Vertical type starter label-printing machine

A marking machine and starter technology, applied in the field of marking machines, can solve problems such as complicated operation, complicated manufacturing process, and slow working speed, and achieve the effect of simple and convenient operation, high degree of automation, and fast marking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

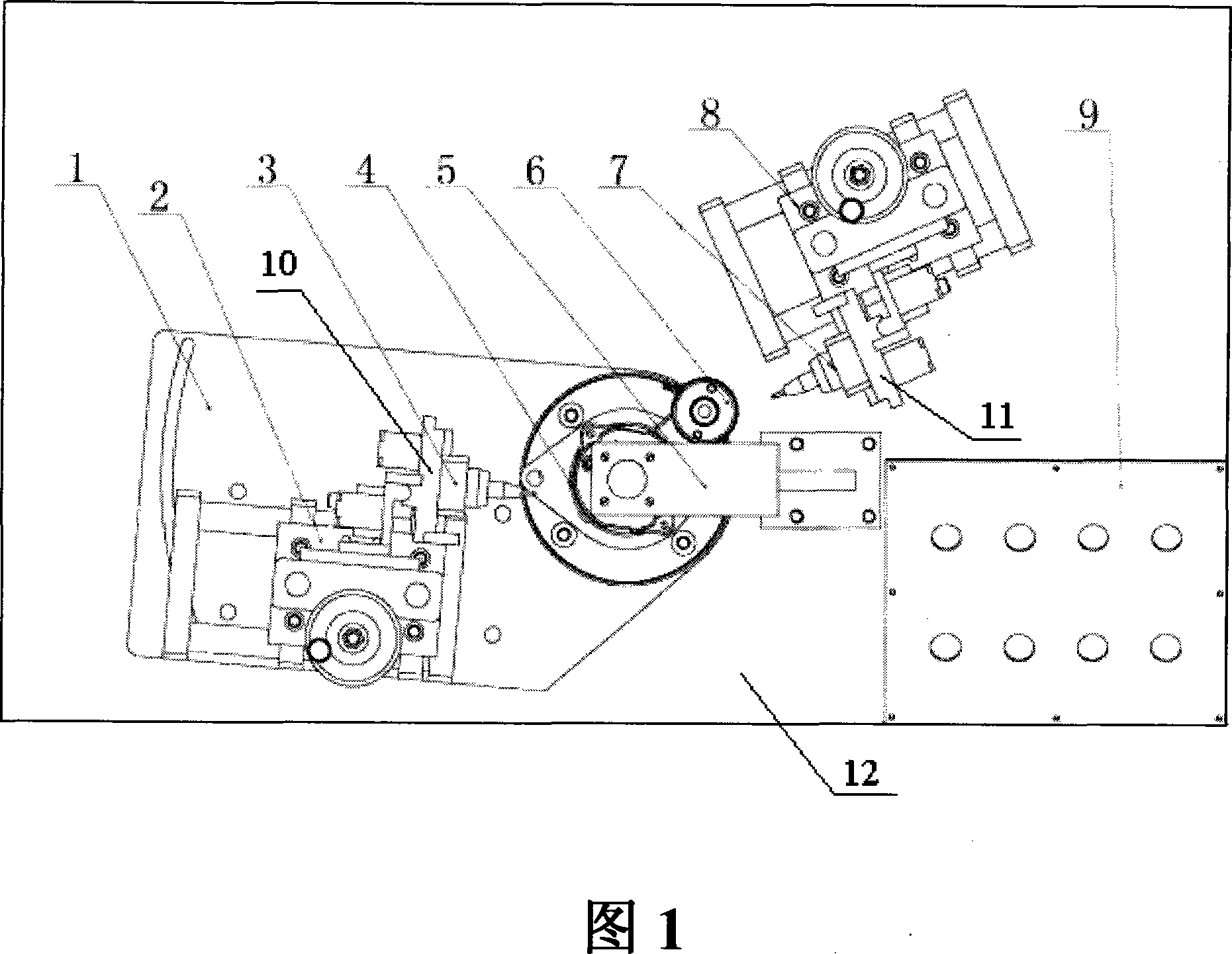

[0009] Vertical starter marking machine, including casing marking machine 3 and switch marking machine 7. The casing marking machine 3 is composed of a flat slide table 2 and a vertical slide table 10 fixed on the rotating base plate 1, and the starter assembly is clamped on the fixed tool by the clamping cylinder 5. The switch marking machine 7 is composed of a plane slide table 8 and a vertical slide table 11 fixed on the workbench panel. The casing marking machine 3 is installed on the panel of the vertical sliding table 10 of the casing marking machine, and the vertical sliding table 10 is fixed on the flat sliding table 2 on the rotating bottom plate 1, so that the casing marking machine 3 can Up and down movement on the worktable and 360-degree rotation along the center line of the fixed tooling can change the position of the marking machine head. The switch marking machine 7 is installed on the vertical slide table 11 of the switch marking machine, and the vertical sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com