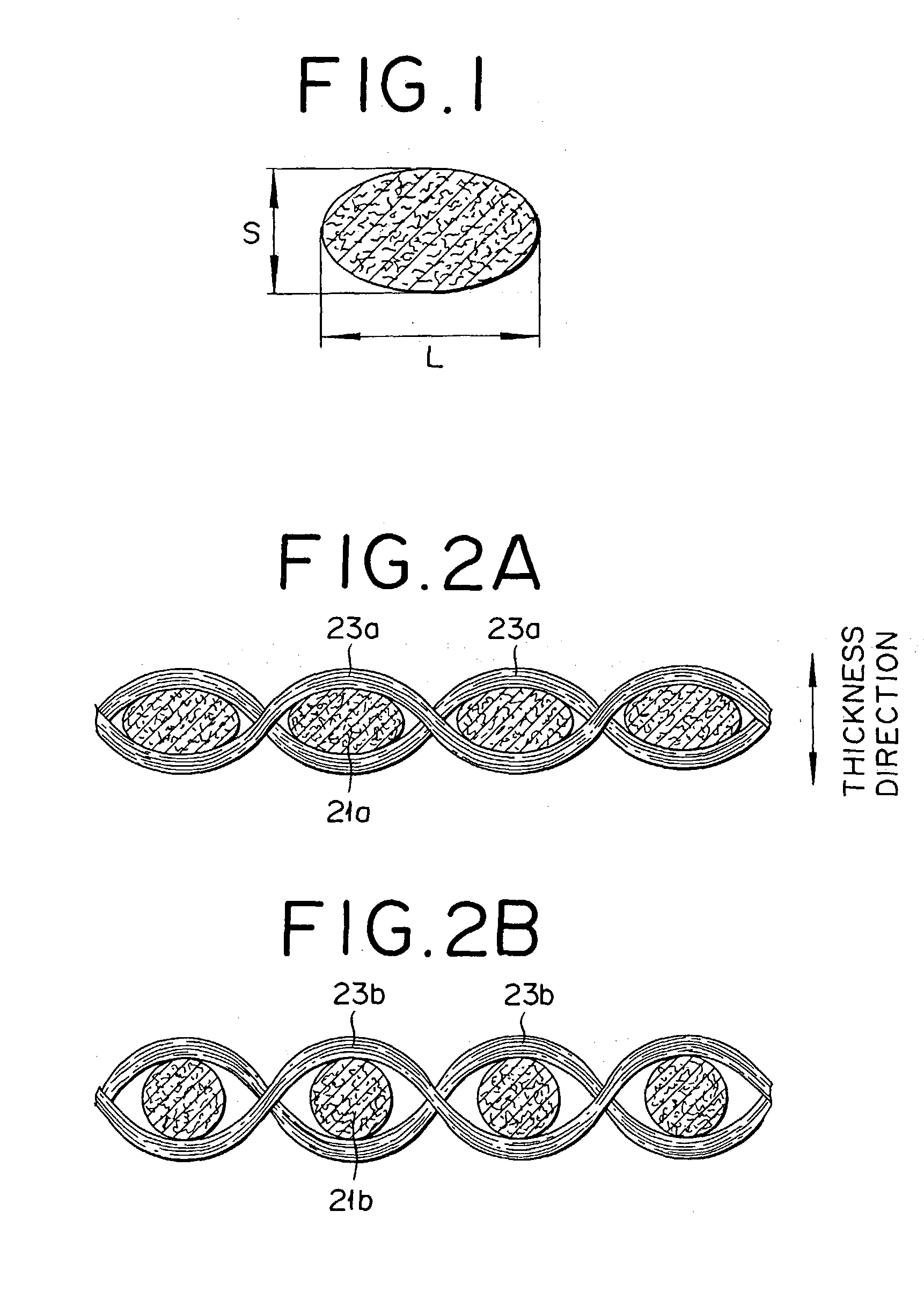

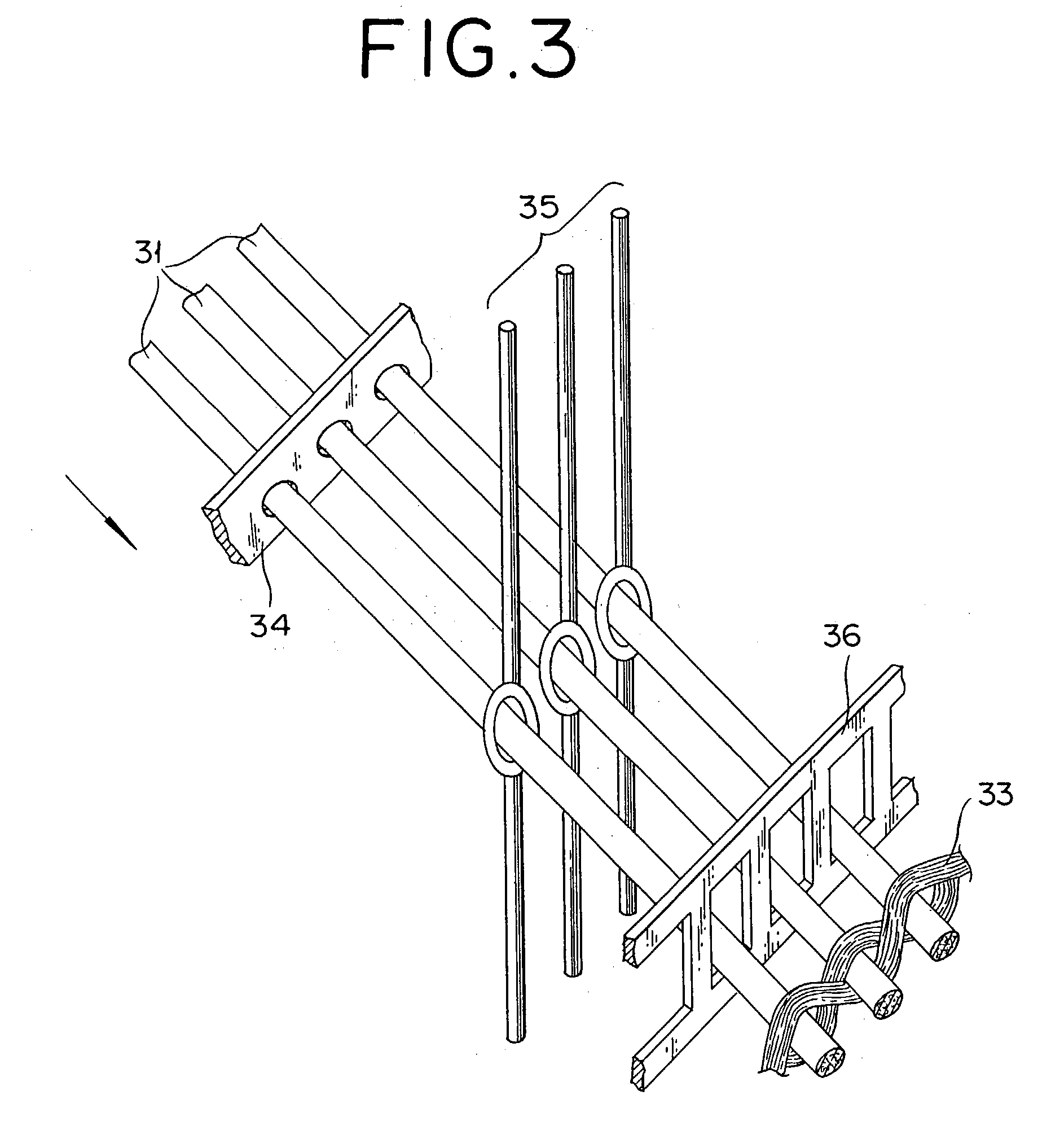

Woven tubing for stent type blood vascular prosthesis and stent type blood vascular prosthesis using the tubing

A woven tubing for use in a stent type blood vascular prosthesis which contains a multifilament formed of two–five single filaments in at least part of warps and has the single filaments disposed in single lines, and a stent type blood vascular prosthesis using the woven tubing are described. The prosthesis combines a shape retaining property that is capable of maintaining its tubular shape without being crushed by the flow of blood with a high liquid tightness that is capable of reducing the leakage of blood to the exterior when implanted at the site of a lesion and allows prevention of the inflow of blood into the site of a lesion.

Owner:TERUMO KK

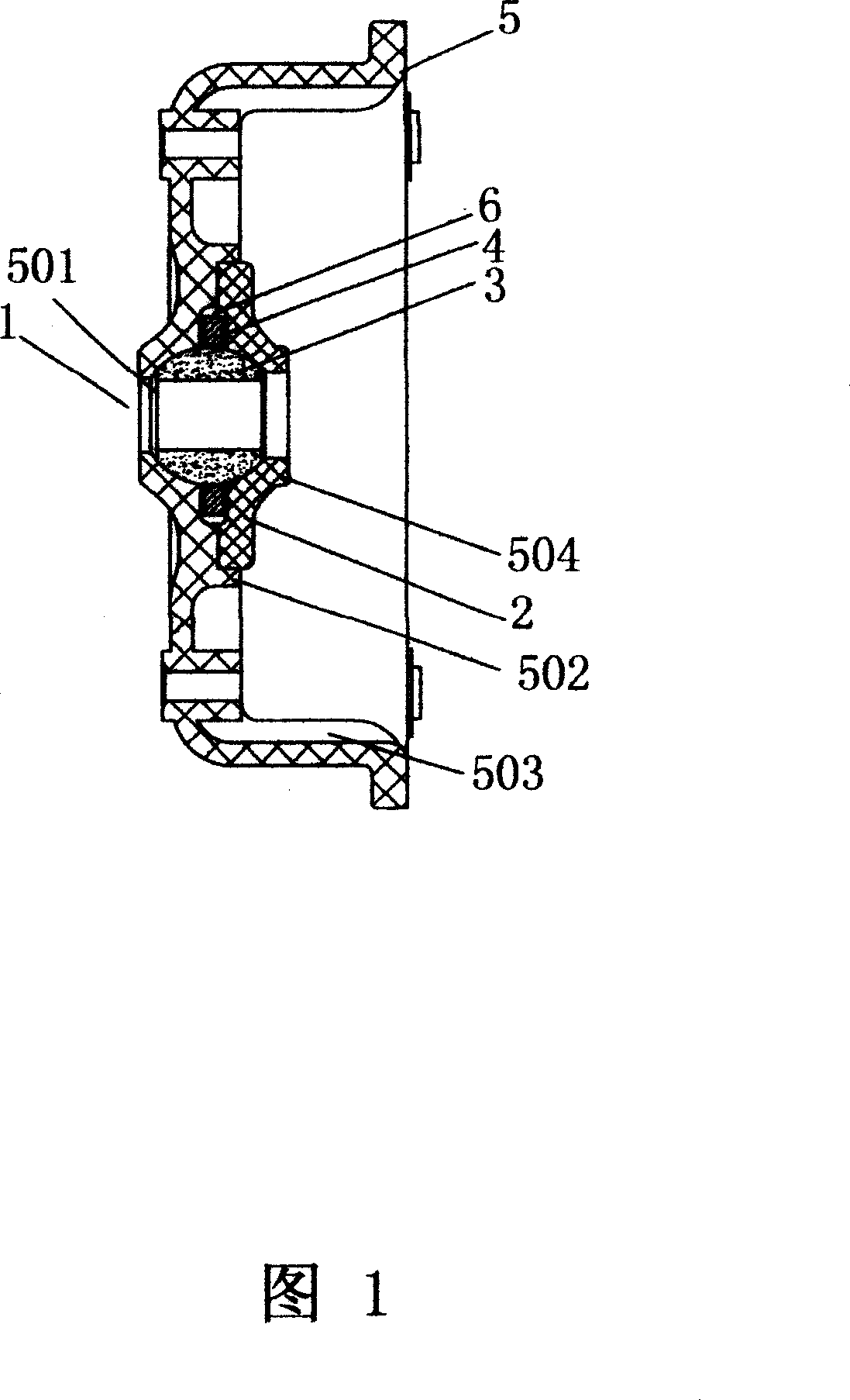

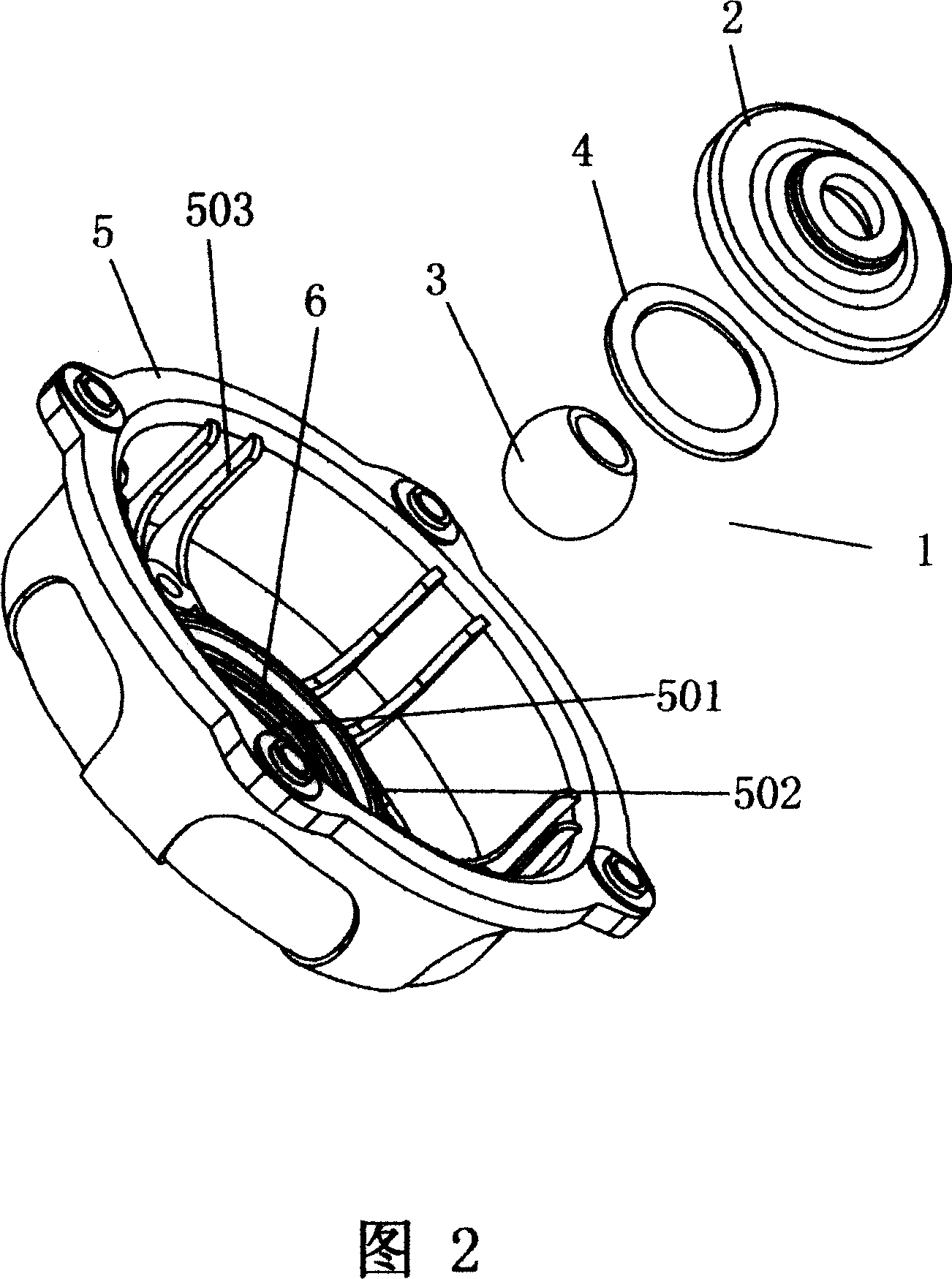

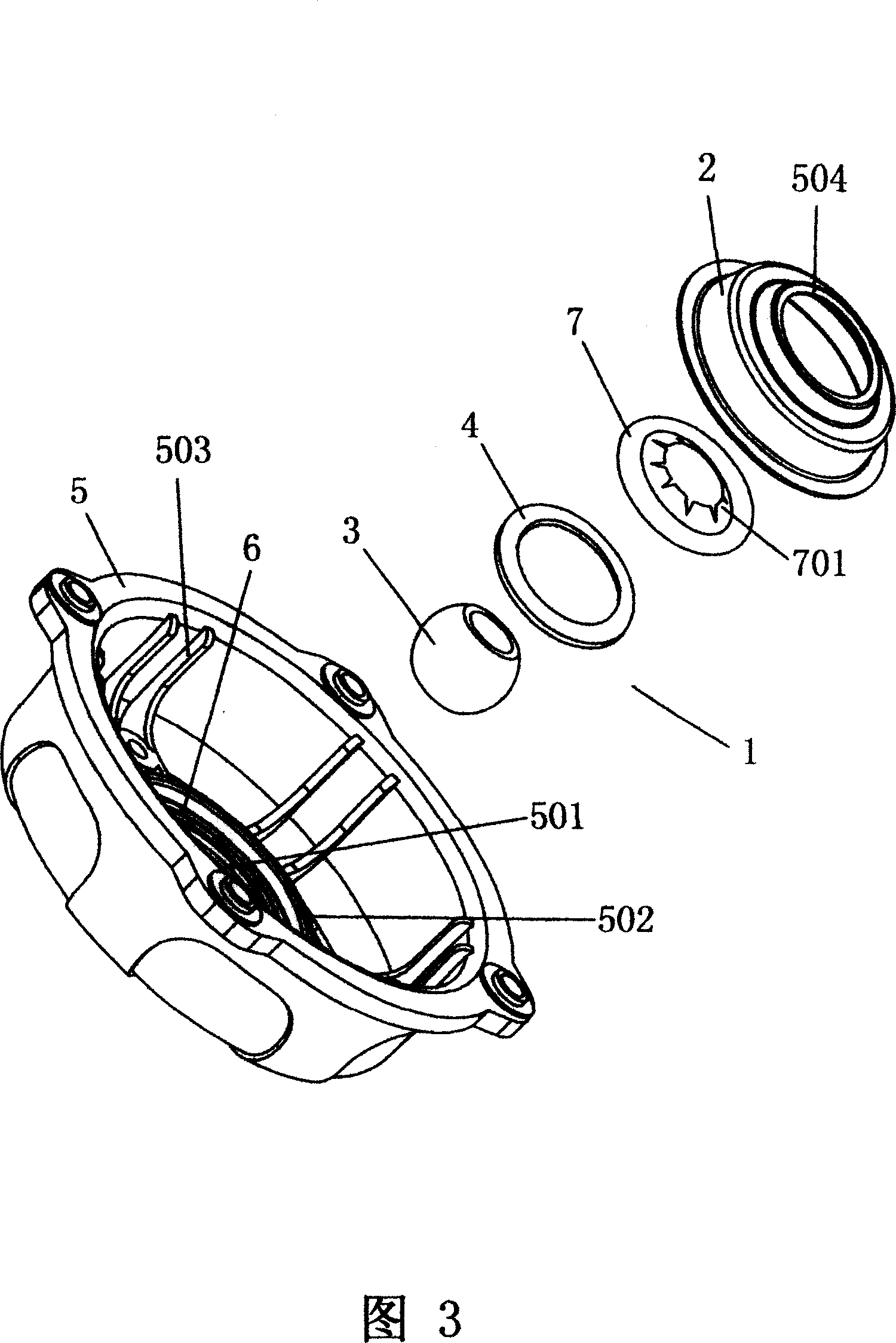

Method for mounting plastic electric machine casing and bearing device

InactiveCN1949632AHigh shaft positioning accuracyExcellent matching adjustment performanceManufacturing dynamo-electric machinesEngineeringInjection moulding

