Patents

Literature

59results about How to "Marking speed is fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

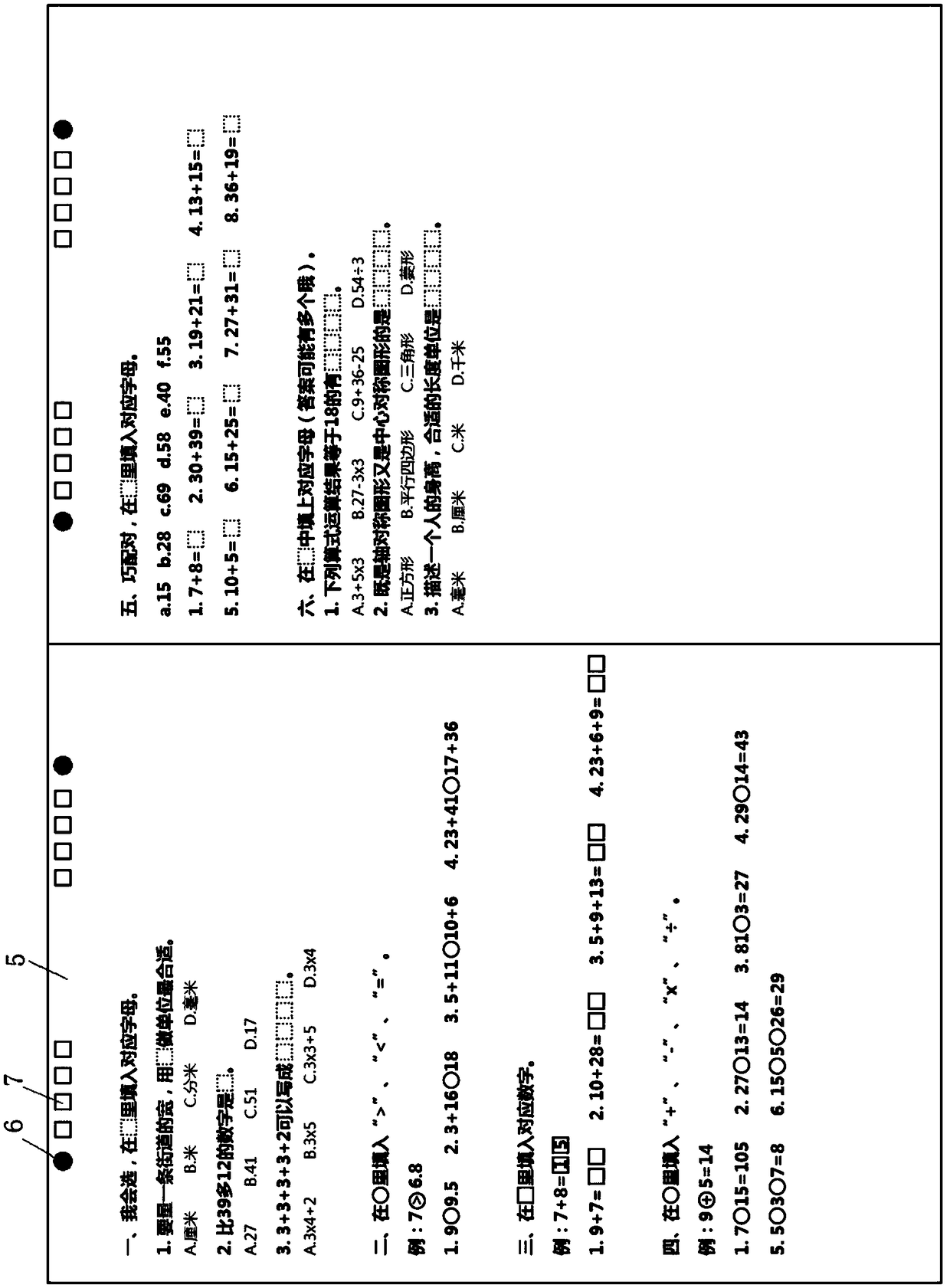

Intelligent correcting method

InactiveCN108764201AMarking speed is fastRaise the gradeData processing applicationsDigital ink recognitionHandwritingShort answer

The invention discloses an intelligent correcting method, comprising: dividing the answer area of an electronic version test paper or an electronic version answer sheet by using different identification areas according to the correct answers which are numbers, letters and symbols, and associating the page numbers, the title numbers and the answering area positions; at the same time, presetting thecorrect answers, then obtaining the handwritten answer handwriting information written in the answering area on the paper test paper or the paper answer sheet, finally identifying the answer handwriting information, comparing with the preset correct answers, and determining correct or not. The invention, which may predict in advance question types such as an objective question, a fill-in-the-blank question, and a short answer question with the correct answer of a number, a letter, and a symbol, narrows the recognition range, improves the recognition accuracy, and lightens the correcting burden of teachers by setting different types of answer areas, and promotes the transformation of the classroom teaching form in the case of reducing the negative emotions generated by the teachers duringthe teaching process, by manually correcting and counting a large number of daily assignments, thereby achieving a truly student-oriented precision teaching.

Owner:宁波宁大教育设备有限公司

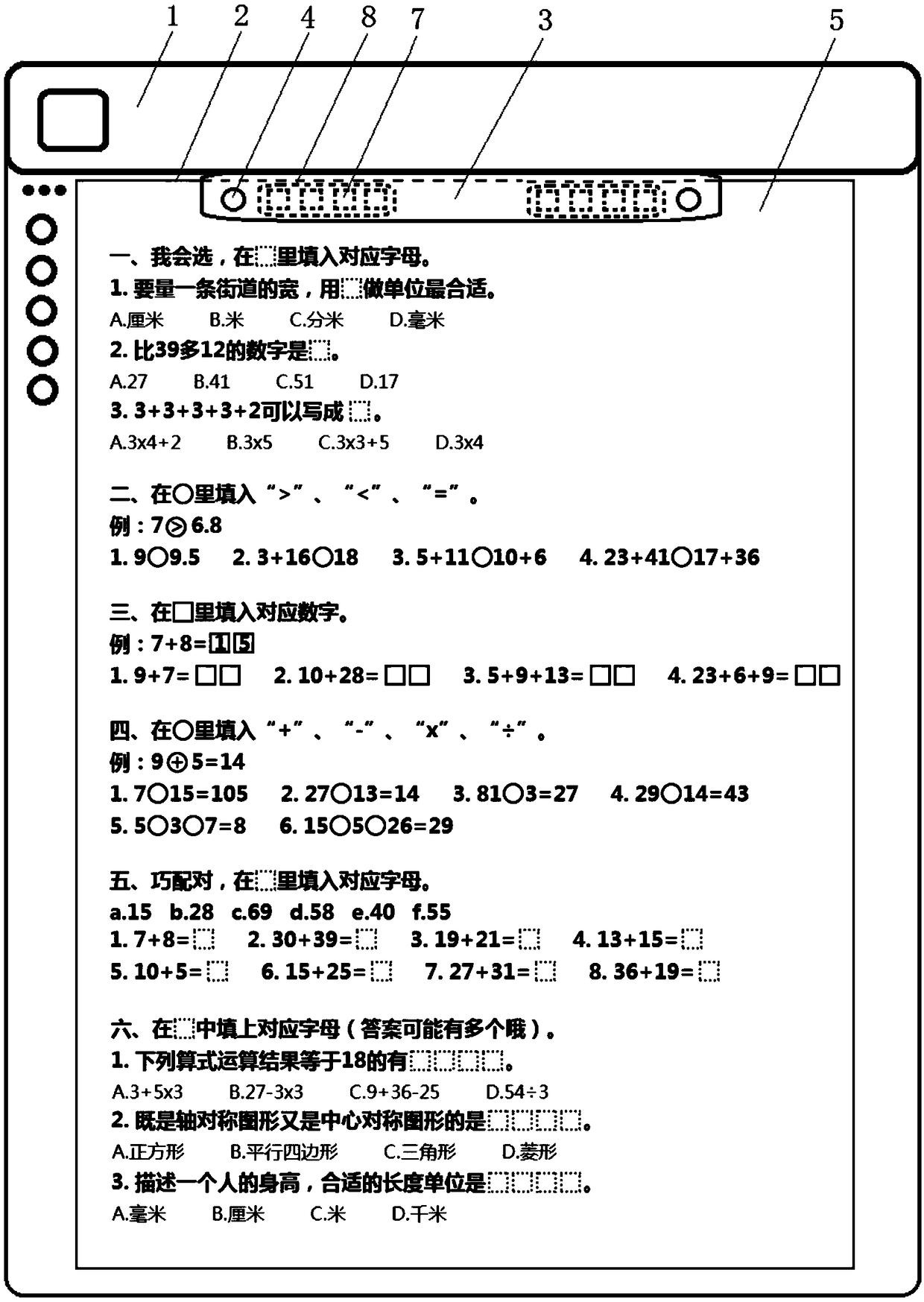

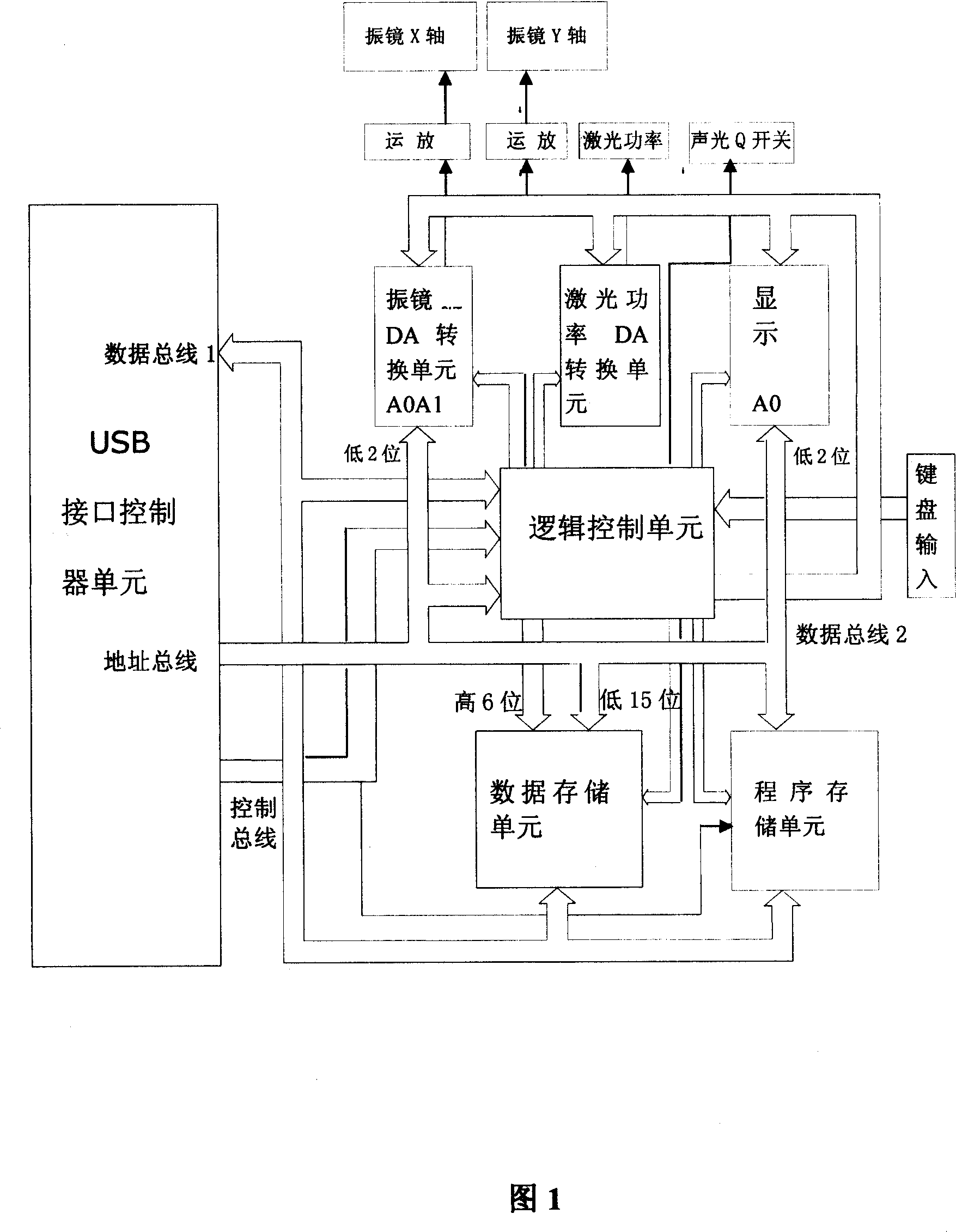

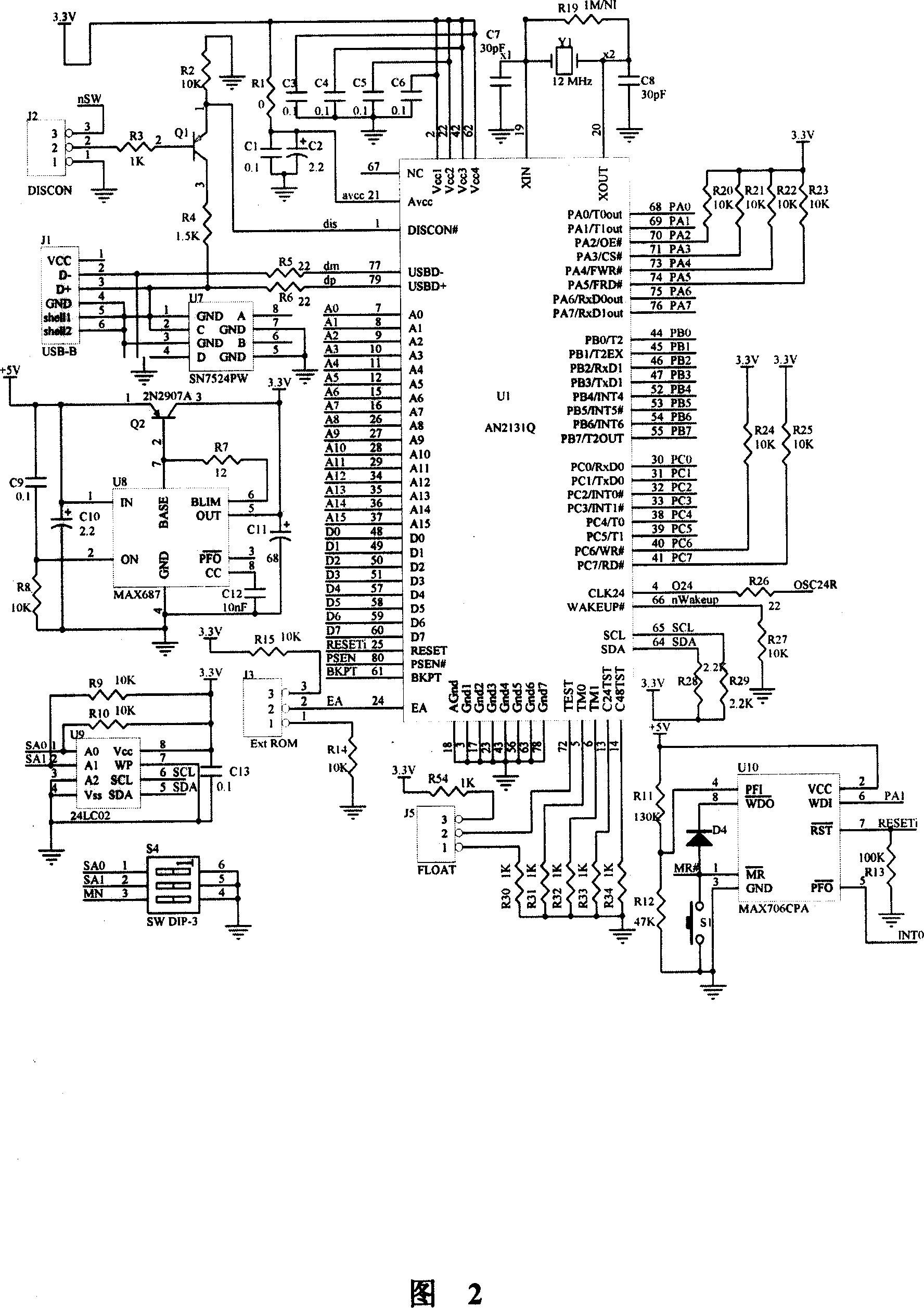

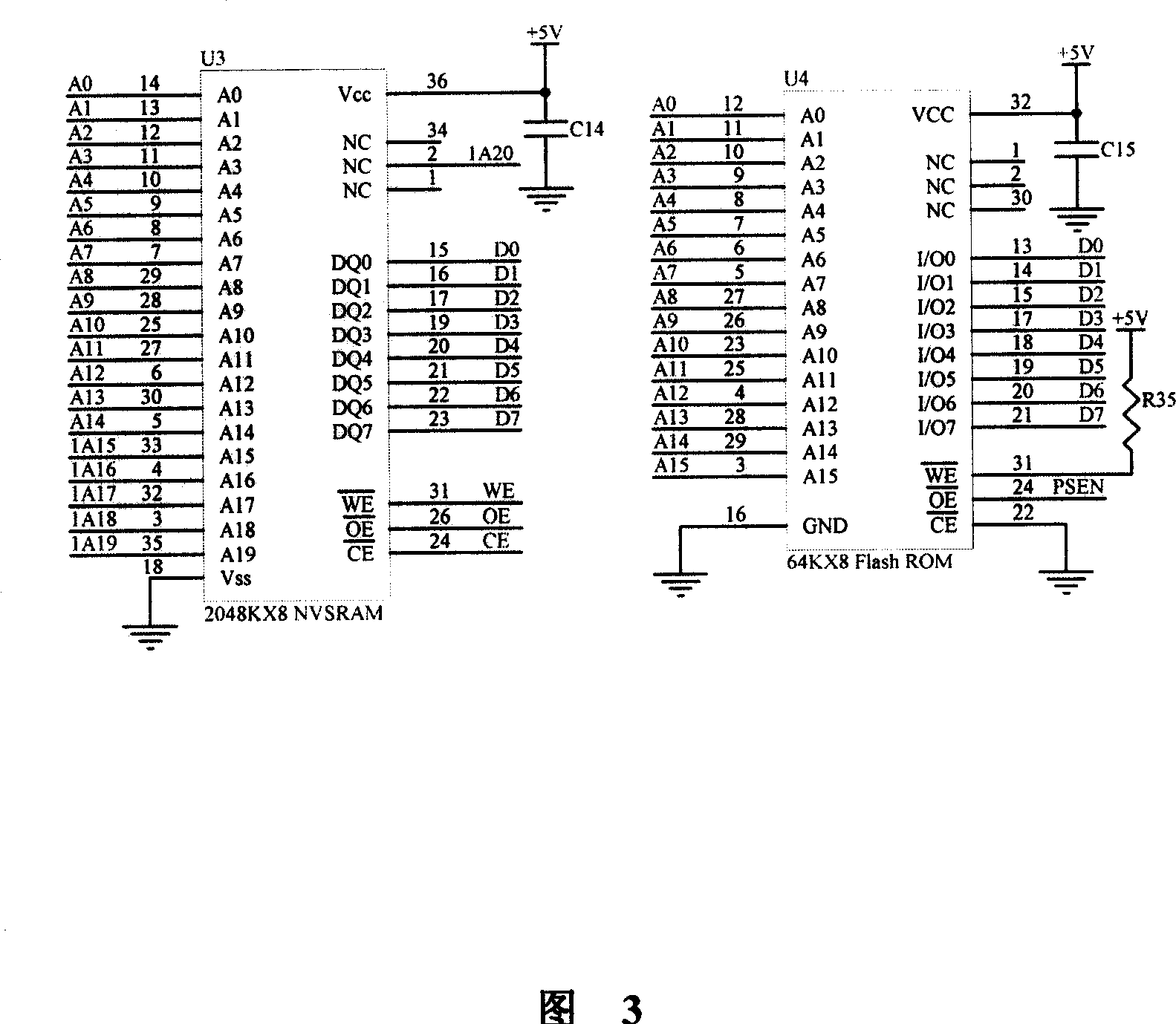

Marking controller based on USB interface

InactiveCN101017424AImprove scalabilityMarking speed is fastTypewritersAblative recordingGraphicsData memory

This invention relates to one target controller based on USB interface in laser marker controller, which comprises USB interface controller unit, data memory unit, program memory unit, D / A conversion unit, logic control unit and human to machine interface unit.

Owner:HUAZHONG UNIV OF SCI & TECH

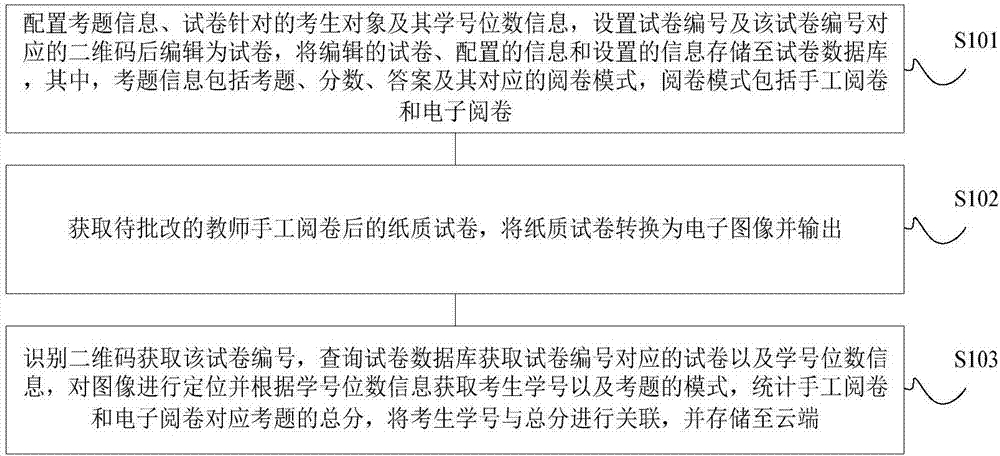

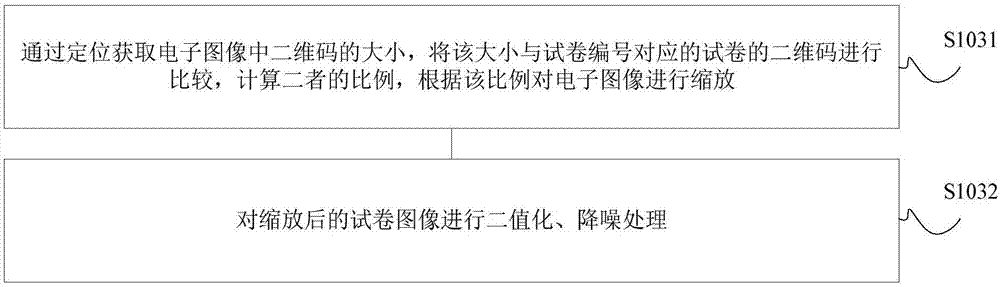

Test paper generating and scoring method and system

InactiveCN106934767AAvoid lossMarking speed is fastImage enhancementGeometric image transformationScore methodComputer science

The invention discloses a test paper generating and scoring method and system. The method comprises: configuring examination question information, an examinee object of a test paper and student number bit information setting a test paper number and a corresponding two-dimensional code of the test paper number, and then carrying out editing to form a test paper, and storing the edited test paper, the configured information, and the set information into a test paper database; obtaining a to-be-corrected papery test paper after manual teacher examination, converting the papery test paper into an electronic image, and outputting the electronic image; and identifing the two-dimensional code to obtain the test paper number, querying the test paper database to obtain the test paper corresponding to the test paper number and the student number bit information, carrying out statistics of scores of examination questions corresponding to manual paper examination and a total score of scores of examination questions corresponding to automatic electronic paper examination, associating the student number with the total score, and storing the information to a cloud terminal. According to the invention, with setting of a two-dimensional code of a test paper, a test paper can be obtained based on a test paper number and automatic electronic paper examination of the test paper is realized, and thus total score statistics of a manual test paper examination result and an automatic electronic paper examination result is realized rapidly.

