Laser automatic edge hooking method for holographic bronzing anti-counterfeiting film strip

A technology of anti-counterfeiting film and hooking, applied in laser welding equipment, metal processing equipment, instruments, etc., can solve the problems of low production efficiency, difficult to control accuracy, slow processing speed, etc., achieve fast marking speed, beautiful appearance, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

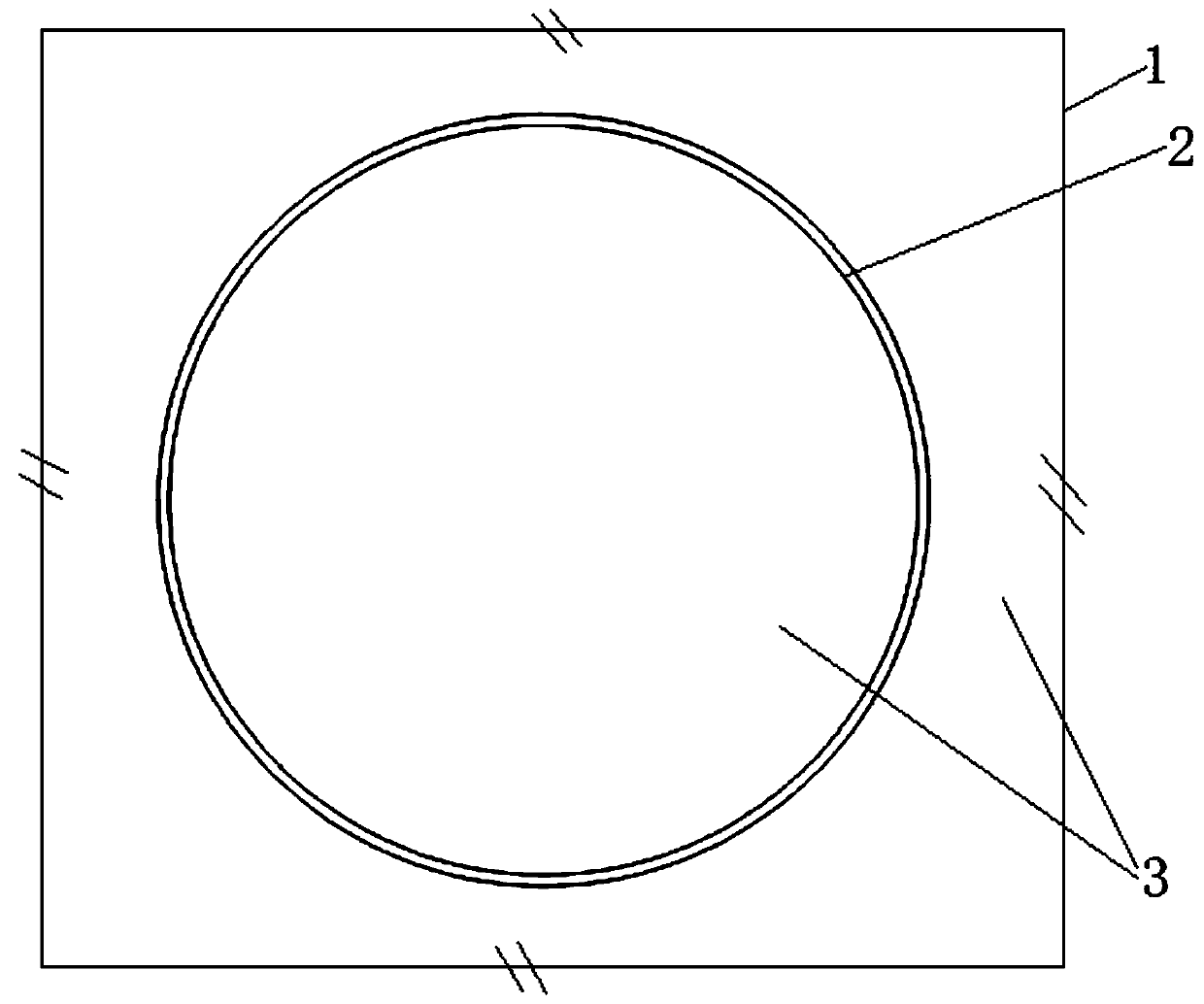

[0034] Such as figure 1 As shown, it is the regular pattern that needs to be formed on the anti-counterfeiting film belt 1, such as the concentric circle pattern area 2; in order to obtain a special pattern area that can be quickly detected and screened by the CCD, 5000 lines are used in the first dealumination Density plate-making hook, that is to say, use 5000 line density in the concentric circle pattern area 2, and use 1500 line density in the other area 3 for the first dealumination. At this time, the aluminum layer in the concentric circle pattern area 2 and the edge still exists, and there is no Hollow out; there is a clear contrast between the concentric circle pattern area 2 and the other area 3, and the hub of the pattern is more distinct;

[0035]Then carry out secondary dealumination to form a hollow pattern; because its outline is clearer and easier to be identified, the computer can significantly save comparison time and quickly find the dealumination position, a...

