Patents

Literature

316results about How to "Guaranteed printing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceramic material for 3D light curing formation printing and preparation method of ceramic element

InactiveCN109400177AHigh ceramic contentEasy to printAdditive manufacturing apparatusOligomerAgent Combination

The invention relates to a ceramic material for 3D light curing formation printing and a preparation method of a ceramic element. The ceramic material is prepared from 30 to 70 vol percent of ceramicpowder and 30 to 70 vol percent of photosensitive resin premixed liquid, wherein the photosensitive resin premixed liquid is prepared from 37 to 50 weight percent of oligomers, 30 to 60 weight percentof reactive diluents, 0.1 to 5 weight percent of photoinitiators, 1 to 5 weight percent of dispersing agents, 0.1 to 0.6 weight percent of ultraviolet blocking agents, 0 to 0.05 weight percent of polymerization inhibitors, 1 to 4 weight percent of anti-foaming agents, 0.5 to 2.35 weight percent of anti-settling agents and 0.3 to 3 weight percent of leveling agents. In the degreasing and sinteringpost-treatment work procedures, specific parameters are used, so that a sintering element can reach good sintering density and mechanical performance. By optimizing the composition and the proportionof light curing ceramic resin, and selecting the excellent dispersing agent combination and the reasonable consumption, the ceramic powder can be better dispersed in the resin; the problems that theexisting light curing ceramic resin has poor flowability and low formation precision, and that a finally prepared ceramic product can easily generate cracks or deformation, and the like are solved.

Owner:西安点云生物科技有限公司

Print control method and device of thermal printer

InactiveCN104309339AGuaranteed printing effectReduce decreaseOther printing apparatusRechargeable cellEngineering

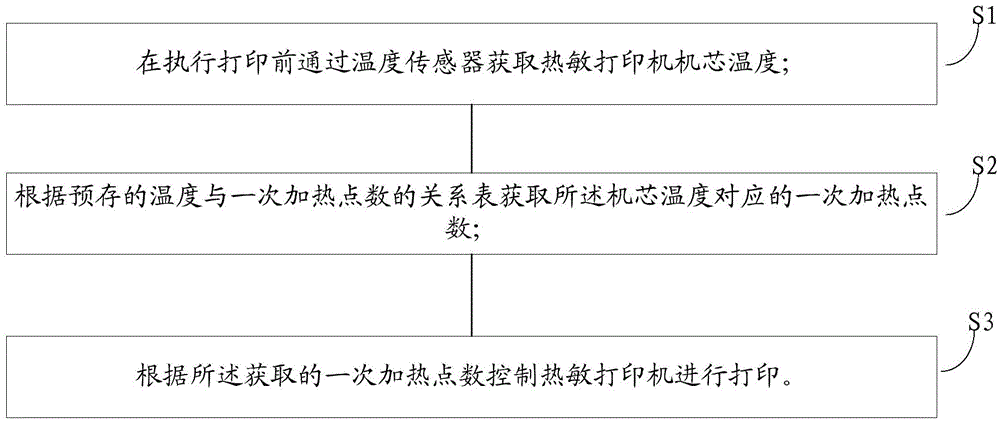

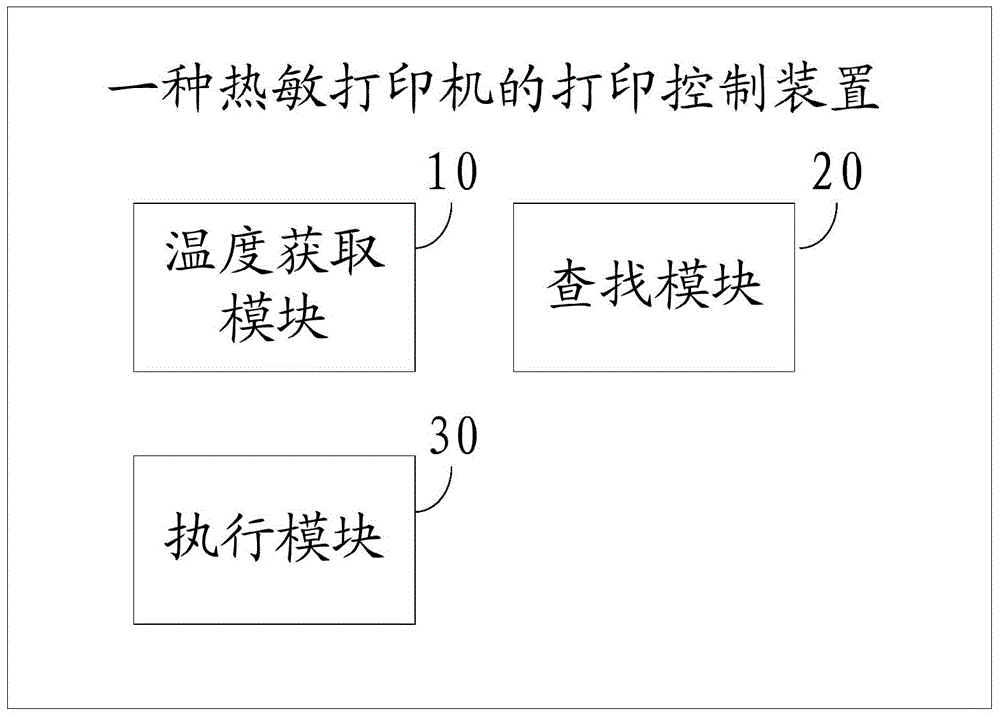

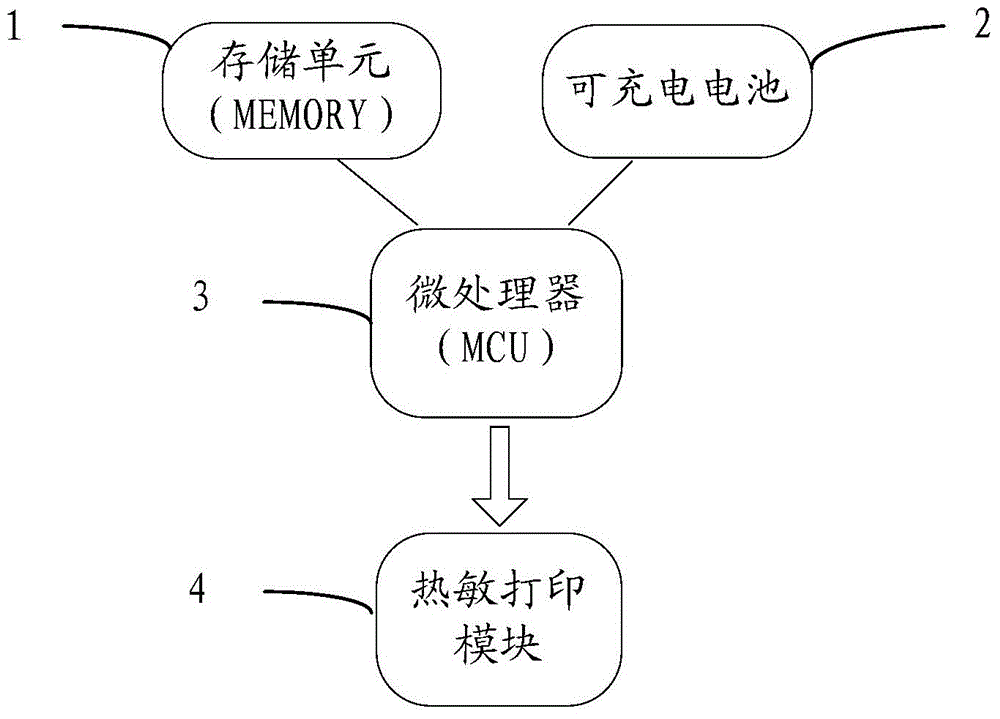

The invention discloses a print control method of a thermal printer. The thermal printer is charged through a rechargeable battery. The print control method of the thermal printer includes steps: obtaining temperature of a core of the thermal printer through a temperature sensor before executing printing; obtaining a singe heat count corresponding to the temperature of the core of the thermal printer according to a pre-stored temperature and single heat time count relationship list; controlling the thermal printer to perform the printing according to the obtained singe heat count. The print control method of the thermal printer effectively improves print effects of the thermal printer under low temperature. The invention further discloses a print control device of the thermal printer.

