Treating liquid feed device

A technology for supplying devices and processing liquids, which is applied in the fields of cleaning methods using liquids, electrical components, and semiconductor/solid-state device manufacturing. It can solve problems such as leakage, improve processing efficiency, suppress leakage, and reduce processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The processing liquid supply device of the present invention is configured as follows: it is installed in the middle of a transport path for transporting a substrate in a horizontal posture, supplies the processing liquid countercurrently from the upper and lower housings to the front and back of the substrate to the substrate being transported, and performs a predetermined process, and The processed treatment liquid can be recovered through the upper and lower housings, that is, it is an improved device of the treatment liquid recovery type.

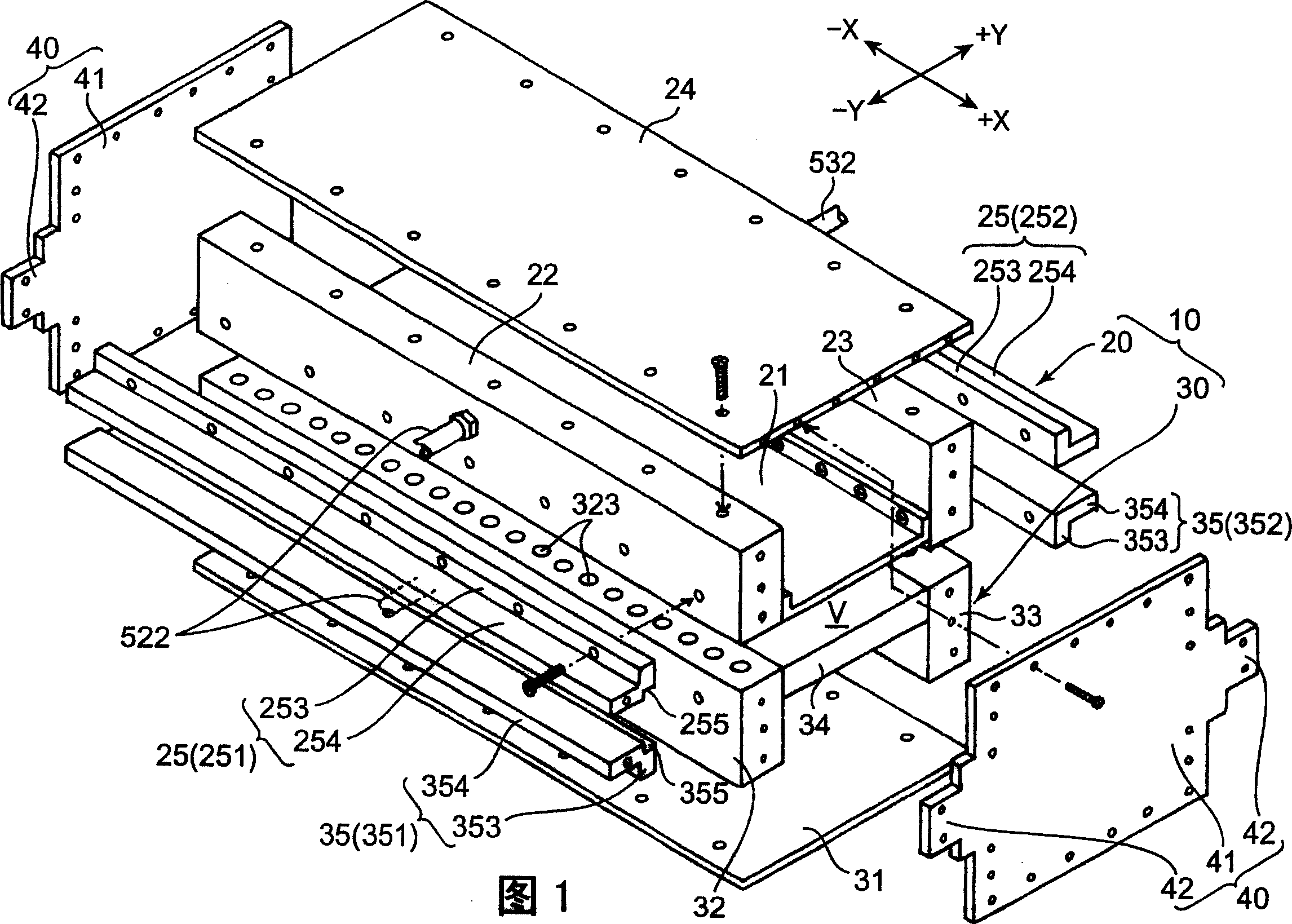

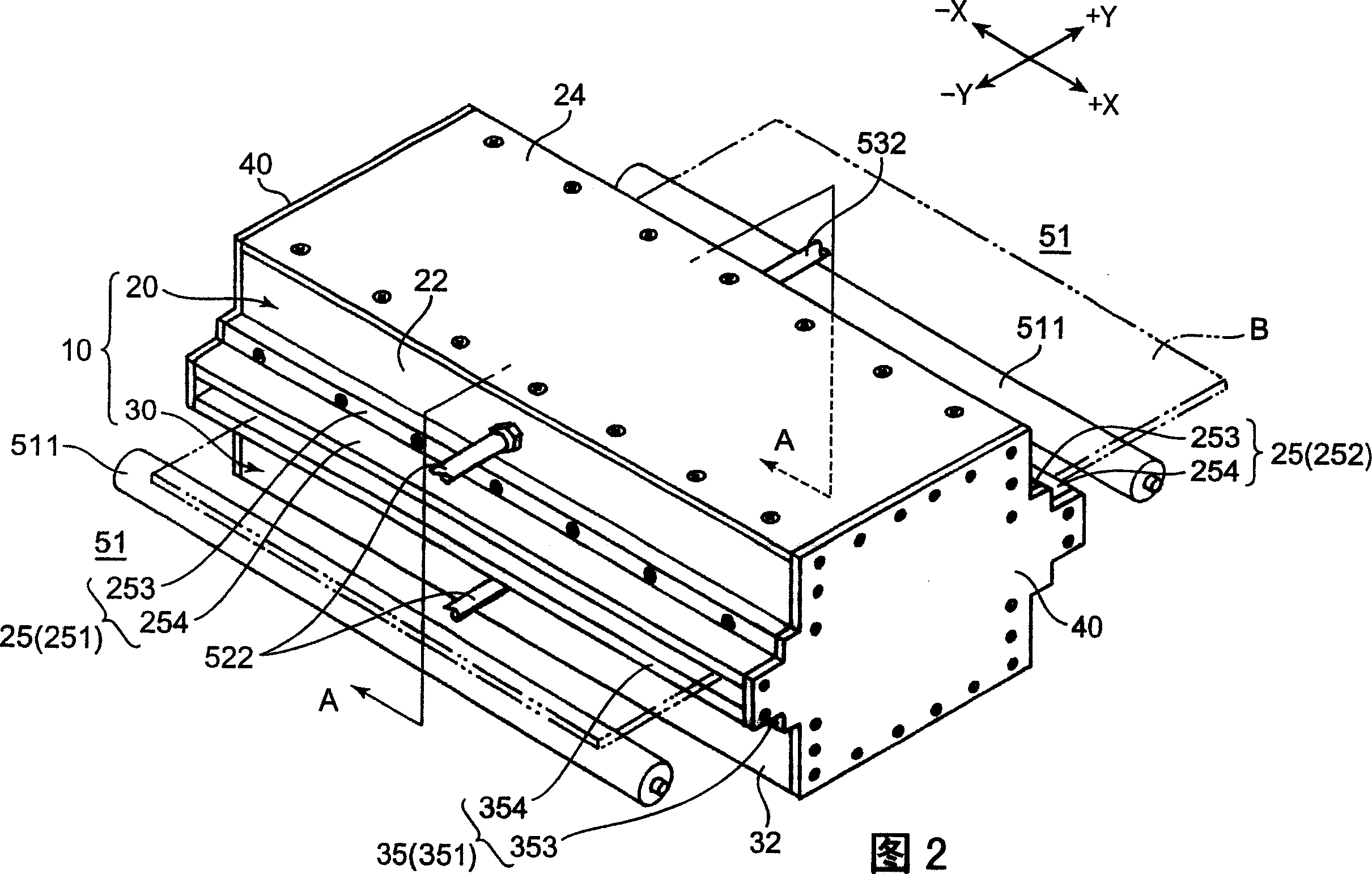

