Overall long-distance pushing slippage construction method for large-span bridge box girder structure of large-span bridge

A technology of large-span bridges and construction methods, which is applied in bridge engineering construction and elevated fields to achieve the effect of ensuring stability and safety and avoiding influences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

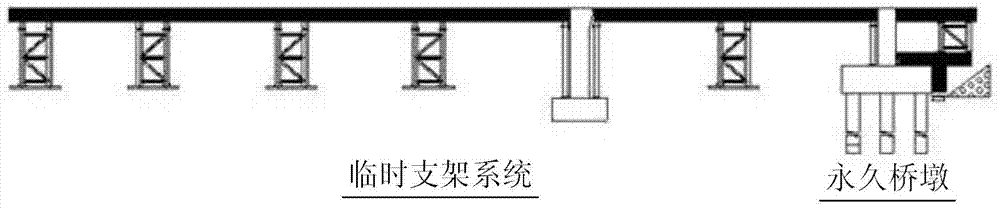

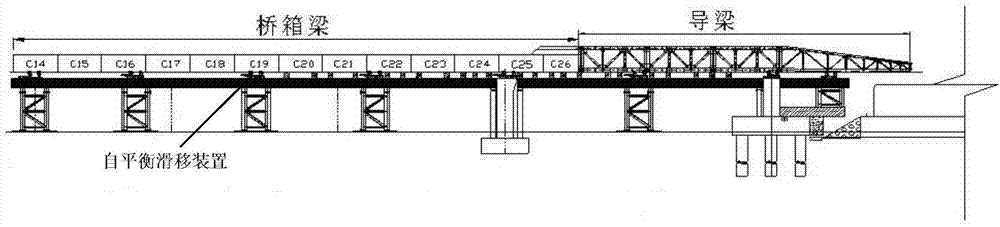

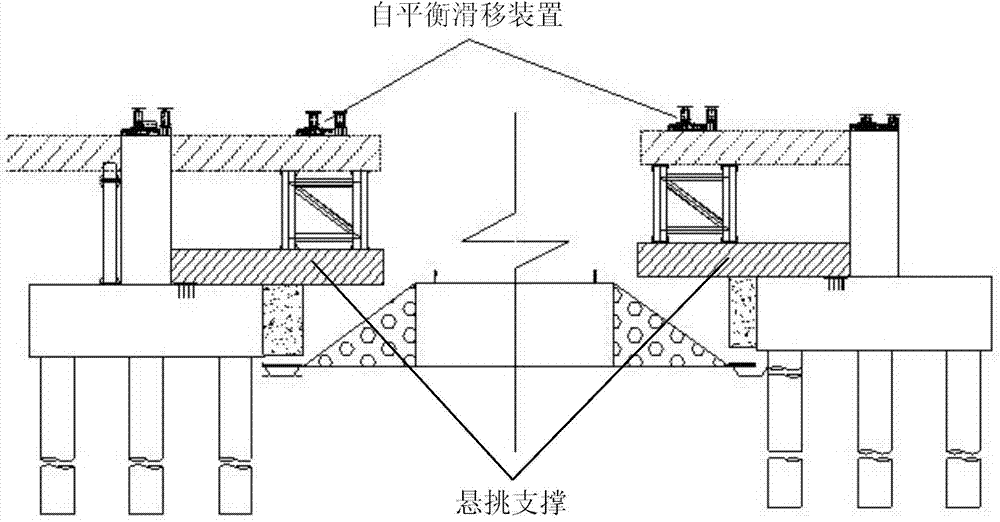

[0030] The overall long-distance pushing and sliding construction method of the long-span bridge box girder structure proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that the drawings are all in a very simplified form and use imprecise ratios, which are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0031] The core idea of the present invention is to provide a long-distance jacking and sliding construction method for the whole long-distance box girder structure of a long-span bridge, which can be used when the topographic conditions of the construction site are special, or the construction work cannot be carried out under the span of the box girder structure of a long-span bridge , us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com