Owner:FUJIAN LANDI COMML EQUIP CO LTD

Organic carrier for crystalline silicon solar cell electrode slurry and preparation method thereof

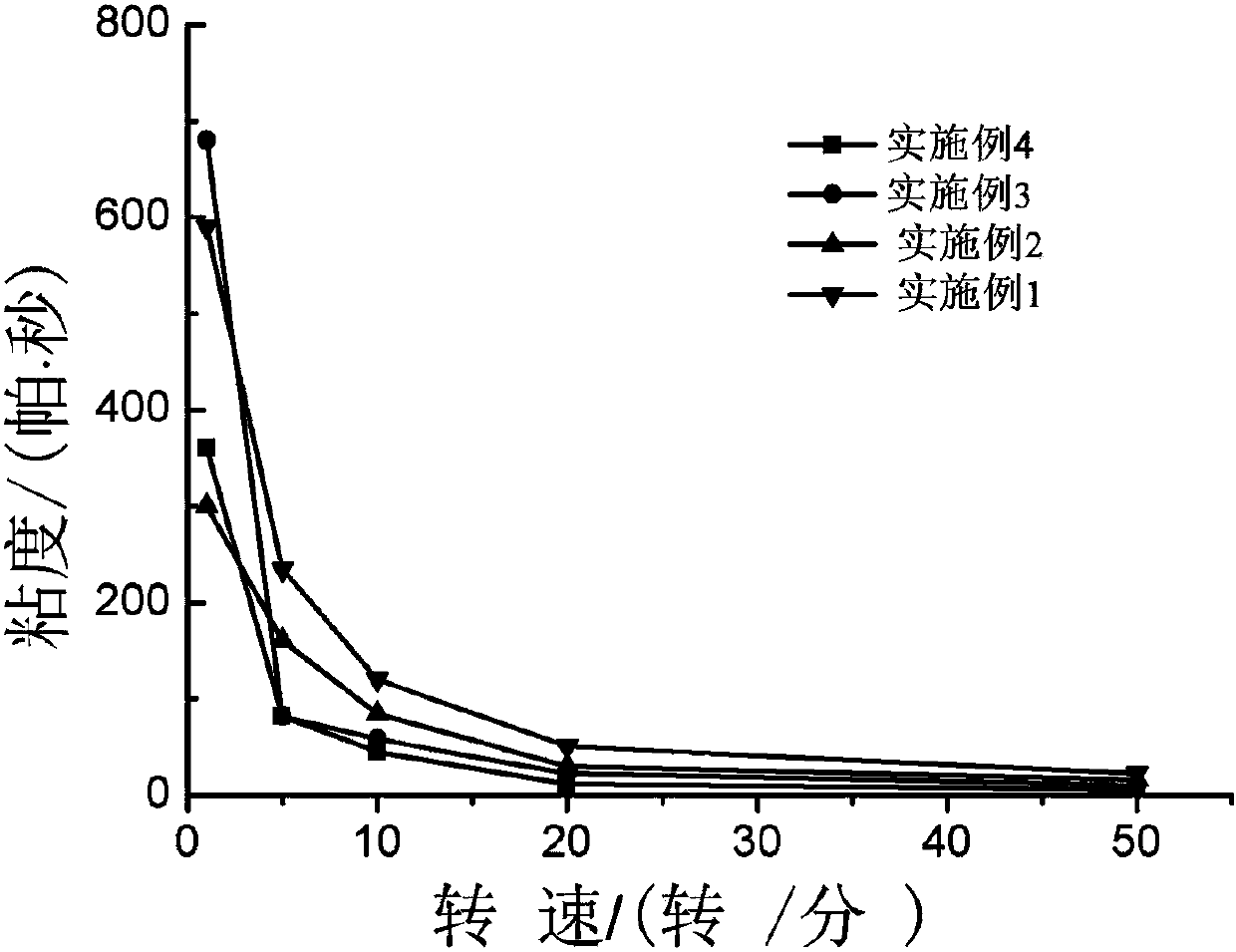

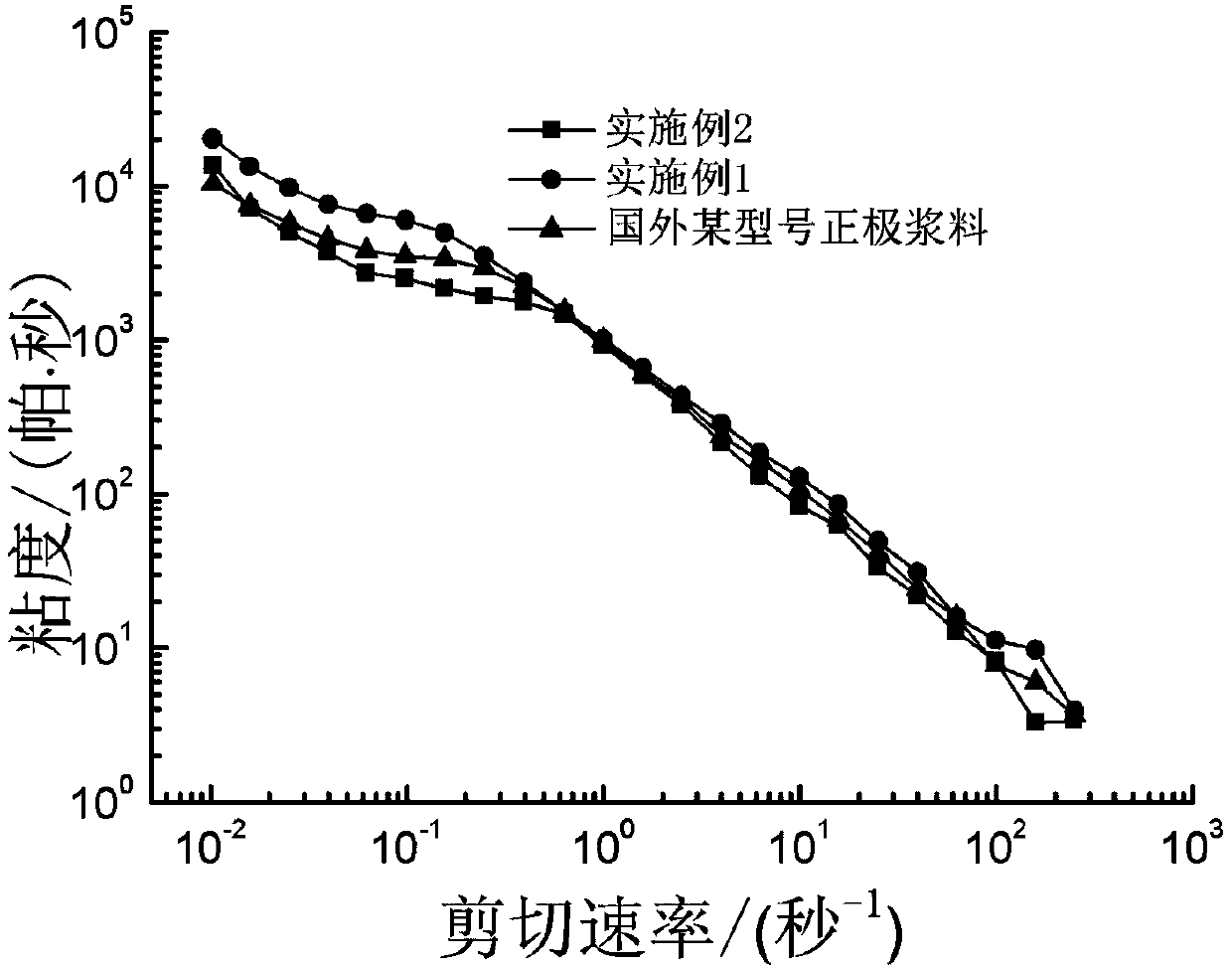

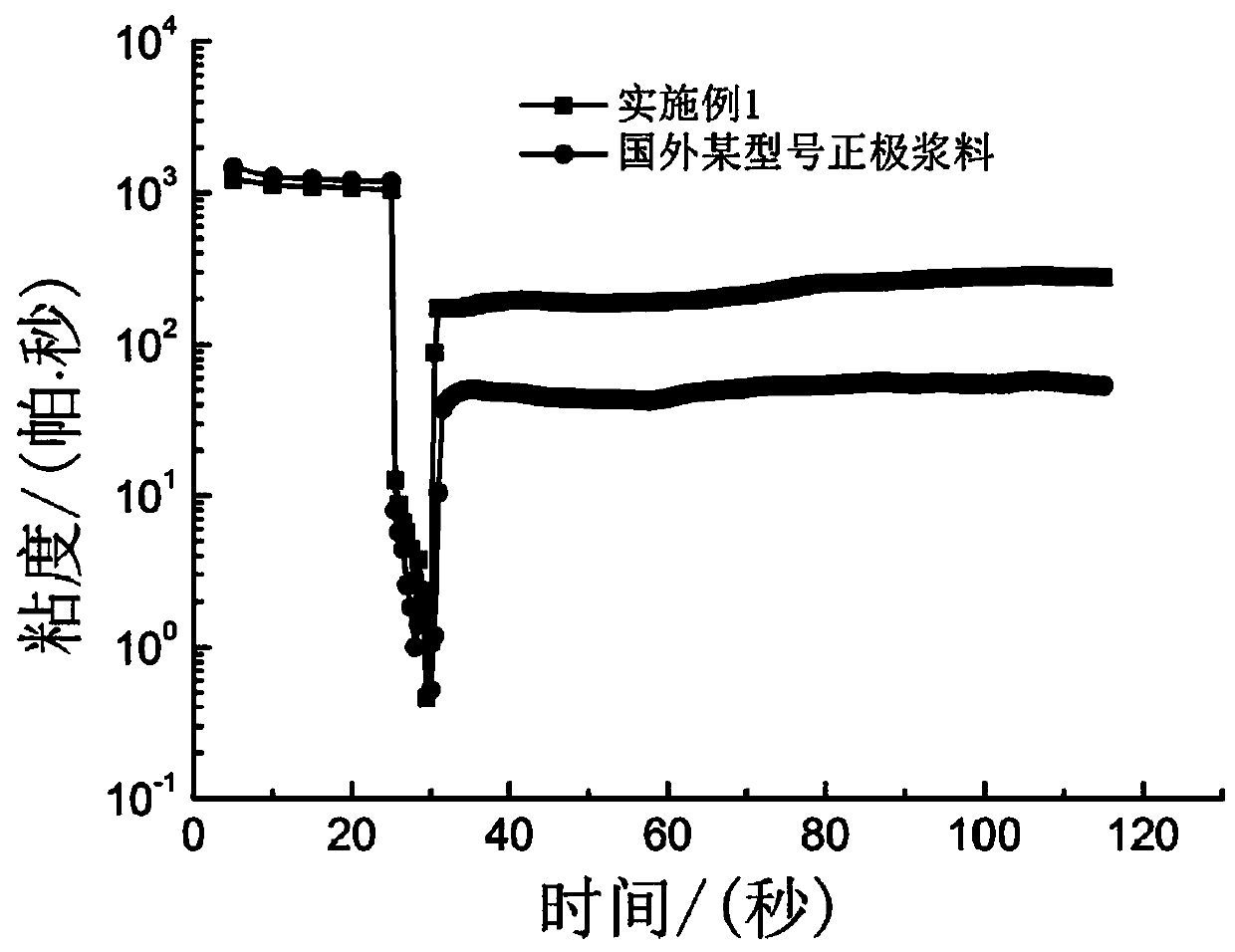

ActiveCN103435854AEvenly dispersedImprove thixotropyInksNon-conductive material with dispersed conductive materialOrganosolvPhysical chemistry

The invention discloses an organic carrier for crystalline silicon solar cell electrode slurry and a preparation method thereof. The organic carrier comprises the following components by mass percent: 5-20% of organic resin, 60-85% of an organic solvent, 1-10% of a thixotropic agent and 1-10% of a wetting dispersant. The preparation method comprises the following steps: (1) mixing and dissolving the organic resin and the organic solvent to obtain transparent resin solution; and (2) adding the thixotropic agent and the wetting dispersant to the transparent resin solution to mix and activate, so as to obtain the organic carrier for the crystalline silicon solar cell electrode slurry. The organic carrier disclosed by the invention is good in thixotropy, significant in shear thinning effect, high in printing resolution, simple in preparation method and process, convenient to operate and low in cost, and can print a thin electrode grid line with large depth-width ratio.