Owner:上海小闲网络科技有限公司

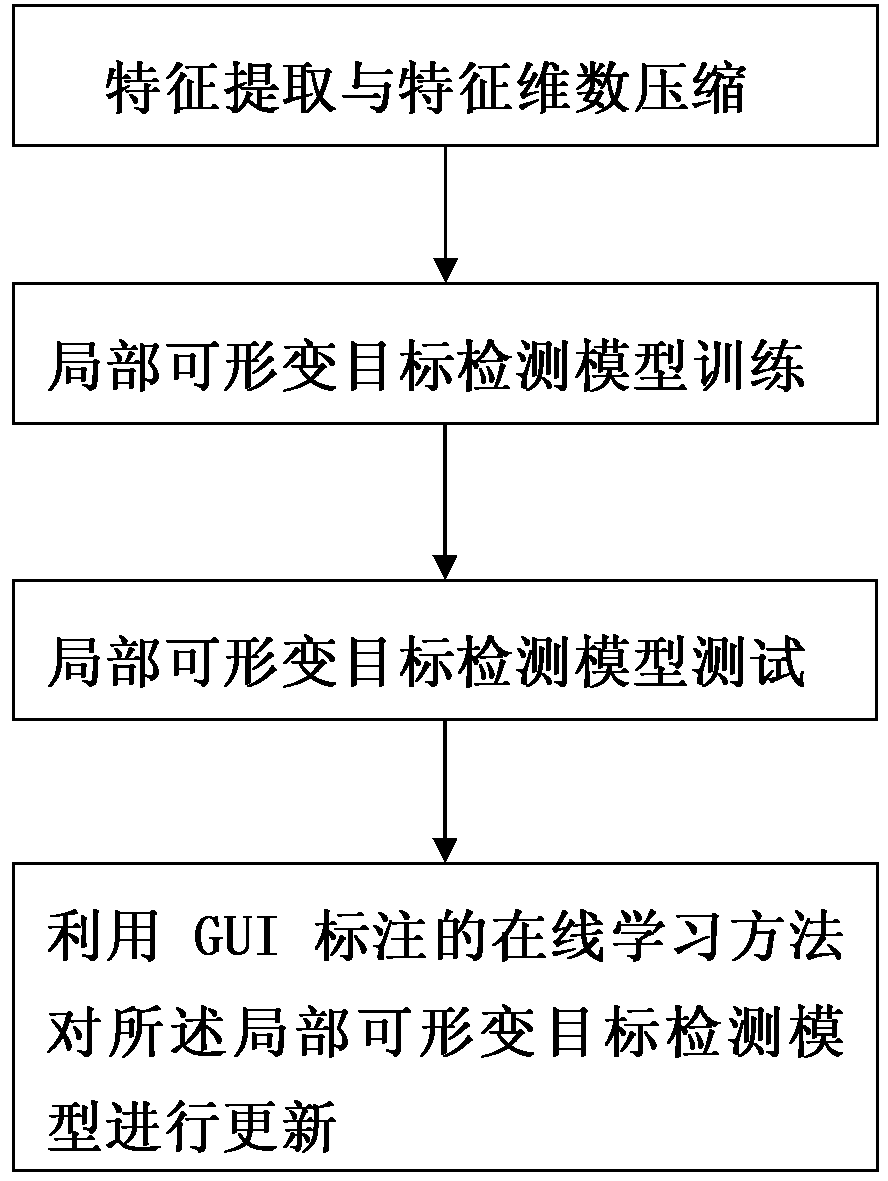

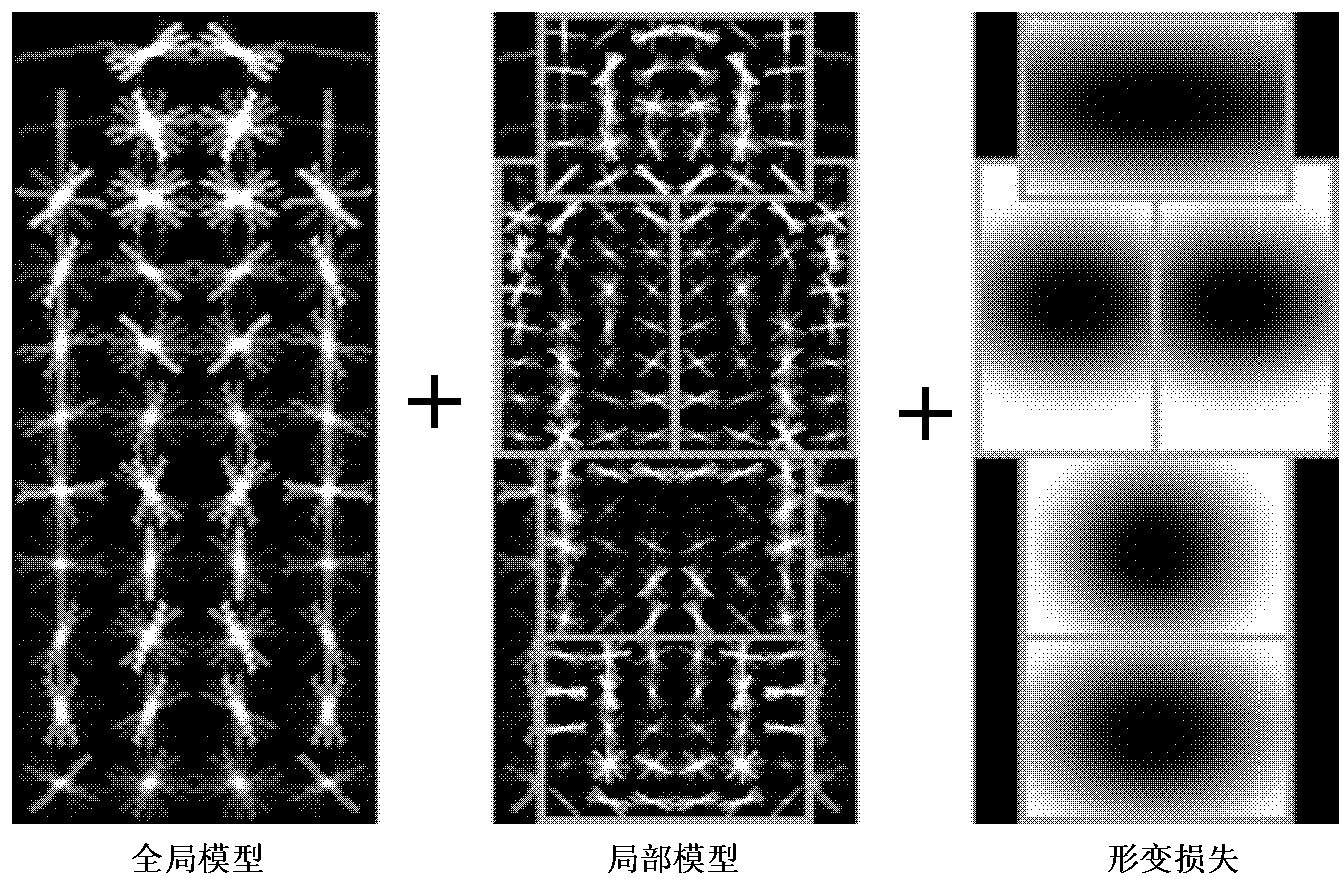

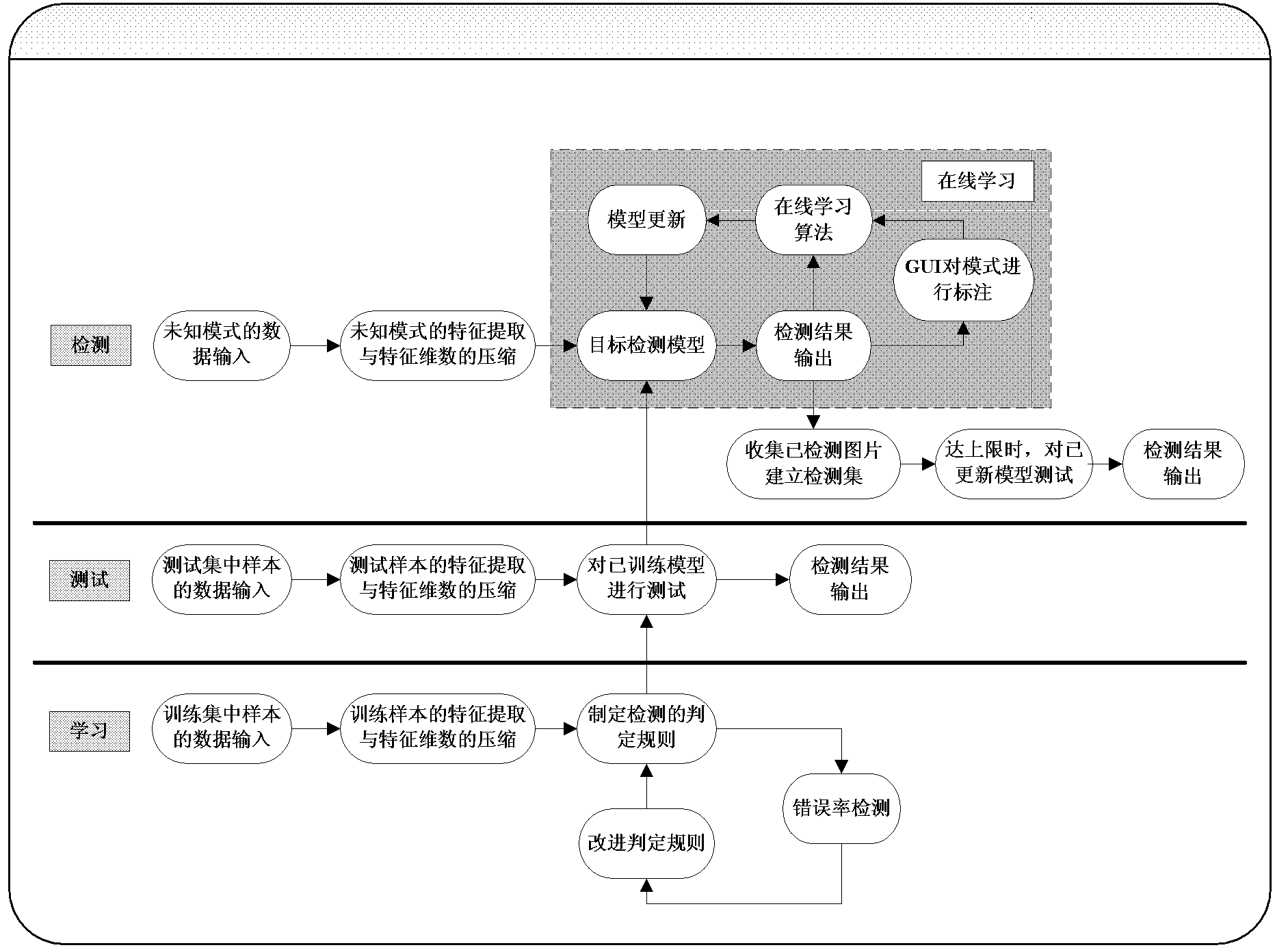

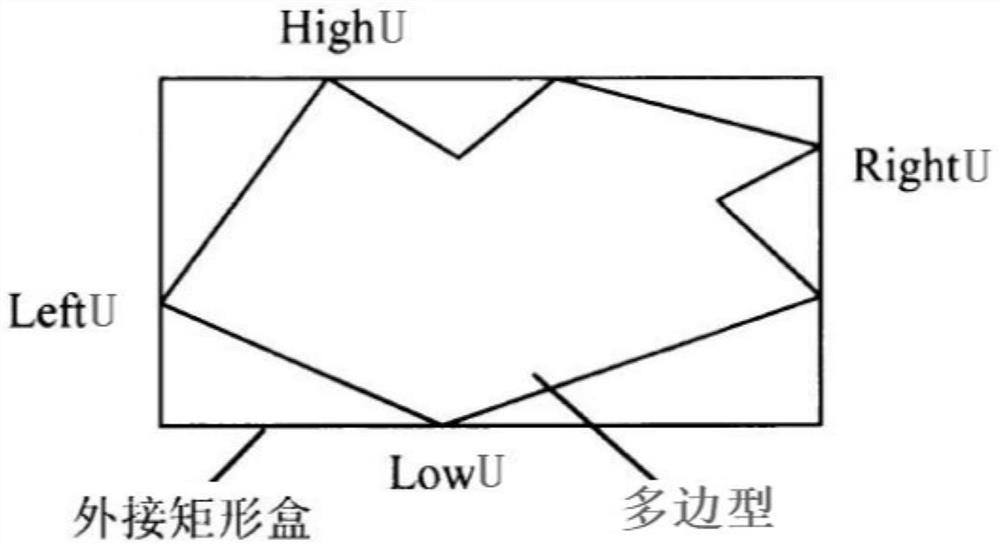

Regional deformation target detection method and system based on online learning

InactiveCN103258216AEasy to handleImprove robustnessCharacter and pattern recognitionSample imageOnline learning

The invention discloses a regional deformation target detection method and system based on online learning. The regional deformation target detection method based on the online learning comprises the following steps: firstly, a sample image is utilized to intensively train a regional deformation target detection model, and the regional deformation target detection model after preliminary training is obtained; secondly, the regional deformation target detection model is utilized to carry out target detection on an image to be detected, and the existing regional deformation target detection model is renewed and optimized by utilizing a GUI label online learning method. The regional deformation target detection method distributes the entire time-consuming training process in each time of target detection, meanwhile, the model can be renewed in real time, the robustness of the regional deformation target detection model is further improved, and the required inner storage is not large. According to the regional deformation target detection method, the data used for the target detection can be effectively and rapidly processed in the background of big data.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

