Inking pot

An ink fountain, ink line technology, applied in workshop equipment, manufacturing tools, etc., can solve problems such as poor ink fountain, assembly operations, increase in the number of parts, cutting, etc., to save installation and replacement effort, and reduce the number of parts. Simplify, improve safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

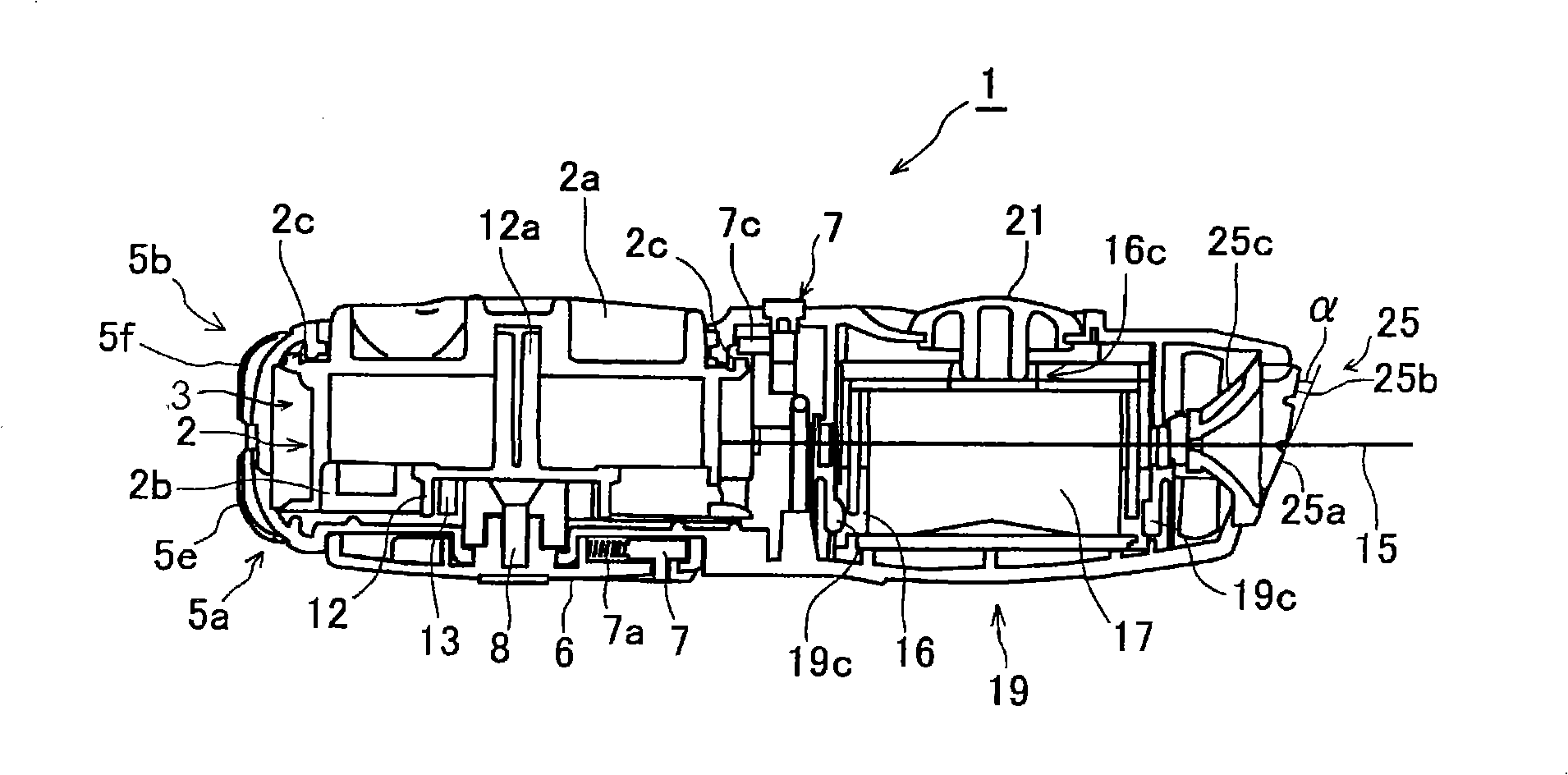

[0082] Such as figure 1 As shown, the ink fountain 1 of the present invention has a spool 3 for accommodating the spool 2 wound with an ink thread 15 at the rear, and a storage chamber 29 (ink chamber) for supplying ink to the ink thread 15 drawn out from the ink fountain 1 .

[0083] (ink thread winding shaft)

[0084] The above scroll 2 as image 3 The ink thread 15 is wound on the outer peripheral surface of the main body of the reel, and the coil spring 4 is housed in the inner periphery of the main body of the reel, and is closed by the shaft cover 5b. In addition, a holding portion 12a for holding the inner peripheral end of the above-mentioned coil spring 4 is formed on one end side, and a first ratchet 12 is rotatably mounted on the other end side to hold the inner peripheral end of the above-mentioned coil spring 4. The first ratchet 12 is formed with a Engagement recessed part 12b which engages with engagement claw 13b of the 2nd ratchet 13 mentioned later.

[008...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com