Owner:NAT UNIV OF DEFENSE TECH +1

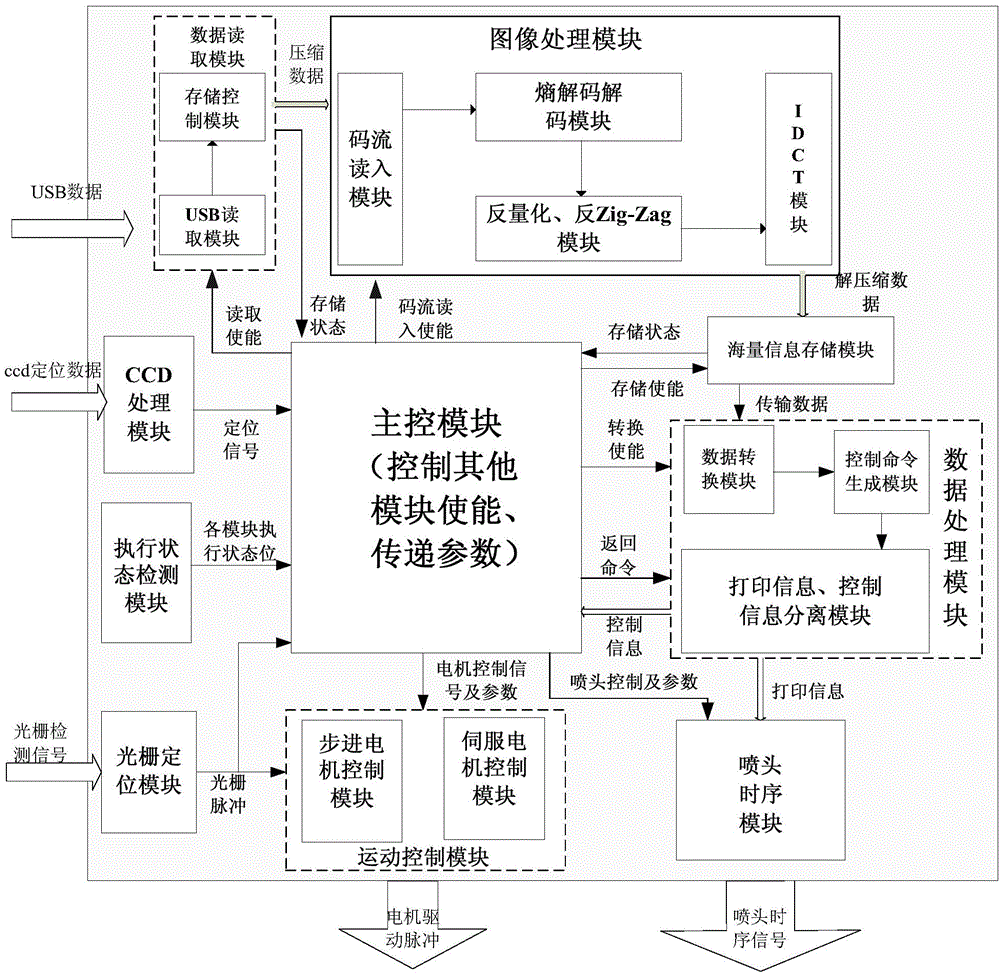

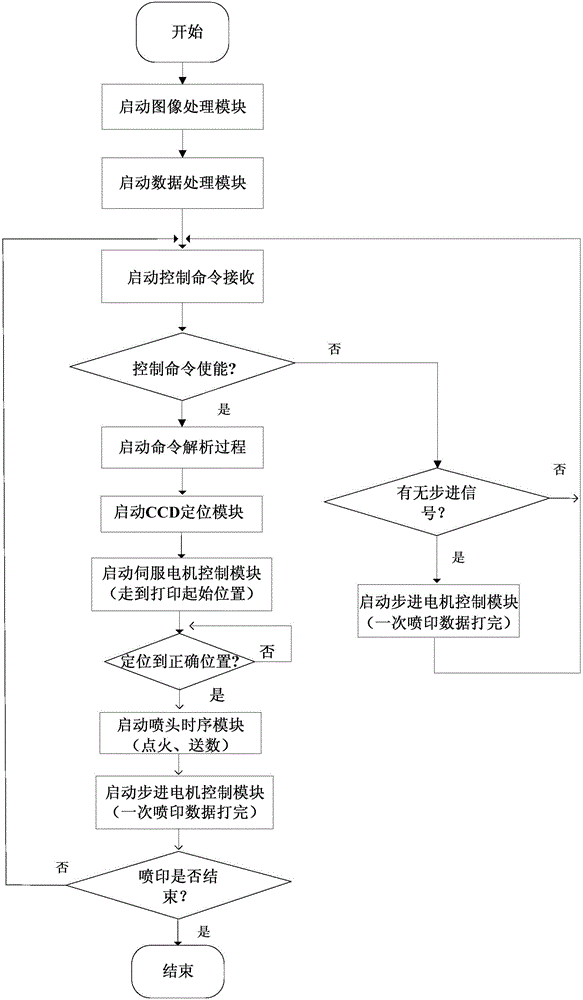

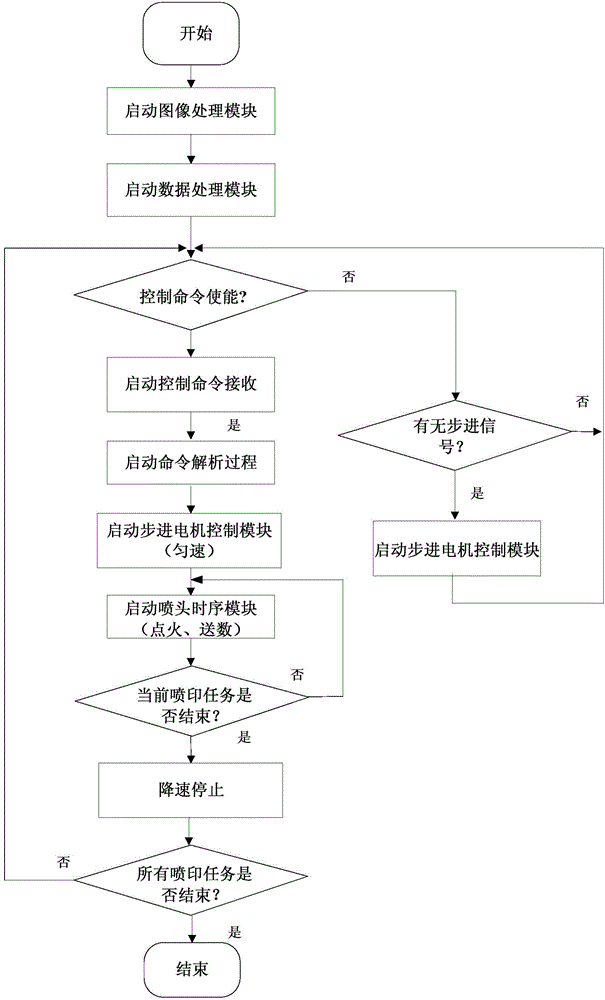

High-speed industrial jet printing control system and method based on FPGA technology

ActiveCN105564028ABreak through the speed bottleneckProcessing supportOther printing apparatusImaging processingControl system

The invention provides a high-speed industrial jet printing control system and method based on the FPGA technology, and the system and method are applied to the industrial full-printing electronic field. The image processing, jet printing control and motion control functions are integrated to realize full-automatic printing, a traditional processing manner that a jet printer system processes images in a PC and then the images are transmitted to a jet printer control system to carry out jet printing at present is replaced, breakthrough is made in the bottleneck of the data processing speed in traditional jet printing, an array of a super large number of nozzles is supported, and the system and method are especially suitable for one-way jet printing of the industrial roll-to-roll jet printing technology. The jet printing control method can be used to coordinate and schedule functional sub modules to realize the jet printing function, the accumulated positioning error is overcome, and flexible acceleration and deceleration motion is carried out to control and ensure the ink jetting state; and the method is simple, and the jet printing precision is higher. Devices are controlled to carry out jet printing in the speed near the highest theoretical speed, and the production efficiency is greatly improved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

