Echelon cradle as well as construction method thereof

A trapezoidal and hanging technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of high anchor bar embedding accuracy, complex anti-tension support design, low slideway reuse rate, etc., to achieve hanging basket Safe running, less embedding process, less pre-embedded reinforcement materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

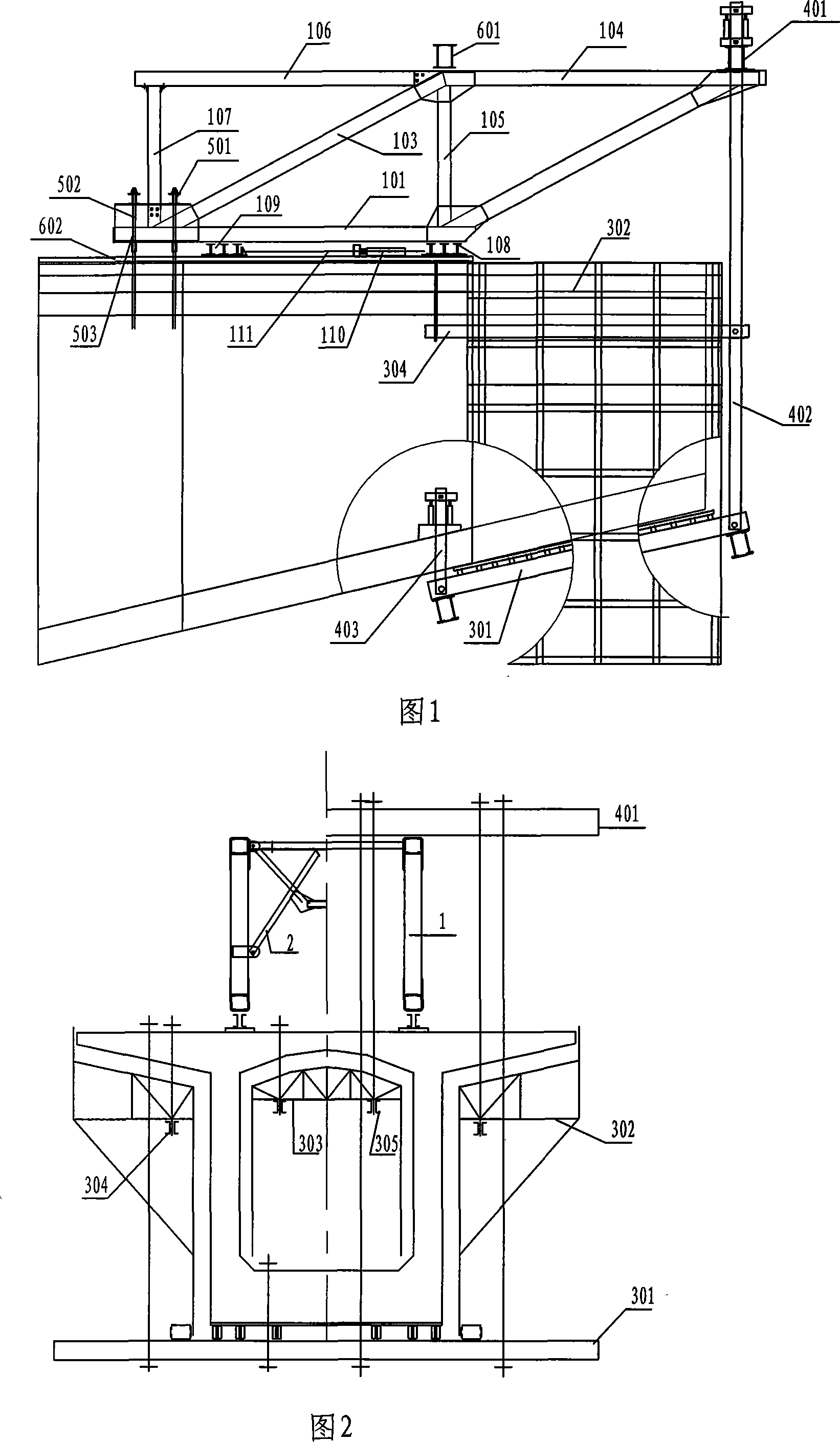

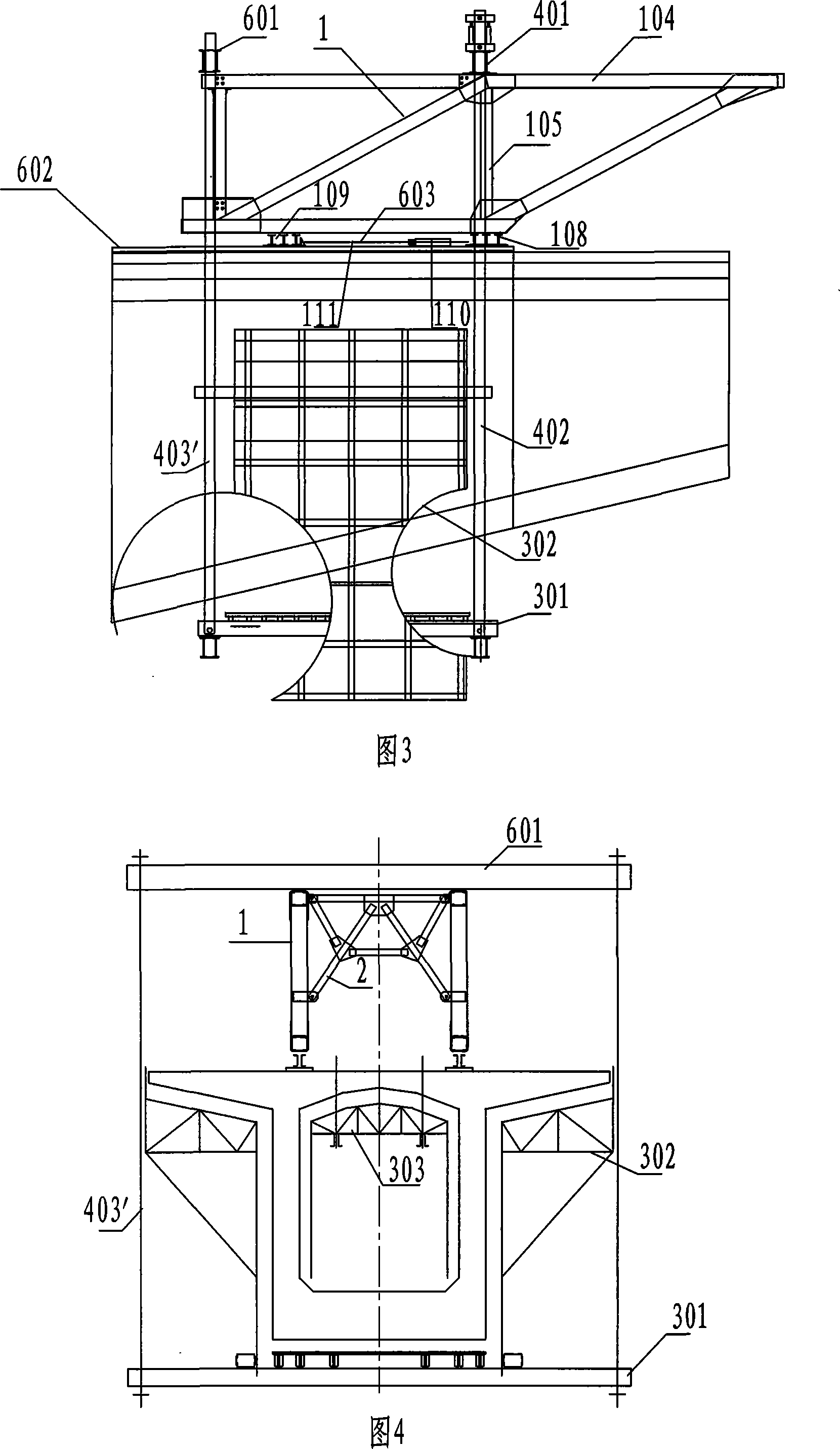

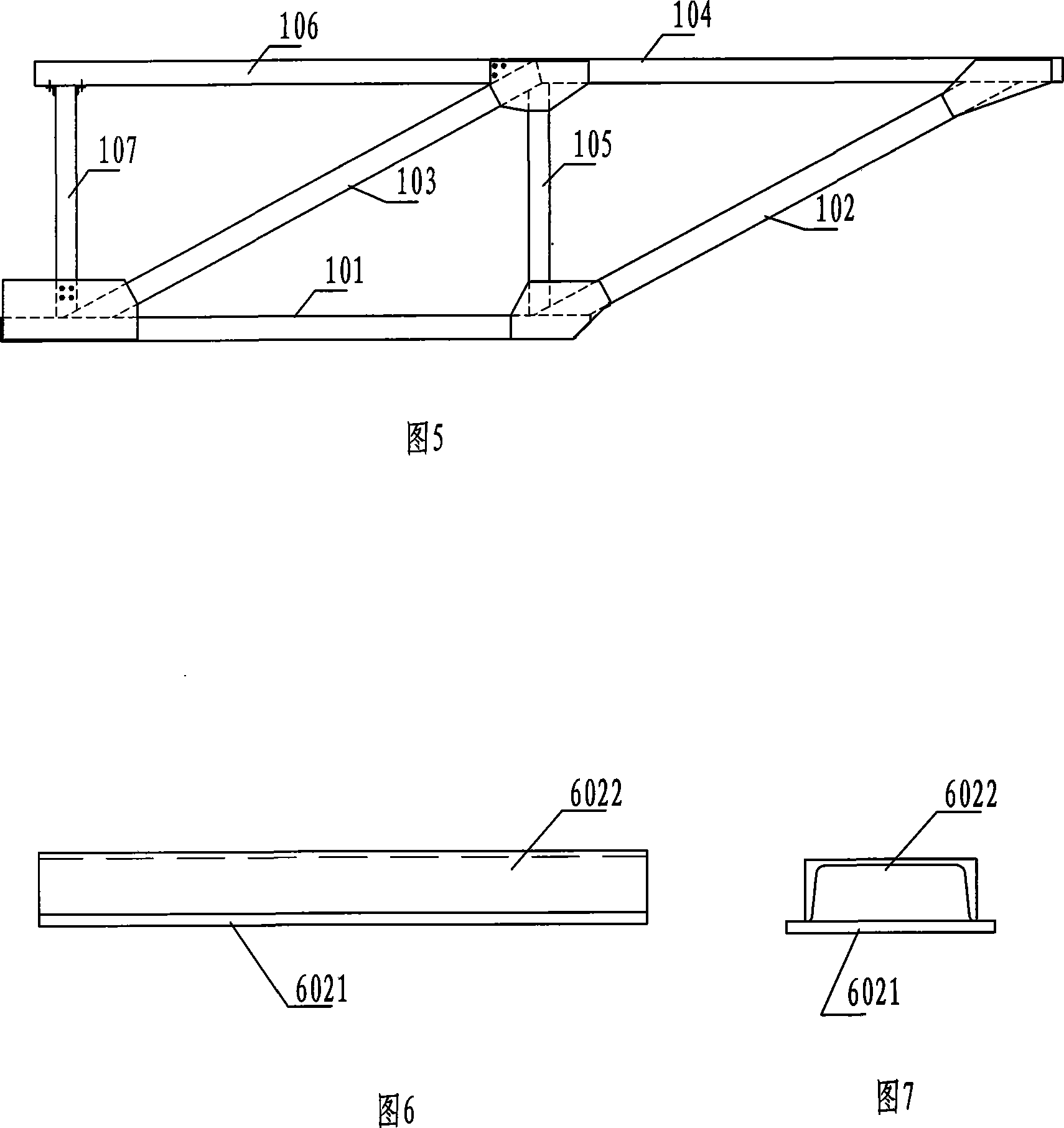

[0022] In the concrete pouring state shown in Figures 1 and 2, the trapezoidal hanging basket is composed of the main girder 1, the connecting system 2, the bottom form platform 301 and its suspension, the inner formwork and its support 303, the outer formwork and its support 302 and the suspension. The main girder 1 is generally arranged at the corresponding position of the web of the cantilevered box girder, the main girder 1 is connected by the connecting system 2, and the front of the lower chord 101 of the main girder 1 is set The support 108 and the rear anchorage system 5 are installed at the end of the lower chord 101. The rear anchor distribution beam 501 is placed above the lower chord 101 of the main truss, and the position of the distribution beam 501 can be adjusted forward and backward; the anchor bar 502 is directly anchored to the poured beam through the connector 503 In general, the position of the anchor rib 502 can be adjusted left and right while the distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com