Copper wire end identifier printing machine

A marking machine and marking technology, which is applied to printing machines, rotary printing machines, printing, etc., can solve the problems of manpower consumption and low work efficiency, and achieve the effects of improving work efficiency, simple operation, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

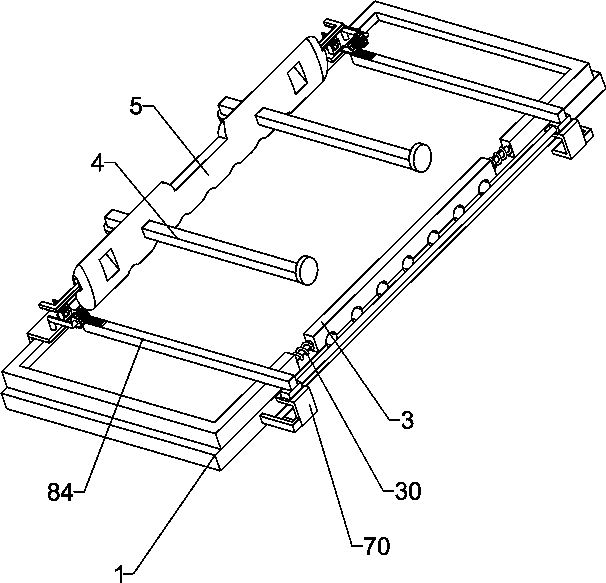

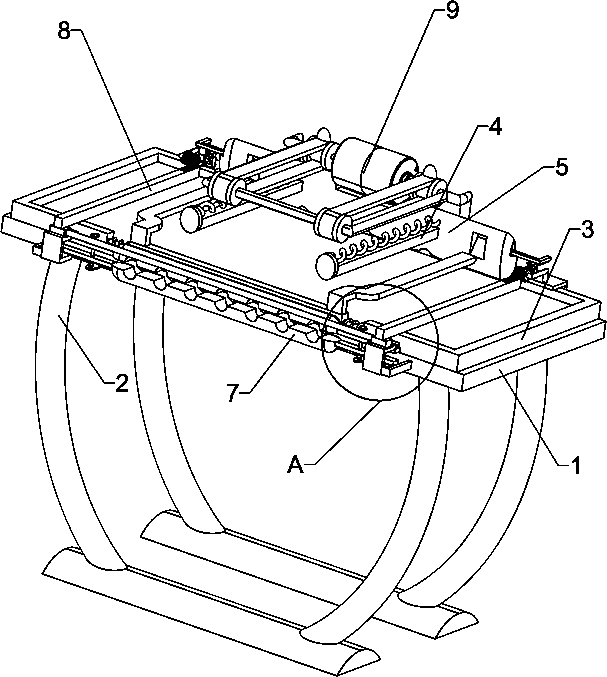

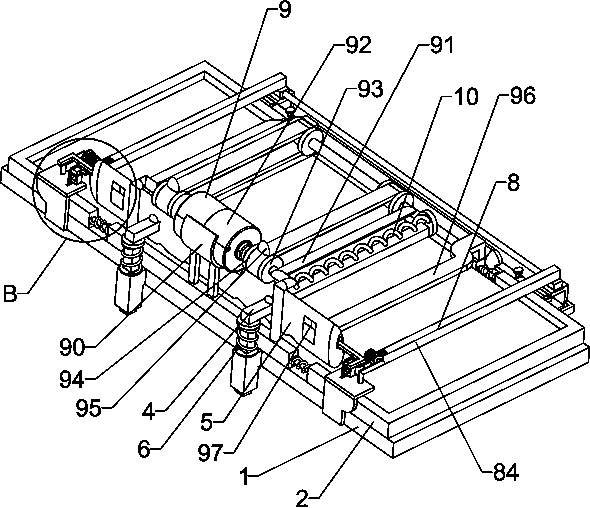

[0026] A copper wire terminal identification marking machine, such as Figure 1-5 As shown, it includes mounting plate 1, leg 2, printing frame 3, compression spring 30, L-shaped sliding rod 4, scraper 5 and telescopic spring 6, the bottom of mounting plate 1 is connected with leg 2, and the top of mounting plate 1 is connected There is a printing frame 3, the two sides of the printing frame 3 are sliding settings, a compression spring 30 is connected between the two sides and the middle of the printing frame 3, and the left and right sides of the rear part of the mounting plate 1 are slidably connected with L-shaped slide bars 4, and the two sides Scraper 5 is slidably connected between L-shaped sliding rods 4, telescopic spring 6 is connected between L-shaped sliding rods 4 and mounting plate 1, and also includes fixing device 7 and transmission device 8, mounting plate 1 and printing frame 3 A fixing device 7 is arranged between them, and a transmission device 8 is arranged...

Embodiment 2

[0031] On the basis of Example 1, such as Figure 4As shown, drive device 9 is also included, and drive device 9 includes arc-shaped connecting plate 90, connecting frame 91, motor 92, sprocket wheel 93, chain 94, push plate 95 and guide rod 96, and the middle part of the rear side of printing frame 3 is connected There is an arc-shaped connecting plate 90, a connecting frame 91 is connected to the rear side of the printing frame 3, and a motor 92 is installed on the arc-shaped connecting plate 90. Wheel 93, chain 94 is wound around between two sprocket wheels 93, two sprocket wheels 93 points front and rear sides are arranged, and two sprocket wheels 93 of rear side are connected with two output shafts of motor 92 respectively, and chain 94 is connected with Push plate 95, printing frame 3 top left and right sides are all connected with guide rod 96, scraper 5 left and right sides all have guide hole 97, and guide hole 97 cooperates with guide rod 96.

[0032] When it is nec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com