Stamping device and printer

A technology of a printing machine and a power device, applied in the field of printing press devices, can solve the problems of inability to adjust the pressure, the top of the printing press device is dead, and the fonts and patterns are not clear, so as to improve printing efficiency, layer thickness and uniformity, and improve printing. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

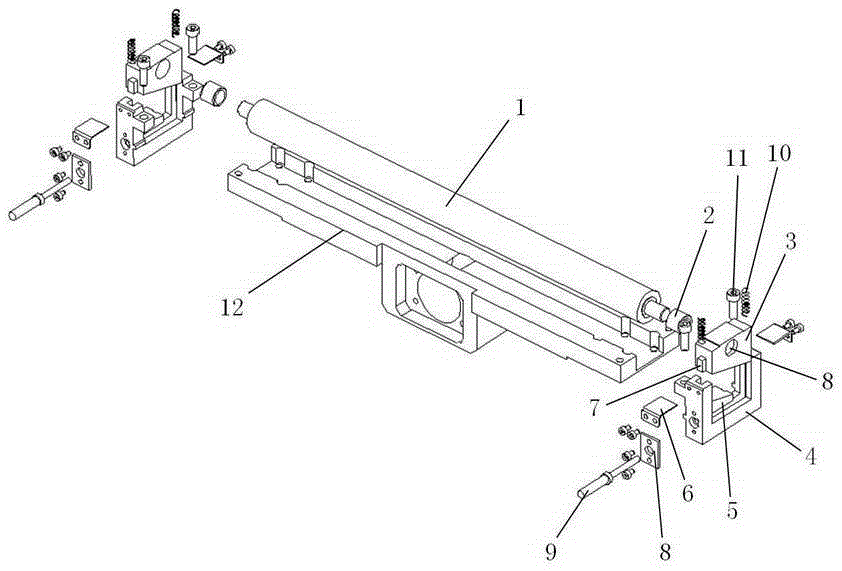

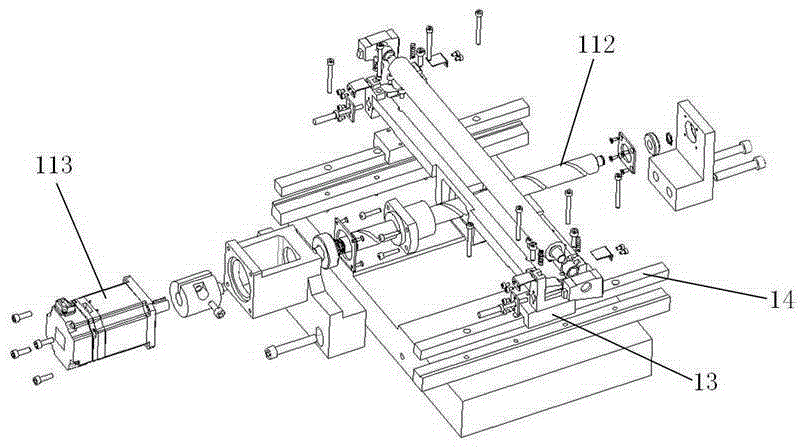

[0026] The detailed exploded view and schematic diagram of the embossing device in the embodiment of the present invention and the printing machine applying the device are as follows: Figure 1-5 shown. The embossing device in the embodiment of the present invention includes a cylindrical roller, a roller height adjusting device, a printing plate, a base and a power device.

[0027] In order to further improve the contact force between the surface of the roller and the substrate while protecting the surface of the substrate, a soft layer can be added to the outer surface of the roller, and the soft layer can be made of tough and soft materials, such as leather, plastic materials, etc. .

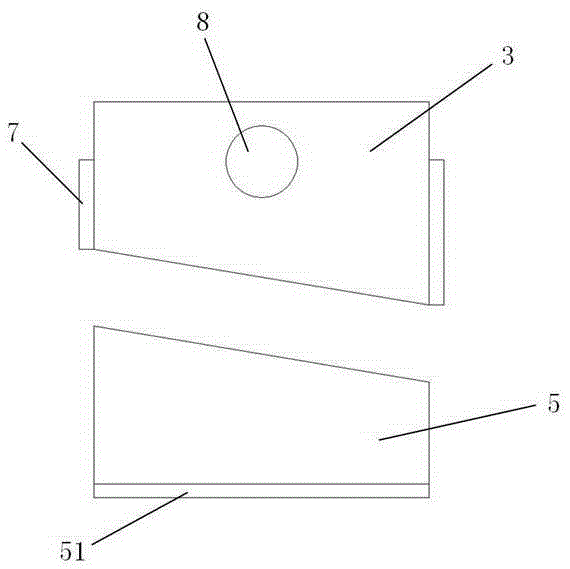

[0028] The roller height adjustment device includes a fixed end 4 and a movable end, wherein the movable end includes the first slider 5 and the second slider 3 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com