Patents

Literature

36results about How to "To achieve the printing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

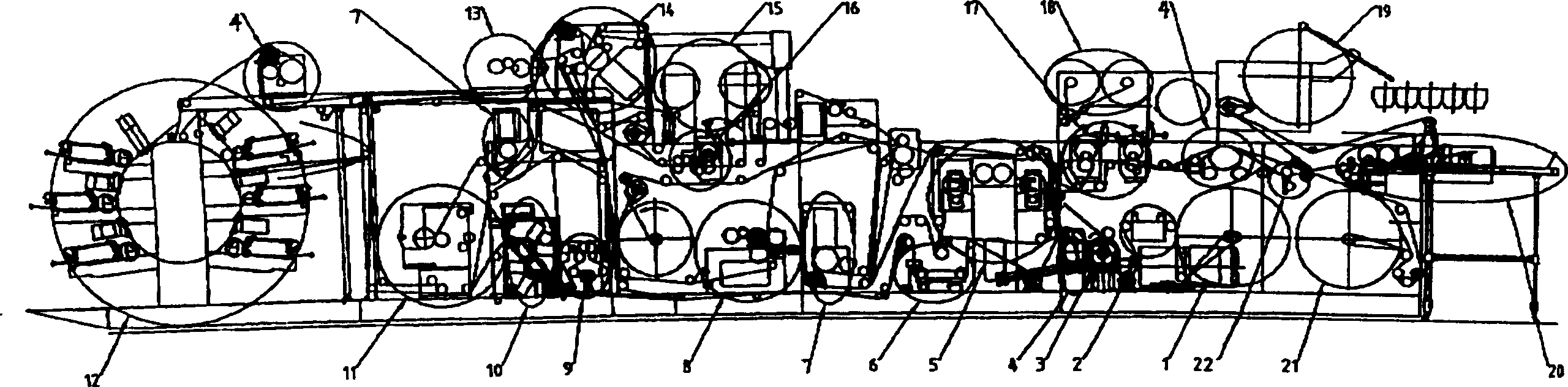

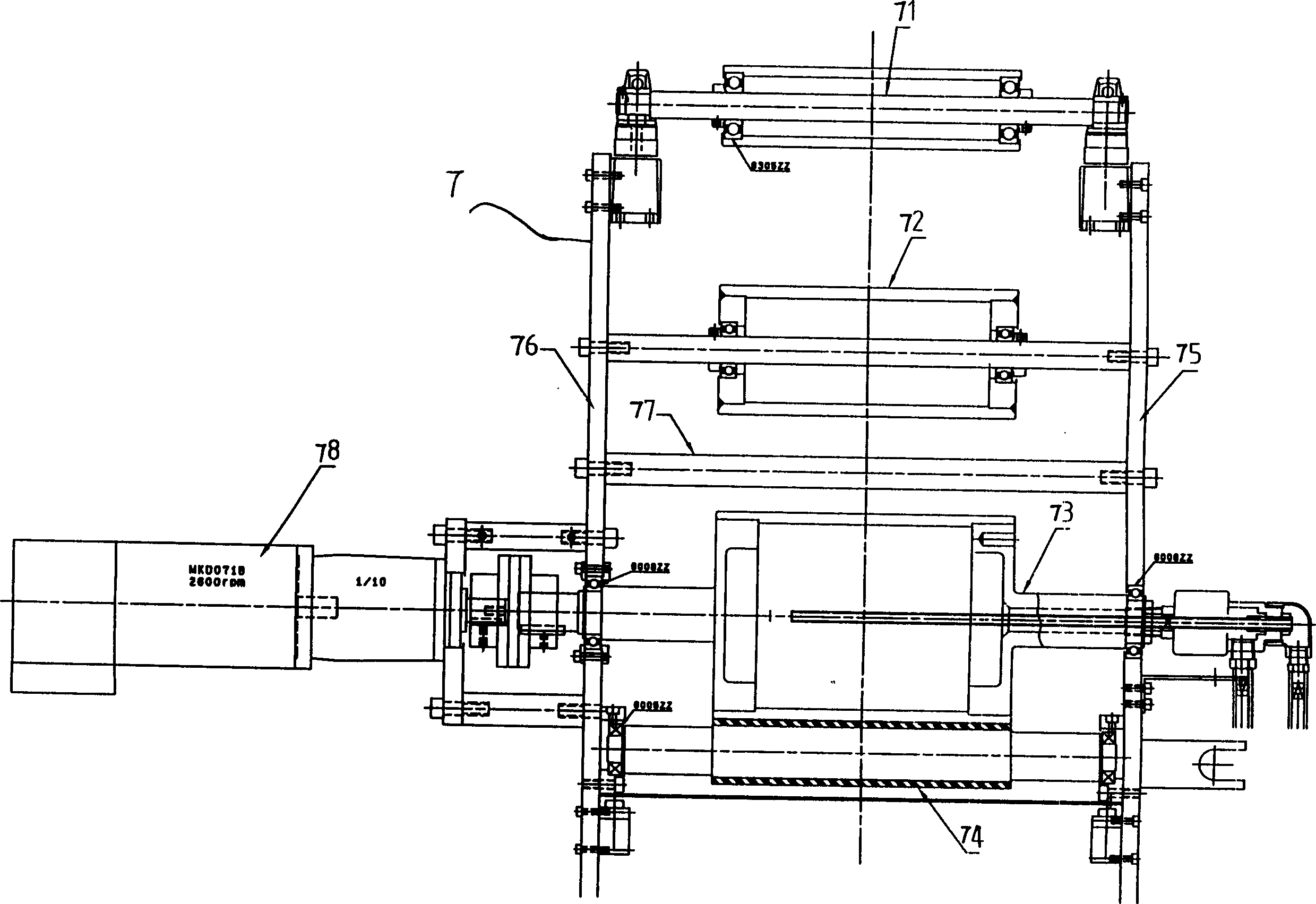

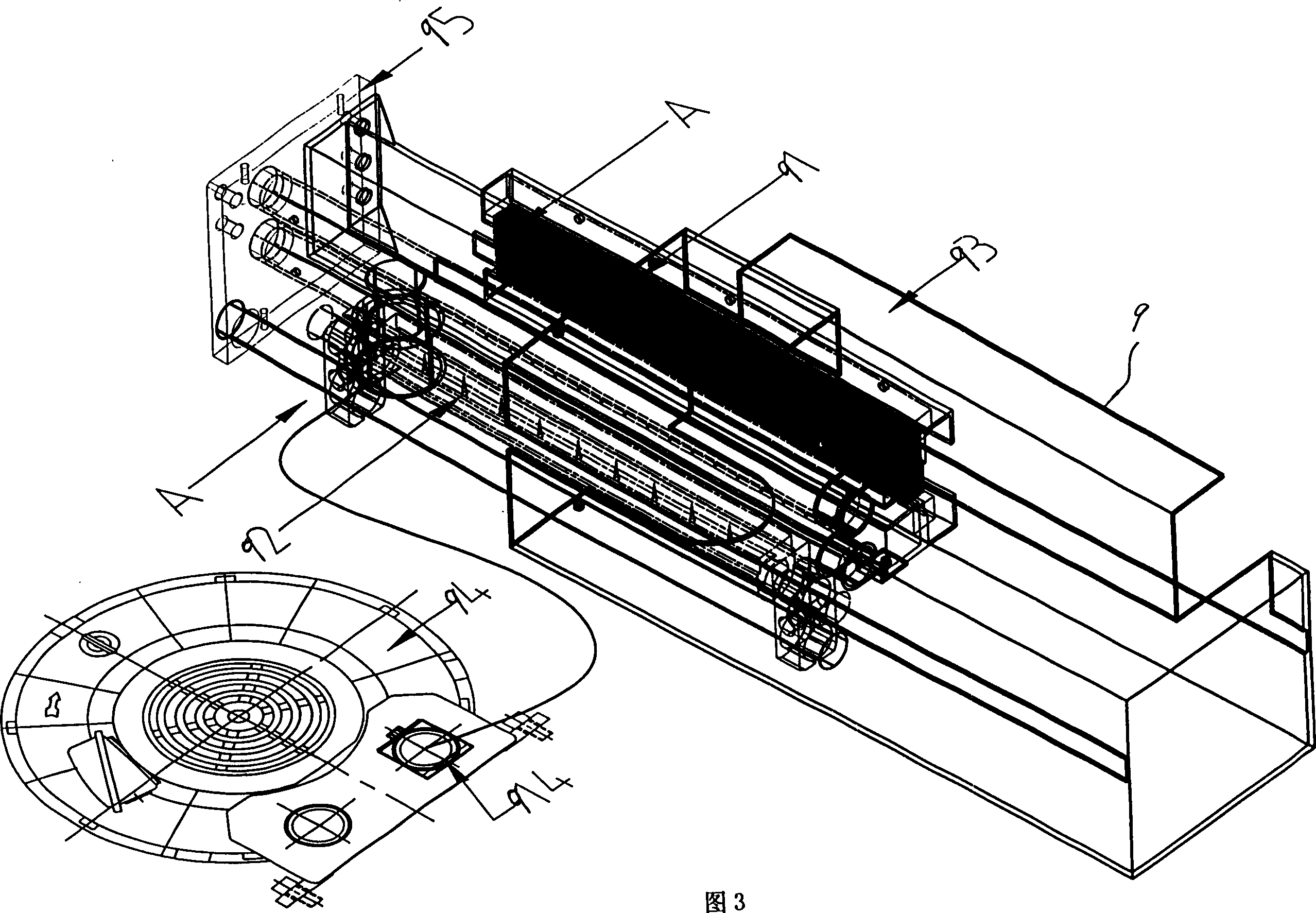

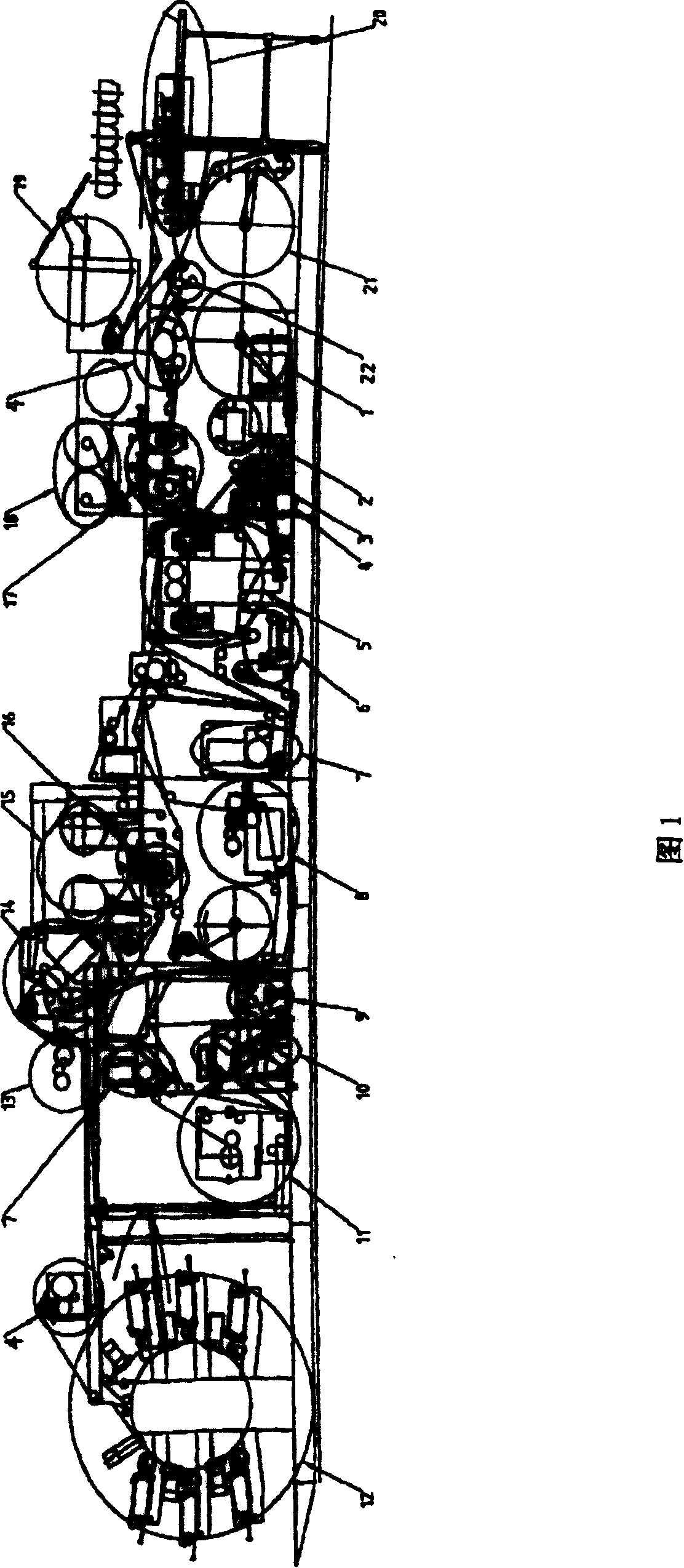

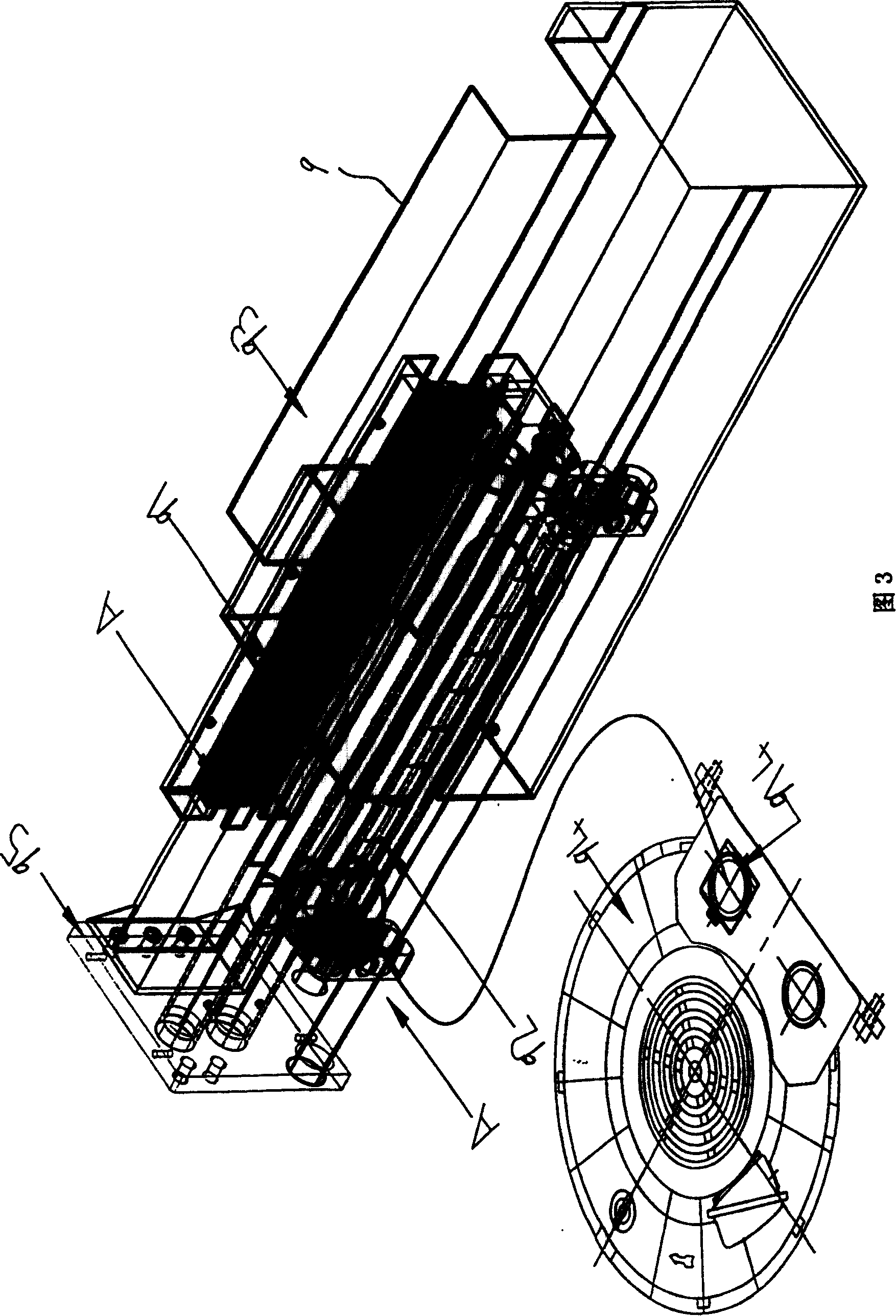

Adhensive rotary printer

A rotary press for printing on non-drying adhesive matter is composed of paper feeder, paper receiver, speed reducer, AC servo tension control and tract unit, platen unit, skew corrector, servo motor cooling and driving unit, flexible plate printing unit, paper chip and static electricity remover, corona unit, silk screen printing unit, satellite relief printing unit, gilded film sticking-UV baking-cooling driver, golden foil feeder, reel, gilded film cutting unit, etc.

Owner:SHANGHAI XINMIN TAIYO KIKAI

Self-crosslinking polyacrylate rubber latex, preparation method thereof and water-based paper printing ink

InactiveCN101870793APrevent sticking backFast dryingPaper coatingCoatingsWater basedHydrophilic monomer

The invention discloses self-crosslinking polyacrylate rubber latex, a preparation method thereof and water-based paper printing ink. The self-crosslinking polyacrylate rubber latex is prepared by the following steps: mixing an acrylic ester monomer, a hydrophilic monomer and ADH in a head tank A; mixing water, an emulsifier, the acrylic ester monomer and DAAM in a head tank B; adding water, the emulsifier and polymerizable self-emulsifying functional monomer, stirring the mixture, heating the mixture to 75 DEG C, and dripping a mixture in the head tank A and an initiator to prepare a protective colloid first; dripping the mixture in the head tank B and the initiator at 85 DEG C; and performing a constant-temperature reaction. The water-based paper printing ink is prepared by the following steps: dissolving a phenylethylene-acrylic acid polymer and a pH value regulator in water at 60 DEG C with stirring; adding a pigment and necessary assistant and mixing the mixture to prepare color paste; and uniformly mixing the color paste with the self-crosslinking polyacrylate rubber latex, a surface tension regulator and water. The water-based paper printing ink can be diluted by one or a mixture of two of water and ethanol, can be dried quickly and has high printing adaptability.

Owner:SUN YAT SEN UNIV +1

Self-crosslinked polyacrylate latex and preparation method thereof, and water-based paper ink

InactiveCN102304262APrevent sticking backFast dryingPaper coatingCoatingsHydrophilic monomerPolymer science

The invention discloses self-crosslinked polyacrylate latex and a preparation method thereof, and water-based paper ink. The preparation method for the self-crosslinked polyacrylate latex comprises the following steps of: mixing acrylate monomers, hydrophilic monomers and alcohol dehydrogenase (ADH) in a head tank A; mixing water, an emulsifier, acrylate monomers and diacetone acrylamide (DAAM) in a head tank B; adding water, an emulsifier and polymerization self-emulsification functional monomers into a normal-pressure reaction tank, stirring, heating to 75DEG C, dripping a mixture in the head tank A and an initiator, and preparing protective colloid; dripping a mixture in the head tank B and an initiator at 85DEG C; and reacting at constant temperature. The water-based paper ink is prepared by the following steps of: stirring and dissolving styrene-acrylate copolymer, a pH regulator and water at 60DEG C; adding pigments and necessary aids, and mixing to obtain color paste; and uniformly mixing the color paste, the self-crosslinked polyacrylate latex, a surface tension regulator and water. The water-based paper ink can be diluted by one of water and ethanol or a mixture of water and ethanol, and has high drying speed and good printing adaptability.