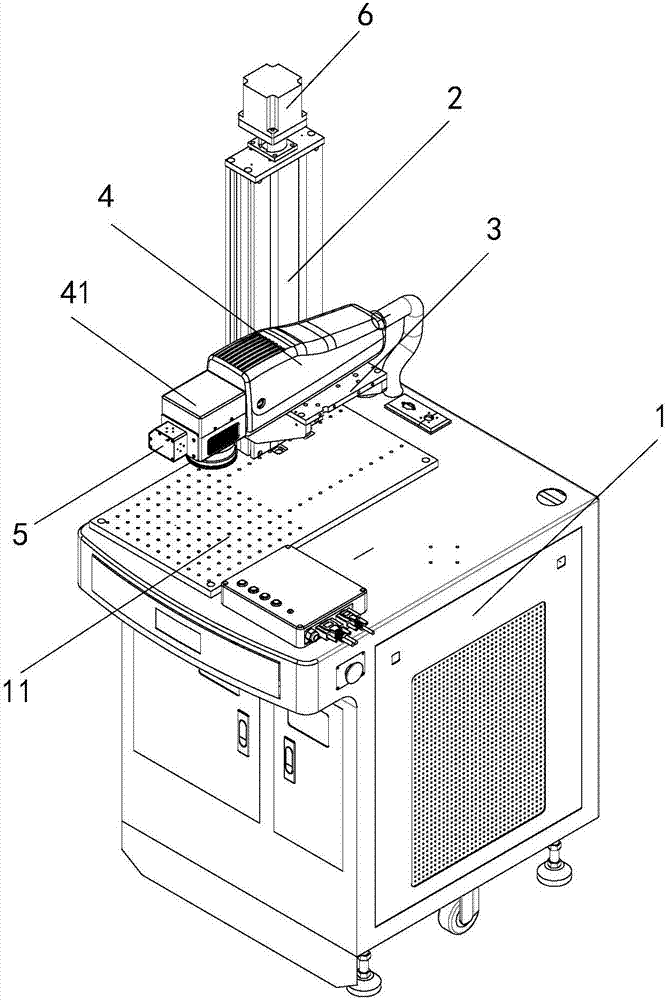

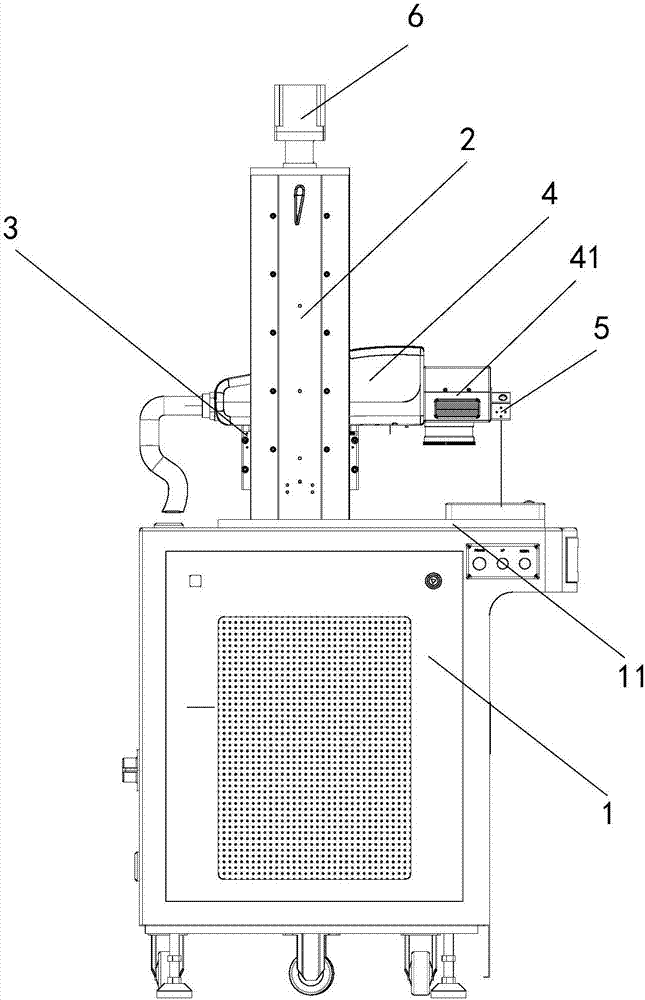

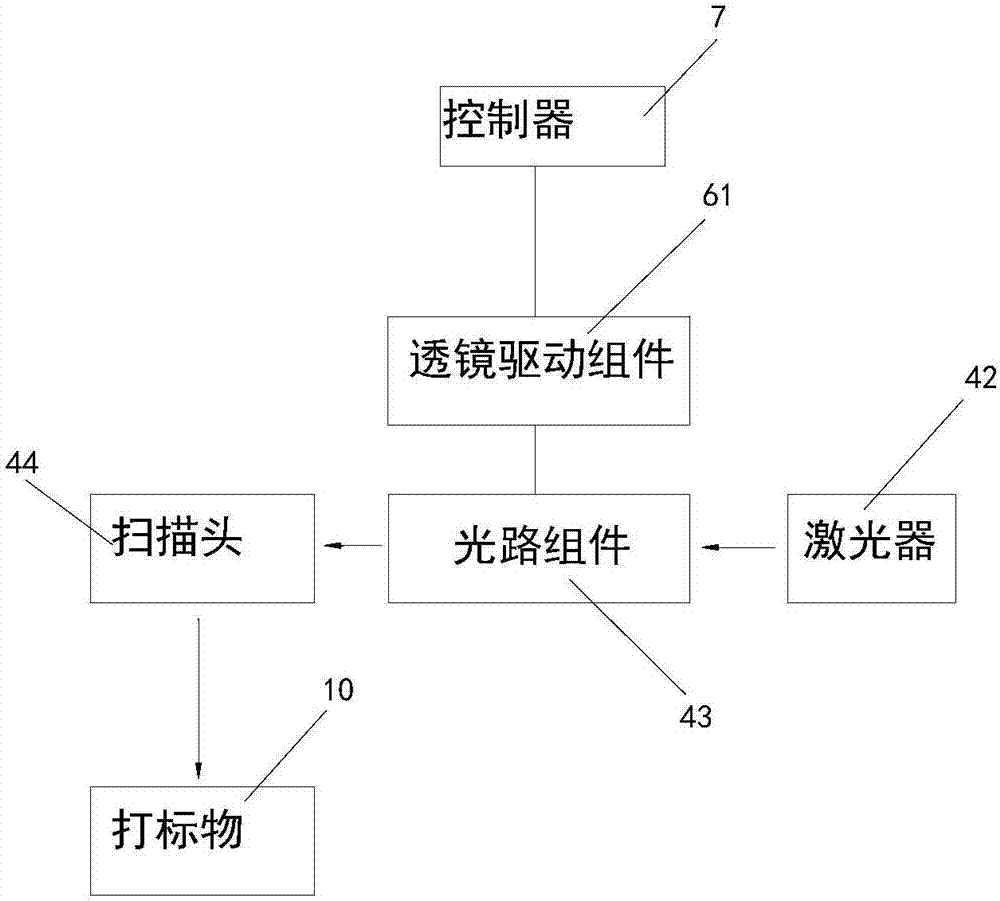

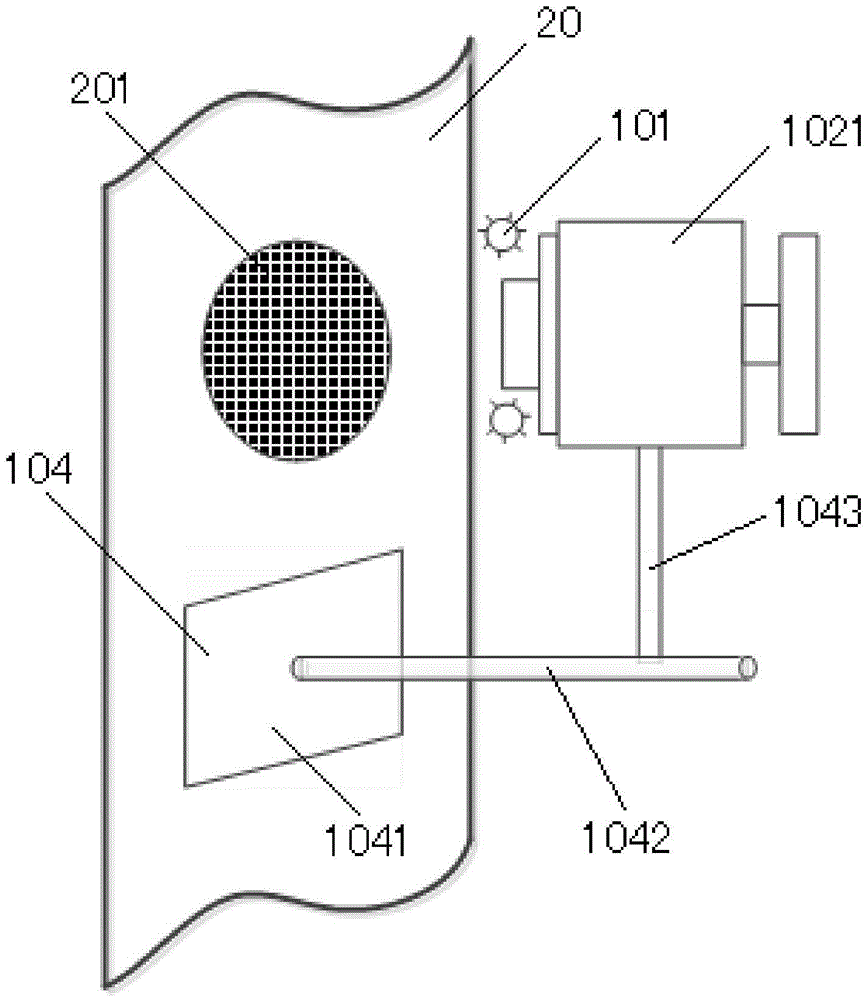

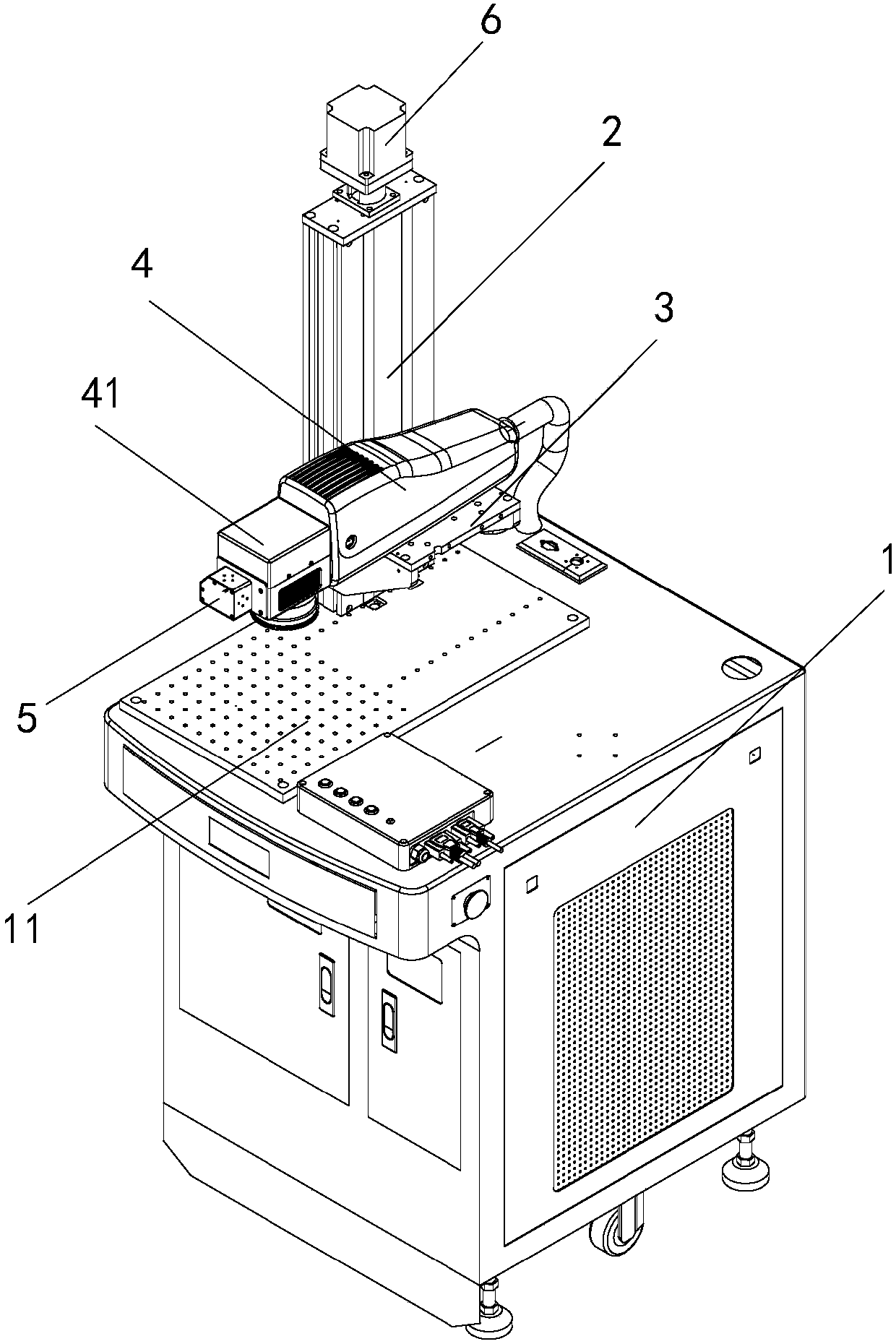

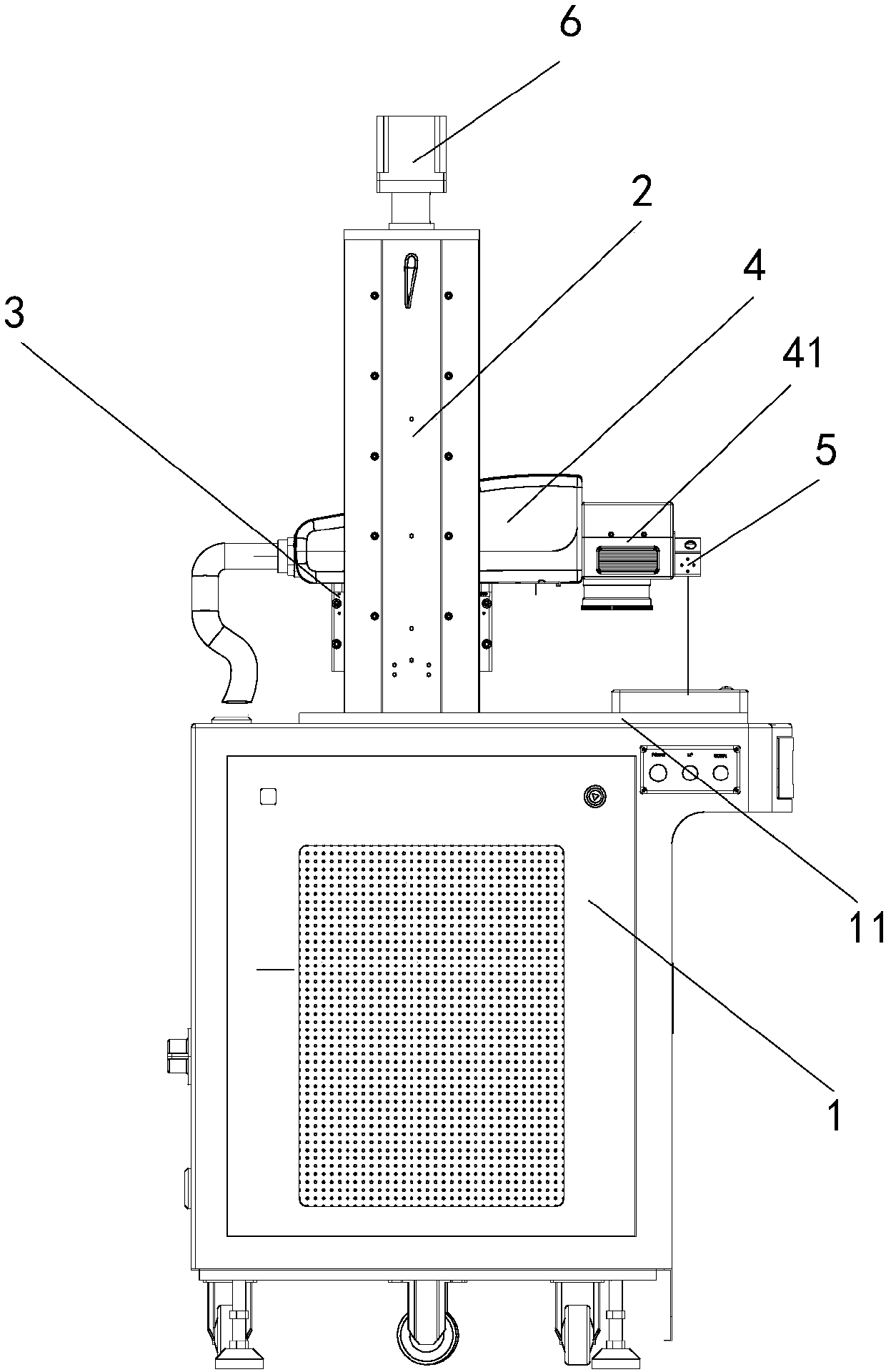

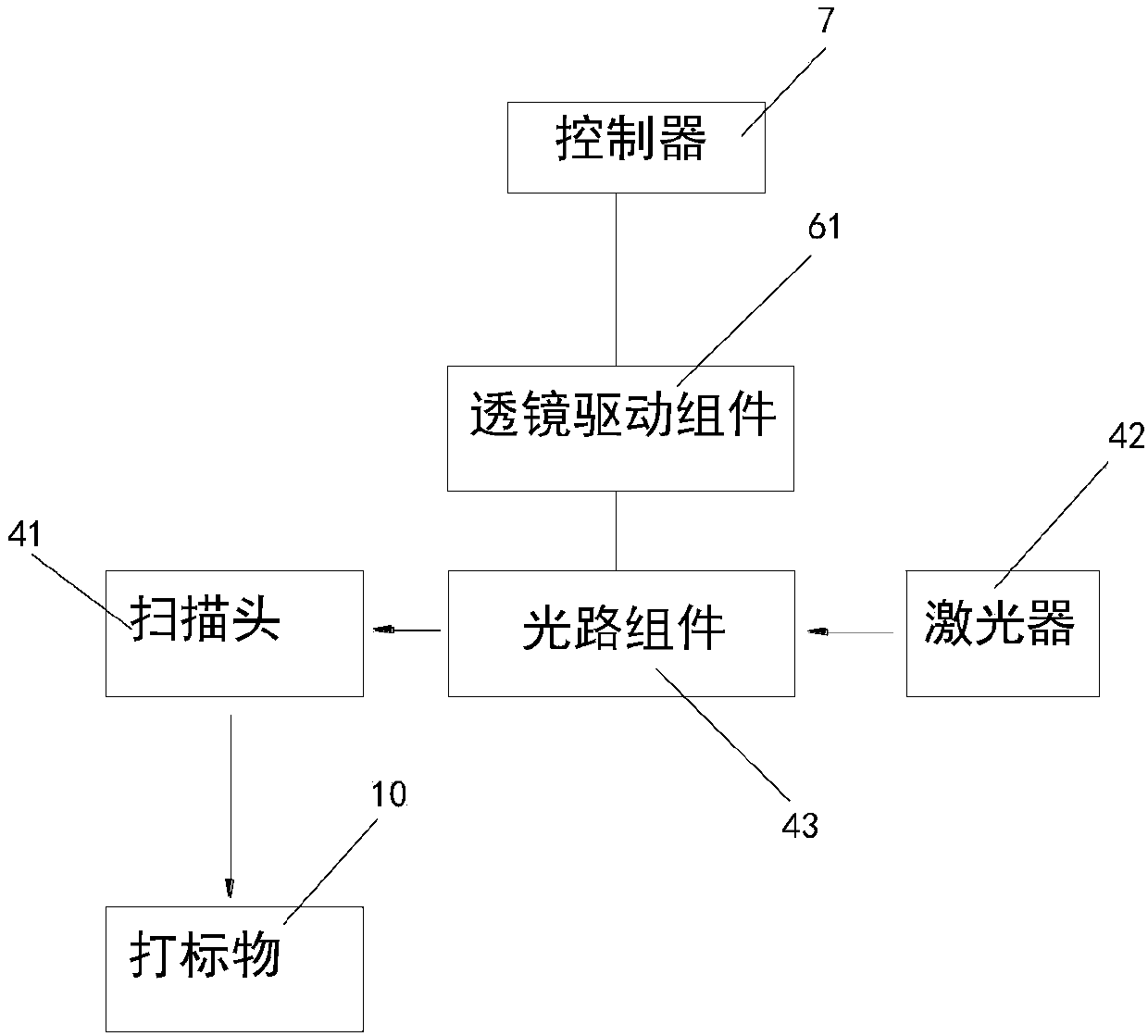

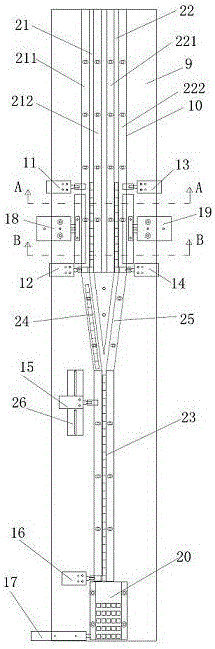

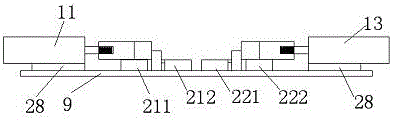

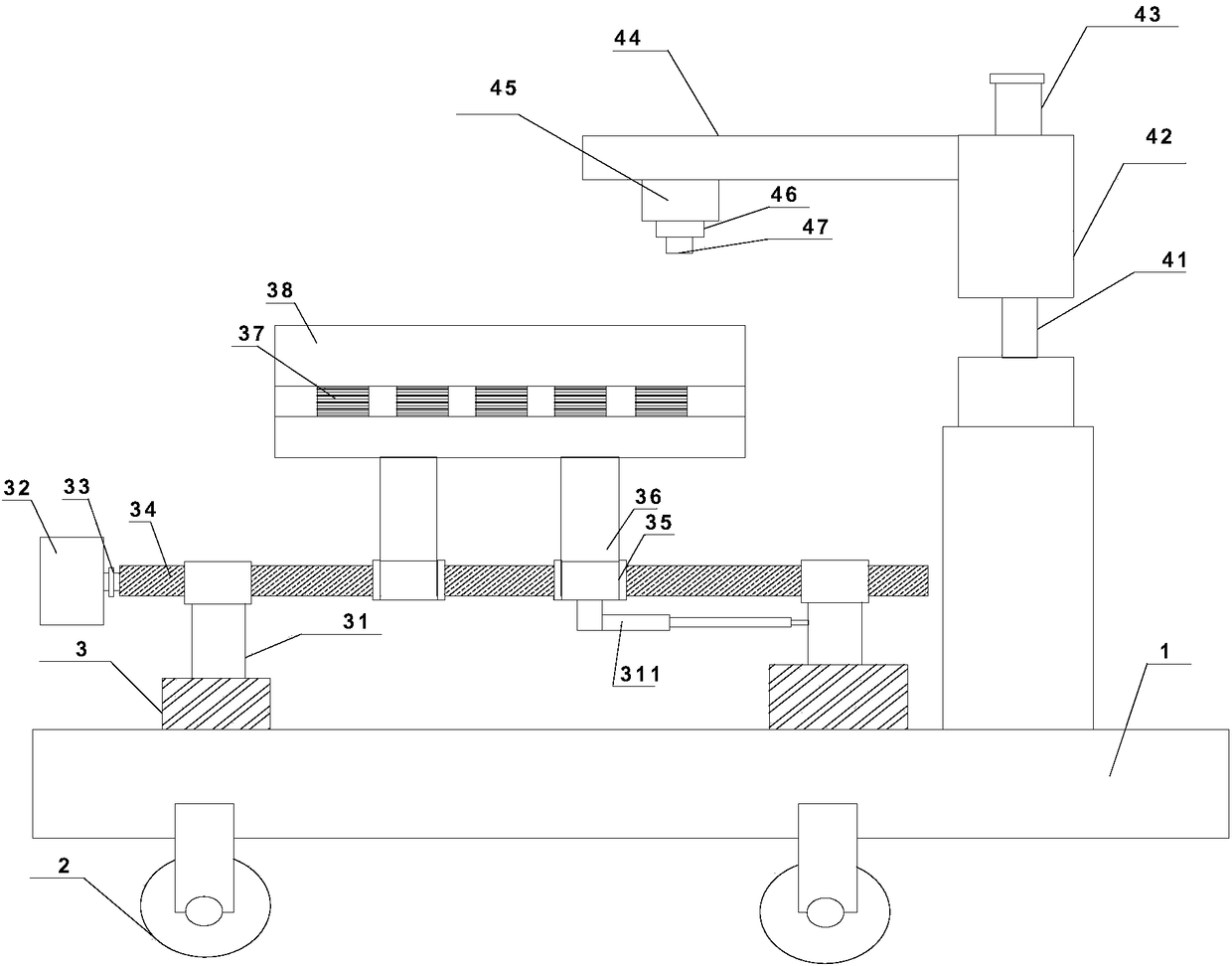

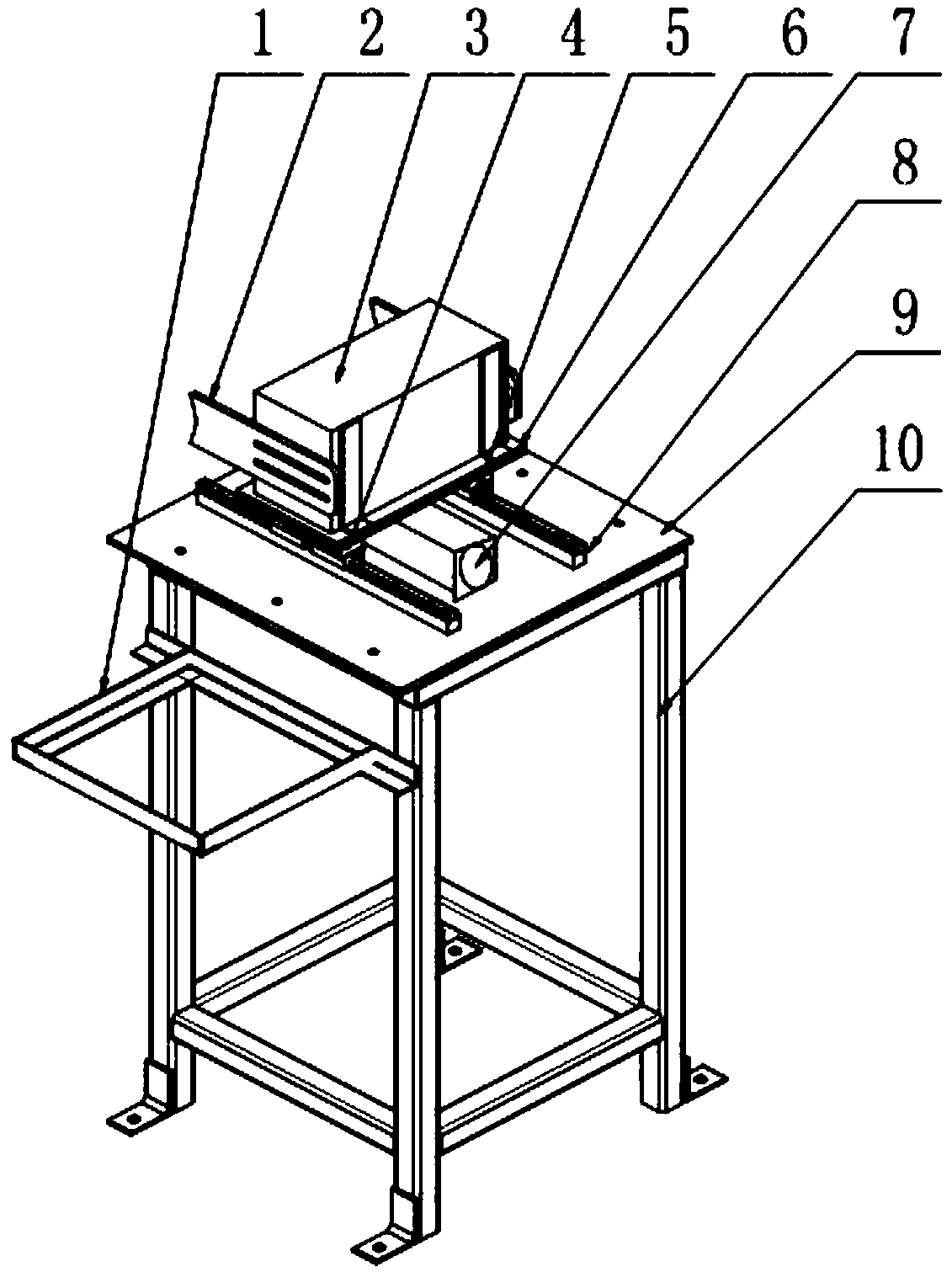

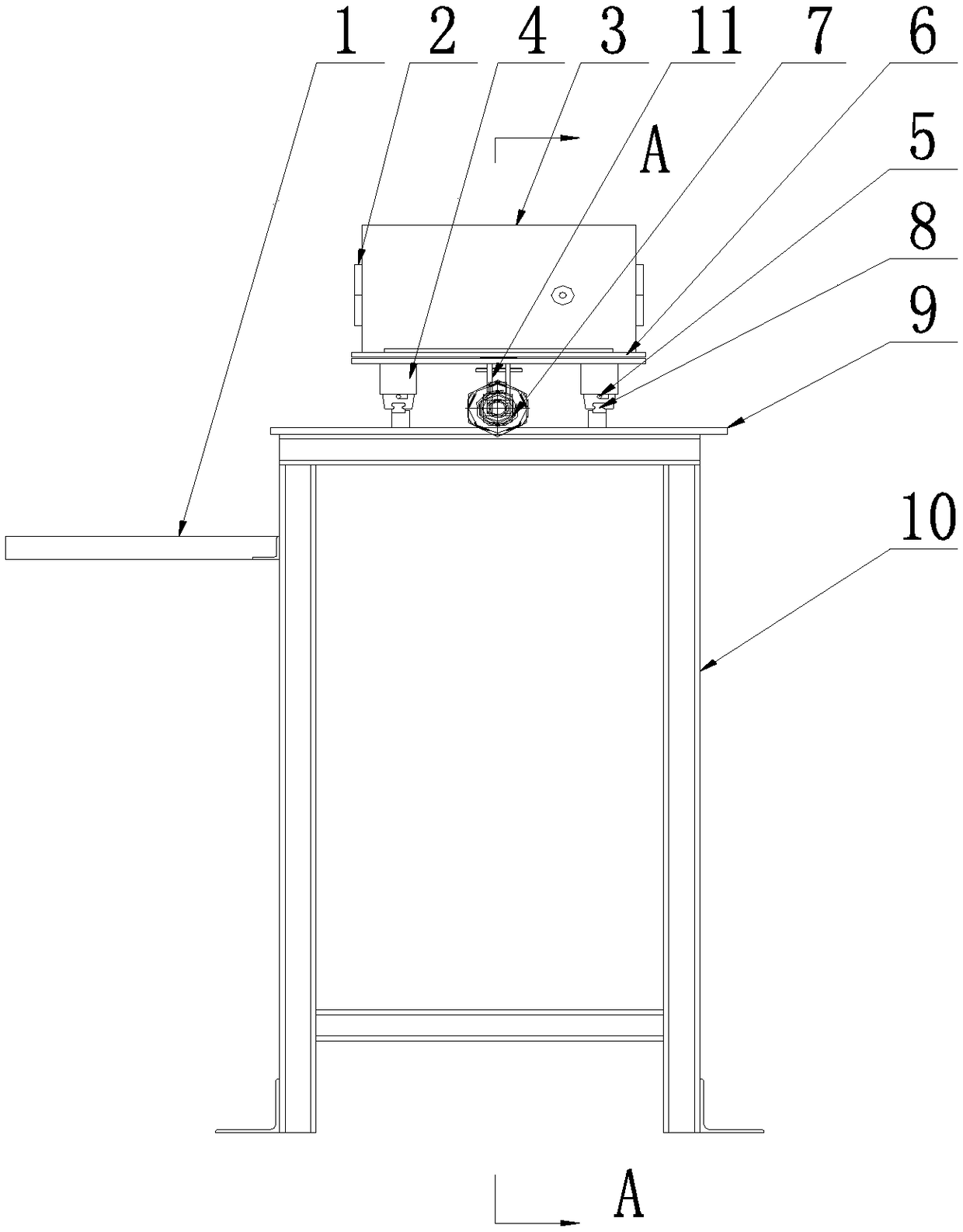

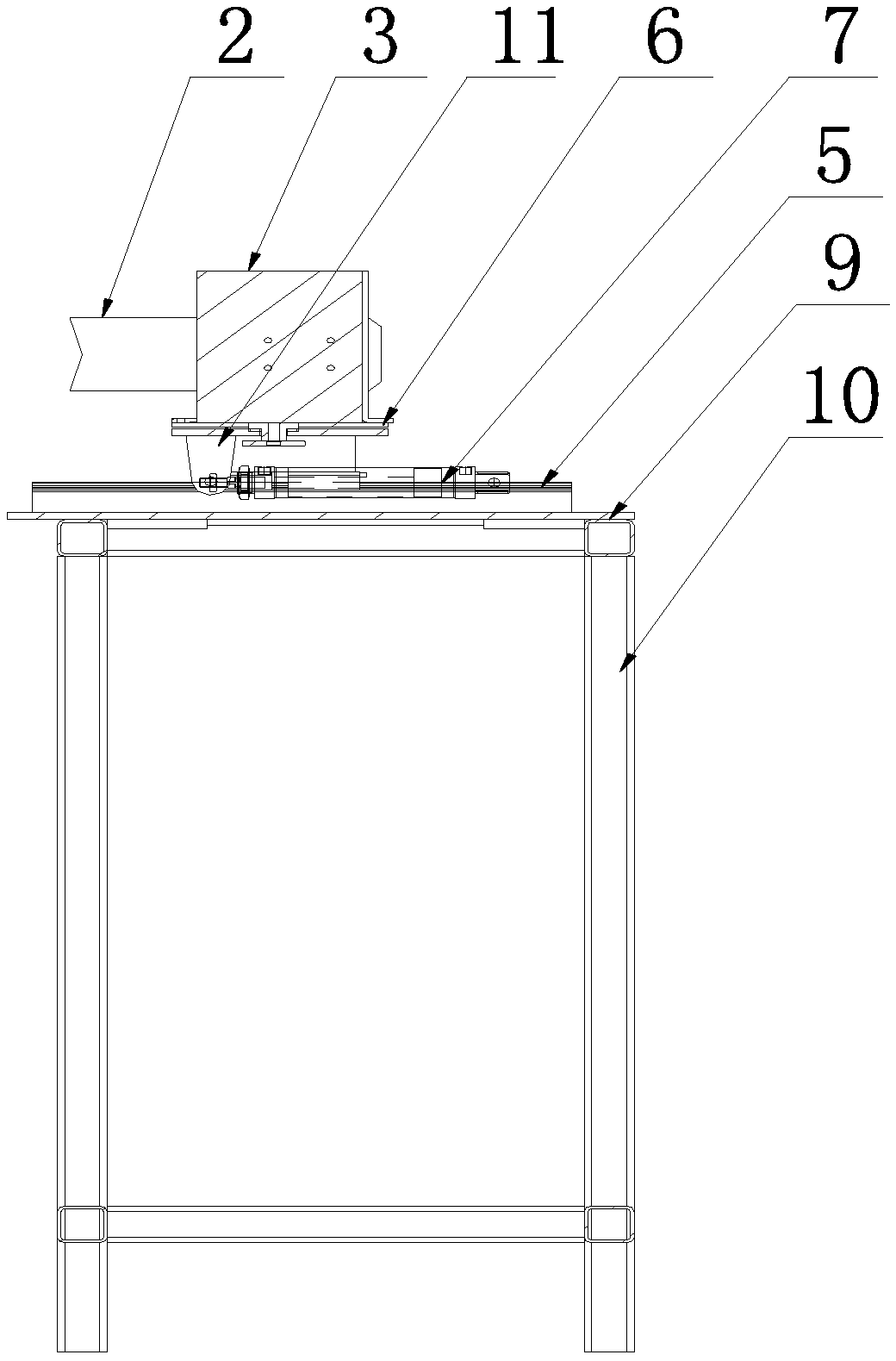

Laser marking machine, method for adjusting distance between scanning head and marked object and automatic focusing method of marking machine

InactiveCN107225322AGuaranteed accuracyMarking speed is fastAblative recordingOther printing apparatusEngineeringLaser sensor

The invention discloses a laser marking machine, a method for adjusting the distance between a scanning head of the laser marking machine and a marked object and an automatic focusing method of the marking machine. The laser marking machine comprises a rack, a support platform, a controller, a first driving assembly and a distance measurement assembly, wherein the support platform is arranged on the rack and can move up and down along the rack, a laser marking assembly is arranged on the support platform, the first driving assembly is arranged on the rack and is used for driving the support platform to move up and down along the rack, the distance measurement assembly is arranged on the laser marking assembly, the distance measurement assembly comprises a laser display and a laser sensor, the laser display is used for emitting laser to the surface of the marked object, the laser sensor is used for receiving laser reflected by the surface of the marked object and sending a signal to the controller, the controller is used for calculating the vertical distance between the surface of the marked object and the distance measurement assembly according to the signal, and the first driving assembly is used for driving the distance between the laser marking assembly which is driven to move to the scanning head by the support platform and the surface of the marked object to reach the preset distance.

Owner:GUANGZHOU CKLASER

Stress monitoring method and stress monitoring device

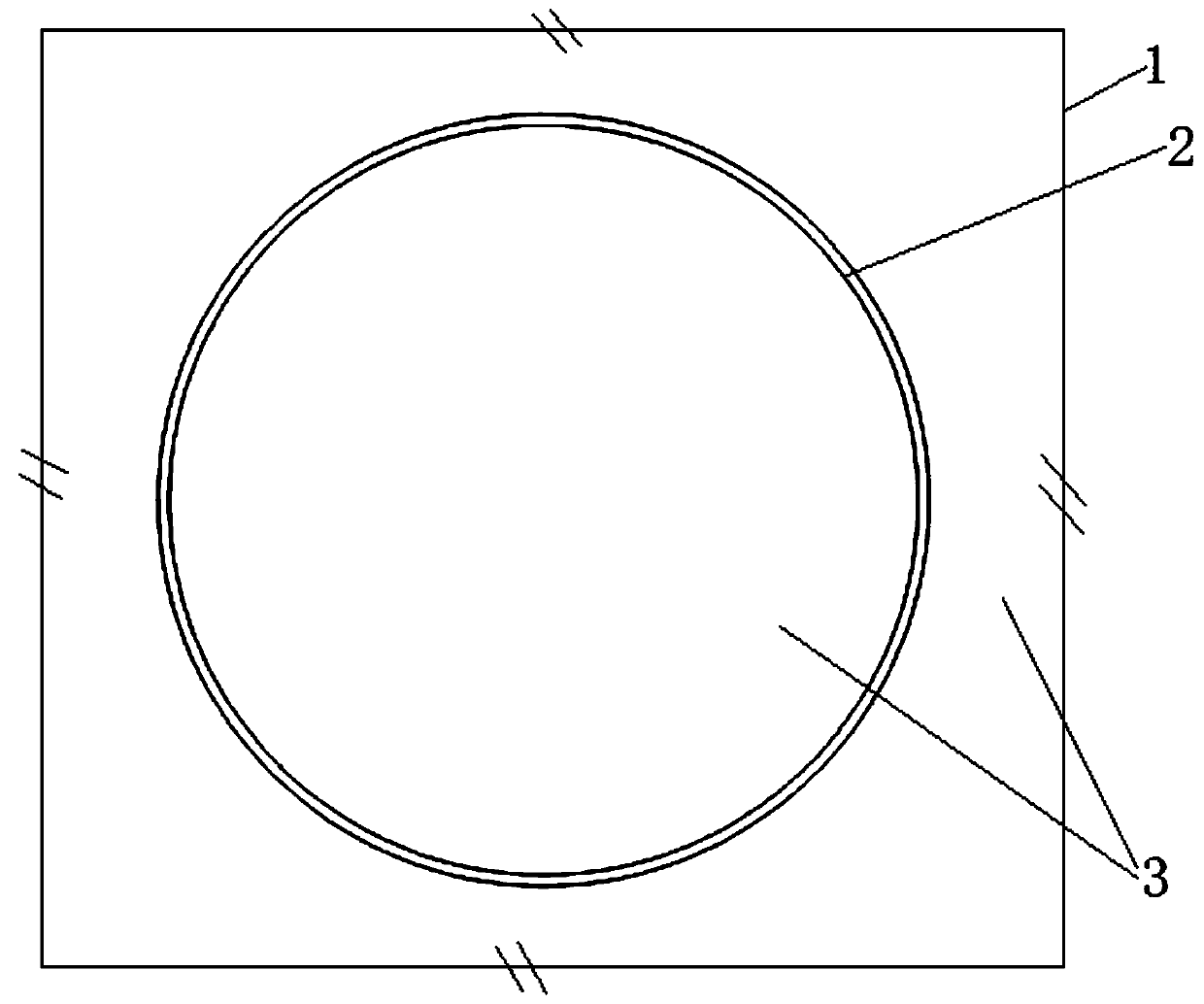

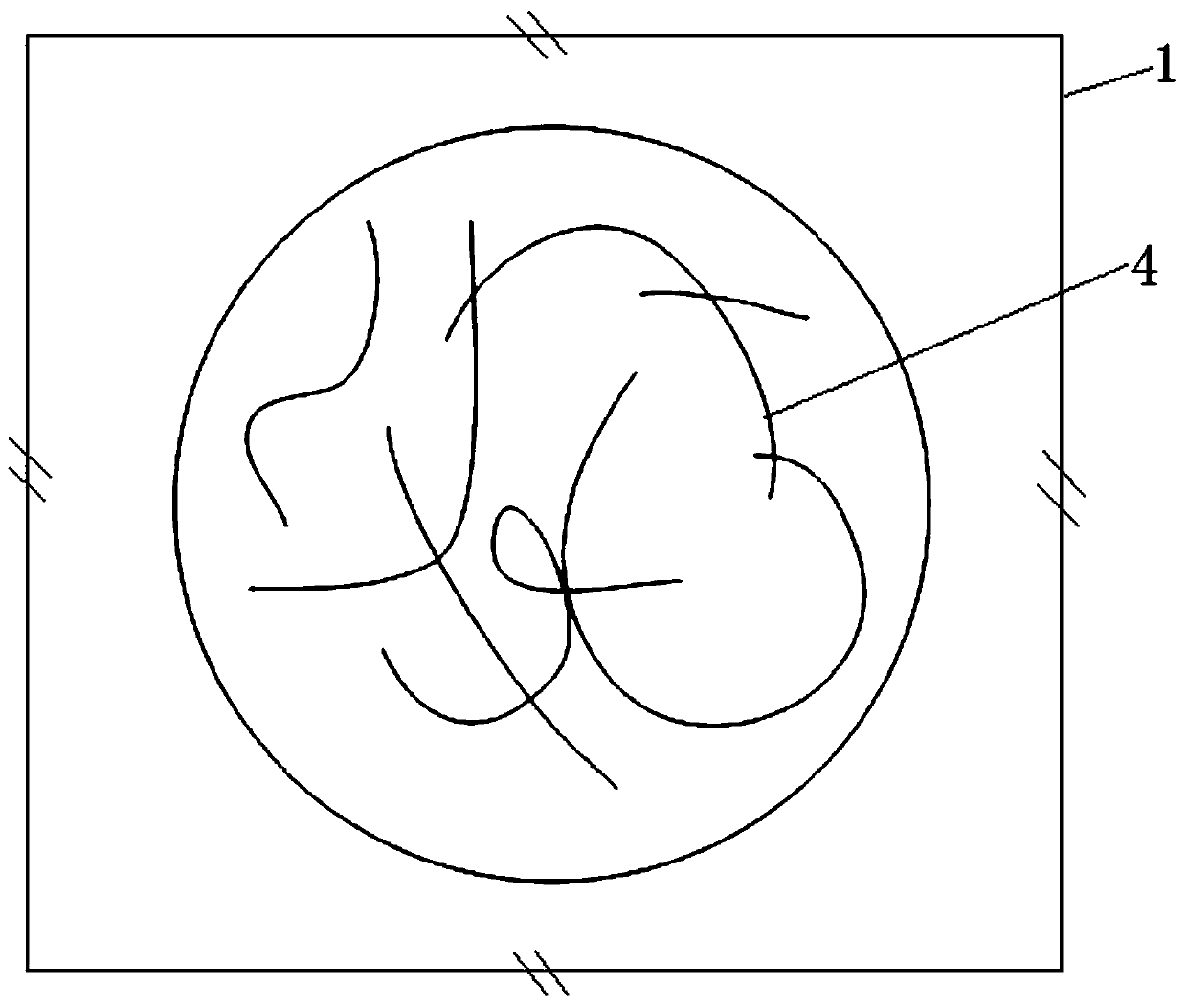

ActiveCN105651198AStress measurementThe stress monitoring method can measure the strain measurement of the measured objectForce measurement by measuring optical property variationUsing optical meansReference imageComputer science

The invention discloses a stress monitoring method and a stress monitoring device. The stress monitoring method comprises the following steps of: A) obtaining images of at least two preset graphs in a measured area of a measured body so as to obtain a reference image before the deformation or loading of the measured body, wherein the preset graphs have characteristic tracking points; B) obtaining images of at least two preset graphs so as to obtain a target image after a predetermined time of deformation and loading; and C) calculating first distances of the characteristic tracking points of at least two preset graphs in the strain measurement direction in the reference image and second distances of the characteristic tracking points of at least two preset graphs in the strain measurement direction in the target image, obtaining the strain of the measured body in the strain measurement direction according to the first and second distances. According to the invention, the strain and stress of the measured body can be measured.

Owner:TSINGHUA UNIV

Laser marking machine and method of adjusting distance between scanning head and marking object and automatic focusing method of marking machine

ActiveCN107755879AGuaranteed accuracyMarking speed is fastAblative recordingOther printing apparatusEngineeringAutofocus

The invention discloses a laser marking machine, a method of adjusting the distance between a scanning head of the laser marking machine and a marking object and an automatic focusing method of the marking machine. The laser marking machine comprises a rack, a supporting table, a controller, a first driving assembly and a distance measuring assembly, wherein the supporting table is arranged on therack and can move up and down along the rack; a laser marking assembly is arranged on the supporting table; the first driving assembly is arranged on the rack and is used for driving the supporting table to move up and down along the rack; the distance measuring assembly is arranged on the laser marking assembly and comprises a laser pointer and a laser sensor; the laser pointer is used for emitting laser to the surface of the marking object; the laser sensor is used for receiving the laser reflected by the surface of the marking object and sending a signal to the controller; the controller calculates the vertical distance from the surface of the marking object to the distance measuring assembly according to the signal; and the first driving assembly is used for driving the supporting table to drive the laser marking assembly to move to the distance between the scanning head and the surface of the marking object according to the signal, thereby achieving the preset distance.

Owner:GUANGZHOU NEW CKLASER CO LTD

Laser univariate color marking system and method

InactiveCN104014935AAchieve marking effectMarking speed is fastLaser beam welding apparatusPattern recognitionRepeatability

The invention discloses a laser univariable color marking method. The method comprises the steps that (1), the marking position of a laser is adjusted; (2), marking parameters of the laser are set; (3), marking areas of marking patterns are selected; (4) the marking speed in the marking areas is preset; (5) the laser is started to form an oxidation film in the areas to be marked at the preset marking speed; (6) marking is repeated until all the marking areas are marked. According to the laser univariable color marking system and method, different colors can be obtained under the situation of setting the same marking parameters by changing the marking speed, colors needed at all positions with patterns to be printed are determined according to preset color combined patterns to be printed, and therefore the printing speed is determined; the marking speed is higher, the color repeatability is good, and the multi-color patterns are integrally formed; the purpose of multi-color combined marking is achieved. The marking effect of the color combined patterns is achieved, the colorful patterns are obtained, and the colorful marking is more flexible and creative.