Owner:罗世明

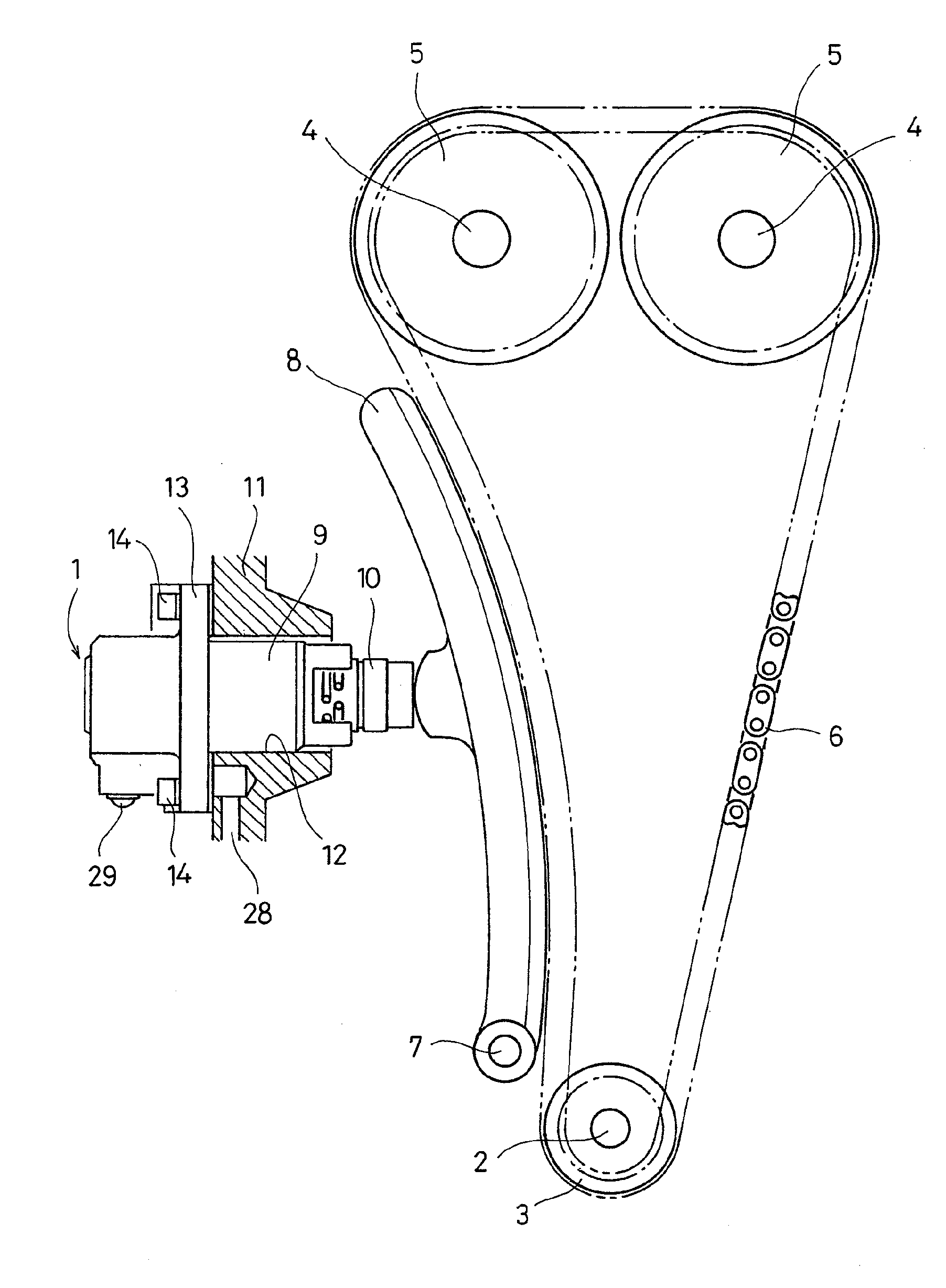

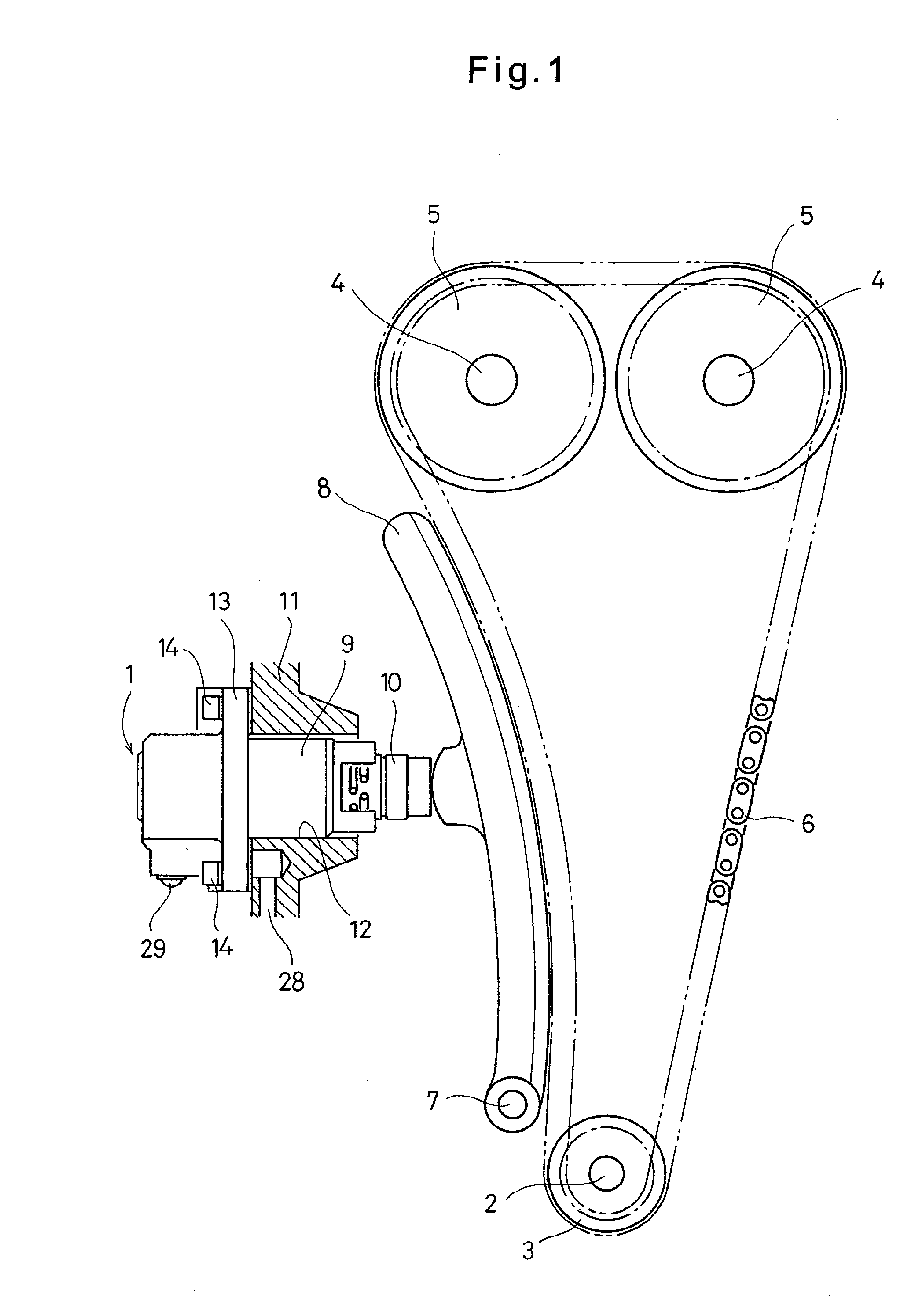

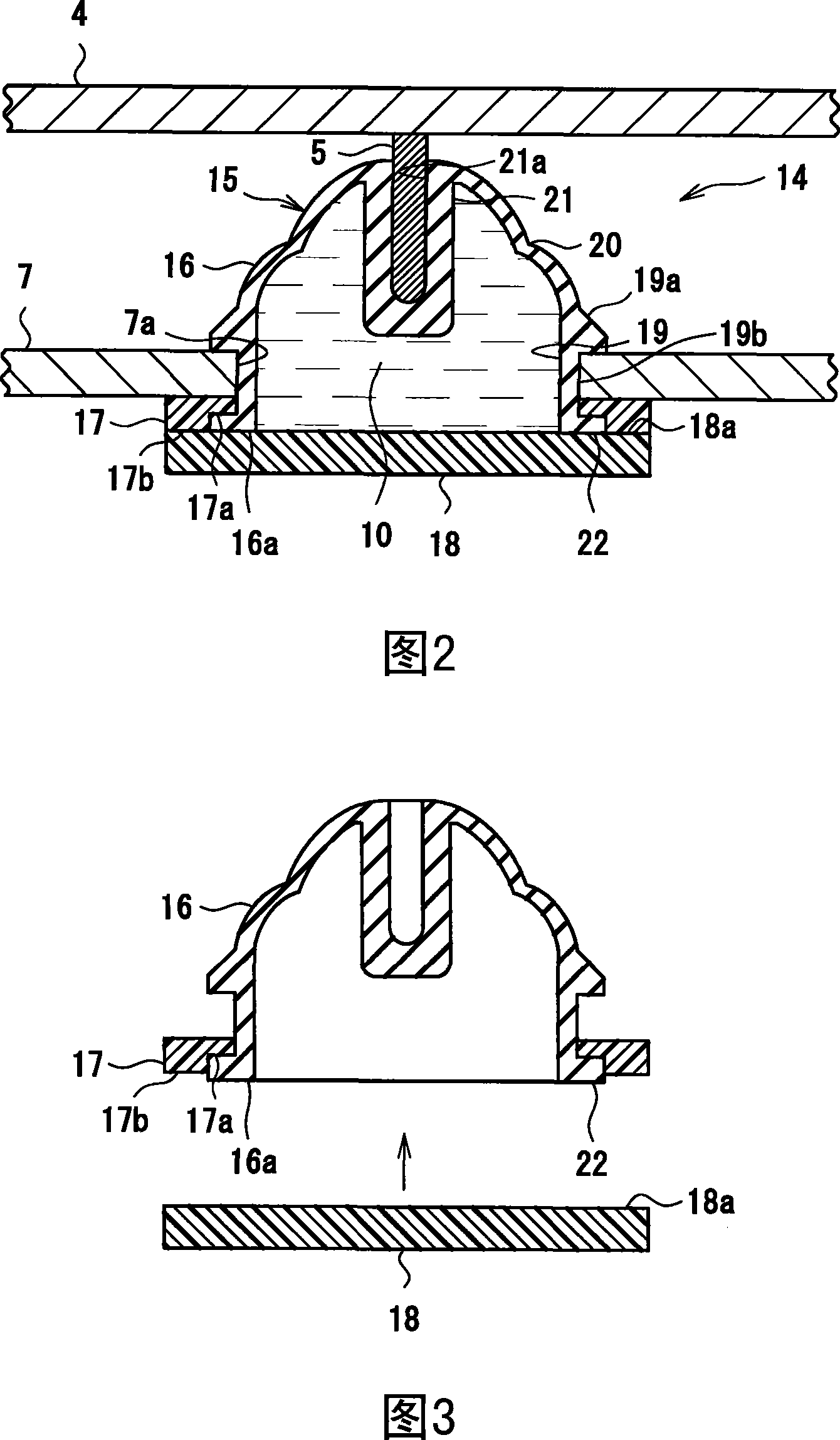

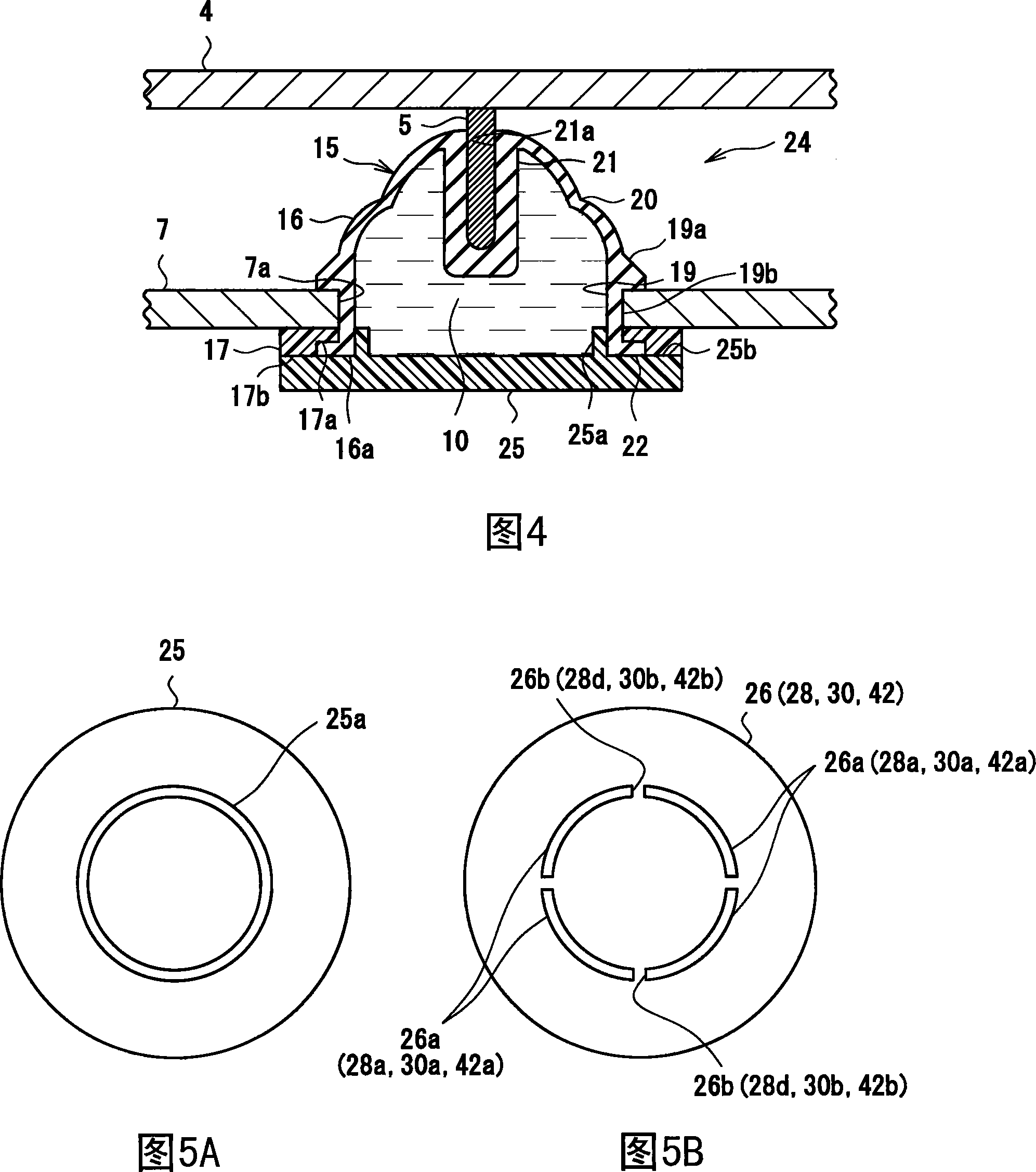

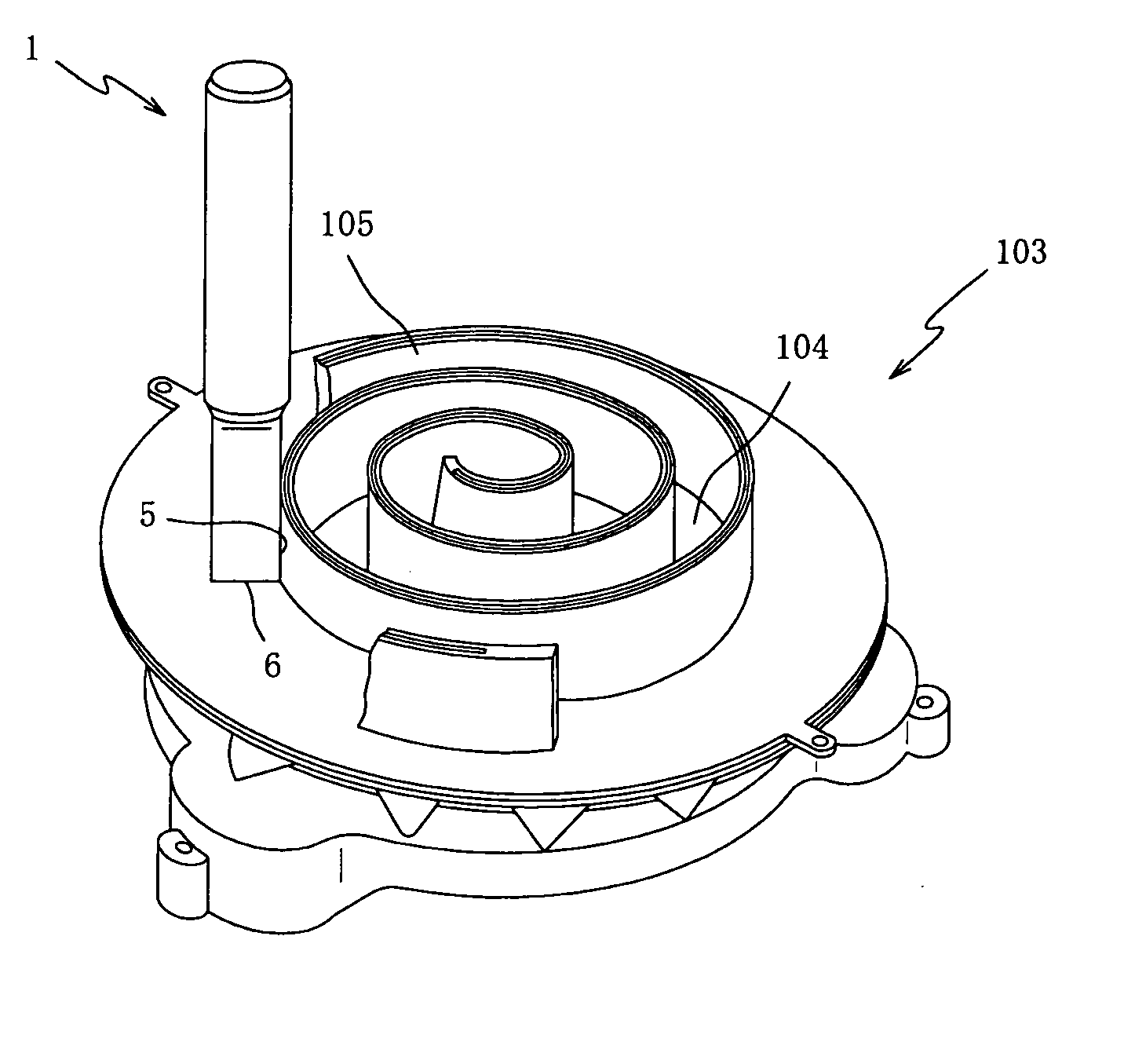

Chain tensioner

A chain tensioner includes a cylinder inserted in a tensioner mounting hole of an engine cover and having a flange fixed to the outer surface of the engine cover. A plunger is axially slidably mounted in the cylinder. The cylinder is formed with an oil supply passage through which hydraulic oil is introduced into a pressure chamber defined by the cylinder and the plunger. The oil supply passage includes a first hole portion extending inwardly from a mating surface of the flange facing the engine cover, and a second hole portion extending from the outer periphery of the flange to the pressure chamber and intersecting the first hole portion. An externally threaded portion of an externally threaded member is in threaded engagement with an internal thread formed on the second hole portion, thereby closing its outer open end. The externally threaded member is fixed in position with an adhesive applied to its externally threaded portion.

Owner:NTN CORP

Woven tubing for stent type blood vascular prosthesis and stent type blood vascular prosthesis using the tubing

InactiveUS7000649B2Improve liquid tightnessReduce blood leakageStentsMulti-ply fabricsVascular prosthesisLesion

A woven tubing for use in a stent type blood vascular prosthesis, using a monofilament having a flattening in the range of 1.2-5.0 and a size in the range of 11-250 dtex in at least part of the warp and a stent type blood vascular prosthesis using the tubing are disclosed. The prosthesis combines a shape retaining property that is capable of maintaining its tubular shape without being crushed by the flow of blood with a high liquid tightness that is capable of reducing the leakage of blood to the exterior and allows prevention of the inflow of blood into the lesion.

Owner:TERUMO KK

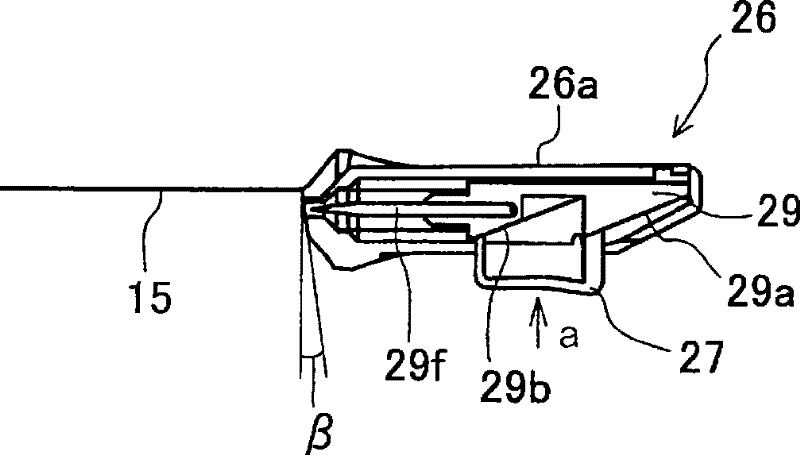

Liquid applicator

ActiveUS20110129288A1Simple structureRobust fixtureLiquid surface applicatorsPackaging toiletriesEngineering

The present invention is a liquid applicator which, in its assembled state an applying part, joint, and front barrel are fixed to a barrel body front end portion, the step of an indented / projected engaging portion on the inner peripheral side of the applying part rear end portion is abutted from behind against and engaged with the step of an indented / projected engaging portion on the outer peripheral side of the forward part of the joint. At the same time, an indented / projected engaging portion on the outer peripheral side of the applying part rear end portion is abutted against and engaged with an indented / projected engaging portion on the inner peripheral side of the front barrel's forward part, and an indented / projected engaging portion on the inner peripheral side of the front barrel rearward part is engaged with an indented / projected engaging portion on the outer peripheral side in the rearward part of joint, whereby applying part, joint and front barrel are formed so as to fix the applying part to barrel body by means of the joint and the front barrel.