Owner:SUN YAT SEN UNIV +1

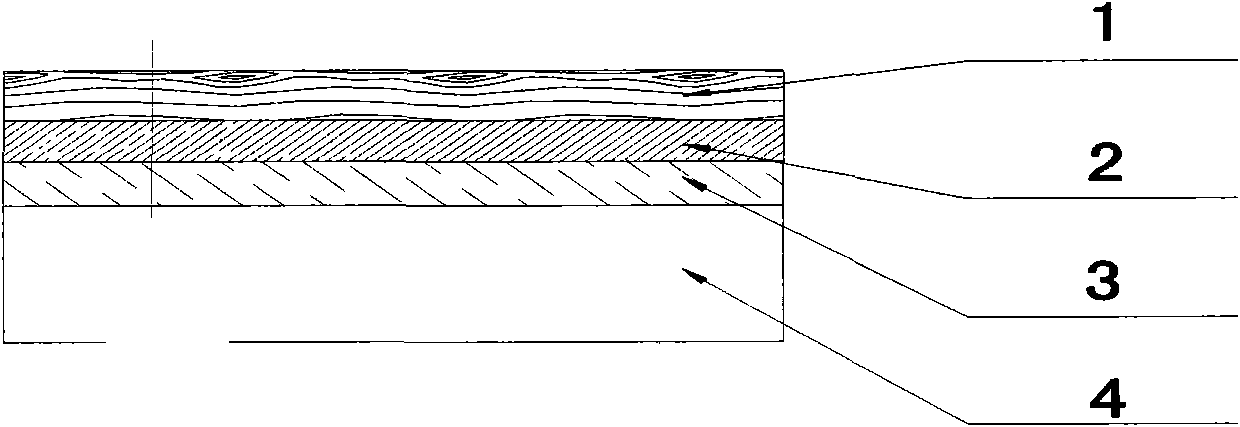

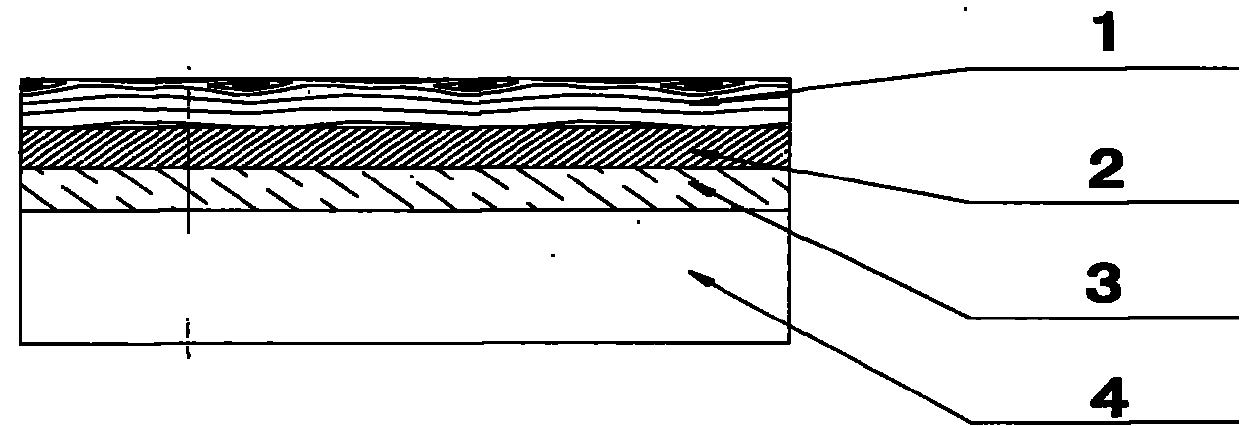

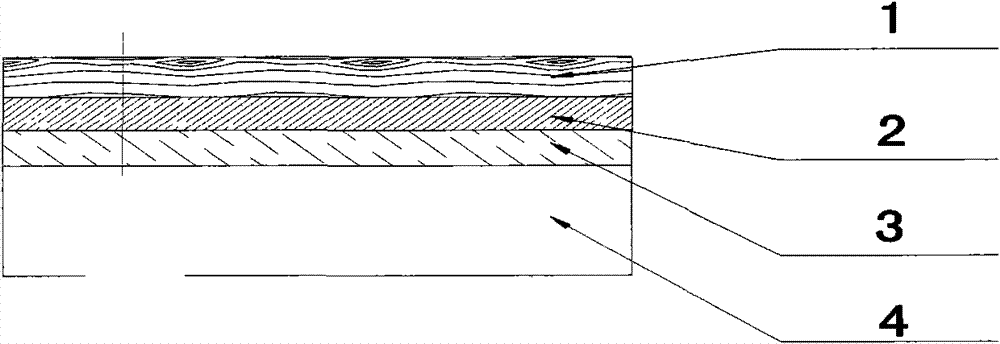

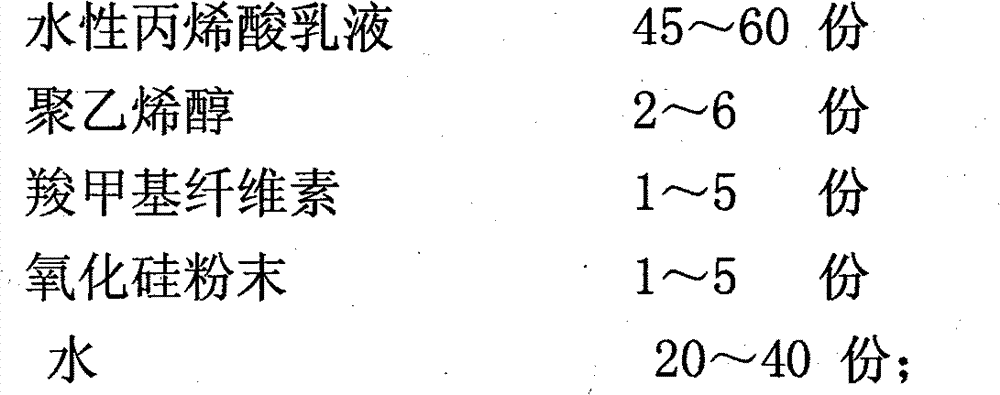

Vacuum aluminum plating ground paperboard and production method thereof

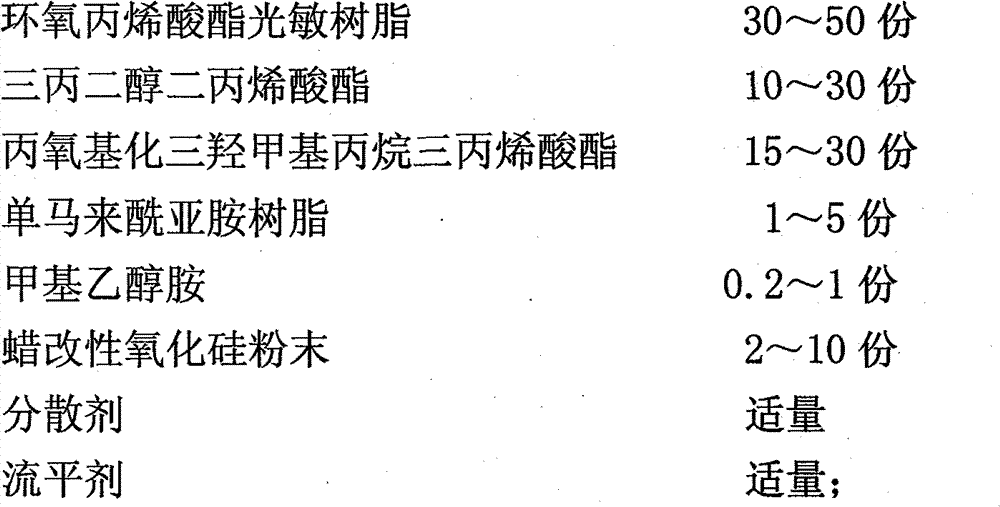

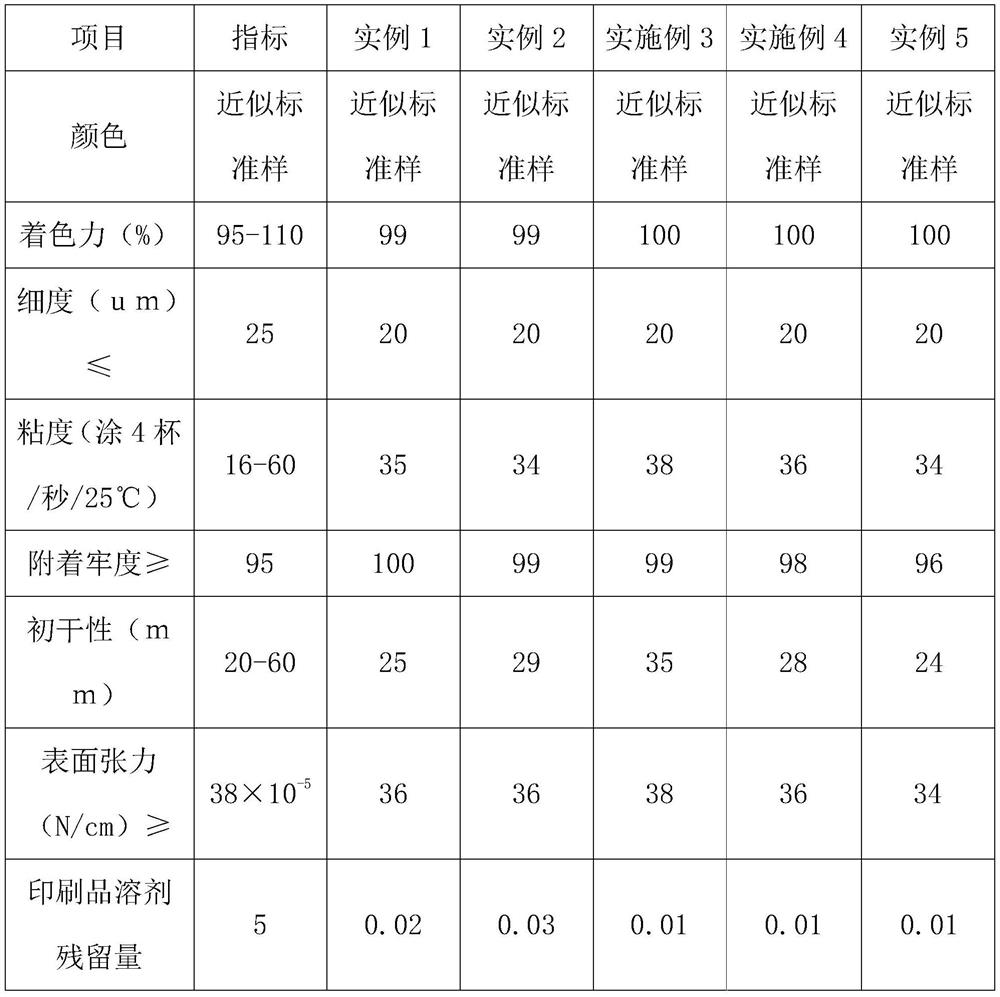

ActiveCN102002895ATo achieve the printing effectLow solvent residueSpecial paperPaper/cardboardScreen printingPaperboard

The invention relates to a vacuum aluminum plating ground paperboard and a production method thereof, which belong to the technical field of package materials and printing materials. The vacuum aluminum plating ground paperboard comprises a paper base material, a ground coating layer and an aluminum plating layer. The production method comprises the following steps of: 1. making a ground coating mixing body; 2. coating a layer of ground coating mixing body on a paper substrate 4 for forming the ground coating layer; and 3. placing the paperboard comprising the ground coating layer with the grounding effect into a vacuum aluminum plating system, directly plating aluminum on the ground surface of the ground coating layer of the paperboard and forming the aluminum plating layer. The production method has the following advantages of simple process, no glue water layer, high production efficiency and no solvent volatilization, and belongs to the environmental-protection production process. The paperboard has exquisite and vivid ground effect and rich metal texture, and the produced ground paperboard can reach the screen painting effect through ordinary offset printing or gravure printing. A large amount of ink is saved, and the solvent volatilization and the solvent residue of printed products are greatly reduced.

Owner:YANTAI BOYUAN TECH MATERIALS

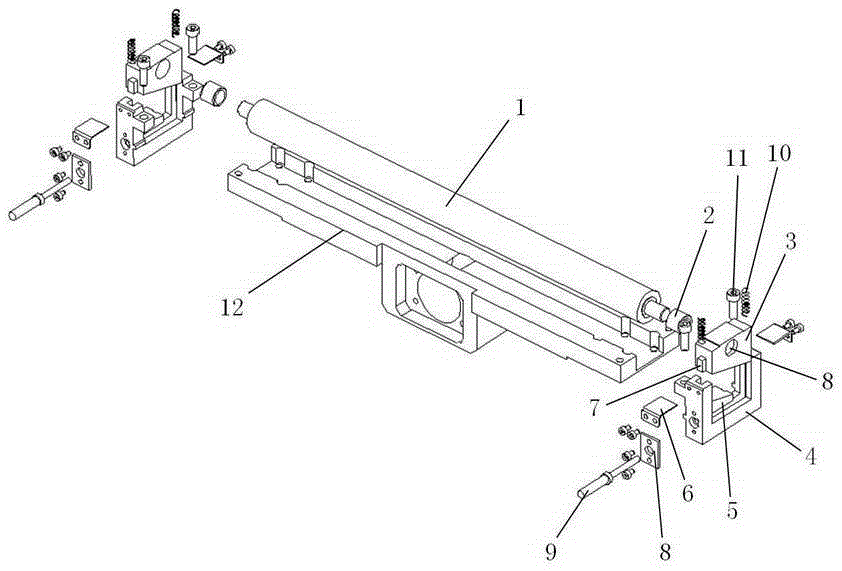

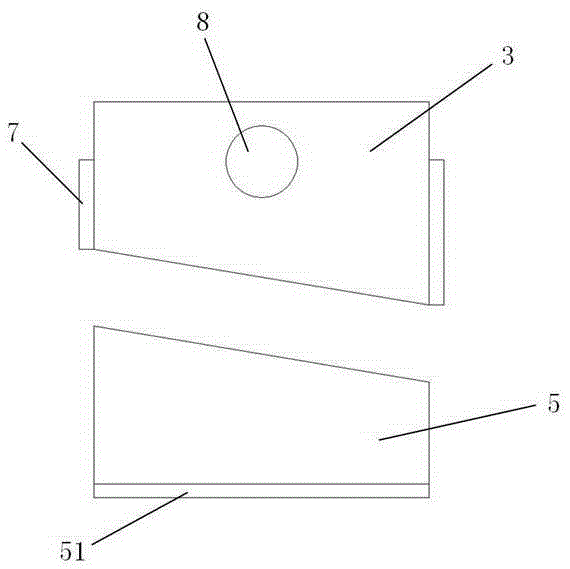

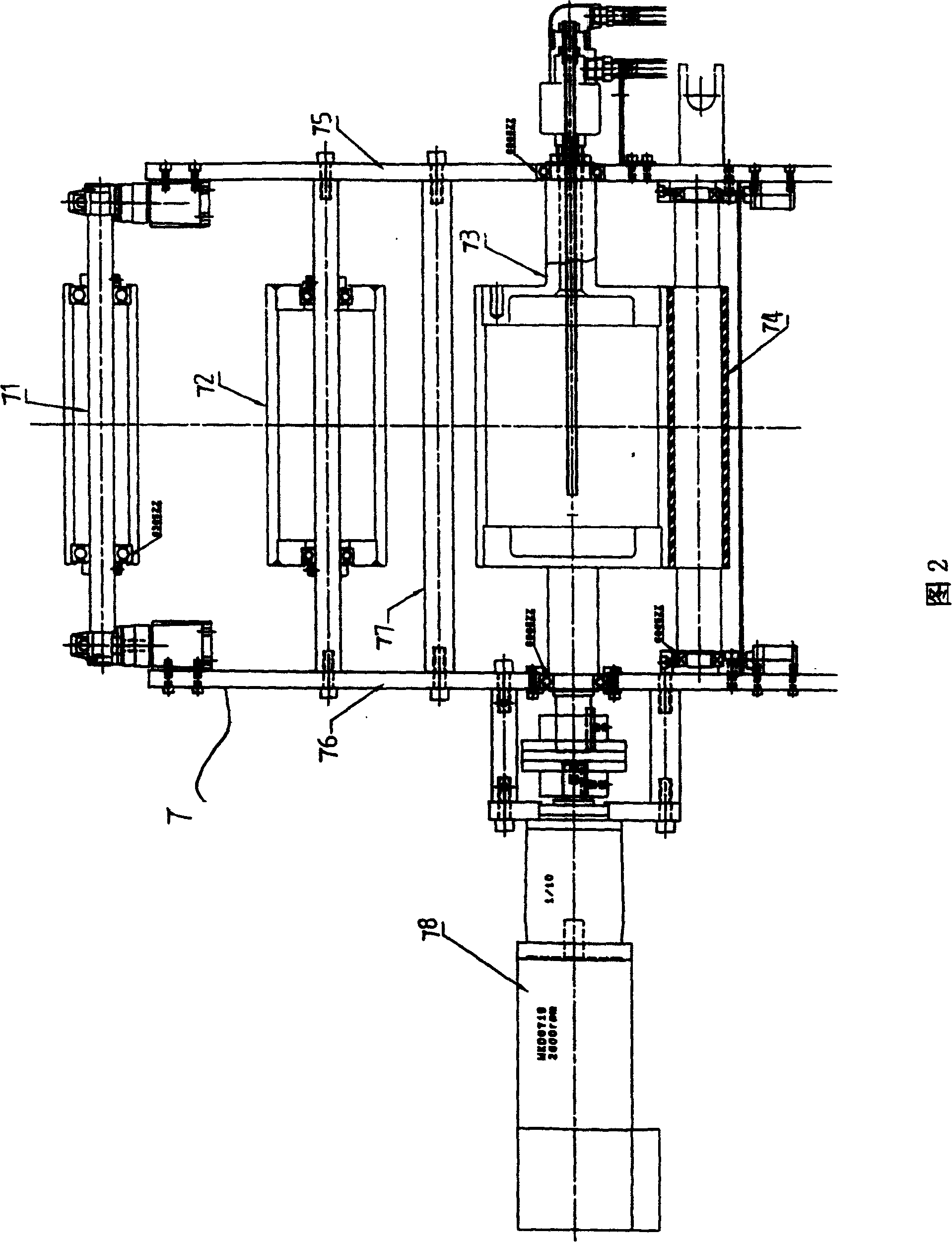

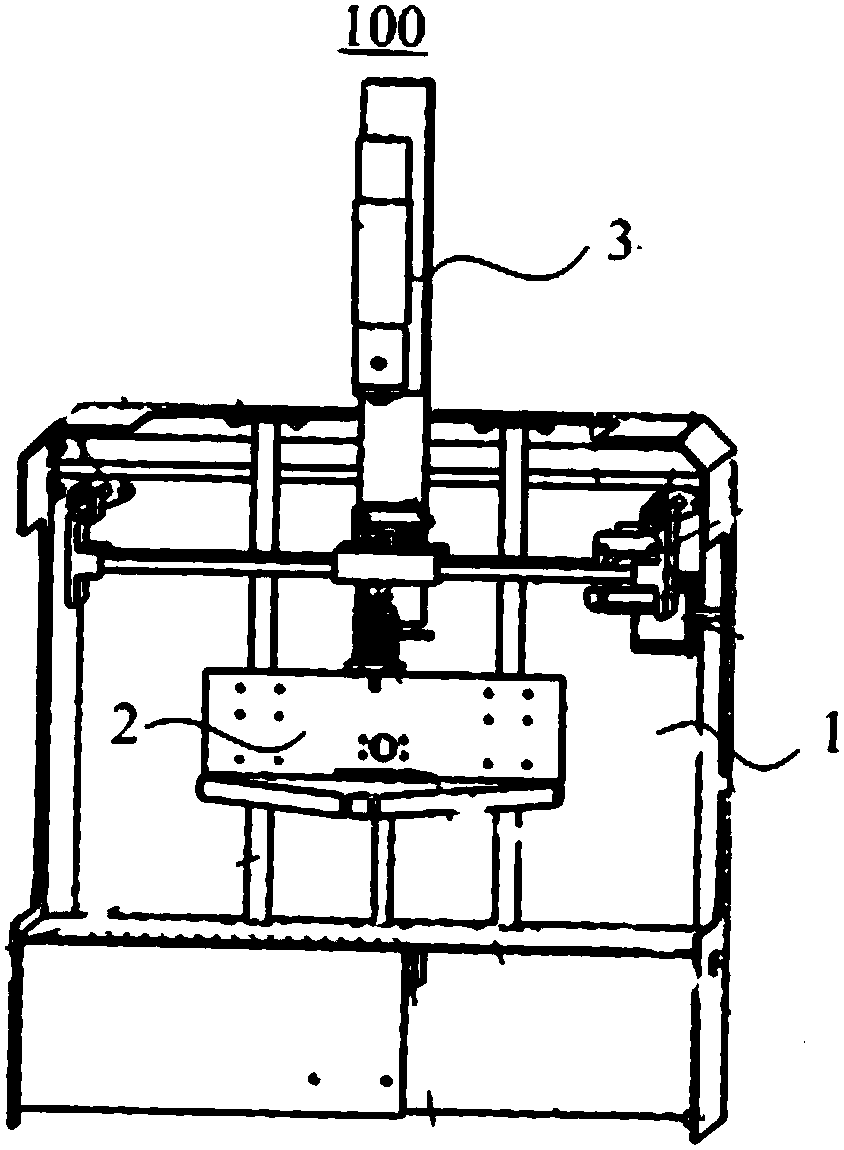

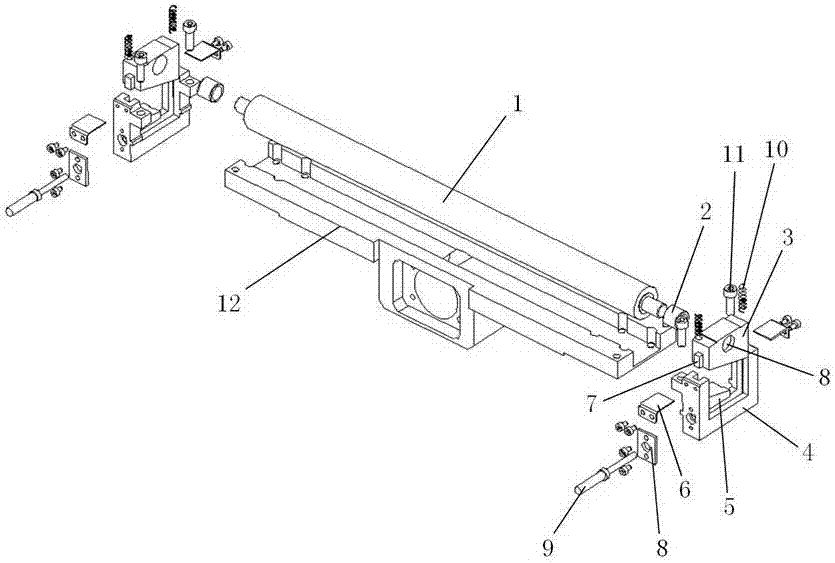

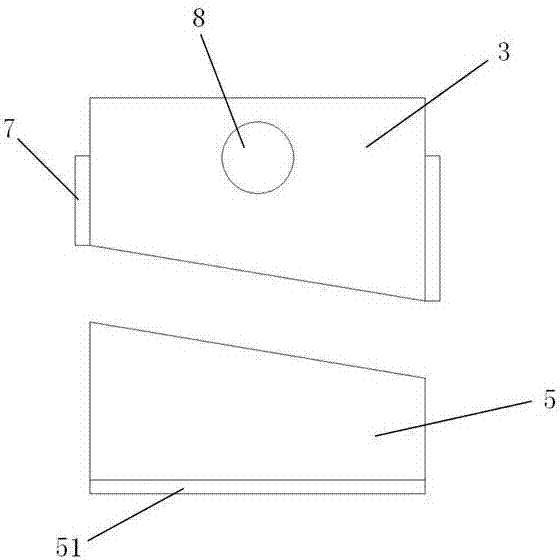

Stamping device and printer

ActiveCN105235361AIncrease pressureHeight adjustableRotary pressesPrinting pressMechanical engineering

The invention discloses a stamping device. The stamping device comprises a cylindrical roller, a roller height adjusting device, a printing plate, a base and a power device, wherein the roller is opposite to the printing plate; a channel through which the printed material passes is reserved between the roller and the printing plate; the roller is fixedly arranged on the base by the roller height adjusting device; the self height of the roller is changed under the action of the roller height adjusting device; the base is subjected to reciprocation movement under the driving of the power device. Through the adoption of the stamping device, the pressure among the printed material, the stamping device and the printing plate can be increased; the stamping device is capable of uniformly stamping, so that the printing quality is improved; meanwhile, due to the design of the roller, the printing efficiency can be improved.