Owner:宁波镭基光电技术有限公司

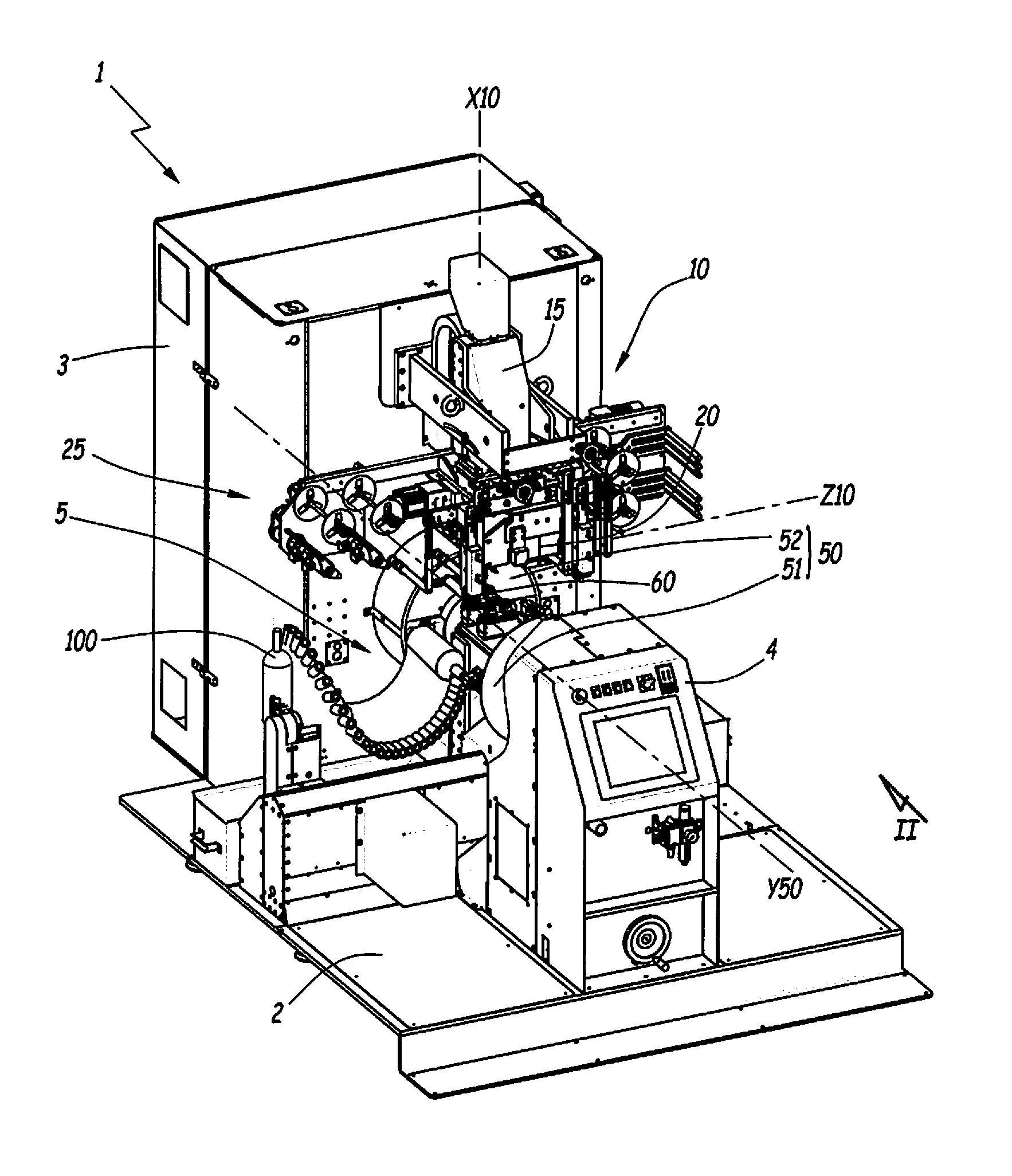

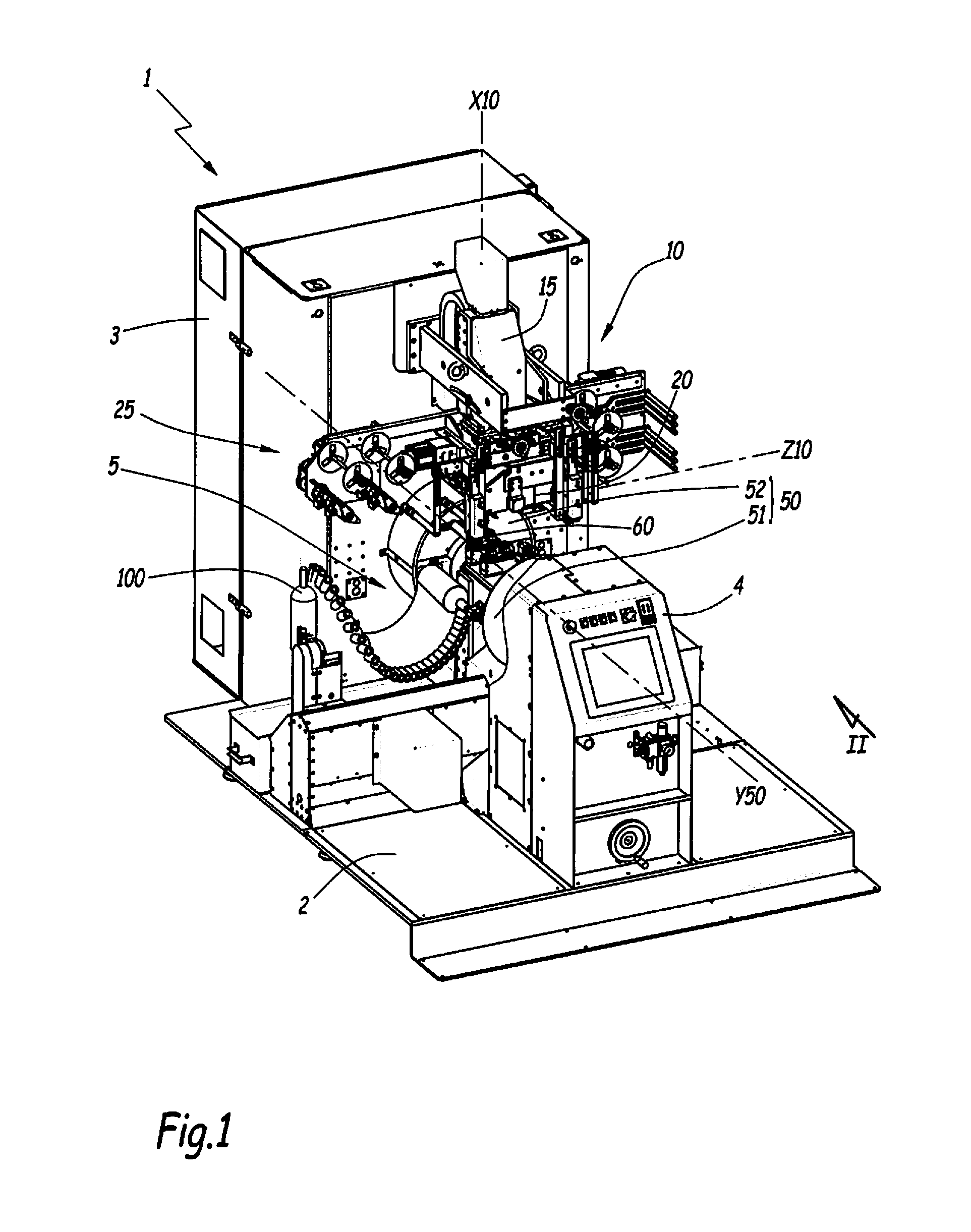

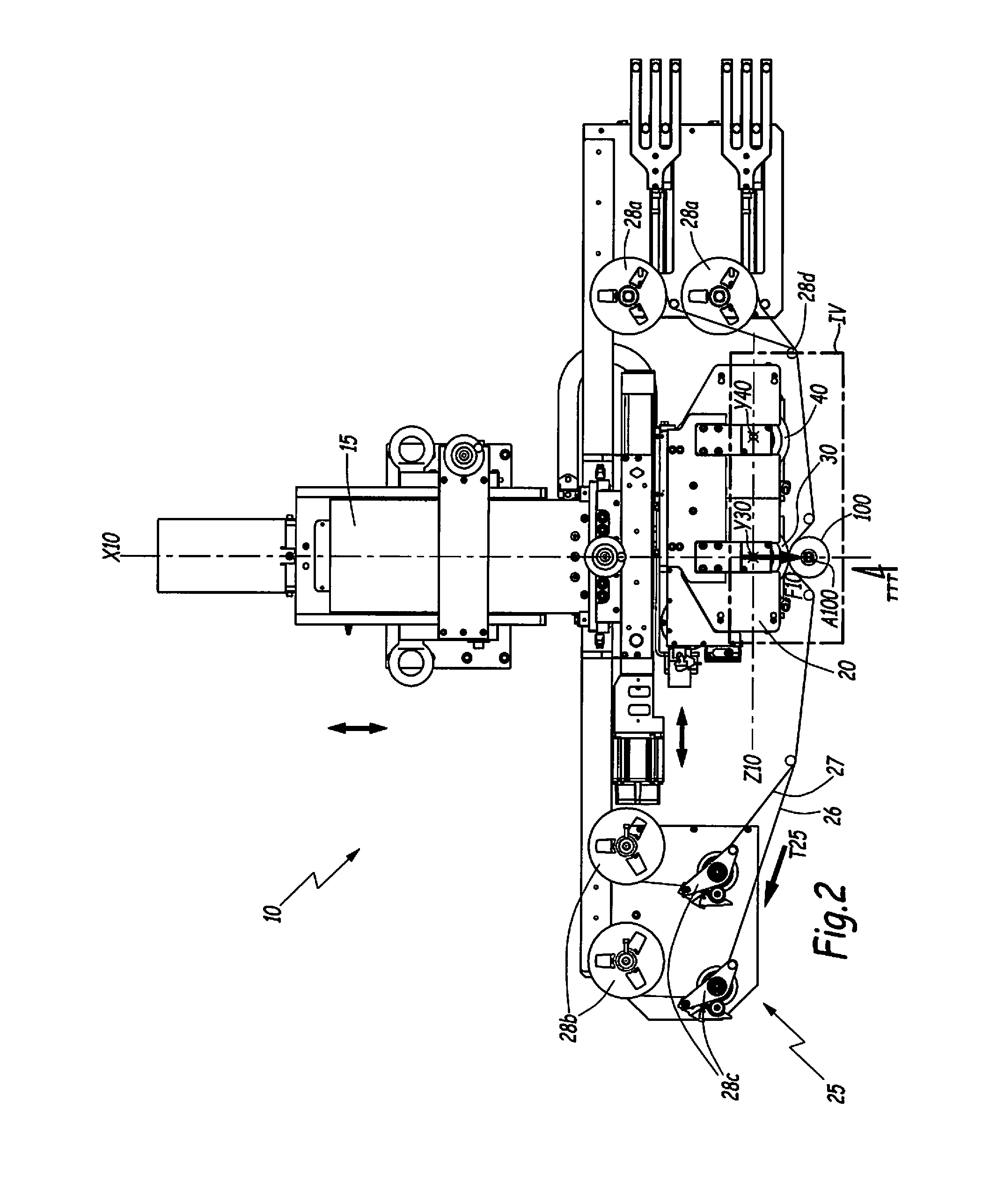

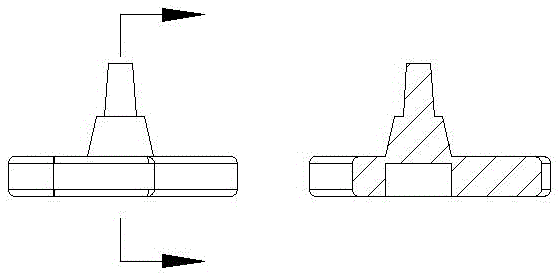

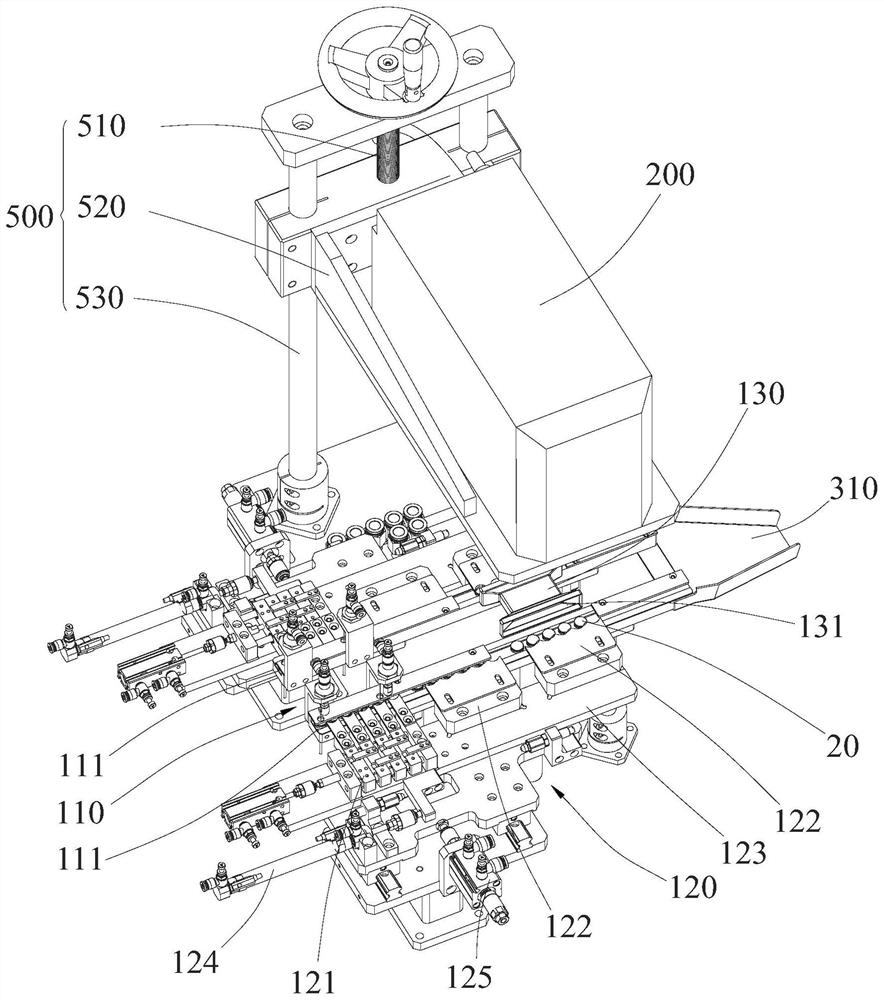

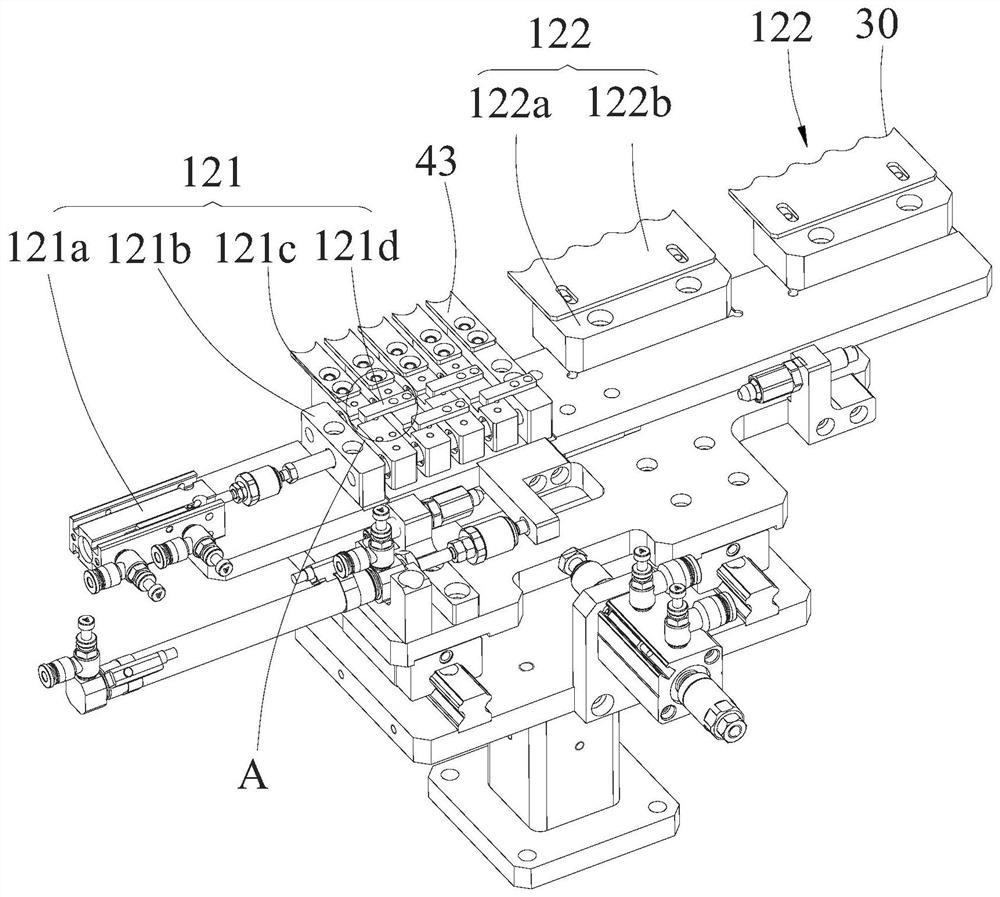

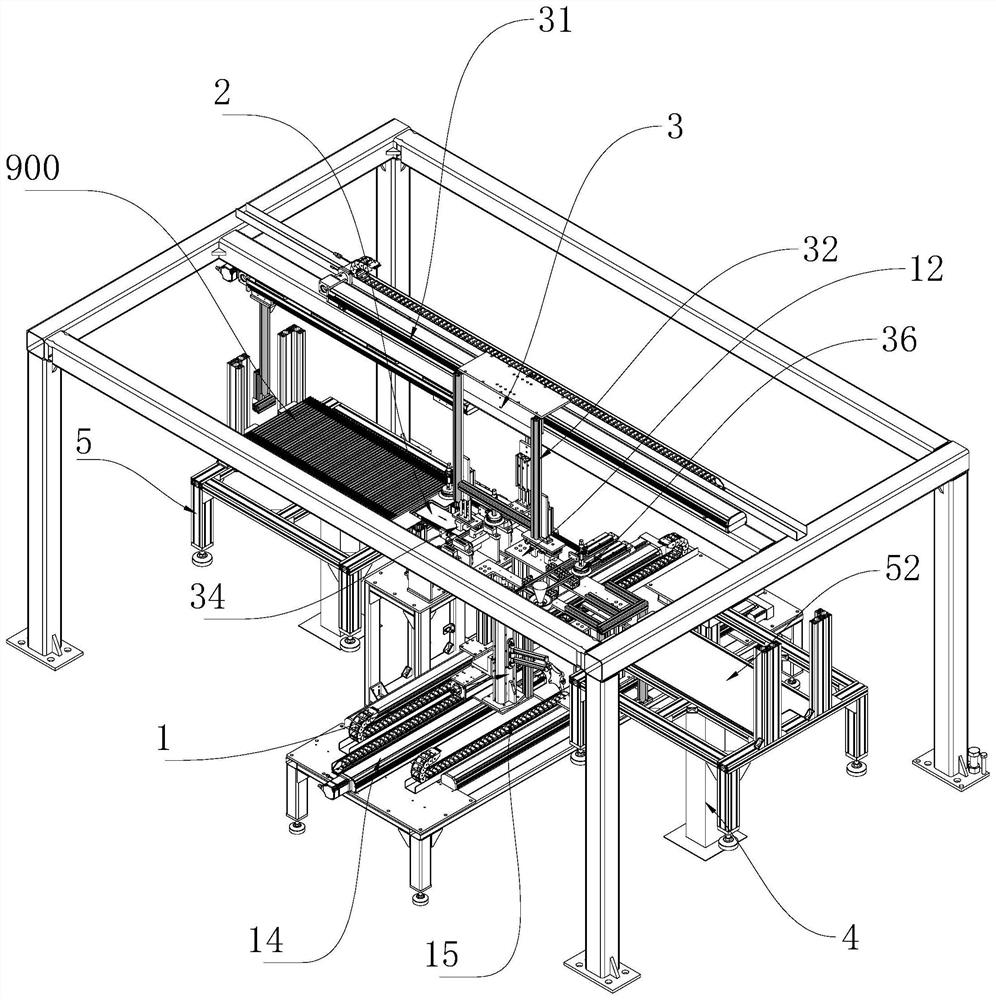

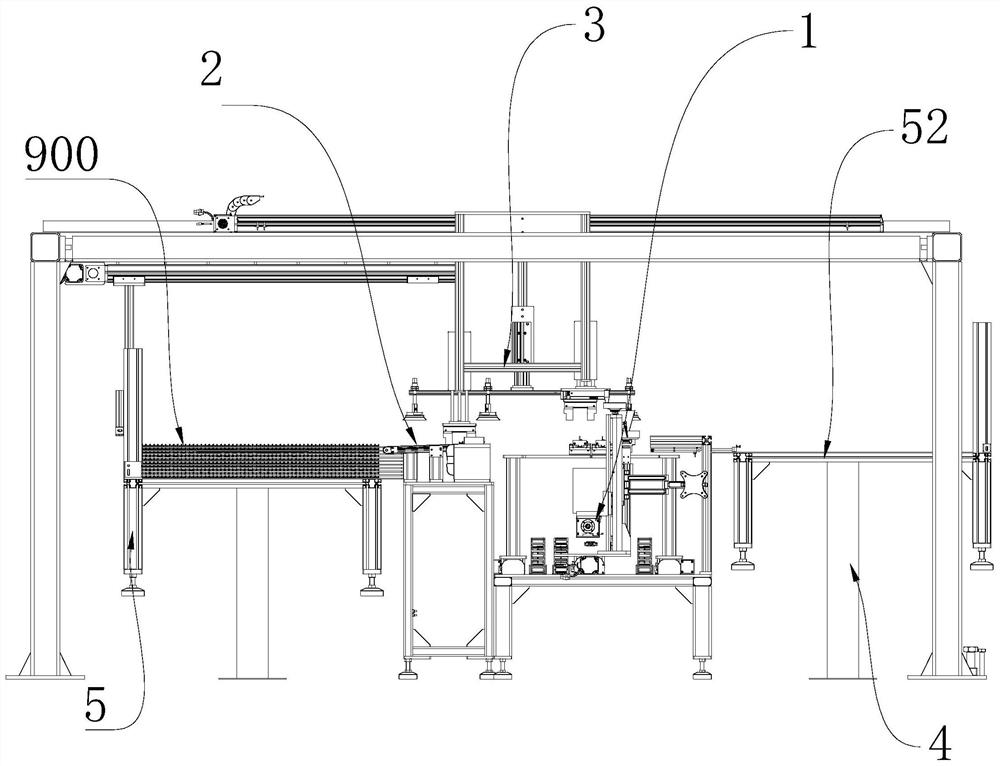

Machine and method for marking articles

ActiveUS20140216284A1Simplify manufacture and assemblyImprove versatilityTransfer printingOther printing apparatusTransverse axisEngineering

The present invention relates to a machine for marking articles, comprising a marking head suitable for applying a marking force on an article along a marking axis. The marking head comprises a carriage movable in translation along the marking axis and along a transverse axis, which is perpendicular to the marking axis (X10). The marking head also comprises a first roller and a second roller carried by the carriage, rotatable respectively around a first axis and a second axis each located in a plane perpendicular to the marking axis. The rollers are capable of alternately marking the same article or two successive articles, depending on movements of the carriage. The invention also relates to a method for marking articles.

Owner:ILLINOIS TOOL WORKS INC

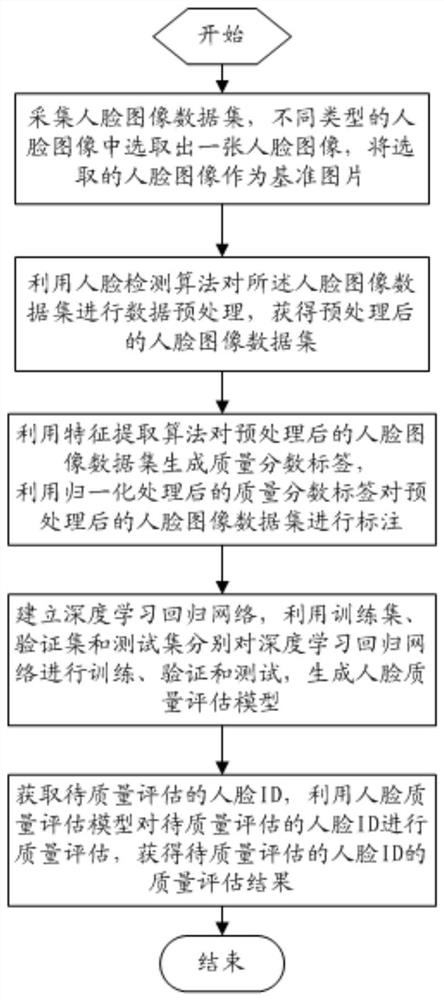

Face image quality evaluation method based on lightweight regression network

ActiveCN112215822AMeet the needs of useImprove recognition accuracyImage enhancementImage analysisFace detectionCosine similarity

The invention relates to the technical field of computer vision, and discloses a face image quality evaluation method based on a lightweight regression network, and the method comprises the steps of collecting a face image data set; performing data preprocessing on the face image data set by using a face detection algorithm; utilizing a feature extraction algorithm to generate a quality score label, training, verifying and testing the deep learning regression network, and generating a face quality evaluation model; and performing quality evaluation on the face ID to be subjected to quality evaluation by utilizing the face quality evaluation model. According to the invention, the cosine similarity and the face confidence coefficient are used for marking the data, errors caused by manual marking are reduced, the marking speed is high, the lightweight deep learning network is used for regression of the quality score of the face image, the regression precision is guaranteed, the reasoningperformance of the face quality evaluation model is improved, the face image can be evaluated more comprehensively, and the recognition accuracy and the system operation efficiency of the face recognition system are improved.