Owner:MITSUBISHI PENCIL CO LTD

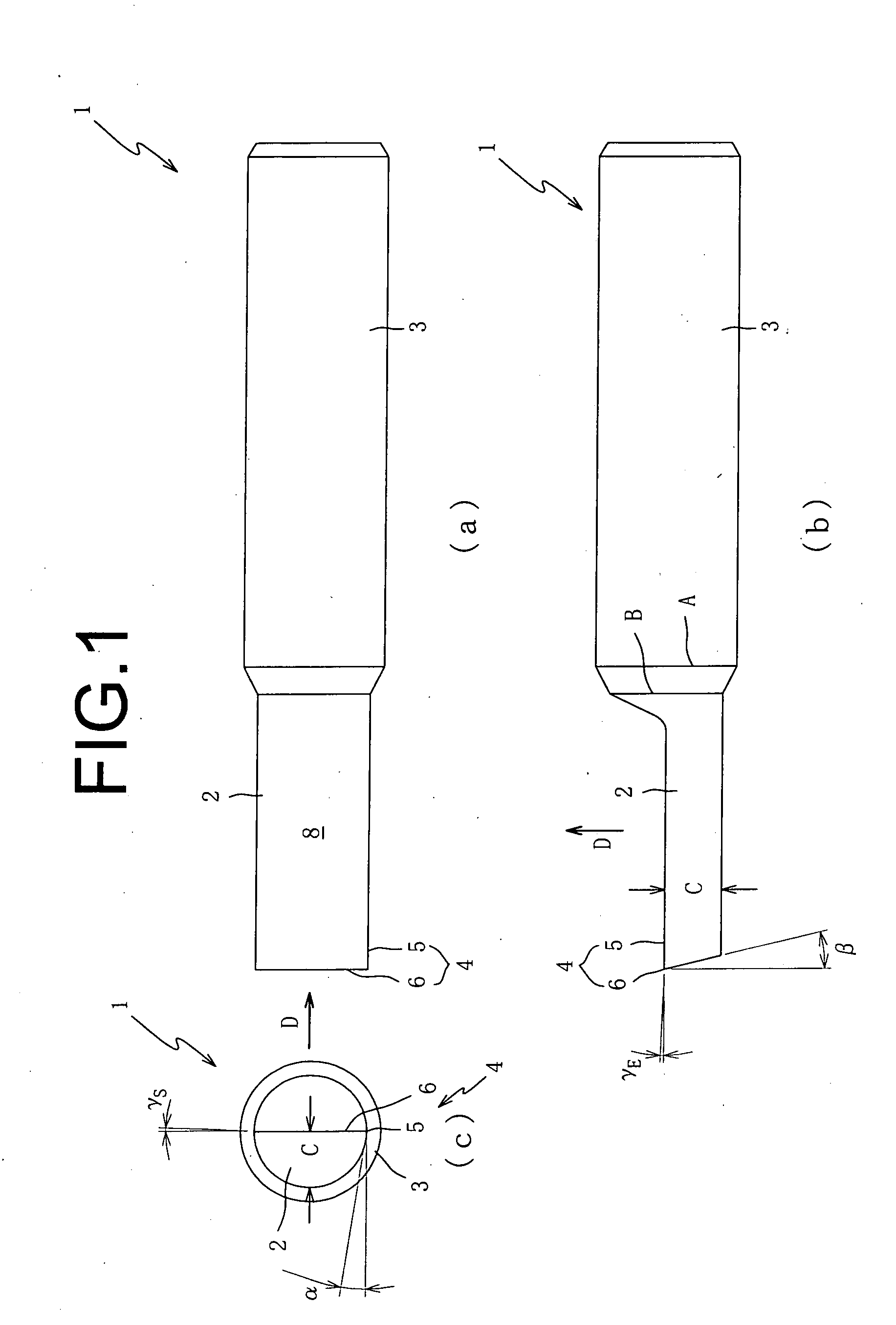

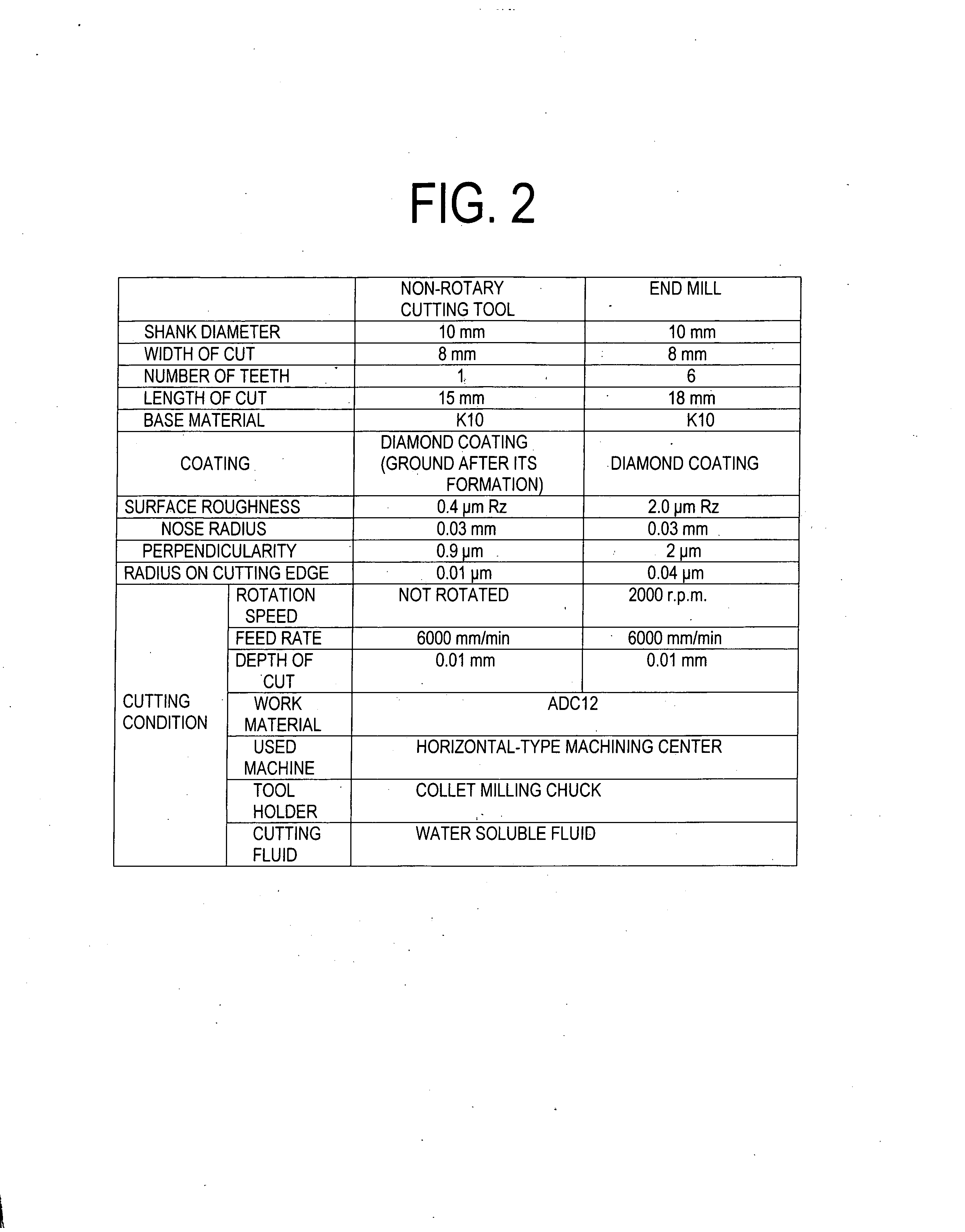

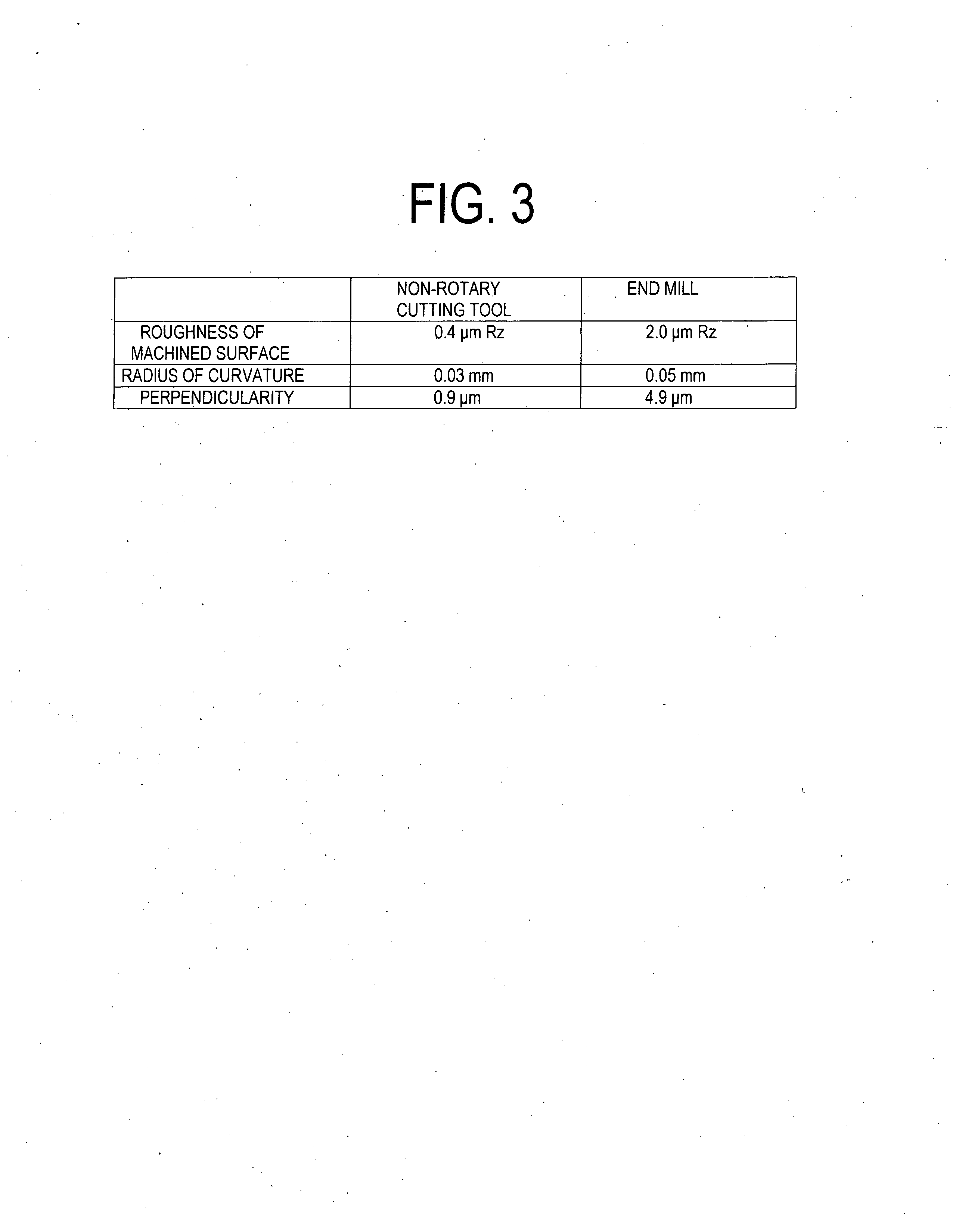

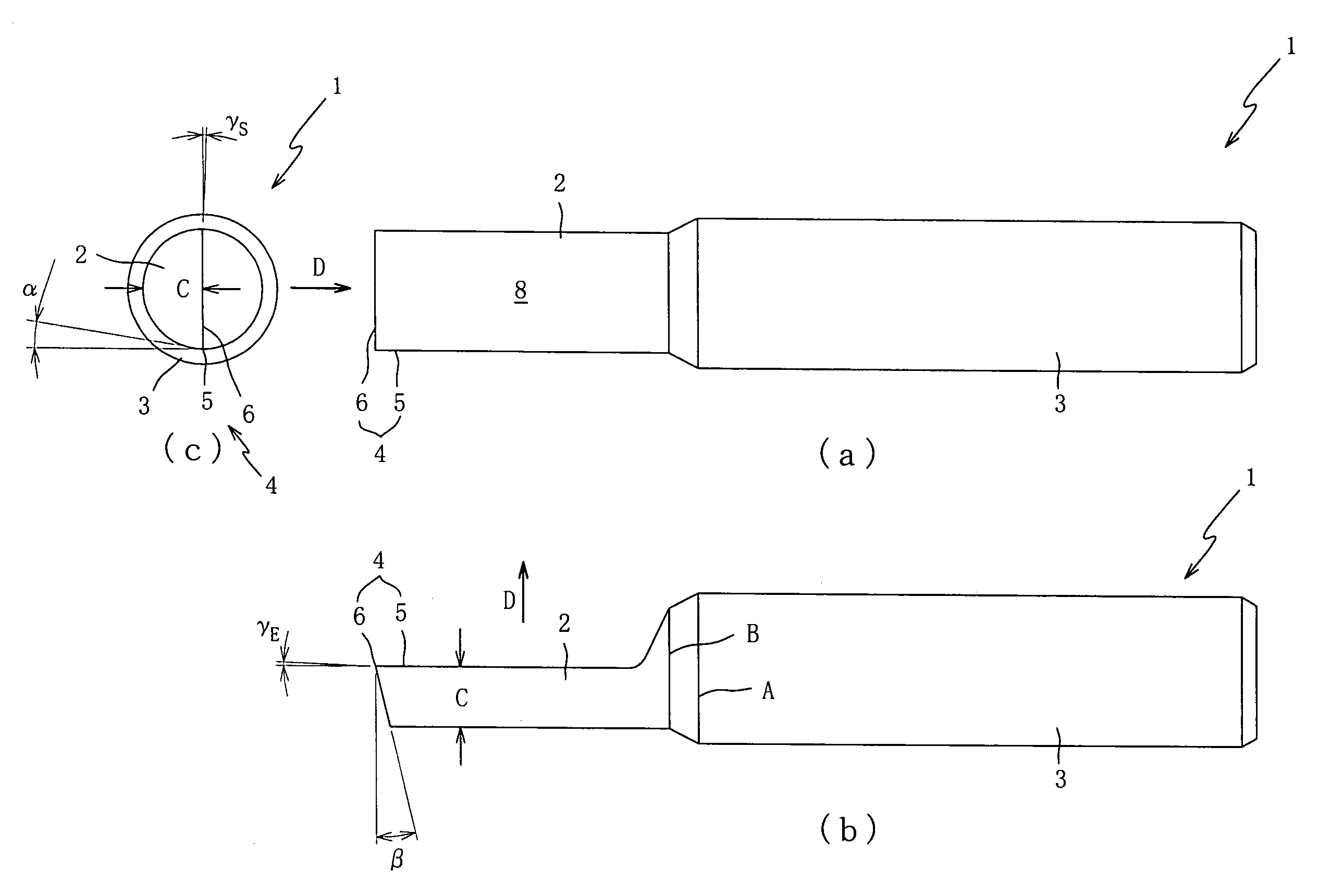

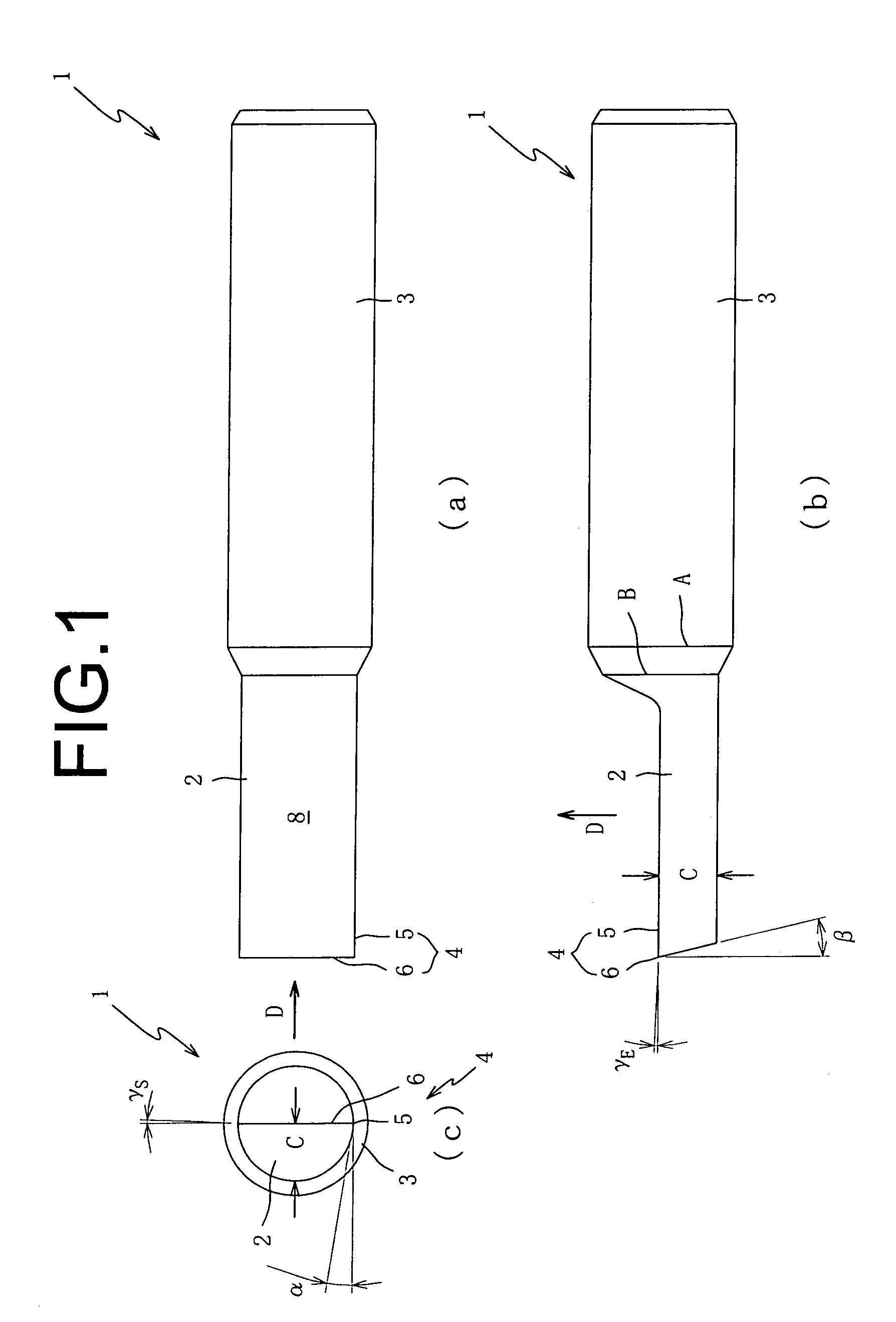

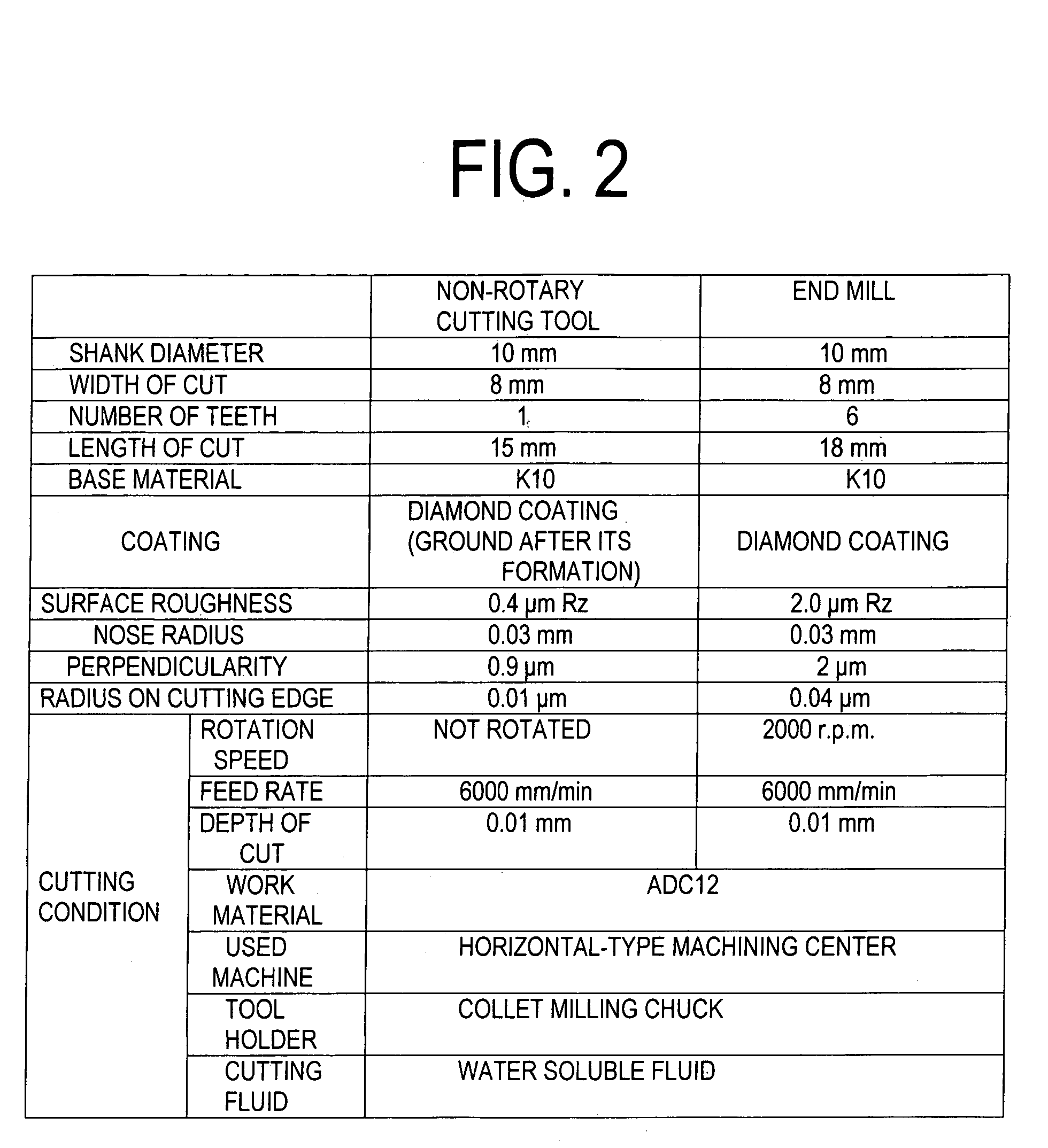

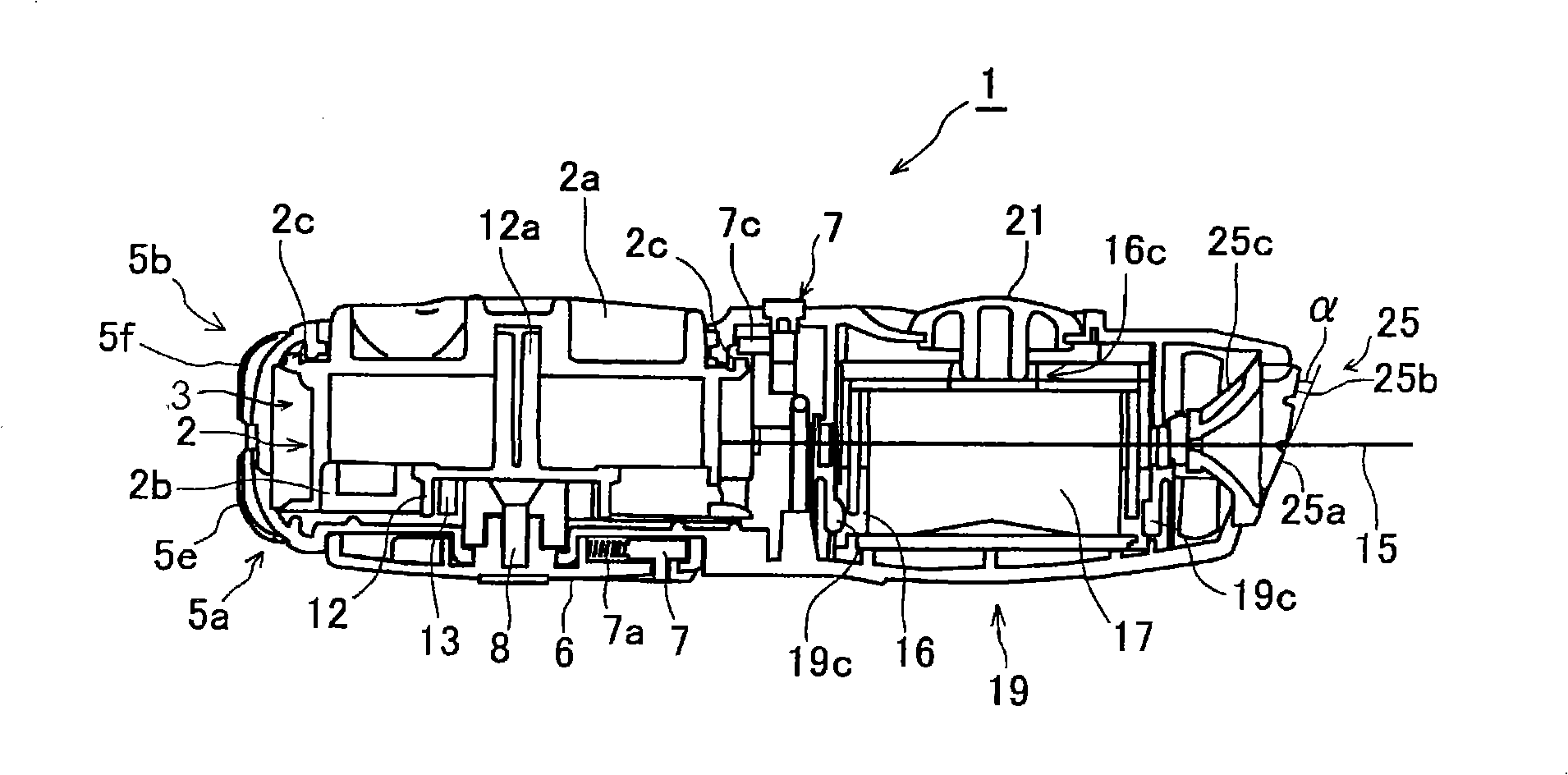

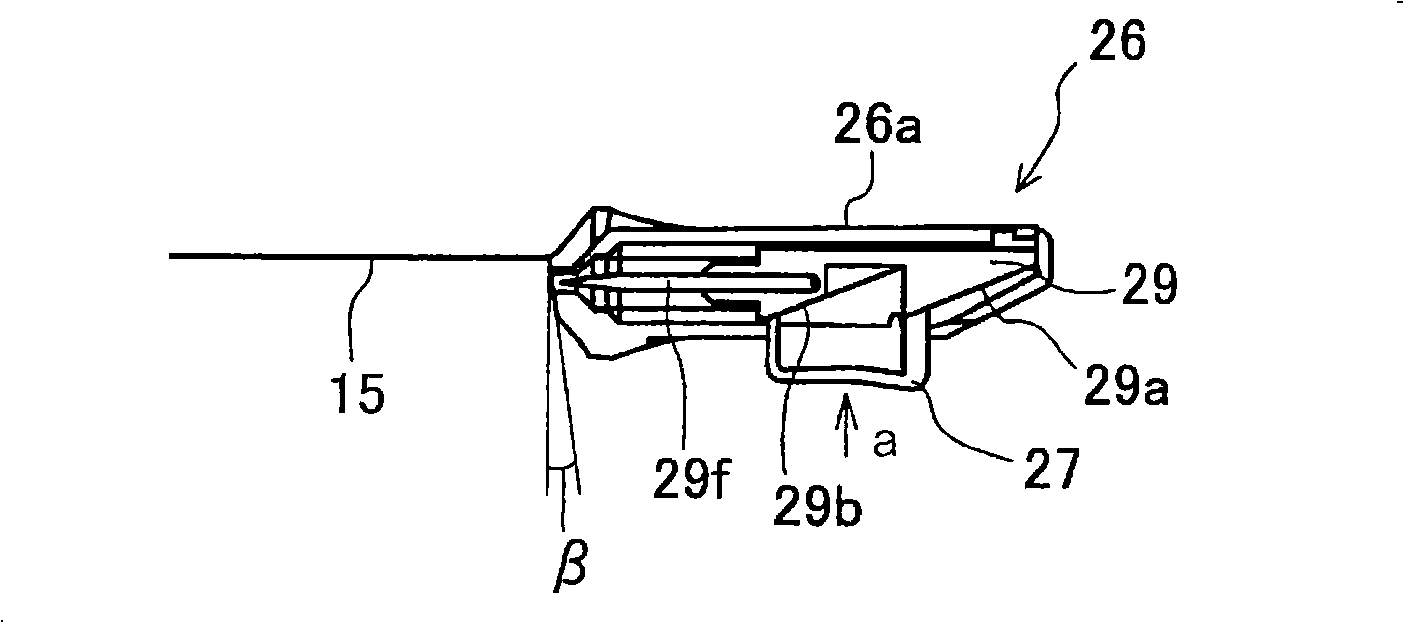

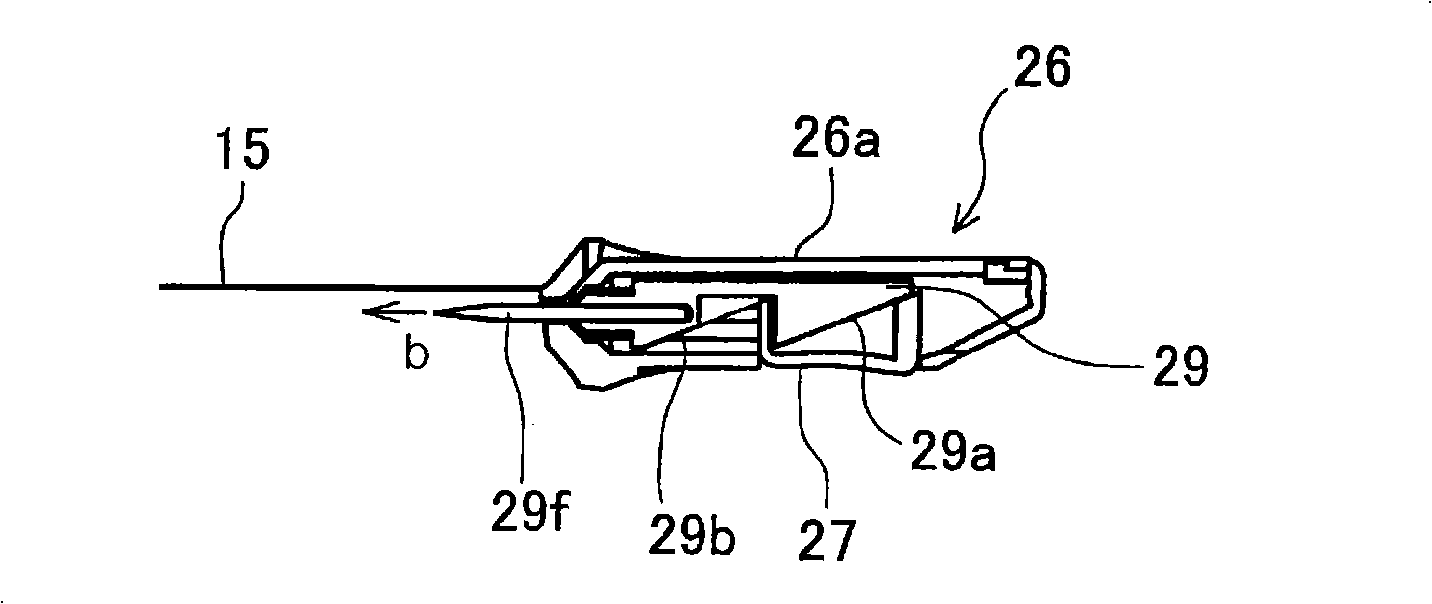

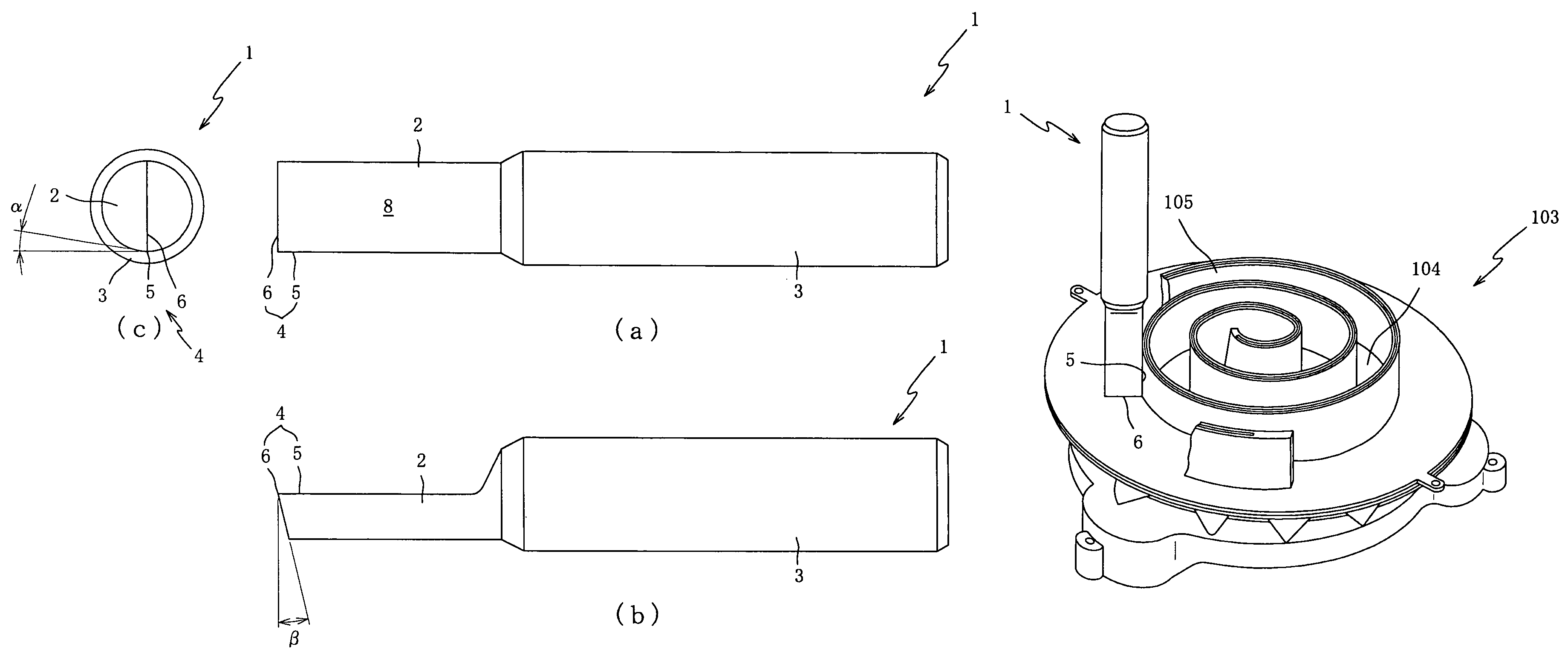

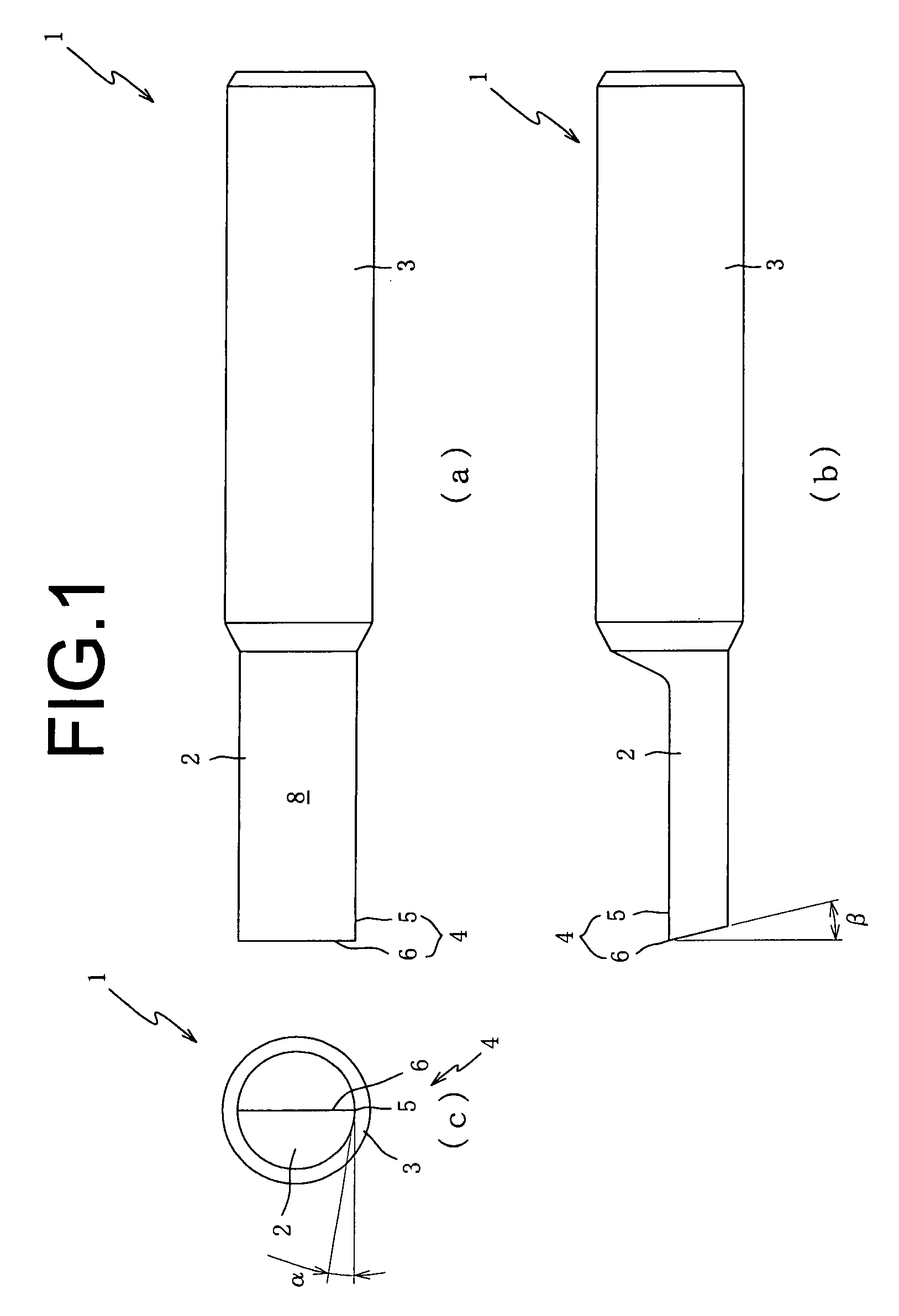

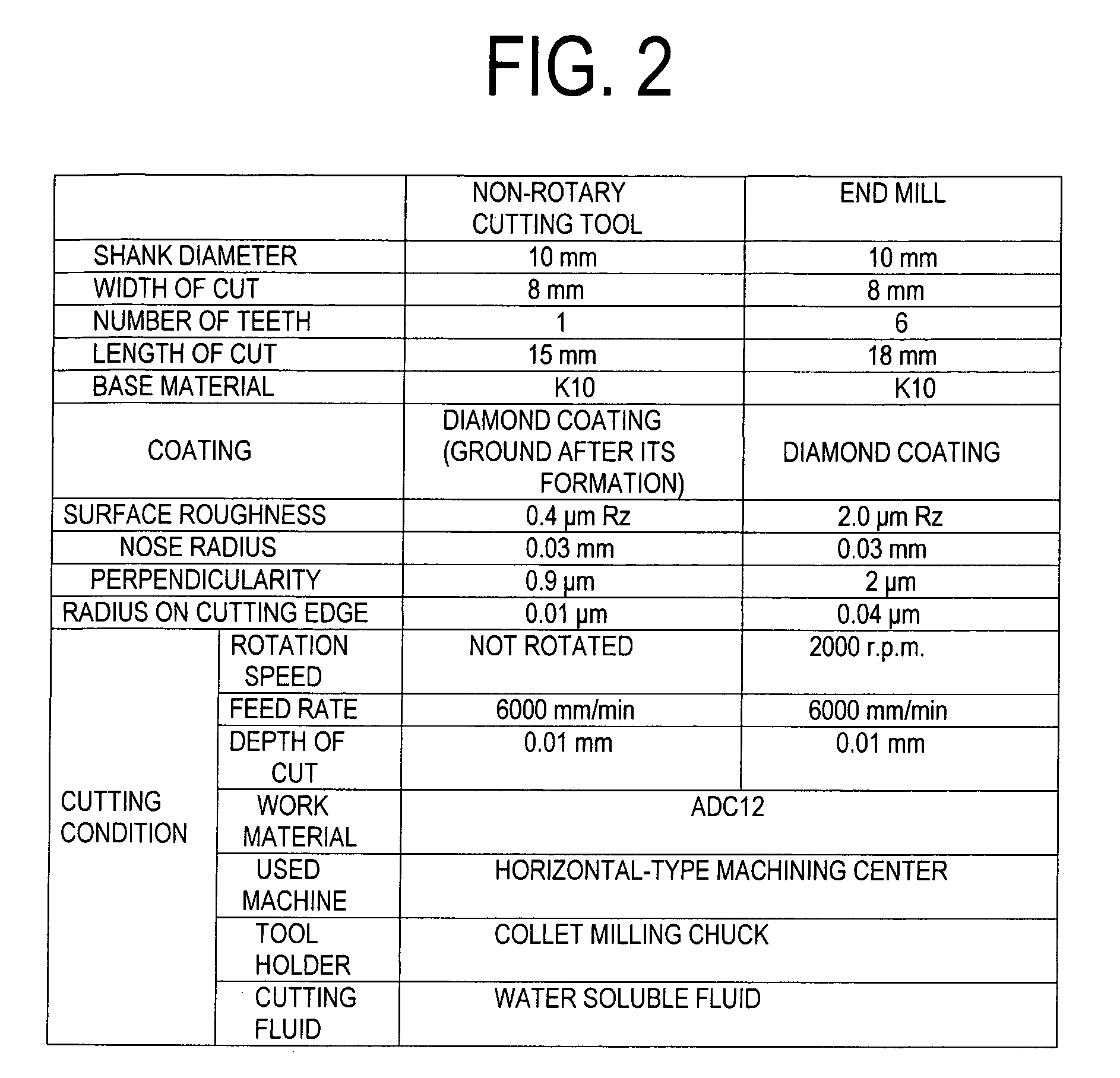

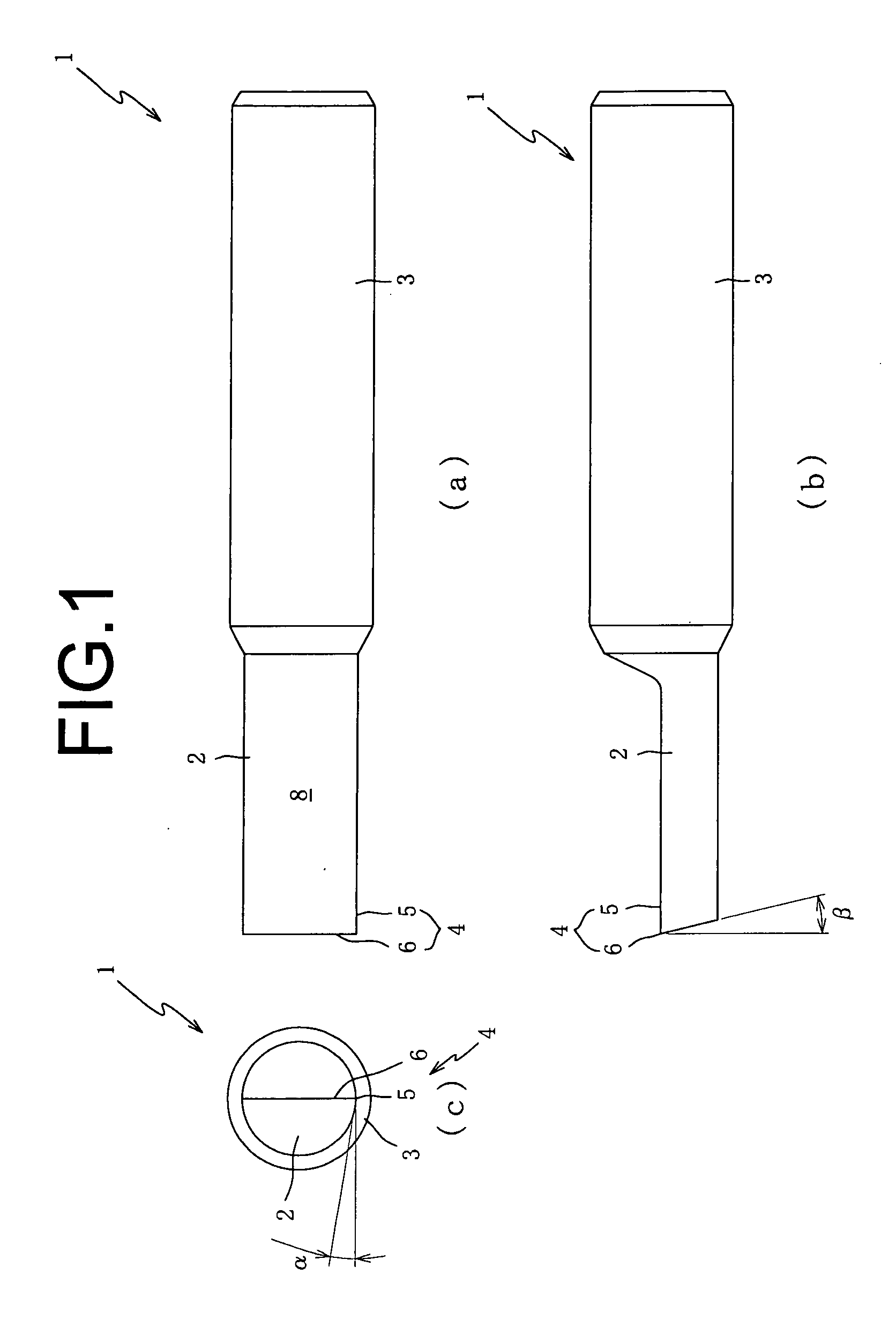

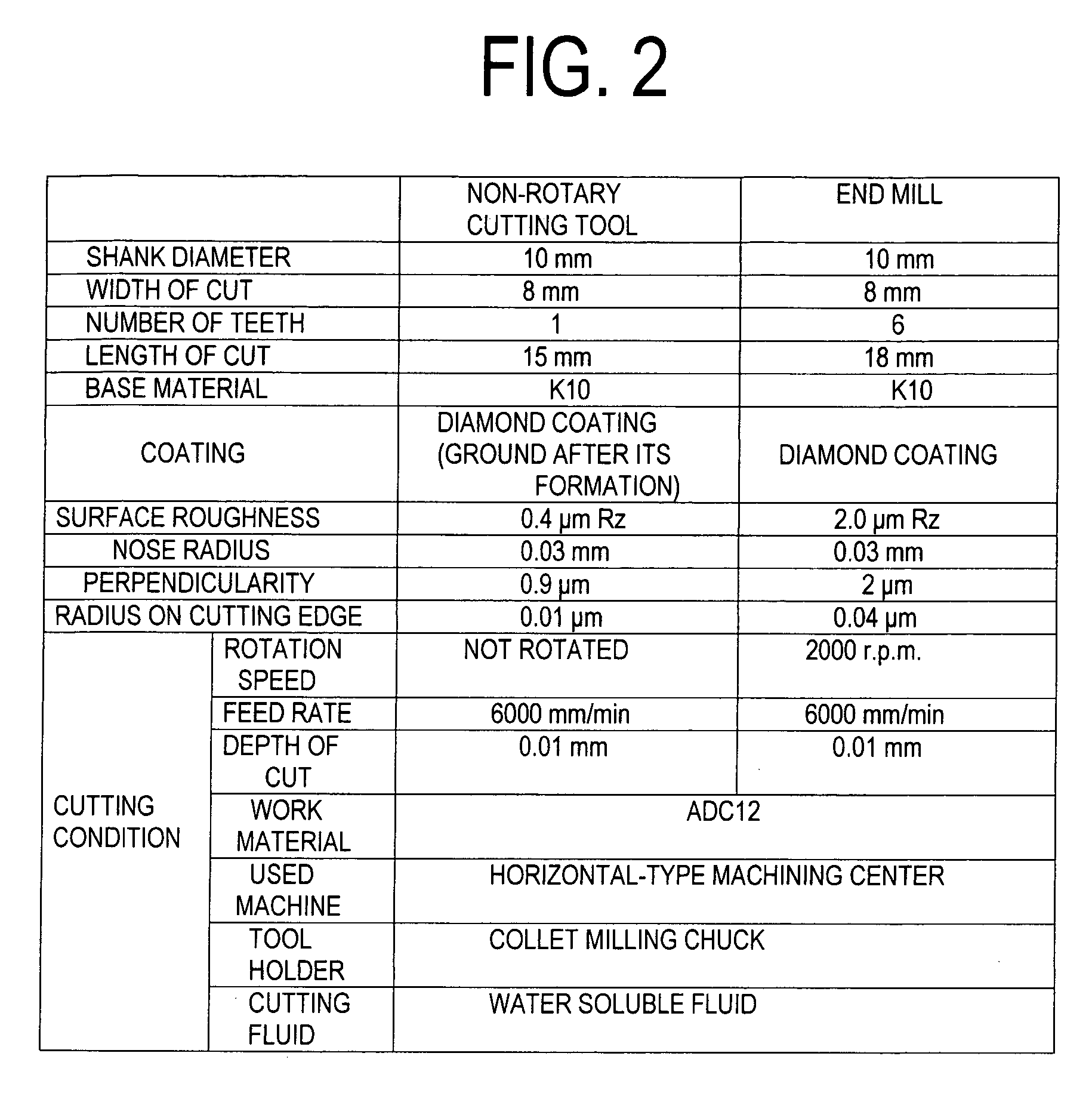

Non-rotary cutting tool and process of machining scroll member by using the same

ActiveUS20060133904A1High degree of accuracyCut errorAttachable planing devicesCutting insertsEngineeringMechanical engineering

A non-rotary cutting tool which is to be moved relative to a workpiece in a predetermined direction for cutting the workpiece, with its rake face being held substantially perpendicular to the predetermined direction. The cutting tool includes (a) a generally cylindrical shank portion, and (b) a generally semi-cylindrical body portion which has an outer circumferential surface constituted by the rake face and a semi-cylindrical surface. The semi-cylindrical body portion has a cutting edge which is defined by an edge of the rake face and which is covered with a diamond coating. Also disclosed is a process of machining a scroll member of a scroll compressor by using this non-rotary cutting tool.

Owner:PANASONIC CORP +1

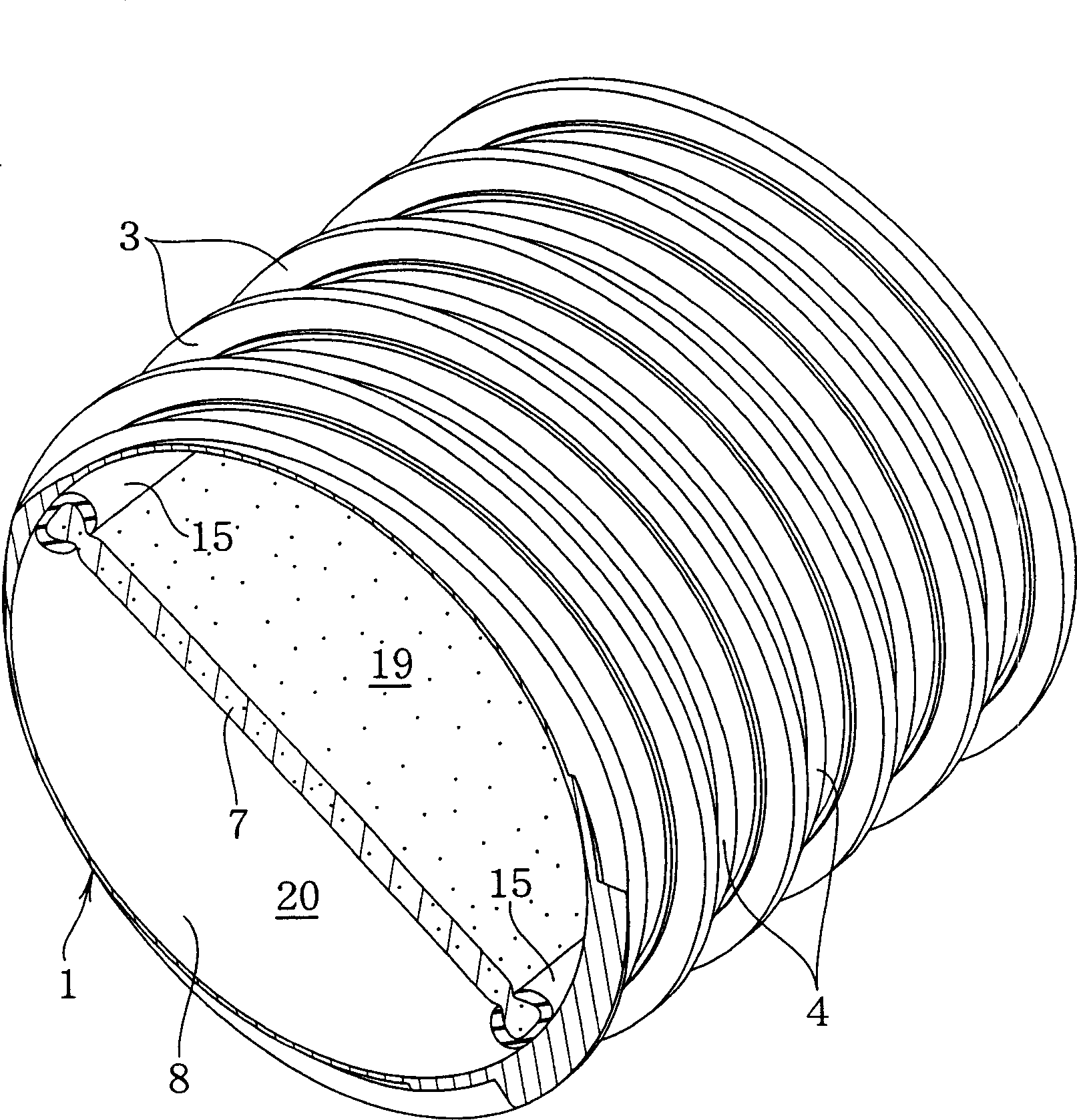

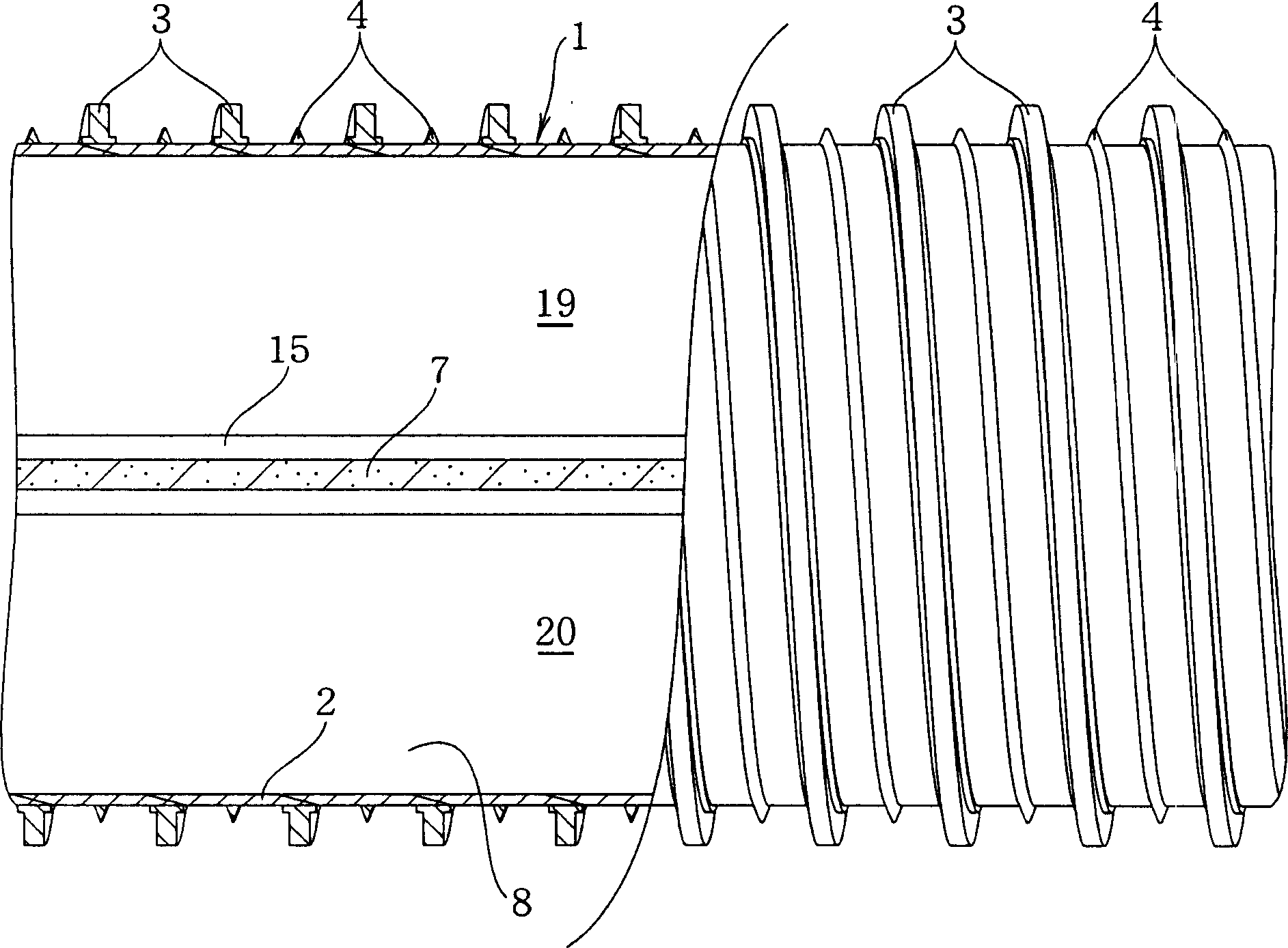

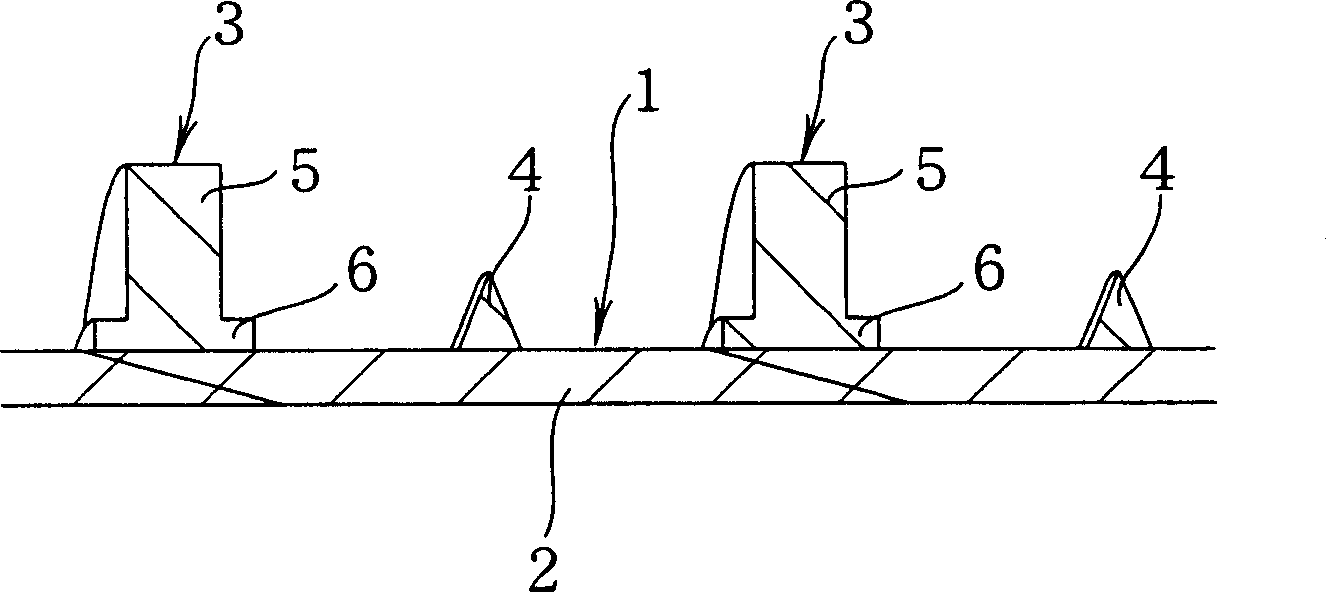

Flexible bimetallic tube

InactiveCN1796859AImprove air tightnessGood liquid tightnessFlexible pipesEngineeringUltimate tensile strength

To provide a flexible double-layer tube excellent in flexibility though its structure is simple, high in joining strength between a tube body inner wall surface and a partition plate, and excellent in the airtightness and liquidtightness of both flow passages. In this double-layer tube, the double flow passages 19 and 20 are formed by partitioning the inside of a tube body 1 by the partition plate 7 by joining both end parts of the soft resin partition plate 7 along the longitudinal direction of the tube to the smooth inner wall surface 8 of the soft resin tube body 1 peripherally reinforced by reinforcement materials 3 and 4 with a hot-melt adhesive agent 15.

