A kind of preparation method of color steel plate

A technology of color steel plate and metal substrate, which is applied to the surface coating liquid device, pretreatment surface, spraying device, etc., which can solve the problems of uneven spraying paint, inconvenient clamping, and lack of paint spraying, etc., to achieve the goal of spraying paint The effect of uniform thickness, faster processing speed and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

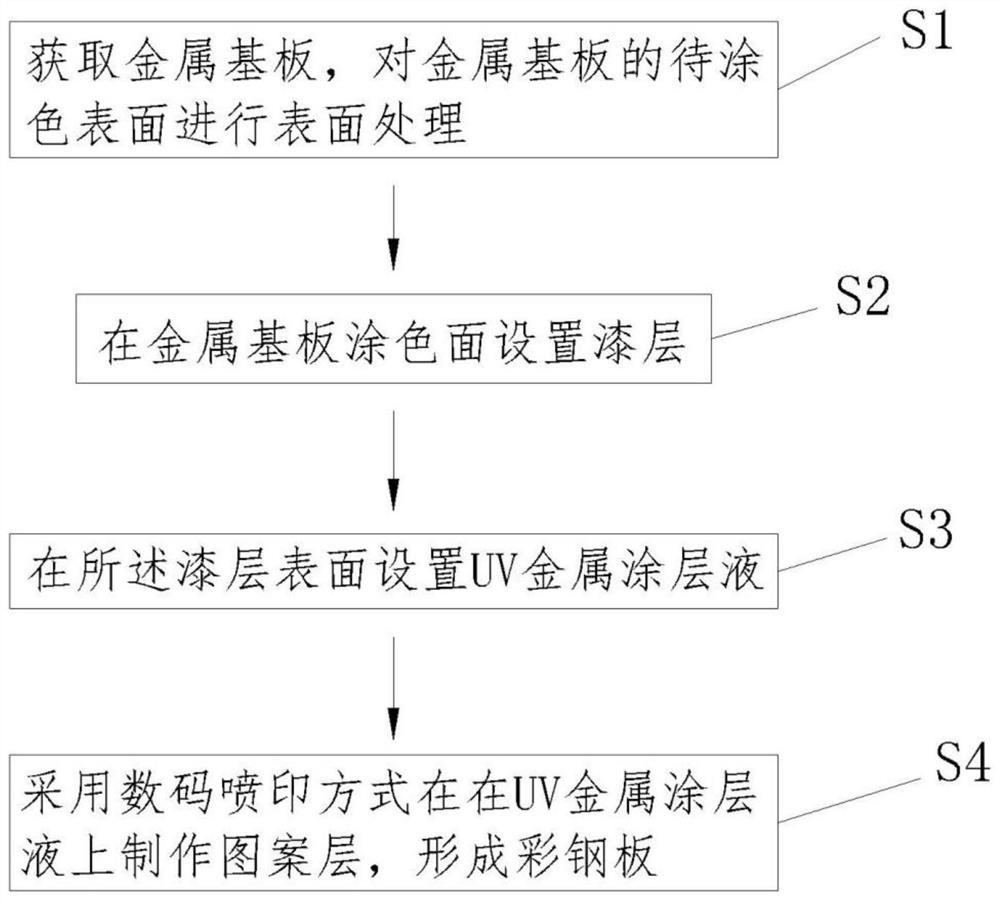

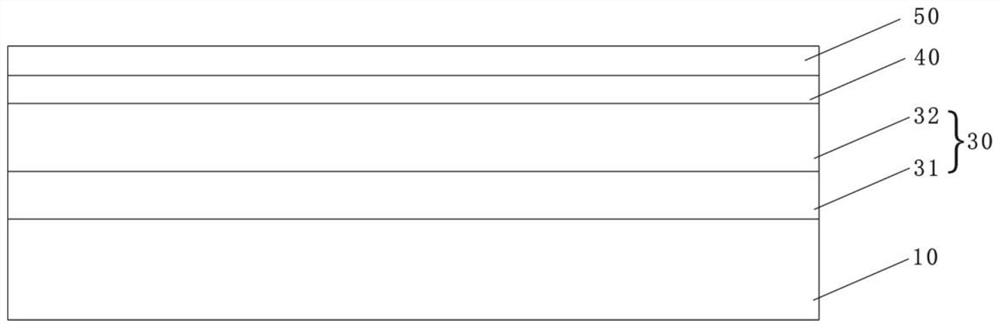

[0048] Please refer to Figure 1 to Figure 2 A preparation method for a color steel plate is shown, comprising the following steps:

[0049] S1: Obtain the metal substrate 10, and perform surface treatment on the surface of the metal substrate 10 to be painted; the surface treatment includes degreasing and cleaning the surface of the metal substrate 10, cleaning the scale layer, and passivating the surface to be painted to increase the metal The roughness of the surface of the substrate 10 improves the adhesion between the metal substrate 10 and the paint layer 30 . Wherein, the type of the metal substrate 10 is not particularly limited, and any base material generally used in the manufacturing process of the color steel plate can be used. For example, the metal substrate 10 may be a hot-dip galvanized sheet, an electro-galvanized sheet, a stainless steel sheet, or the like.

[0050] It should be noted that the surface treatment described in S1 includes cleaning the metal su...

Embodiment 2

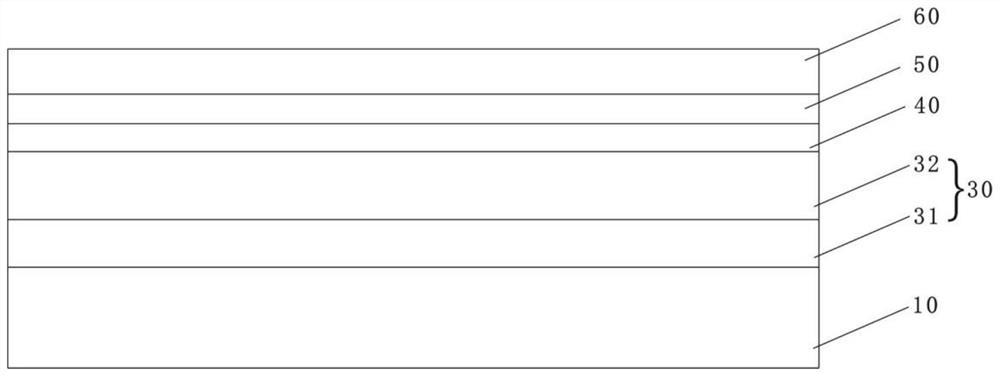