Owner:谢成虎

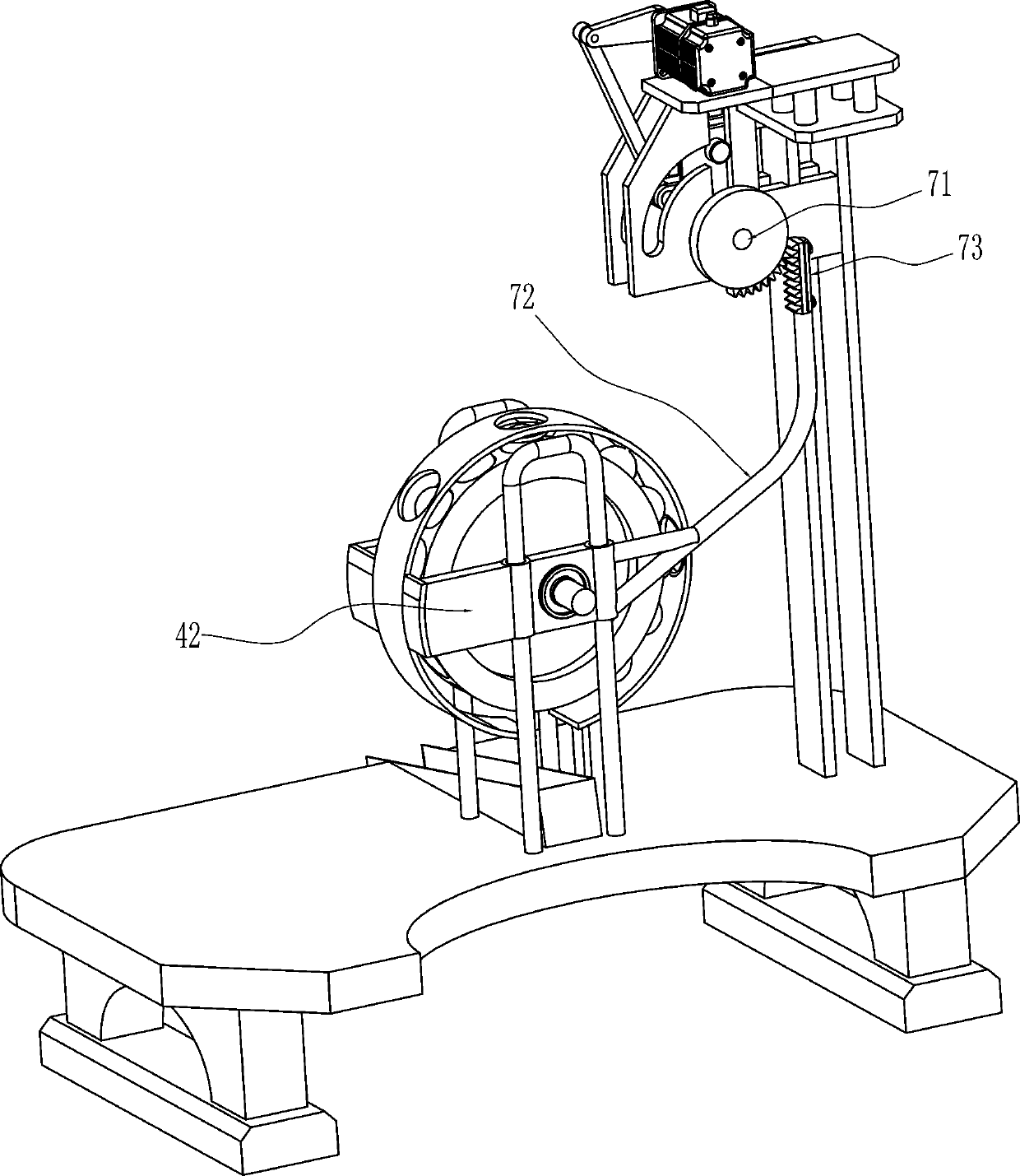

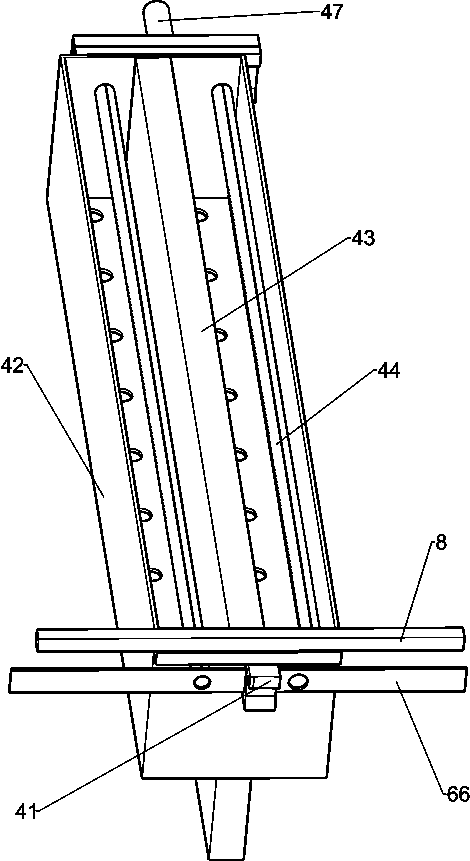

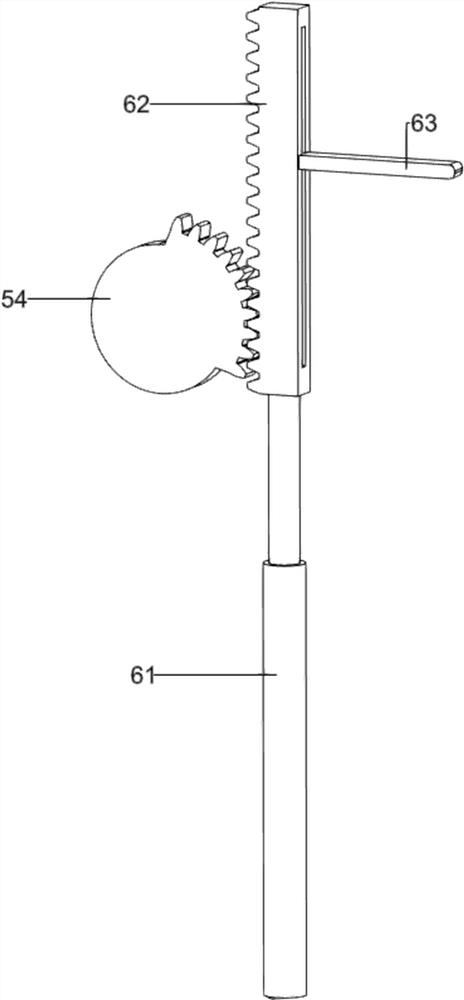

Label printing device for table tennis ball processing

ActiveCN111514555AReduce labor intensityImprove work efficiencyBall sportsEngineeringStructural engineering

The invention relates to a printing device, in particular to a label printing device for table tennis ball processing. The label printing device for table tennis ball processing can improve the working efficiency and reduce the labor intensity of workers. The label printing device for table tennis ball processing comprises a supporting base, wherein a discharging plate is installed in the middle of the top of the supporting base in an embedded mode, the discharging plate is obliquely arranged, and an installation frame is fixedly connected to the top of the supporting base; a discharging assembly arranged at the top of the supporting base and used for containing table tennis balls; and a driving assembly mounted on the installation frame. Table tennis balls can be placed in the dischargingassembly, a printing assembly is driven by the driving assembly to print labels of the table tennis balls after the table tennis balls are placed, and therefore the effect of printing the labels of the table tennis balls can be achieved.

Owner:陆仙红

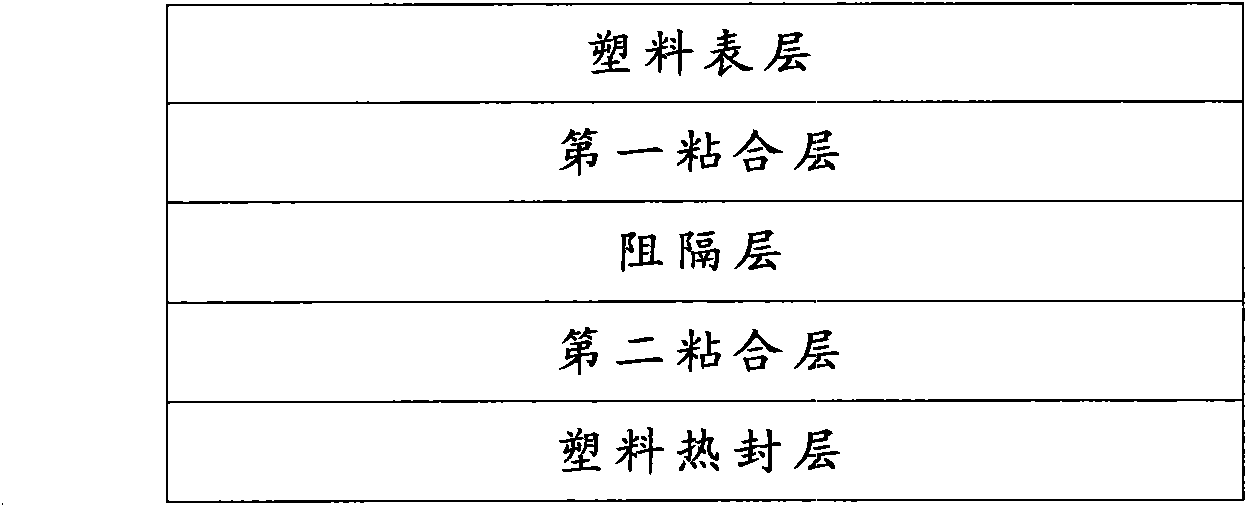

Novel manufacturing process of plastic tube and plastic tube manufactured thereby

The invention relates to a novel manufacturing process of a plastic tube. The manufacturing process firstly utilizes a reverse printer combined with the surface printing and imaging principle to carry out surface printing to a block layer used for manufacturing the plastic tube; preferably, after surface printing, the manufacturing process also comprises the following steps of: a, obtaining a composite sheet rolling film by extruding and compositing; b, welding two sides of the composite sheet rolling film for manufacturing a tube, thus obtaining a tube body; c, casting the shoulders on the tube body obtained in the step b by extruding and injecting; and more preferably, the manufacturing process further comprises the step between the step a and the step b of carrying out varnish printing on the surface of the composite sheet material film by utilizing a surface printer. The invention further provides a plastic tube manufactured by the manufacturing process. The plastic tube has skillful design of the manufacturing process, greatly improves the production efficiency and reduces the production cost, and the appearance of the produced flexible tube is delicate.

Owner:三樱包装(江苏)有限公司

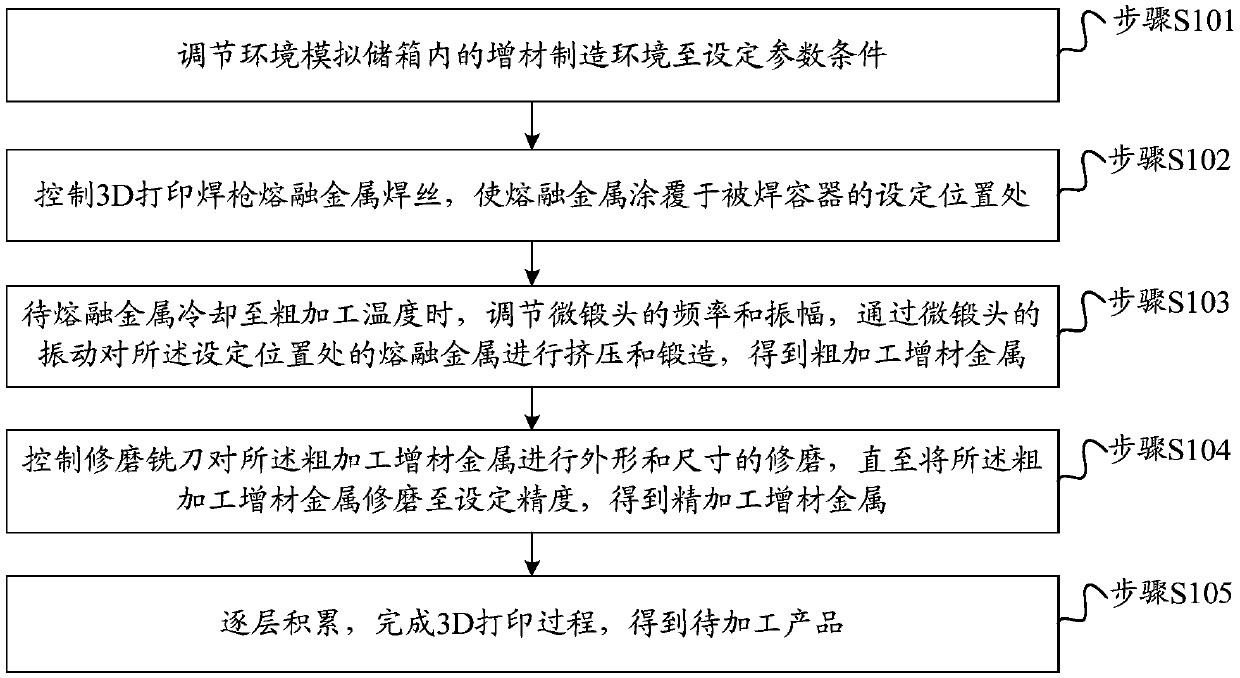

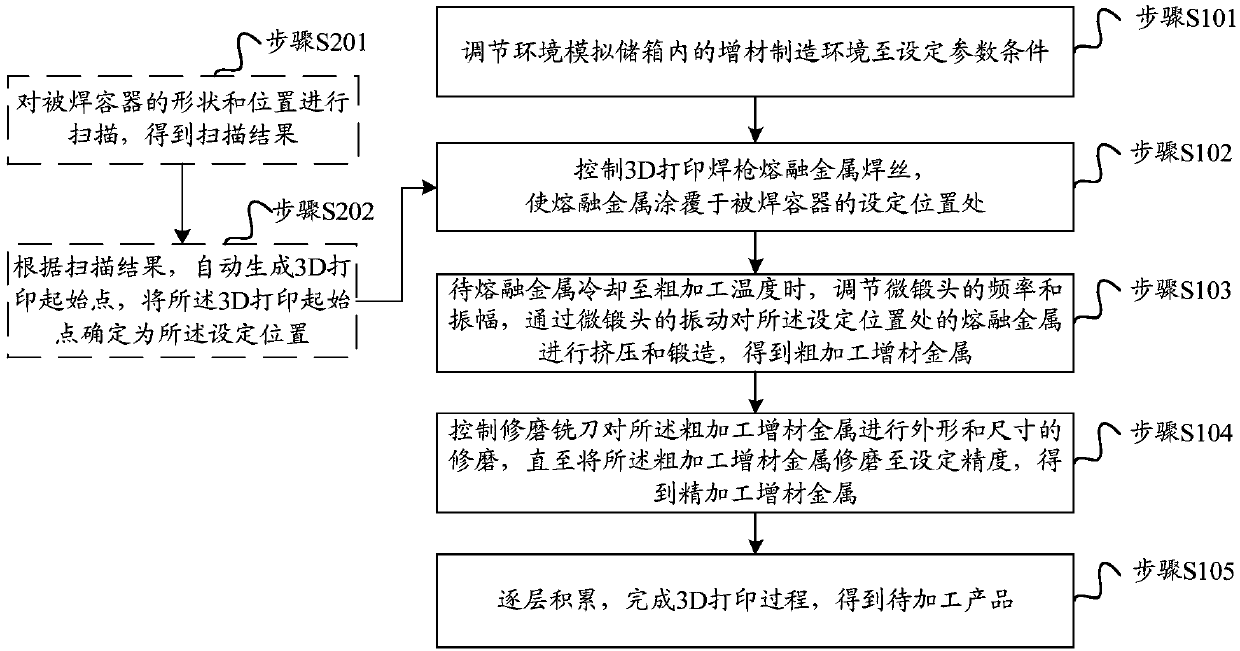

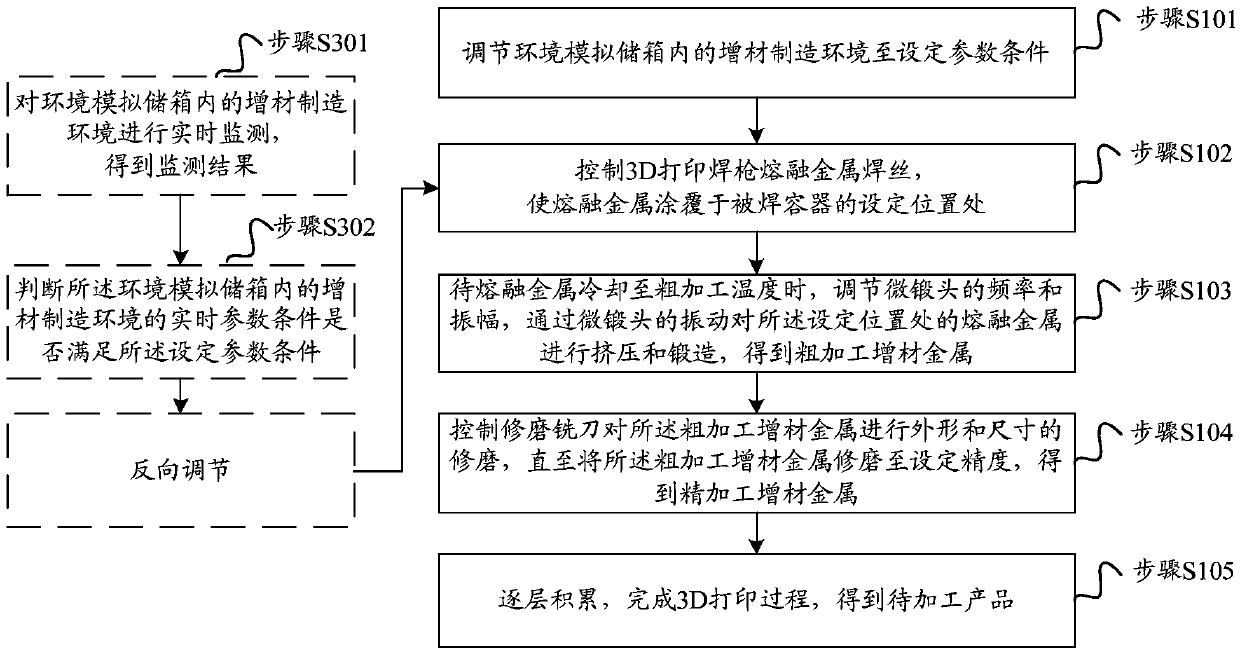

Method and device for manufacturing metal lining of 3D printing composite material space pressure vessel

InactiveCN109590678AGuaranteed printing effectTo achieve the printing effectOther manufacturing equipments/toolsMilling cutterEnvironmental simulation

The invention discloses a method and device for manufacturing a metal lining of a 3D printing composite material space pressure vessel. The manufacturing method comprises the steps that an additive manufacturing environment of an environmental simulation storage tank is adjusted to a set parameter condition; a 3D printing welding gun is controlled to fuse a metal welding wire, and molten metal iscoated to a set position of the welded vessel; after the molten metal is cooled to the rough machining temperature, the frequency and the amplitude of a micro forging head are adjusted, the molten metal at the set position is pressed and forged through vibration of the micro forging head, and rough machining additive metal is obtained; a grinding milling cutter is controlled to conduct appearanceand size grinding on the rough machining additive metal until the rough machining additive metal is ground to the set accuracy, and finish machining additive metal is obtained; and layer-by-layer accumulation is carried out, the 3D printing process is completed, and a product to be processed is completed. According to the method and device, the fusing-forging integration process is used for producing the lining of the pressure vessel or a thin-walled pressure vessel, influences of machining like welding on the product quality are reduced, and the precision and the tissue performance of the molded product are improved.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

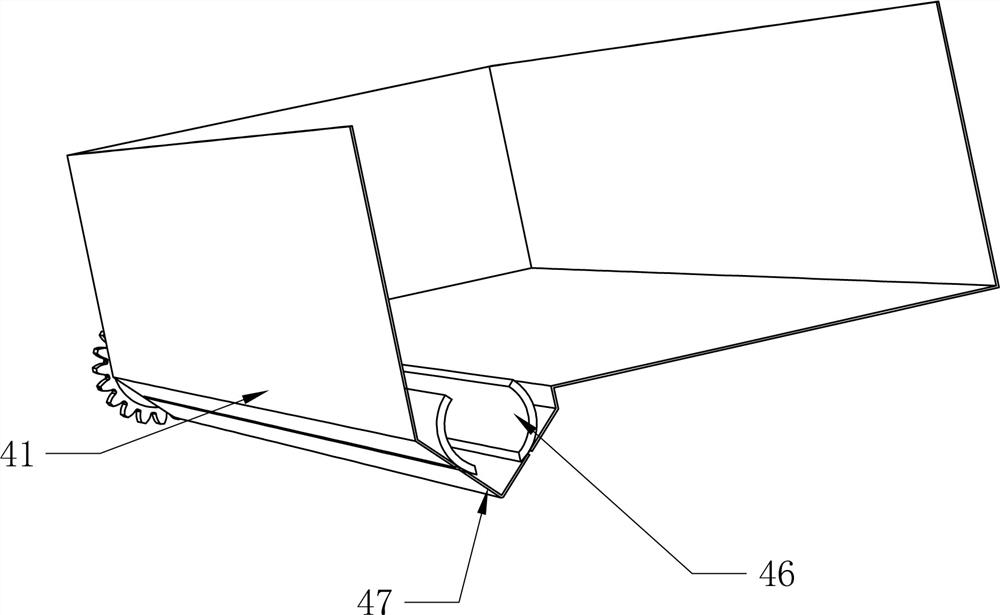

Angle-adjustable scraper device for printing and dyeing mechanism of flat screen printing machine

InactiveCN101574862AQuality improvementReduce the effectScreen printersScreen printingComputer engineering

The invention relates to an angle-adjustable scraper device for a printing and dyeing mechanism of a flat screen printing machine. A scraper is fixedly connected with a scraper holder, the scraper holder is fixedly connected with a slide arm, the slide arm is fixedly arranged on a slide arm base, a control slide block is fixedly connected with an adjusting disc, an arc T-shaped groove guide rail is formed on the adjusting disc, the corresponding slide arm base is provided with a T-shaped guide post, and the T-shaped guide post is plugged in the arc T-shaped groove guide rail; and a bayonet is formed on the adjusting disc, a spring positioning pin is fixedly arranged on a turned-up part of the slide arm base, and a plug pin of the spring positioning pin is blocked in the bayonet. The angle-adjustable scraper device breaks through the defects that the conventional calico printing machine cannot adjust the angle of the scraper directly and has light printing colors, and is quite convenient to operate.

Owner:周林

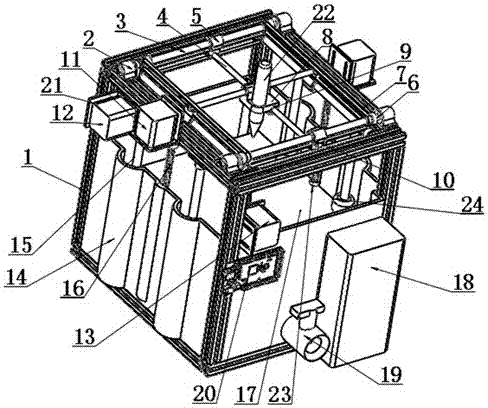

Photocuring 3D printing machine based on FDM printing technology

PendingCN107379520ASimple structure and transmission modeSimple transmissionManufacturing enclosures3D object support structures3d printComputer printing

The invention relates to the field of 3D printing, and discloses a photocuring 3D printing machine based on an FDM printing technology. An FDM printing machine body and an SLA printing machine body are combined, an FDM nozzle is changed into a laser head, laser irradiates 0.01 mm of the photosensitive resin liquid surface, controlled by a base plate, in a photosensitive resin containing box, a curable material is irradiated by laser, a cured body with a single layer thickness is formed, then the base plate moves downwards by 0.01 mm, the photosensitive resin liquid surface is 0.01 mm away from the first cured body, laser irradiates again, a second-layer cured body is formed, a three-dimensional module needing to be printed is finally formed through stacking layer by layer, the advantages of two printing methods are combined by the photocuring 3D printing machine based on the FDM printing technology, some unnecessary parts and modules are omitted, the printing precision is improved compared with the FDM printing technology, cost is reduced compared with an SLA printing technology, and the SLA printing effect is achieved.