Owner:BEIJING ICHINAE SCI & TECH CO LTD

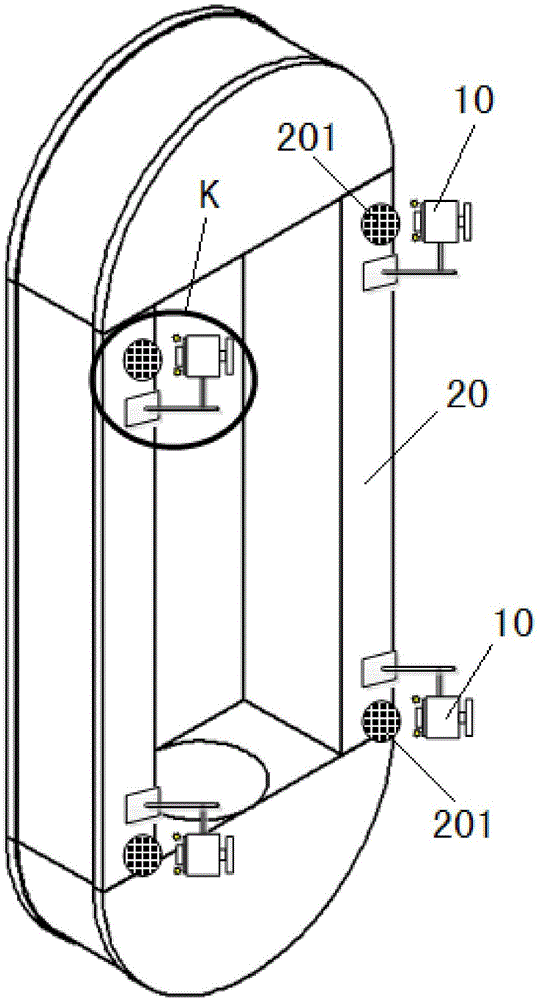

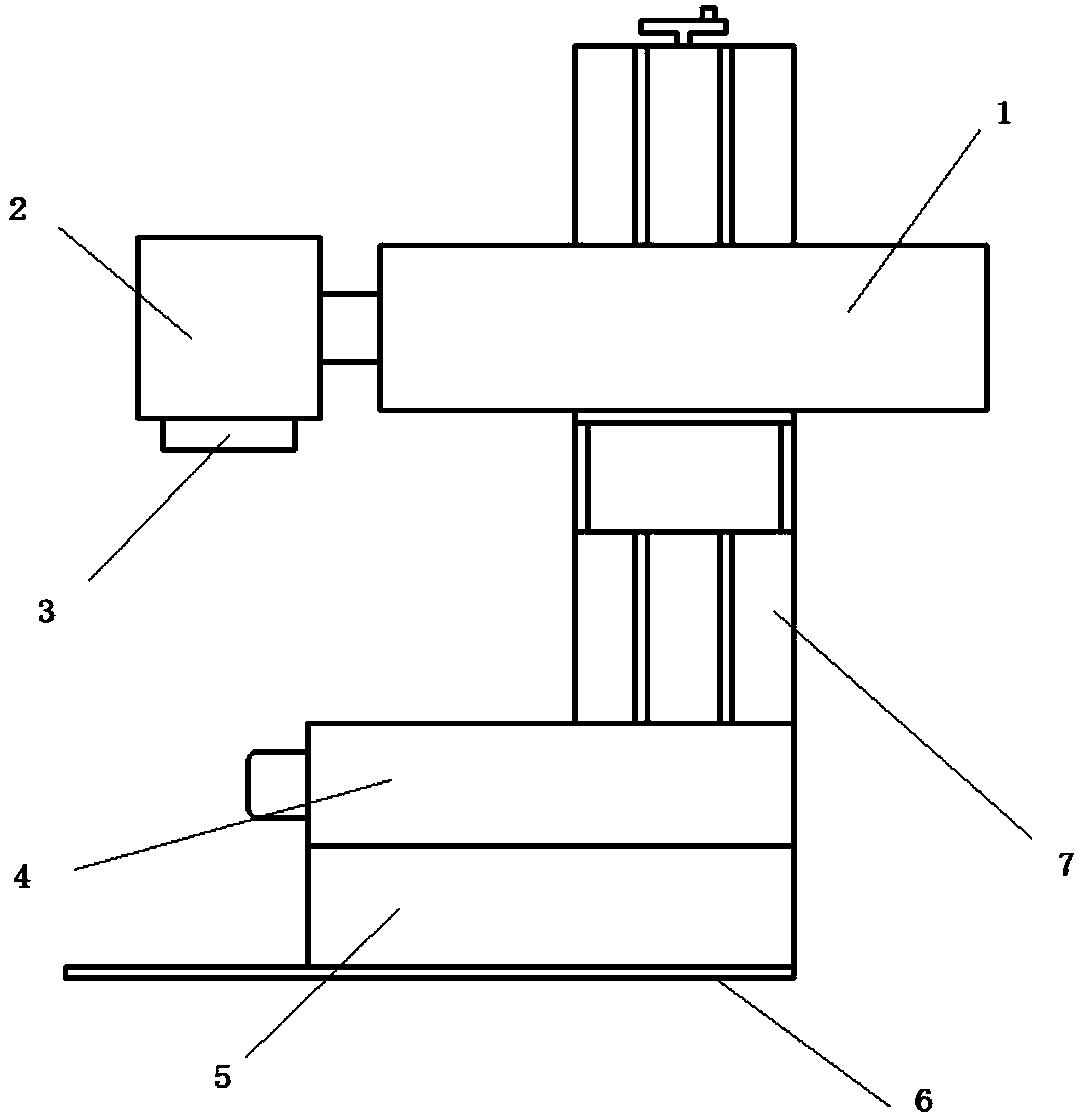

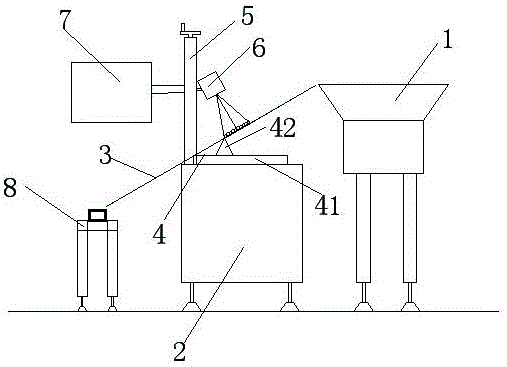

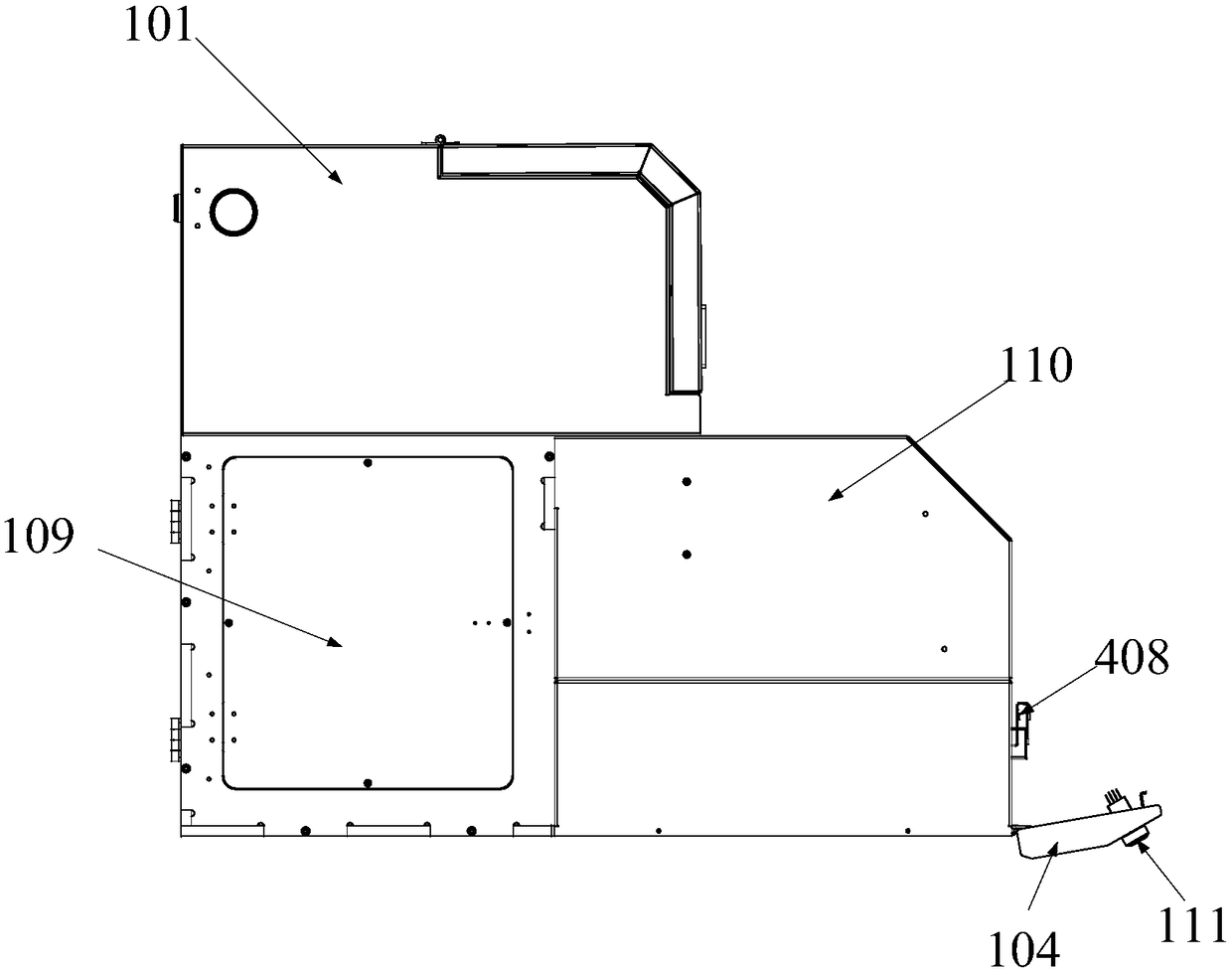

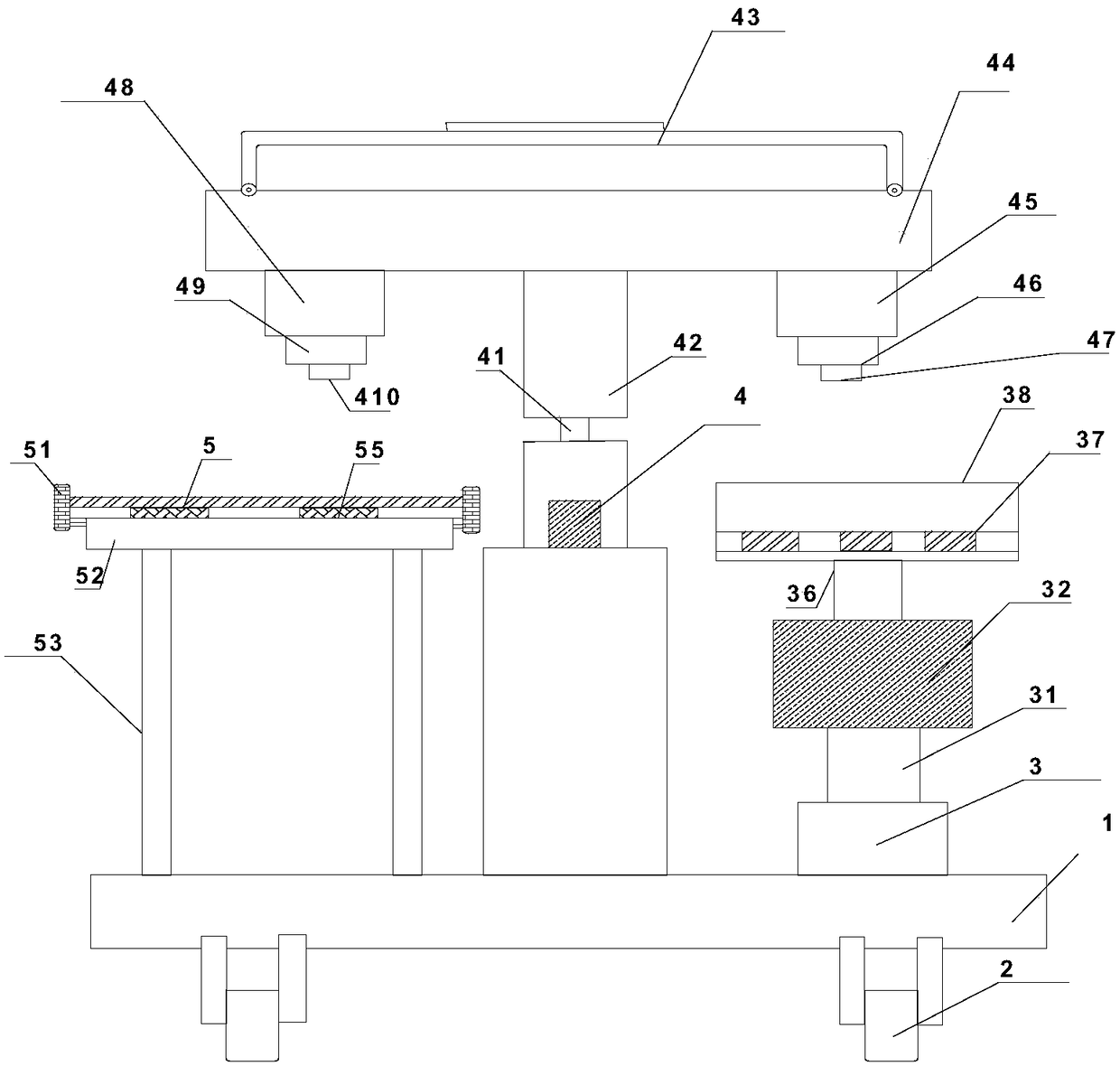

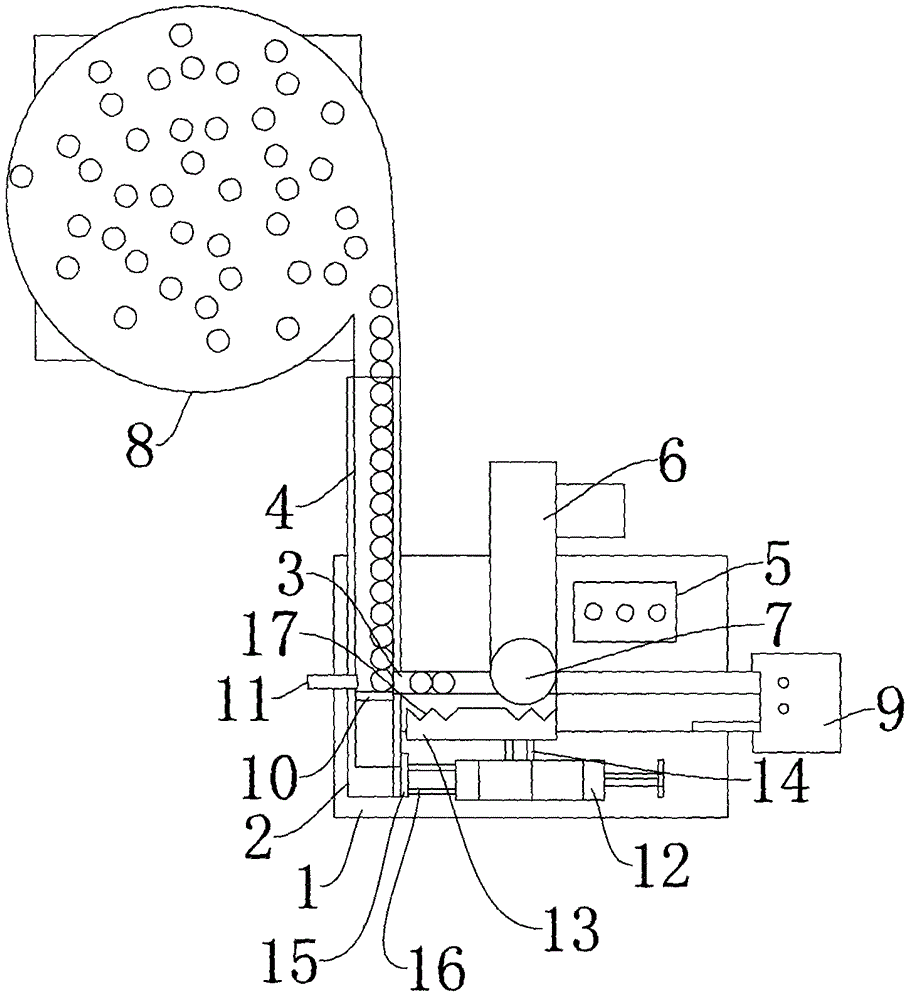

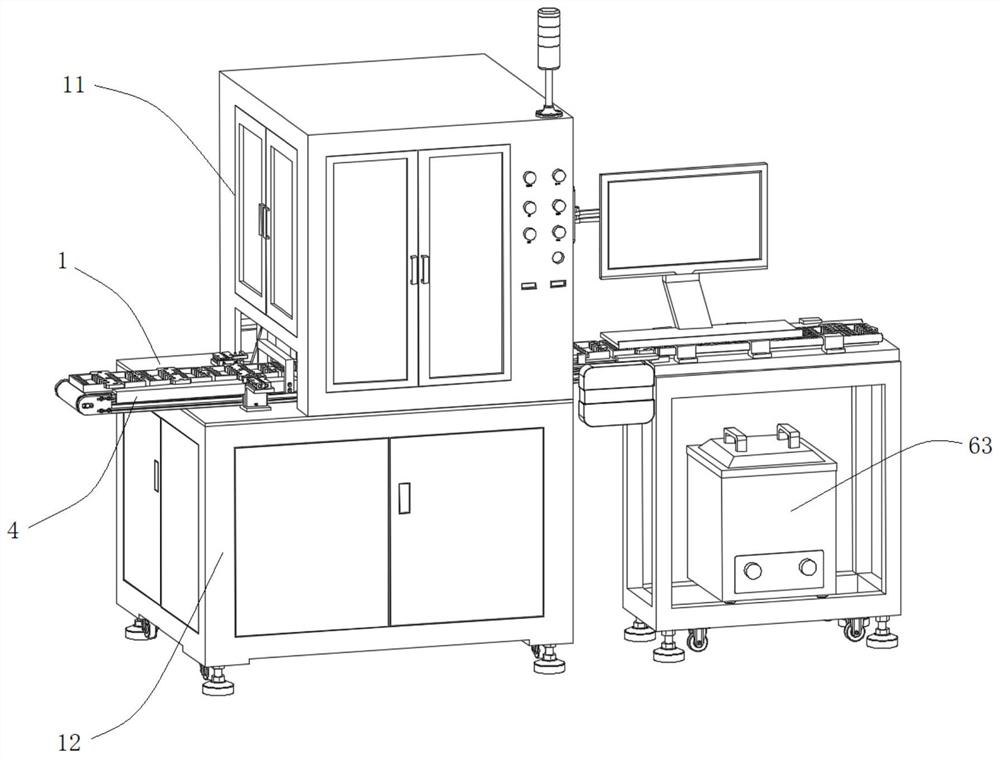

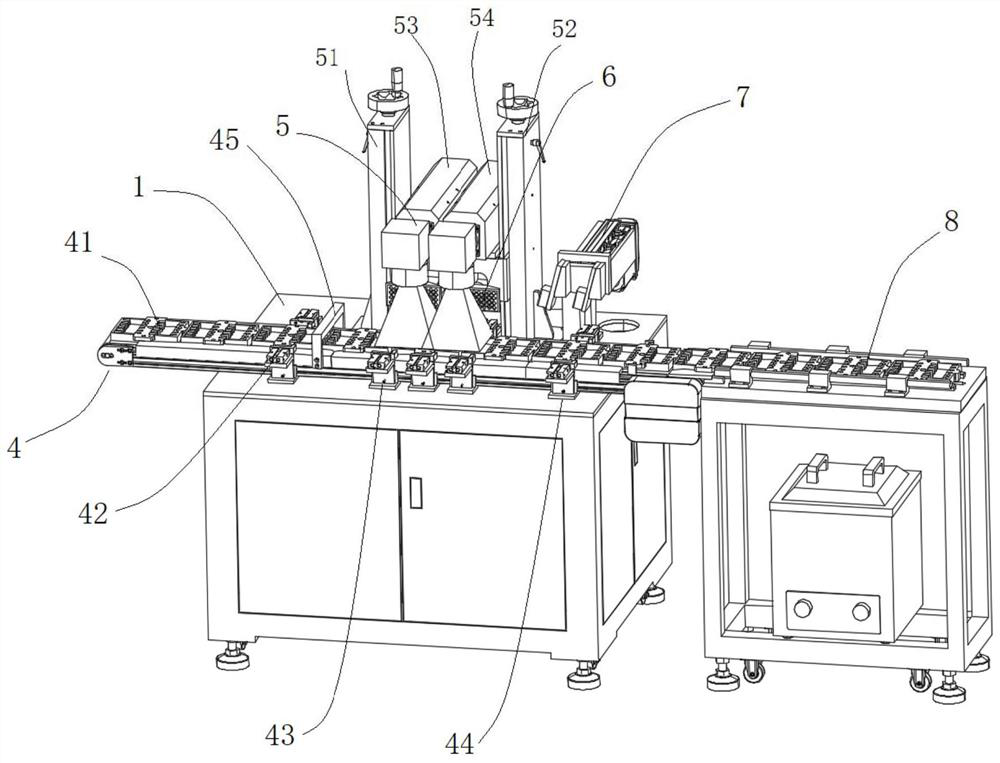

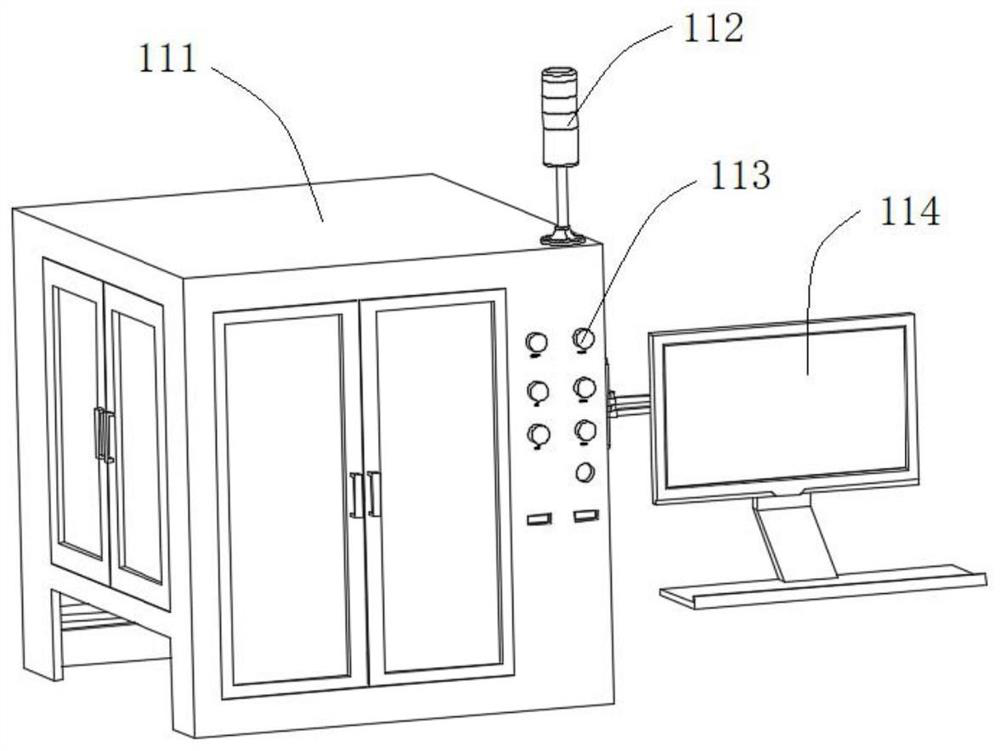

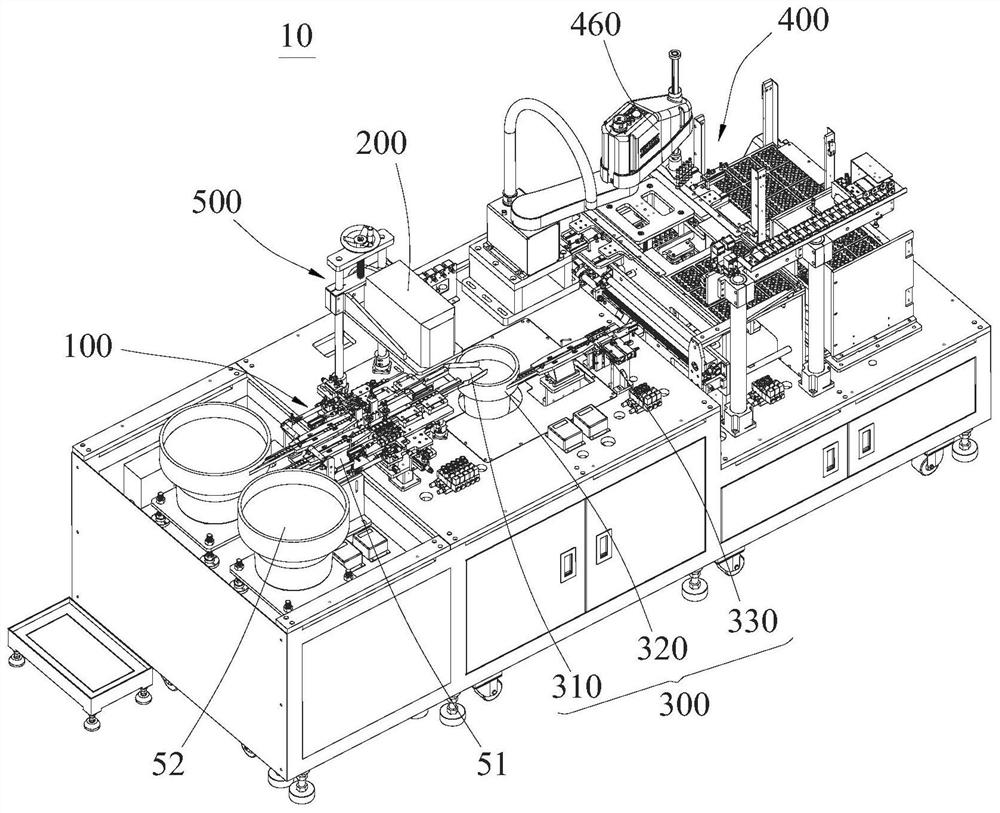

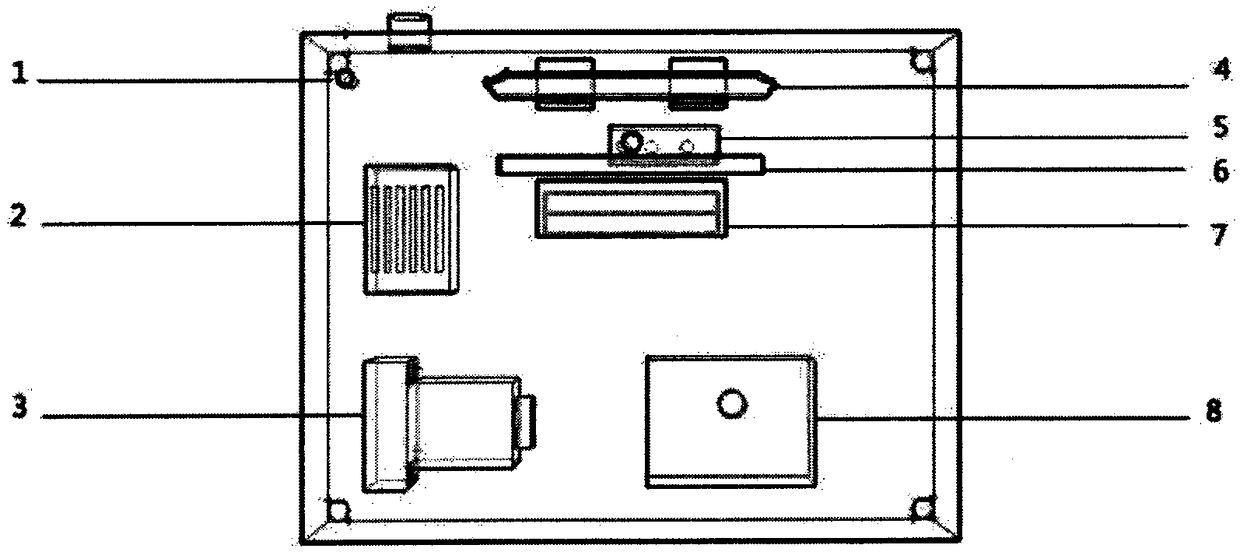

Automatic equipment and method for achieving high-speed laser marking and discharging packaging

ActiveCN105691769AMarking speed is fastImprove counting accuracyPackagingAutomatic test equipmentDisplay device

The invention discloses automatic equipment and method for achieving high-speed laser marking and discharging packaging. The automatic equipment comprises a vibration disc, a control cabinet, a discharging sliding rail, a height adjusting mechanism, a mounting column, a laser marking head, a displayer and a conveying mechanism. The discharging sliding rail is obliquely mounted above the control cabinet through the height adjusting mechanism. The mounting column is mounted on the control cabinet. The laser marking head and the displayer are mounted on the mounting column. The vibration disc is arranged at the high end of the discharging sliding rail. The conveying mechanism is mounted at the lower end of the discharging sliding rail. According to the automatic equipment for achieving high-speed laser marking and discharging packaging, automatic feeding, automatic marking, automatic counting and discharging packaging of nuts are combined together, meanwhile marking is conducted in a double-row manner, and high-speed marking can be achieved effectively.

Owner:EC PRECISION TECHJIANGSUCORP

Circuit board detection device and test system

PendingCN108427070AHigh degree of intelligenceMarking speed is fastPrinted circuit testingControl systemEngineering

The invention provides a circuit board detection device and a test system, relates to the technical field of circuit board detection and aims at solving the problem that the detection efficiency of the FPC soft board is low. The circuit board detection device comprises a body. A detection mechanism, a marking mechanism, a moving mechanism and a control system are arranged in the body. The detection mechanism, the marking mechanism and the moving mechanism are respectively connected with the control system. The detection mechanism includes a first driver and a detection needle used for detecting materials. The first driver drives the detection needle to move in the first direction; the marking mechanism comprises a second driver and a marking element. The marking element is used for markingthe material which is not qualified on the detection result. The second driver drives the marking element to move; the moving mechanism is used for driving the material to be detected to move in thesecond direction to reach the detection area of the detection needle and the marking area of the marking element. The circuit board detection device is applied to the FPC soft board detection, integrated with movement, detection and striking functions, and has high automation degree and high efficiency.

Owner:淮安杰鼎唐科技有限公司

Semiconductor-apparatus packaging device

PendingCN108565233ARealize automatic replacementRealize batch markingSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention relates to a semiconductor-apparatus packaging device. The semiconductor-apparatus packaging device comprises a marking machine and a processing platform, wherein a first support is rotationally connected on the processing platform, a second support is fixed on the processing platform, and the marking machine is installed on the first support; a gear is rotationally connected on themarking machine, a plurality of marking heads are coaxially installed between the gear and the marking machine, and are evenly distributed with a circle of the gear as the center, and extruding switches abutting against a semiconductor apparatus are arranged on the marking heads; a sector disk is rotationally connected on the second support, a rack engaged with the gear is arranged on the sector disk, and comprises two connecting parts and two arc parts, angles of the arc parts are equal to the angle of the sector disk, lengths of the connecting parts are equal to the length of the sector disk, the arc parts are located on the two side faces of the sector disk respectively, the connecting parts are connected between the ends of the two arc parts, and a plurality of clamps are arranged on the sector disk, and are evenly distributed with the circle center of the sector disk as the center. According to the technical scheme, it is achieved that the two side faces of the semiconductor apparatus are automatically marked.

Owner:重庆市嘉凌新科技有限公司

Multifunctional portable marking machine

InactiveCN108081759AImprove work efficiencyImprove efficiencyTypewritersAgricultural engineeringOperating table

The invention discloses a multifunctional portable marking machine. The machine is suitable for various marking occasions, and comprises a base, a fixing base, a second motor and a second supporting column, a cross arm is arranged at the upper end of the connecting shaft, and handles are arranged at the two ends of the upper side of the cross arm, a first marking head is arranged on the lower sideof the first marking device, a second marking device is arranged at the lower end of the left side of the cross arm through a second telescopic column, a second marking head is arranged on the lowerside of the second marking device, two operating tables are arranged on the base and can carry two or more types of samples to be standard, the working efficiency is improved, and the cost is reduced.; the two marking heads are arranged above the two operation tables respectively, the marking speed is increased, and the efficiency is further improved; and the whole cross arm can rotate left and right through the second motor, to switch the positions to realize the marking on the two operation tables, and the operation is convenient and rapid to use, the practicability is very high; pulleys andhandles are arranged at the bottom of the base and the upper end of the cross arm, and convenient pushing and pulling, and displacement are achieved.