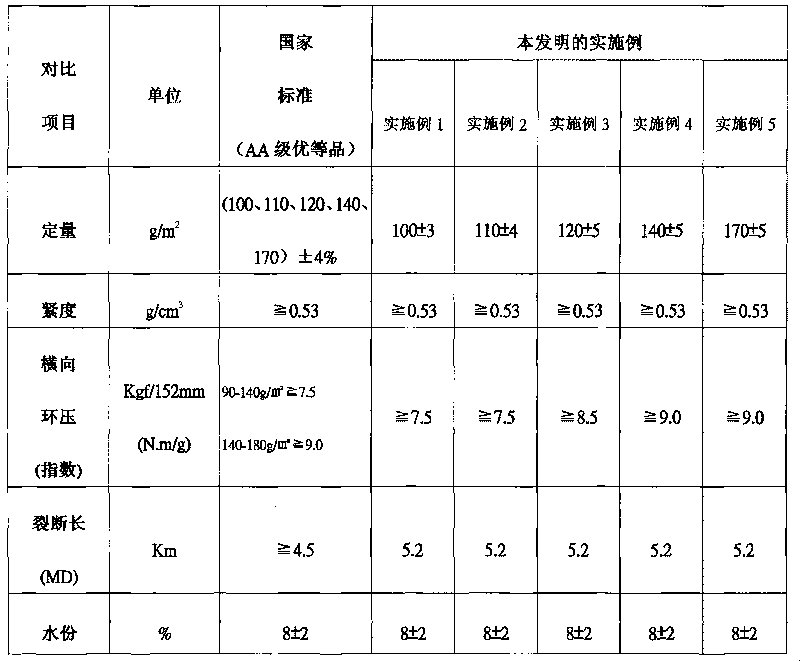

Corrugated paper and manufacturing method thereof

The invention discloses a corrugated paper and a manufacturing method thereof. The corrugated paper is composed of the raw materials according to parts by weight: 45-60 parts of USA No.11 waste paper, 30-55 parts of EOCC and 10 parts of Chinese domestic high-grade carton paper. The technical scheme provided by the invention utilizes Chinese domestic high-grade waste carton paper, USA No.11 waste paper and EOCC as raw materials, thus not only ensuring the reuse of Chinese domestic high-grade waste carton paper, embodying circular economy, saving resources, and protecting environment; meanwhile, the strength of the corrugated paper is obviously improved, and the surface is fine and beautiful and is favourable for ensuring printing effect. All the technical links of the provided manufacture method do not have rigorous requirements, so that the manufacturing method is suitable for industrial production and can fully embody the technical effect of the corrugated paper.

Owner:JIANGSU LEE & MAN PAPER MFG

Biaxially oriented polypropylene hot-pressing film and its making process

ActiveCN103223759AGuaranteed printing effectMeet the use requirementsSynthetic resin layered productsPolymer scienceBoPET

The invention discloses a biaxially oriented polypropylene hot-pressing film, which is made by three-layer co-extrusion and biaxial stretching. The middle layer is a homo-polypropylene core layer, the inner surface layer is a hot pressing layer, and the external surface layer is a printing layer. The homo-polypropylene core layer comprises 2%wt of an antistatic agent and 98%wt of homo-polypropylene. The hot pressing layer comprises 70%-80%wt of a thermal adhesive masterbatch, 2%-5%wt of an anti-adhesion agent and 15%-28%wt of an ethylene-propylene-butene copolymer. The printing layer comprises 3%wt of the anti-adhesion agent and 97%wt of homo-polypropylene. The invention also provides a production method of the biaxially oriented polypropylene hot-pressing film. The biaxially oriented polypropylene hot-pressing film provided in the invention can achieve good printing effects of conventional biaxially oriented polypropylene films, gluing is not needed during paper-plastic lamination, and hot-pressing lamination can be carried out directly. The bonding strength of the coated film completely meets the use requirements. Downstream processing procedures are greatly simplified, and the use cost is substantially reduced. Organic solvent evaporation and residual are absent in the production process, so that the process is green and environment-friendly.

Owner:ANHUI GUOFENG PLASTIC

Composition for increasing hydrophobic and oleophobic behavior of paper product and method of making the same

InactiveCN1629399AGuaranteed printing effectExcellent water and oil repellencyWater-repelling agents additionPaper coatingParaffin waxEmulsion

The invention provides a composition for increasing hydrophobic and oleophobic behavior of paper product and method which comprises, preparing slurry from 50-100 parts of gasket material, or gasket material and pigment, high speed agitating, low speed agitating and charging 1-20 parts of bonding agent, 1-10 parts of organic fluorine resin emulsion, 0.5-15 parts of crosslinkable wax emulsion, 0.05-5 parts of flowing deformation modifier, diluting to obtain a solid content of 20-80%.

Owner:中科纳米技术工程中心有限公司

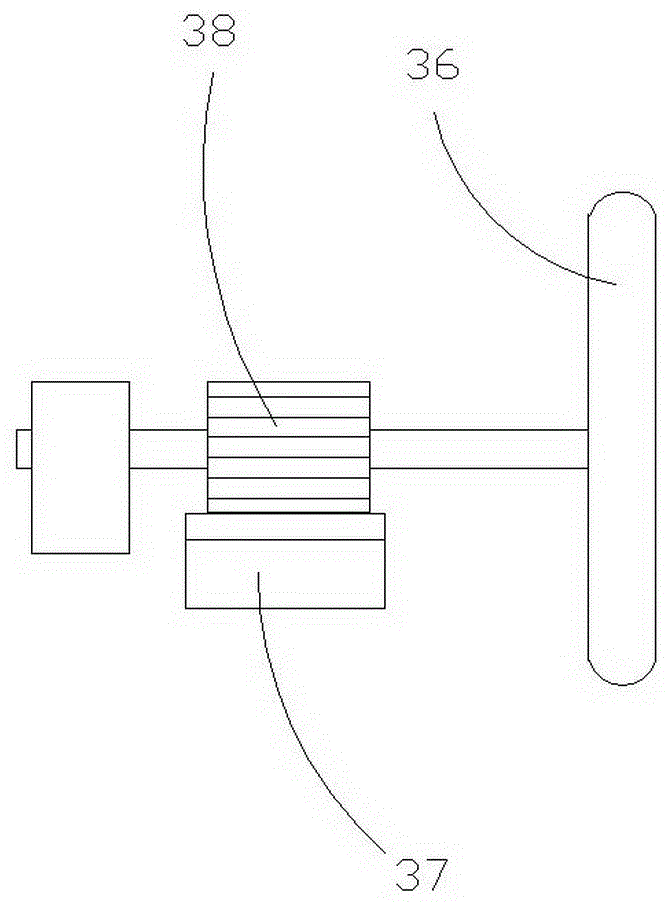

Circular screen printer adjusting mechanism adopting magnetic bar printing mechanism

The invention discloses a circular screen printer adjusting mechanism adopting a magnetic bar printing mechanism. The circular screen printer adjusting mechanism comprises a rack, support plates are fixed on two side plates below the rack, a magnetic table is fixed on the back of a top plate of the rack, driving motors are fixed on the support plates, output shafts of the driving motors are inserted into holes in the support plates and are fixed with vertical adjusting rods via couplers, and the lower ends of the vertical adjusting rods and the couplers are arranged in the holes. The vertical adjusting rods are inserted into adjusting sleeves, the adjusting sleeves are inserted into through holes of the top plate of the rack, the top ends of the vertical adjusting rods extend out of the adjusting sleeves, the top ends of the vertical adjusting rods are connected with connectors in a threaded manner, and two ends of a nickel screen roller are hinged with the connectors correspondingly. The nickel screen roller can be adjusted up and down so as to be pressed against cloth for printing. Meanwhile, paste discharge amount and speed of a pulp delivery roller can be controlled, and printing effect is ensured.