Owner:TOTAKU IND INC

Viscous fluid-sealed damper

InactiveCN101145382APrecise positioningIncrease fit areaRotating vibration suppressionSpringsAdhesiveEngineering

Provided is a viscous fluid-sealed damper which helps to achieve an increase in degree of freedom in terms of the selection of the material of a sealing container, which can be produced with high production efficiency, and which helps to avoid leakage of the viscous fluid. A lid member (18) is fixed to a container main body (16) while compressing and holding a flange portion (22) between a sealing member (17) and the lid member (18), so an opening end (16a) of the container main body (16) can be sealed with the lid member (18) without having to effect fixation through fusion-bonding as in the prior art, and the degree of freedom in terms of material selection can be increased. Further, if the container main body (16) is formed of a butyl rubber, the container main body (16) can be fixed to the lid member (18) without using any adhesive, so it is possible to achieve a reduction in production time and in cost. Further, it is possible to avoid leakage of the viscous fluid (10) due to defective adhesion.

Owner:SEKISUI POLYMATECH CO LTD

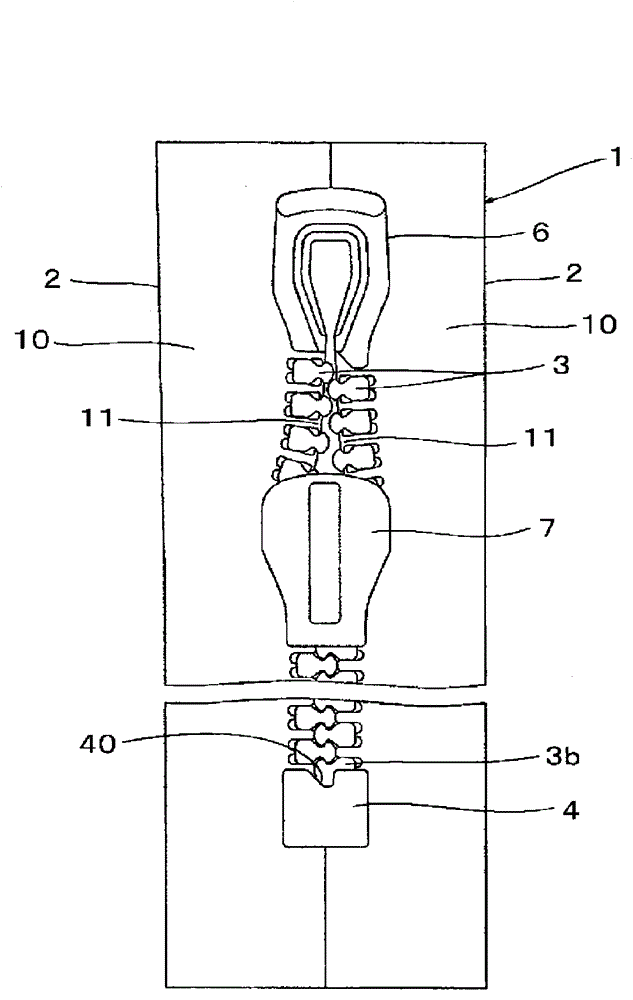

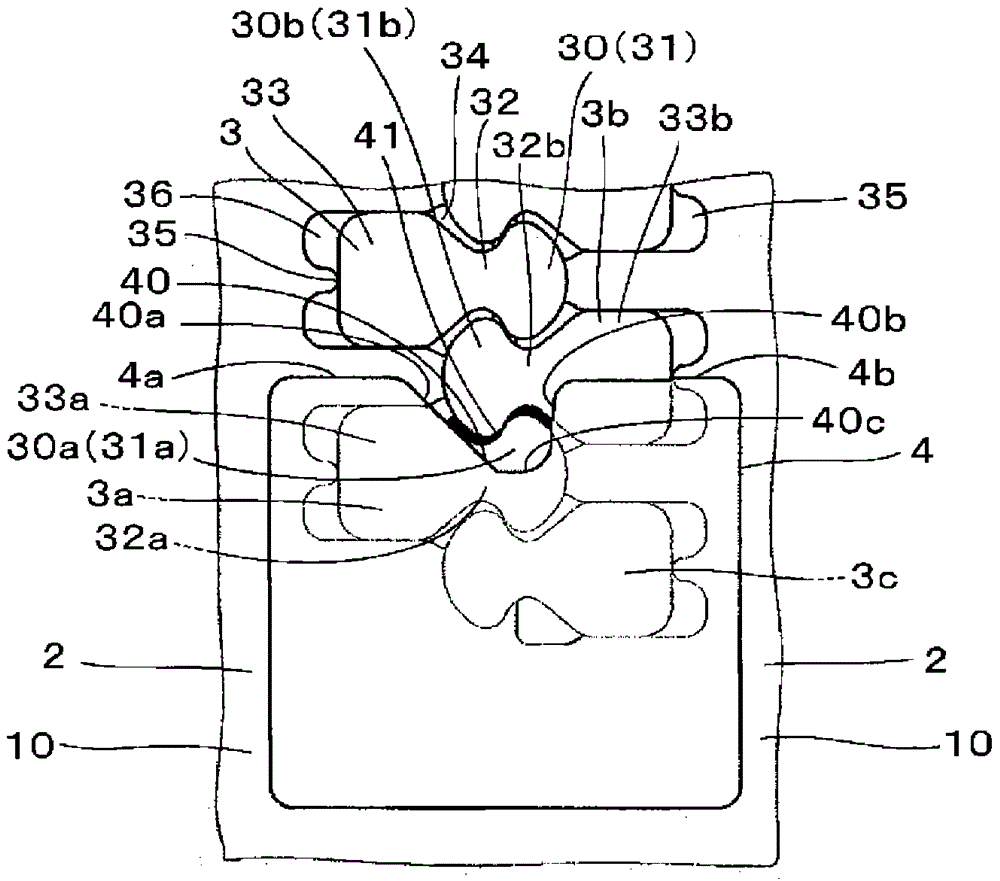

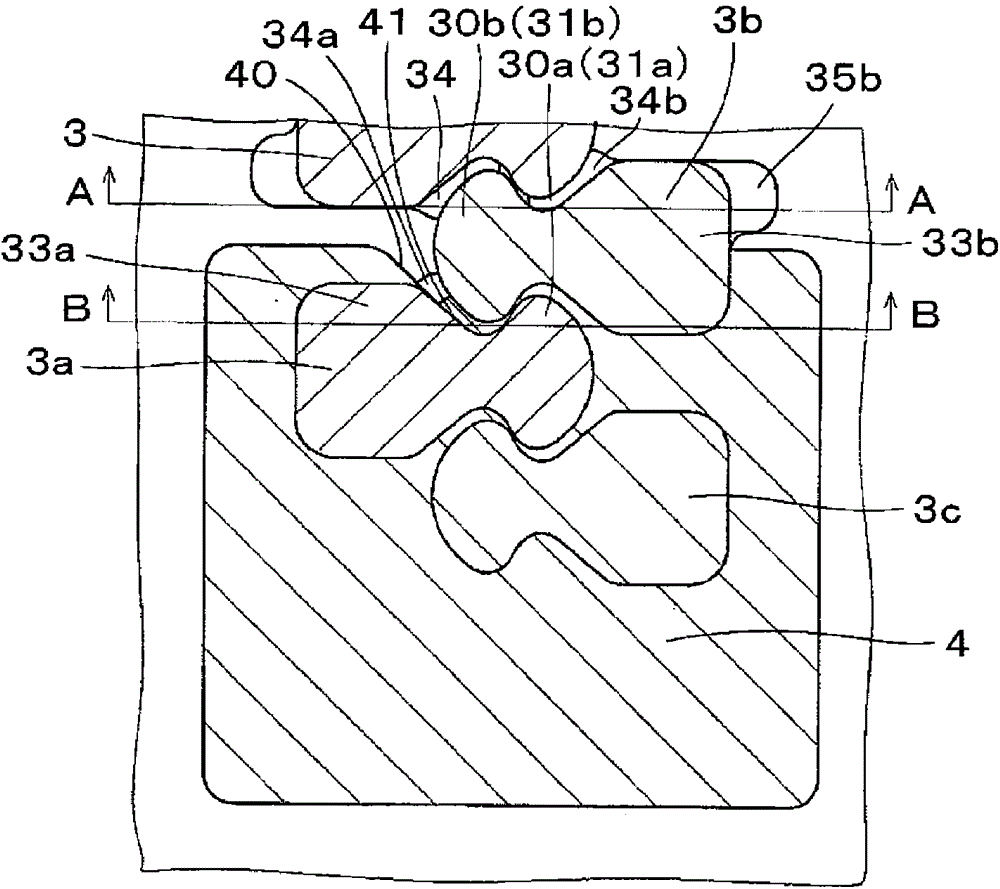

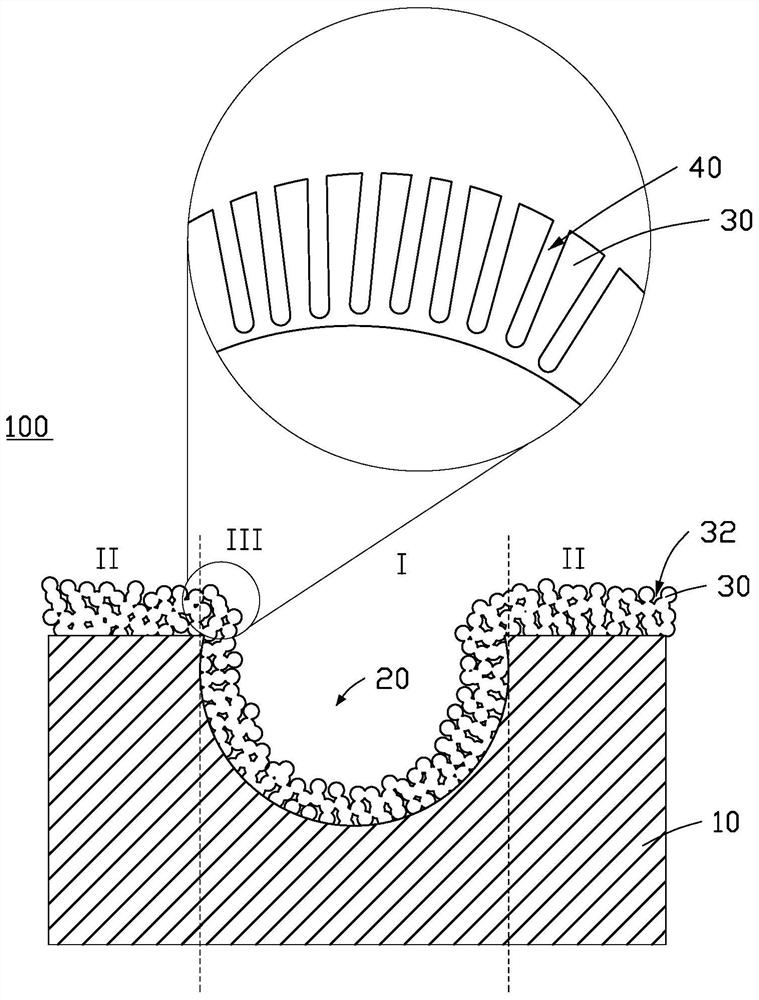

Slide fastener

Provided is a slide fastener whereby waterproof properties near a bottom stop can be enhanced in cost-effective manner. A slide fastener (1) having a waterproof structure comprises a left-right pair of fastener stringers (2) each having a plurality of fastener elements (3) arranged in a row along an opposing edge (11) of each of a left-right pair of waterproof fastener tapes (10), a slider (7) for engaging and disengaging the left and right fastener elements (3) with each other, and a bottom stop (4) formed at the bottom end of the rows of fastener elements (3) so as to straddle the left and right fastener tapes (10). Each fastener element (3) includes an engaging head part (30), a base part (33), a neck part (32), and a shoulder part (34), and the bottom stop (4) covers a first fastener element (3a) near the lowermost end except for an upper portion of an engaging head part (30a) of the first fastener element, and covers a lower portion of a base part (33b) of a second fastener element (3b) that is above and adjacent to the first fastener element (3a). In the bottom stop (4), a recess (40) is provided that is downwardly indented at the top of the bottom stop. The upper portion of the engaging head part (30a) of the first fastener element (3a), and the lower portions of the neck part (32b) and the engaging head part (30b) of the second fastener element (3b) are disposed in the recess (40). A linking part (41) between the first and second fastener elements (3a, 3b) may be provided in the recess (40).