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

Plastic board printing equipment

ActiveCN111497432ASave human effortEasy to operateRotary pressesPrinting press partsManufacturing engineeringMechanical engineering

Owner:青州市亿恒包装机械有限公司

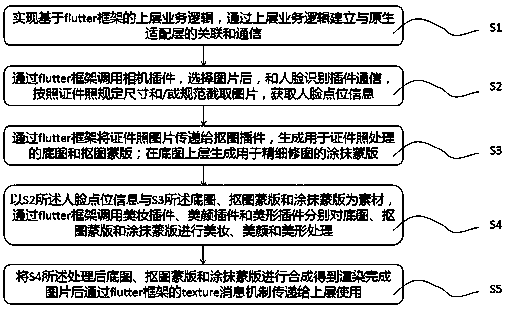

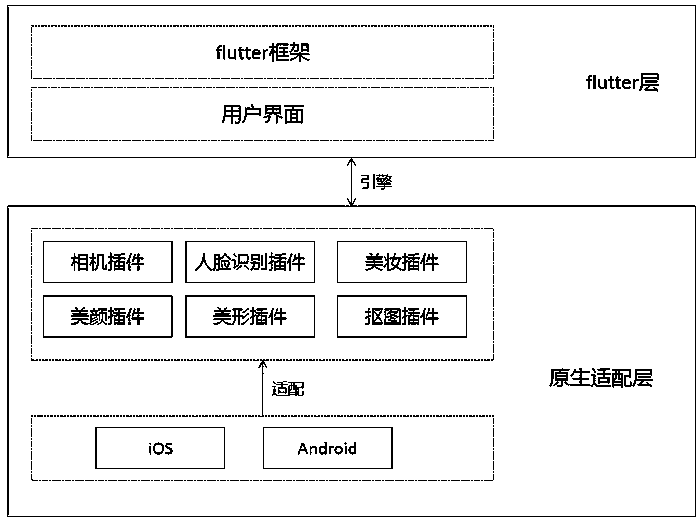

Flutter-based cross-platform identification photo mobile terminal system and use method thereof

InactiveCN110634102AFine matting serviceMeet the needsGeometric image transformationInput/output processes for data processingPattern recognitionUser needs

The invention relates to the field of identification photo mobile terminal design, and provides a flutter-based cross-platform identification photo mobile terminal system and a use method thereof. Theflutter-based cross-platform identification photo mobile terminal system utilizes a flutter technology to realize a cross-platform scheme of an identification photo, enables plug-ins such as face recognition, beautifying, shape beautifying and makeup beautifying to be accessed to an identification photo system, and provides better identification photo experience for a user. The flutter-based cross-platform identification photo mobile terminal system comprises a flutter frame, a user interface, a camera plug-in, a face recognition plug-in, a beauty makeup plug-in, a beauty plug-in, a beauty plug-in and a matting plug-in. The flutter-based cross-platform identification photo mobile terminal system establishes association and communication with the native adaptation layer through upper-layerservice logic, calls the camera plug-in, the face recognition plug-in, the image matting plug-in, the beauty makeup plug-in, the beauty plug-in and the shape beautifying plug-in to render an image, and realizes cross-platform development and quick response iteration, saves development time; and meanwhile, the scheme can adapt to different certificate photo specifications, achieves the specified printing effect, provides the functions of later beautifying, shape beautifying, makeup beautifying, fine smearing and the like, and better meets the requirements of users.

Owner:CHENDU PINGUO TECH

High-resolution water-based flexible printing ink and preparation method thereof

The invention discloses a high-resolution water-based flexible printing ink comprising ink paste and acrylic emulsion. The ink is characterized in that the ink paste comprises the following components in parts by weight: 20 to 30 parts of water-based acrylic resin, 30 to 60 parts of pigment, 2 to 8 parts of dispersant 760W, 10 to 20 parts of water, 10 to 15 parts of ethanol, and 0.5 to 1 part of defoaming agent. The invention further discloses a preparation method for the ink. The quantity of the pigment is increased in the ink paste of the ink disclosed by the invention, and meanwhile, the dispersant 760W is adopted, so that a large dose of pigment can be well dispersed, and the ink has good stability and good dyeing property. The ink can reach more than 100 resolution cables and can be used for directly printing line boards, and the inking effect is similar to an offset printing effect. The third dimension of printed pictures can be reflected, and the pictures are exquisite and vivid. Moreover, the ink disclosed by the invention is water-based ink, so the ink accords with the national environmental protection policy, and can achieve the printing effect of an oil-based ink.

Owner:CHONGQING HONGYUAN PRINTING INK

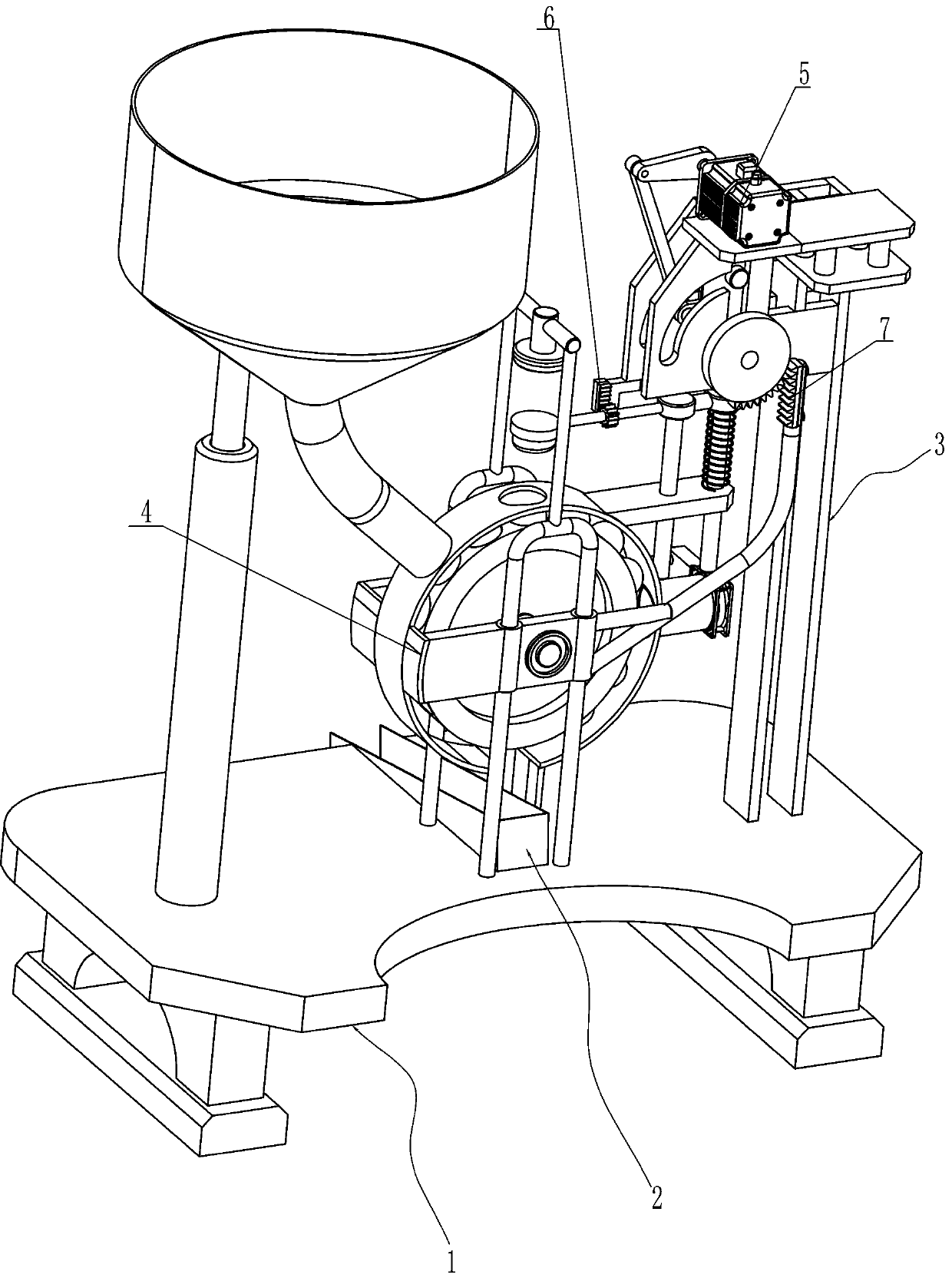

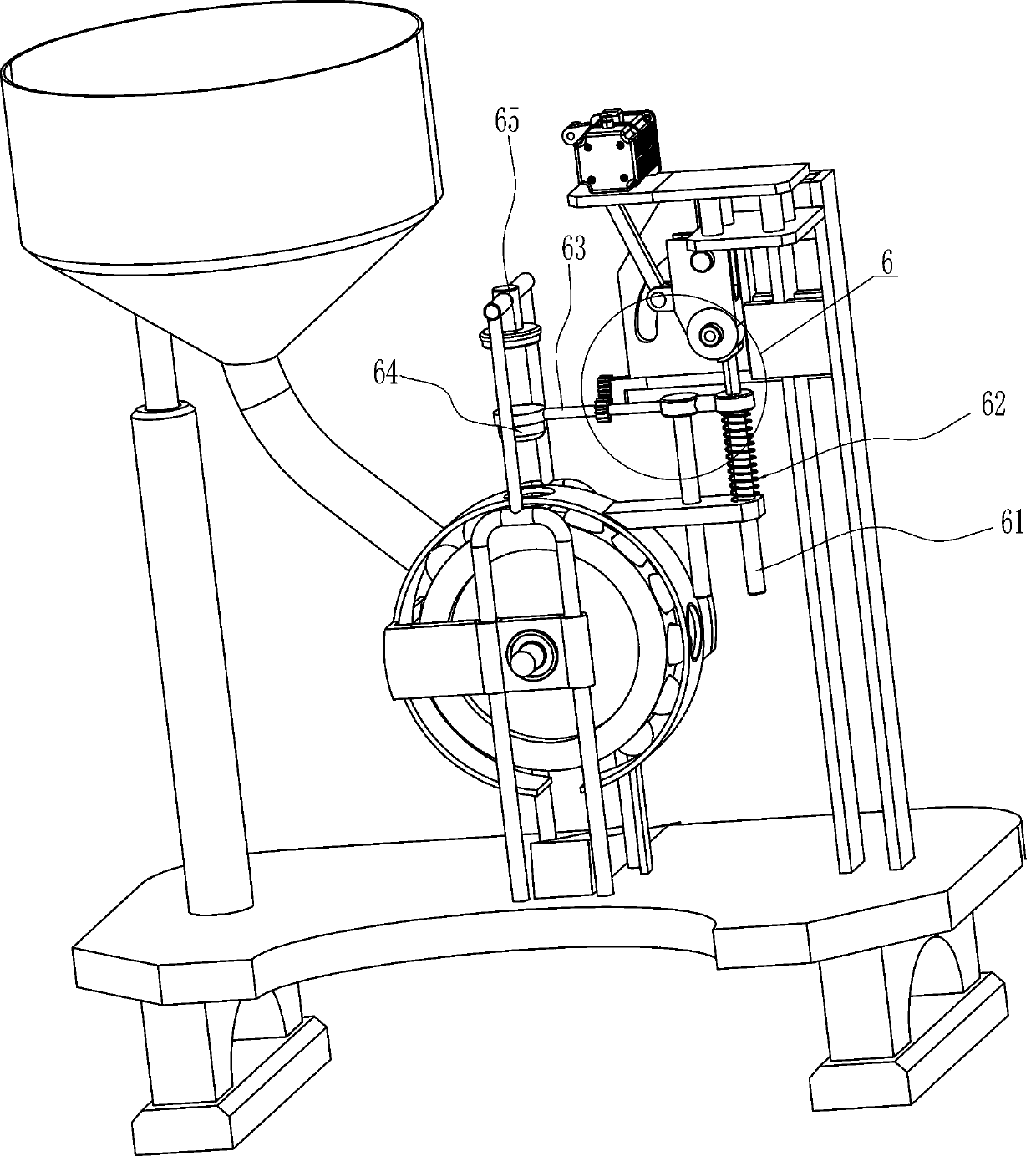

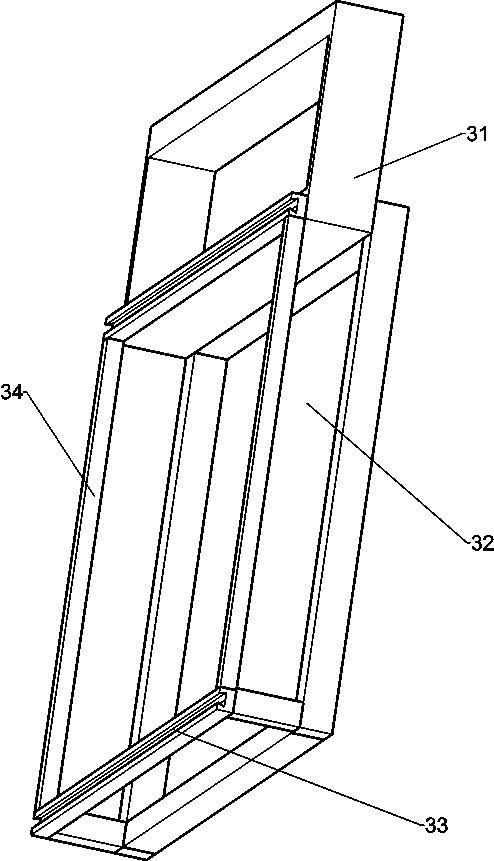

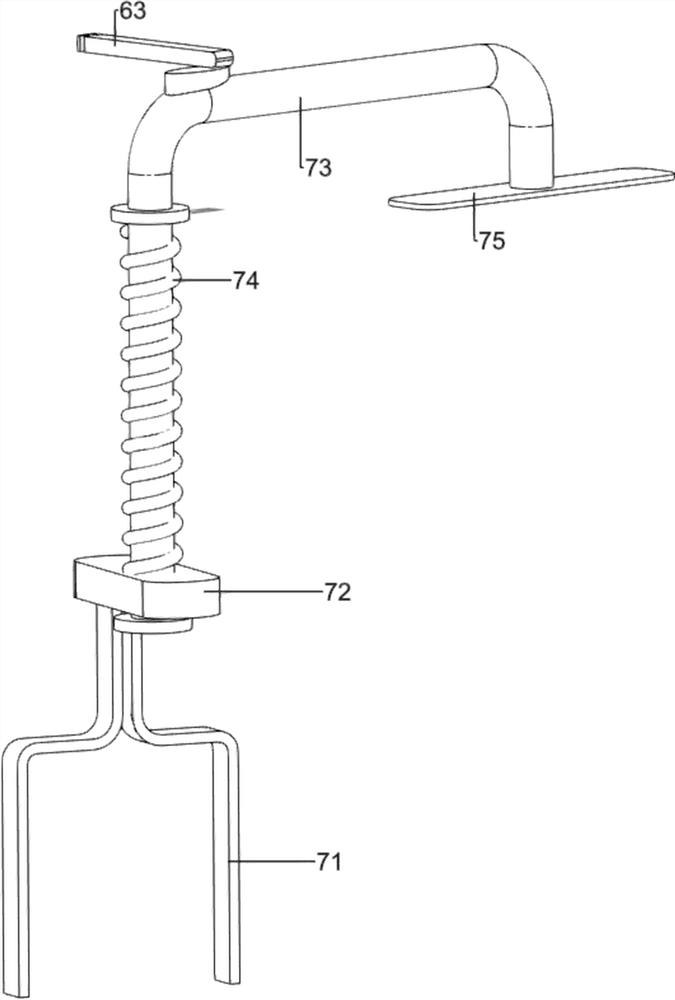

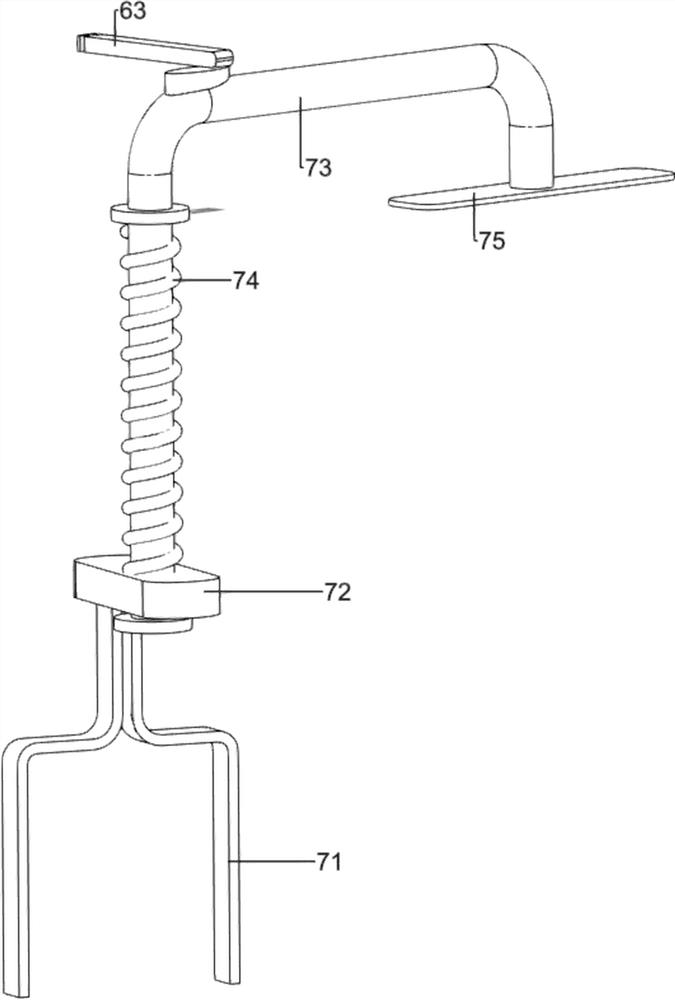

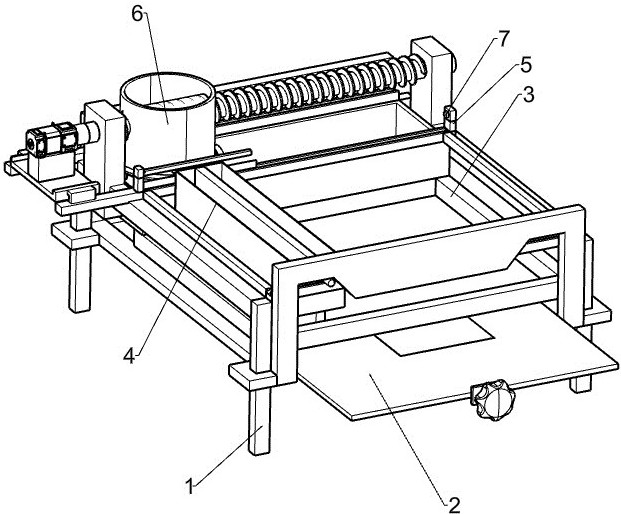

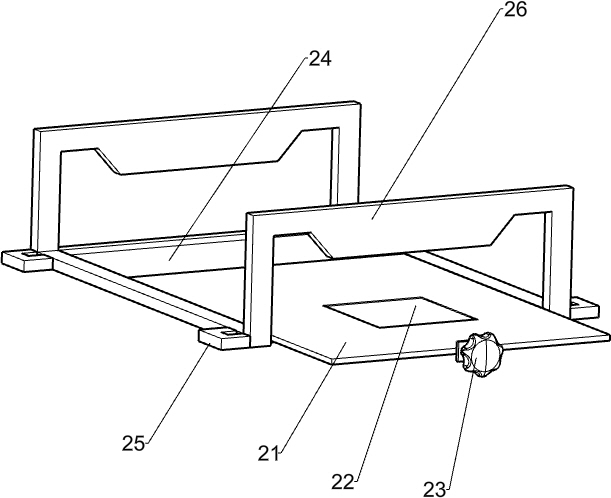

Handheld cloth bag silk screen printing device

ActiveCN111559159ATo achieve the printing effectSave human effortScreen printersScreen printingEngineering

The invention relates to a printing device, in particular to a handheld cloth bag silk screen printing device. The invention aims to design the handheld cloth bag silk screen printing device which issimple to operate, can improve the working efficiency and save the manpower. The handheld cloth bag silk screen printing device comprises a base, a downwards pressing mechanism, and a coating mechanism, wherein a support table is connected with the top of the base, the downwards pressing mechanism is arranged between the base and the support table, and the coating mechanism is arranged between thebase and the support table. According to the device, a handheld cloth bag is printed through the cooperative operation of the downwards pressing mechanism and the coating mechanism, so that the effect of printing the handheld cloth bag is achieved; and according to the device, the handheld cloth bag is placed on a conveying belt and is moved to a printing position through the conveying belt, thehandheld cloth bag is not needed to be frequently placed manually, and thus the manpower is effectively saved.

Owner:网都河北科技服务有限公司

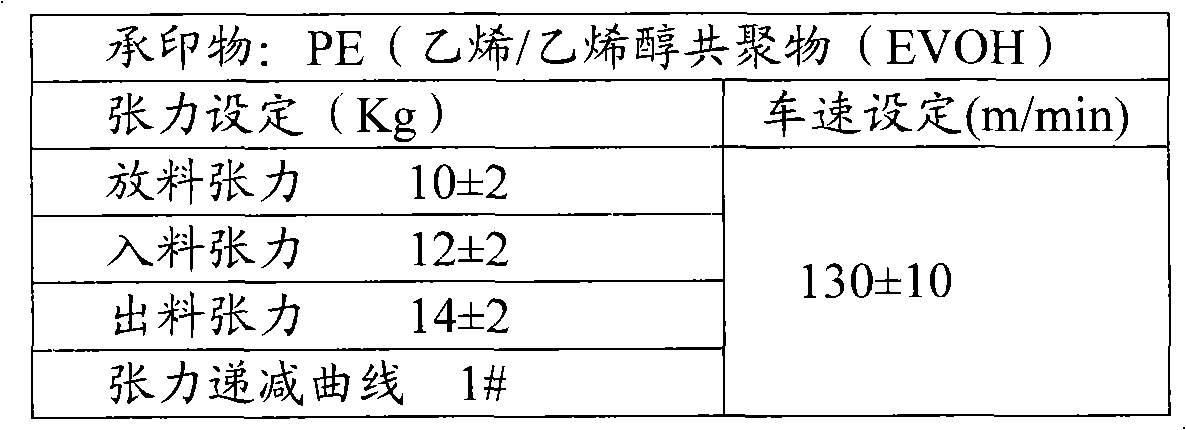

Adhensive rotary printer

InactiveCN100382963CViscous stabilitySticky and flexibleRotary pressesScreen printingSmall footprint

A rotary press for printing on non-drying adhesive matter is composed of paper feeder, paper receiver, speed reducer, AC servo tension control and tract unit, platen unit, skew corrector, servo motor cooling and driving unit, flexible plate printing unit, paper chip and static electricity remover, corona unit, silk screen printing unit, satellite relief printing unit, gilded film sticking-UV baking-cooling driver, golden foil feeder, reel, gilded film cutting unit, etc.