Owner:威海毛纺织集团有限公司

Method for producing coating light-weight super-sensitive paper

InactiveCN101581058AEasy to processImprove performanceCoatings with pigmentsPaper/cardboardAdhesiveTitanium

The invention relates to a method for producing coating light-weight super-sensitive paper. The super-sensitive base paper is subjected to coating processing; the coating process adopts a 1,760mm coating machine, the speed is 150m / min, the single-sided coating quantity is 15g / m, and the after-coating loose depth is 1.4cm / g; and coatings comprise pigment and a rubber latex adhesive. The pigment is white titanium pigment and porcelain clay specially treated, and the rubber latex adhesive is a mixture of styrene butadiene rubber latex and starch. The surface of the base paper of the invention is not calendered and finished, and the flock paper with natural and native texture is formed on a mesh; on the premise of ensuring the printing effect, the coating light-weight super-sensitive paper produced by the method has the advantages of fewer processing steps, increasing natural and native texture of the paper, high loose depth, strong stereo aesthetic feeling, less reflected light, no dazzling, and soft and comfortable vision. Moreover, the method has the advantages of easy production and low production cost.

Owner:SHANDONG KAILI SPECIAL PAPER

Digital color-spray color matching technique used for intaglio printing

InactiveCN105437806AReduce wasteShorten development timeDuplicating/marking methodsPhotogravurePrinting press

The invention discloses a digital color-spray color matching technique used for intaglio printing. A color manuscript is provided for intaglio printing through digital color-spray printing. Color pre-matching is conducted on a digital printer and a photogravure press before the color manuscript is printed through digital color-spray. By means of the digital color-spray color matching technique used for intaglio printing, the time for developing a new color can be greatly shortened, the success rate of new color designing and platemaking is increased, the printing effect is guaranteed, the waste of printing rollers is reduced, and the development cost is substantially reduced.