Owner:YKK CORP

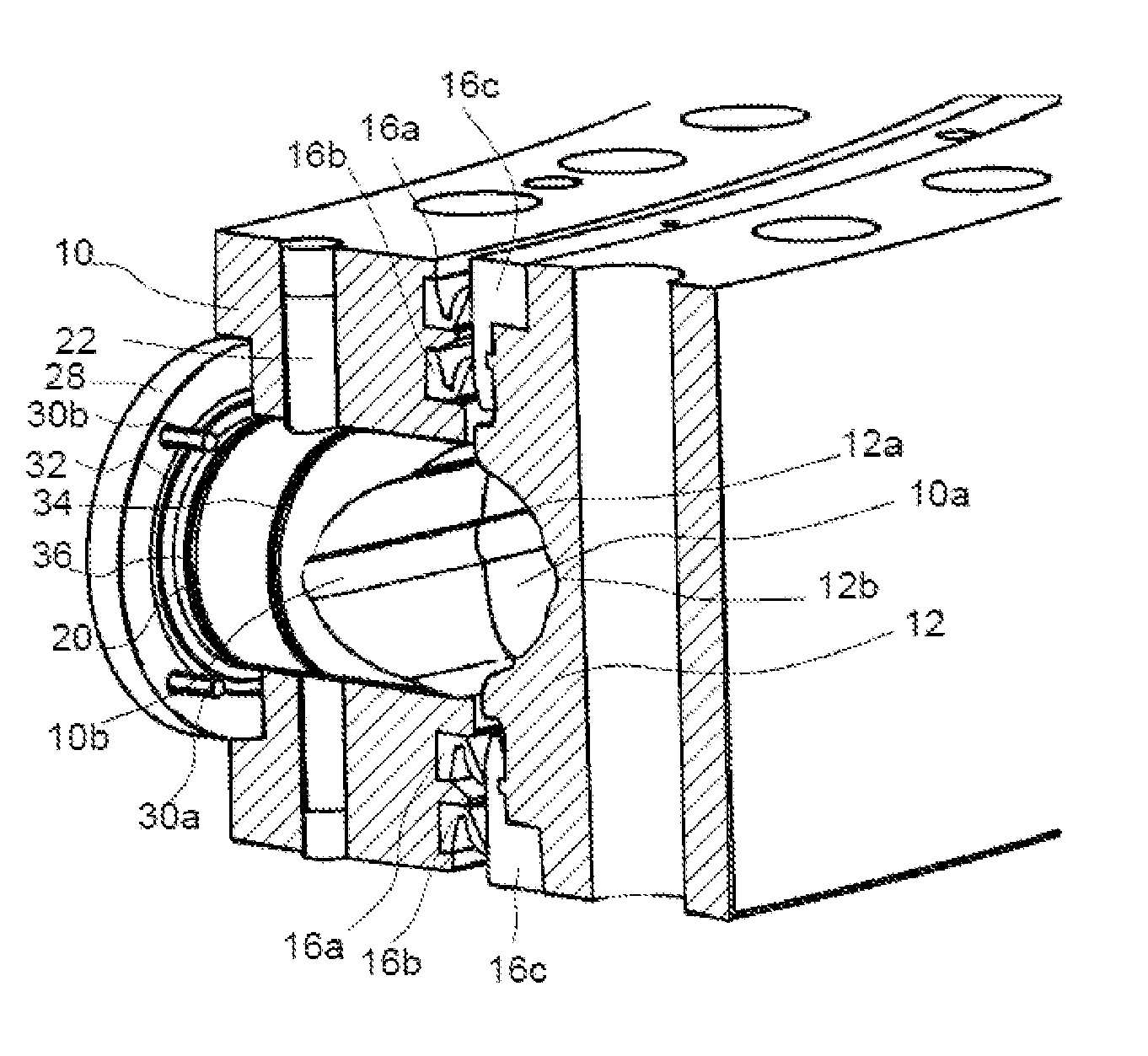

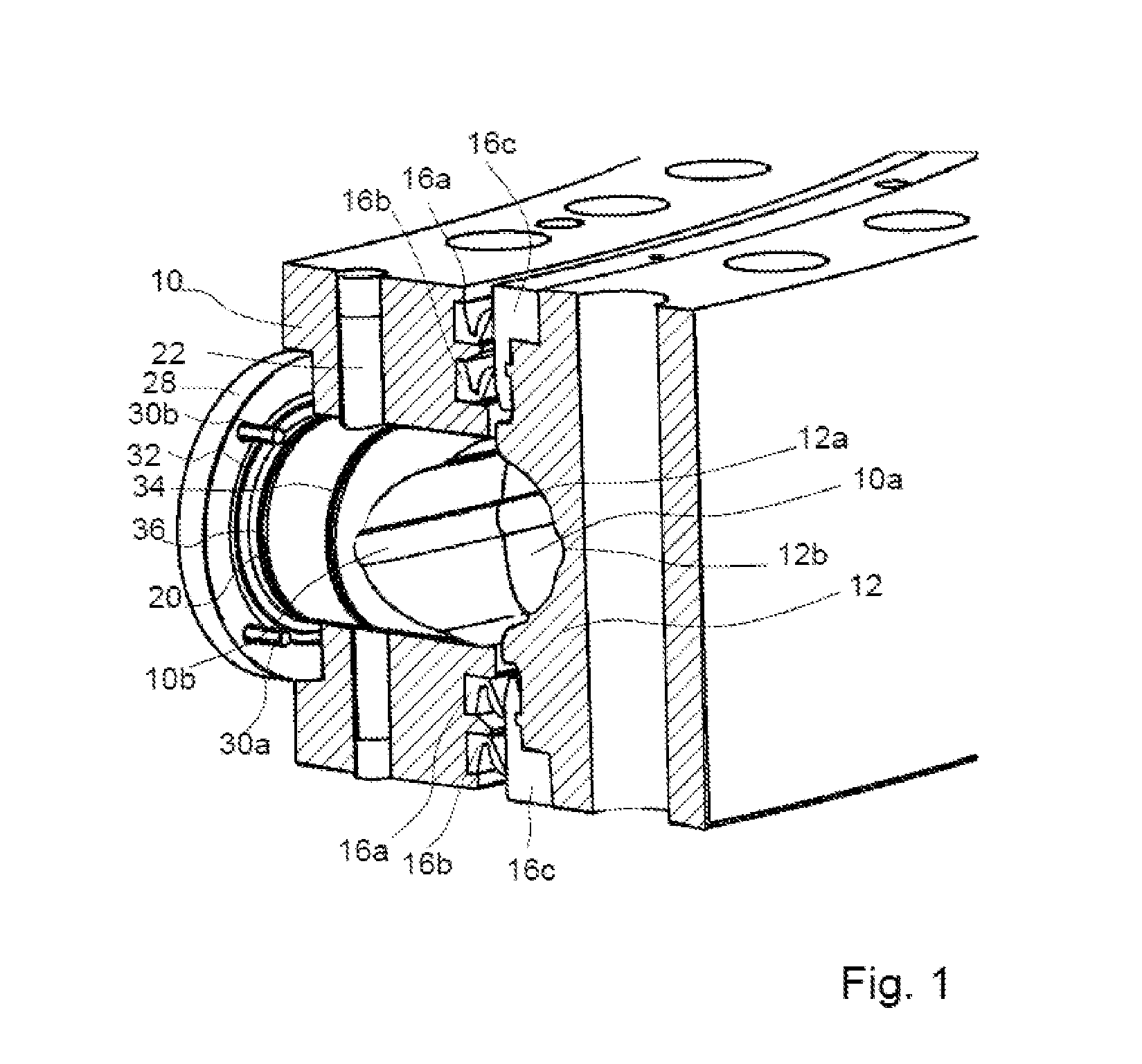

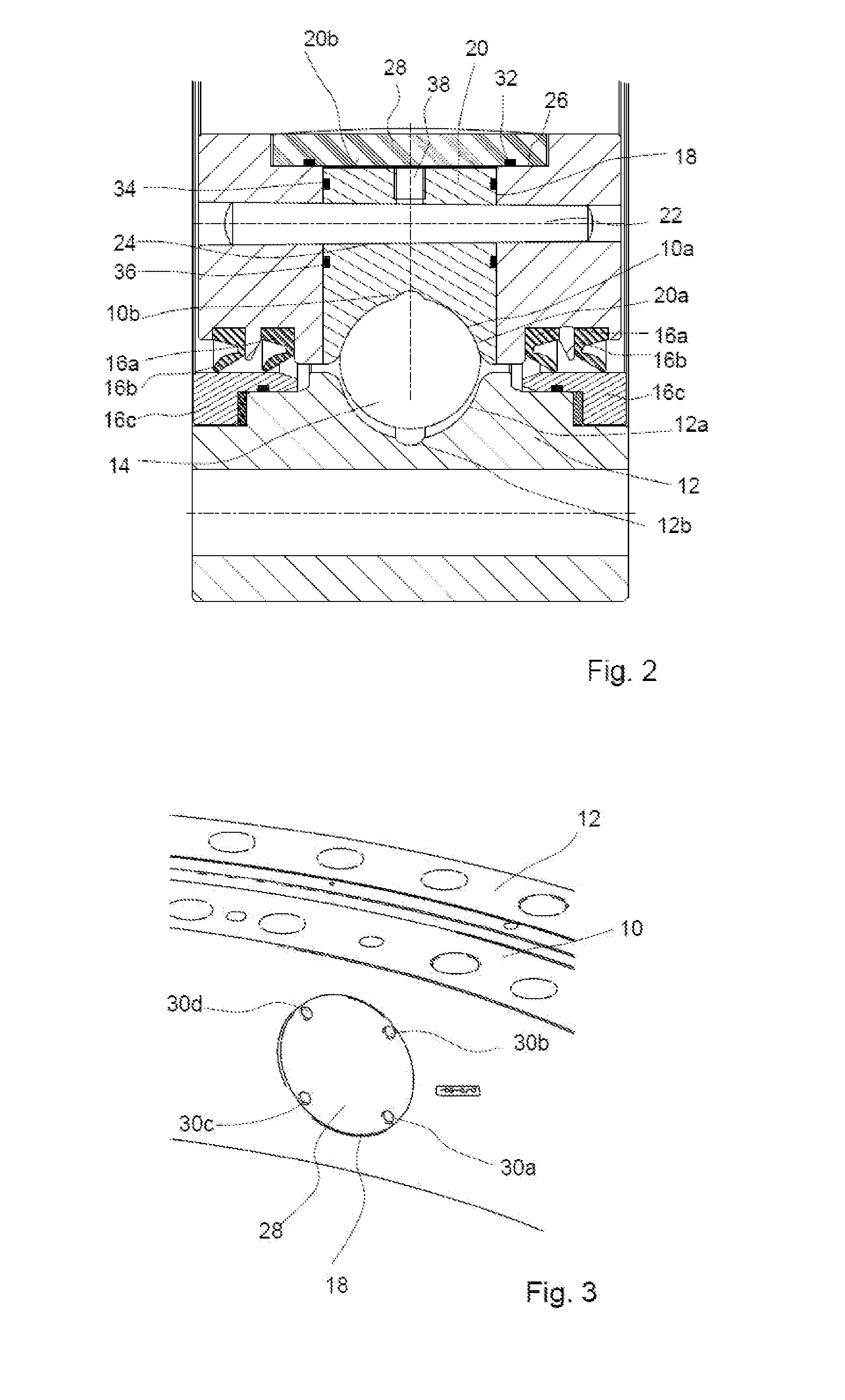

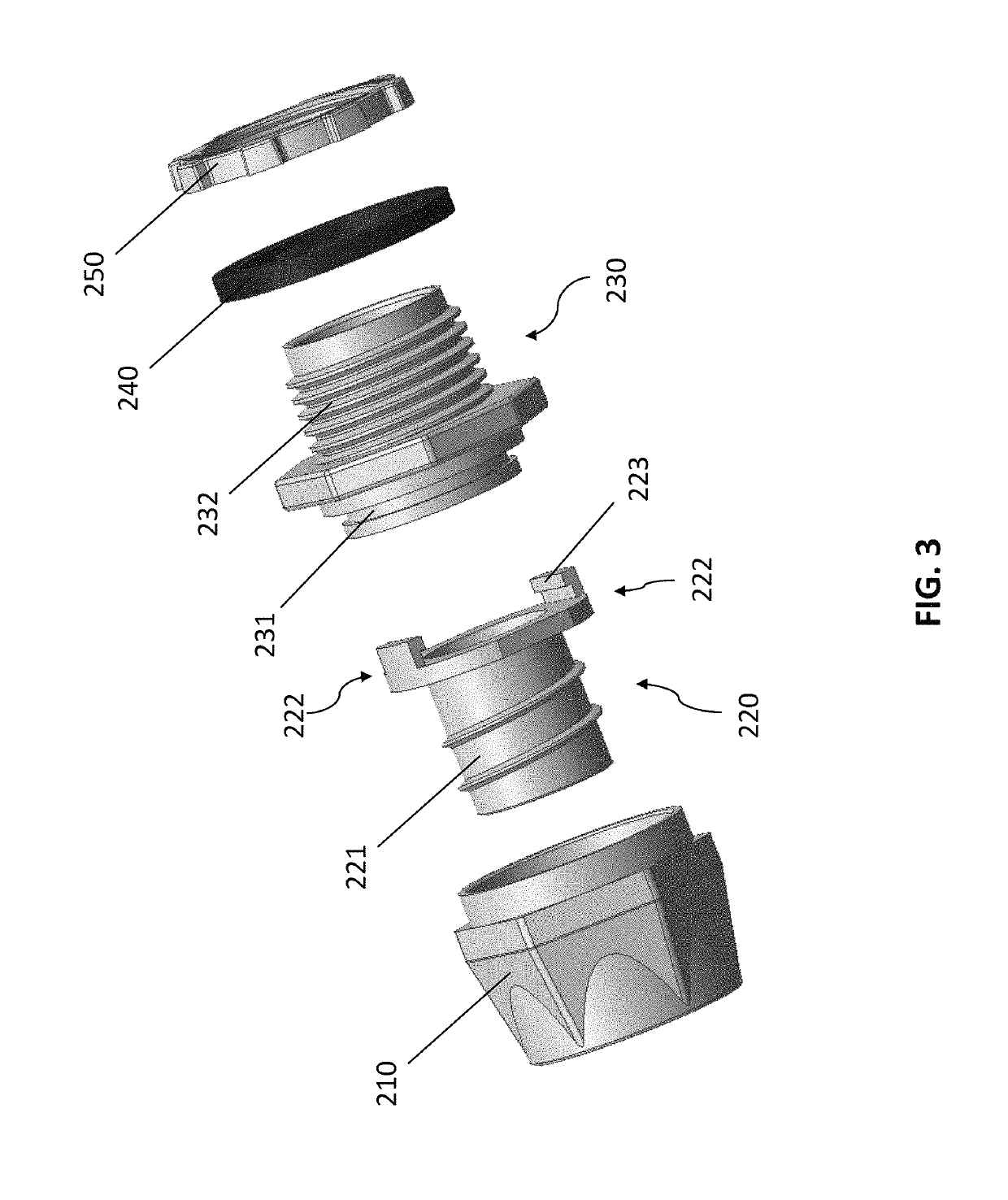

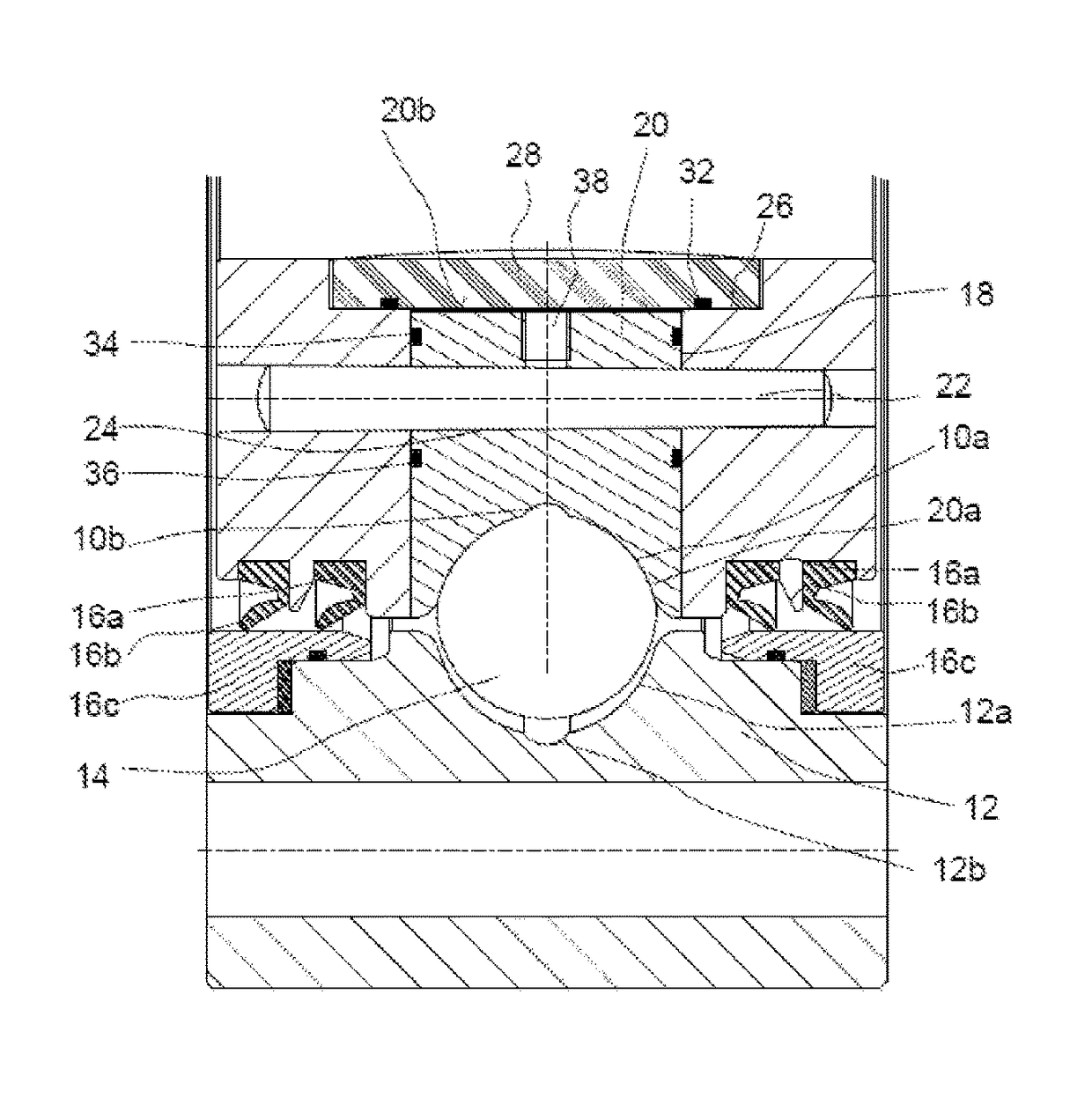

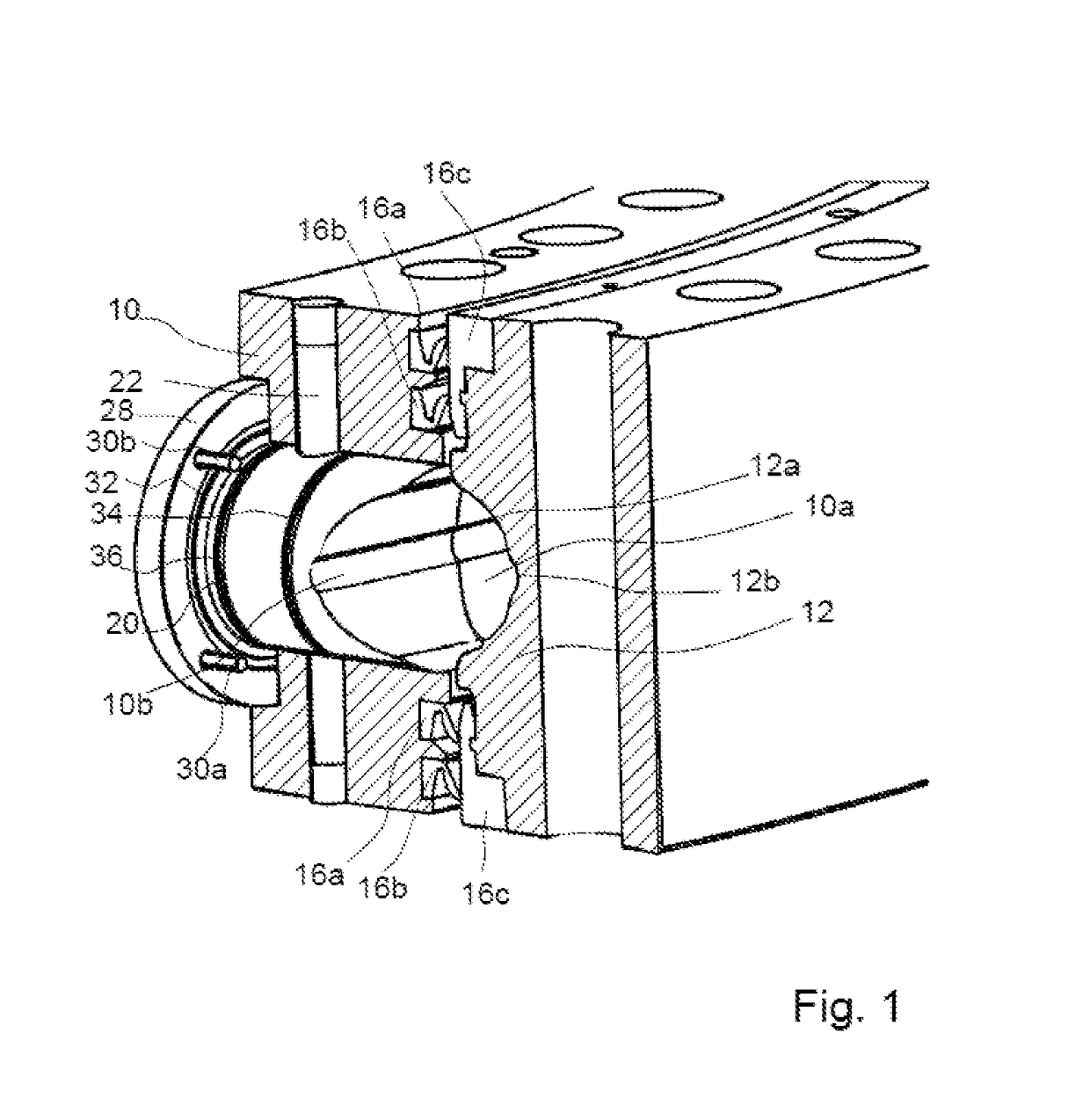

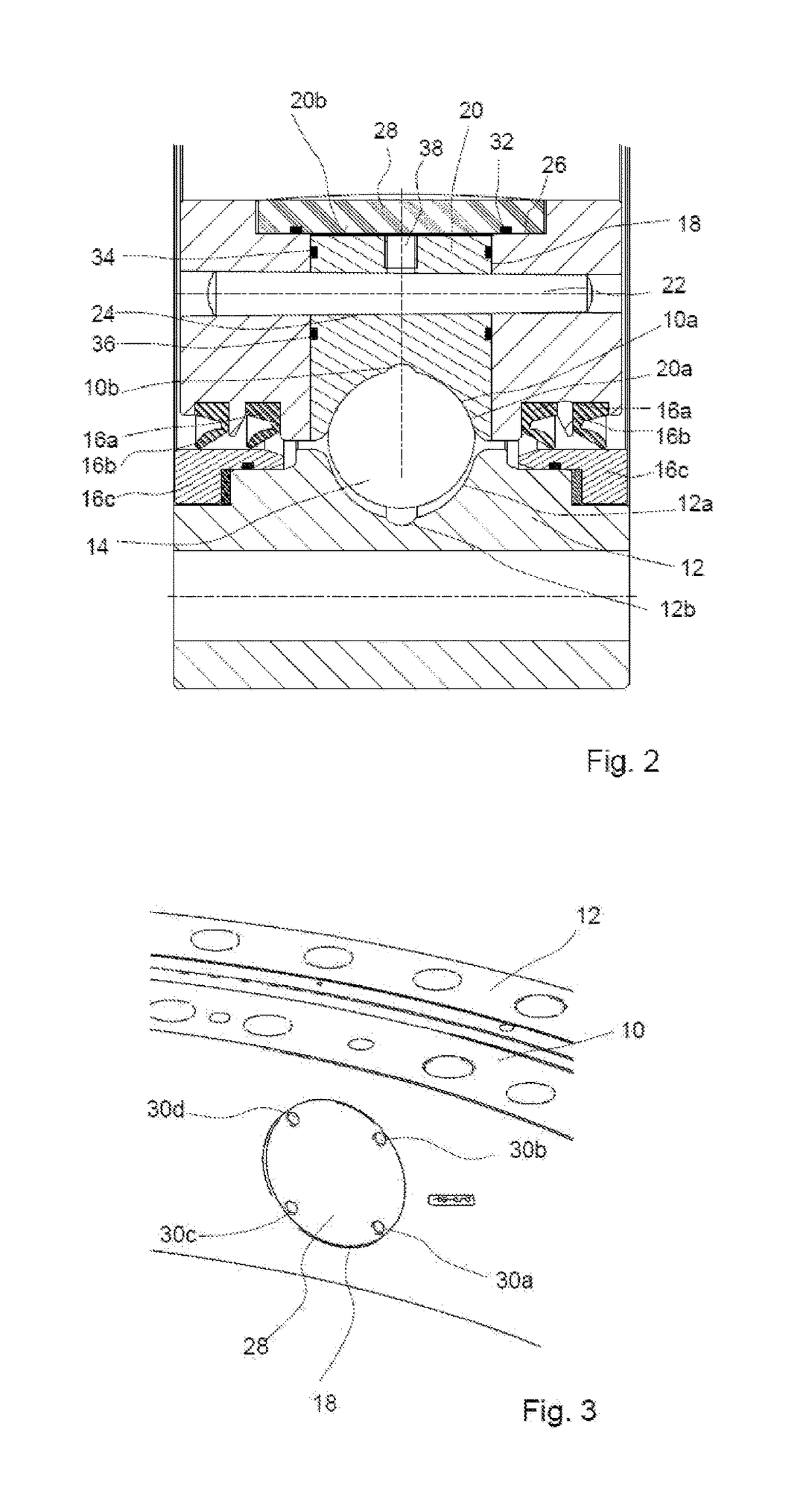

Plug assembly, rolling bearing comprising such plug assembly and machine comprising such rolling bearing

ActiveUS20160091025A1Reduction of watertightnessAvoid corrosionRoller bearingsShaftsRolling-element bearingMechanical engineering

A plug assembly for use in a rolling bearing comprising at least a first ring, at least one second ring, and at least one row of rolling elements arranged between the rings. The first ring is provided with an opening for inserting rolling elements into a space between raceways or for taking rolling elements out of the space between the raceways for assembly and maintenance. The plug assembly comprises a plug configured to close the opening when the bearing is operating. The plug includes an inner end face facing the rolling elements and an outer end face opposite to the inner end face. The bearing can further comprise a protective cap shielding the outer end face of the plug from a corrosive environment of the bearing.

Owner:AB SKF

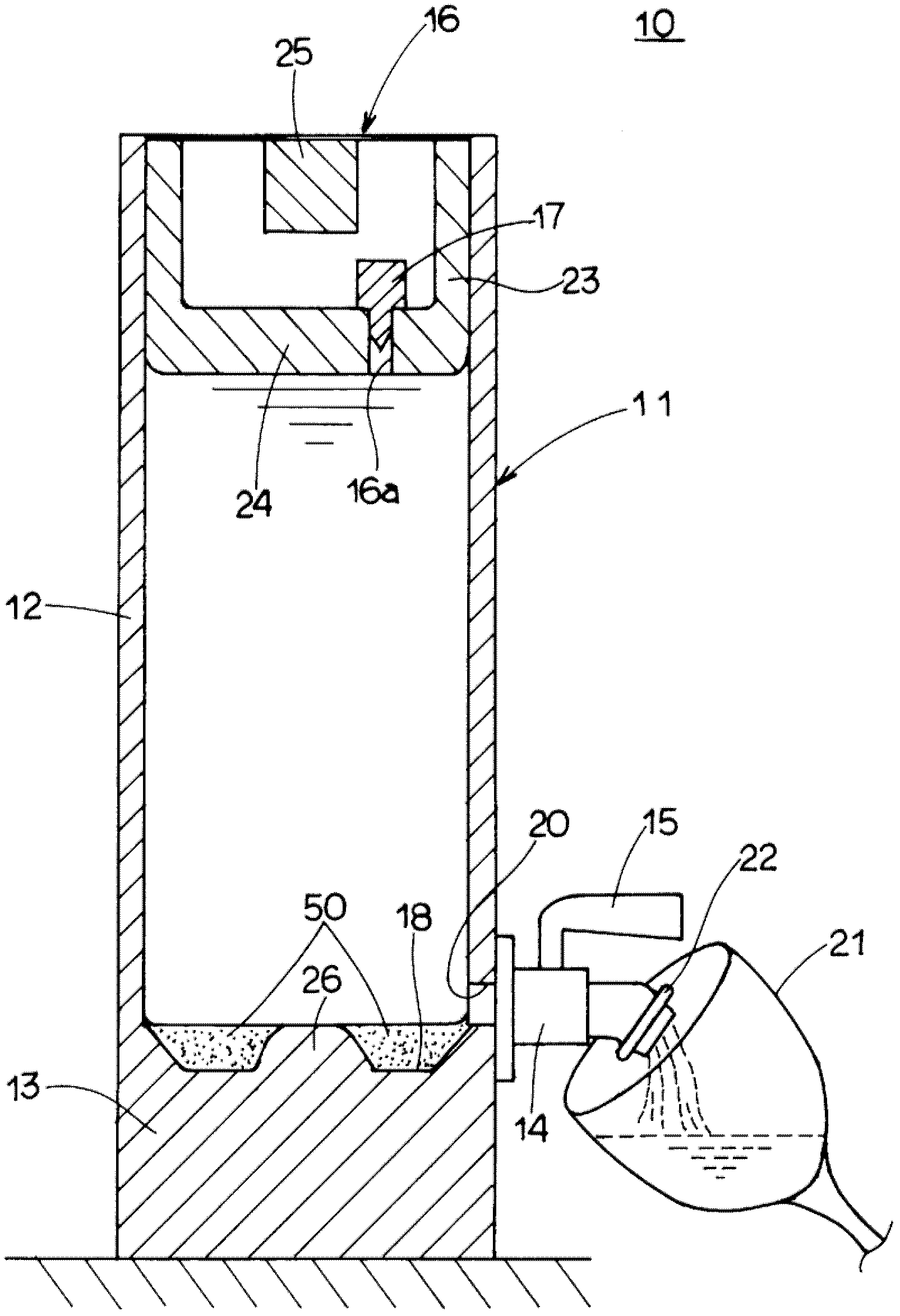

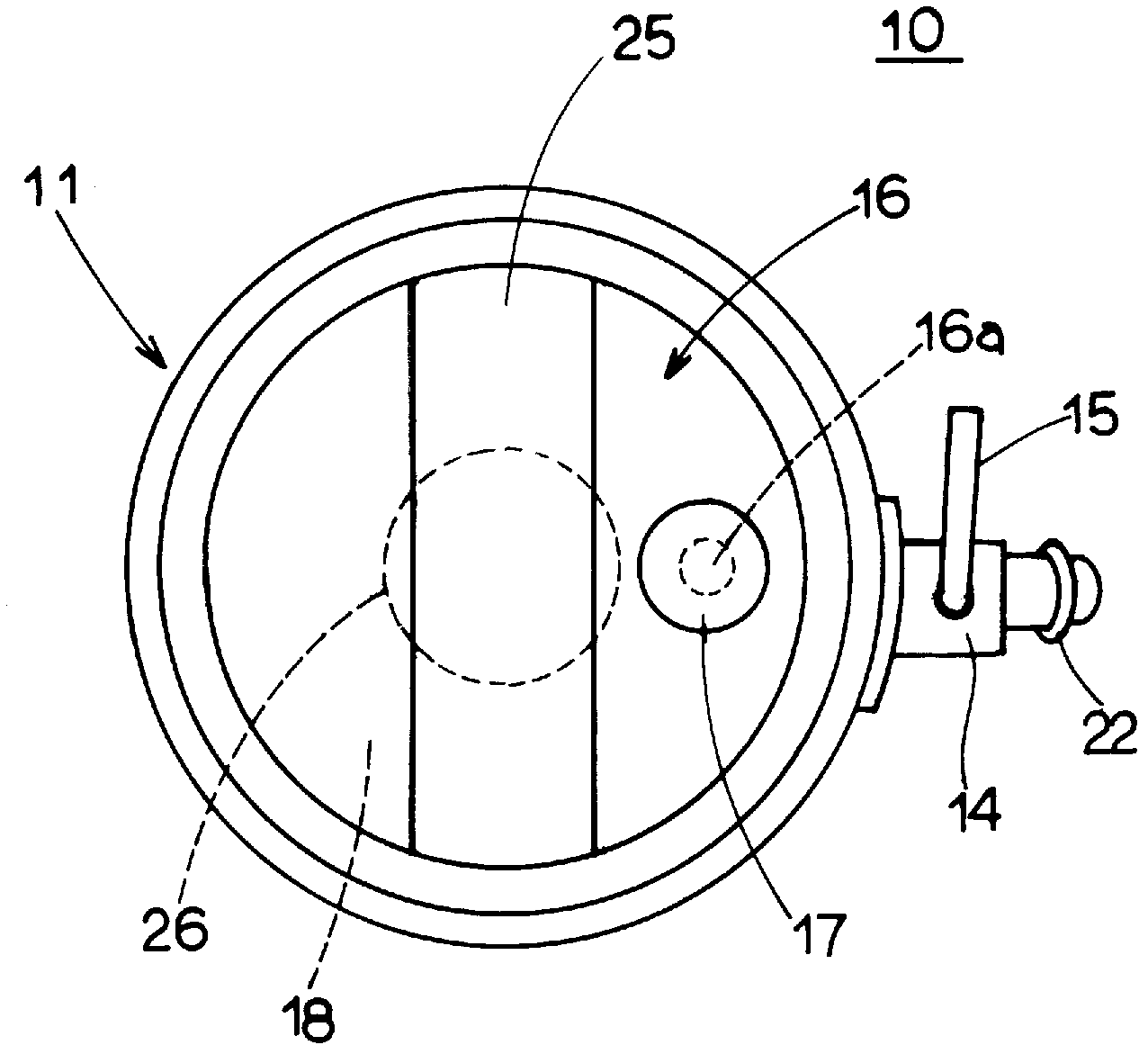

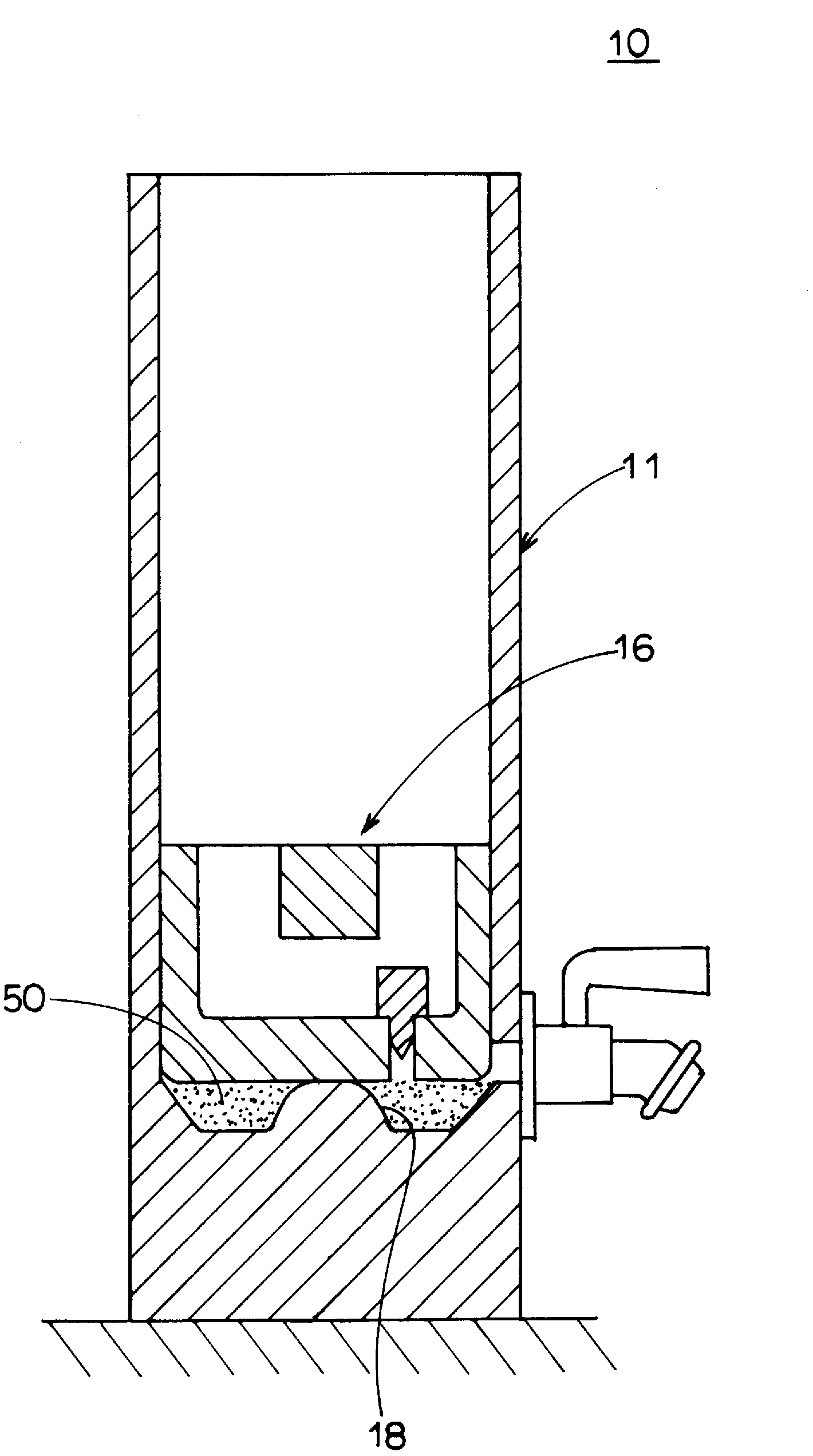

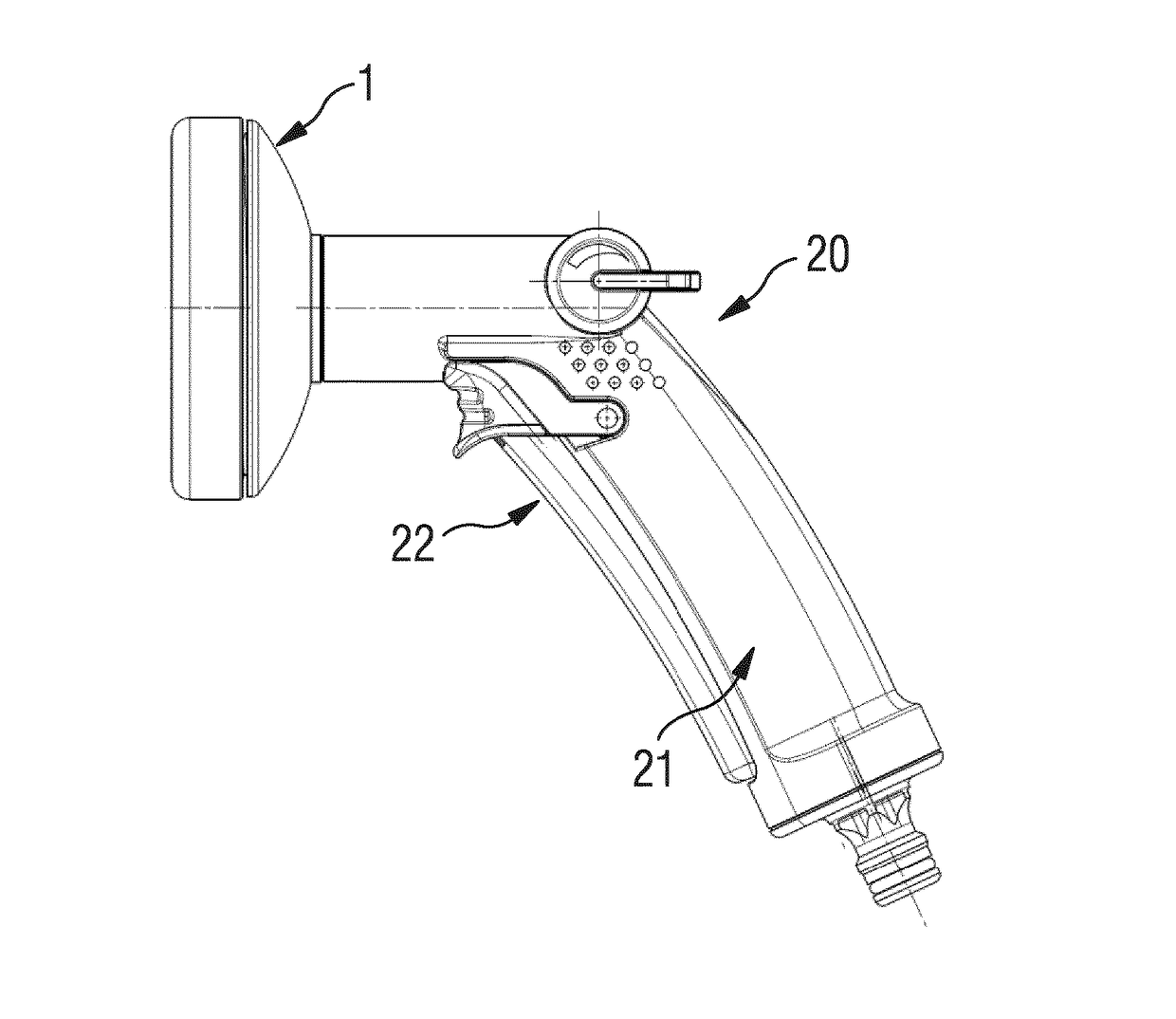

Wine dispenser

InactiveCN102421696APrevent oxidationImprove liquid tightnessLiquid flow controllersLiquid dispensingForeign matterEngineering

An upstanding cylinder and a loading lid are produced respectively from glass. On the upper face of the bottom plate of the cylinder, a substance-pooling concave in which wine lees and tartar are pooled is formed. Owing to this constitution, there is little risk that the external air enters through a gap between the sliding faces of these members into the wine-pooling section in the cylinder and causes the oxidation of the wine. Since the cylinder comprises glass, the wine can be stored under almost the same conditions as in bottles. Further, sanitary precautions can be easily taken. Furthermore, problems such as the sticking of the cylinder to the loading lid due to stainless steel rust and so on can be overcome.