Embodiment 2

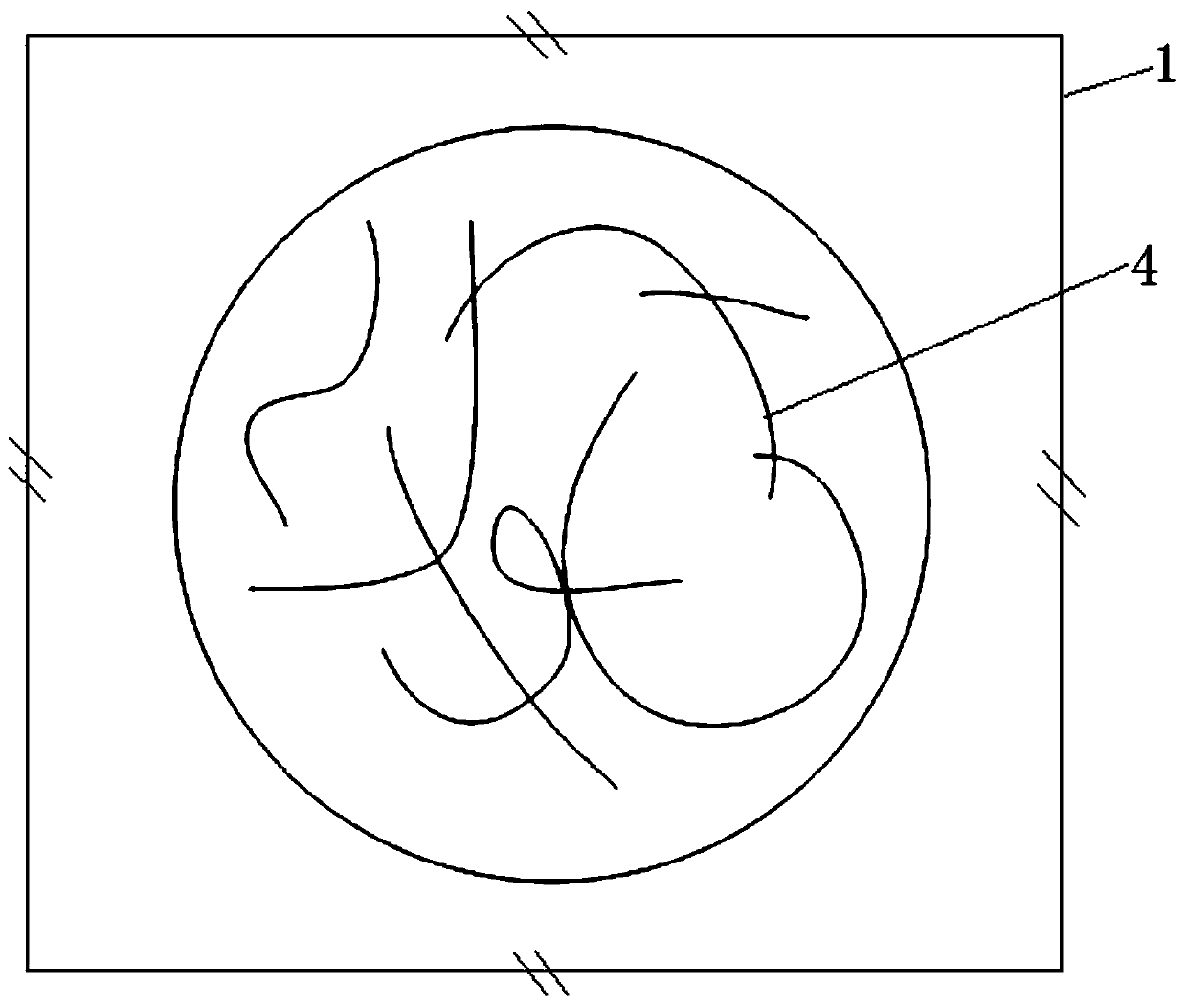

[0037] Such as figure 2 As shown, it is the garbled pattern that needs to be formed on the anti-counterfeiting film belt 1, such as a plurality of garbled superlines 4;

[0038] When drawing, for random garbled super-line 4, you only need to adjust the super-line plate-making line density to more than 5000, and you can form random super-line garbled patterns during marking;

[0039] Then carry out secondary dealumination to form a hollow pattern; because its outline is clearer and easier to be identified, the computer can significantly save comparison time and quickly find the dealumination position, and quickly complete the comparison in the computer, and the computer directs the laser according to the imaging The marking machine deals aluminum on the anti-counterfeiting film strip.