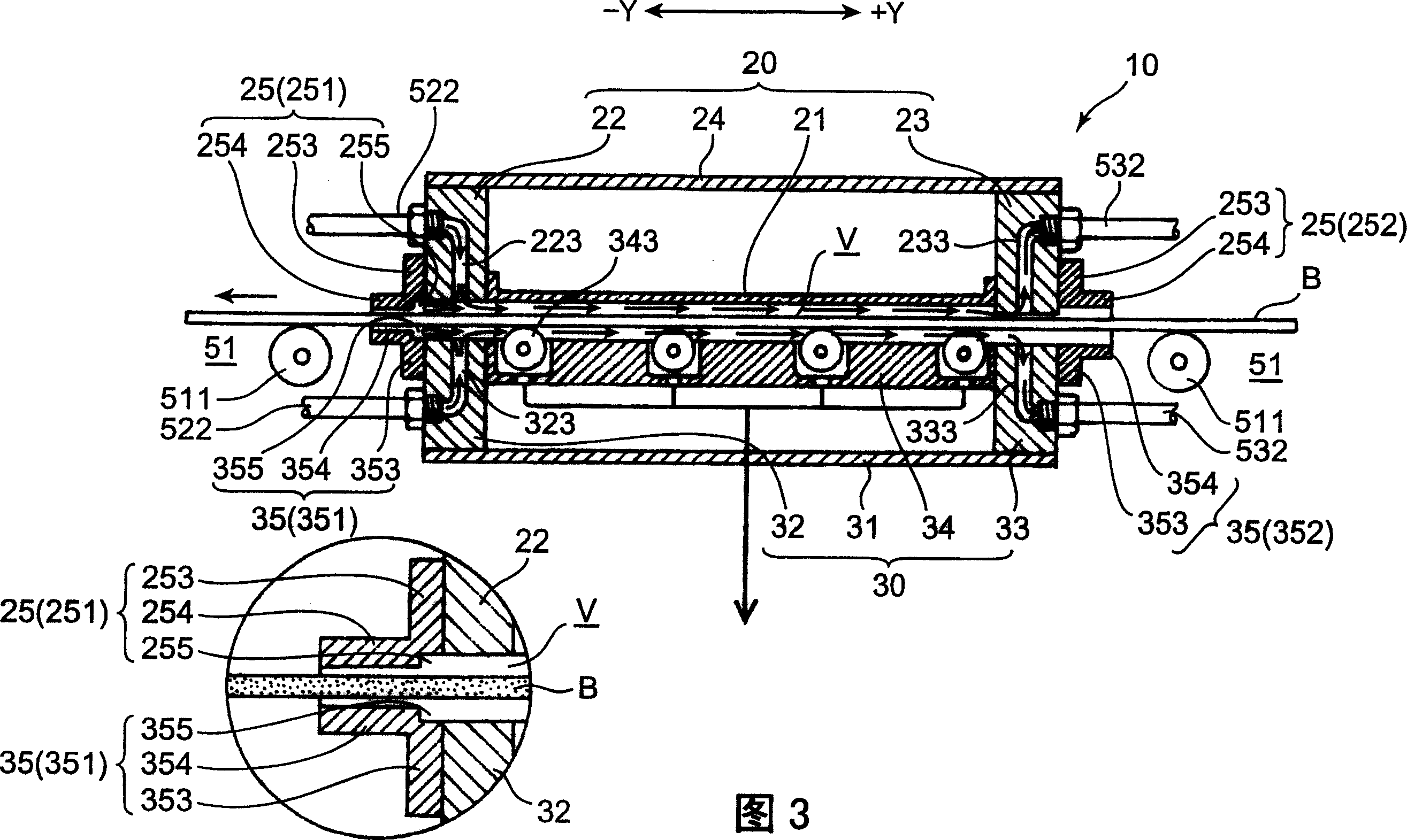

[0034] FIG. 1 is an exploded perspective view showing one embodiment of the processing liquid supply device of the present invention, and FIG. 2 is an assembled perspective view. In addition, FIG. 3 is a sectional view taken along line A-A of FIG. 2 . In addition, the front upper wing 251 and the front lower wing 351 are shown enlarged within the circle in FIG. 3 . Incidentally, these figures are all so-called schematic diagrams...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com