Owner:SHANGHAI XINMIN TAIYO KIKAI

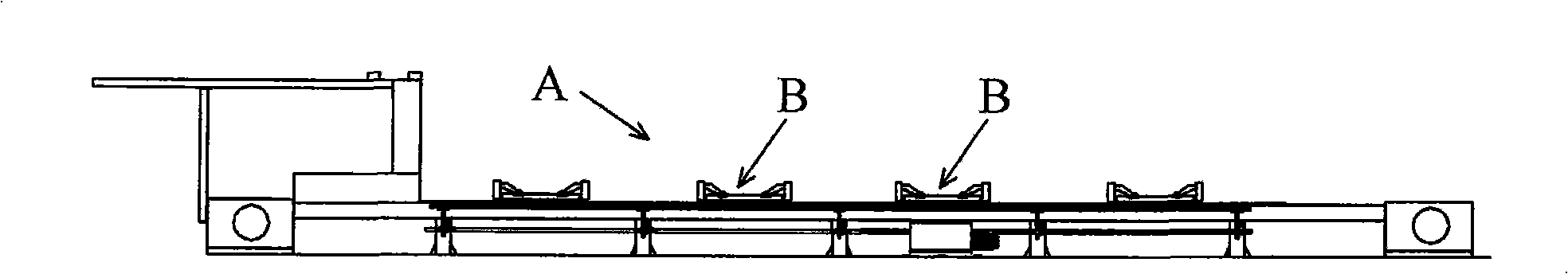

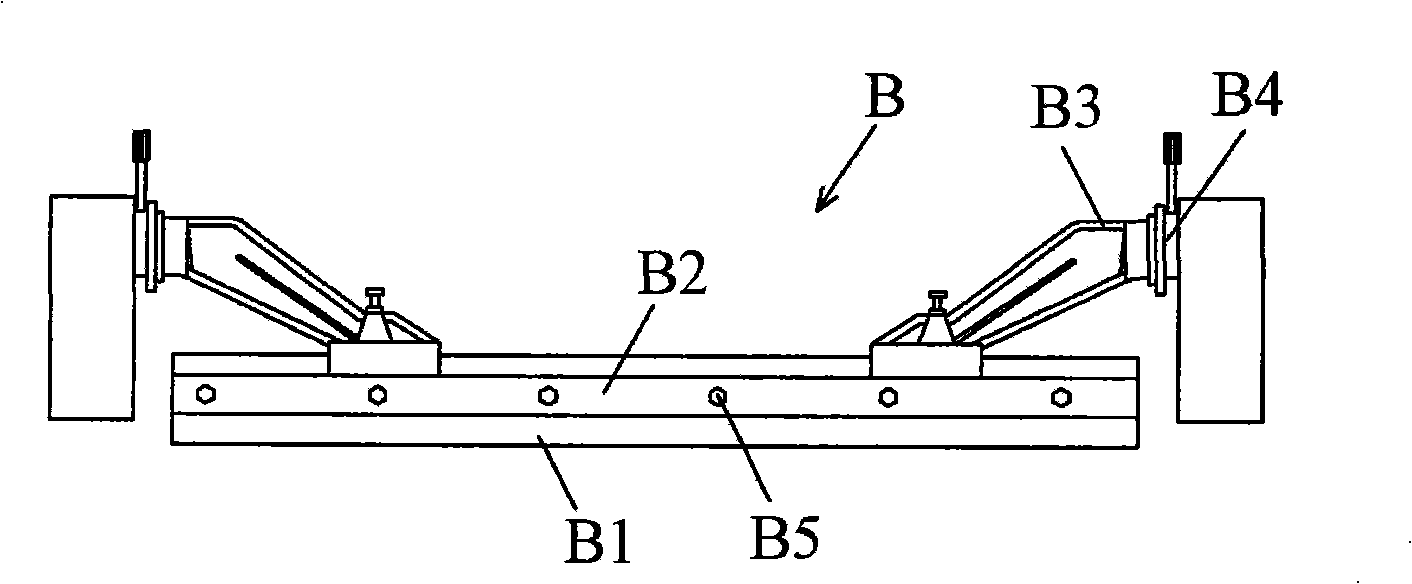

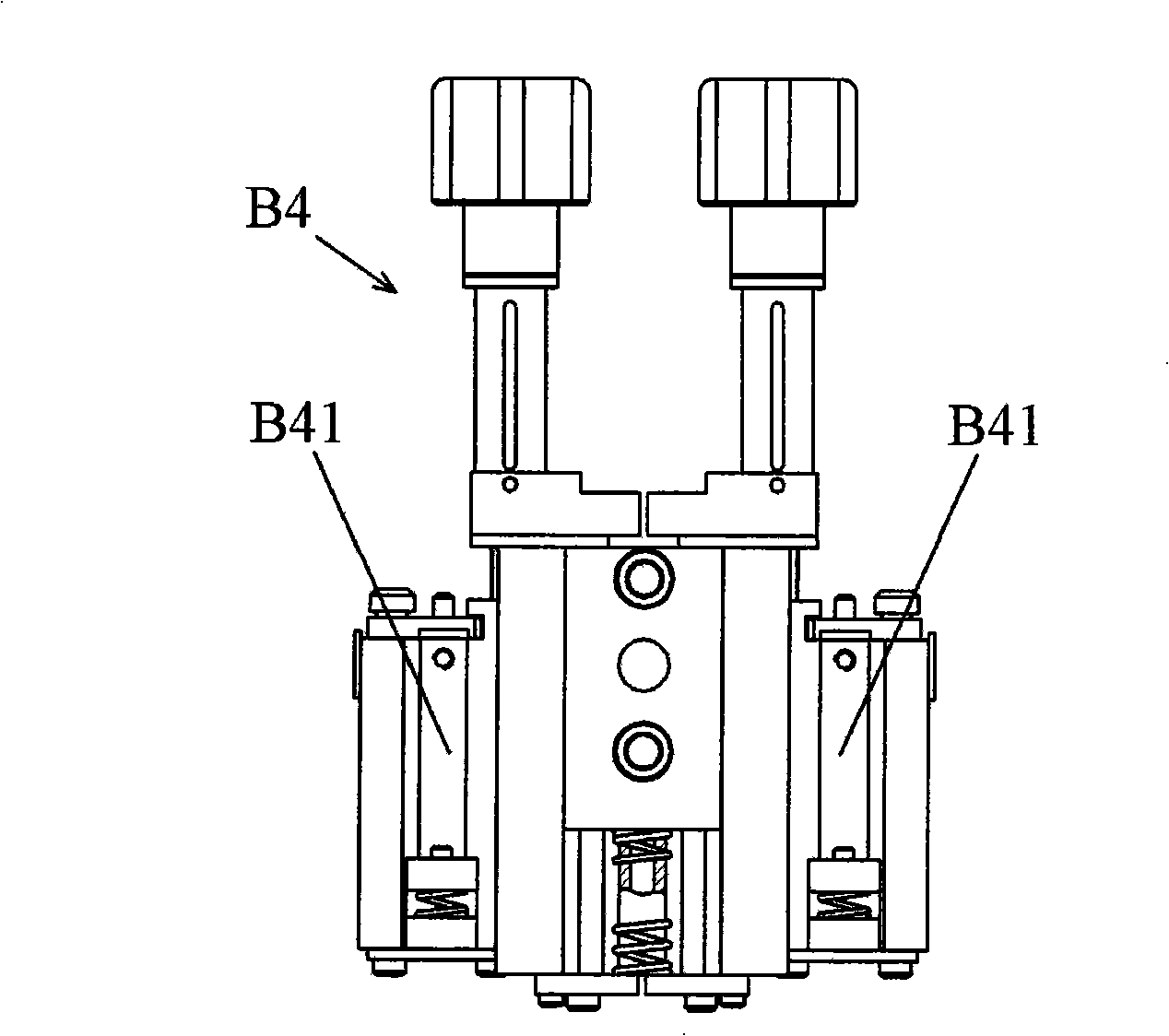

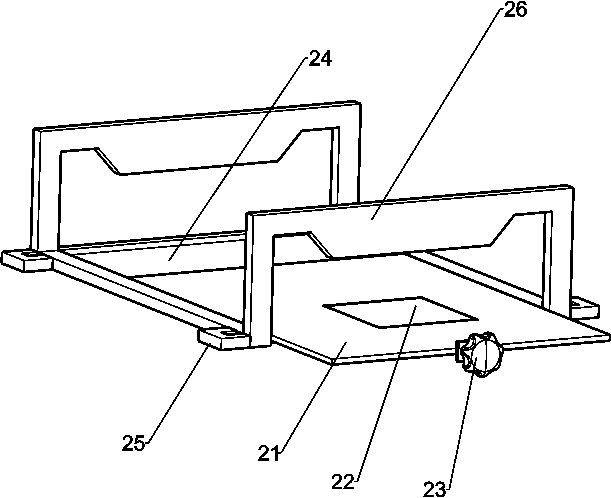

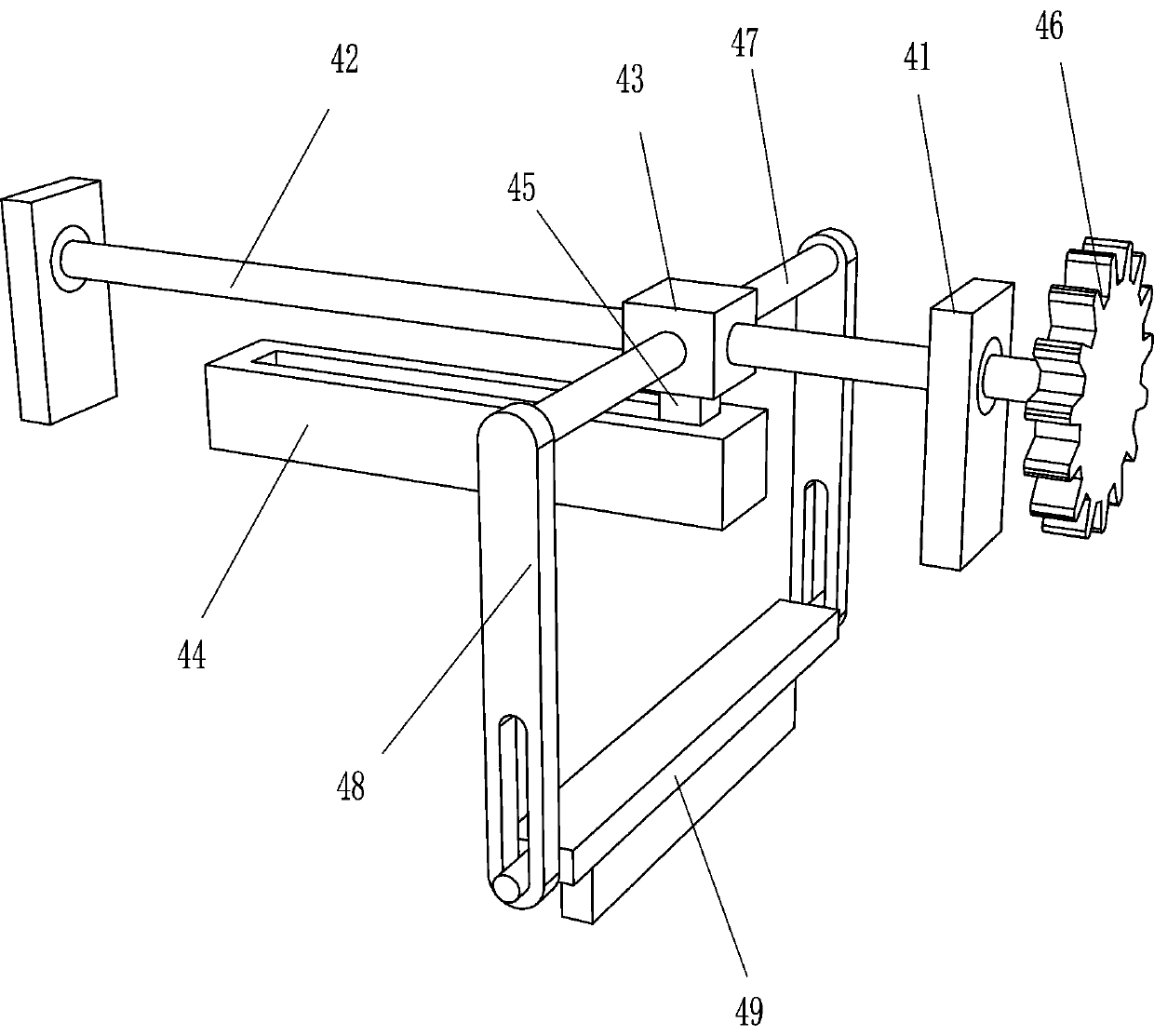

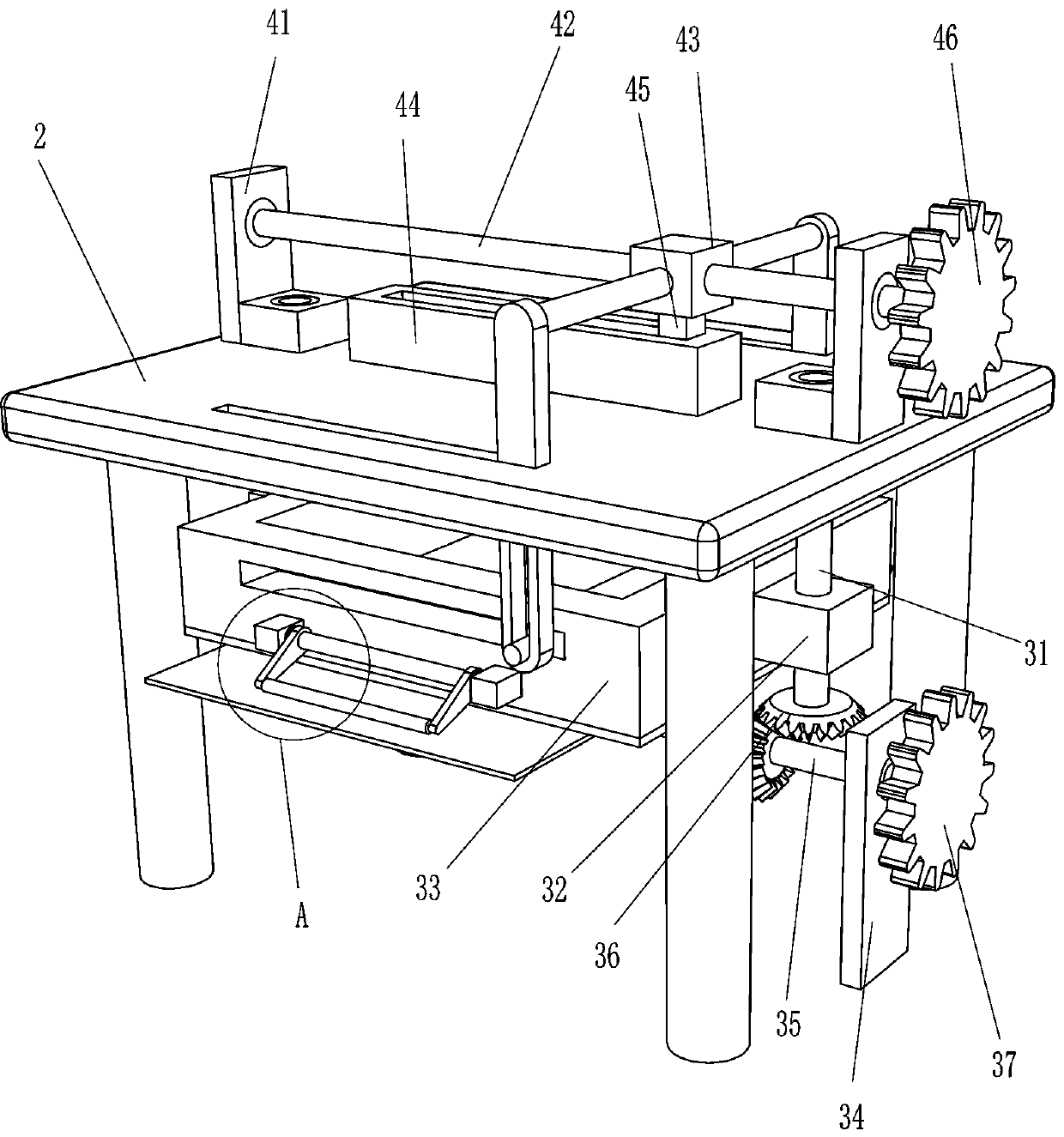

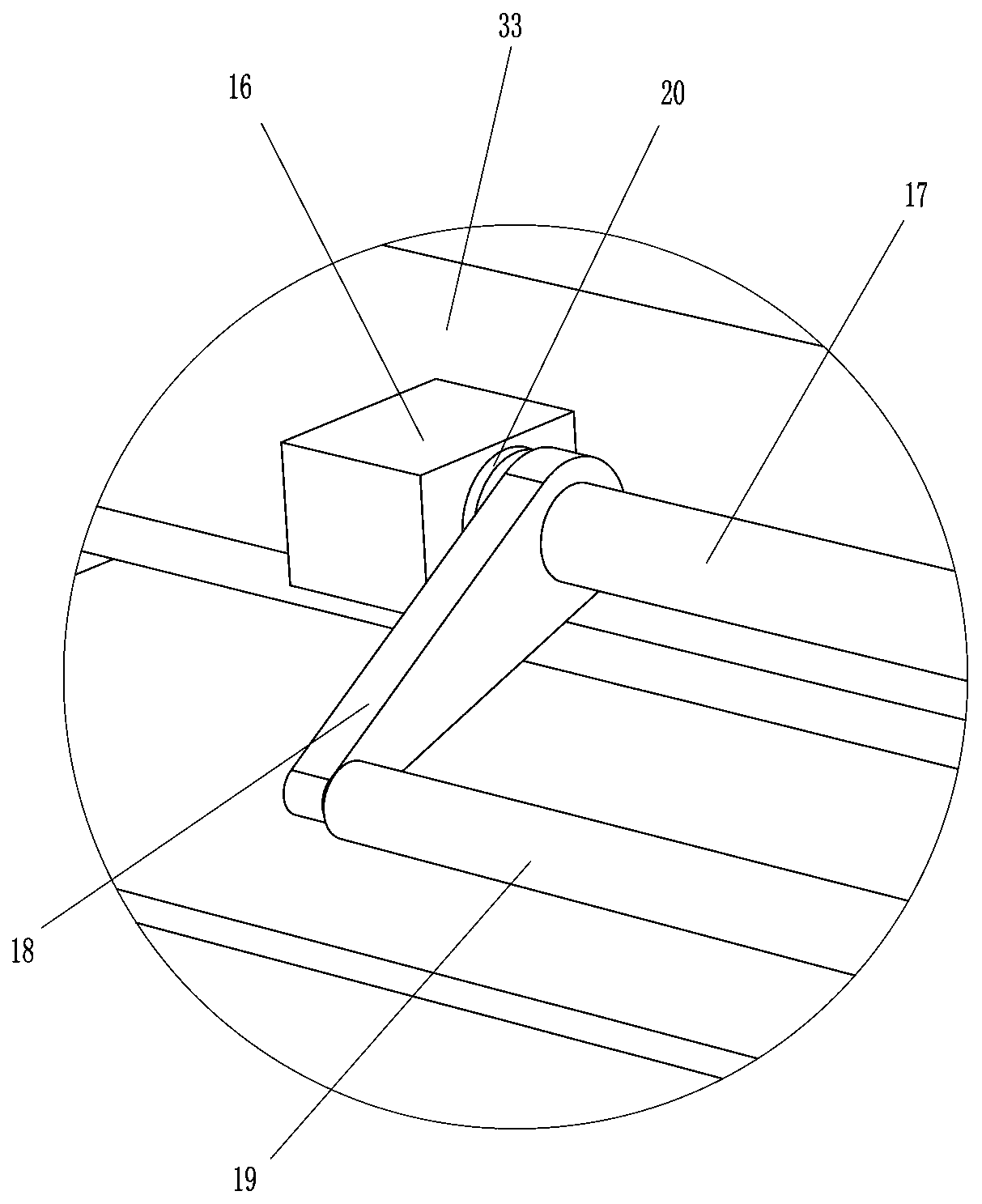

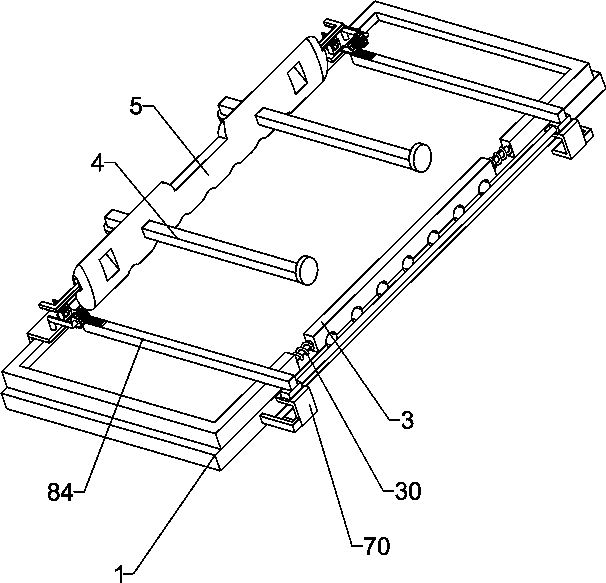

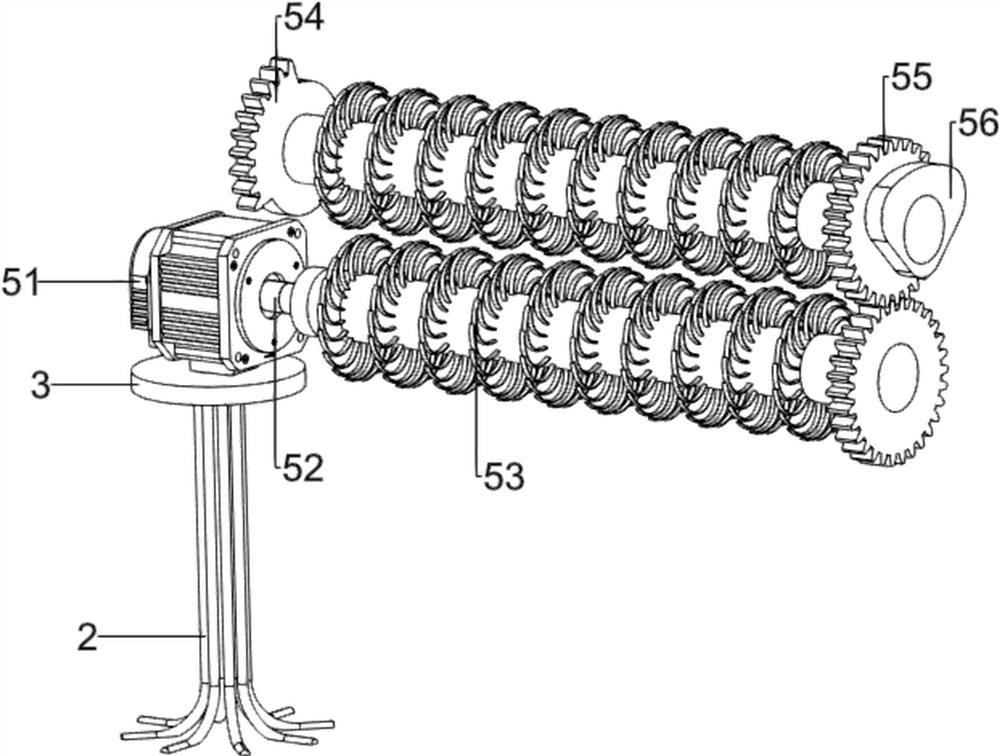

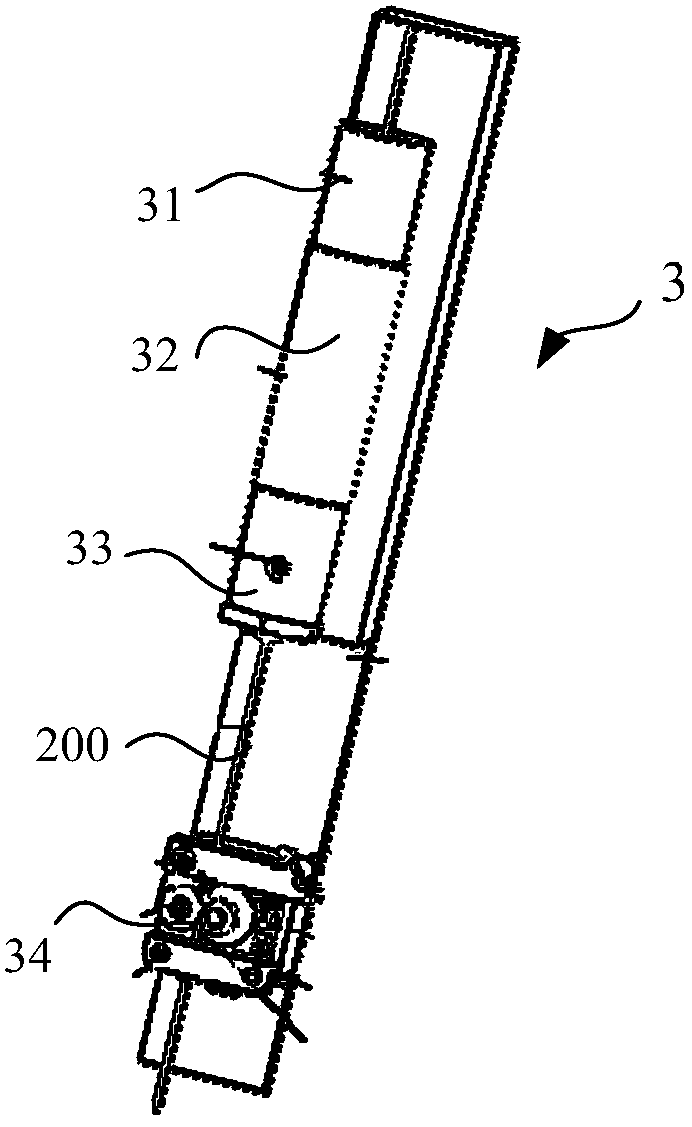

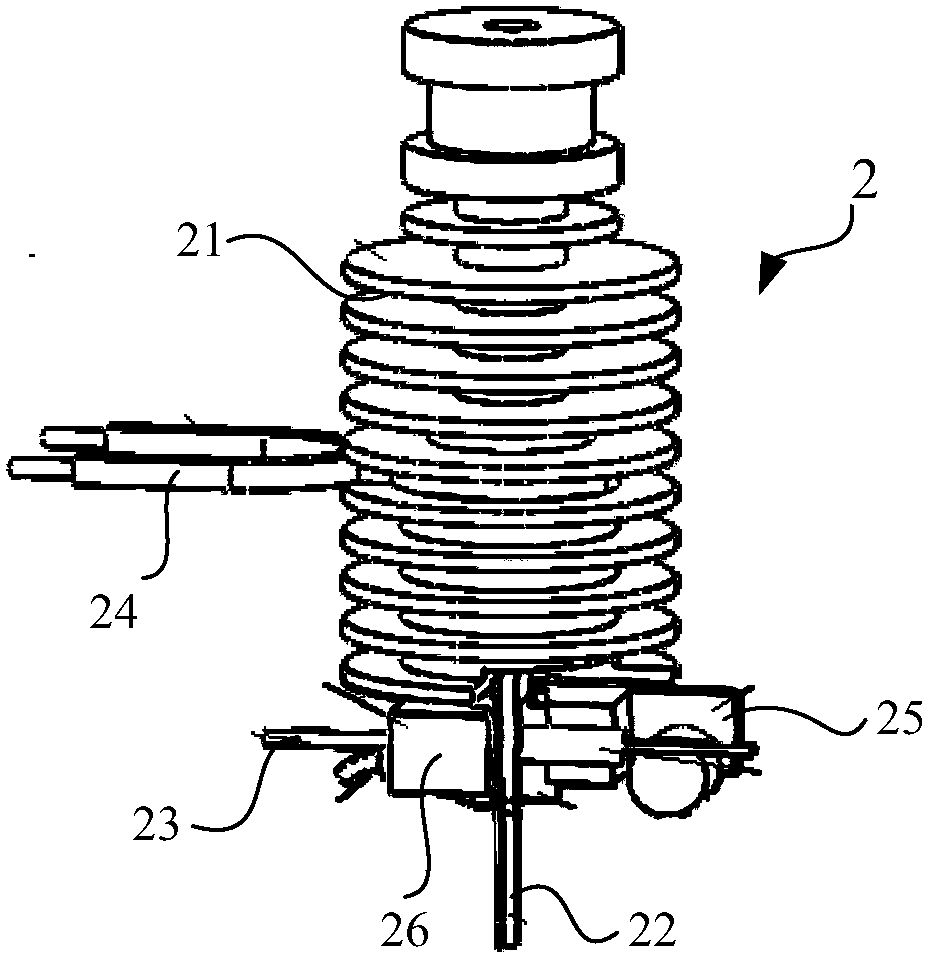

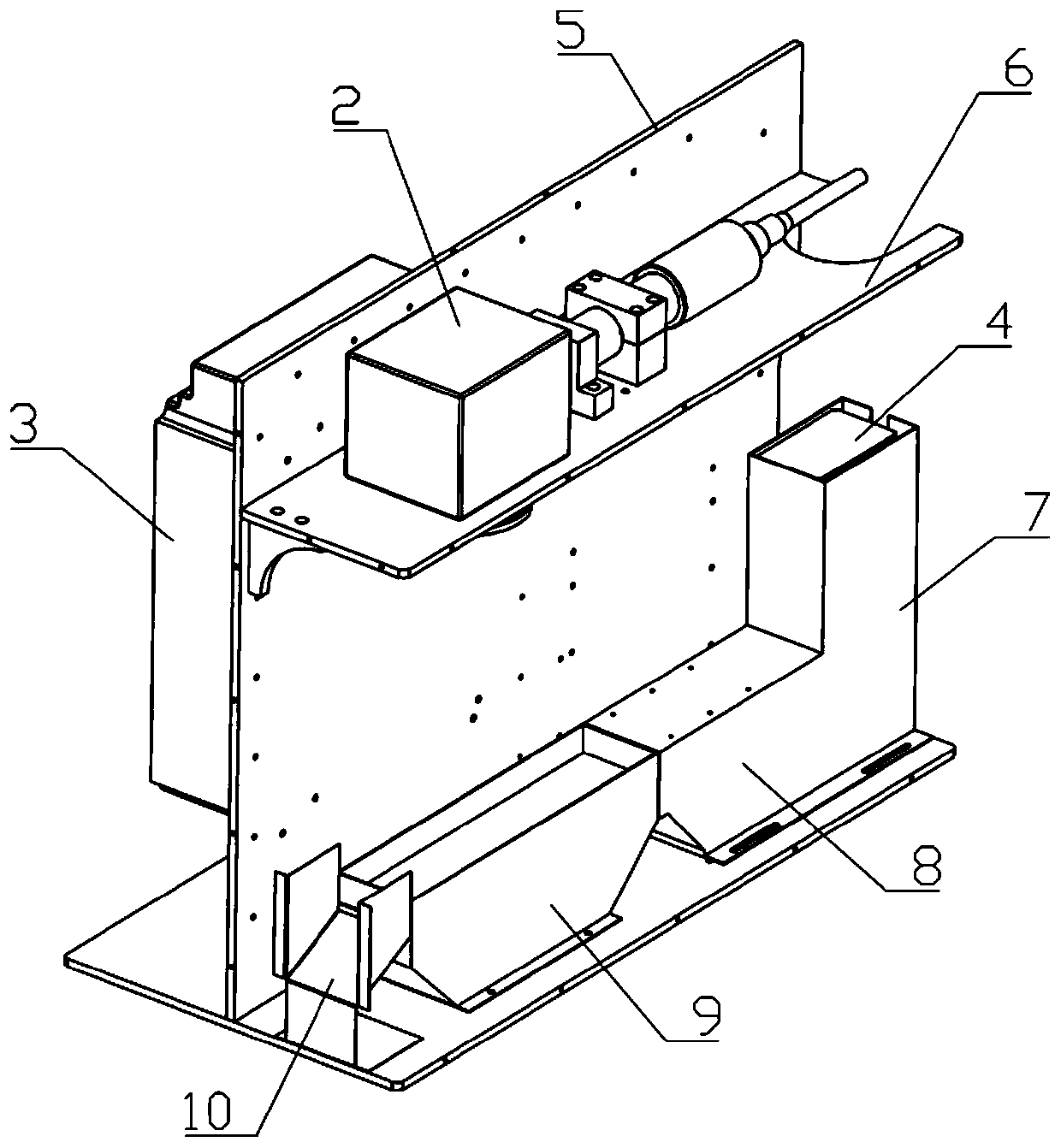

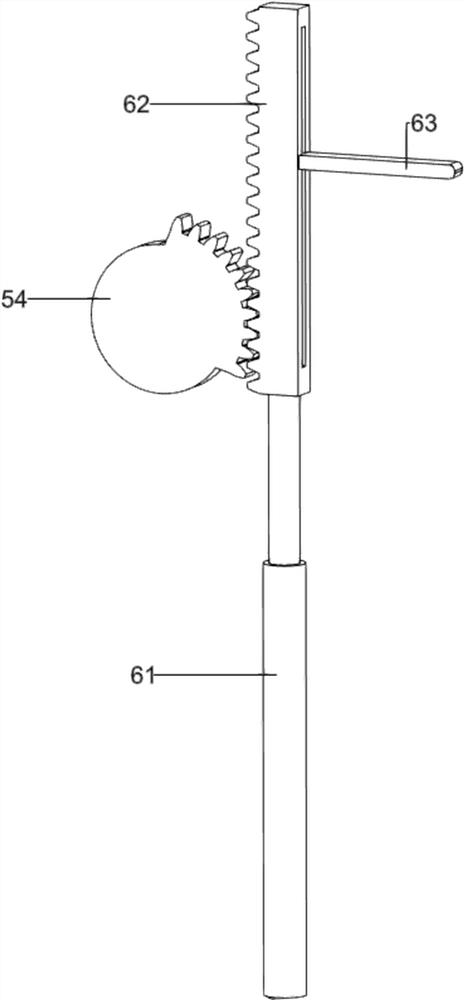

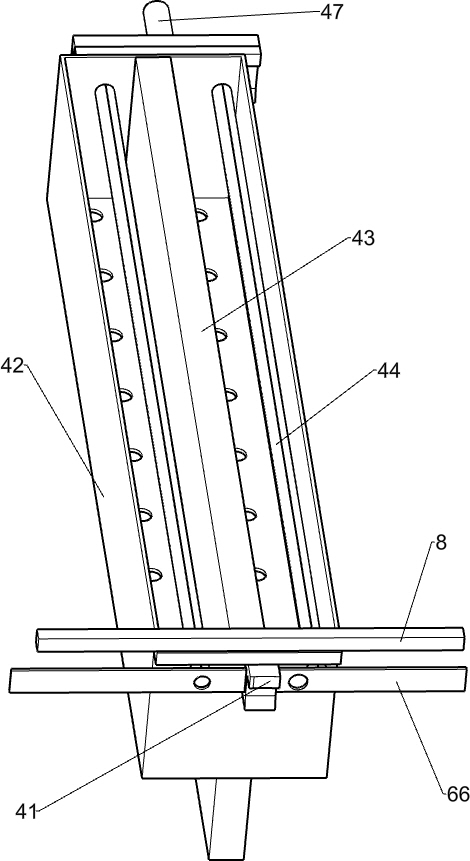

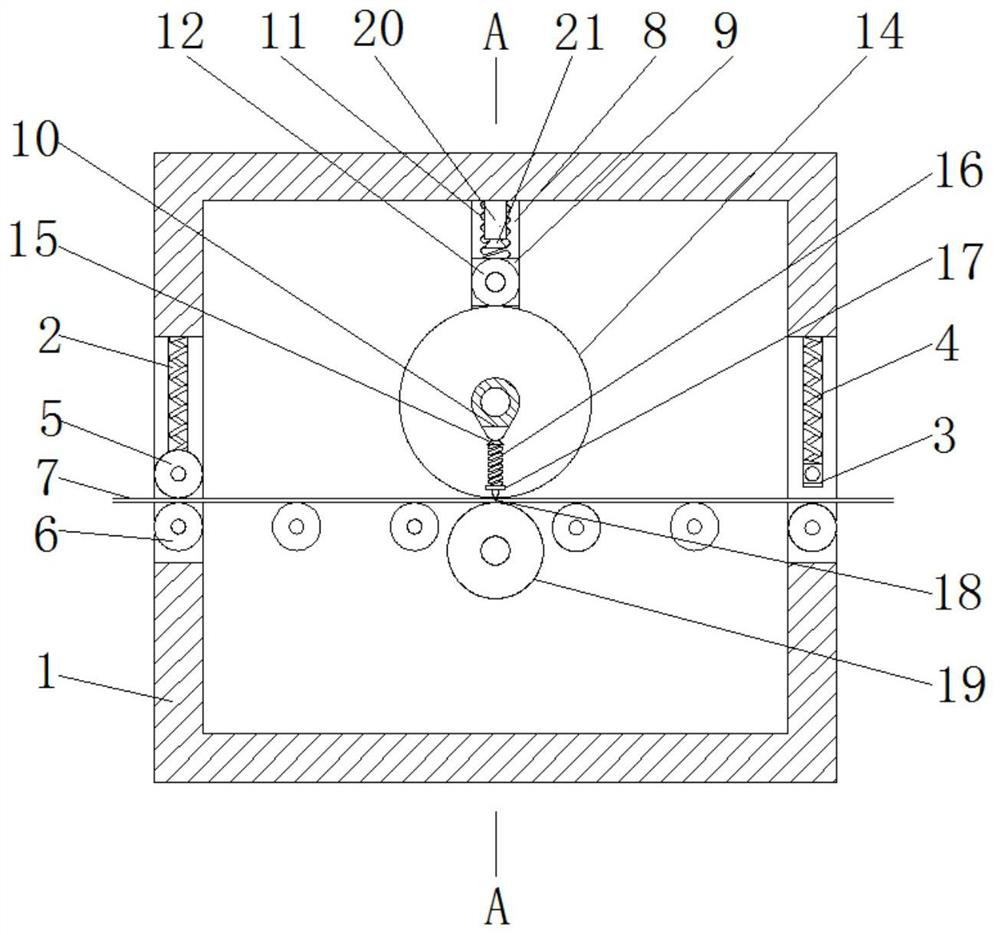

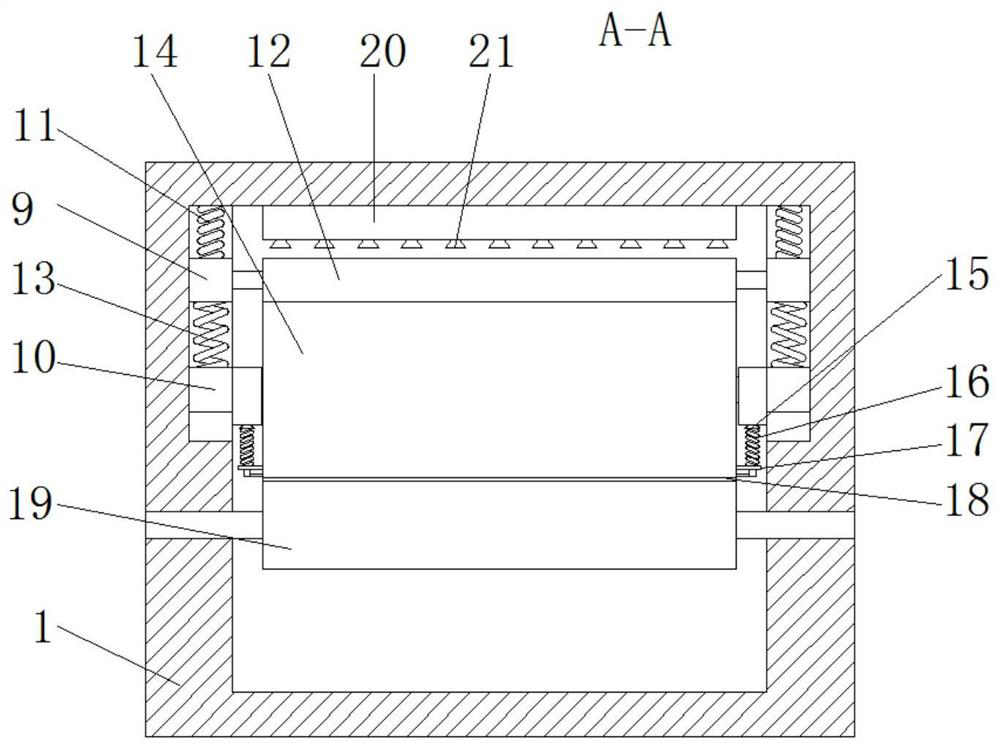

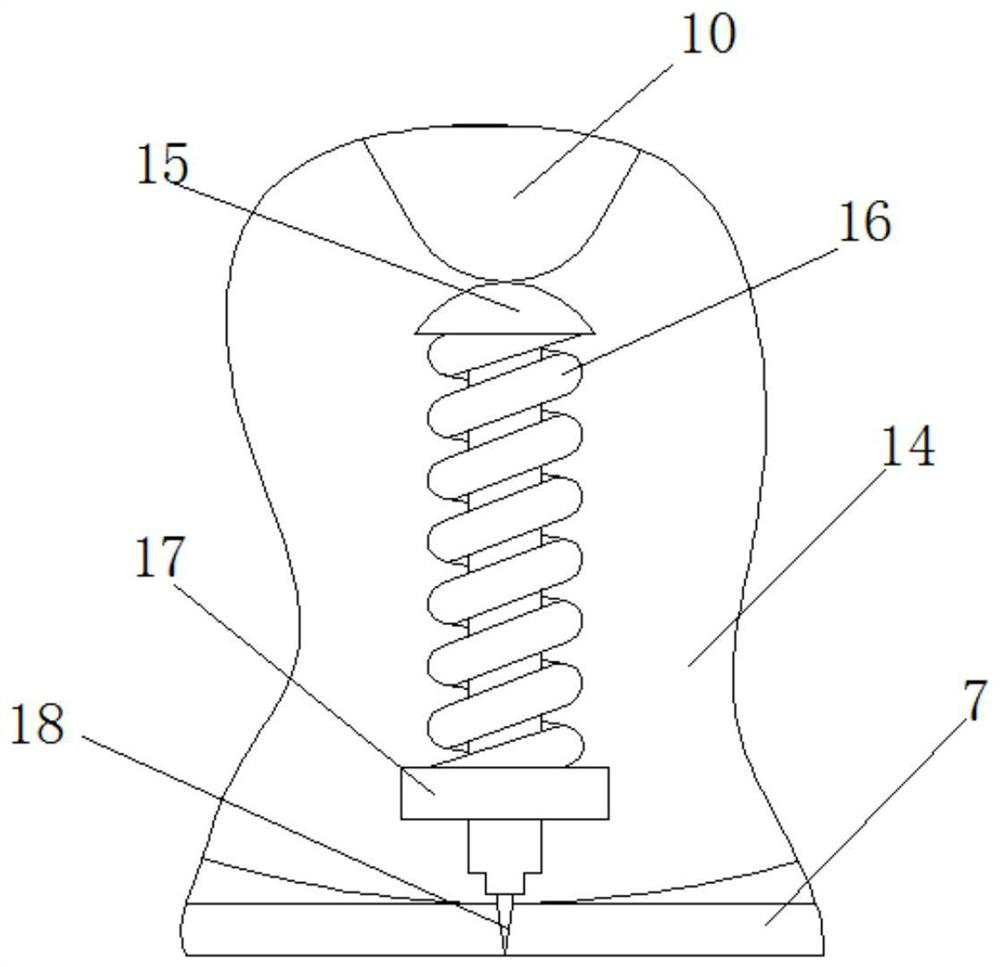

Copper wire end identifier printing machine

ActiveCN111591028ATo achieve the printing effectSave human effortRotary pressesCopper wireMechanical engineering

The present invention relates to an identifier printing machine, particularly to a copper wire end identifier printing machine. The technical problem to be solved by the present invention is how to design a copper wire end identifier printing machine that can save the manpower and can once print multiple ends to improve the working efficiency. In order to solve the technical problem, provided in the present invention is such a copper wire end identifier printing machine, comprising: a mounting plate connected with support legs at the bottom; a printing frame connected to the top of the mounting plate, both sides of the printing frame being slidably arranged, and a compression spring being connected between both sides of the