Embodiment 3

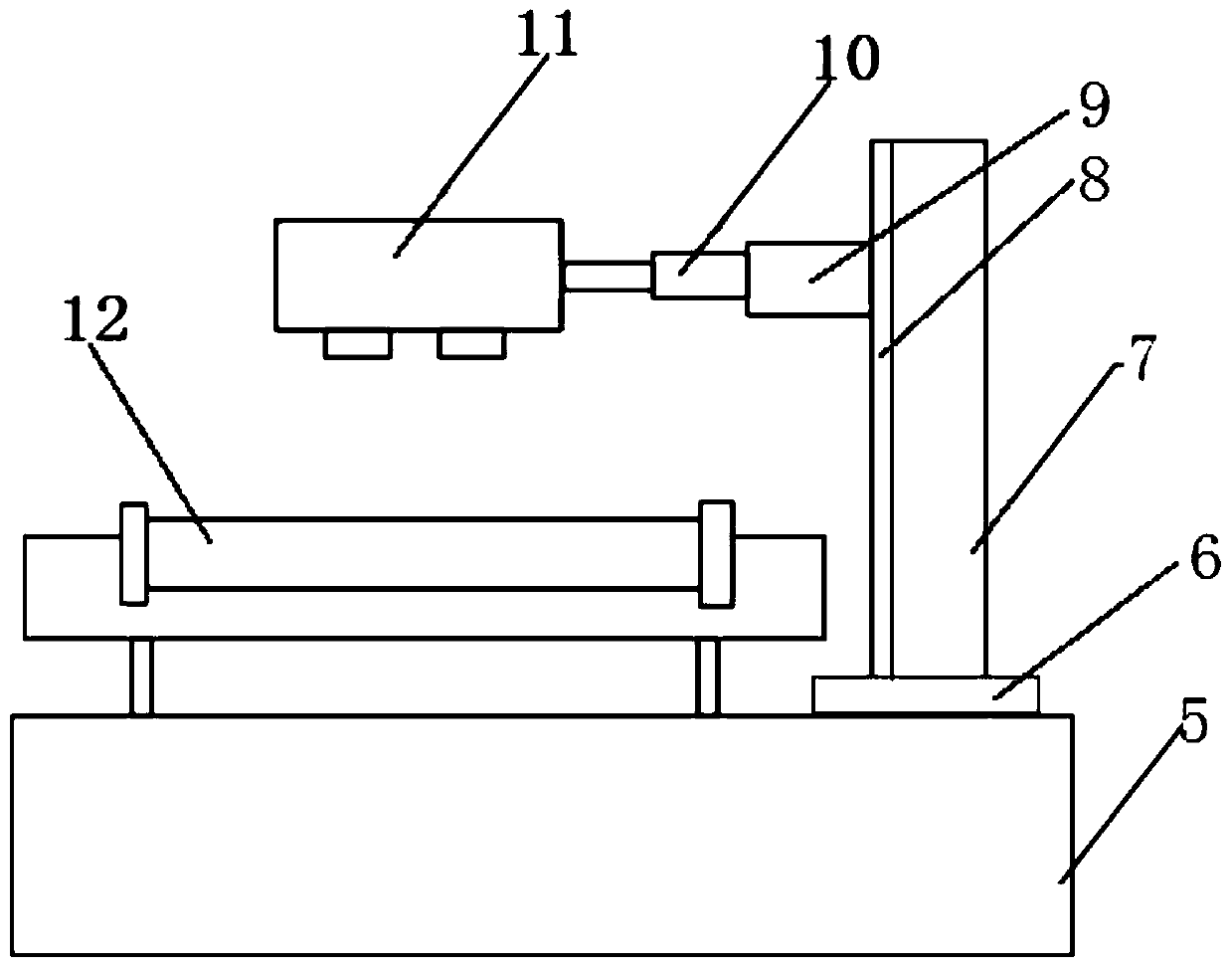

[0041] This embodiment provides a marking machine and its connection and installation structure for realizing the edge hooking method.

[0042] Such as image 3 As shown, a marking machine and its connection and installation structure for realizing the crochet method include a base 5 on which a marking platform 12 is arranged, and the anti-counterfeiting film belt plays a role in the winding and unwinding device. Next, the film can be continuously moved on the marking platform 12; the right side of the base 5 is provided with an electric slide 6, and the electric slide 6 is screwed with a column 7, and the column 7 is close to the marking One side of the standard platform 12 is provided with a slide rail 8, the slide rail 8 is equipped with a side slide block 9, and the slide block 9 is horizontally connected with a telescopic rod 10, and the end of the telescopic rod 10 is installed The plate is connected with a marking mechanism 11, and a CCD camera and a laser marking galv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com