Laser univariate color marking system and method

A laser, single-variable technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., to achieve multi-flexibility and creativity, colorful patterns, and good color repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

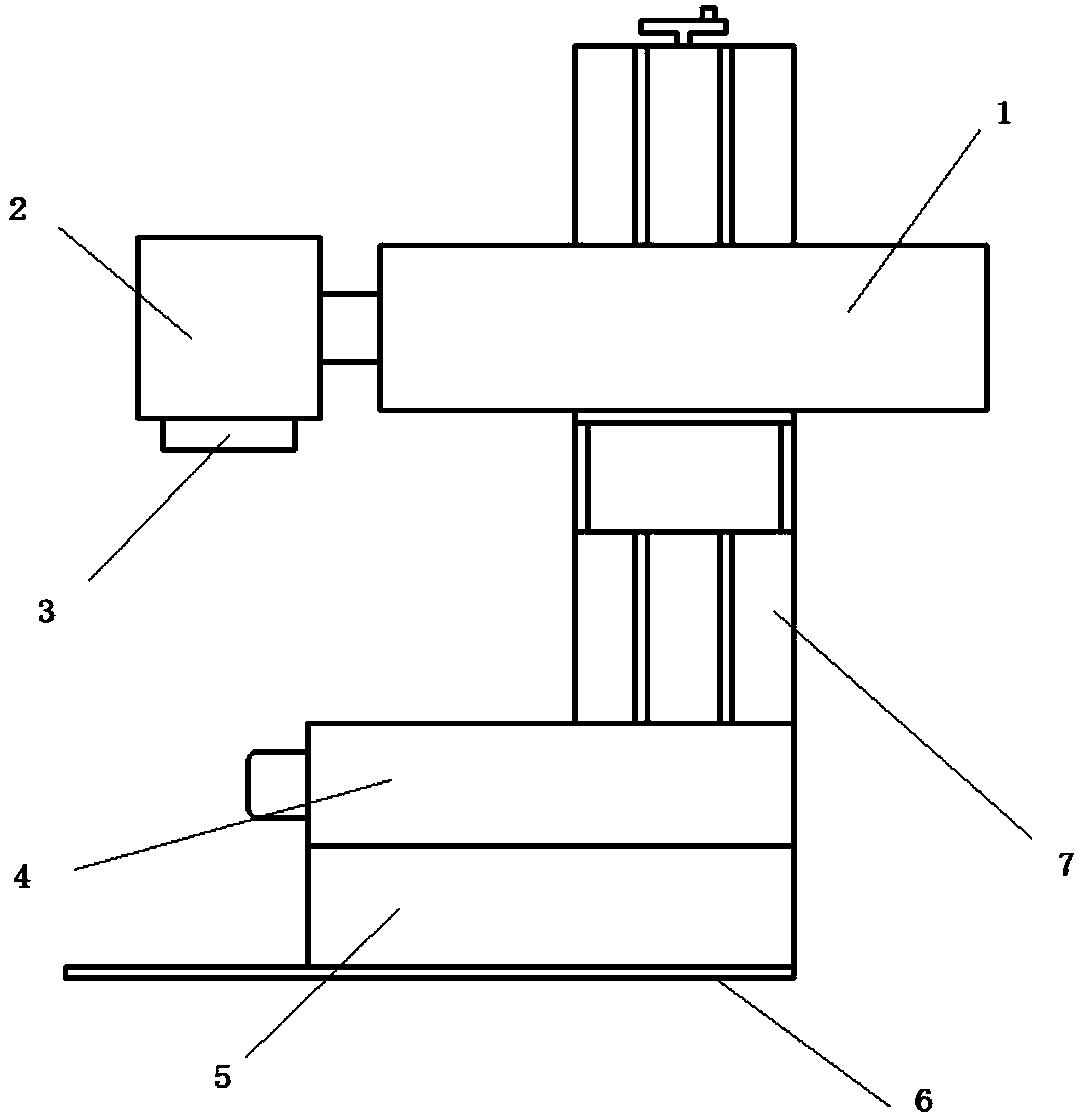

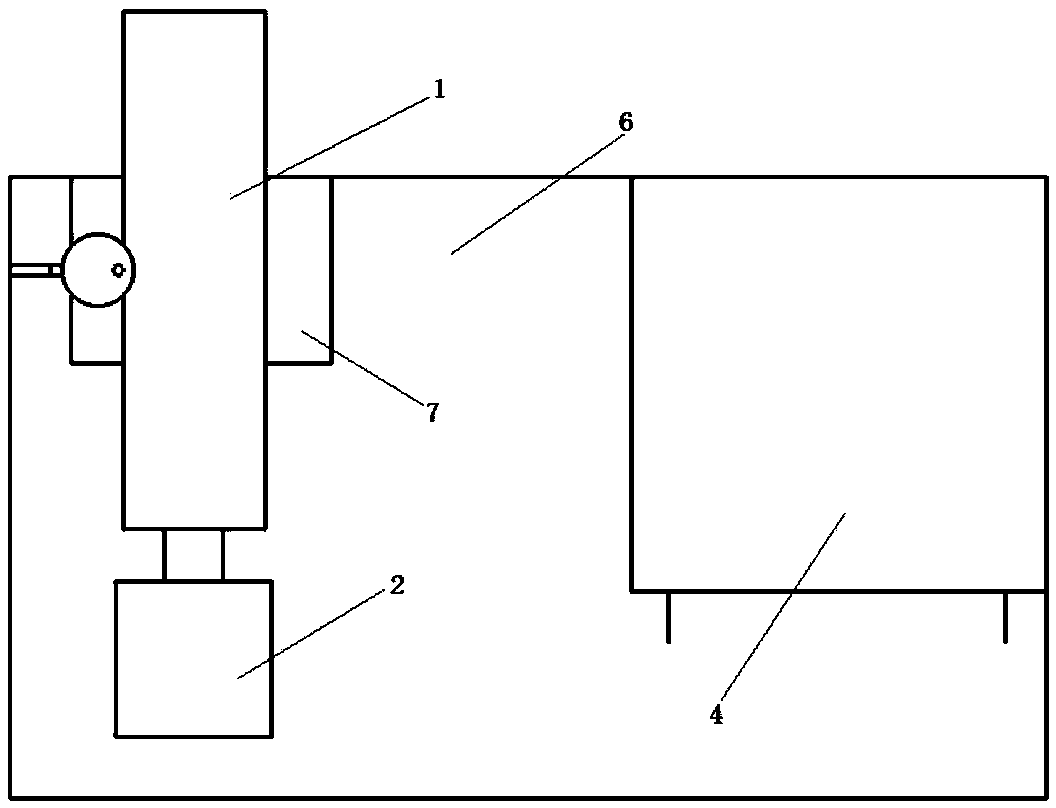

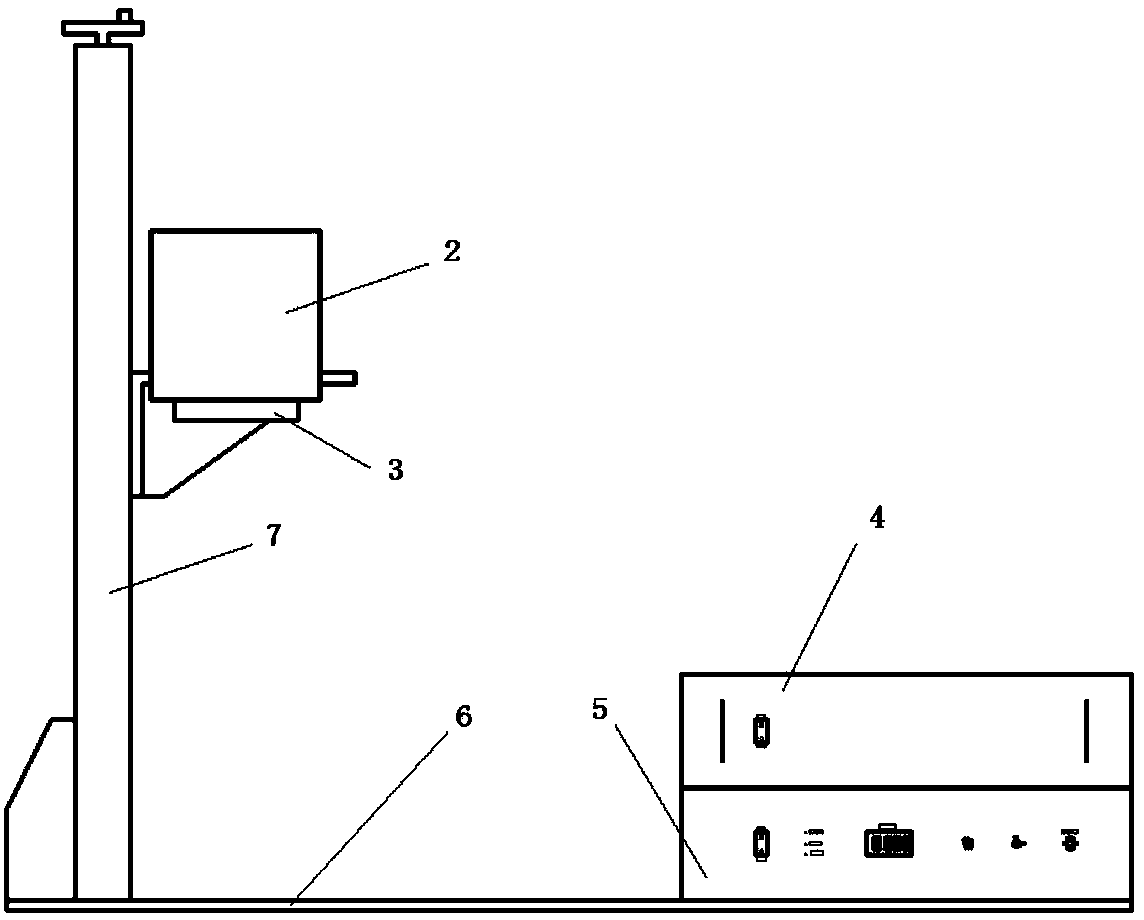

[0049] Examples, see Figure 1-4 As shown, among them, figure 1 The front view of the laser univariate color marking system provided by the embodiment of the present invention; figure 2 The top view of the laser univariate color marking system provided by the embodiment of the present invention; image 3 A side view of the laser univariate color marking system provided by the embodiment of the present invention; Figure 4 The flow chart of the laser single-variable color marking method provided by the embodiment of the present invention: The laser single-variable color marking system provided by this embodiment includes a bracket, a laser 1, a galvanometer scanning system 2, a focusing system 3, and a computer control system 4 and laser power supply 5;

[0050] Described support comprises base 6 and the fram...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com