printing frame and the middle portion; and L-shaped slide rods, two of which are provided and slidably connected to both sides of the mounting plate respectively. The ends of copper wires are printed by means of cooperative operation of a scraper and the printing frame, so that the printing effect on the ends of the copper wires is achieved.

Owner:江西源广顺科技协同创新有限公司 +1

High-resolution water-based flexographic ink and preparation method thereof

The invention discloses a high-resolution water-based flexible printing ink comprising ink paste and acrylic emulsion. The ink is characterized in that the ink paste comprises the following components in parts by weight: 20 to 30 parts of water-based acrylic resin, 30 to 60 parts of pigment, 2 to 8 parts of dispersant 760W, 10 to 20 parts of water, 10 to 15 parts of ethanol, and 0.5 to 1 part of defoaming agent. The invention further discloses a preparation method for the ink. The quantity of the pigment is increased in the ink paste of the ink disclosed by the invention, and meanwhile, the dispersant 760W is adopted, so that a large dose of pigment can be well dispersed, and the ink has good stability and good dyeing property. The ink can reach more than 100 resolution cables and can be used for directly printing line boards, and the inking effect is similar to an offset printing effect. The third dimension of printed pictures can be reflected, and the pictures are exquisite and vivid. Moreover, the ink disclosed by the invention is water-based ink, so the ink accords with the national environmental protection policy, and can achieve the printing effect of an oil-based ink.