Owner:XINGUANG NUMERICAL CONTROL TECH

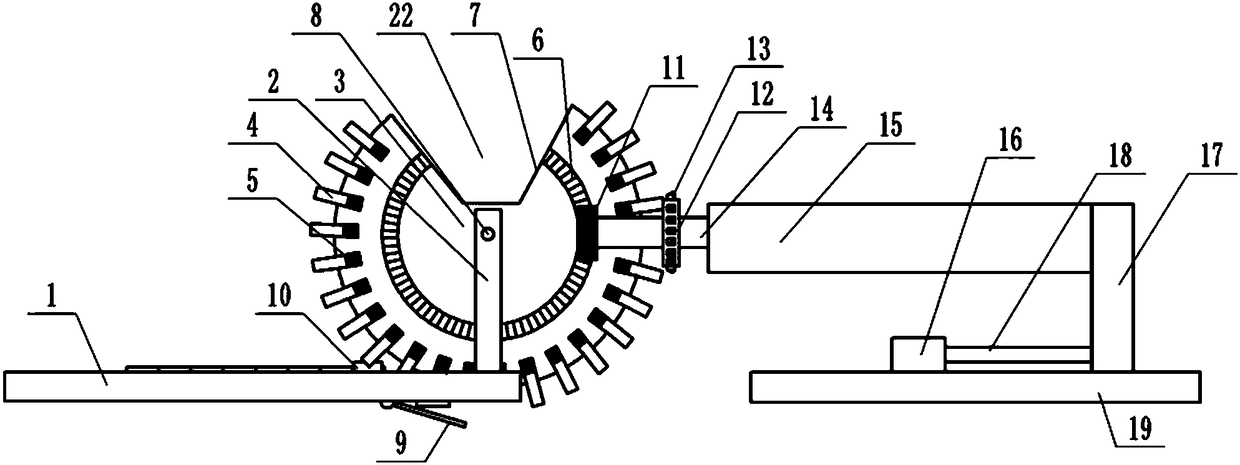

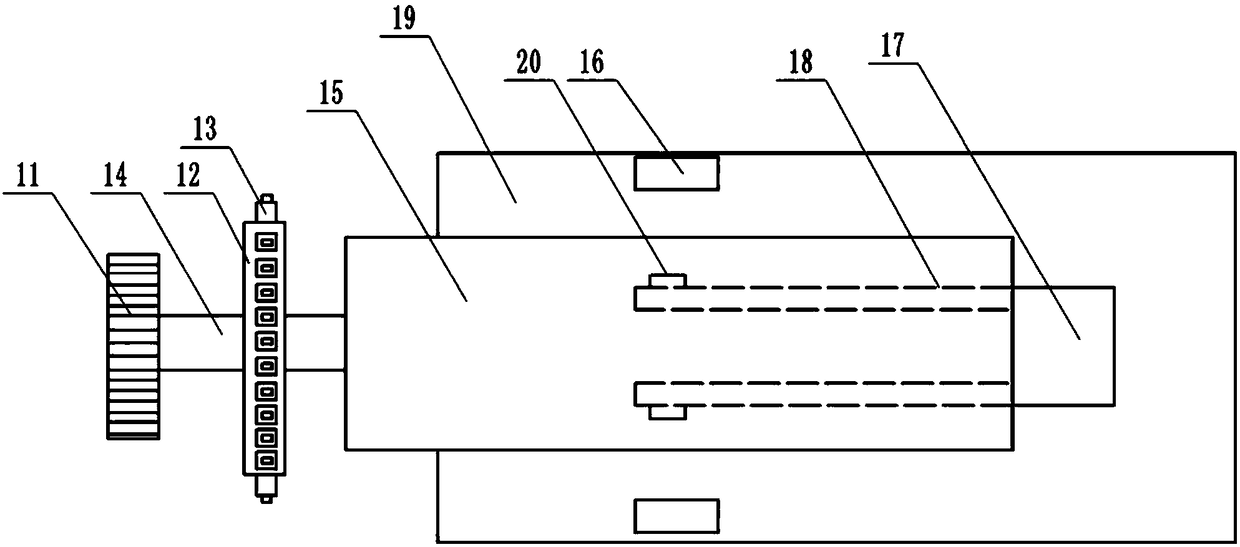

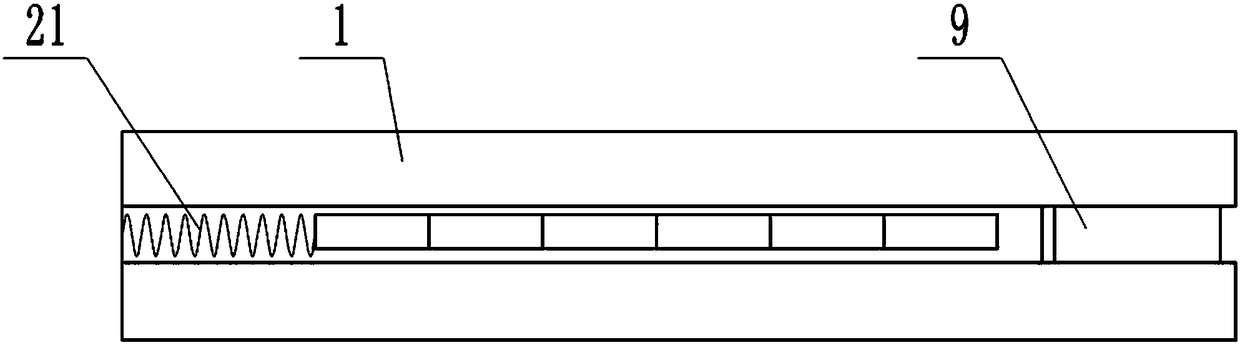

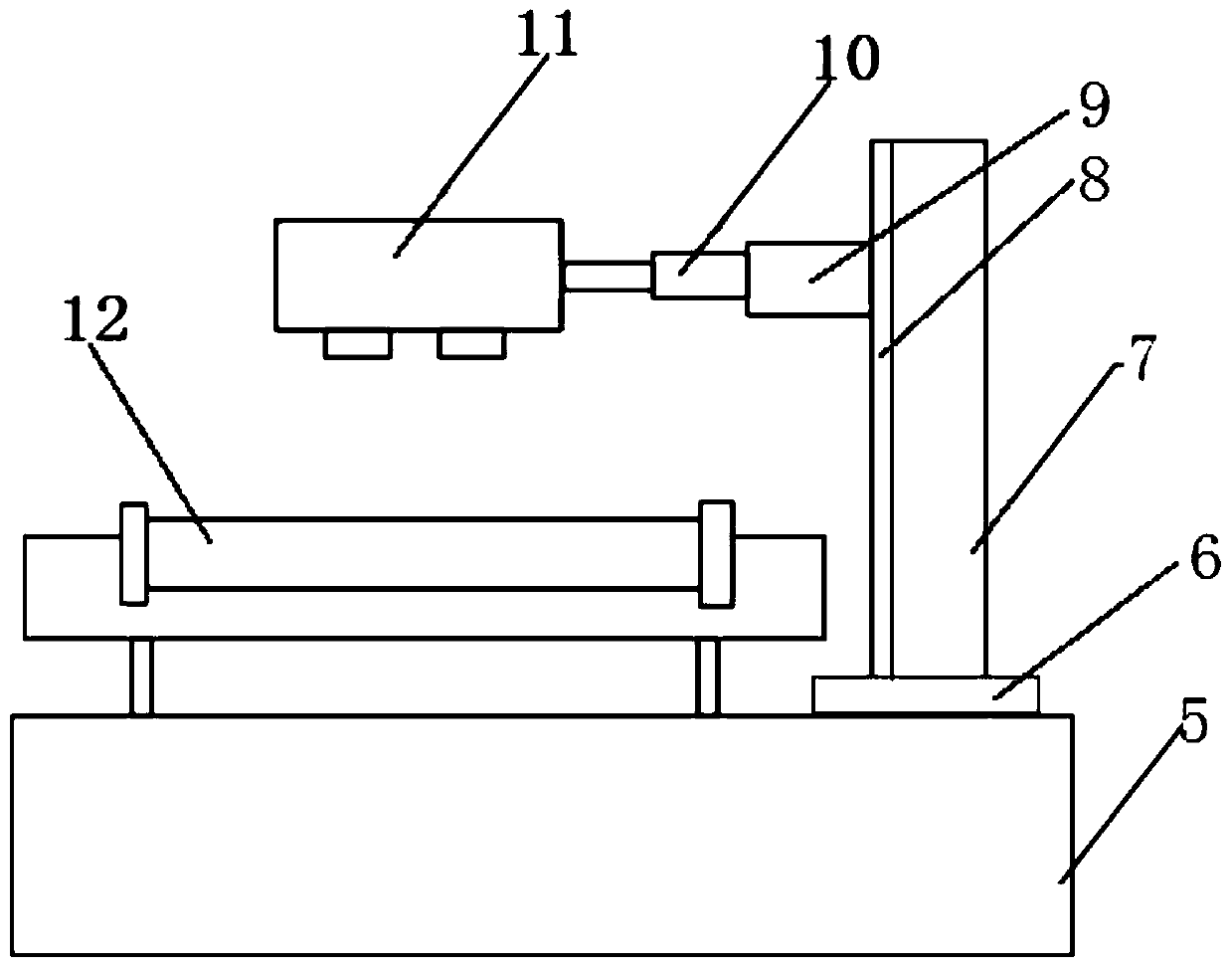

Automatic laser marking machine for bearing

InactiveCN104999803AMarking speed is fastImprove work efficiencyTypewritersEngineeringMechanical engineering

The invention discloses an automatic laser marking machine for a bearing. The automatic laser marking machine comprises a frame, a conveying table and a conveying guiderail; wherein the conveying table and the conveying guiderail are arranged on the frame. A conveying belt is arranged on the conveying table. The frame is also provided with a control host computer and a laser seat. The laser seat is provided with a laser head. One end of the conveying belt is connected with a material arranging turntable. One end of the conveying guiderail is connected with the conveying belt, and the other end is provided with a material accommodating box. The frame is also provided with a material pushing mechanism which is used for pushing the bearing into the conveying guiderail, and a clamping mechanism which is used for clamping the bearing and drives the bearing to move frontwards. The automatic laser marking machine has advantages of high marking speed and high operation efficiency.

Owner:NINGBO KELEISHI LASER TECH CO LTD

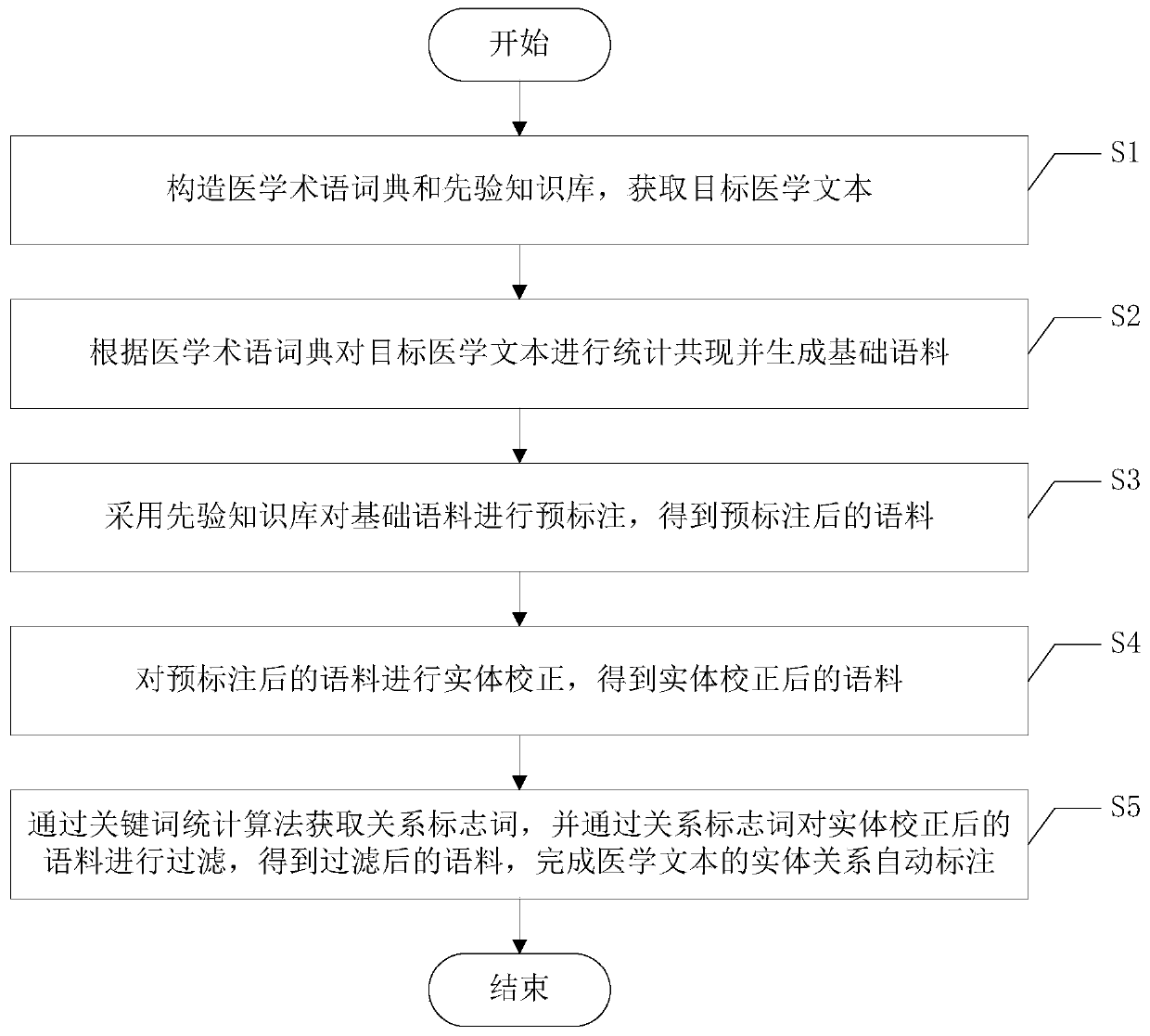

Entity relationship automatic labeling method applied to medical text

ActiveCN111291568AReduce investmentSolve the problem of labeling difficultiesNatural language data processingSpecial data processing applicationsNatural language processingMedicine

The invention discloses an entity relationship automatic labeling method applied to a medical text. The entity relationship automatic labeling method comprises the following steps: S1, constructing amedical term dictionary and a priori knowledge base, S2, performing statistical co-occurrence on the target medical text according to the medical term dictionary and generating a basic corpus, S3, pre-annotating the basic corpus by adopting a priori knowledge base to obtain a pre-annotated corpus, S4, performing entity correction on the pre-annotated corpus to obtain an entity-corrected corpus, and S5, filtering the corpus subjected to entity correction through relationship marker words to finish automatic labeling of the entity relationship of the medical text. According to the invention, anautomatic labeling form is adopted, the labor input of researchers in relation extraction is reduced, the labeling speed is high, meanwhile, the method does not need to depend on labeling of experts,the problem that medical texts are difficult to label is solved, the labeled texts are further filtered through relation marker words, and the labeling precision can be obviously improved.

Owner:SOUTHWEST JIAOTONG UNIV

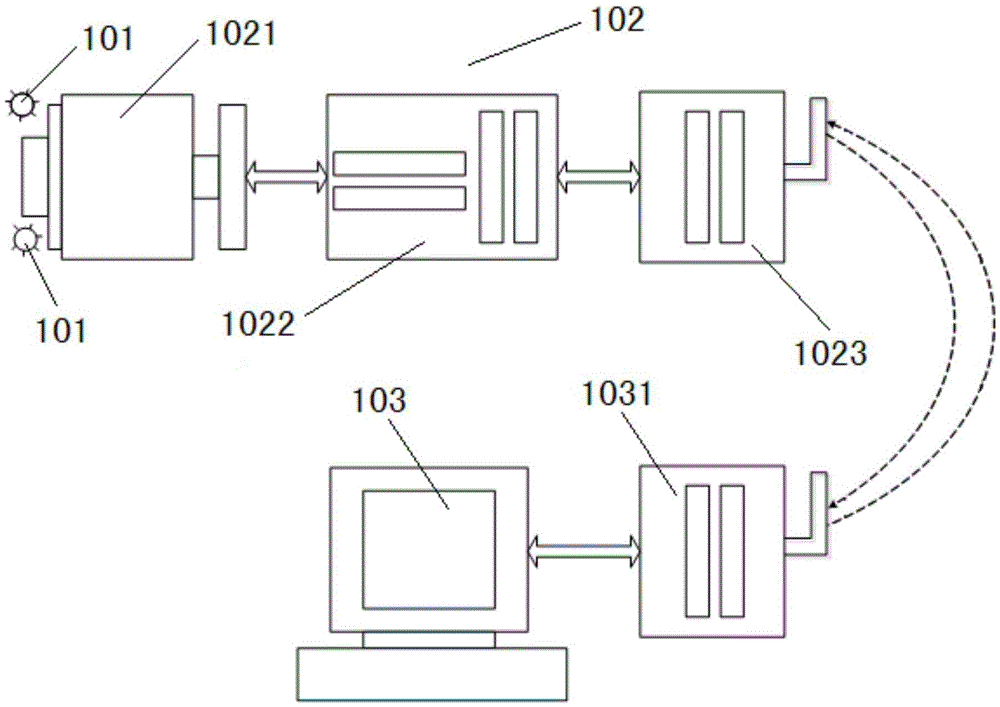

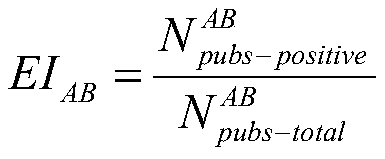

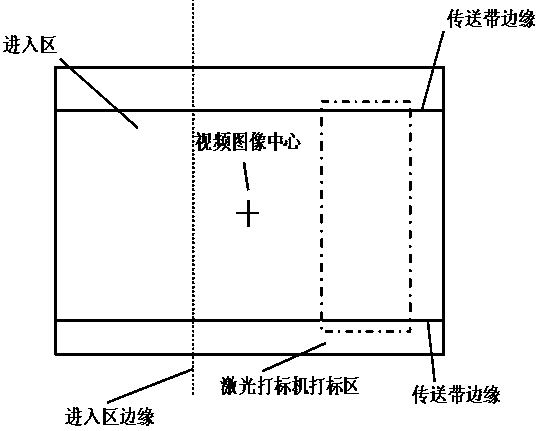

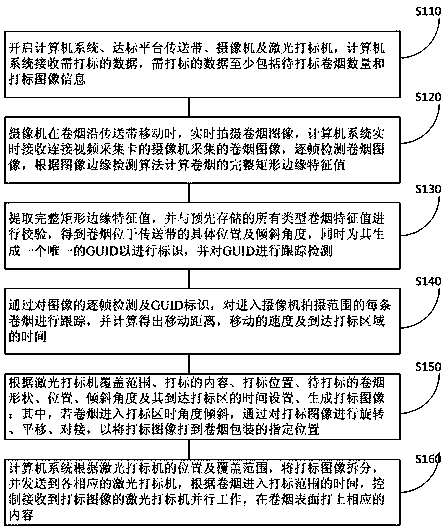

Cigarette laser marking system and method based on image processing

InactiveCN108391847AMarking speed is fastImprove stabilityCigarette manufactureComputer visionImage based

The invention relates to a cigarette laser marking method and system based on image processing. The cigarette laser marking method comprises the following steps: detecting a cigarette image on a conveyor belt to obtain a shape, a position and a movement speed of a cigarette; judging proper marking time and combining corresponding marking content; controlling a plurality of laser marking heads to mark appointed positions of the cigarette at the same time, so as to completely solve the problems of incomplete marking and missed marking. By adopting a multi-laser marking parallel work manner, a marking speed is effectively improved and the problem of the working stability is effectively solved through a redundancy method. A control system provides a complete interface so that data butting is very easy to realize. A ventilation channel design is adopted, and wind is blown from the lower side and is sucked from the upper side, so that the treatment problem of harmful gas generated by laser marking is completely solved.

Owner:SHANXI UNIV

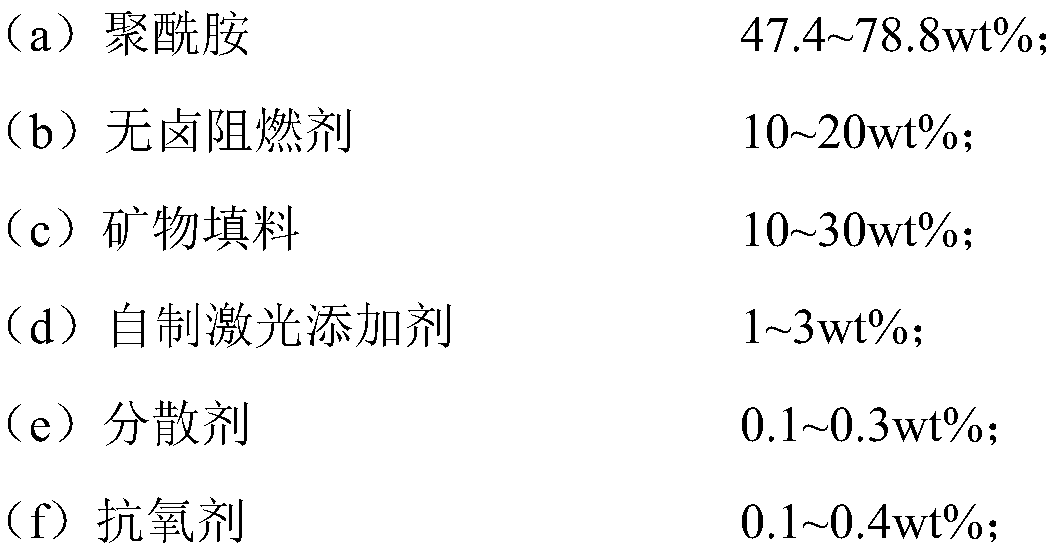

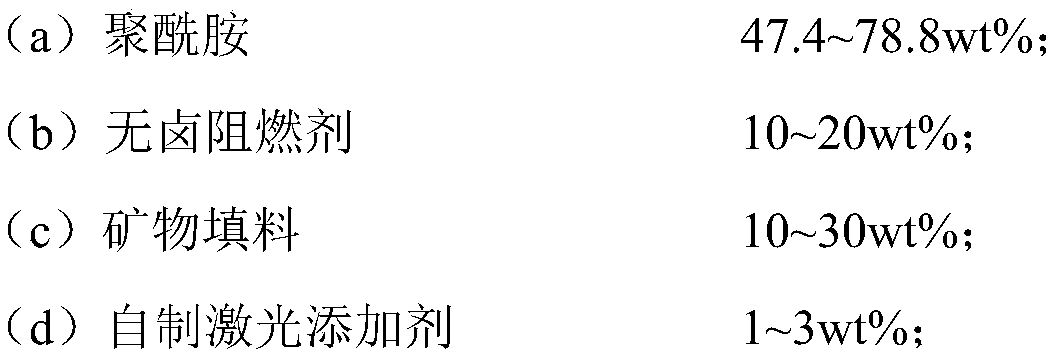

Laser-labelable, halogen-free and flame-retardant polyamide composition and preparation method thereof

InactiveCN110229507AImprove flame retardant performanceImprove electrical performanceAntioxidantPolyamide

The invention discloses a laser-labelable, halogen-free and flame-retardant polyamide composition and a preparation method thereof. The composition comprise 47.4-78.8 wt% of a polyamide, 10-20 wt% ofa halogen-free flame retardant, 10-30 wt% of a mineral filler, 1-3 wt% of a self-made laser additive, 0.1-0.3 wt% of a dispersant and 0.1-0.4 wt% of an antioxidant, wherein the self-made laser additive is a mixture composed of titanium dioxide, mica powder, nanometer tin antimony oxide and copper according to a mass ratio of (10-10.4):(2.5-7.2):(1.4-1.5):1, and is prepared by melt blending througha screw extruder. The obtained polyamide composition can simultaneous be clearly deeply labeled with infrared laser and ultraviolet laser, and maintains good mechanical and electrical performances.

Owner:江苏晋伦塑料科技有限公司

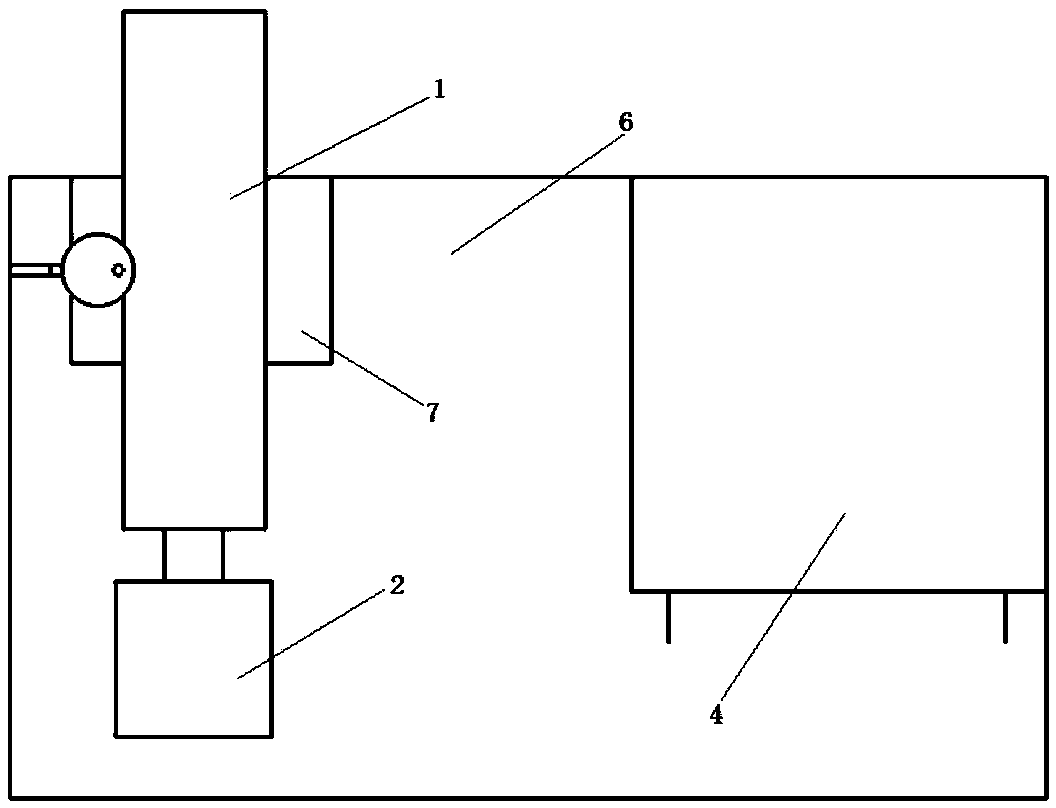

Vertical type starter label-printing machine

A vertical starter marking machine comprises a shell marking machine and a switch marking machine. The shell marking machine consists of a plane sliding table fixed on a rotary bottom plate and a vertical sliding table. A starter assembly is tightly clamped on a fixed frock by a claming cylinder. The switch marking machine consists of a plane sliding table and a vertical sliding table fixed on a working table-board. The shell marking machine is arranged on the sliding table of the shell marking machine; the shell marking machine can move up and down and be rotated. The switch marking machine is arranged on the vertical sliding table of the switch marking machine and can slide forwards, backwards, upwards and downwards. The starter clamping cylinder is fixed on the working table-board; according to the shell marking position and the starter switch marking position after the starter shell is tightly clamped, the shell marking machine and the switch marking machine are respectively arranged, which ensures the head of the shell marking machine to be aligned with the shell marking position and the head of the switch marking machine is aligned with the position of the starter switch marking; the automatic control is carried out by the PLC when normal working. The invention has the advantages of simple and convenient operation, clear marking number, good effect, fast marking speed and high automation.

Owner:杨旭伟

Automatic laser marking and tracing equipment

PendingCN112692442AReduce manual operationsReduce labor intensityLaser beam welding apparatusSensing by electromagnetic radiationErbium lasersMechanical engineering

The invention relates to the technical field of laser marking, and particularly discloses automatic laser marking and tracing equipment. The automatic laser marking and tracing equipment comprises a rack, and a control mechanism, a laser, a jig transfer mechanism, a laser marking mechanism, a dust collection mechanism and a code-scanning mechanism which are installed on the rack; the jig transfer mechanism comprises a flow-line assembly, a jig obverse and reverse detection assembly, a first jig positioning assembly, a second jig positioning assembly and a third jig positioning assembly; the laser marking mechanism is located above the flow-line assembly, and corresponds to the second jig positioning assembly in position; the dust collection mechanism is located above the first jig positioning assembly, and is near the lower end of the laser marking mechanism; and the code-scanning mechanism is located above the flow-line assembly, and corresponds to the third jig positioning assembly in position. According to the automatic laser marking and tracing equipment, flow-line work is adopted, automatic operation of product marking is achieved, product marks are scanned, and it is guaranteed that quality standard of products is reached.