Owner:ZHEJIANG DILONG NEW MATERIAL

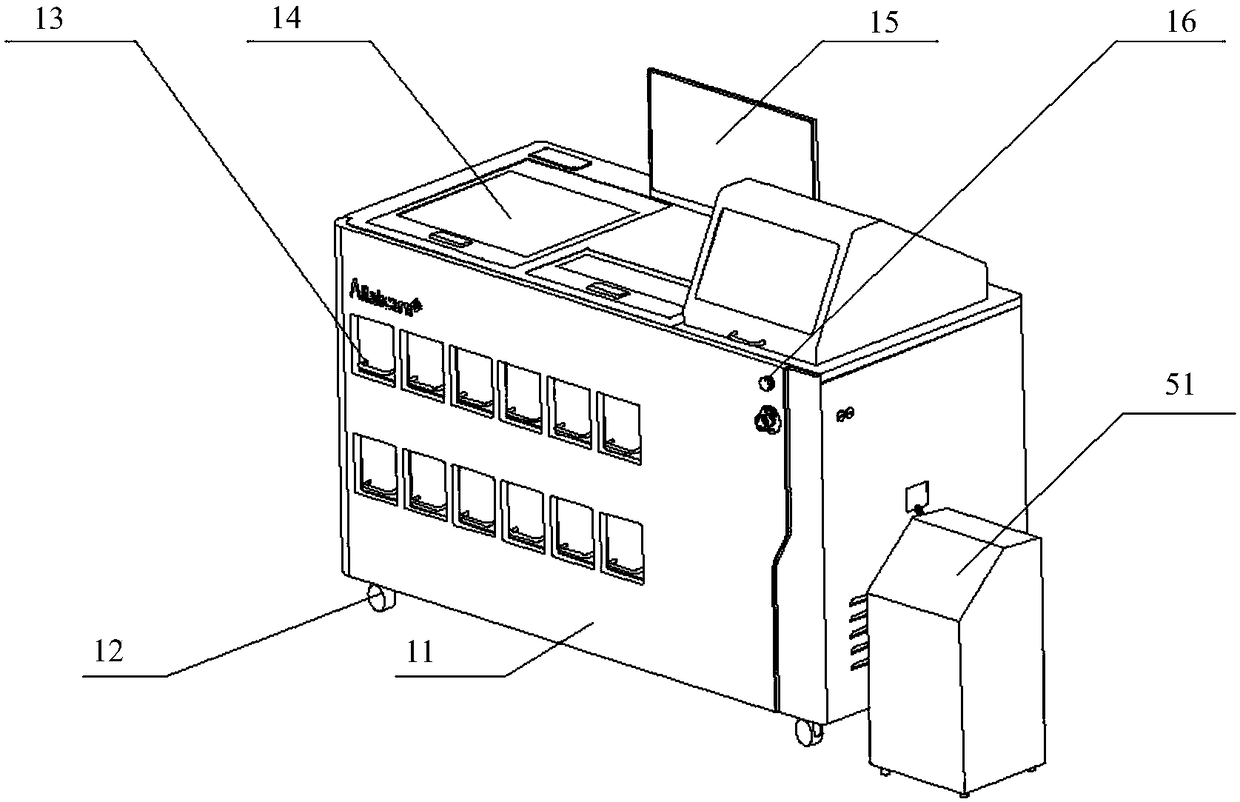

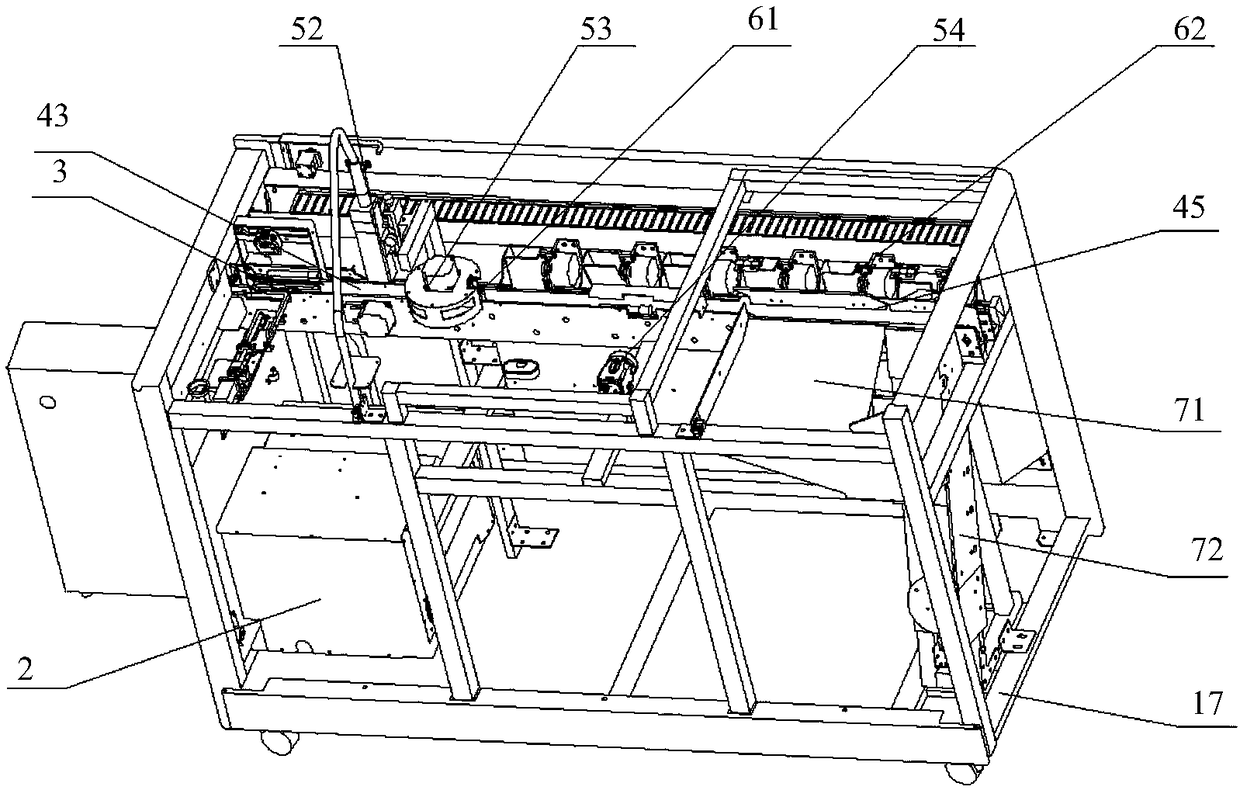

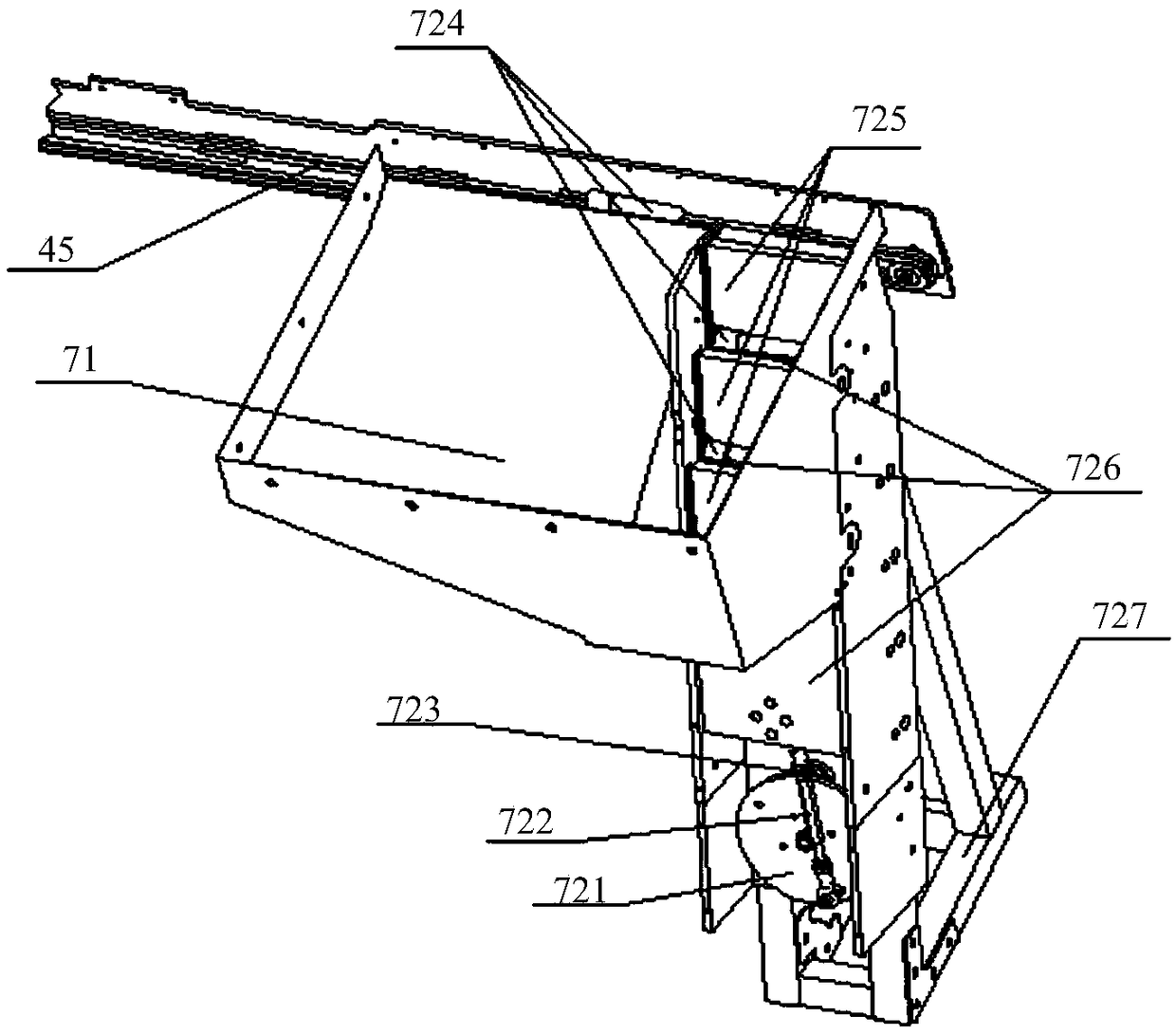