[0073] Such as image 3 As shown, the structure of the color steel plate of this embodiment is basically the same as that of Embodiment 1, the difference is that the color steel plate of this embodiment is provided with a finishing paint 60 on the surface of S4.

[0074] It should be noted that the varnish 60 is incompatible with the UV metal coating solution 40 , and is a transparent non-yellowing varnish resistant to chemical corrosion and ultraviolet rays.

[0075] Based on the technical scheme that has used varnish 60, compare embodiment one and have following progress:

[0076] 1. T-bend: There is no cracking or peeling off of the surface film layer at the lower bend after the sample is continuously bent 3 times to reach 3T.

[0077] 2. MEK wiping: Use a rag soaked in liquid MEK solvent to wipe back and forth 100 times in the cleaned unit area, and the coating surface does not fall off.

Embodiment 3

[0079] Such as Figure 4 As shown, the color steel plate structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the paint layer 30 in S2 is a single-layer paint that increases the adhesion of the pattern layer 50 and provides a base color for the pattern layer 50 , and the thickness of the single-layer paint is 25 μm.

[0080] It should be noted that in this embodiment, the surface-treated metal substrate 10 is directly coated with a colored paint layer 30 after drying, and the paint layer 30 is dried after the roller coating is completed. Or spray the UV optical adhesive and then roll the paint layer 30 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com