Portal crane

A gantry hoist and gantry technology, which is applied in water conservancy projects, marine engineering, coastline protection and other directions, can solve problems such as unfavorable saving of project investment, operation at work sites, and increase of project investment, etc. The effect of convenient maintenance and saving project investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

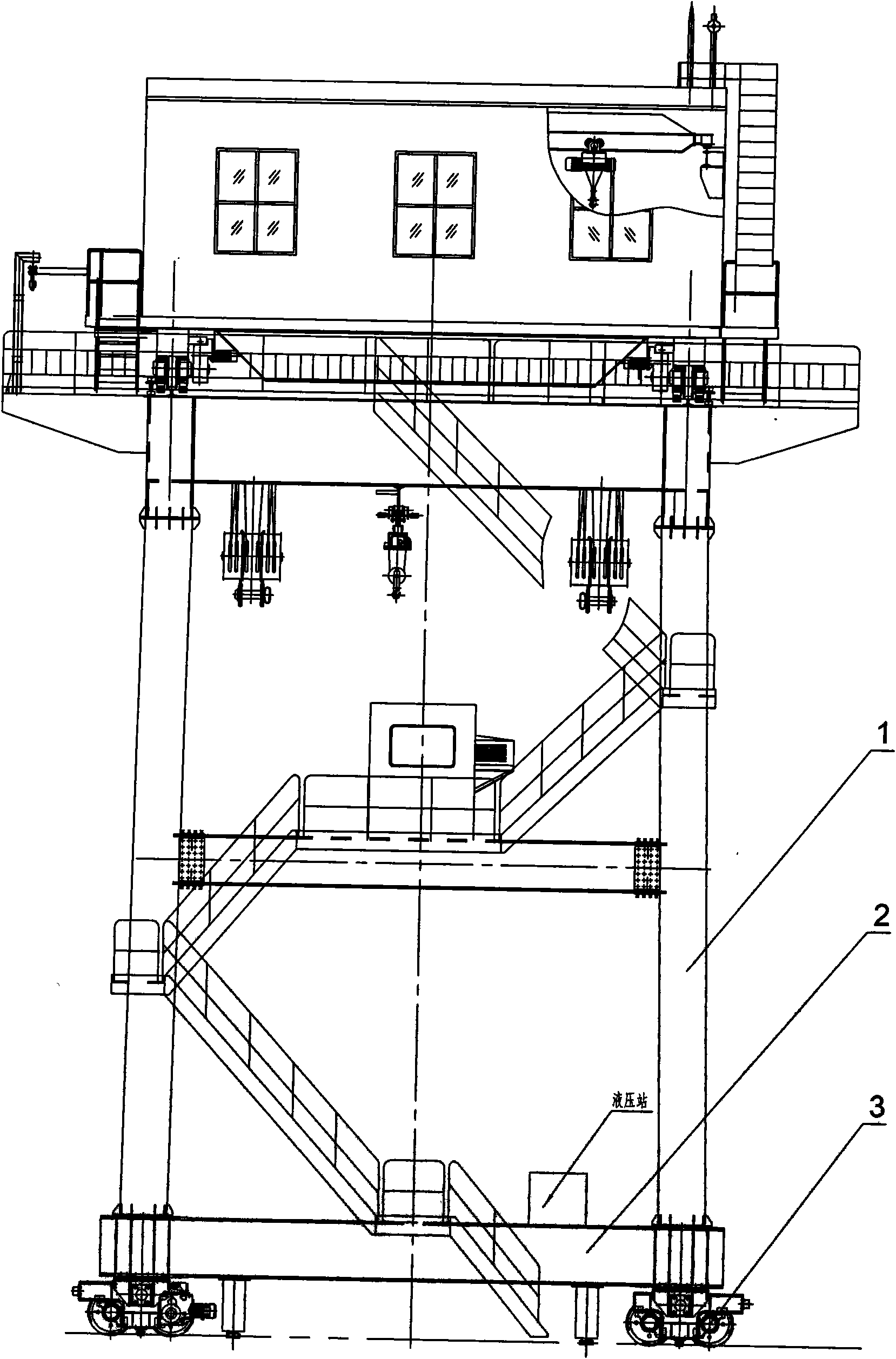

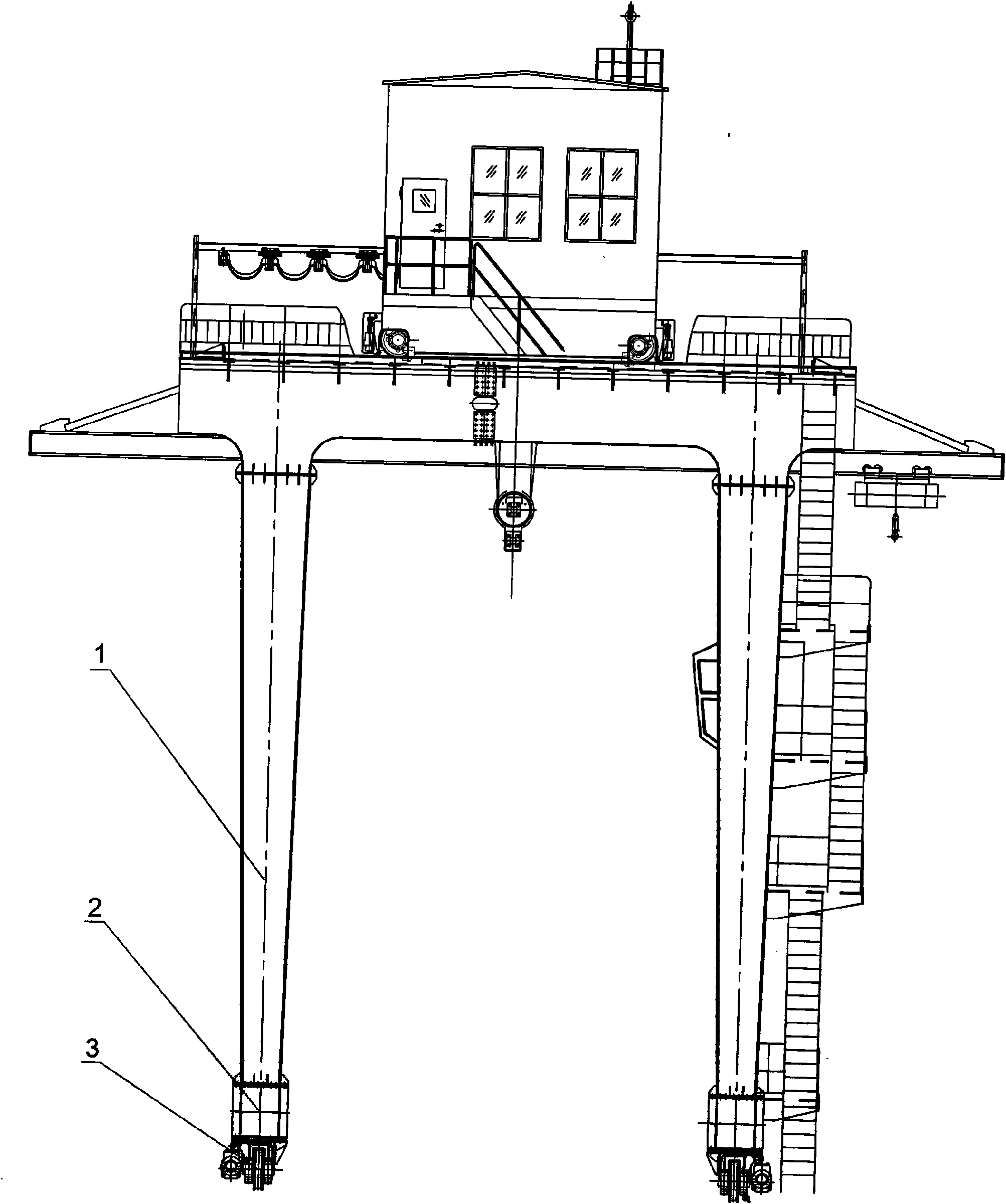

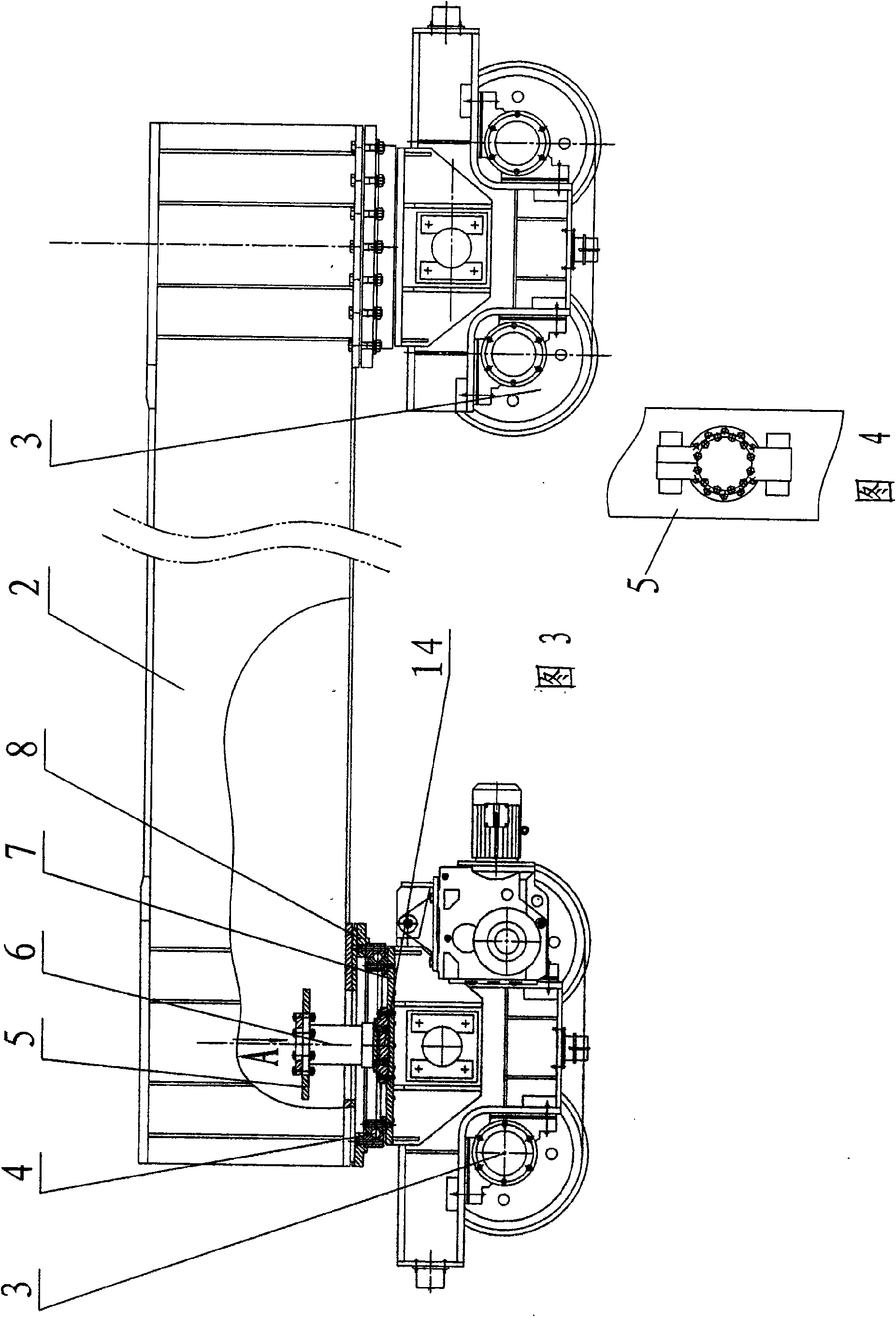

[0022] as attached figure 1 , figure 2 , image 3 , Figure 4 As shown, a gantry hoist includes a gantry 1 and a main traveling mechanism located at the bottom of the gantry 1. The gantry 1 is provided with a lifting mechanism, which adopts the prior art. The main traveling mechanism comprises 4 wheel sets 3, and the top of each wheel set 3 is provided with a top plate 7, and the top plate 7 of each wheel set 3 is provided with a slewing bearing 4. The slewing bearing 4 is a slewing bearing, its inner ring is fixedly connected with the top plate 7 of the wheel set through screws, its outer ring is connected with the connecting plate 8 through