Knuckle pivot marking machine

A steering knuckle and marking machine technology, applied in typewriters, printing and other directions, can solve the problems of poor steering knuckle quality, time-consuming and laborious, and inability to keep the marking position consistent, so as to overcome the time-consuming and labor-intensive, fast marking speed, and difficult marking. High precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

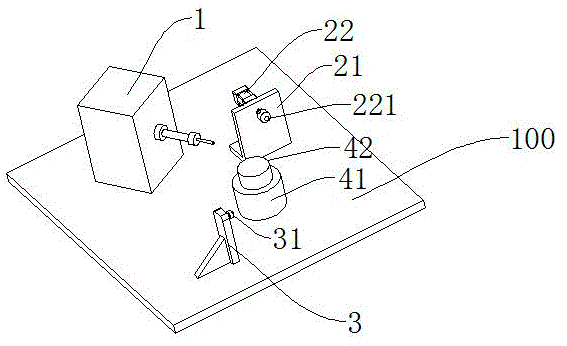

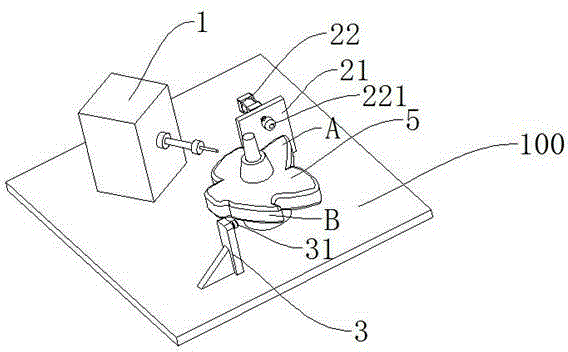

[0013] refer to figure 2 , a steering knuckle marking machine, including a base plate 100, a laser marking machine 1, a steering knuckle pushing unit, a steering knuckle blocking unit, and a steering knuckle placing unit are fixedly connected to the base plate; the steering knuckle pushing unit includes a The cylinder fixing plate 21 fixed on the base plate is fixedly connected with a steering knuckle pushing cylinder 22, and the front end of the steering knuckle pushing cylinder is connected with a pushing block 221; the steering knuckle blocking unit includes a The support plate 3 fixed on the base plate, one side of the support plate is fixed with a blocking block 31; the steering knuckle placement unit includes a first cylinder 41 and a second cylinder 42 fixed together, the first A cylinder has a larger diameter than the second cylinder.

[0014] Sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com