A trajectory planning method for over-span spraying of a cable-parallel robot for ships

A trajectory planning and robot technology, applied in the field of machinery, can solve the problems of high-altitude work painting efficiency, health damage, etc., and achieve the effects of high spraying efficiency, uniform spraying thickness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

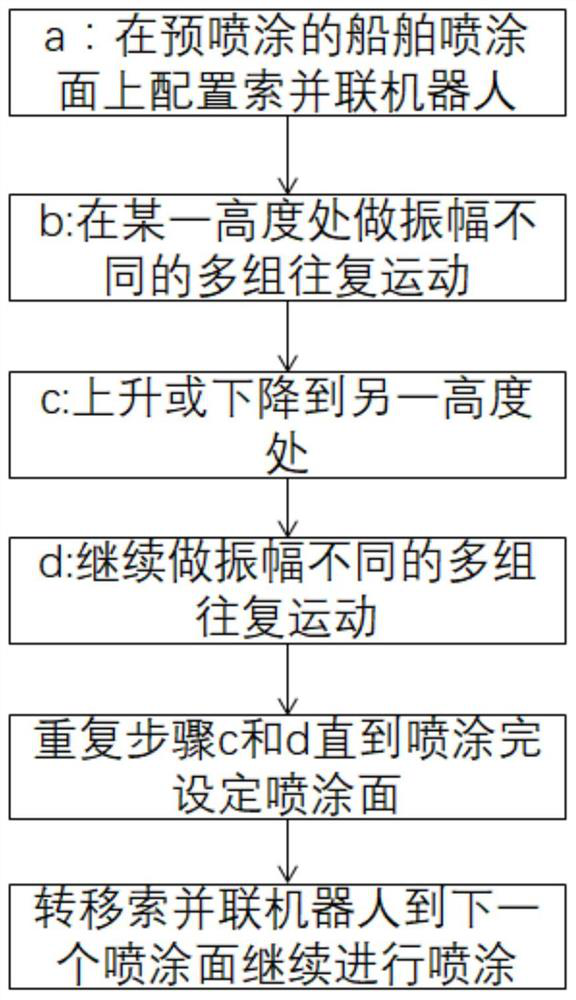

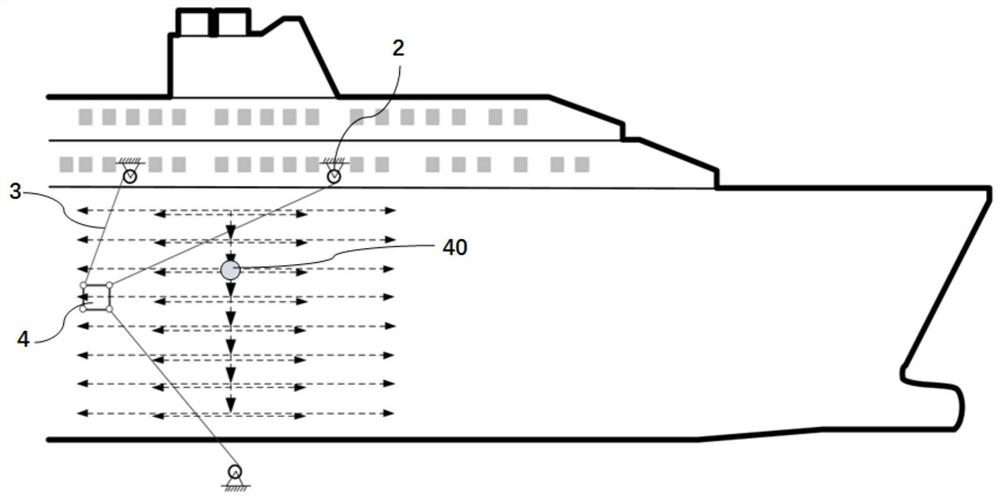

[0023] Such as figure 1 and 2 As shown, a cable parallel robot super-span spraying trajectory planning method for ships is characterized in that it comprises the following steps:

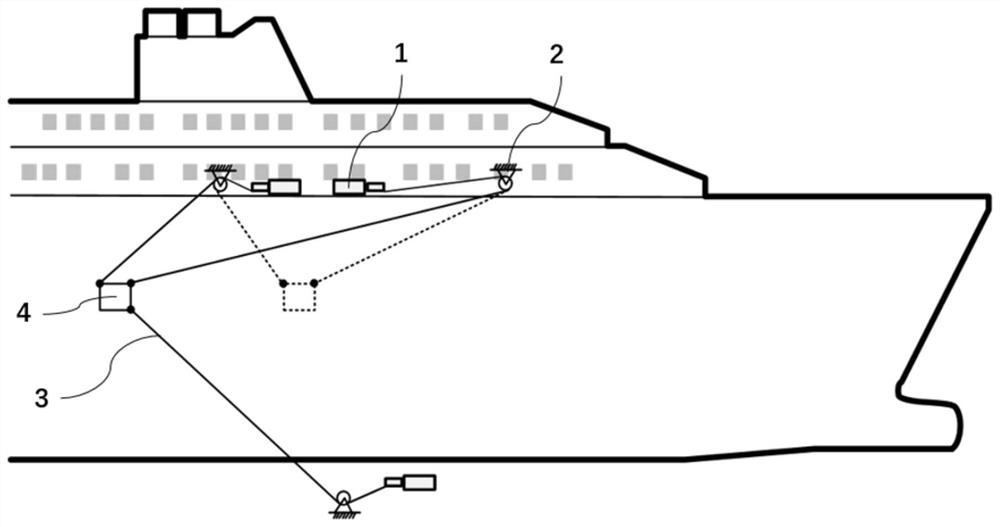

[0024] (a) configure the cable parallel robot on the pre-sprayed ship spraying surface 100; the robot includes a driving device 1, a pulley 2, a rope 3, and an end effector 4; the driving device 1 is provided with multiple groups; the driving device can be provided with multiple groups Groups can be two groups, three groups, four groups, five groups, etc., three groups are shown in the figure, Figure 3-5 The middle driving device is not shown; each group includes a motor, a shaft coupling, a reducer and a drum; one end of the rope 3 is connected to the end effector 4, and the other end is connected to a drum of a driving device 1 respectively, through The work of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com