Sinter quality prediction method based on process parameters

A technology for quality prediction and process parameters, applied in prediction, data processing applications, instruments, etc., can solve problems such as single process parameters, local infinitesimal generalization, and failure to consider the influence of the quality of sinter physical performance indicators parameters, etc. The effect of high prediction accuracy and strong generalization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

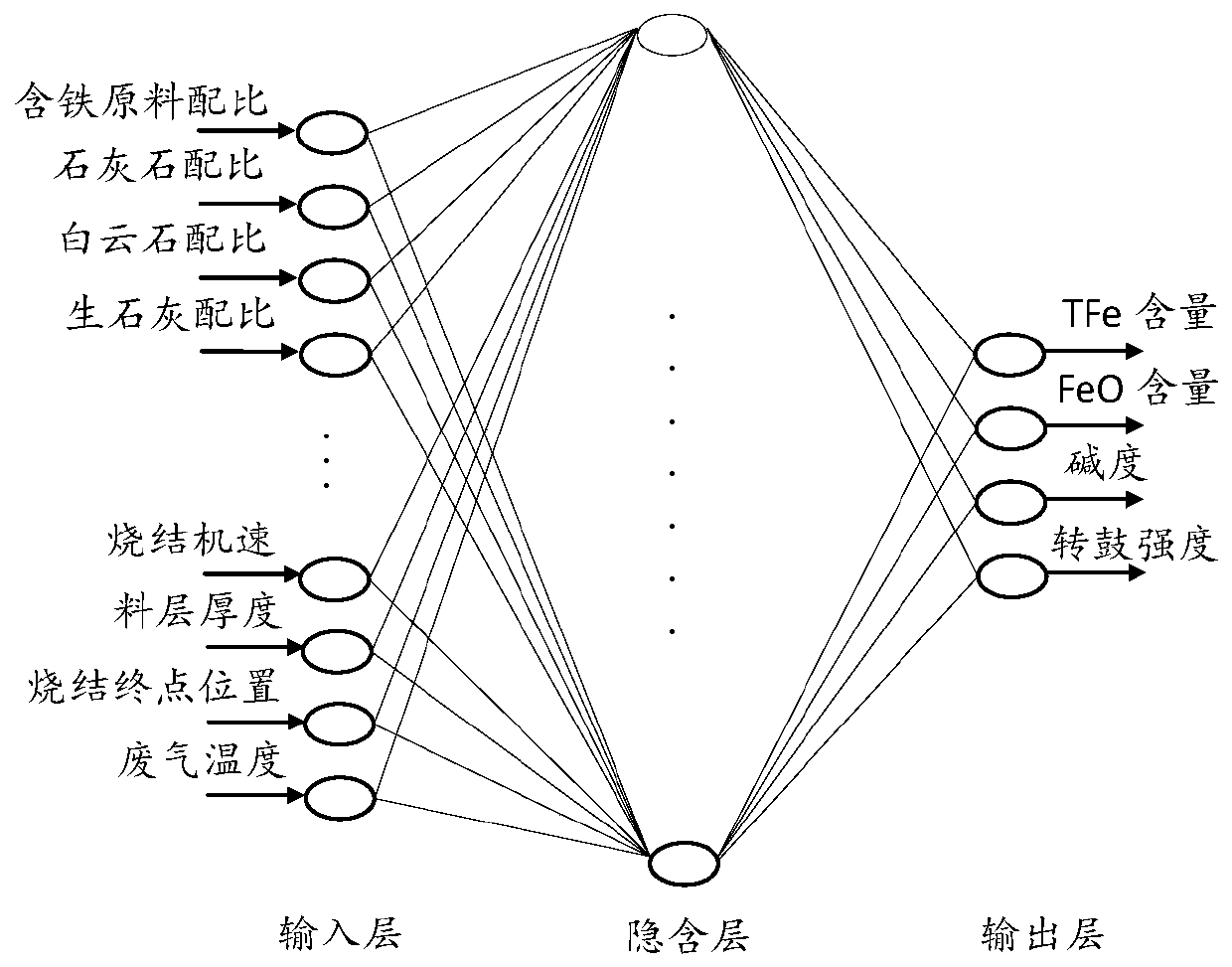

[0041] A sinter quality prediction method based on process parameters. The steps of the sinter quality prediction method described in this embodiment are:

[0042] S1. Determine the parameters of the sintering process: the proportion of iron-containing raw materials; the amount of quicklime added; the amount of limestone added; the amount of dolomite added; ; Sintering machine speed; material layer thickness; sintering end position; waste gas temperature.

