Linear motor test platform

A test platform, linear motor technology, applied in the direction of motor generator testing, measuring devices, force/torque/work measuring instruments, etc., can solve the problems of low running speed, maximum thrust limit, difficult structure simplification, etc., to improve safety , improve the compatibility, the effect of simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In the following, the present invention will be further described in conjunction with the drawings and specific implementations. It should be noted that, provided that there is no conflict, the following embodiments or technical features can be combined to form new embodiments. .

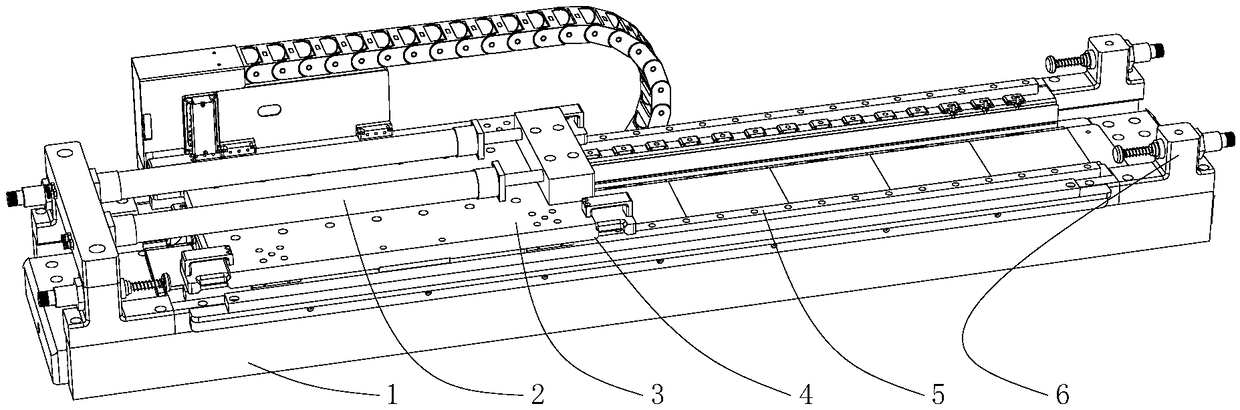

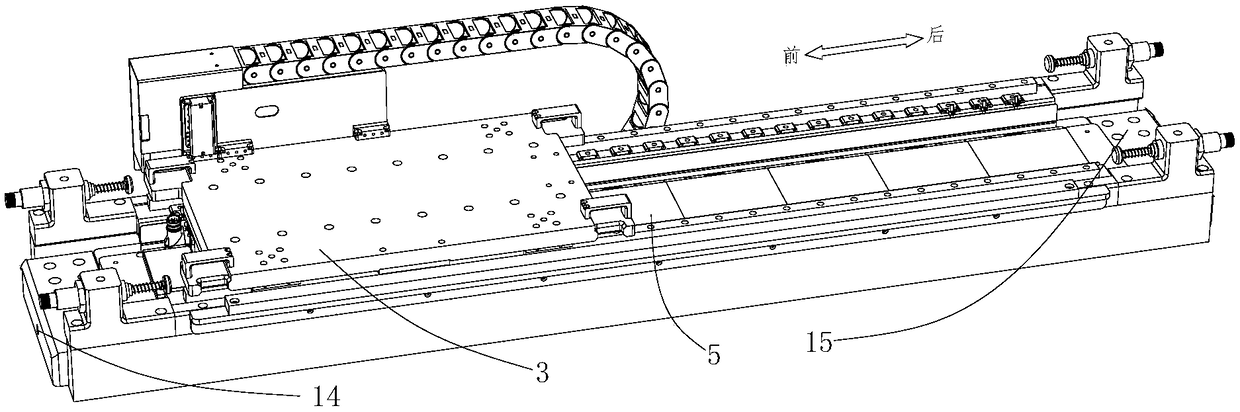

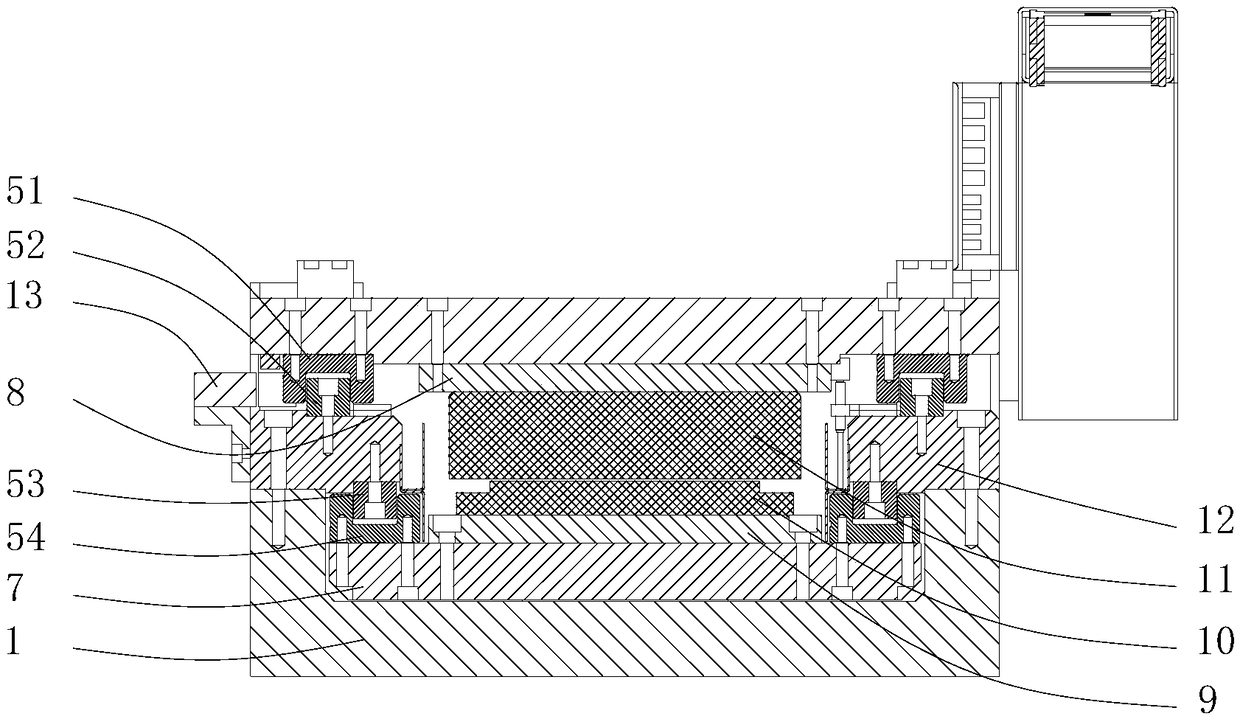

[0040] Such as Figure 1-9 A linear motor test platform shown includes a bed 1, a linear track 5, a test platform 4, a grating ruler 13, a pre-tensioning mechanism 14 and a force measuring mechanism 15. The linear track 5 is set on the bed 1, and the test platform 4 Located on the linear track 5, the test platform 4 and the linear track 5 are movably connected. The test platform 4 is formed with an accommodation chamber for accommodating the linear motor under test. The test platform 4 is used to connect with the linear motor under test. The measuring linear motor drives the test platform 4 to move on the linear track 5. The grating ruler 13 is located on one side of the test platform 4, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com