Full-automatic double-station device for spraying paint on outer surfaces of cast iron pipes

A kind of painting equipment and double-station technology, which is applied in the direction of spraying device, coating, and surface coating liquid device, etc., which can solve the problem of operator safety and health, uneven painting thickness of cast iron pipes, and reduce the use of cast iron pipes Life and other issues, achieve beautiful equipment, solve uneven painting, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the purpose, technical solutions and advantages of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings of the specification. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

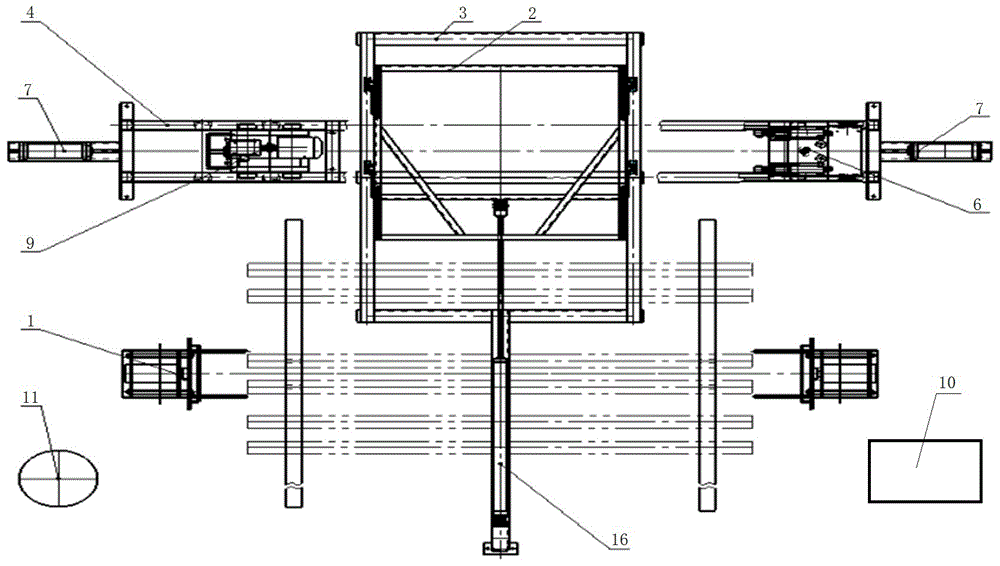

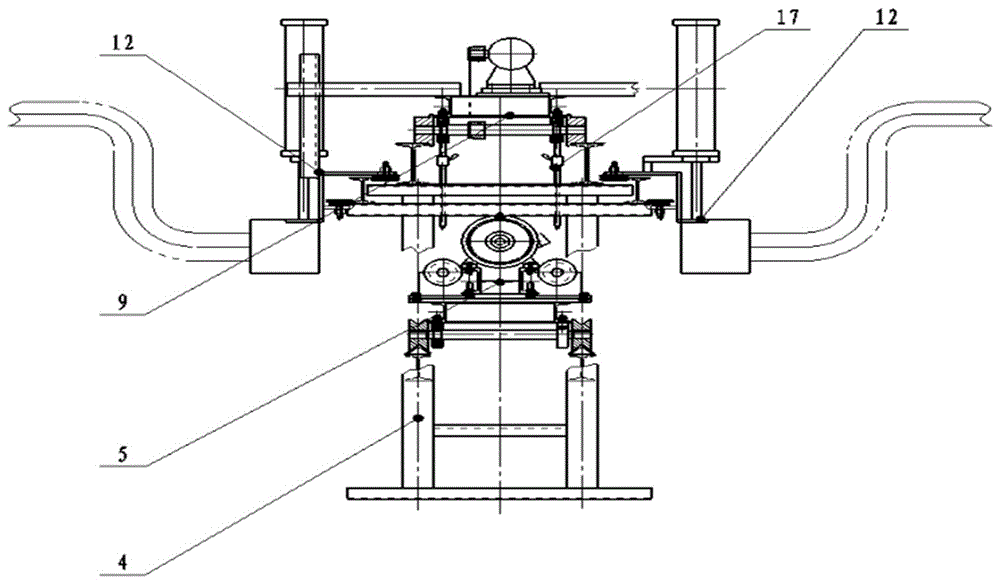

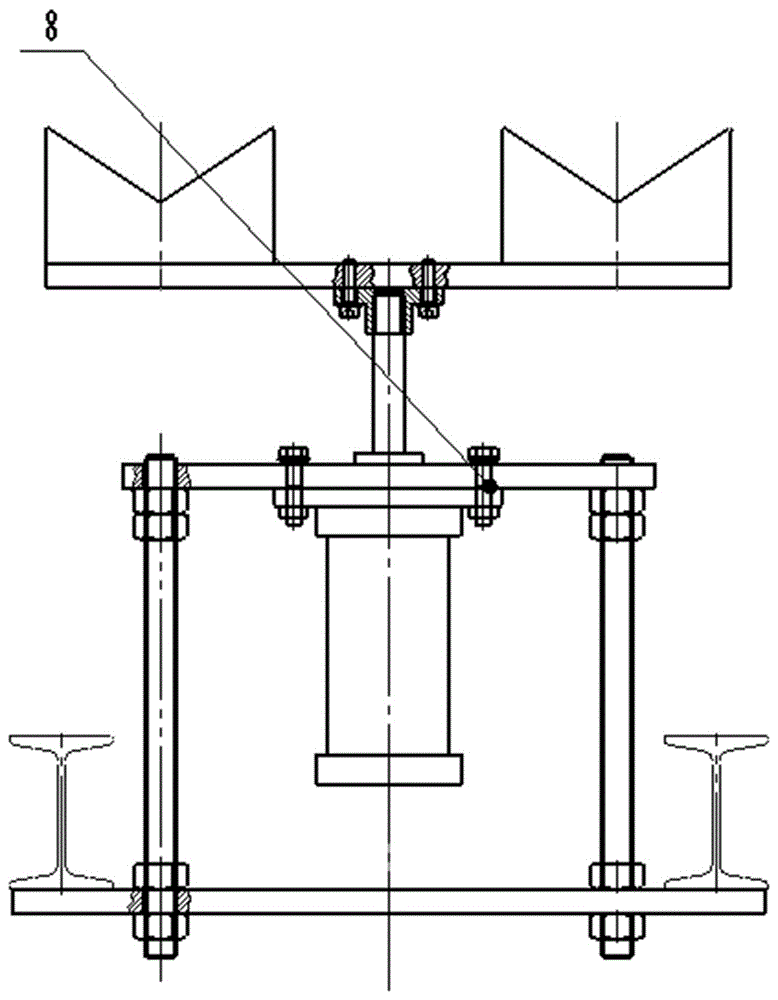

[0032] A full-automatic double-station cast iron pipe exterior painting equipment, such as figure 1 , figure 2 , image 3 As shown, the bracket 4 is an independent integrated bracket, the upper part of the bracket 4 is the walking rail of the painting trolley 9 and the dust removal trolley 12, the middle part is the main top trolley 5 and the top trolley 6 walking rails, and the bracket 4 is connected to the ground by anchor bolts , Fixed after adjusting the level. The cylinder in the pneumatic device 7 is fixed at the tails of the main center trolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com