Owner:广东镭泰激光智能装备有限公司

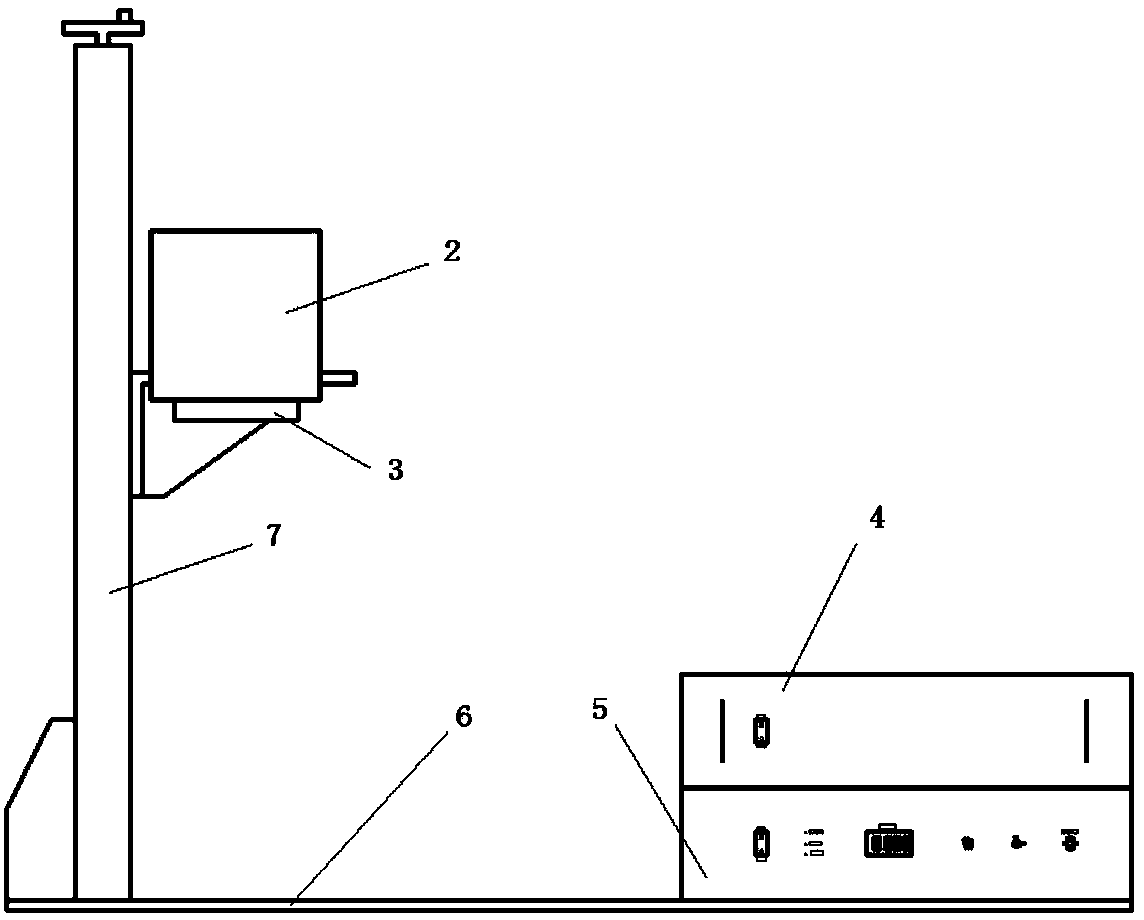

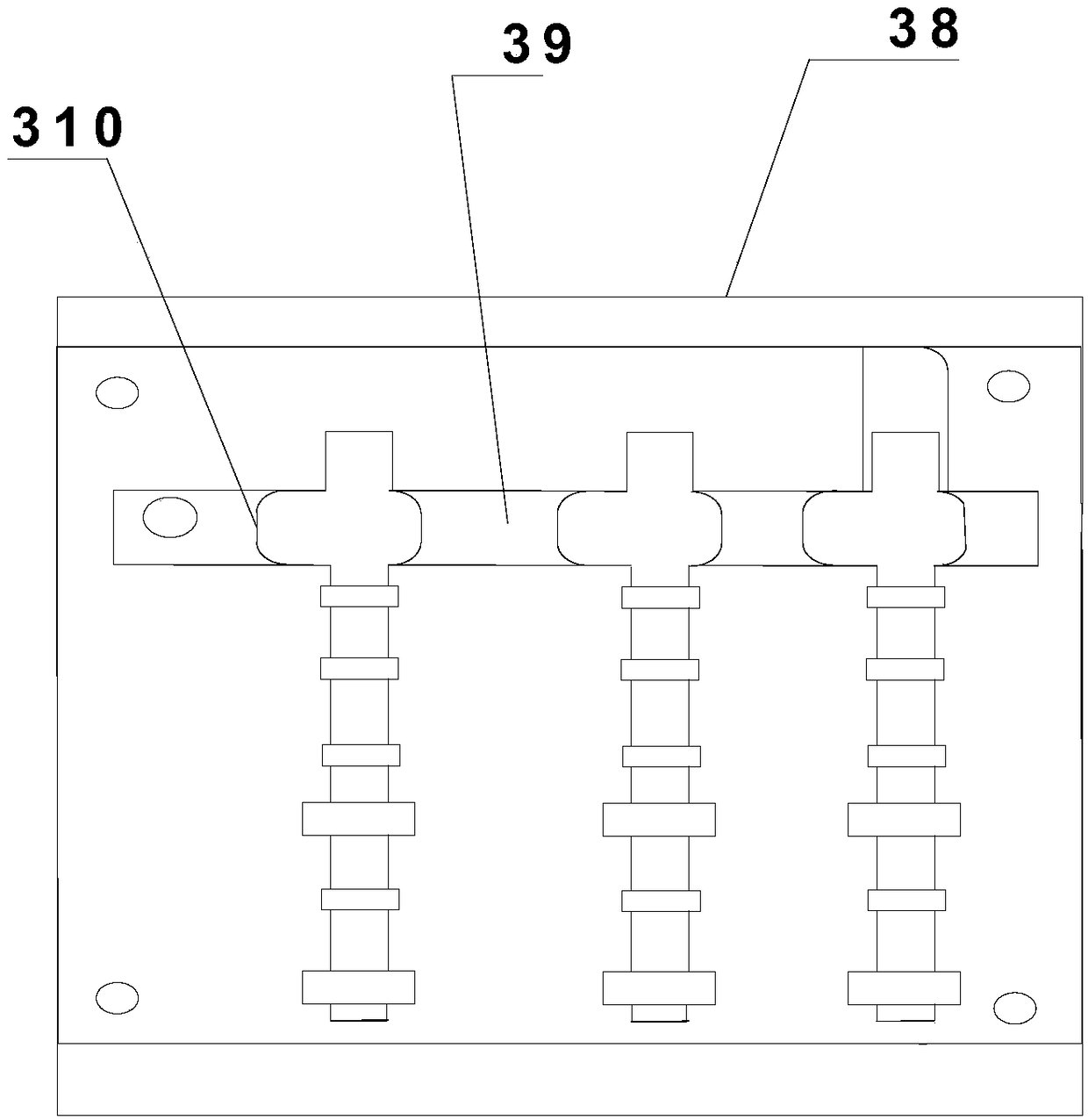

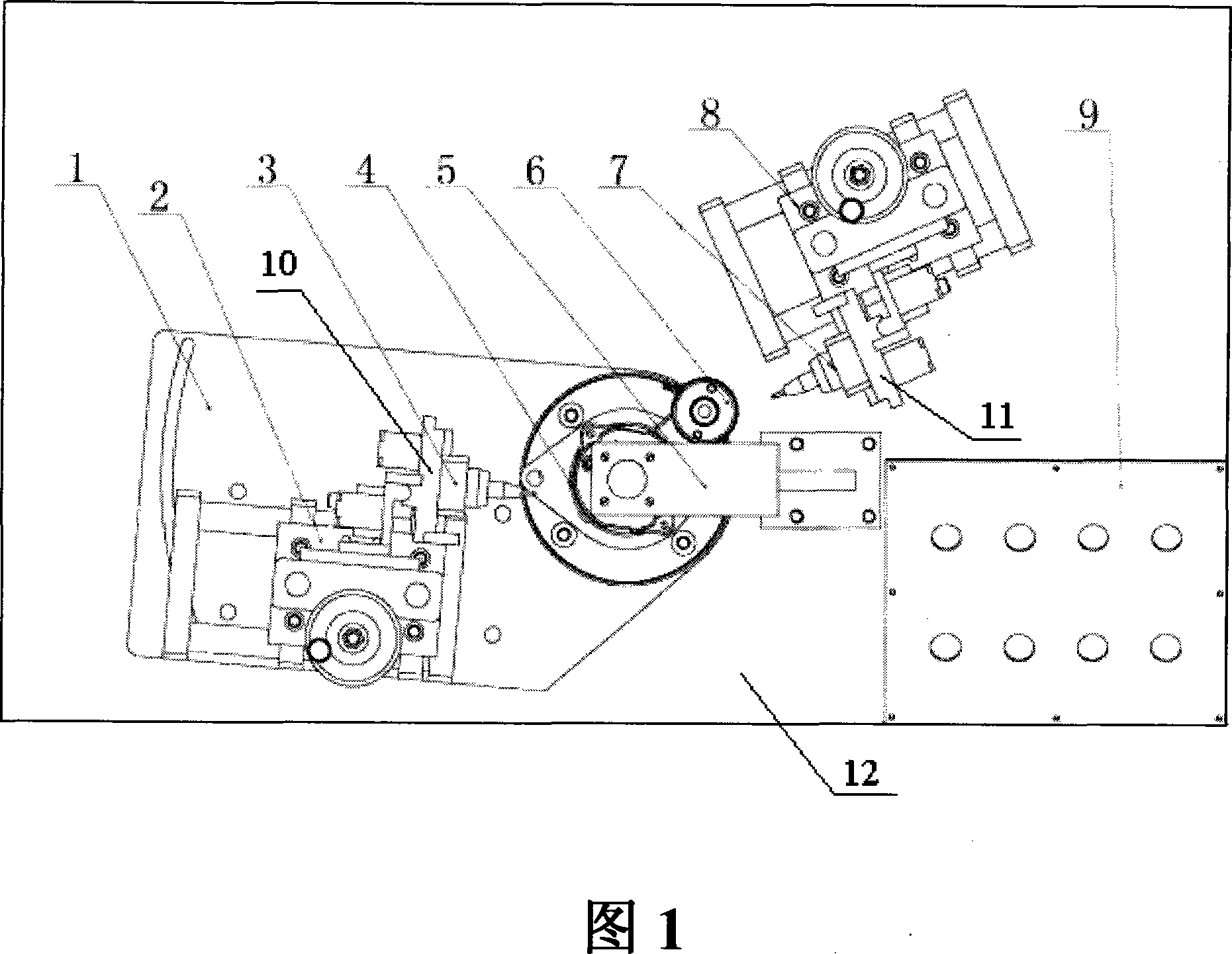

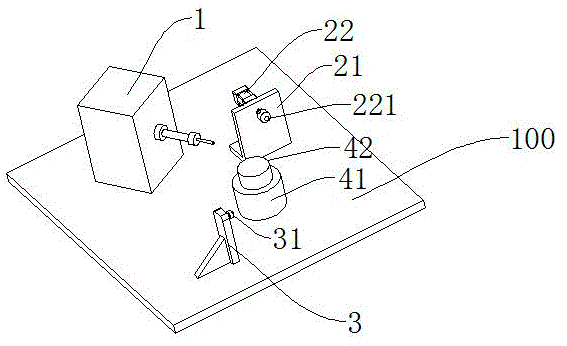

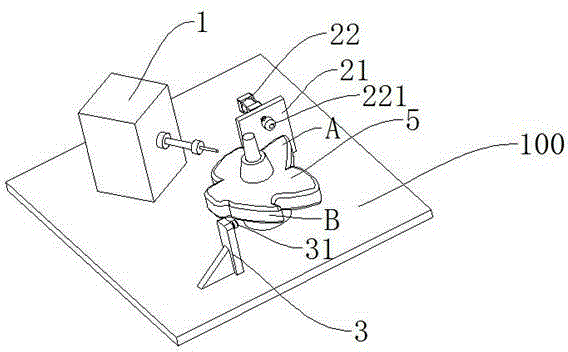

Knuckle pivot marking machine

InactiveCN104859314AOvercoming time-consuming and laboriousMarking speed is fastTypewritersKnuckleFast speed

The invention discloses a knuckle pivot marking machine comprising a substrate fixedly connected with a laser making machine, a knuckle pivot push unit, a knuckle pivot stop unit and a knuckle pivot placing unit; the knuckle pivot push unit comprises a cylinder fixing plate fixed on the substrate; the cylinder fixing plate is fixedly connected with a knuckle pivot push cylinder, and a front end of the knuckle pivot push cylinder is connected with a push block; the knuckle pivot stop unit comprises a support plate fixed on the substrate, and one side of the support plate is fixedly connected with a stop block; the knuckle pivot placing unit comprises fixedly connected a first cylinder rod and a second cylinder rod, wherein the diameter of the first cylinder rod is bigger than that of the second cylinder rod. The beneficial effects are that the knuckle pivot marking machine can solve the time and labor wasting problems in a conventional mode, is fast in marking speed, and high in marking precision.

Owner:FAGOR EDERLAN AUTO PARTS KUNSHAN CO LTD

Code engraving equipment and battery

PendingCN111969219AIncrease the feeding speedIncrease the number ofPrimary cell manufactureAssembling battery machinesMirror imageMechanical engineering

The invention discloses code engraving equipment and a battery. The code engraving equipment comprises a mirror image feeding mechanism, a code engraving machine, a turnover device and a tray loadingmechanism which are sequentially arranged in the conveying direction of shells, wherein the mirror image feeding mechanism comprises a feeding guide rail and two intermittent material shifting units,two rails are arranged on the feeding guide rail, the two intermittent material shifting units are arranged on the two opposite sides of the feeding guide rail respectively, the two intermittent material shifting units are oppositely arranged, each intermittent material shifting unit comprises a distance adjusting assembly and a material shifting piece, the distance adjusting assembly is used fordriving the multiple shells to be separated from one another, and the material shifting piece is used for shifting the multiple shells to horizontally move in the direction close to the code engravingmachine at the same time. According to the invention, shells are pushed to move in two rails at the same time through two intermittent material shifting units, so that the feeding speed of the shellsis increased, and the number of the shells entering the working range of a code engraving machine in unit time is increased so as to improve the code engraving speed of the shell; and a turnover device and a tray loading mechanism turn over and load the code engraved shell into a tray, so that preparation is made for the assembly operation of the battery.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

Aluminum bottom laser marking device

PendingCN112620956AHigh degree of automationMarking speed is fastLaser beam welding apparatusPhysicsTransfer mechanism

The invention relates to an aluminum bottom laser marking device which comprises a laser marking mechanism. The aluminum bottom laser marking device further comprises a conveying mechanism arranged at one side of the laser marking mechanism and used for conveying an aluminum bottom to be marked, a discharging mechanism arranged at the other side of the laser marking mechanism and used for containing the marked aluminum bottom and a transferring mechanism arranged above the laser marking mechanism and capable of moving between the conveying mechanism and the discharging mechanism; and the transferring mechanism transfers the aluminum bottom to be marked on the conveying mechanism to the laser marking mechanism to mark the aluminum bottom and then transfers the marked aluminum bottom to the discharging mechanism. The marking device is high in automation degree and high in marking speed.

Owner:SELF ELECTRONICS CO LTD

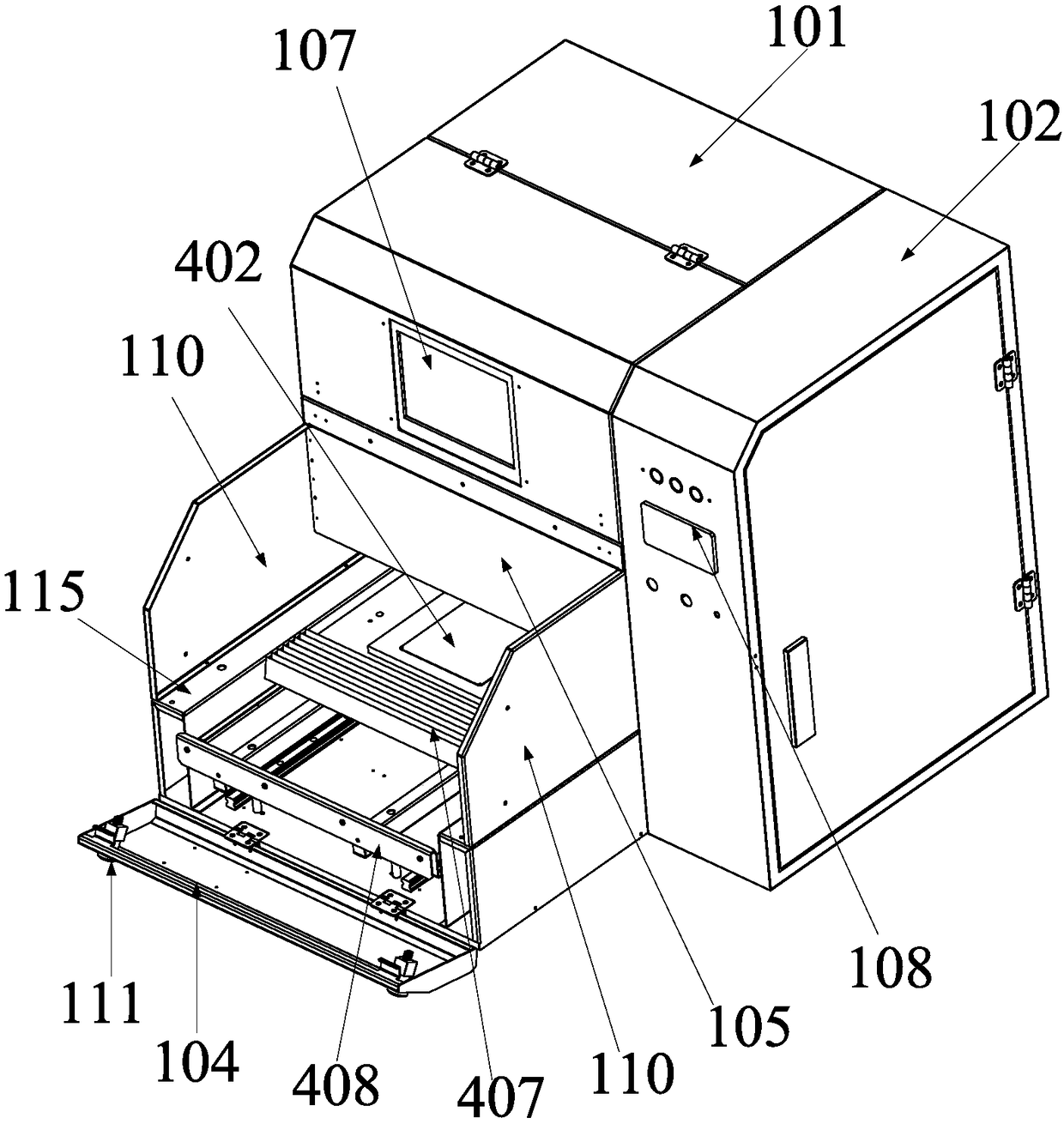

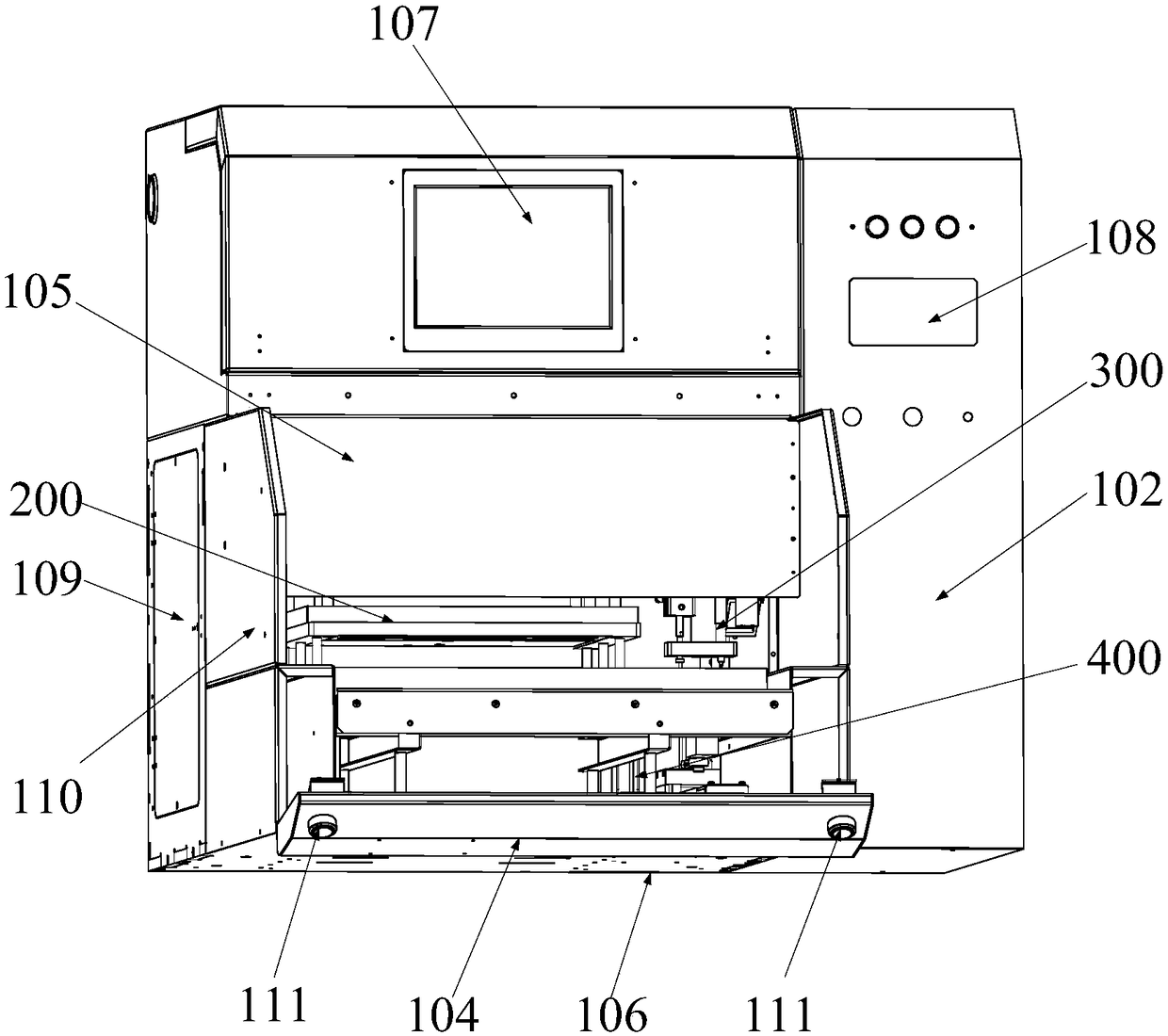

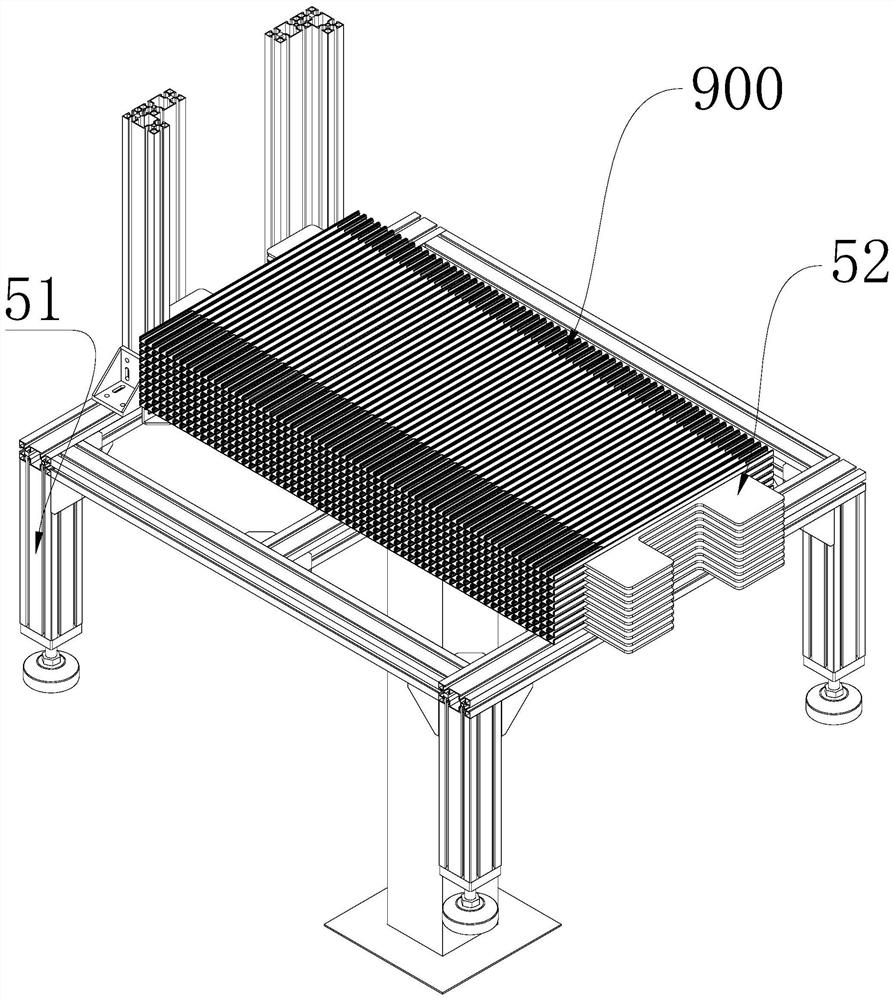

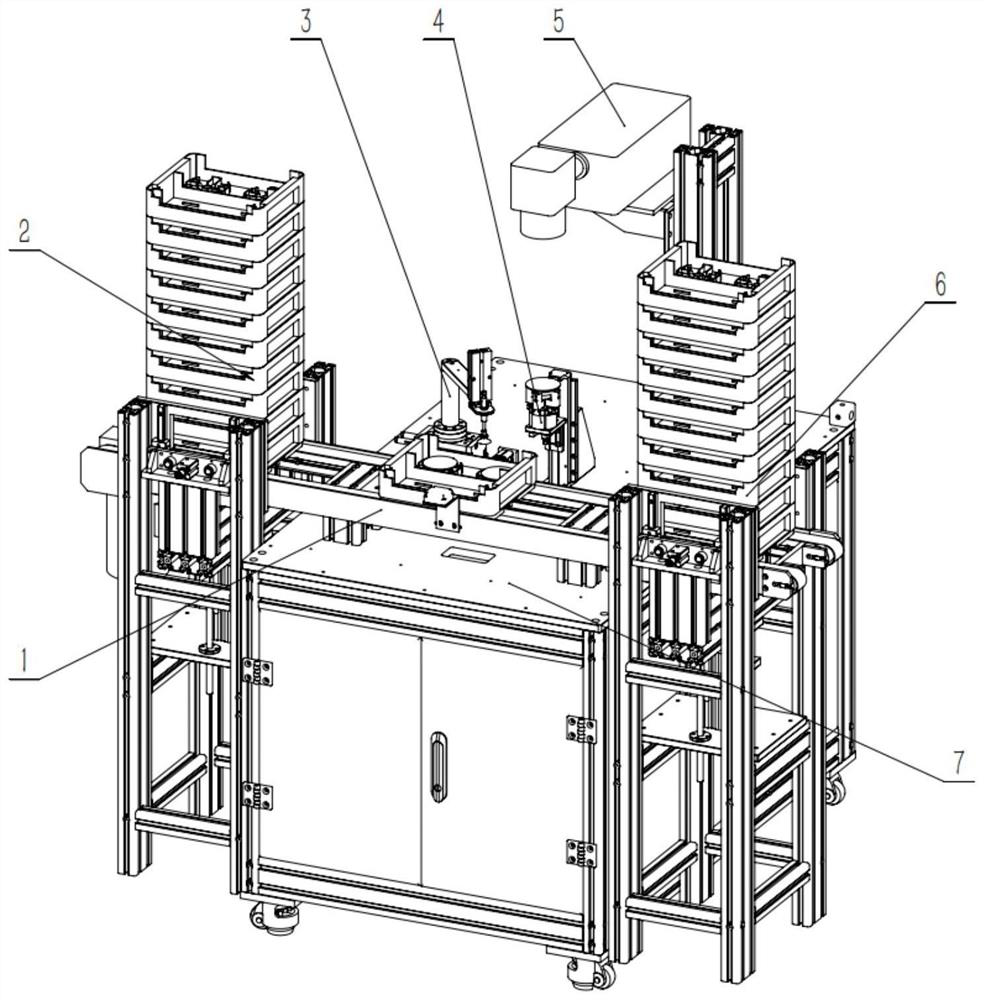

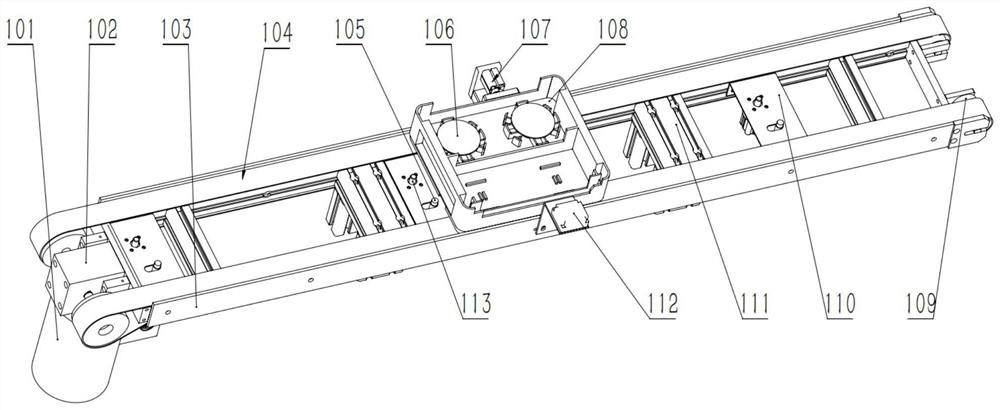

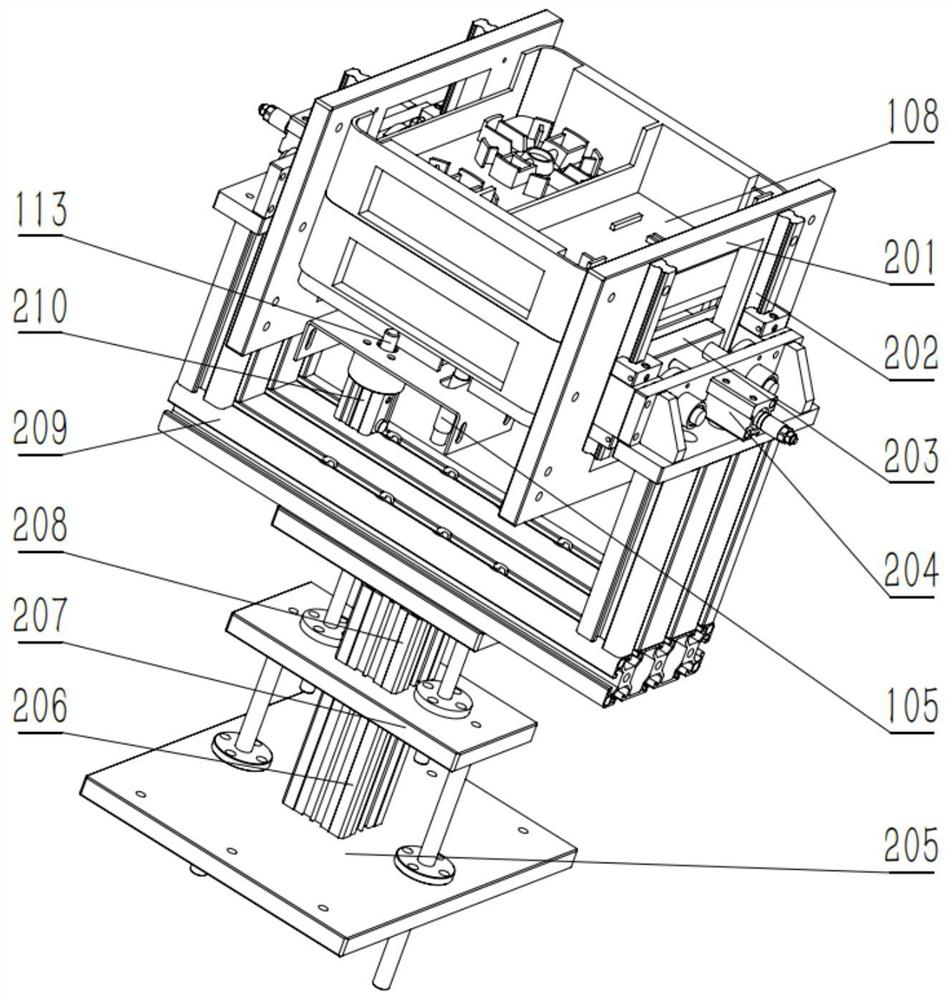

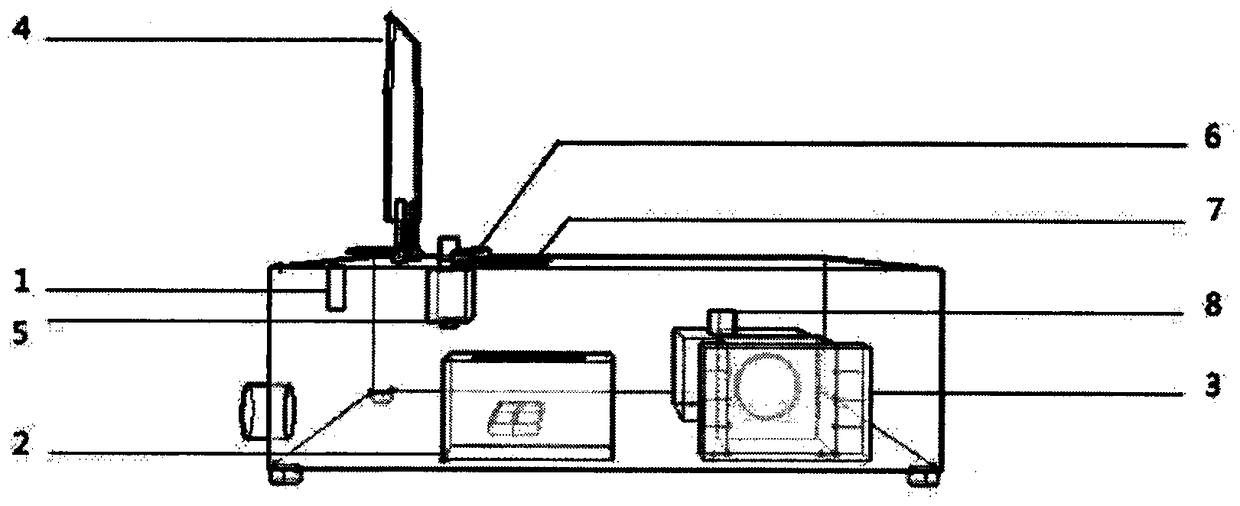

Automatic marking machine for micro-engraving invisible mark in inner progressive resin lens

PendingCN112045317ANo manual operationHigh degree of automationLaser beam welding apparatusManipulatorWorkbench

The invention relates to an automatic marking machine for micro-engraving an invisible mark in an internal progressive resin lens. The automatic marking machine for micro-engraving the invisible markin the internal progressive resin lens comprises a workbench, a manipulator (3) and a marking system (5), wherein mounting frames are located on two sides of the workbench; a conveying belt for conveying a material box to move is mounted on the mounting frames; an automatic discharging system (6) is arranged on the mounting frame on one side; an automatic material receiving system (2) is arrangedon the mounting frame on the other side; the manipulator (3) is arranged on the workbench (7), located on one side of the conveying belt (1), and used for taking out the lens in the material box (108)and placing the lens on a lifting clamping mechanism (4) located on the workbench (7); and the marking system (5) is arranged on the workbench (7), located right above the lifting clamping mechanism(4) and used for marking the lens on the lifting clamping mechanism (4). The invisible mark is engraved to the interior of the resin lens by adopting a laser-micro-engraving process and cannot be covered by a subsequent processing process, so that the mark is continuously and clearly visible.