Owner:MANHONG CO LTD

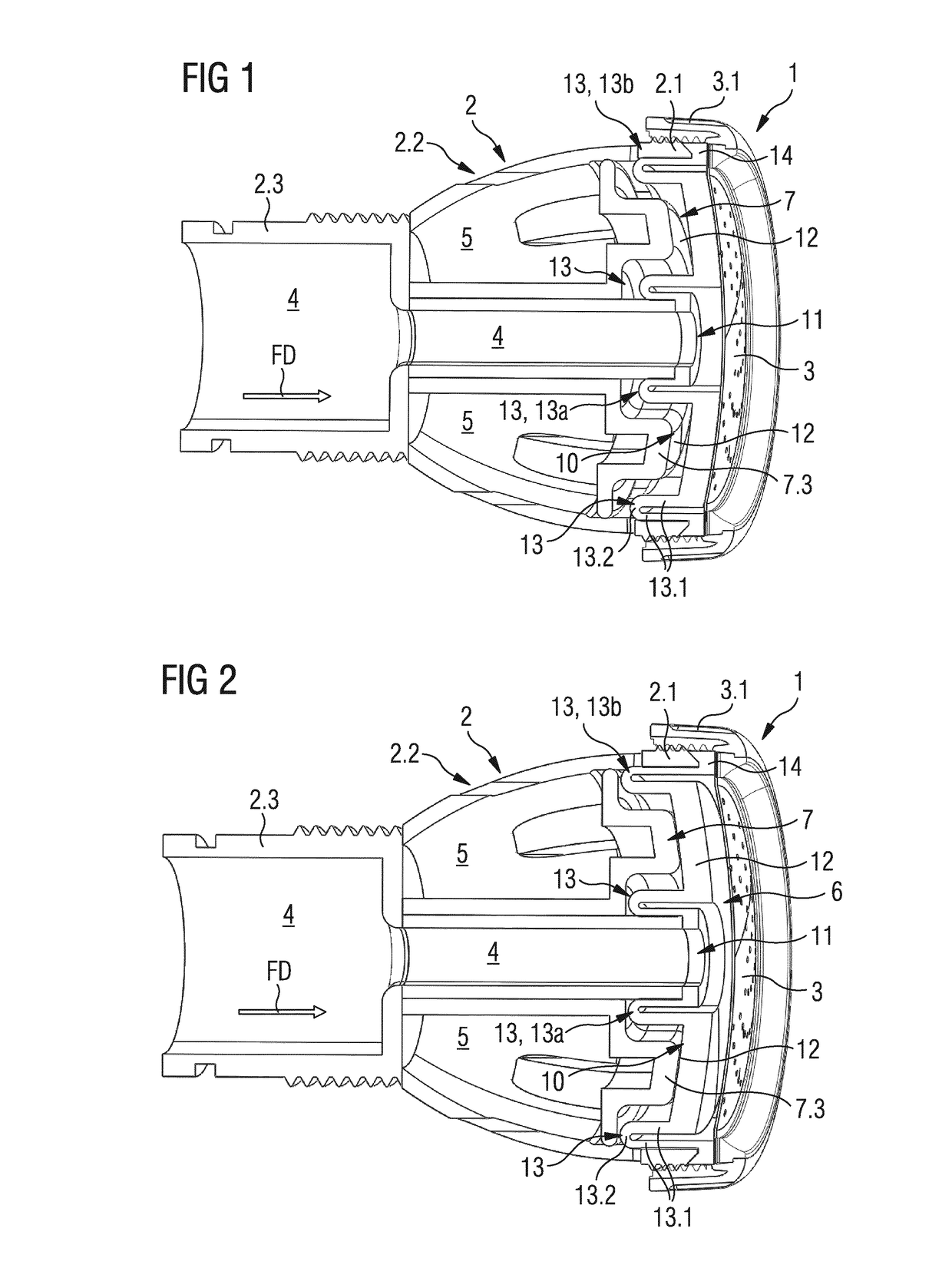

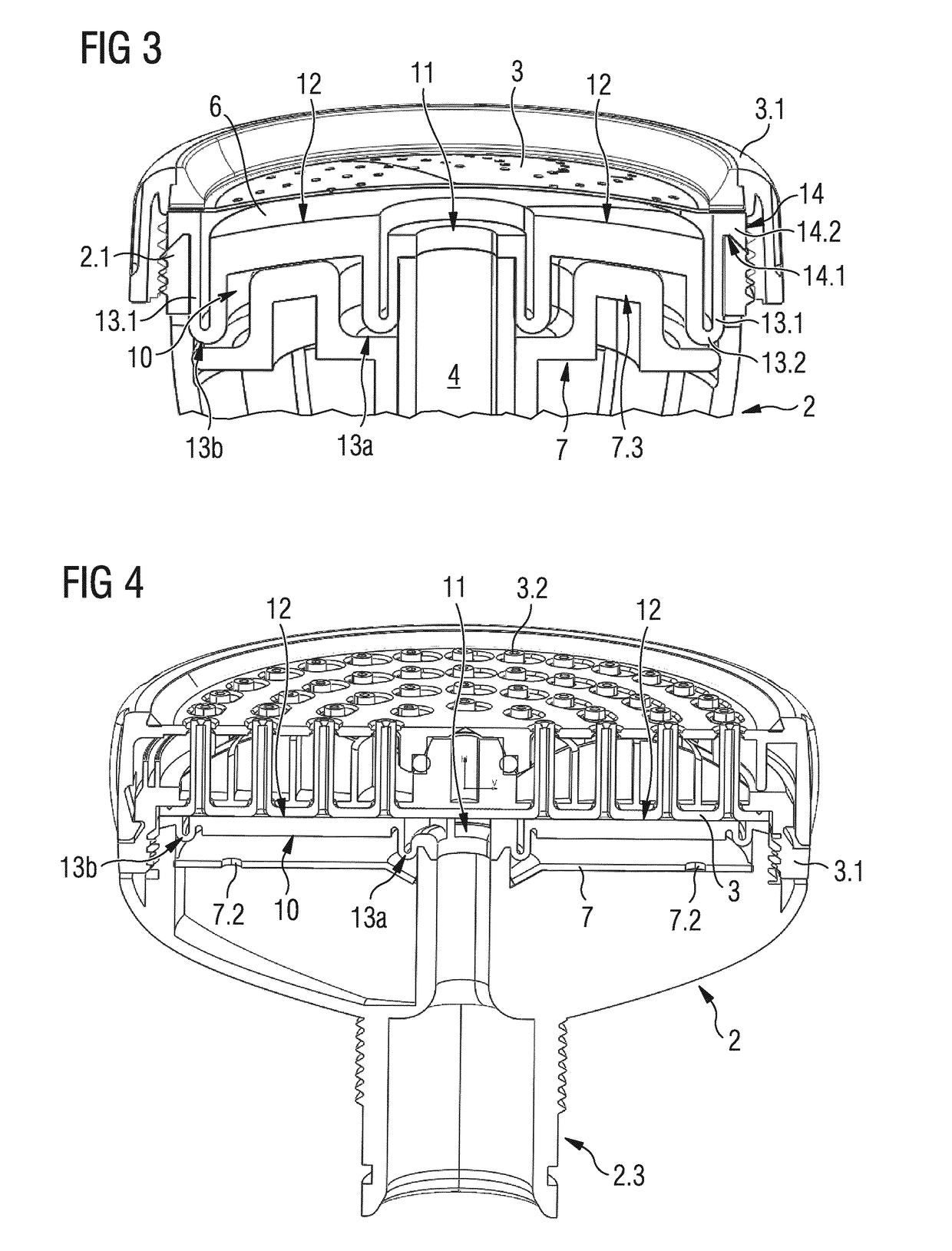

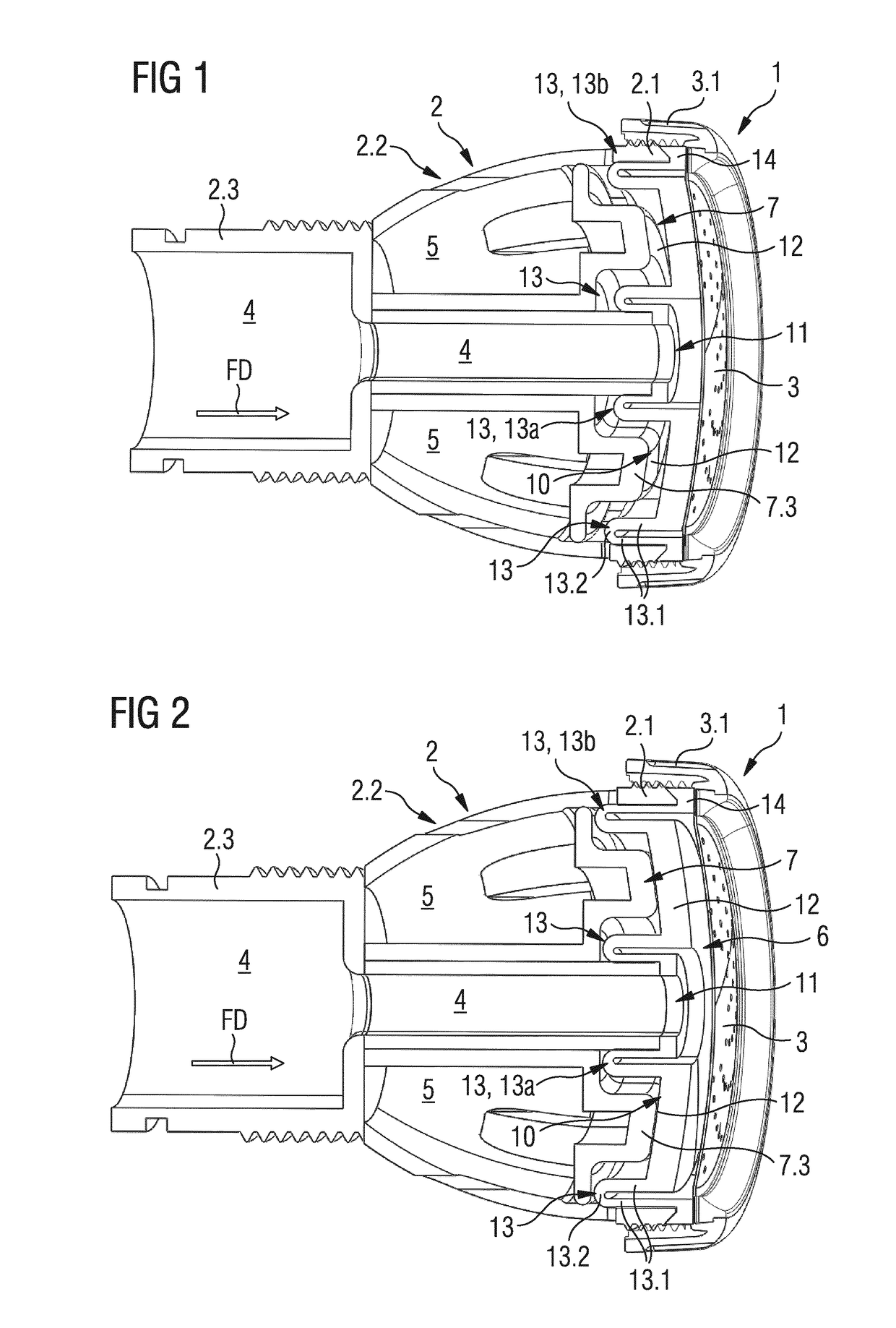

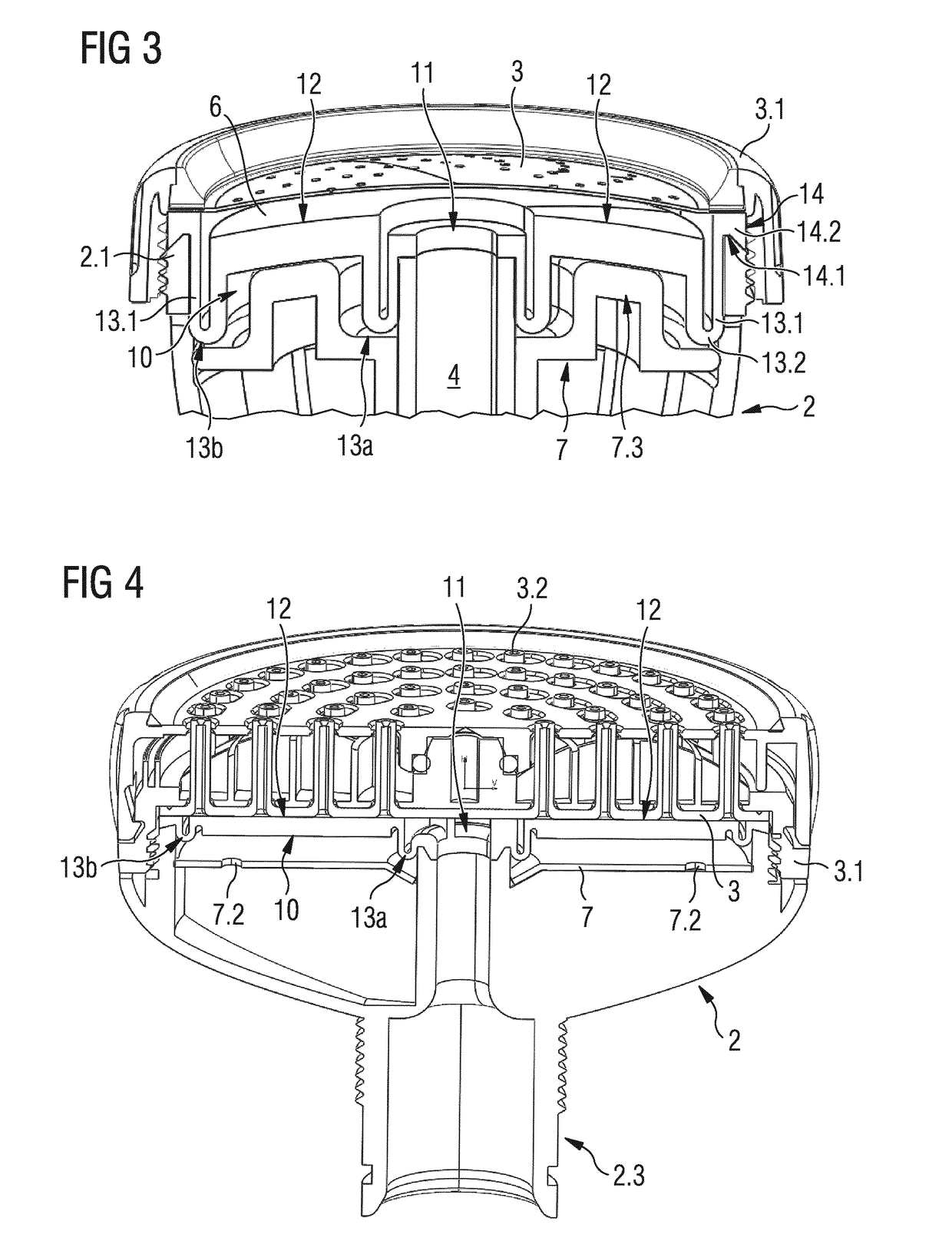

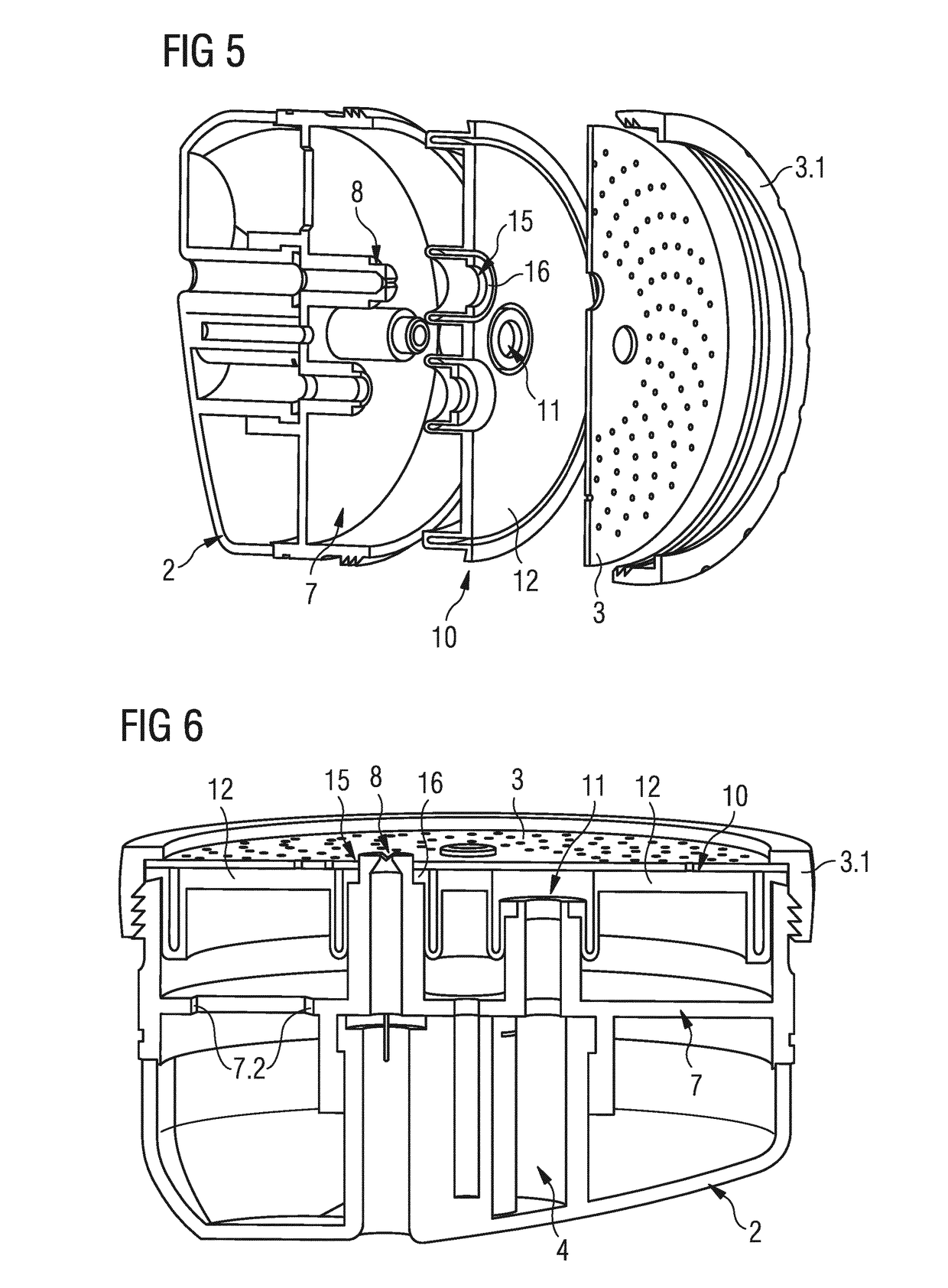

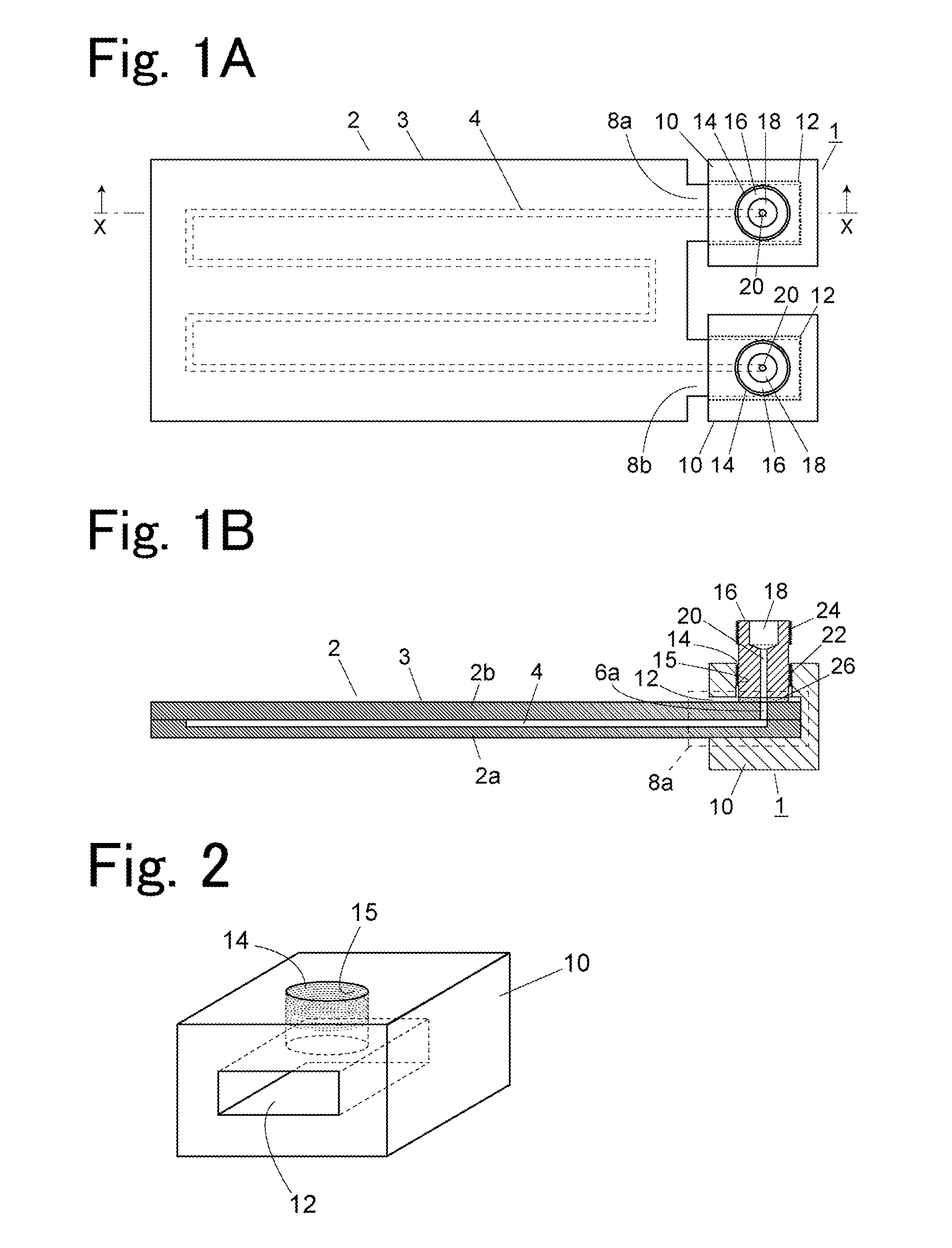

Spray head and spraying apparatus

ActiveUS20180078953A1Easy to handleImprove frost resistanceSpray nozzlesVenting valvesEngineeringNozzle

The invention relates to a spray head comprising a spray head base body (2) and a nozzle plate (3), the spray head base body (2) comprising at least one liquid channel (4) for providing a liquid flow towards the nozzle plate (3), wherein a drip-stop element (10) is located between the spray head base body (2) and the nozzle plate (3), said drip-stop element (10) comprising at least one opening (11) being fluidly coupled with said liquid channel (4) for providing a fluid flow into a space (6) between the drip-stop element (10) and the nozzle plate (3), wherein at least a top portion (12) of said drip-stop element (10) is movably mounted within a spray head chamber (5) in order to perform a stroke movement, wherein said top portion (12) is preloaded such that the top portion (12) rests against the nozzle plate (3) without applying any external forces to the top portion (12) and said top portion (12) is lifted off the nozzle plate (3) in case that a liquid flow is provided through the liquid channel (4) into the space (6) between said top portion (12) and the nozzle plate (3).

Owner:HUSQVARNA AB

Non-rotary cutting tool and process of machining scroll member by using the same

ActiveUS7293945B2Convenient and accurateHigh precisionAttachable planing devicesCutting insertsEngineeringMechanical engineering

A non-rotary cutting tool which is to be moved relative to a workpiece in a predetermined direction for cutting the workpiece, with its rake face being held substantially perpendicular to the predetermined direction. The cutting tool includes (a) a generally cylindrical shank portion, and (b) a generally semi-cylindrical body portion which has an outer circumferential surface constituted by the rake face and a semi-cylindrical surface. The semi-cylindrical body portion has a cutting edge which is defined by an edge of the rake face and which is covered with a diamond coating. Also disclosed is a process of machining a scroll member of a scroll compressor by using this non-rotary cutting tool.

Owner:PANASONIC CORP +1

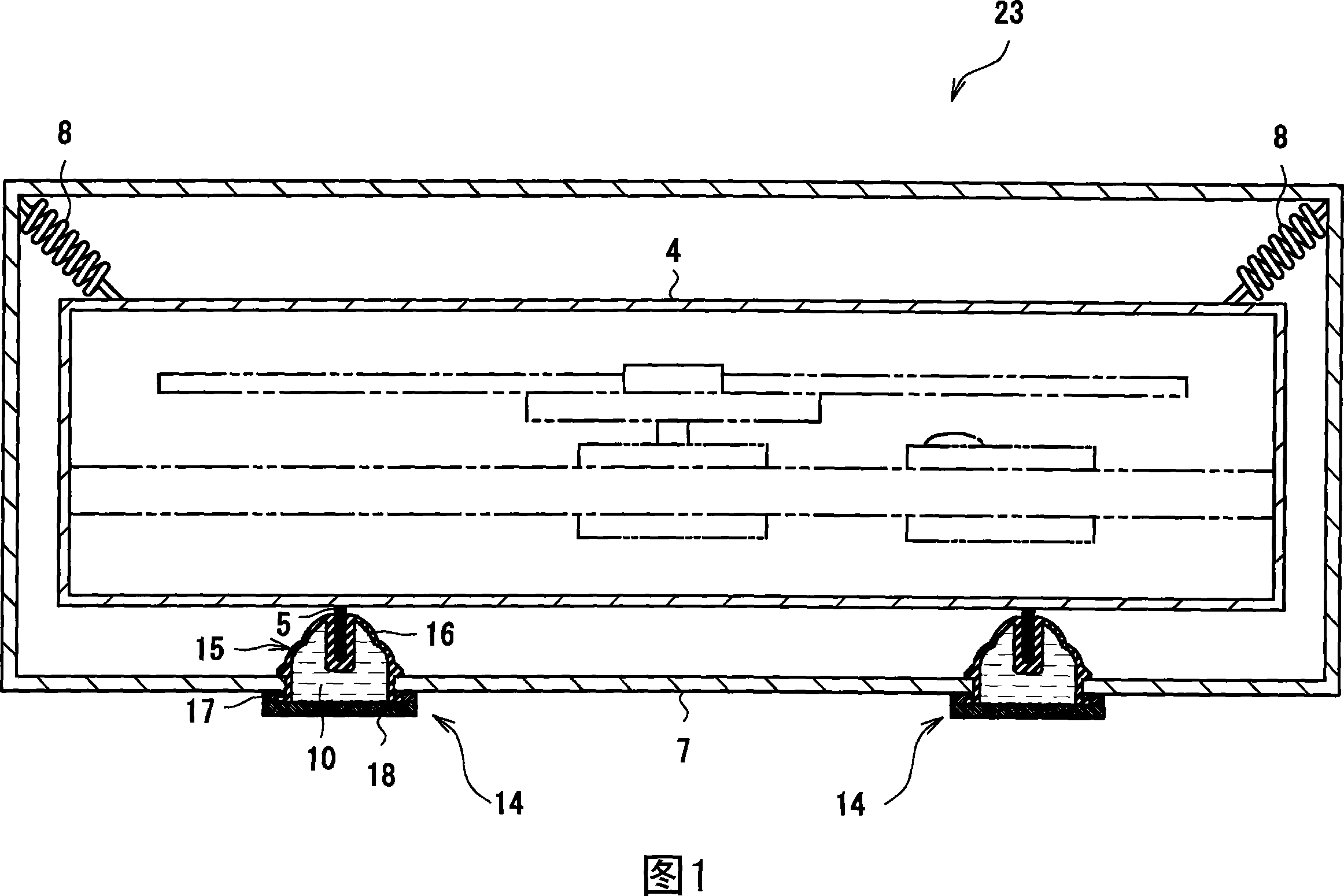

Inking pot

InactiveCN101402197ASave installationSave time for replacementOther workshop equipmentCoil springEngineering

An ink fountain allows ink lines wrapped on the scroll body to contact with ink immersing components immersed with ink; uses a needle component to pierce into the surface of timber or the like objects; performs ink lines on the object surface; arranges a coil spring in the internal circumstance of the scroll body for rollback ink lines, wherein, a rotor plate for storing power for the coil spring is configured to expose from the upper surface of the body; and provides a block on the rotor plate for limiting the rollback of the coil spring, wherein, the block is introduced to freely project from and fall back to the lateral surface of the rotor plate, and is blocked to a blocking dent provided on the body side through a force application apparatus. The invention provides an ink fountain in which the load application of coil spring of the revolution axis can be easily released only by a hand, and the ink will not stick on the fingers upon replacing the ink immersing components.

Owner:LEIYU SHANGHAI PACKAGING PROD

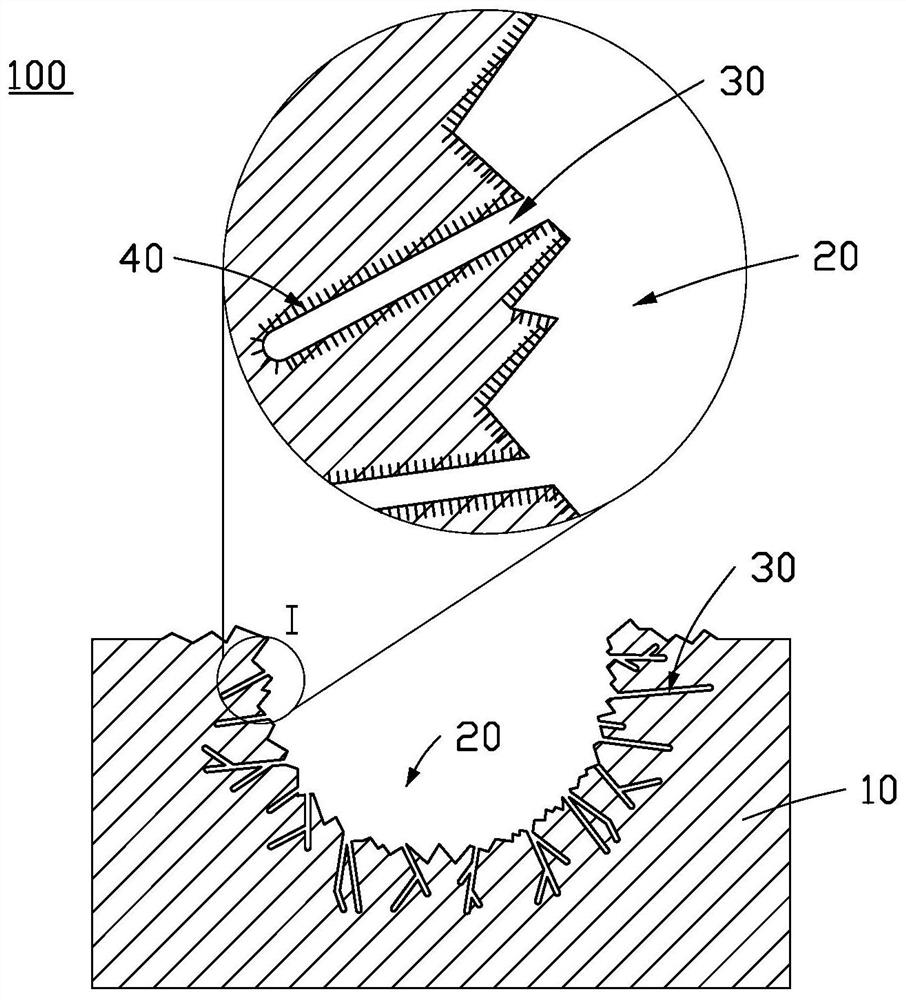

Process of machining scroll member by using non-rotary cutting tool

ActiveUS7237992B2Convenient and accurateHigh precisionLathesAttachable planing devicesMechanical engineeringCoating

A process of machining a scroll member of a scroll compressor by using a non-rotary cutting tool. The non-rotary cutting tool is moved relative to a workpiece in a predetermined direction for cutting the workpiece, with its rake face being held substantially perpendicular to the predetermined direction. The cutting tool includes (a) a generally cylindrical shank portion, and (b) a generally semi-cylindrical body portion which has an outer circumferential surface constituted by the rake face and a semi-cylindrical surface. The semi-cylindrical body portion has a cutting edge which is defined by an edge of the rake face and which is covered with a diamond coating. The rake face has a planar surface and a constant width throughout the cutting edge.

Owner:PANASONIC CORP +1

Woven tubing for stent type blood vascular prosthesis and stent type blood vascular prosthesis using the tubing

ActiveUS20030181971A1Prevent inflowImprove liquid tightnessStentsMulti-ply fabricsVascular prosthesisLesion

A woven tubing for use in a stent type blood vascular prosthesis, using a monofilament having a flattening in the range of 1.2-5.0 and a size in the range of 11-250 dtex in at least part of the warp and a stent type blood vascular prosthesis using the tubing are disclosed. The prosthesis combines a shape retaining property that is capable of maintaining its tubular shape without being crushed by the flow of blood with a high liquid tightness that is capable of reducing the leakage of blood to the exterior and allows prevention of the inflow of blood into the lesion.

Owner:TERUMO KK

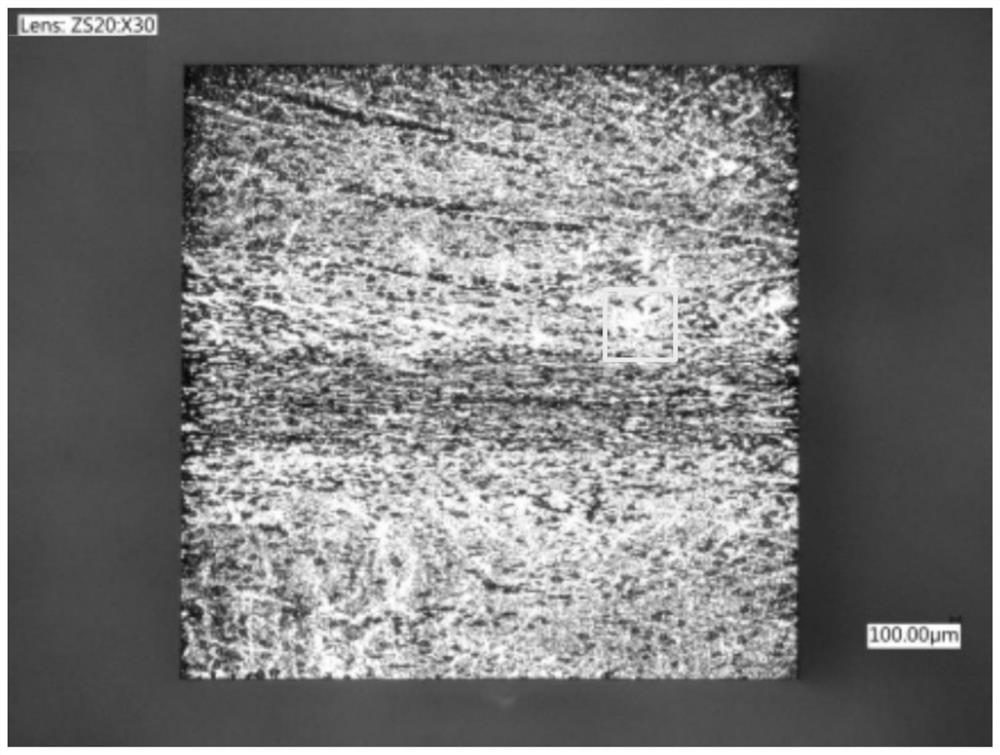

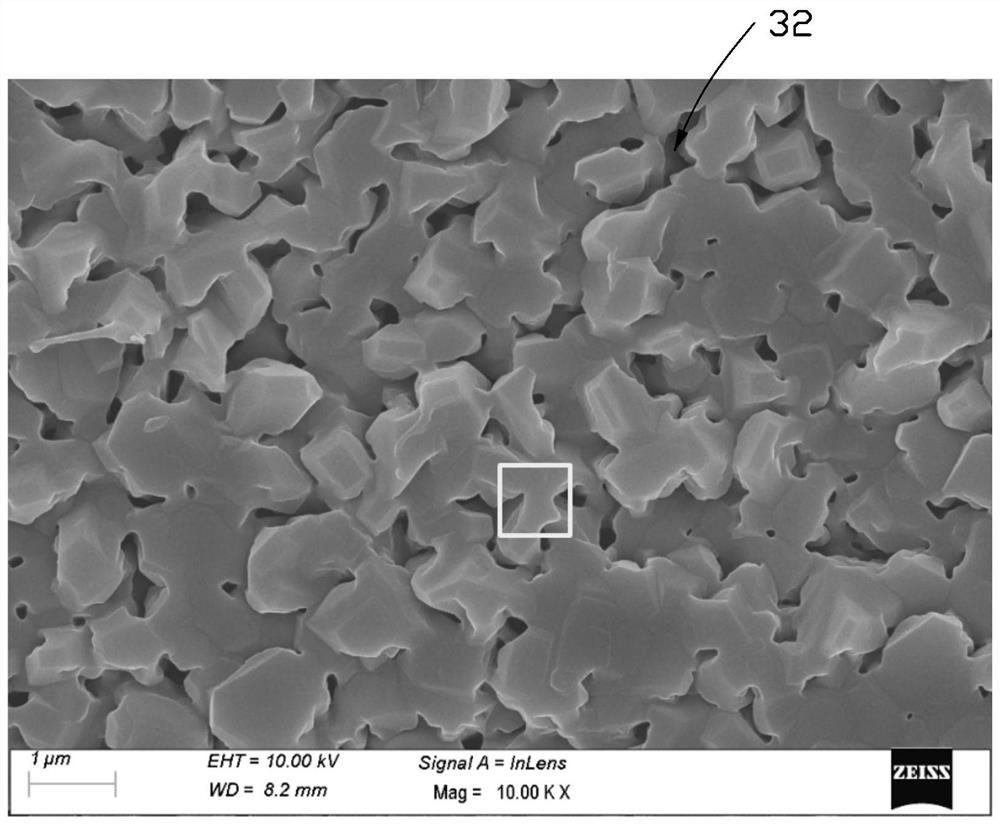

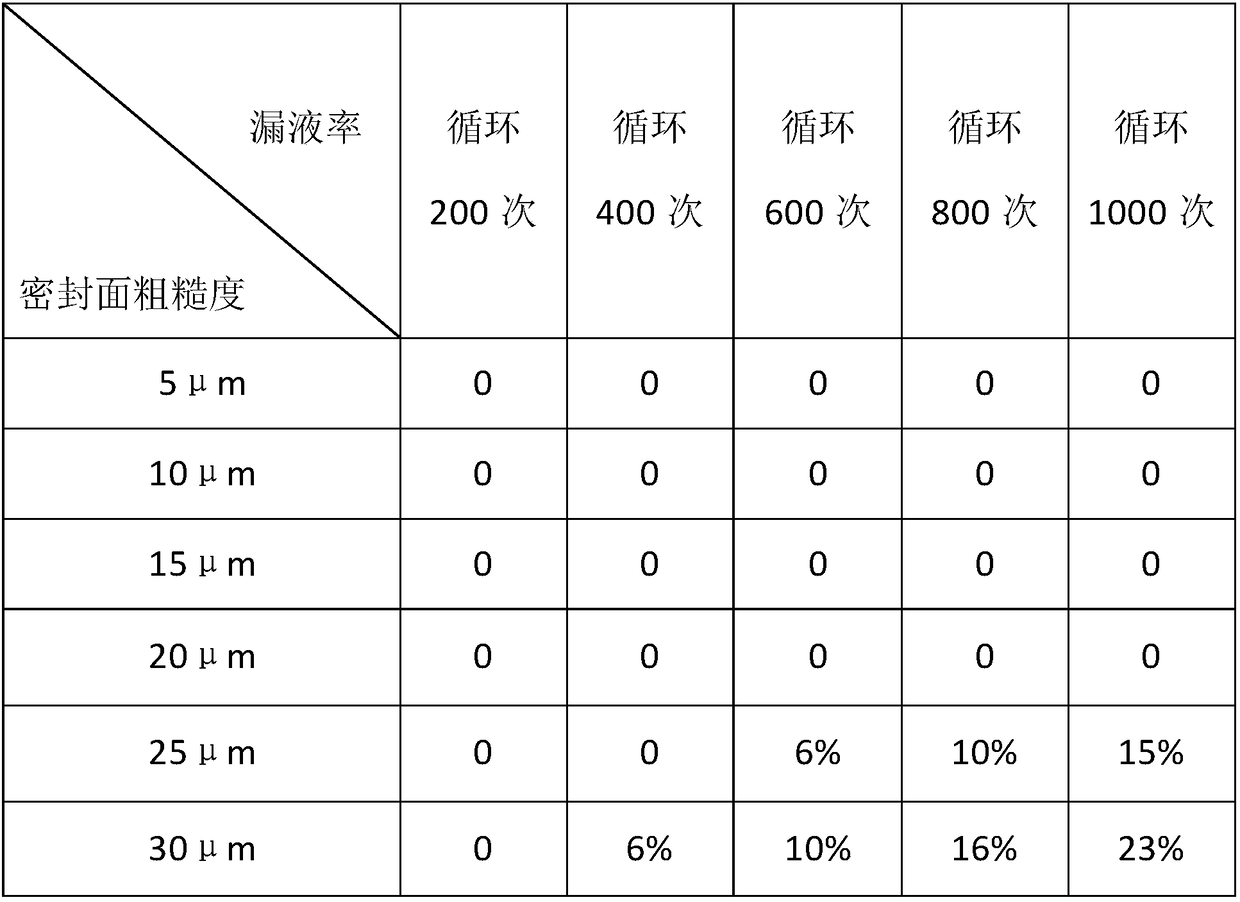

Metal product, preparation method for metal product, metal complex and preparation method for metal complex