Owner:CHONGQING HONGYUAN PRINTING INK

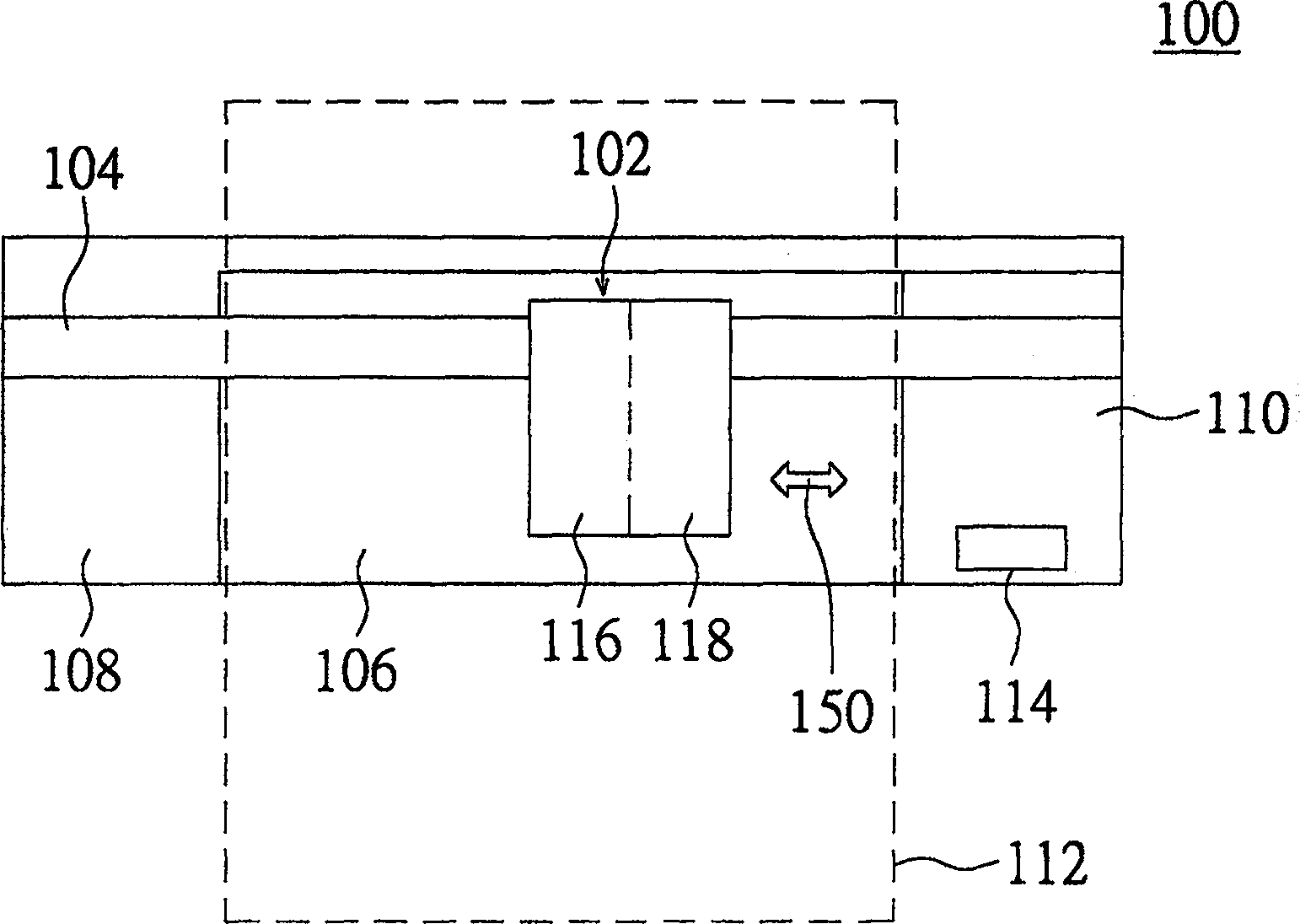

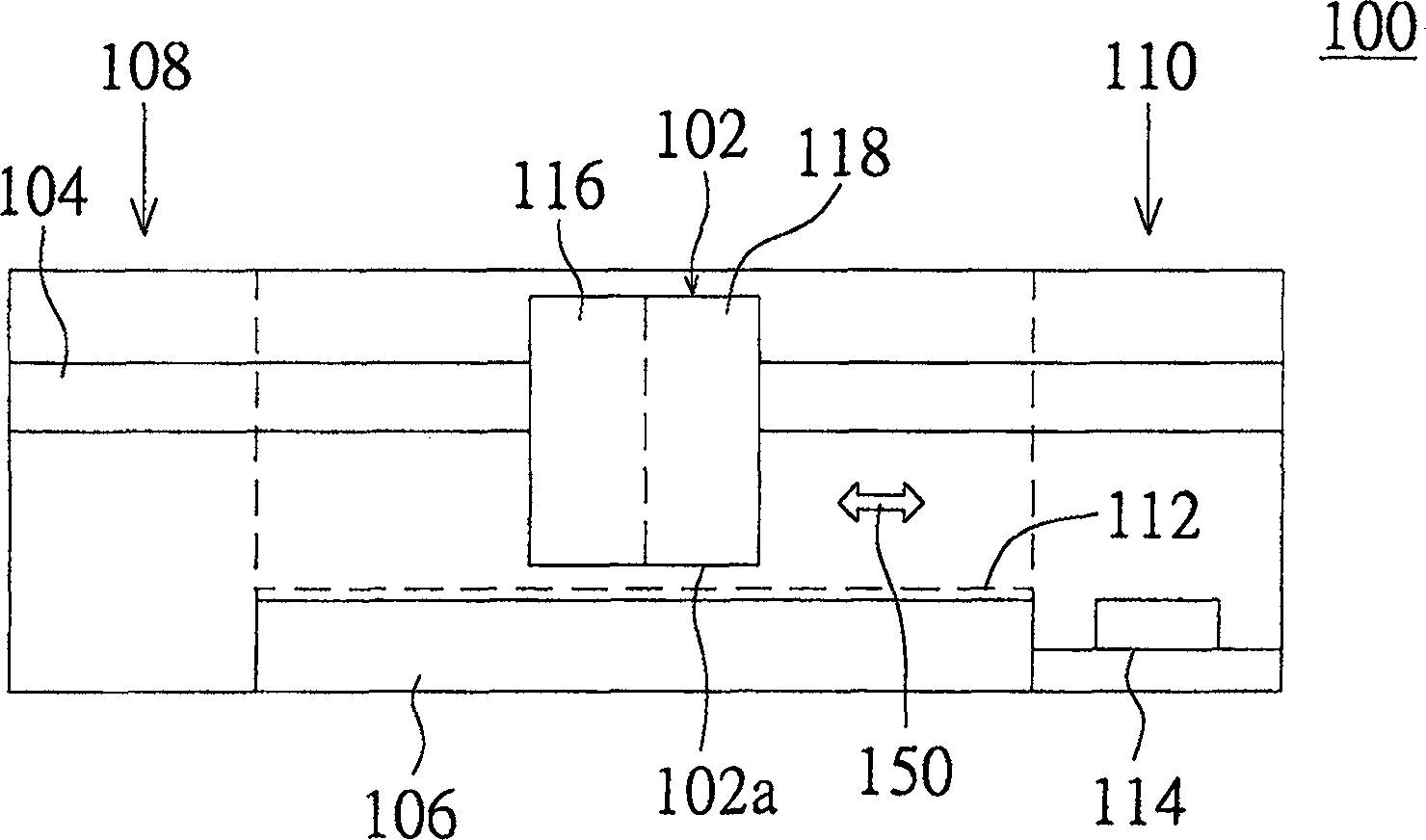

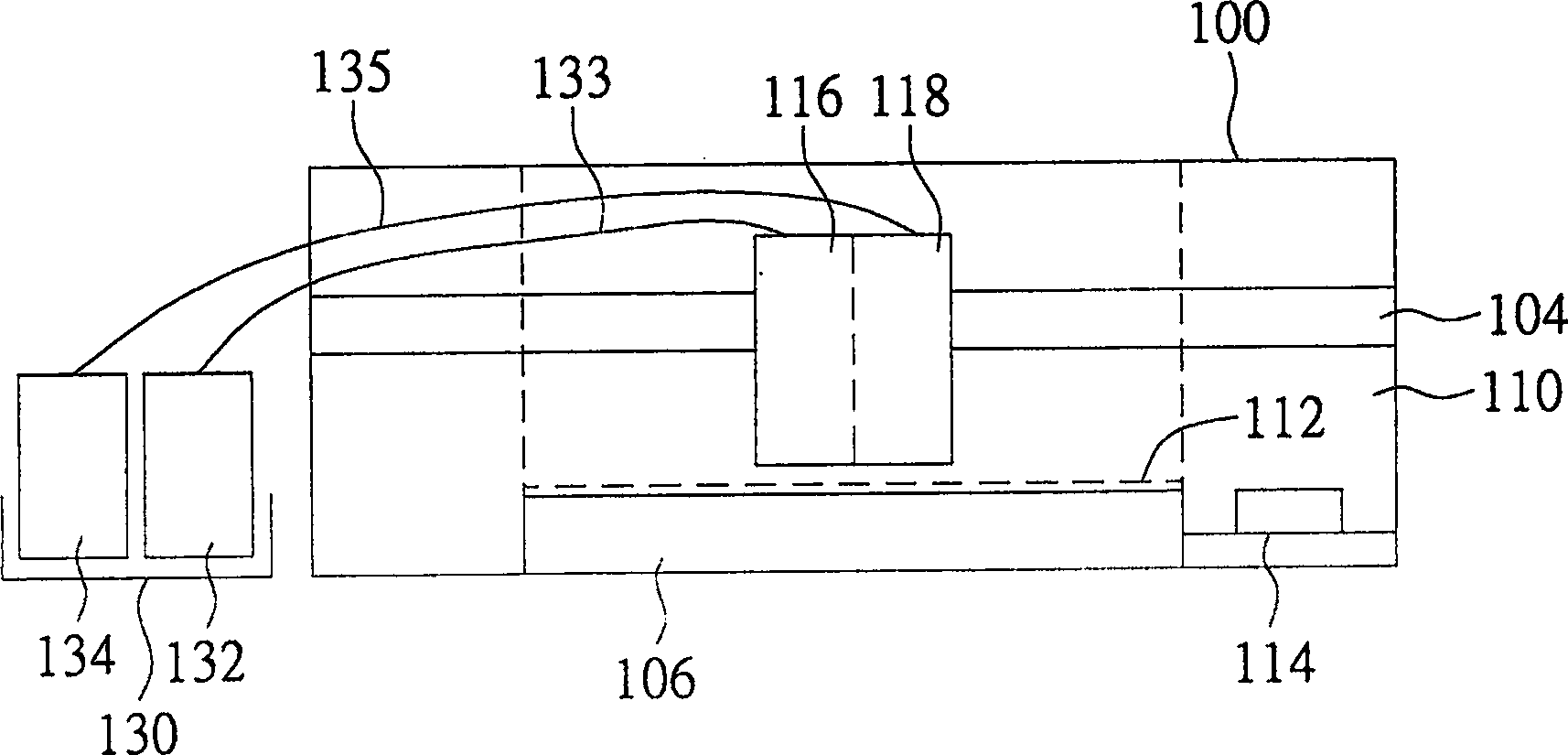

Ink jet printing device

InactiveCN1872558AIncrease printing speedTo achieve the printing effectOther printing apparatusFull widthElectrical and Electronics engineering

Owner:AVISION PRECISION IND (SUZHOU) CO LTD

Efficient cleaning silk-screen printing device

ActiveCN112389081AEasy to operateOperation saves time and effortScreen printersPrinting press partsManufacturing engineeringMechanical engineering

The invention relates to a printing device, in particular to an efficient cleaning silk-screen printing device. The efficient cleaning silk-screen printing device is easy to operate, capable of savingtime and labor and uniform in printing. The efficient cleaning silk-screen printing device comprises a bottom plate, a first supporting frame, a table plate, a discharging mechanism, a cleaning mechanism, a coining automatic auxiliary mechanism and a coining mechanism, wherein the first supporting frame is arranged on the bottom plate; the table plate is arranged on the first supporting frame; the discharging mechanism is arranged on the bottom plate; the cleaning mechanism is arranged on the discharging mechanism, and the cleaning mechanism is connected with the table plate; the bottom plateis provided with the automatic coining auxiliary mechanism, and the automatic coining auxiliary mechanism is matched with the cleaning mechanism; and the coining mechanism is arranged on the bottom plate, and the coining mechanism is matched with the discharging mechanism and the coining automatic auxiliary mechanism. Through mutual meshing of the full gears on the upper side and the lower side,the cleaning brushes on the upper side and the lower side rotate to clean the silk screen, the automatic cleaning effect is achieved, operation is easy and convenient, and time and labor are saved.

Owner:SHANXI JINYE PRINTING CO LTD

Vacuum aluminum plating ground paperboard and production method thereof

ActiveCN102002895BTo achieve the printing effectLow solvent residueSpecial paperPaper/cardboardScreen printingPaperboard

The invention relates to a vacuum aluminum plating ground paperboard and a production method thereof, which belong to the technical field of package materials and printing materials. The vacuum aluminum plating ground paperboard comprises a paper base material, a ground coating layer and an aluminum plating layer. The production method comprises the following steps of: 1. making a ground coating mixing body; 2. coating a layer of ground coating mixing body on a paper substrate 4 for forming the ground coating layer; and 3. placing the paperboard comprising the ground coating layer with the grounding effect into a vacuum aluminum plating system, directly plating aluminum on the ground surface of the ground coating layer of the paperboard and forming the aluminum plating layer. The production method has the following advantages of simple process, no glue water layer, high production efficiency and no solvent volatilization, and belongs to the environmental-protection production process.The paperboard has exquisite and vivid ground effect and rich metal texture, and the produced ground paperboard can reach the screen painting effect through ordinary offset printing or gravure printing. A large amount of ink is saved, and the solvent volatilization and the solvent residue of printed products are greatly reduced.

Owner:YANTAI BOYUAN TECH MATERIALS

High-scratch-resistant plastic surface printing extinction oil and preparation method thereof

InactiveCN112694787AImprove stabilityExcellent retort resistanceInksPolymer sciencePolymer chemistry

The invention provides scratch-resistant plastic surface printing extinction oil and a preparation method thereof. The surface printing extinction oil comprises the following components: 20-30% of a vinyl chloride-vinyl acetate resin solution, 15-25% of a polyurethane solution, 1-5% of an auxiliary agent, 10-20% of a filler, 1-3% of polyethylene wax and 25-40% of a mixed solvent. By adding polyurethane and vinyl chloride-vinyl acetate resin, the cooking resistance of the ink is improved, and by adding the scratch-resistant agent, the scratch resistance of the ink is remarkably improved, so that the produced ink has the characteristics of scratch resistance (no scratch after fingernail scratching), high temperature resistance, no discoloration, safety, environmental protection and high stability, and the product of the PET base material is packaged, after extinction oil is printed on the back face according to the design layout, the extinction film printing effect can be achieved, meanwhile, the bright layer and the dark layer are clear, the emphasizing effect is prominent, and the packaging aesthetic feeling is enhanced. At present, online shopping is popular, a plurality of dried fruits, red dates, masks and other products sold online are packaged by adopting the package, and the market demand becomes larger and larger.

Owner:HUANGSHAN SHINING INK TECH

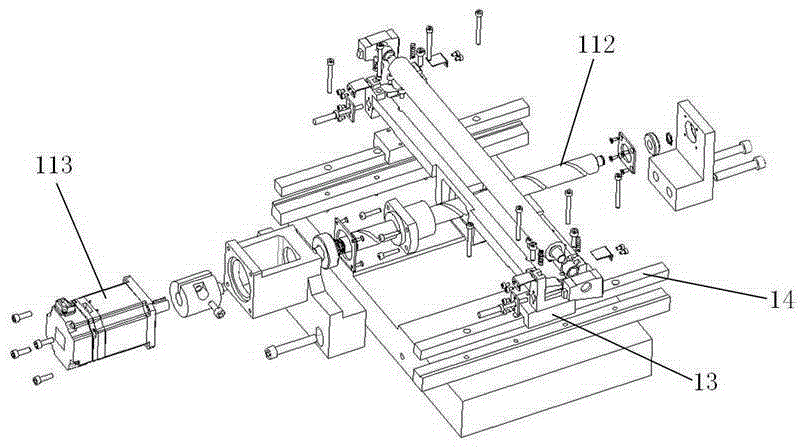

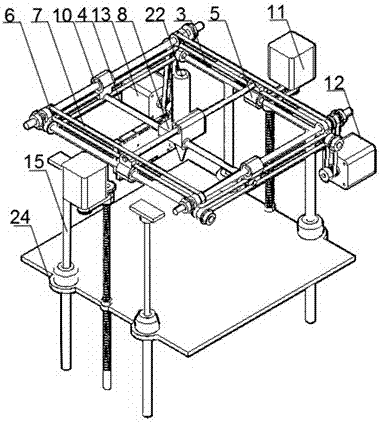

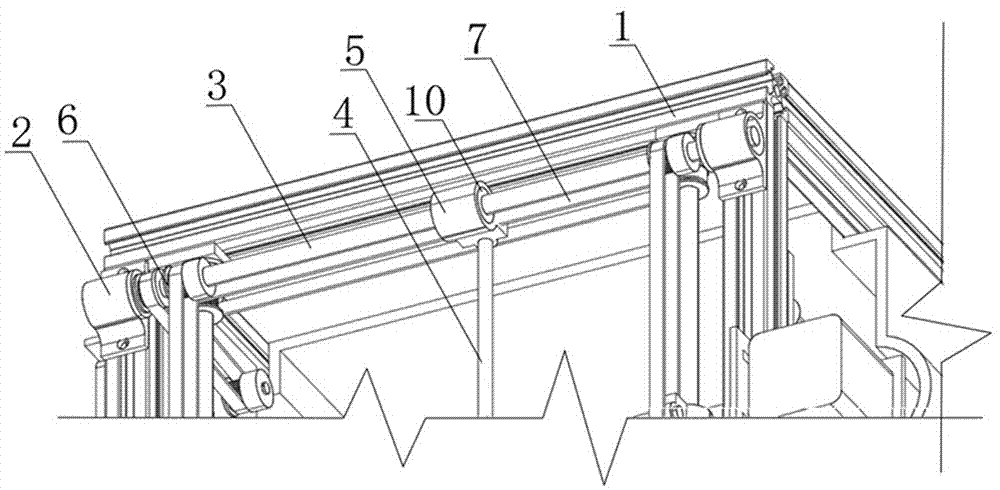

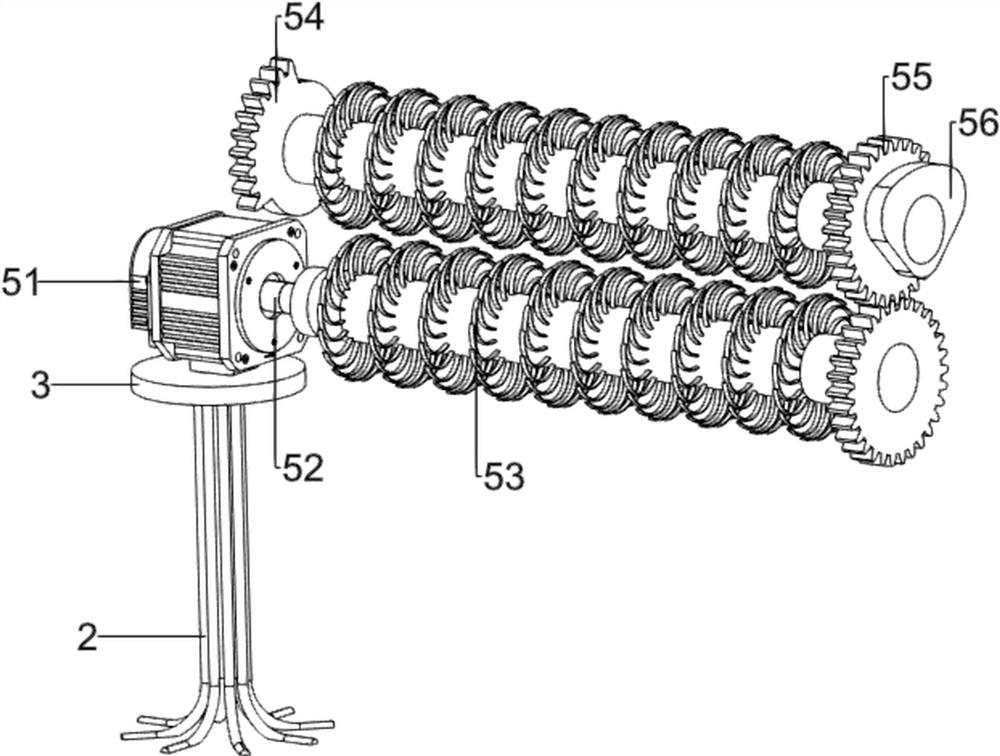

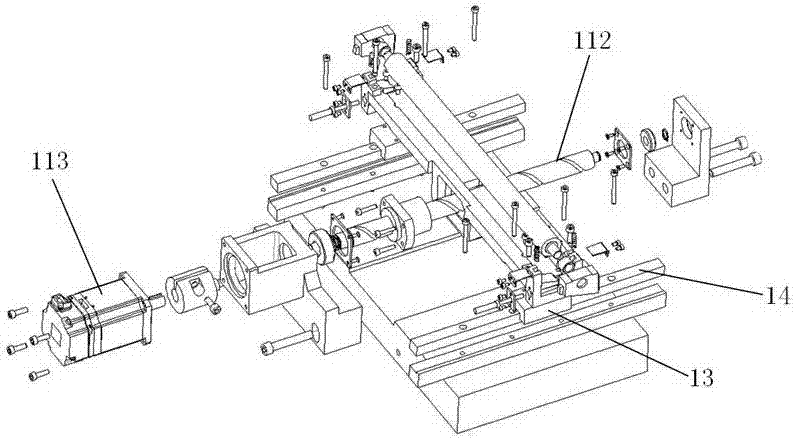

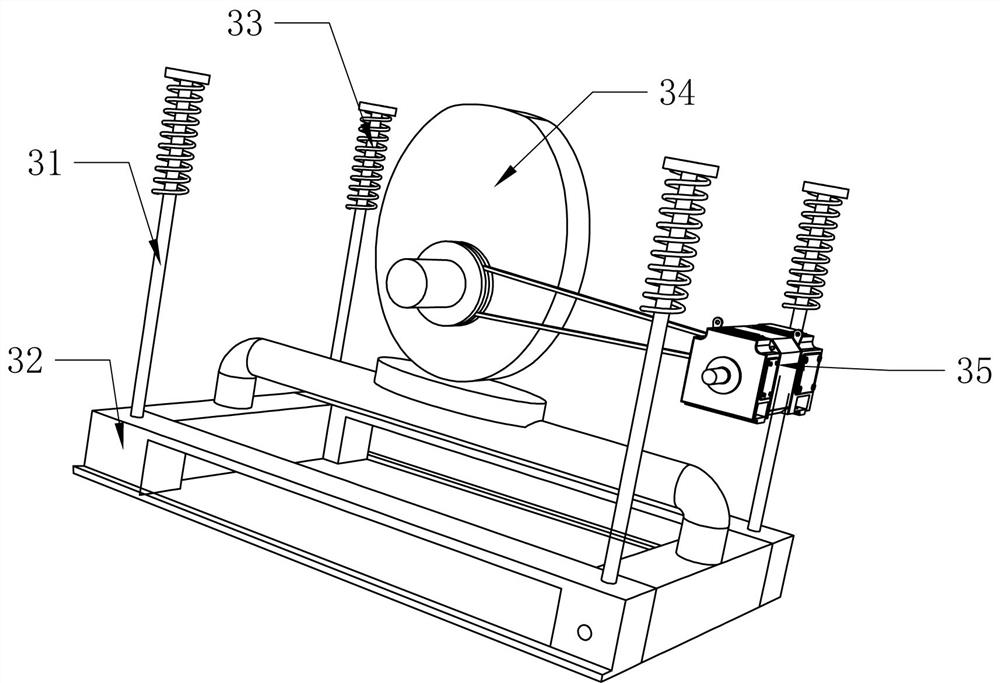

A 3D printer capable of printing continuous fibers, a printer nozzle and a printer feed structure

ActiveCN106087113BControl the direction of transportReduce frictionAdditive manufacturing apparatusArtificial filament chemical after-treatmentFiberFixed frame

The invention discloses a 3D printer capable of printing continuous fibers, a printer spray head and a printer feeding structure. The 3D printer comprises a fixing frame, a feeding portion, a material extruding portion, a guide assembly, a spray head portion, a spray nozzle and at least one heating portion, wherein the feeding portion comprises a first heat transfer part, a heating part is installed on the first heat transfer part, the material extruding portion is connected with the first heat transfer part, the guide assembly is opposite to the material extruding portion, the spray head portion is fixedly connected with the feeding portion and fixedly arranged on the fixing frame, comprises a second heat transfer part and is arranged between the second heat transfer part and the material extruding portion, the spray nozzle connected with the second heat transfer part, and the heating portion is arranged on the second heat transfer part so as to conduct point-to-point heating on the second heat transfer part. The technical problem that a 3D printing material is limited in the prior art is solved or partially solved, and the technical effect of printing the continuous fibers through 3D printing is achieved.

