Reverse mounting type locking device for large aperture vacuum sealing elements

A technology of vacuum sealing and locking device, applied in optical components, installation, instruments, etc., can solve the problems of lack of quick locking mechanism for large-diameter optical components, time-consuming and labor-intensive efficiency, etc., to overcome time-consuming, labor-intensive, low efficiency and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

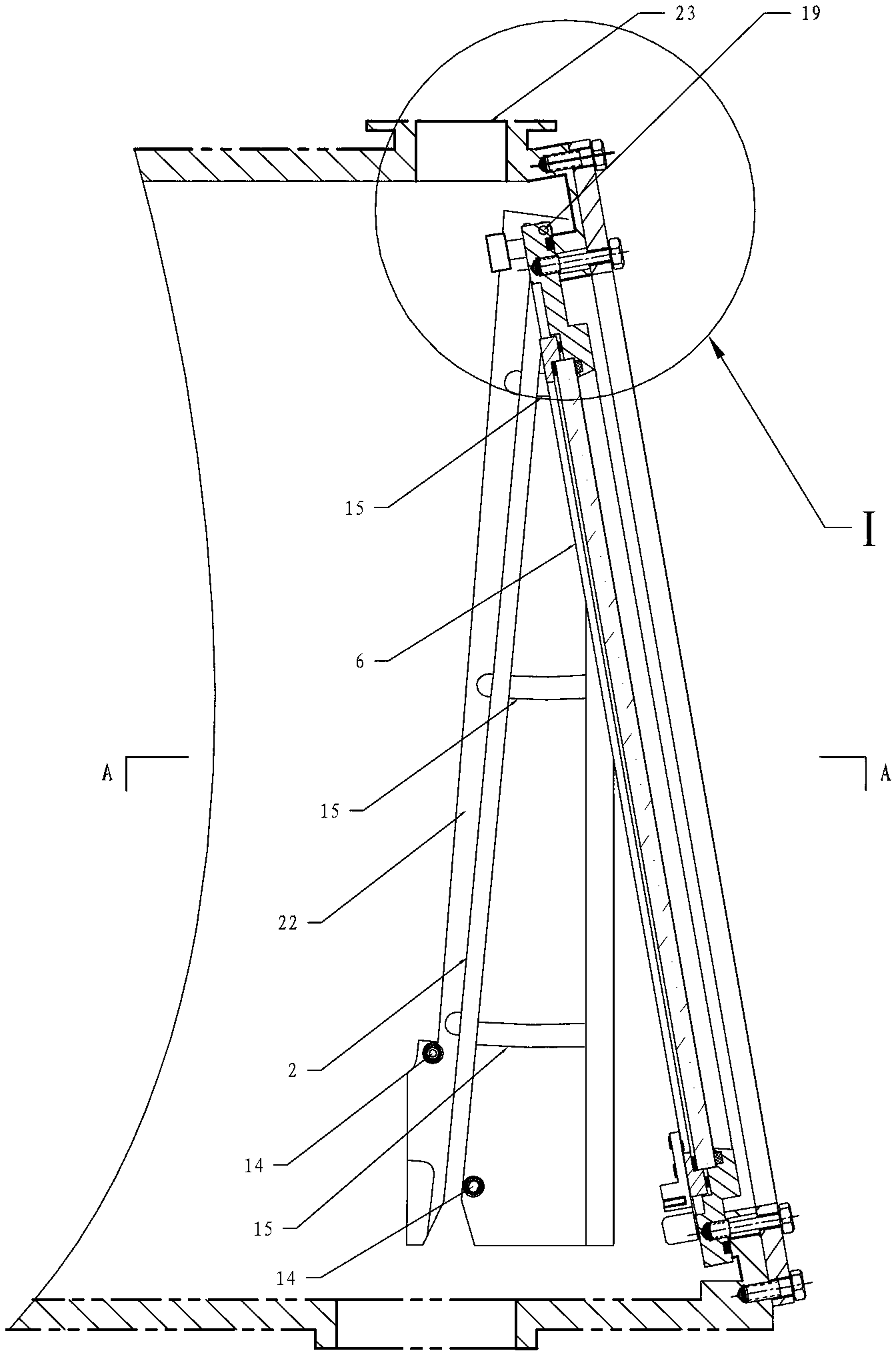

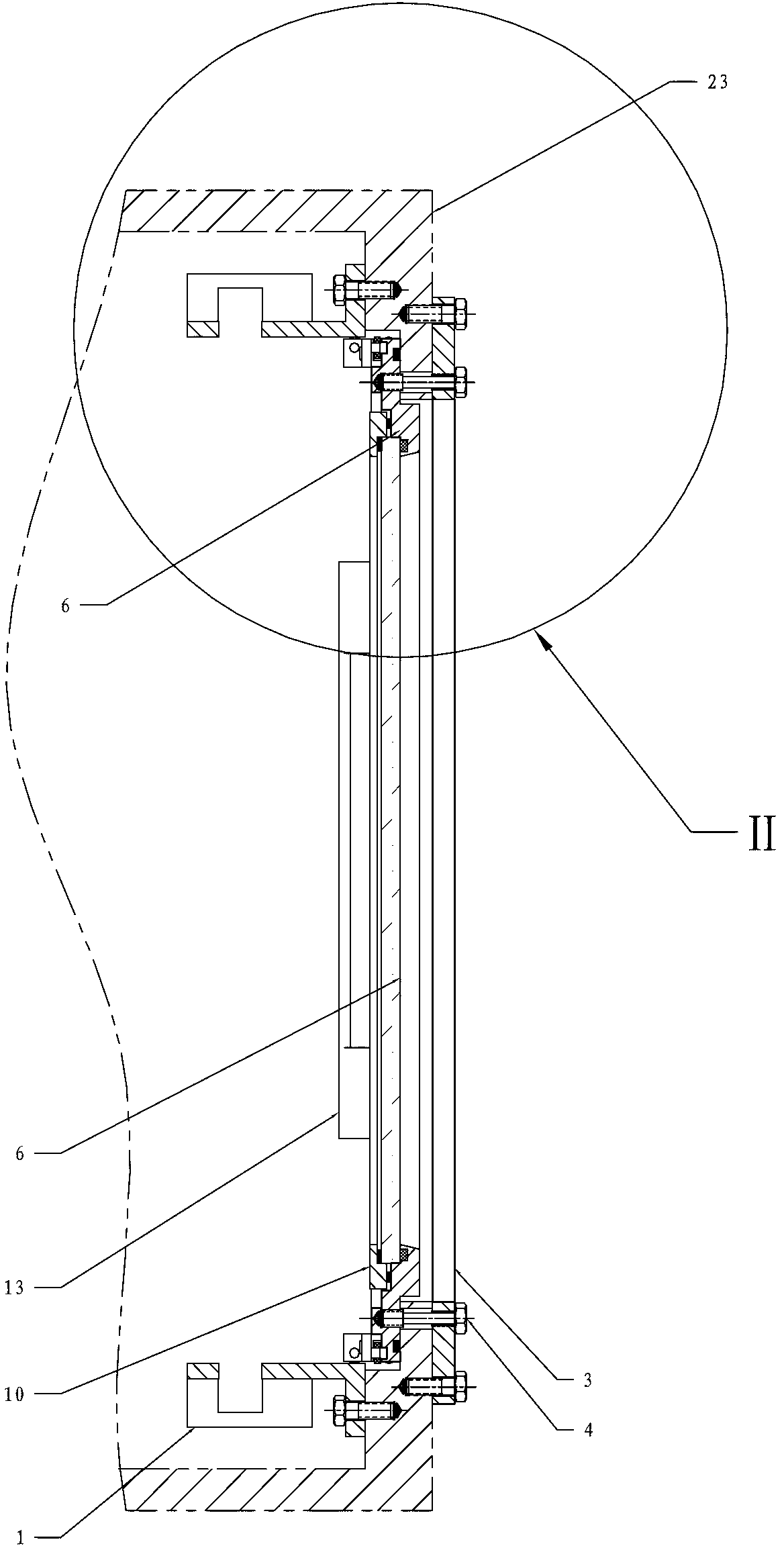

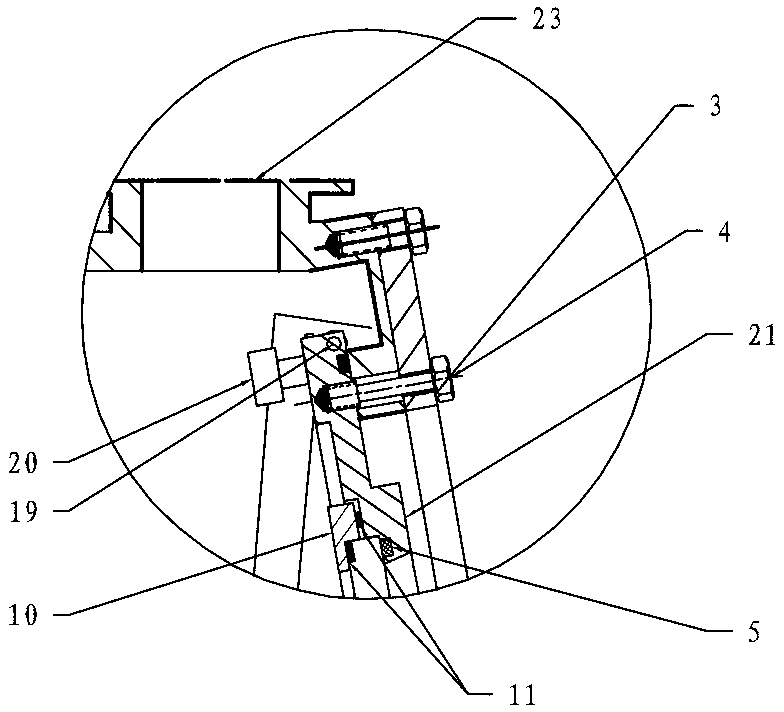

[0008] Specific implementation mode one: combine figure 1 , figure 2 and Figure 8 Describe this embodiment, a back-mounted locking device for a large-diameter vacuum sealing element described in this embodiment, which includes a lens module housing 23, and