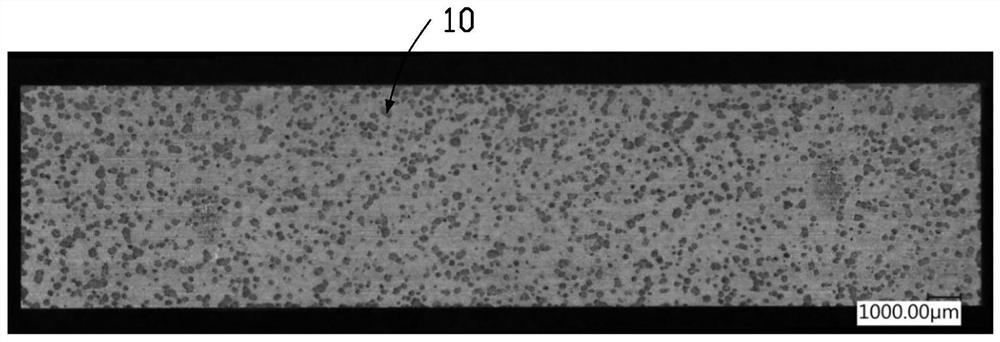

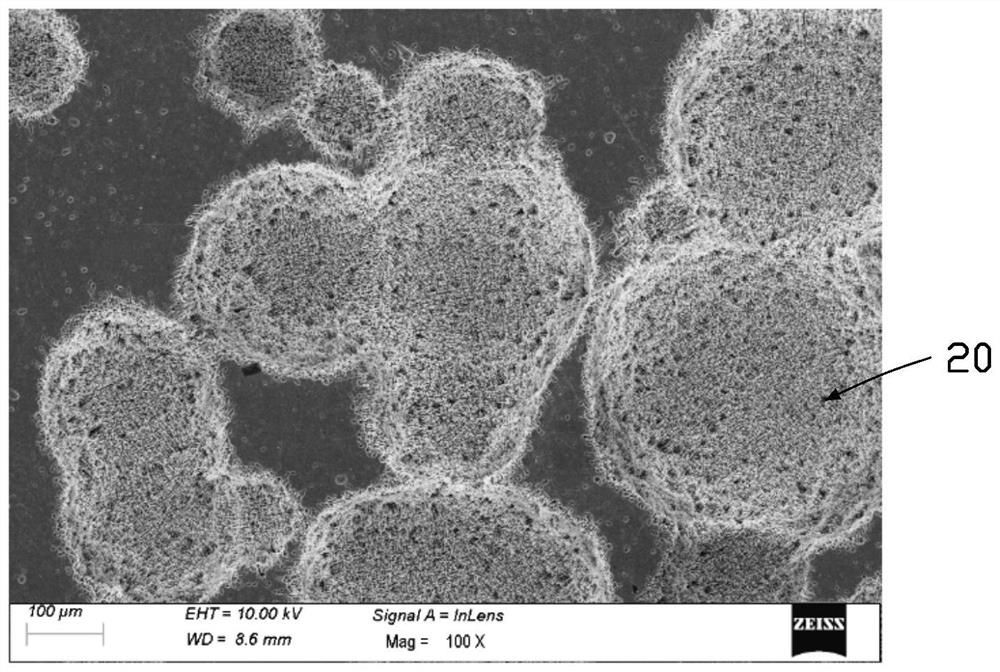

PendingCN112342508AImprove air tightnessImprove liquid tightnessAnodisationVacuum evaporation coatingMicron scaleUltimate tensile strength

The invention discloses a metal product. The metal product comprises a metal matrix, a first hole, protrusions and third holes; the first hole is formed in the surface of the metal matrix; the protrusions are located on at least one surface of the surface, not provided with the first hole, of the metal matrix and the surface of the first hole; second holes are defined by the protrusions; and the third holes are located in at least one surface of the surfaces of the protrusions and the surface, not covered by the protrusions, of the metal matrix. According to the metal product, the micron-sizedfirst hole, the sub-micron-sized second holes and the nano-sized third holes are formed in the metal matrix, so that the bonding strength between the metal product and a material body is enhanced. The invention further provides a preparation method for the metal product, a metal complex and a preparation method for the metal complex.

Owner:SHENZHENSHI YUZHAN PRECISION TECH CO LTD

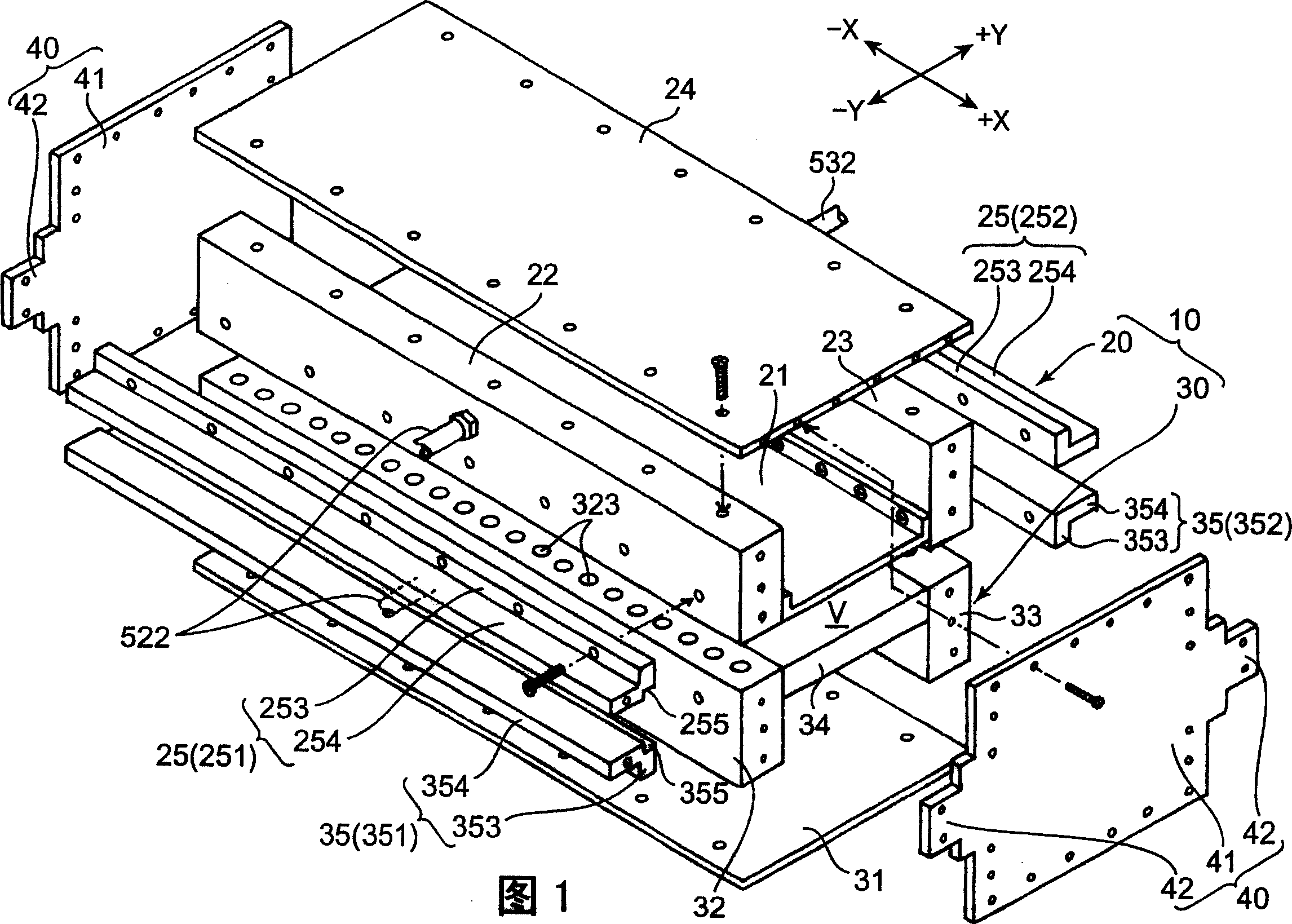

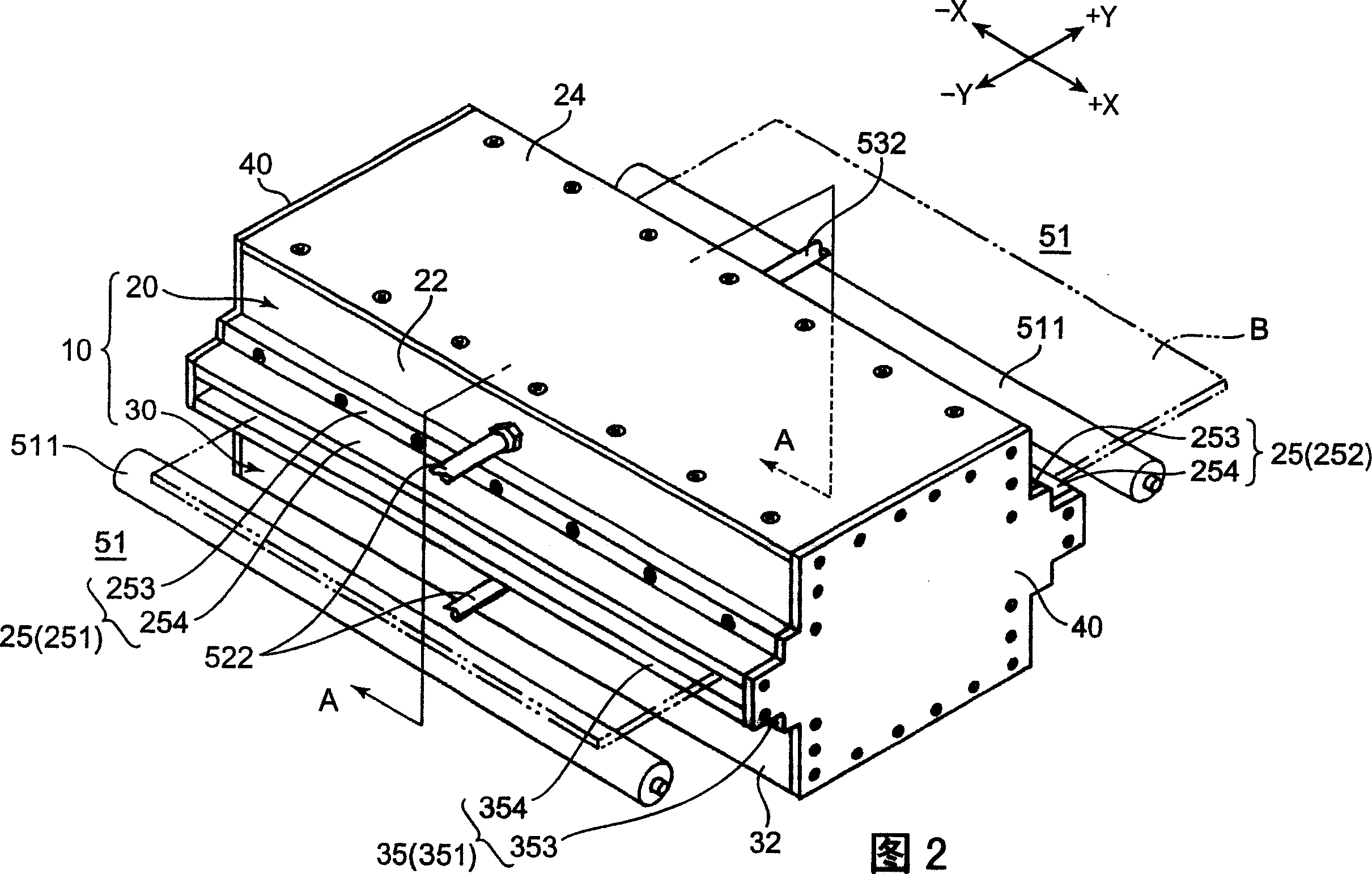

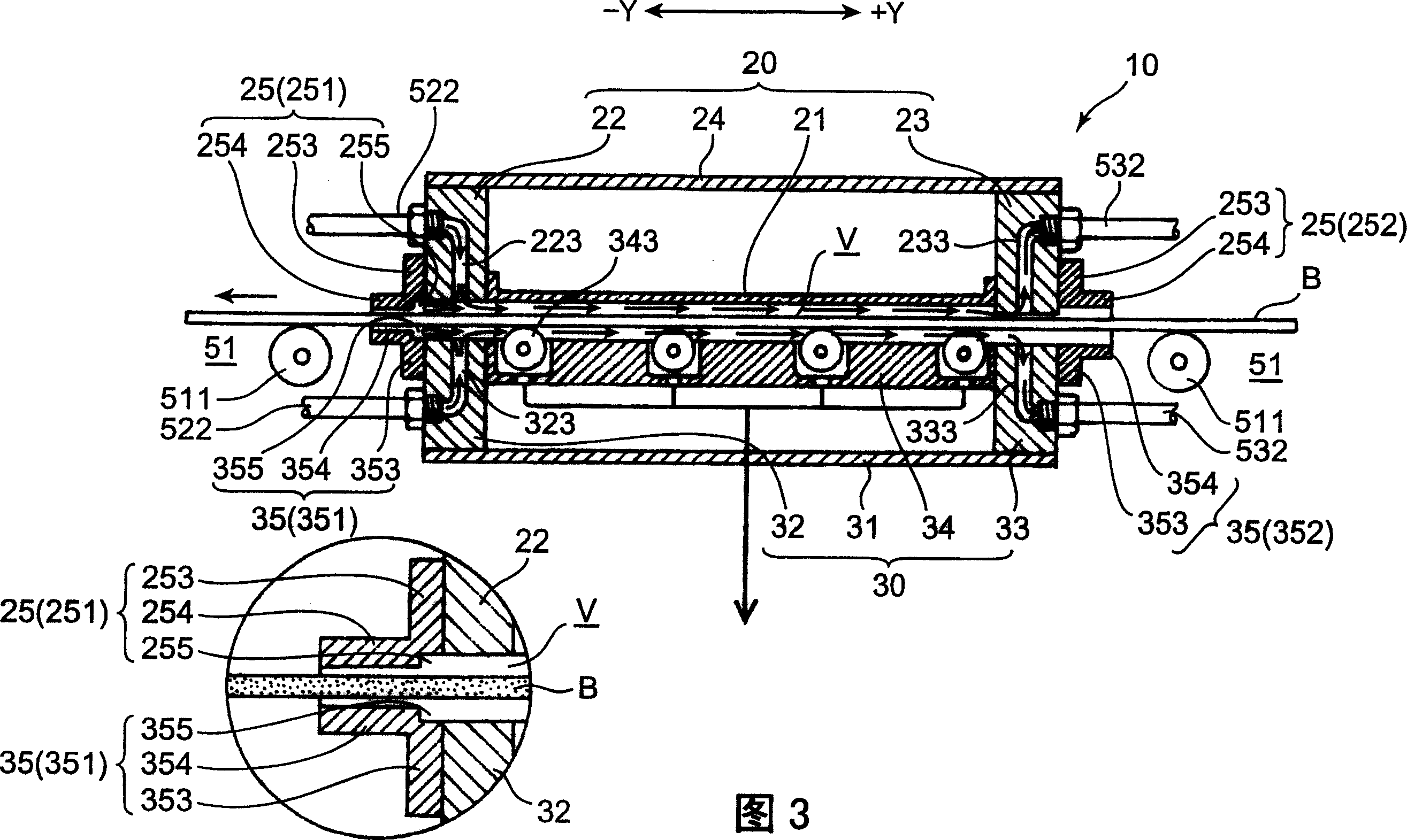

Treating liquid feed device

InactiveCN1907582AImprove liquid tightnessImprove processing efficiencySemiconductor/solid-state device manufacturingCleaning using liquidsEngineeringNozzle

The invention provides a processing liquid feeder of a processing liquid recovery type which allows effective prevention of leakage of the processing liquid from the enclosure during processing of a substrate even when the upper and lower enclosures are made of a hydrophobic material and are long in both the width direction and the substrate-carrying direction. An upper wing 25 and a lower wing 35 are arranged on each outside surface of upper and lower nozzle blocks 22 and 32 arranged in the upper and lower enclosures, respectively, so as to protrude in the substrate-carrying direction and allow the substrate B to pass through. The upper and lower wings 25 and 35 are located so that the distance between their opposing surfaces is shorter than that between the opposing surfaces of the upper bottom plate 21 and the lower top plate 34.

Owner:FUTURE VISION

Process of machining scroll member by using non-rotary cutting tool

ActiveUS20050166739A1Easy to processHigh precisionLathesAttachable planing devicesEngineeringMechanical engineering

A process of machining a scroll member of a scroll compressor by using a non-rotary cutting tool. The non-rotary cutting tool is to be moved relative to a workpiece in a predetermined direction for cutting the workpiece, with its rake face being held substantially perpendicular to the predetermined direction. The cutting tool includes (a) a generally cylindrical shank portion, and (b) a generally semi-cylindrical body portion which has an outer circumferential surface constituted by the rake face and a semi-cylindrical surface. The semi-cylindrical body portion has a cutting edge which is defined by an edge of the rake face and which is covered with a diamond coating.

Owner:PANASONIC CORP +1

Metal product, preparation method for metal product, metal complex and preparation method for metal complex

InactiveCN112342604AAvoid corrosionImprove air tightnessAnodisationConstructions elementsMicron scaleMetallurgy

The invention discloses a metal product. The metal product comprises a metal matrix, a first hole, second holes and third holes; the first hole is formed in the surface of the metal matrix; the secondholes are formed in the surface of the first hole; and the third holes are formed in at least one surface of the surface of the metal matrix, the surface of the first hole and the surfaces of the second holes. According to the metal product, the micron-sized first hole, the sub-micron-sized second holes and the nano-sized third holes are formed in the metal matrix, so that the bonding strength between the metal product and a material body is enhanced. The invention further provides a preparation method for the metal product, a metal complex and a preparation method for the metal complex.

Owner:SHENZHENSHI YUZHAN PRECISION TECH CO LTD

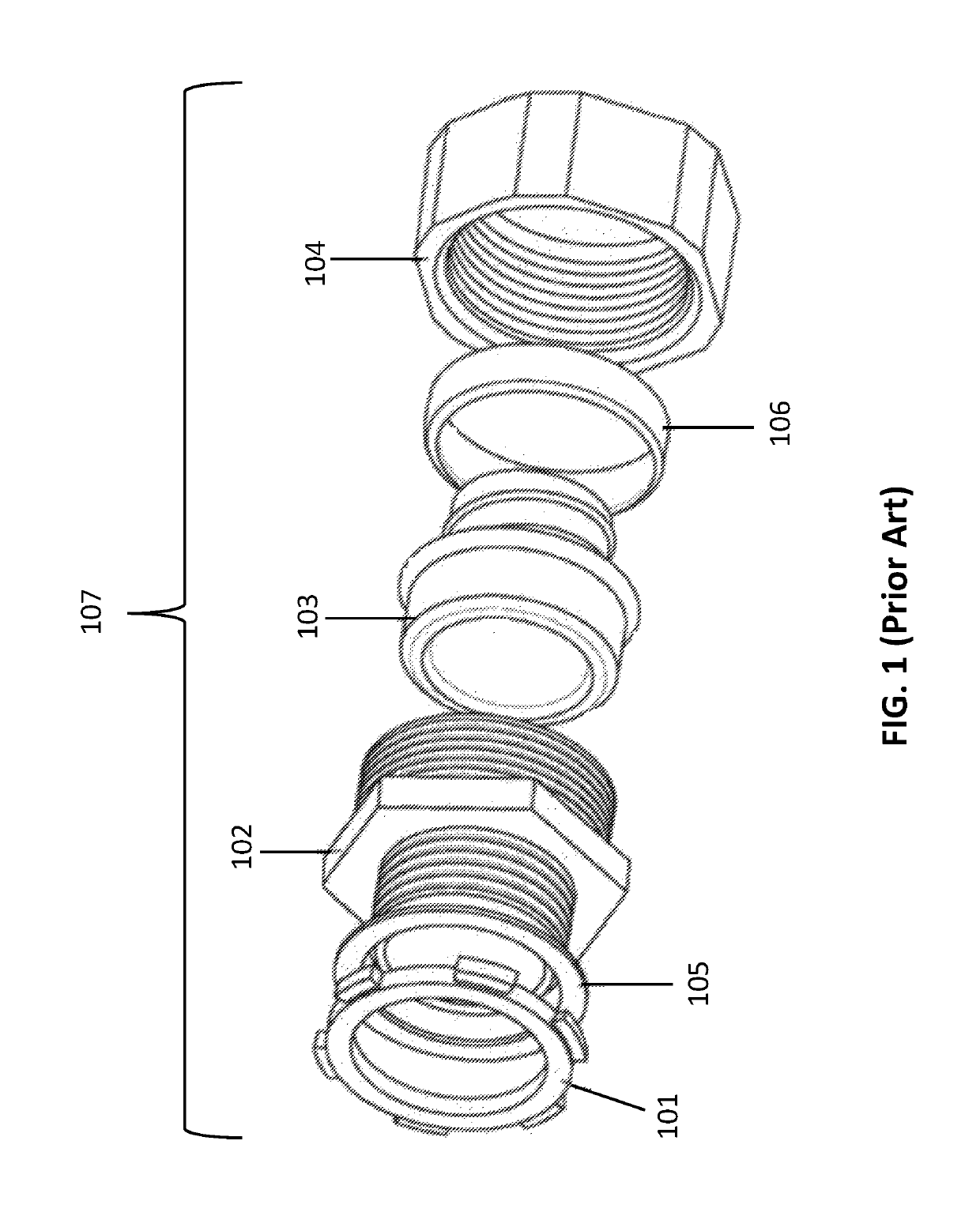

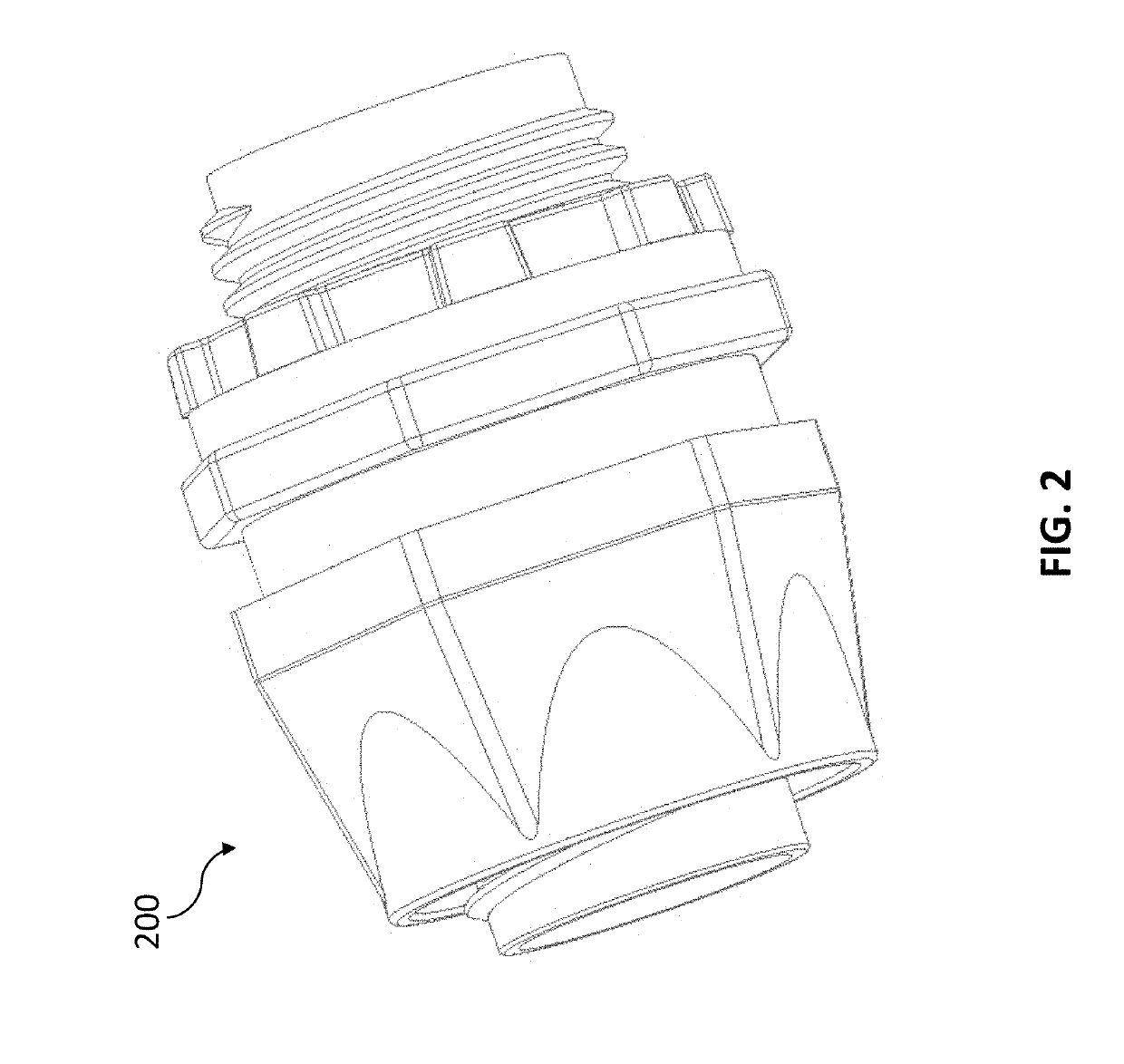

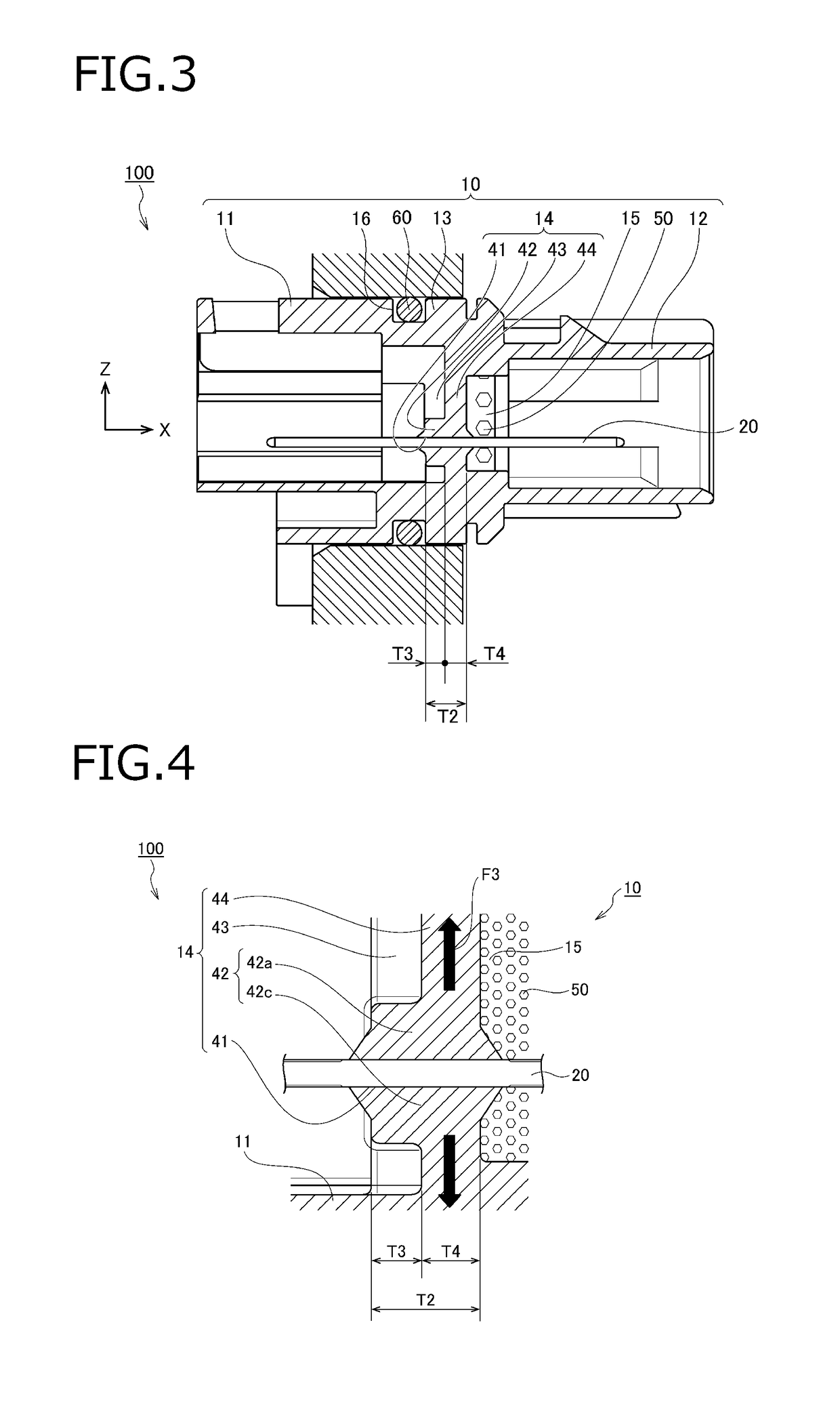

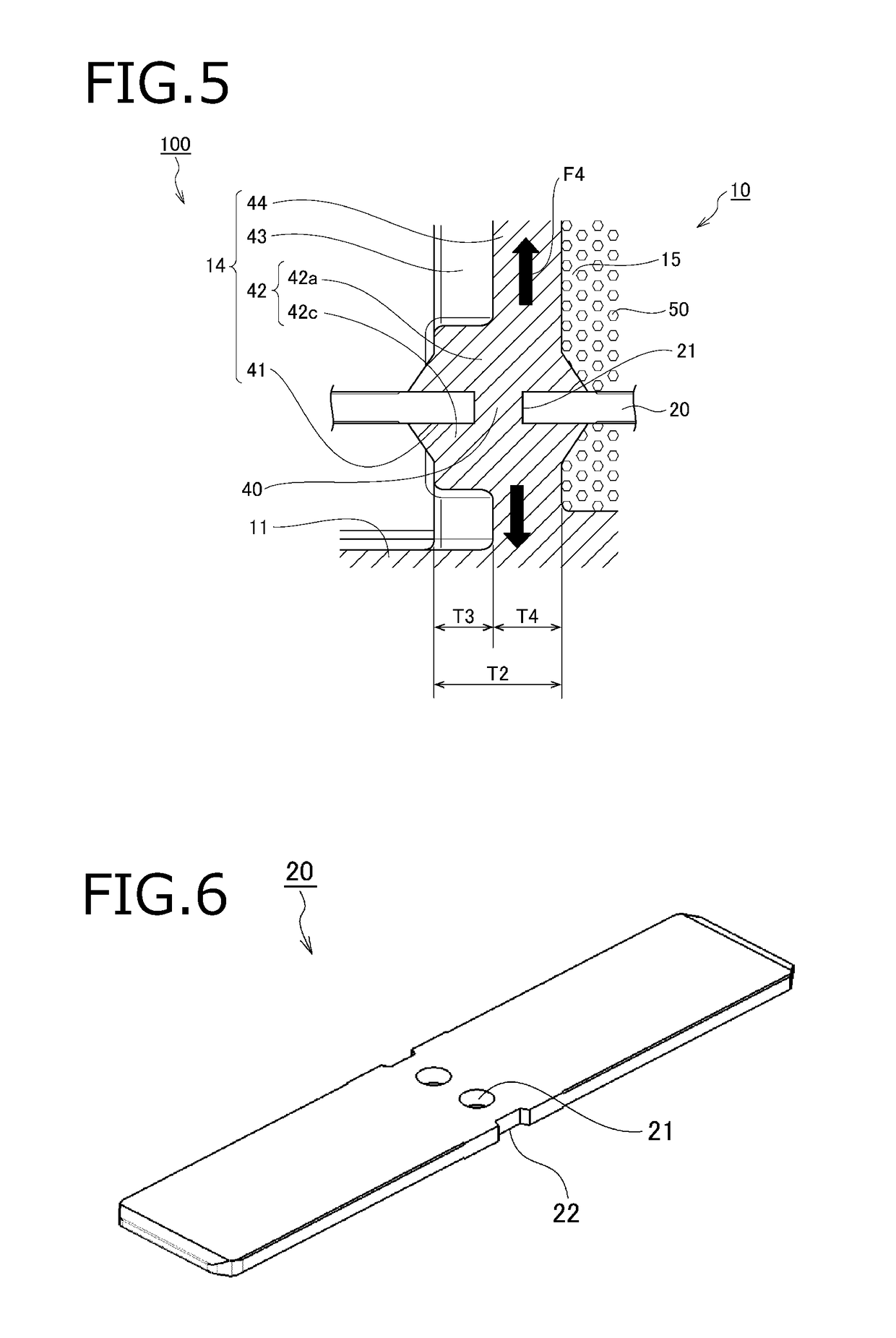

Liquid-tight connector

InactiveUS10411446B2Easy to fixImprove liquid tightnessElectrical apparatusAdjustable jointsScrew threadLocknut

Owner:YANG JINXING

Plug assembly, rolling bearing comprising such plug assembly and machine comprising such rolling bearing

ActiveUS9638259B2Avoid corrosion of a plugReduction of watertightnessRoller bearingsNutsRolling-element bearingEngineering

A plug assembly for use in a rolling bearing comprising at least a first ring, at least one second ring, and at least one row of rolling elements arranged between the rings. The first ring is provided with an opening for inserting rolling elements into a space between raceways or for taking rolling elements out of the space between the raceways for assembly and maintenance. The plug assembly comprises a plug configured to close the opening when the bearing is operating. The plug includes an inner end face facing the rolling elements and an outer end face opposite to the inner end face. The bearing can further comprise a protective cap shielding the outer end face of the plug from a corrosive environment of the bearing.