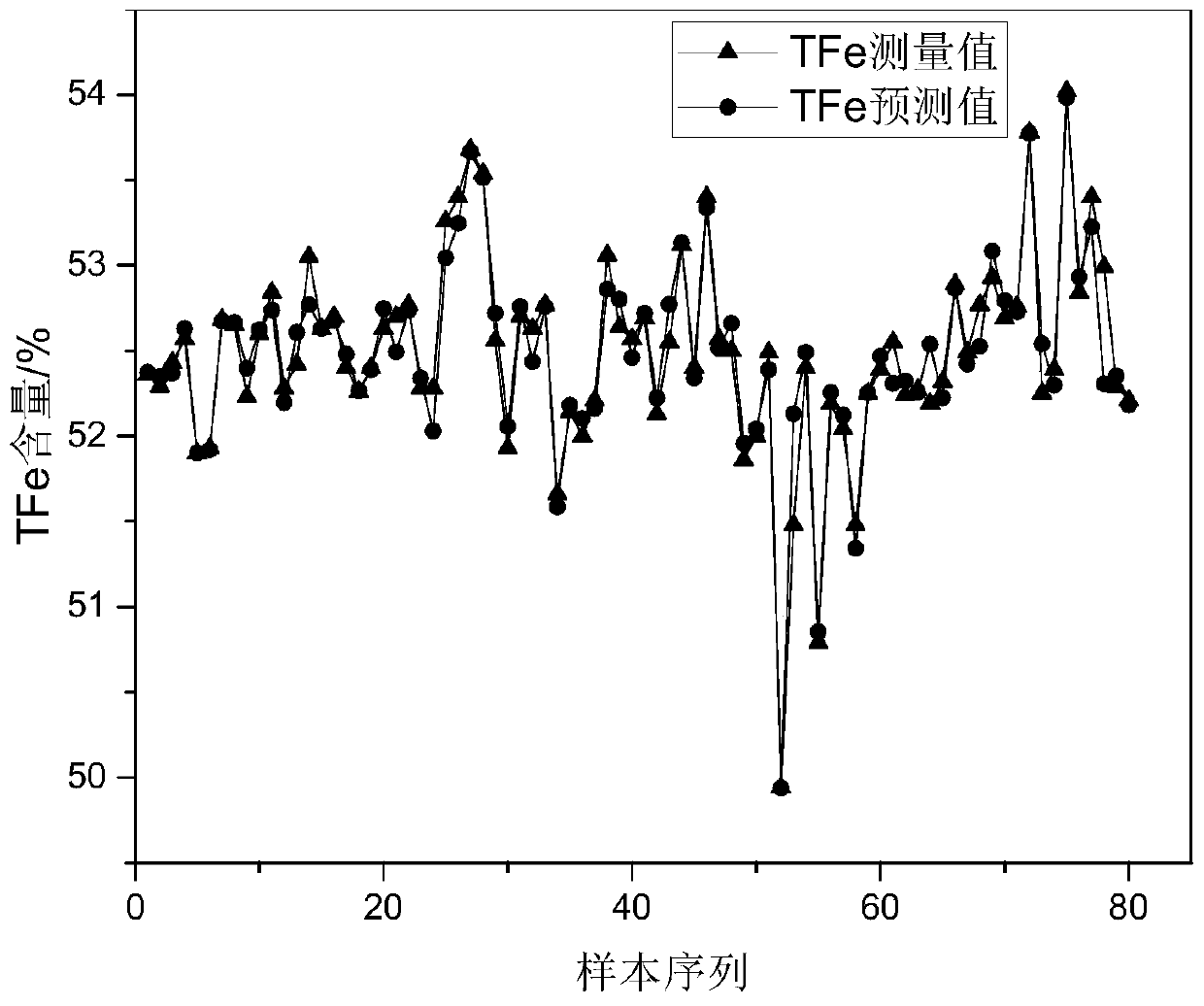

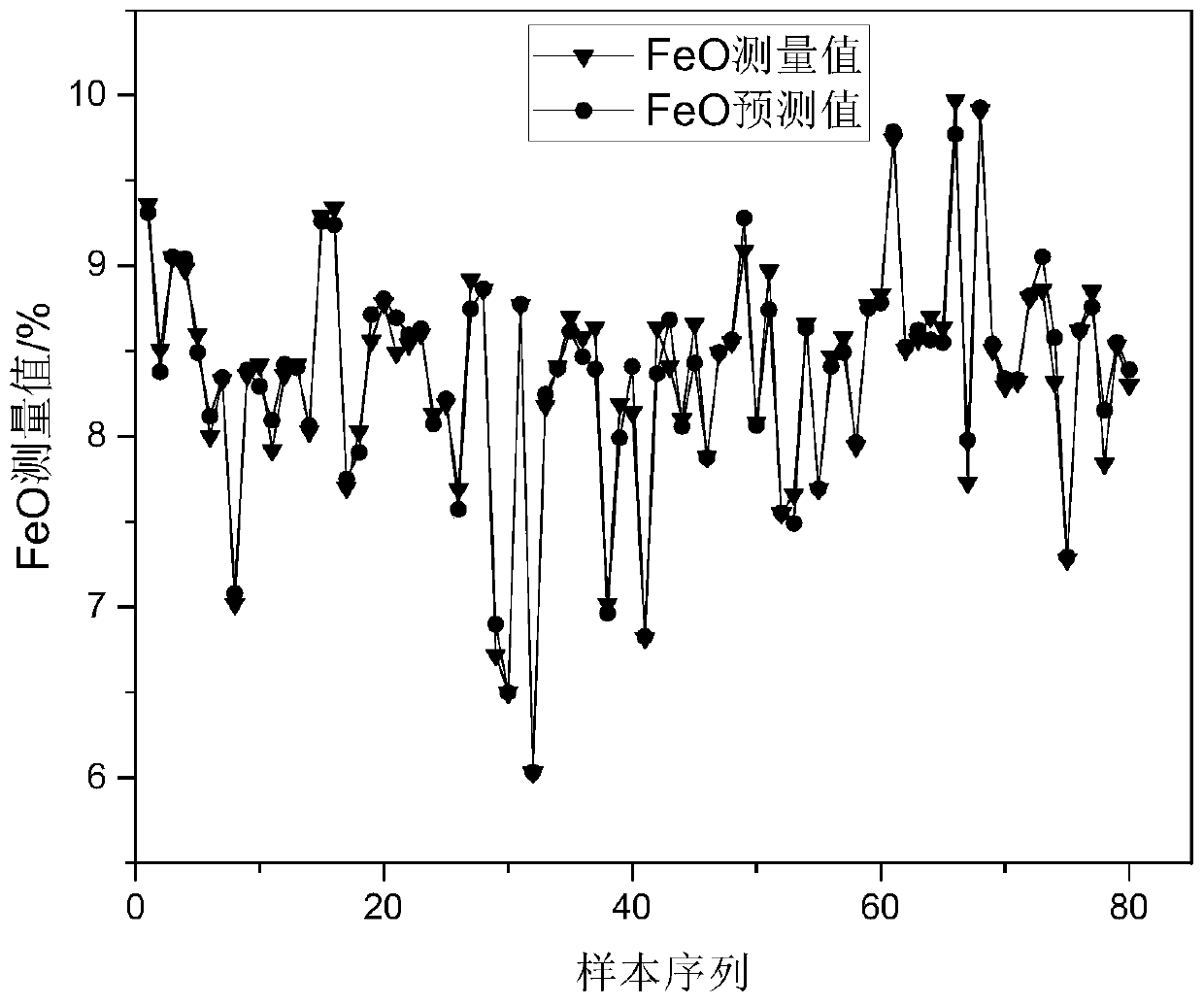

[0043] Determine the sinter quality parameters are: TFe content; FeO content; basicity; drum strength.

[0044]S2. Sampling recent production data of the 15 sintering process parameters and 4 sinter quality parameters to establish a recent production data sample library. In this embodiment, the specific process of establishing the recent production data sample database is as follows: Obtain the historical production data of the sintering workshop of a large domestic steel plant in the past year, the production data collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com