it also includes a vacuum isolation assembly 6, a vacuum isolation guide assembly 1, and a screw stopper that does not come out. Plate 3 and N non-protruding screws 4, N is an integer greater than 1; the vacuum isolation guide assembly 1 includes two guide frames 22 and two guide grooves 2, the guide grooves 2 are arranged along the inner side of the guide frame 22, and the two guide The openings of the guide grooves 2 in the frame 22 are relatively fixed on opposite sides of the lens module housing 23; the vacuum isolation assembly 6 enters / exits the inner cavity of the lens module housing through the guide groove 2; the vacuum isolation assembly 6, the vacuum isolation guide The components 1 are all arranged in the inn...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 2 and Figure 5 Describe this embodiment. This embodiment is a further limitation of the back-mounted locking device for a large-diameter vacuum sealing element described in Embodiment 1. The vacuum isolation assembly 6 also includes a spacer disassembly assembly. Assembly assembly is made up of spacer disassembly peg 20 and peg base, spacer disassembly peg 20 is affixed on the peg base, and peg base is affixed to the front upper end of vacuum isolation assembly 6.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 2 Describe this embodiment. This embodiment is a further limitation of the back-mounted locking device for a large-diameter vacuum sealing element described in Embodiment 1. The vacuum isolation assembly 6 also includes a handle 13, and the handle 13 is fixed to the At the front lower end of the vacuum insulation assembly 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com