Owner:AB SKF

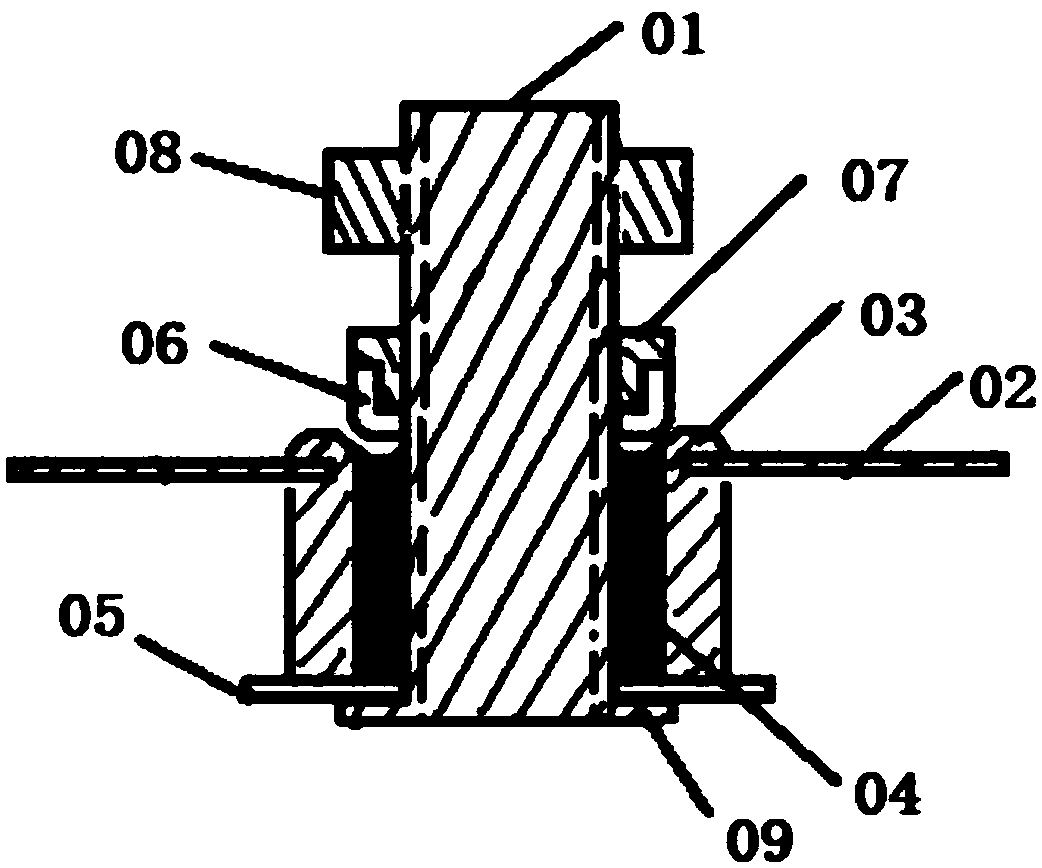

Storage battery pole sealing method

InactiveCN109411649AImprove liquid tightnessSimple processSmall-sized cells cases/jacketsSecondary cellsElectrical batteryLaser

The invention relates to a storage battery pole sealing method. By the storage battery pole sealing method, a pole (01) and a shell cover (02) are sealed through a sealing sleeve (04); the storage battery pole (01) is shaped like a bolt, and the cross section of a tail end (09) is larger than that of a pole body; a through hole in the battery shell cover is welded to a hollow cylinder (03) in a sealed manner through argon arc or laser, and the hole diameter of the hollow cylinder (03) is larger than the outer diameter of the pole and smaller than the outer diameter of the section of the tail end (09) of the pole; the pole (01) is inserted into the cylindrical through hole in the battery shell cover, then the sealing sleeve (04), an insulating gasket (05), an insulating washer (06) and a metal washer (07) are sequentially assembled and compressed on the pole, and the sealing sleeve (04) is compressed by a compressive locking nut (08) to seal the pole (01) and the through hole, so that aliquid sealing effect is achieved.

Owner:JIANGSU JINYI NEW ENERGY TECH CO LTD

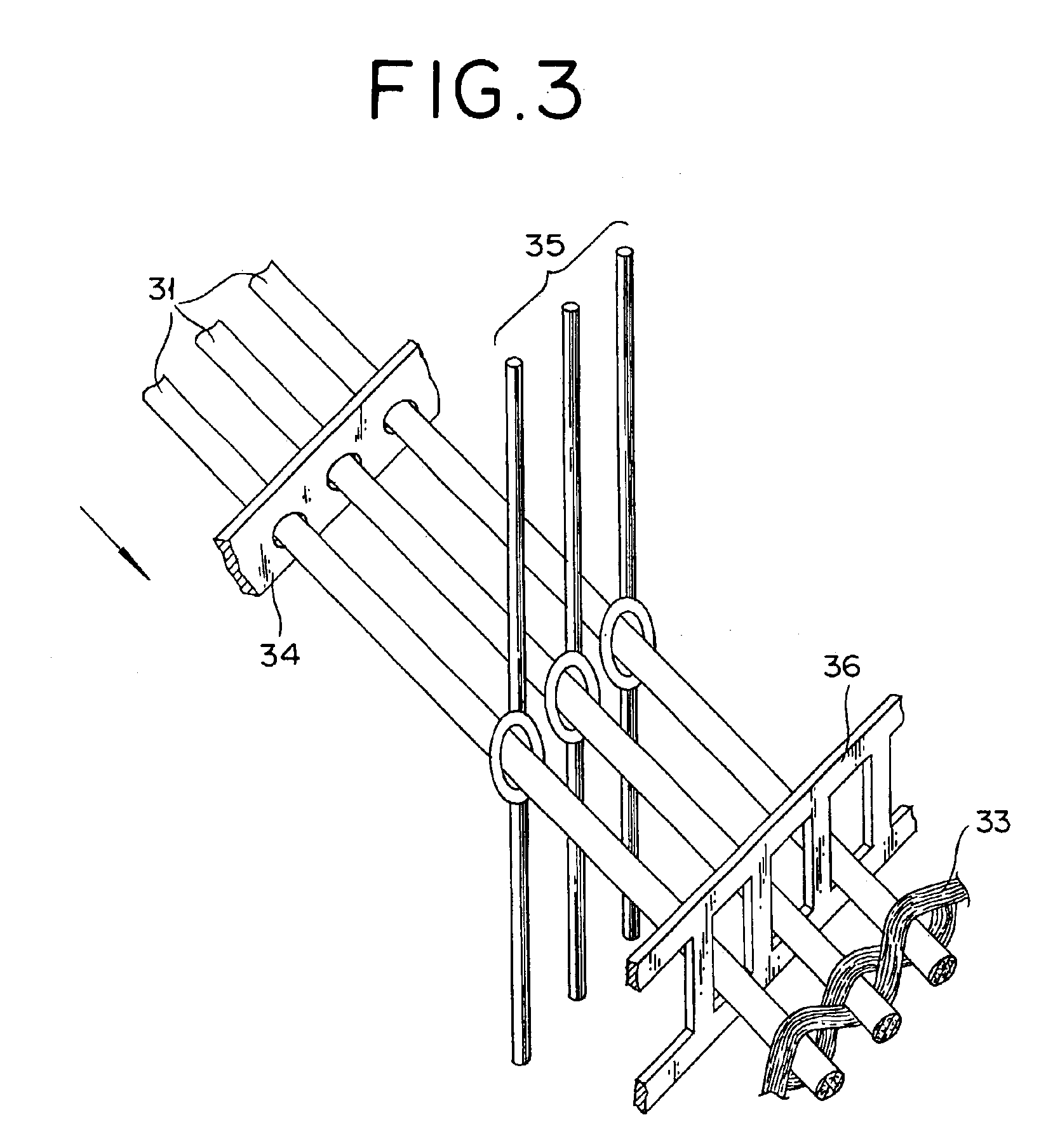

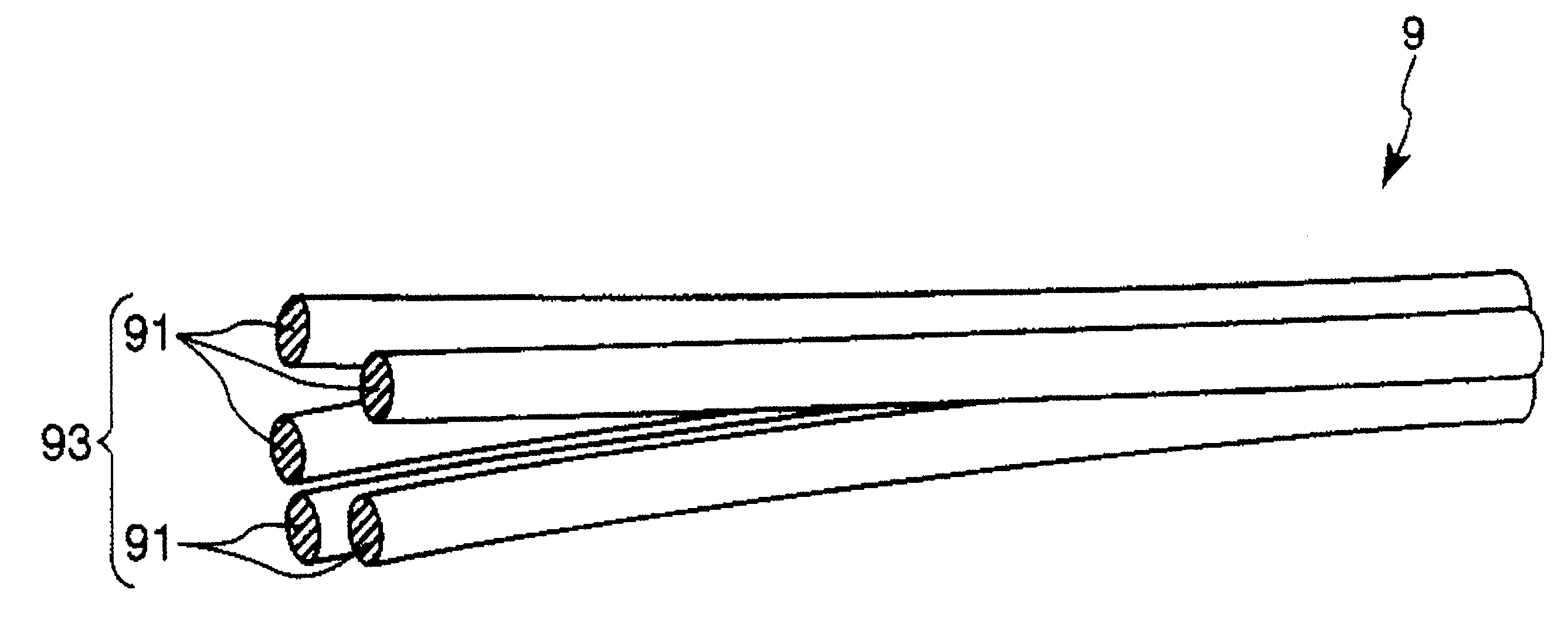

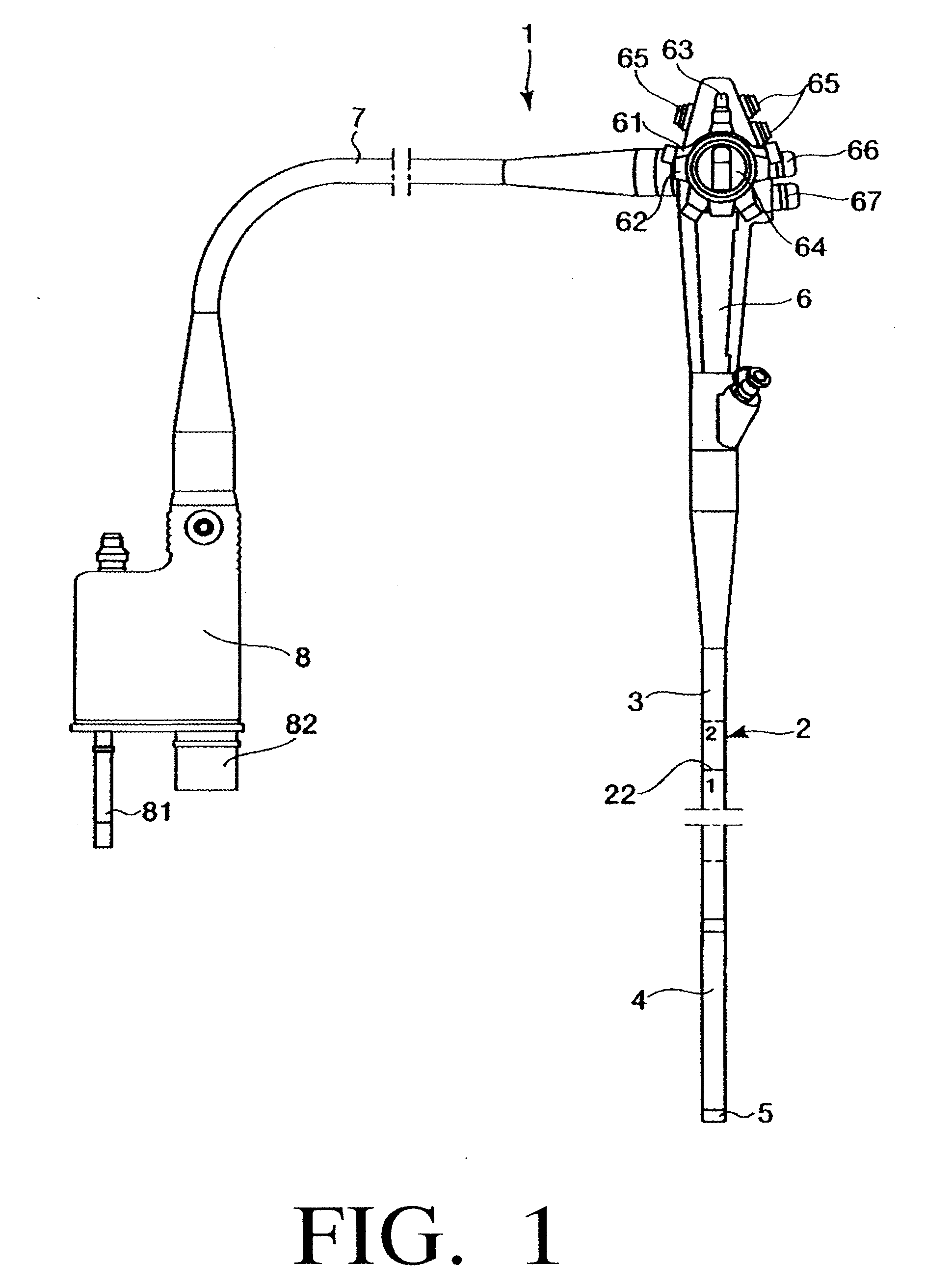

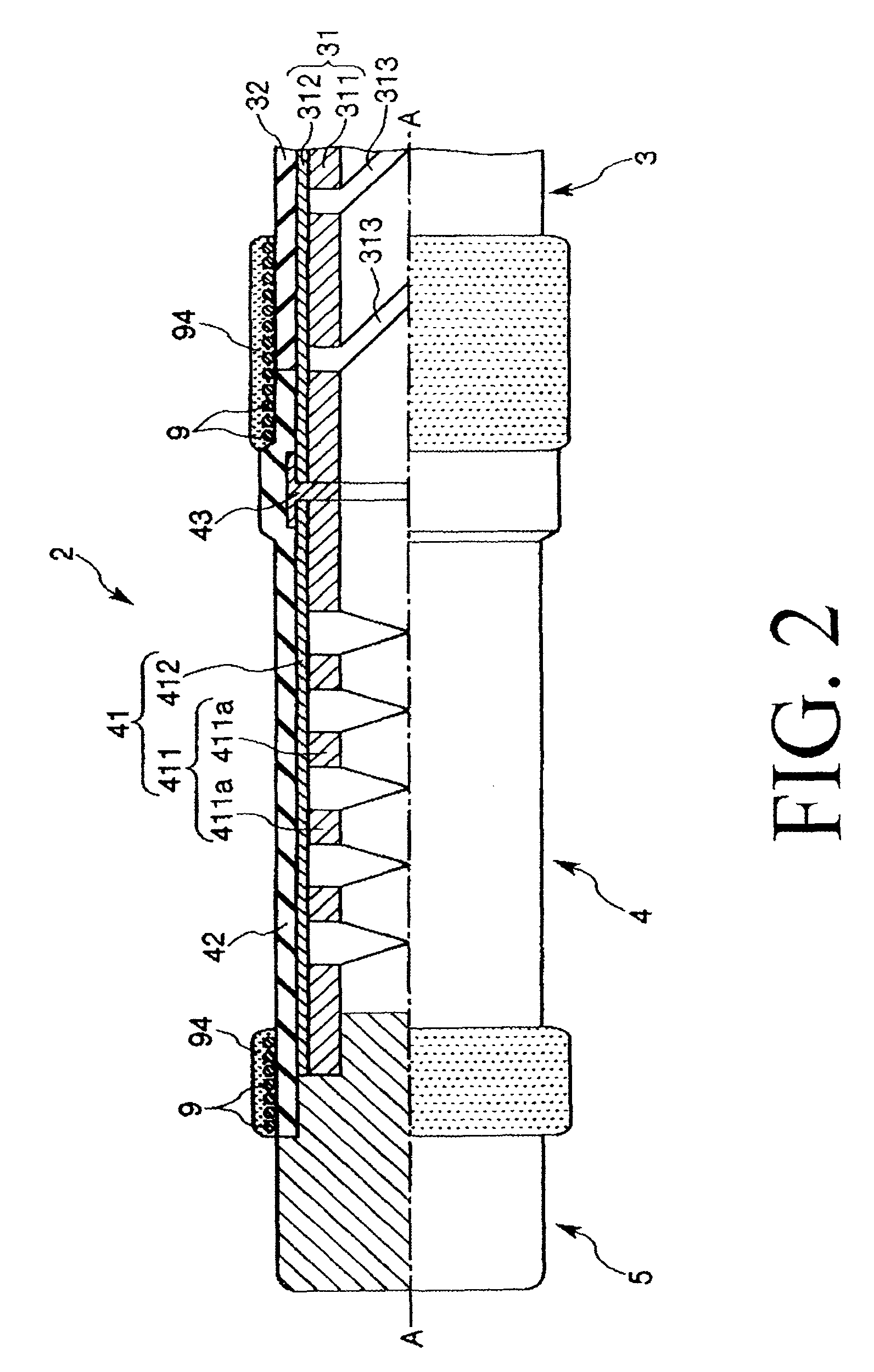

Tightening string for an endoscope, outer cover securing method, flexible tube for an endoscope, and an endoscope

A tightening string is used in an endoscope for firmly securing an outer cover of a flexible tube of the endoscope onto an internal member disposed inside the outer cover. The tightening string is comprised of a filament assembly formed by bundling a plurality of filaments made of a synthetic resin. The invention also provides an outer cover securing method, a flexible tube for an endoscope, and an endoscope equipped with the flexible tube. An outer cover securing method using the tightening string, a flexible tube for an endoscope equipped with the thus secured outer cover, and an endoscope equipped with the flexible tube are also provided.

Owner:HOYA CORP

Inking pot

InactiveCN101402197BPrevent leakageImprove liquid tightnessOther workshop equipmentCoil springEngineering

An ink fountain allows ink lines wrapped on the scroll body to contact with ink immersing components immersed with ink; uses a needle component to pierce into the surface of timber or the like objects; performs ink lines on the object surface; arranges a coil spring in the internal circumstance of the scroll body for rollback ink lines, wherein, a rotor plate for storing power for the coil springis configured to expose from the upper surface of the body; and provides a block on the rotor plate for limiting the rollback of the coil spring, wherein, the block is introduced to freely project from and fall back to the lateral surface of the rotor plate, and is blocked to a blocking dent provided on the body side through a force application apparatus. The invention provides an ink fountain inwhich the load application of coil spring of the revolution axis can be easily released only by a hand, and the ink will not stick on the fingers upon replacing the ink immersing components.

Owner:LEIYU SHANGHAI PACKAGING PROD

Spray head and spraying apparatus

ActiveUS10159992B2Easy to handleImprove frost resistanceDiaphragm valvesEngine diaphragmsEngineeringNozzle

A spray head includes a spray head base body (2) and a nozzle plate (3). The spray head base body (2) includes at least one liquid channel (4) for providing a liquid flow towards the nozzle plate (3). A drip-stop element (10) is located between the spray head base body (2) and the nozzle plate (3). The drip-stop element (10) includes at least one opening (11) being fluidly coupled with liquid channel (4) for providing a fluid flow into a space (6) between the drip-stop element (10) and the nozzle plate (3). At least a top portion (12) of the drip-stop element (10) is movably mounted within a spray head chamber (5) in order to perform a stroke movement. The top portion (12) is preloaded such that the top portion (12) rests against the nozzle plate (3) without applying any external forces to the top portion (12) and the top portion (12) is lifted off the nozzle plate (3) responsive to a liquid flow being provided through the liquid channel (4) into the space (6) between the top portion (12) and the nozzle plate (3).

Owner:HUSQVARNA AB

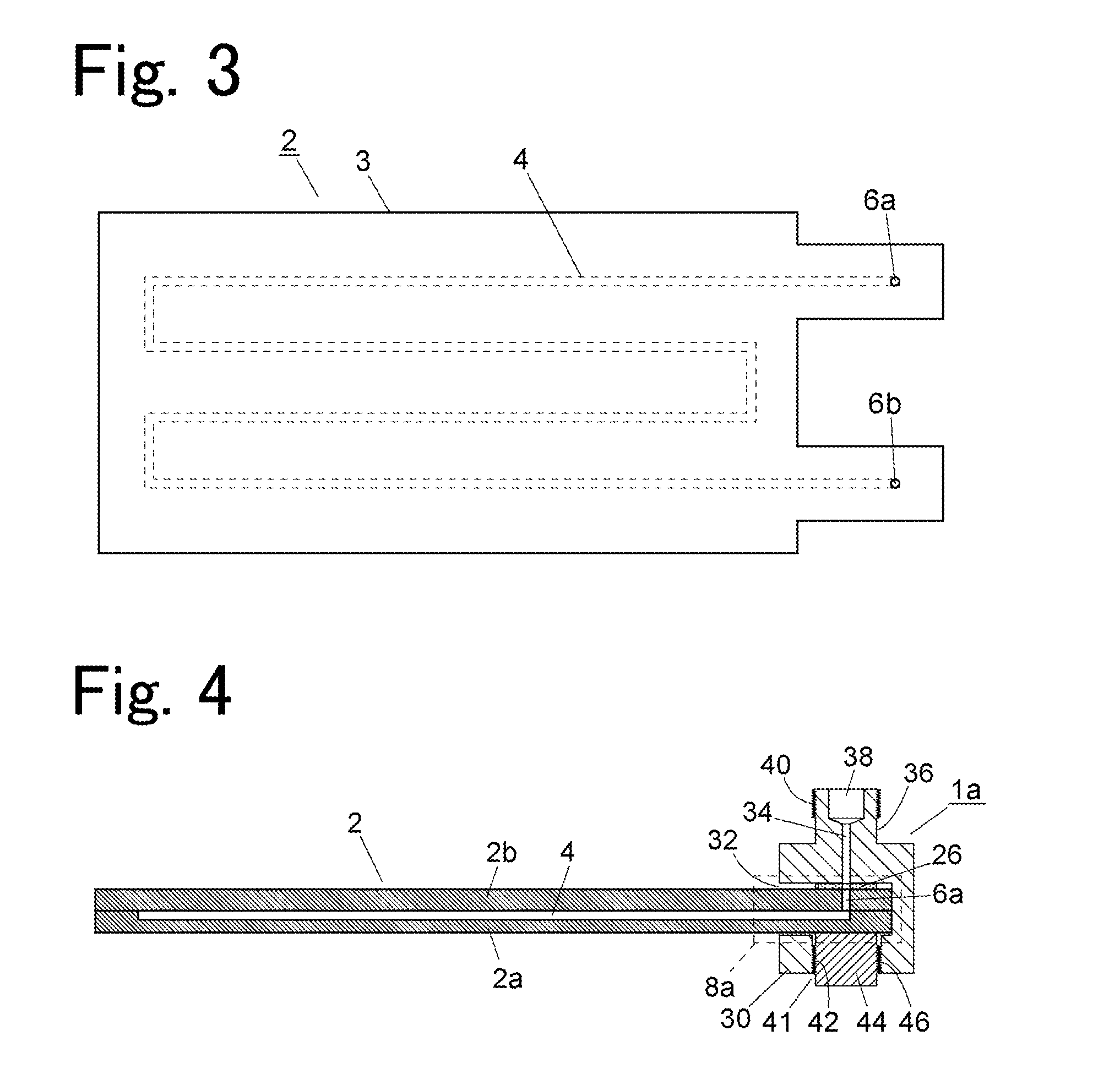

Flow channel module and chromatograph provided with the flow channel module

ActiveUS20150233872A1Reduce dead volumeImprove air tightnessComponent separationTesting waterEngineeringAir tightness

A flow channel module comprises a flow channel plate, a flow channel connection block, and a pressing mechanism. The flow channel plate is provided with a main body and a protrusion section protruding in the circumferential direction from the peripheral edge of the main body, the protrusion section having a port communicating with an inner flow channel. The flow channel connection block is provided with a concave section for being engaged with the protrusion section and having inside a port facing surface for facing the port, and an outer flow channel connection section that is connected to the port facing surface by a flow channel. The pressing mechanism is configured to press the protrusion section inserted in the concave section and the port facing surface against each other so that the flow channel and the port are connected while maintaining air tightness or liquid tightness.

Owner:SHIMADZU CORP

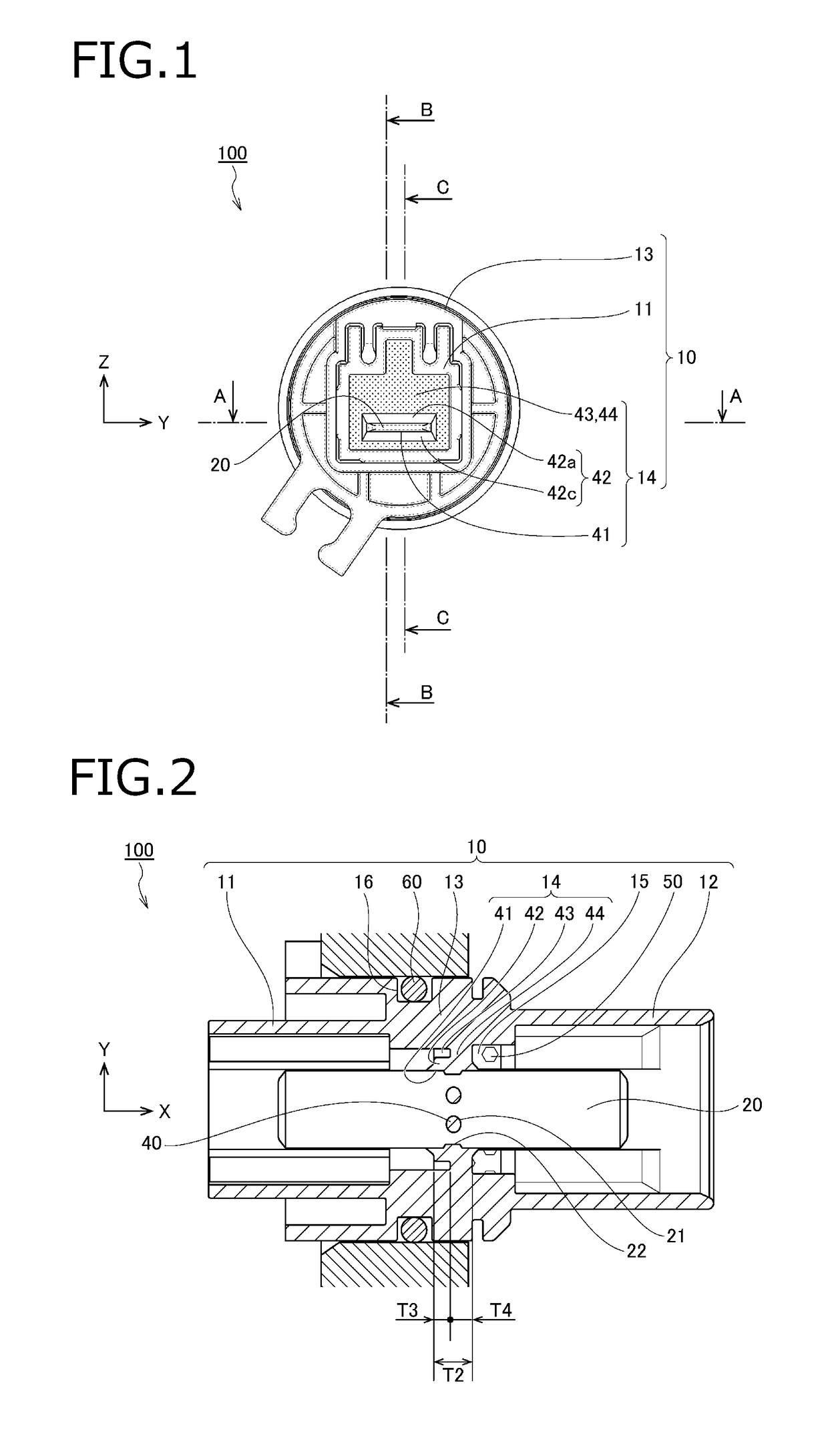

Electrical connector

ActiveUS10224667B2Improve liquid tightnessLower the volumeVehicle connectorsSwitchgear arrangementsEngineeringElectrical connector

An electrical connector includes a tubular housing having a partition wall extending in a direction perpendicular to a longitudinal direction of the tubular housing and a bus bar embedded in the partition wall of the housing in a state of penetrating the partition wall in the longitudinal direction. The partition wall is located at a substantially center in the longitudinal direction. A through hole is formed at a position of the bus bar at which the bus bar is embedded in the partition wall. A part of the partition wall is filled in the through hole. A range of the partition wall away from the position at which the bus bar is embedded in the partition wall has a thinned part.

Owner:YAZAKI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com