Cigarette laser marking system and method based on image processing

A laser marking method and laser marking technology, applied in the field of tobacco anti-counterfeiting, can solve the problems of poor redundancy, air pollution, damage to the laser head, etc., and achieve the effects of fast marking speed, less harmful gas emission and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

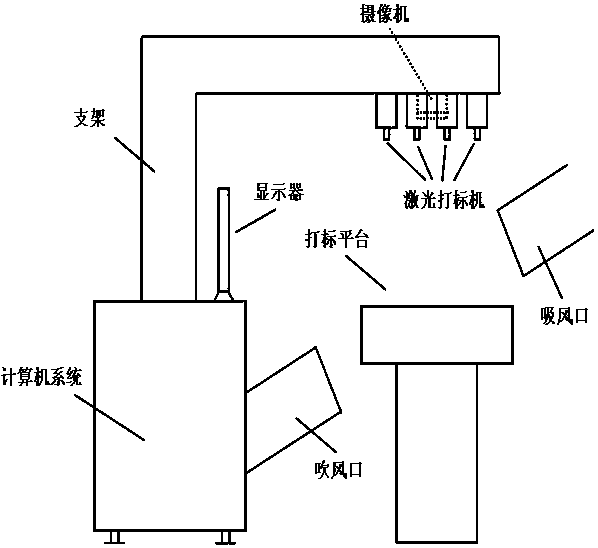

[0062] (1) Fix the position of the cabinet and bracket, and install the camera to the designated position of the bracket system, such as figure 1 shown. Install the laser marking machine so that its irradiation direction points to the specified direction. The installation position of the laser marking machine can accommodate multiple laser marking machines, and the position of the laser marking machine can be fine-tuned through the fixing nut. In order to ensure the marking effect, multiple laser marking machines are arranged in a straight line, and the center line is guaranteed to be perpendicular to the conveying direction of the conveyor belt. It is advisable to use at least one laser marking machine, and use the maximum number to completely cover the conveying area of the conveyor belt.

[0063] (2) Turn on the camera, turn on the computer system, adjust the camera position and obtain images on the computer screen, adjust the camera focal length, white balance, color, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com