screws, and the connecting plate 8 is connected with the bottom beam 2 through bolts. The output end of the swing oil cylinder 6 is fixedly connected with the top plate 7 through the connecting plate 14 , and its cylinder body is fixed on the bottom beam 2 through the connecting steel plate 5 .

[0023] Under the action of pressure o...

Embodiment 2

[0029] as attached figure 1 , figure 2 , Figure 5 , Figure 6 As shown, this embodiment is basically the same as Embodiment 1, except that the rotary mechanism in this embodiment adopts a structure in which a reciprocating mechanism drives a link mechanism to move. Its rotary mechanism comprises hydraulic oil cylinder 11, connecting rod 10 and rotary shaft 9. One end of the rotary shaft 9 is fixedly connected with the top plate 7 of the wheel set 3 , the other end is connected with the connecting rod 10 , the cylinder body of the hydraulic cylinder 11 is fixedly connected with the bottom beam 2 , and its cylinder rod is connected with the connecting rod 10 . In this embodiment, through the reciprocating motion of the hydraulic cylinder, the connecting rod 10 and the rotary shaft 9 connected thereto are driven to rotate, thereby driving the wheel set to rotate, and realizing the steering of the main traveling mechanism of the gantry hoist. In this embodiment, the reciproc...

Embodiment 3

[0032] as attached figure 1 , figure 2 , Figure 7 , Figure 8 As shown, this embodiment is basically the same as Embodiment 1, except that the outer ring of the slewing support 4 in this embodiment is a gear-type structure. The inner ring of the slewing support 4 is fixedly connected to the connecting plate 8 by screws, and its outer ring is fixedly connected to the top plate 7 by screws. The outer ring of the slewing bearing 4 is driven by a rack 12 meshed with its gear teeth. The rack 12 is connected with the cylinder rod of the hydraulic cylinder 11, and the cylinder body of the hydraulic cylinder 11 is fixed on the bottom beam 2.

[0033] In this embodiment, the rack 12 reciprocates under the action of the cylinder rod of the hydraulic cylinder 11, driving the outer ring of the slewing bearing 4 to rotate, thereby driving the wheel set 3 to rotate, and realizing the steering of the main traveling mechanism of the door machine.

[0034] In this embodiment, the mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com