Owner:深圳华纤创新科技有限公司

Self-crosslinked polyacrylate latex and preparation method thereof, and water-based paper ink

InactiveCN102304262BPrevent sticking backFast dryingPaper coatingCoatingsHydrophilic monomerPolymer science

The invention discloses self-crosslinked polyacrylate latex and a preparation method thereof, and water-based paper ink. The preparation method for the self-crosslinked polyacrylate latex comprises the following steps of: mixing acrylate monomers, hydrophilic monomers and alcohol dehydrogenase (ADH) in a head tank A; mixing water, an emulsifier, acrylate monomers and diacetone acrylamide (DAAM) in a head tank B; adding water, an emulsifier and polymerization self-emulsification functional monomers into a normal-pressure reaction tank, stirring, heating to 75DEG C, dripping a mixture in the head tank A and an initiator, and preparing protective colloid; dripping a mixture in the head tank B and an initiator at 85DEG C; and reacting at constant temperature. The water-based paper ink is prepared by the following steps of: stirring and dissolving styrene-acrylate copolymer, a pH regulator and water at 60DEG C; adding pigments and necessary aids, and mixing to obtain color paste; and uniformly mixing the color paste, the self-crosslinked polyacrylate latex, a surface tension regulator and water. The water-based paper ink can be diluted by one of water and ethanol or a mixture of water and ethanol, and has high drying speed and good printing adaptability.

Owner:SUN YAT SEN UNIV +1

Self-crosslinking polyacrylate rubber latex, preparation method thereof and water-based paper printing ink

InactiveCN101870793BPrevent sticking backFast dryingPaper coatingCoatingsWater basedHydrophilic monomer

The invention discloses self-crosslinking polyacrylate rubber latex, a preparation method thereof and water-based paper printing ink. The self-crosslinking polyacrylate rubber latex is prepared by the following steps: mixing an acrylic ester monomer, a hydrophilic monomer and ADH in a head tank A; mixing water, an emulsifier, the acrylic ester monomer and DAAM in a head tank B; adding water, the emulsifier and polymerizable self-emulsifying functional monomer, stirring the mixture, heating the mixture to 75 DEG C, and dripping a mixture in the head tank A and an initiator to prepare a protective colloid first; dripping the mixture in the head tank B and the initiator at 85 DEG C; and performing a constant-temperature reaction. The water-based paper printing ink is prepared by the following steps: dissolving a phenylethylene-acrylic acid polymer and a pH value regulator in water at 60 DEG C with stirring; adding a pigment and necessary assistant and mixing the mixture to prepare color paste; and uniformly mixing the color paste with the self-crosslinking polyacrylate rubber latex, a surface tension regulator and water. The water-based paper printing ink can be diluted by one or a mixture of two of water and ethanol, can be dried quickly and has high printing adaptability.

Owner:SUN YAT SEN UNIV +1

Ink-free laser printing machine

InactiveCN110202270AEasy to replaceAchieve separationLaser beam welding apparatusCommunication interfaceModular design

The invention relates to the technical field of plastic card printing, and discloses an ink-free laser printing machine. A printing scanning head is used for generating the laser with the wavelength being 1670 nm, the laser is used for etching the plastic card surface, and the effect of printing the plastic card surface is achieved. The machine is simple and compact in structure, an electronic device inside is arranged in a modular manner, and whole replacing of modules is facilitated. The printing scanning head is arranged on an optical plate, the stability can be increased, and the separation between a component and the work area can be achieved. A card inlet groove, a card reader, a turnover device and a card collection groove form a complete plastic card inlet and outlet system, modular design is completely adopted, according to actual needs, configuration is carried out, a state indication lamp has the button function, the whole engine starting control is achieved, the whole machine state can be displayed in real time, a power socket and a communication interface adopt pulling and plugging interfaces, maintaining and moving are facilitated, the power socket has the safe function, and the current of a whole engine circuit is subjected to overload protection effect.

Owner:臧铭心

A high-efficiency and clean screen printing device

ActiveCN112389081BAchieve the effect of automatic cleaningEasy to operateScreen printersPrinting press partsScreen printingProcess engineering

The invention relates to a printing device, in particular to an efficient and clean screen printing device. The invention provides a high-efficiency and clean screen printing device with simple operation, time-saving and labor-saving and uniform printing. An efficient and clean screen printing device, comprising: a base plate and a first support frame, the base plate is provided with the first support frame; a table plate, the first support frame is provided with a table plate; a feeding mechanism, the base plate is provided with a material mechanism; cleaning mechanism, a cleaning mechanism is provided on the feeding mechanism, and the cleaning mechanism is connected with the table; an automatic auxiliary mechanism for printing and pressing is provided on the bottom plate, and the automatic auxiliary mechanism for printing and pressing cooperates with the cleaning mechanism; Mechanism, a stamping mechanism is arranged on the bottom plate, and the stamping mechanism cooperates with the feeding mechanism and the stamping automatic auxiliary mechanism. The present invention achieves the effect of automatic cleaning through the mutual meshing of all the gears on the upper and lower sides, and the rotation of the cleaning brushes on the upper and lower sides to clean the screen, and the operation is simple and convenient, and saves time and effort.

Owner:SHANXI JINYE PRINTING CO LTD

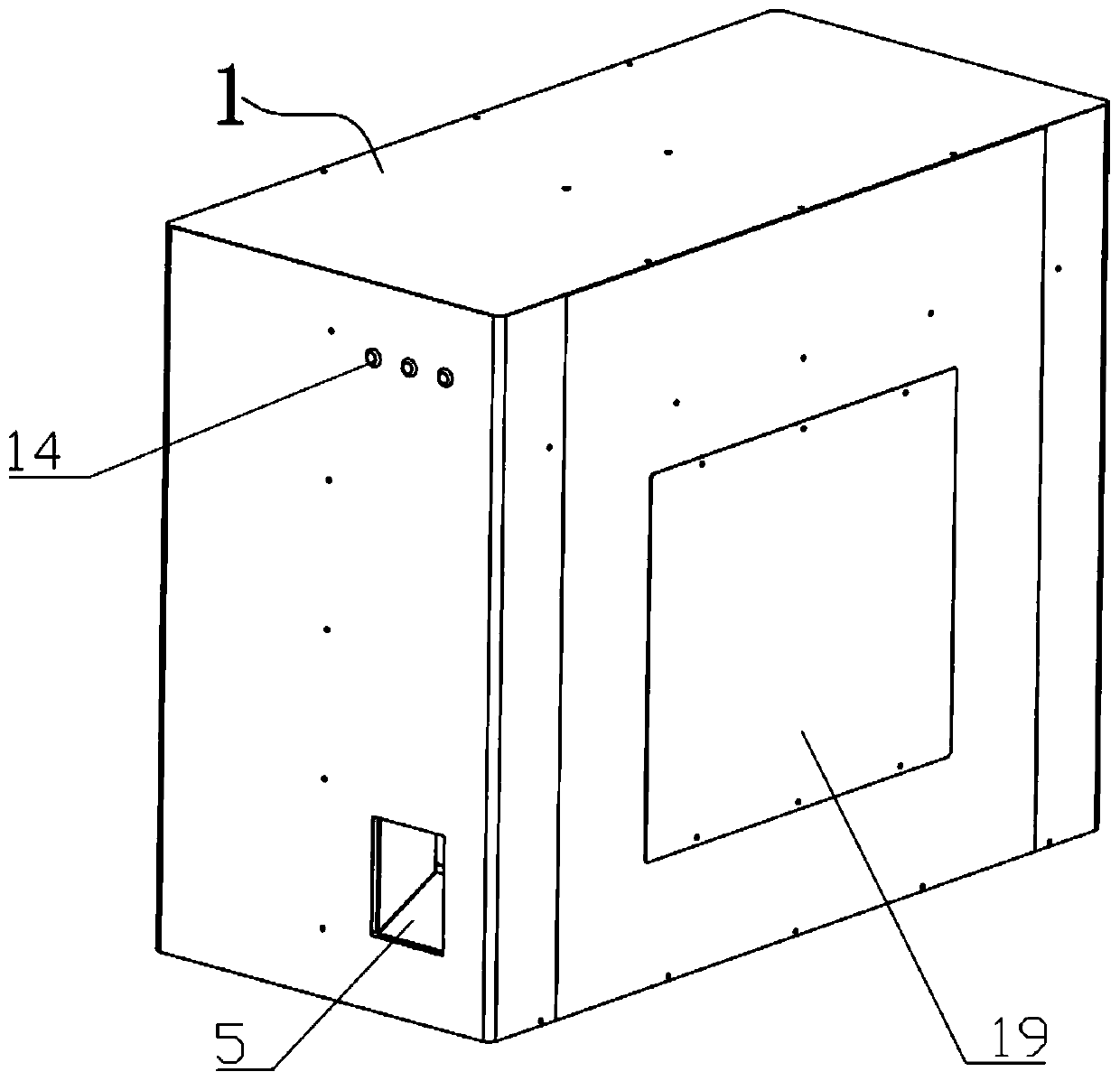

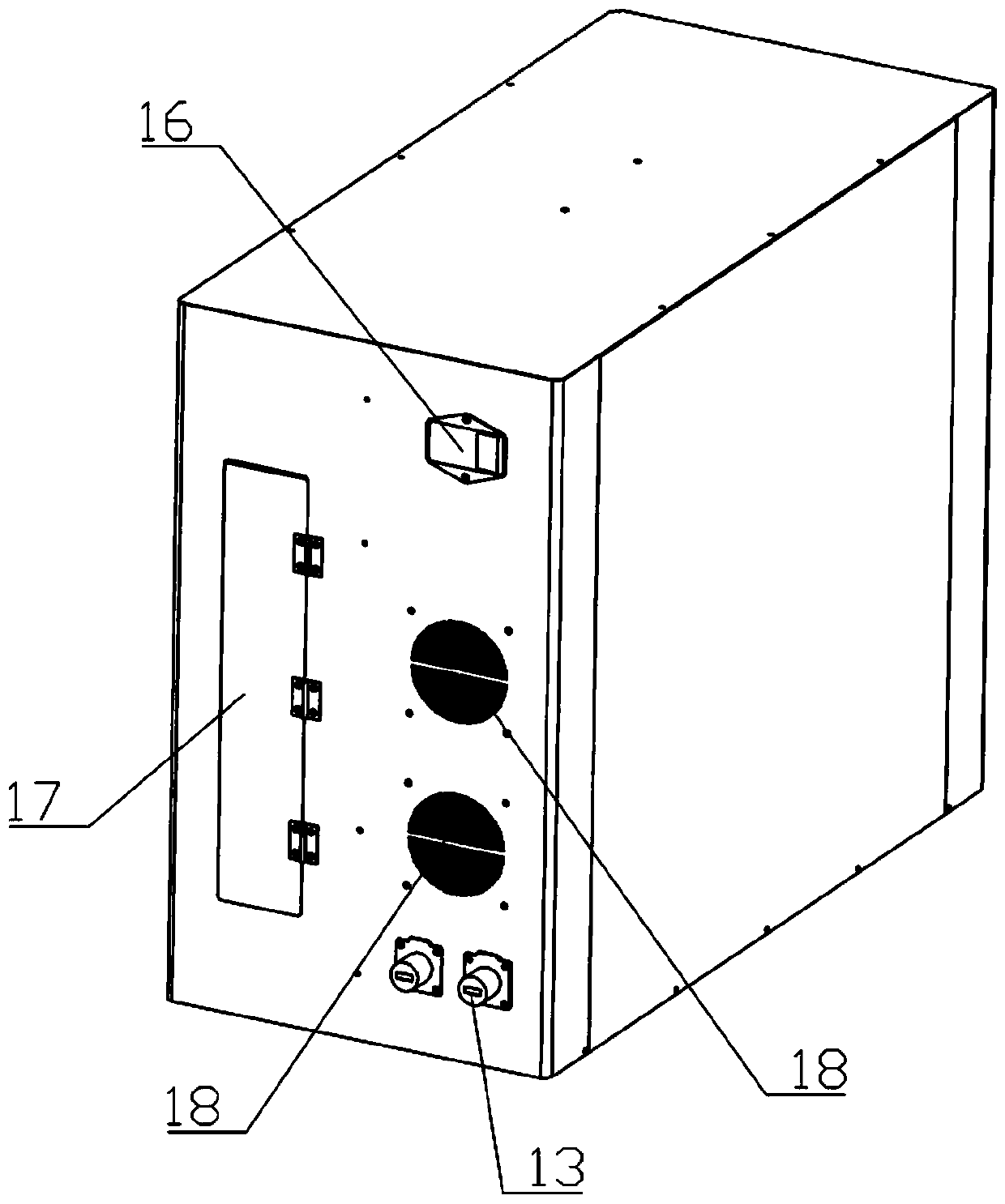

A printing press device and a printing machine

ActiveCN105235361BIncrease pressureTo achieve the printing effectRotary pressesReciprocating motionEngineering

The invention discloses a stamping device. The stamping device comprises a cylindrical roller, a roller height adjusting device, a printing plate, a base and a power device, wherein the roller is opposite to the printing plate; a channel through which the printed material passes is reserved between the roller and the printing plate; the roller is fixedly arranged on the base by the roller height adjusting device; the self height of the roller is changed under the action of the roller height adjusting device; the base is subjected to reciprocation movement under the driving of the power device. Through the adoption of the stamping device, the pressure among the printed material, the stamping device and the printing plate can be increased; the stamping device is capable of uniformly stamping, so that the printing quality is improved; meanwhile, due to the design of the roller, the printing efficiency can be improved.

Owner:谢成虎

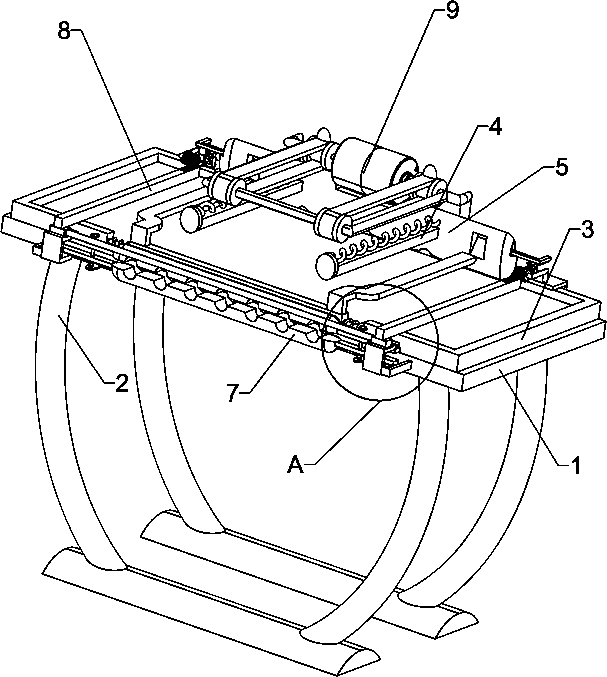

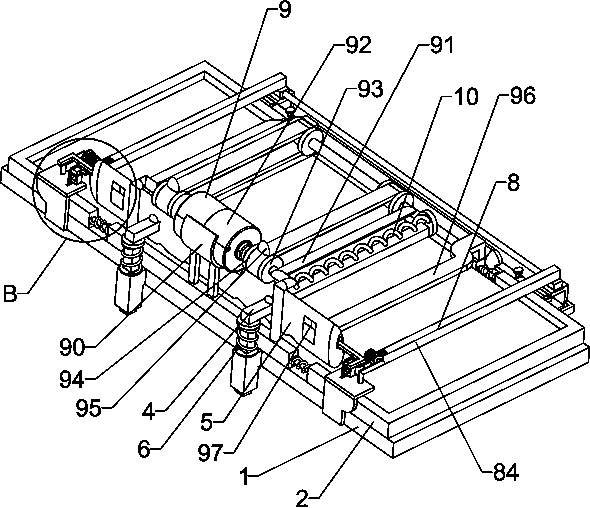

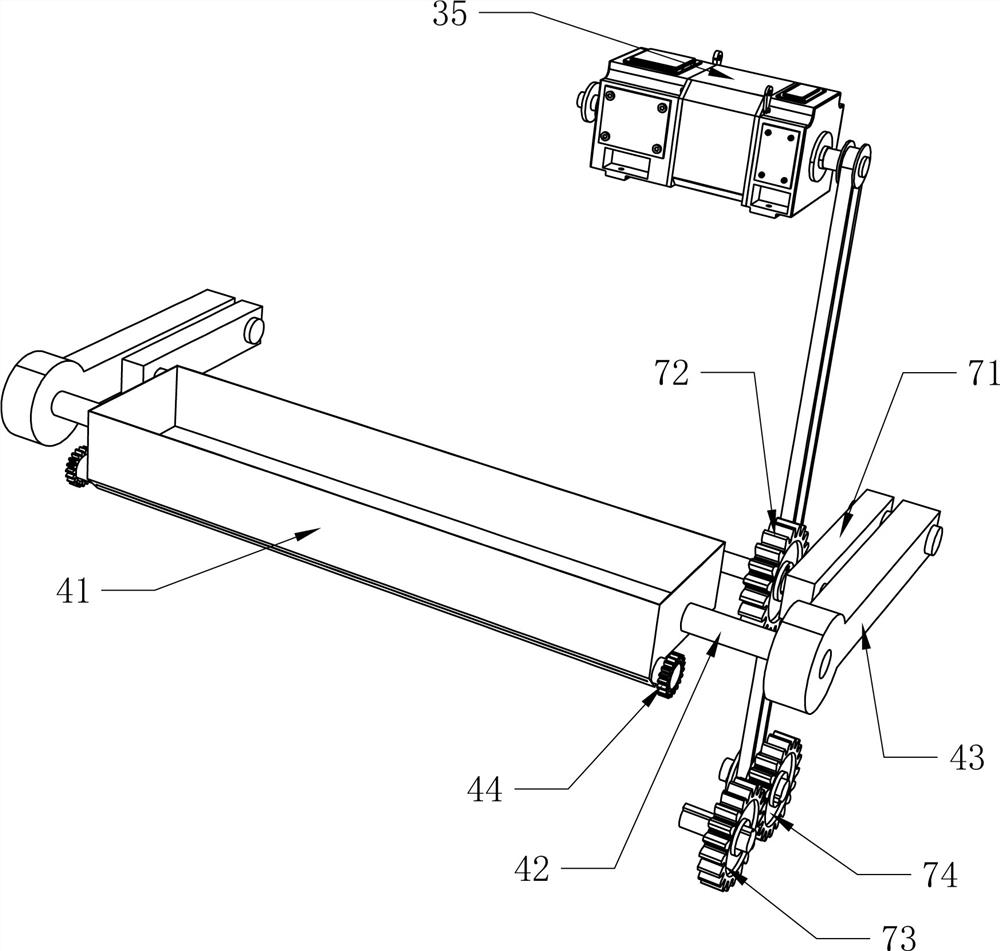

A plastic plate printing equipment

ActiveCN111497432BTo achieve the printing effectSave human effortRotary pressesPrinting press partsMechanical engineeringIndustrial engineering

The invention relates to a printing device, in particular to a plastic plate printing device. The technical problem to be solved by the present invention is how to design a plastic plate printing equipment that is easy to operate, can improve work efficiency, and saves manpower. The invention provides such a plastic plate printing equipment, which includes: a frame, with baffles connected to both sides; a lower mold assembly, which is arranged at the lower part of the frame; an upper mold assembly, which is arranged at the upper part of the frame ; The scraper assembly is set on the upper die assembly. The present invention prints the plastic board through the cooperative operation of the lower mold assembly, the upper mold assembly and the scraper assembly, so as to achieve the effect of printing on the plastic board. The present invention drives the scraper assembly to print through the drive assembly without manual labor Printing effectively saves manpower.

Owner:青州市亿恒包装机械有限公司

A tote bag advertisement printing equipment

ActiveCN111619202BTo achieve the printing effectSave human effortPlaten pressesMechanical engineeringIndustrial engineering

The invention relates to a printing device, in particular to a bag advertisement printing device. The technical problem to be solved by the present invention is how to design a handbag advertising printing device that is easy to operate, can improve work efficiency, and saves manpower. The present invention provides such a handbag advertisement printing device, which includes: a frame, the lower part of which is connected with a support plate; a pressing assembly, which is arranged on the frame; a scraper assembly, which is arranged on the frame; The printing mold is arranged on the lower pressing assembly, and the upper printing mold is detachable; the lower printing mold is slidably connected to the support plate, and the lower printing mold is detachable. The invention prints the handbag through the cooperation of the scraper assembly and the pressing assembly, so as to achieve the effect of printing the handbag.

Owner:深圳市建鸿兴数字包装科技有限公司

Printing device for automatic printing and cutting paperboards with different sizes

InactiveCN111605302ATo achieve the printing effectAchieve the effect of cutting cardboardRotary pressesPrinting press partsPaperboardEngineering

The invention relates to the technical field of paperboard printing, and discloses a printing device for automatic printing and cutting paperboards with different sizes. The printing device comprisesa machine body, a large sliding groove is formed in the top of the rear wall in the machine body, a large sliding block and a cam sliding block are slidably connected to the inner wall of the slidinggroove, an ink cylinder is rotatably connected to the front side of the large sliding block, a printing drum is rotatably connected to the front side of the cam sliding block, a movable rod is slidably connected to the outer wall of the cam sliding block, a reset spring is connected to the outer wall of the movable rod in a sleeving mode, a baffle block is fixedly connected to the bottom of the reset spring, and a cutter is fixedly installed at the bottom of the movable rod. The movable rod is driven by the printing drum to move, the cutter is driven by the movable rod to move, through matching use of the cam sliding block and the movable rod, when the printing drum rotate for one circle, printing is just finished, the cutter extends out of a cutter groove, and thus the effect of cutting the paperboards is achieved.

Owner:HAINING XIANFENG PRINTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com