Owner:江苏工大金凯高端装备制造有限公司

Semiautomatic steel pipe marking device

PendingCN109177524ARealization of automatic steel pipe markingHigh degree of automationTypewritersSemi automaticPush pull

The invention belongs to the technical field of steel pipe machining and relates to a semi-automatic steel pipe marking device. The semiautomatic steel pipe marking device comprises a pneumatic marking machine and further comprises a support, an installation bottom plate, a push-pull mechanism and a supporting plate final assembly. The installation bottom plate is arranged on the support. The push-pull mechanism is arranged on the installation bottom plate. The supporting plate assembly is arranged on the push-pull mechanism, and the pneumatic marking machine is rotationally arranged on the supporting plate final assembly. The push-pull mechanism is composed of a linear guide rail, a sliding block, a cushion plate, a push-pull air cylinder, a push-pull plate and positioning plates. The linear guide rail is fixedly arranged on the installation bottom plate, and the sliding block is movably arranged on the linear guide rail. The cushion plate is fixedly arranged on the sliding block. Thepush-pull plate is fixedly arranged between the cushion plate and the supporting plate final assembly. The push-pull air cylinder is fixedly arranged on the installation bottom plate and is connectedwith the push-pull plate. The positioning plates are symmetrically fixedly installed on the pneumatic marking machine. The semiautomatic steel pipe marking device is scientific and reasonable in structural design and has the beneficial effects of being high in marking speed, high in efficiency, high in automation degree, capable of saving time and labor and the like, and the semiautomatic steel pipe marking device is high in innovativeness.

Owner:天津市联通钢管有限公司

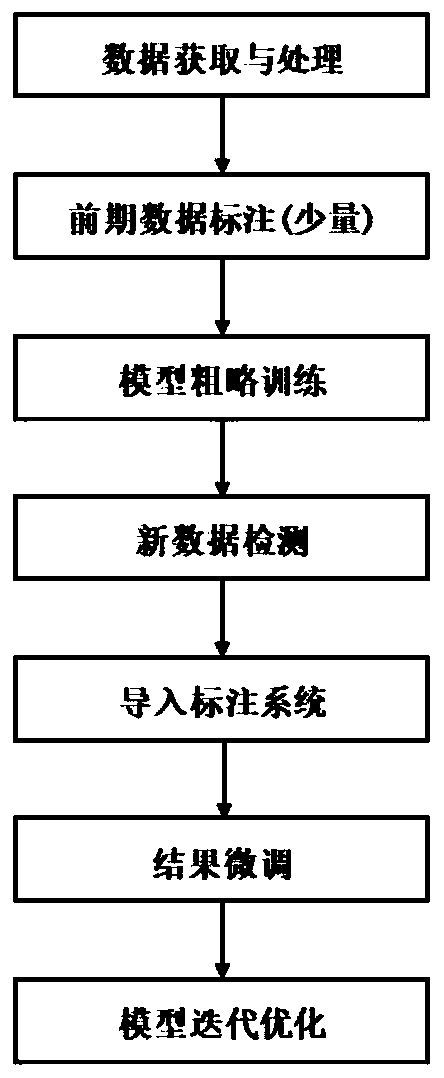

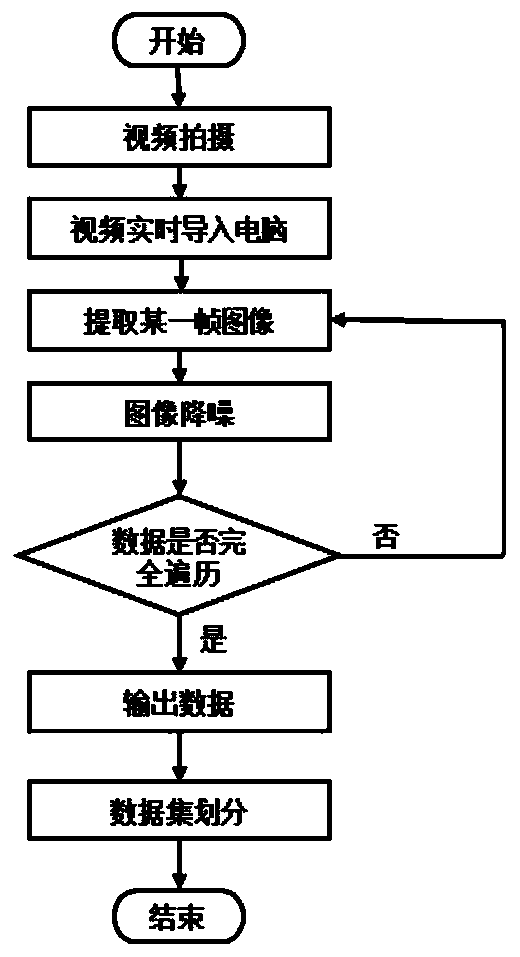

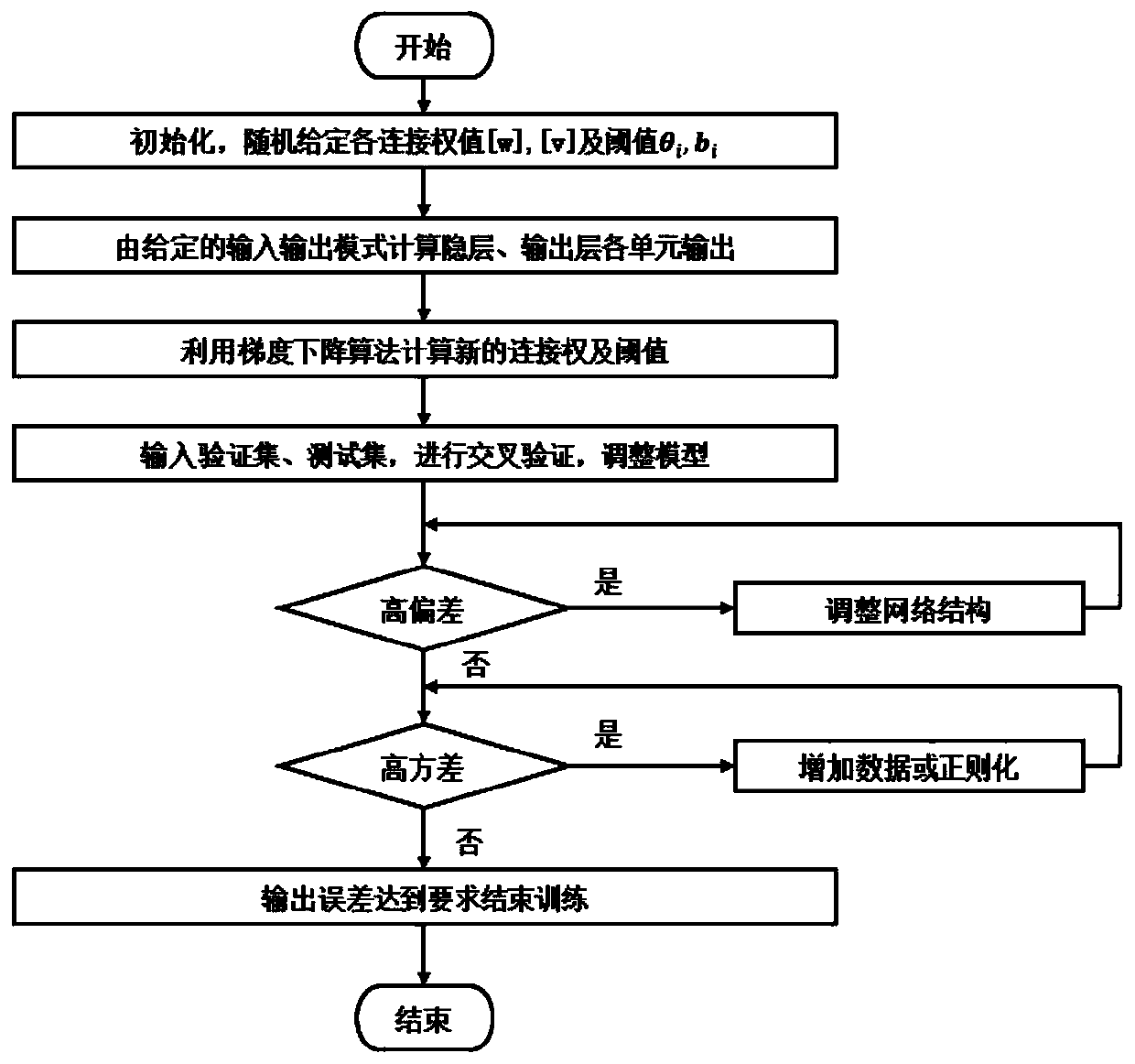

Apparent characteristic monitoring data intelligent labeling method based on target detection

PendingCN111222462AReduce dependenceMarking speed is fastCharacter and pattern recognitionNeural architecturesLandslideEngineering

The invention discloses an apparent characteristic monitoring data intelligent labeling method based on target detection. The apparent characteristic monitoring data intelligent labeling method comprises the following steps: acquiring and processing data; marking the acquired data; carrying out preliminary training on the model; detecting the new data; importing the existing annotation data and the model training result thereof into a data annotation system; finely adjusting a result, detecting the classified and trained data, and correcting an error result; and iterative optimization is performed on the model, the adjusted data are used for iterative optimization of the model, the learning rate eta and regularization parameter lambda hyper-parameter calculation in the neural network modelin the model is adjusted until the output error reaches the final requirement, and training is ended. According to the method, the time for apparent characteristic target detection and data annotation in various fields of slope and landslide disaster prevention and control and weir dam disaster treatment is saved, the efficiency and accuracy of data annotation are improved, and the method conforms to intelligent application of various technologies of big data storage and cloud calculation in the fields of engineering construction and disaster prevention and control.

Owner:HOHAI UNIV

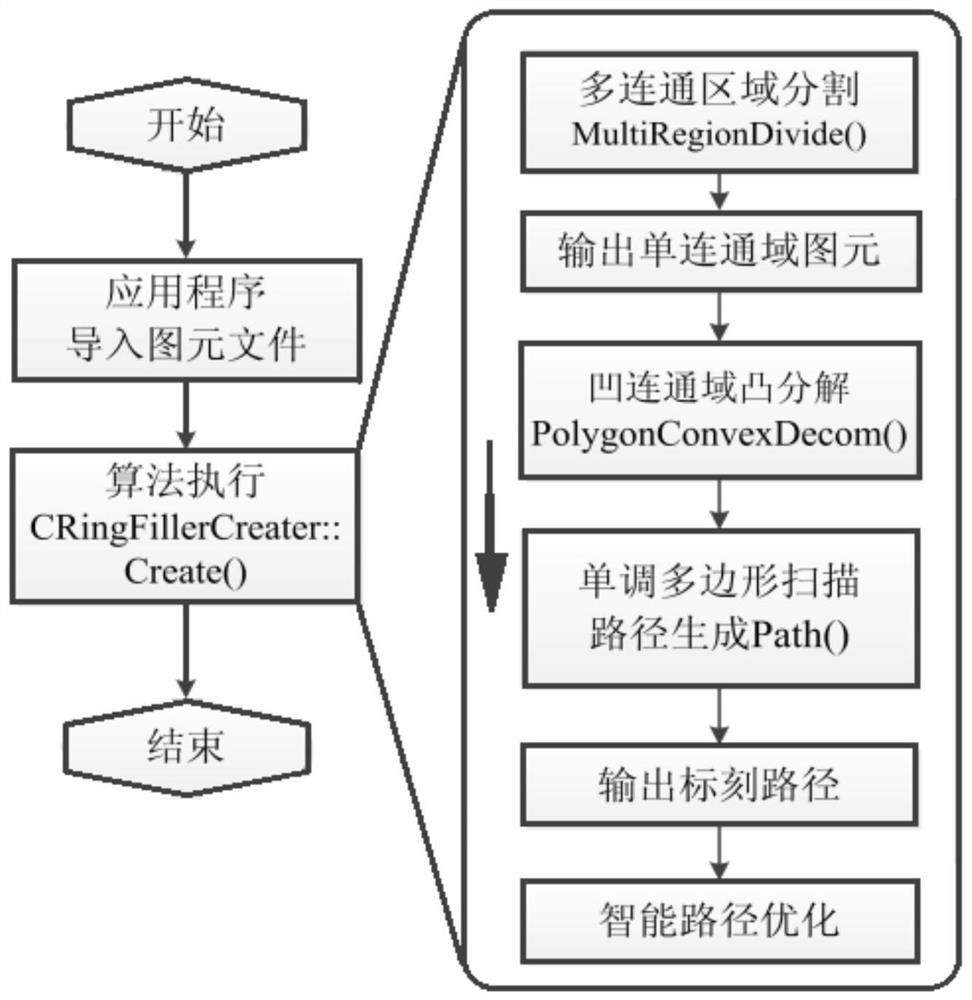

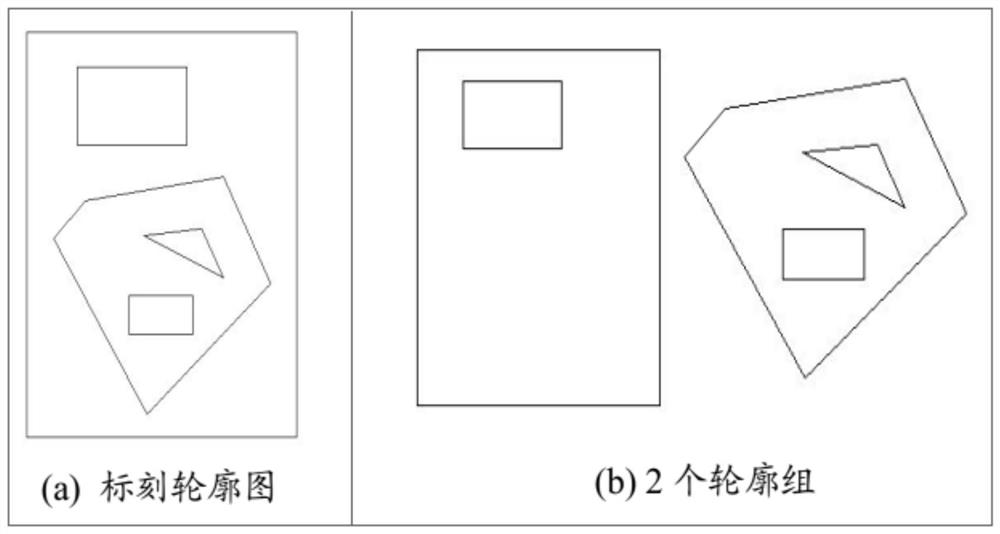

Automatic fragmentation contour intelligent scanning method for laser marking path

PendingCN113865507AReduce build timeHigh speedImage analysisUsing optical meansComputation complexityScan line

According to the invention, firstly, a complex multi-connected region primitive is divided into a plurality of single-connected region primitives, the marking of one complex multi-connected region primitive is converted into marking of a plurality of simple single-connected region primitives, and then convex division is performed on a concave connected region; a single connected region primitive with concave points is divided into a plurality of monotone polygon primitives to adapt to the complex condition of character marking, then monotone polygons are marked, and finally an optimal shortest scanning path is selected by using an intelligent path method; the laser marking method is easy to implement, high in marking speed, short in marking time, high in efficiency, short in empty row distance and small in calculation complexity, scanning lines generated in the marking process are few, the number of times of optical switching is small, the probability that a device is damaged is small, under the condition that it is guaranteed that the number of skipping times and the skipping distance are as small as possible, the path generation time is greatly shortened, and the marking speed and efficiency are improved.

Owner:扆亮海

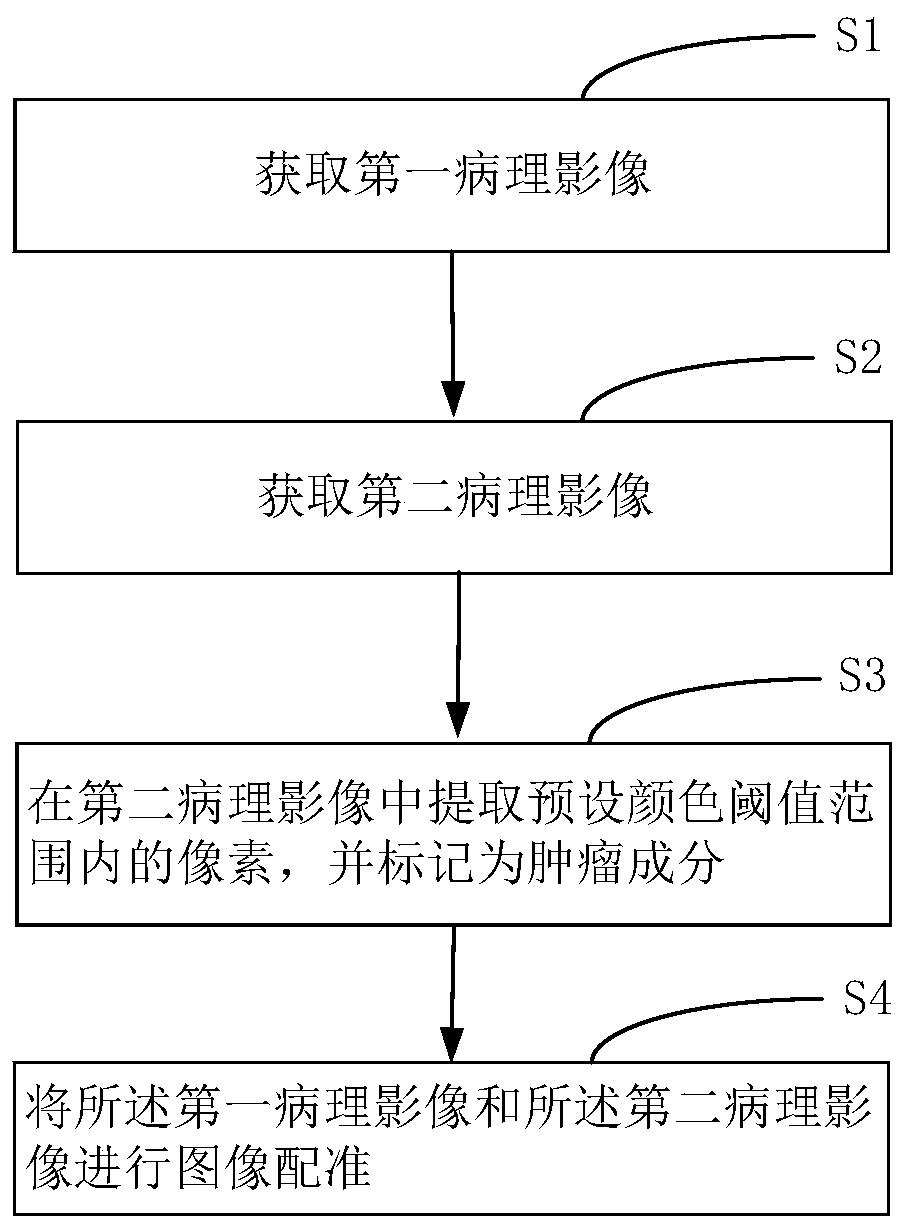

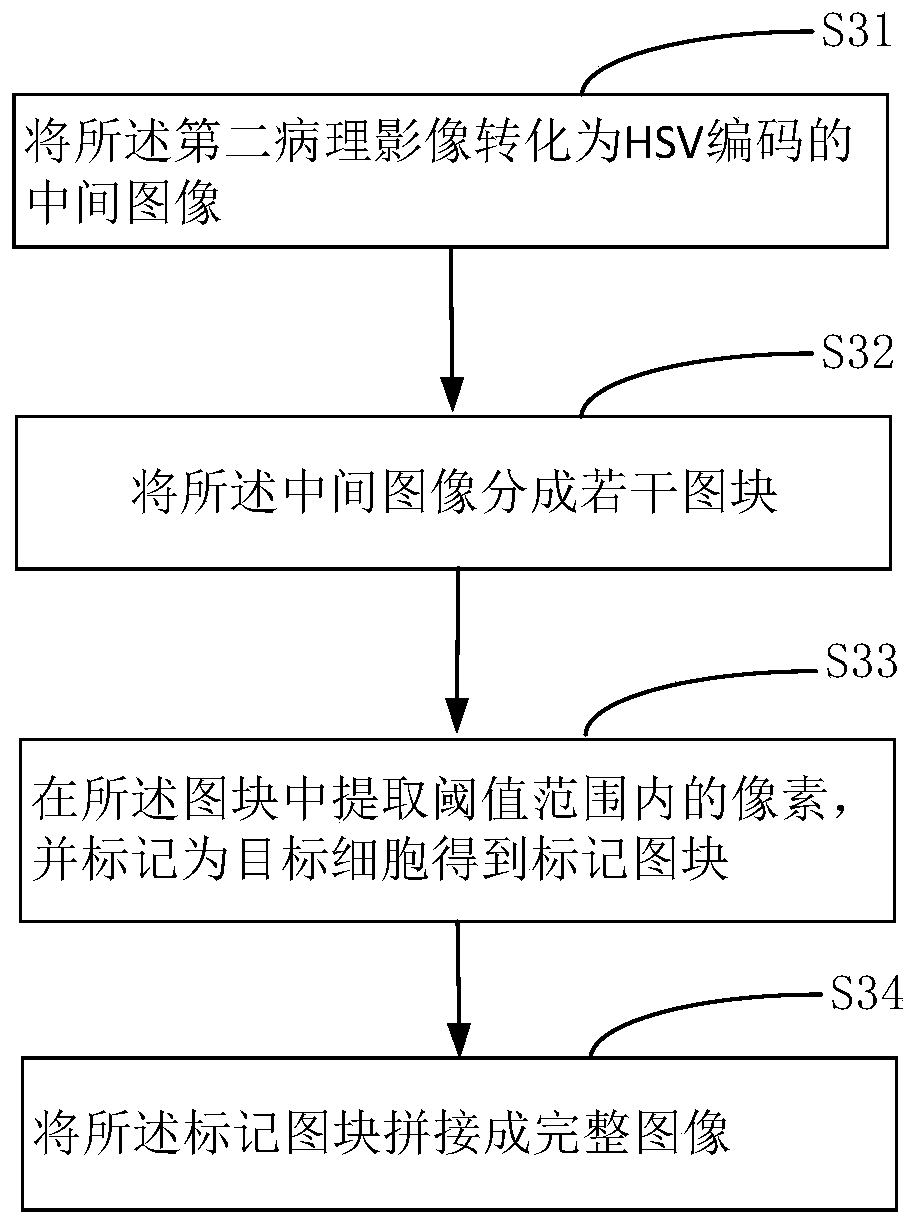

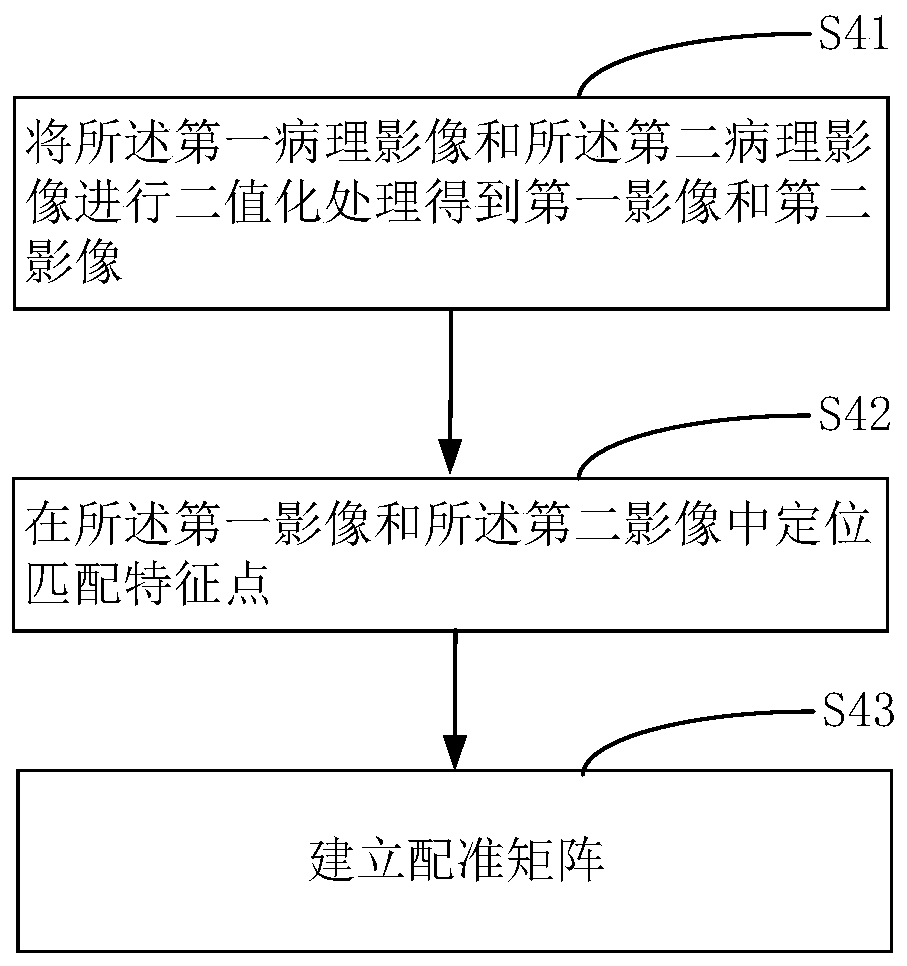

Tumor component labeling method, device and equipment and storage medium

PendingCN111180048AMarking speed is fastHigh precisionImage analysisMedical imagesNuclear medicineDigitization

The invention discloses a tumor component labeling method, device and equipment and a storage medium, and the method comprises the steps: obtaining a first pathological image, wherein the first pathological image is an image obtained through the digitalized scanning of a pathological section after HE staining; acquiring a second pathological image, wherein the second pathological image is an imageobtained by performing HE fading on the pathological section, then performing immunohistochemical staining and then performing digital scanning; extracting pixels in a preset color threshold range from the second pathological image, and marking the pixels as tumor components; and performing image registration on the first pathological image and the second pathological image. Tumor components canbe automatically marked in pathological images, manual marking is not needed, the marking speed is high, and the precision is high.

Owner:上海镜观生物科技有限公司

Laser automatic edge hooking method for holographic bronzing anti-counterfeiting film strip

ActiveCN111531284AHigh precisionHigh speedInstrumentsLaser beam welding apparatusLaser patterningEngineering

The invention discloses a laser automatic edge hooking method for a holographic bronzing anti-counterfeiting film strip. The method comprises the steps of plate making and edge hooking, wherein when drawing is carried out on an anti-counterfeiting film strip, edge hooking is carried out on the edge of a pre-designed pattern by 4000-6000 linear density, and the anti-counterfeiting film strip is enabled to obtain a pattern area which is detected and discriminated by a CCD detection device; and pattern dealumination, wherein the pattern area is shot by the CCD detection device, the shot pattern is subjected to pixel comparison with a standard pattern pre-existed in a computer, and the computer instructs a laser marking machine to dealuminate the anti-counterfeiting film strip according to imaging to form a hollowed holographic pattern. According to the laser automatic edge hooking method, a high-precision and high-speed laser pattern edge hooking effect can be achieved, and the method issuitable for large-scale production and processing of film strip marking where only pattern edge hooking or special super lines is needed; and moreover, the hollowed edge hooking precision of the formed holographic pattern is high, the marking speed is high, the method can be applied to any variable pattern, the appearance is attractive, and the effect is good.

Owner:湖北银琅兴科技发展有限公司

A radiograph marking machine and marking method

ActiveCN106855682BLow costIncrease production ratePhotomechanical exposure apparatusMicrolithography exposure apparatusFilm baseTransformer

The invention provides a radiogram marking machine and marking method. The radiogram marking machine comprises a transformer used for converting high-voltage alternating current into low-voltage direct current; two ends of the transformer are respectively connected with a power supply and a microswitch; the microswitch is connected with a time relay; the time relay is connected with a light modulator; the light modulator is connected with a LED exposure lamp and a signal lamp; an exposure screen is arranged to face the LED exposure lamp; and one side of the exposure screen is provided with a spring bearer plate used for positioning a marking scope and triggering the microswitch. The invention also provides a radiogram marking method. According to the method, a radiographic testing photograph having undergone exposure is subjected to secondary exposure to visible light so as to mark the photograph with a marking; after exposure to rays, the photograph still has unreacted ions; and the exposure screen gives off character-shape light rays to irradiate the film base of the photograph, so compounding of the unreacted ions is promoted and imaging is realized so as to accomplish marking of the photograph. The radiogram marking machine provided by the invention is simple in structure, convenient to install and maintain and low in price, and improves the production efficiency of ray detection and the automation level of flaw detection.

Owner:SHANGHAI BOILER WORKS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com