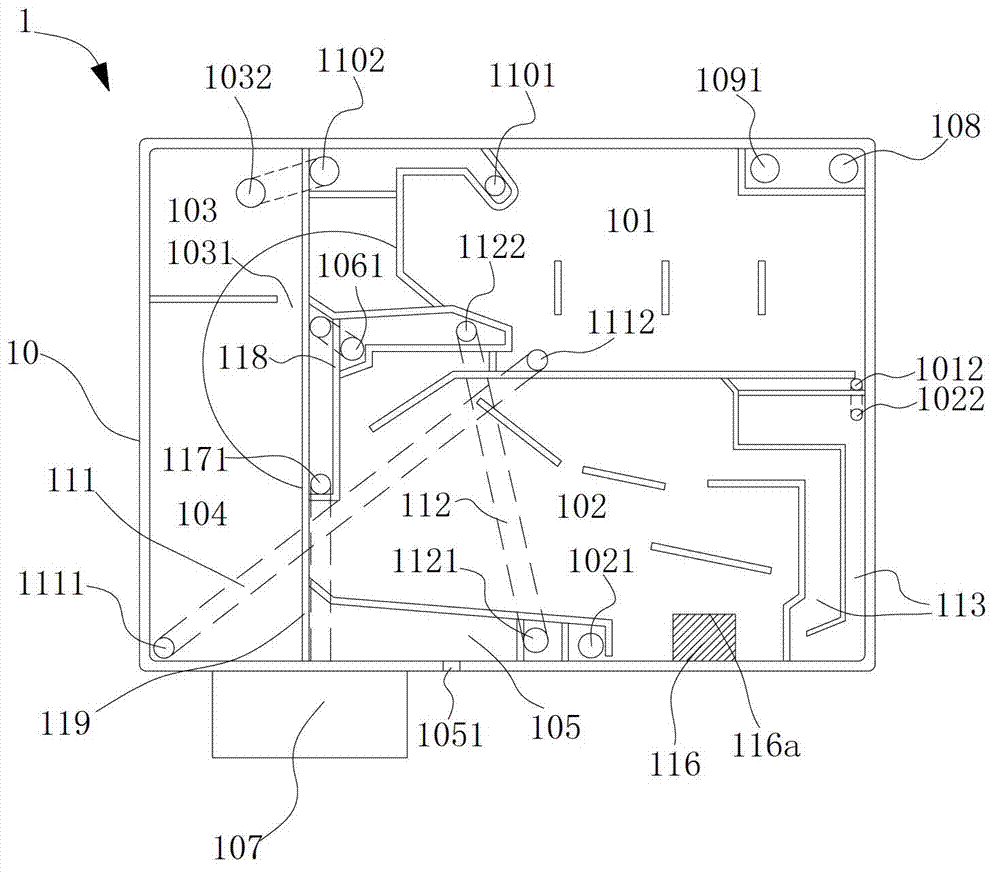

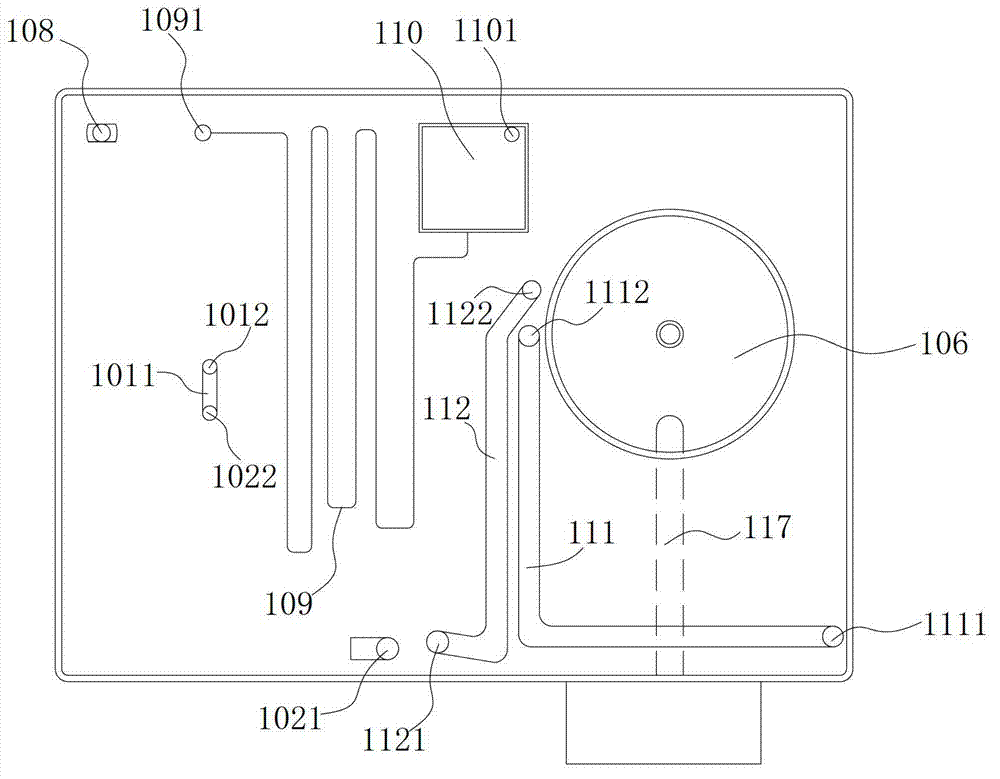

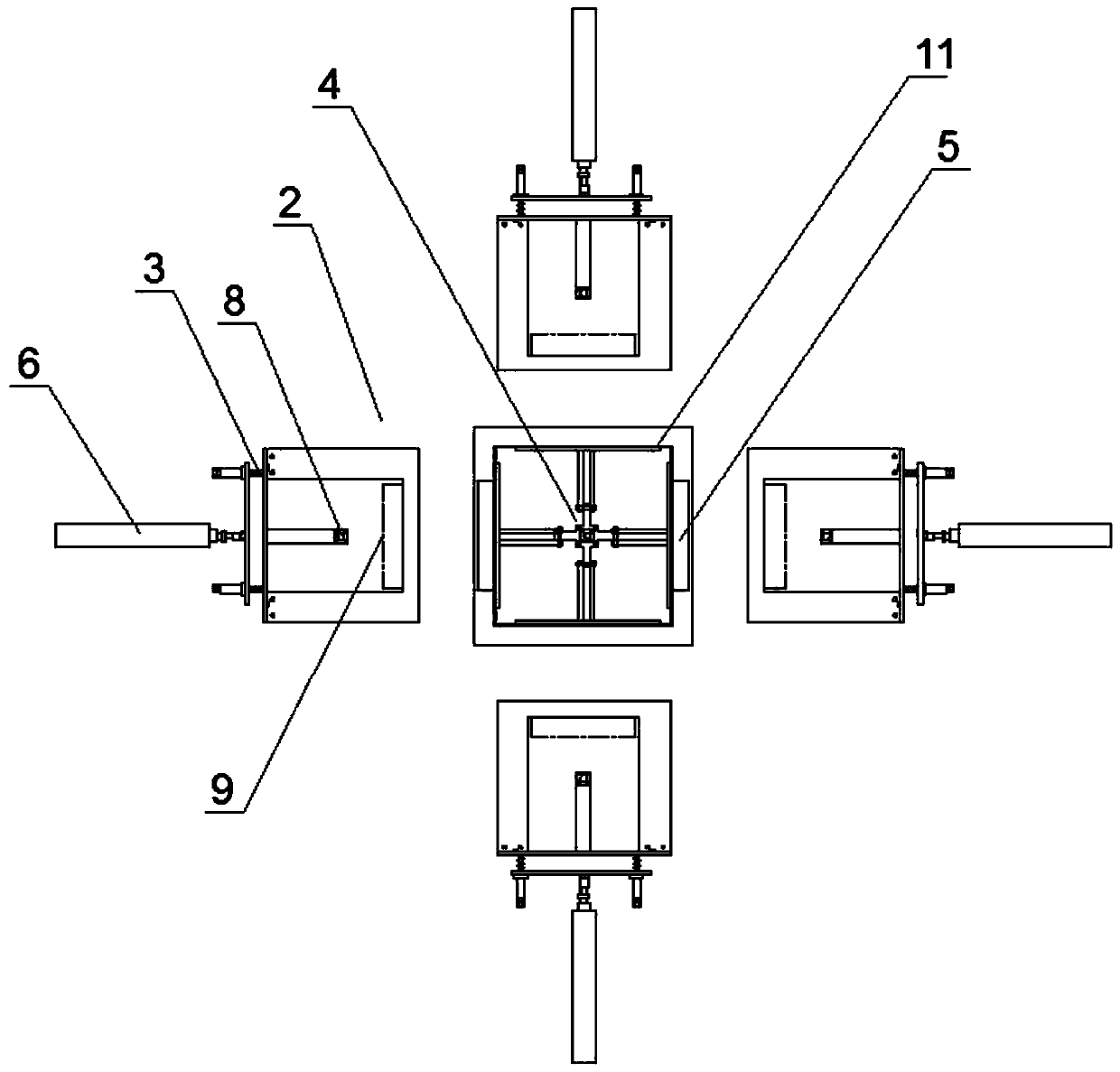

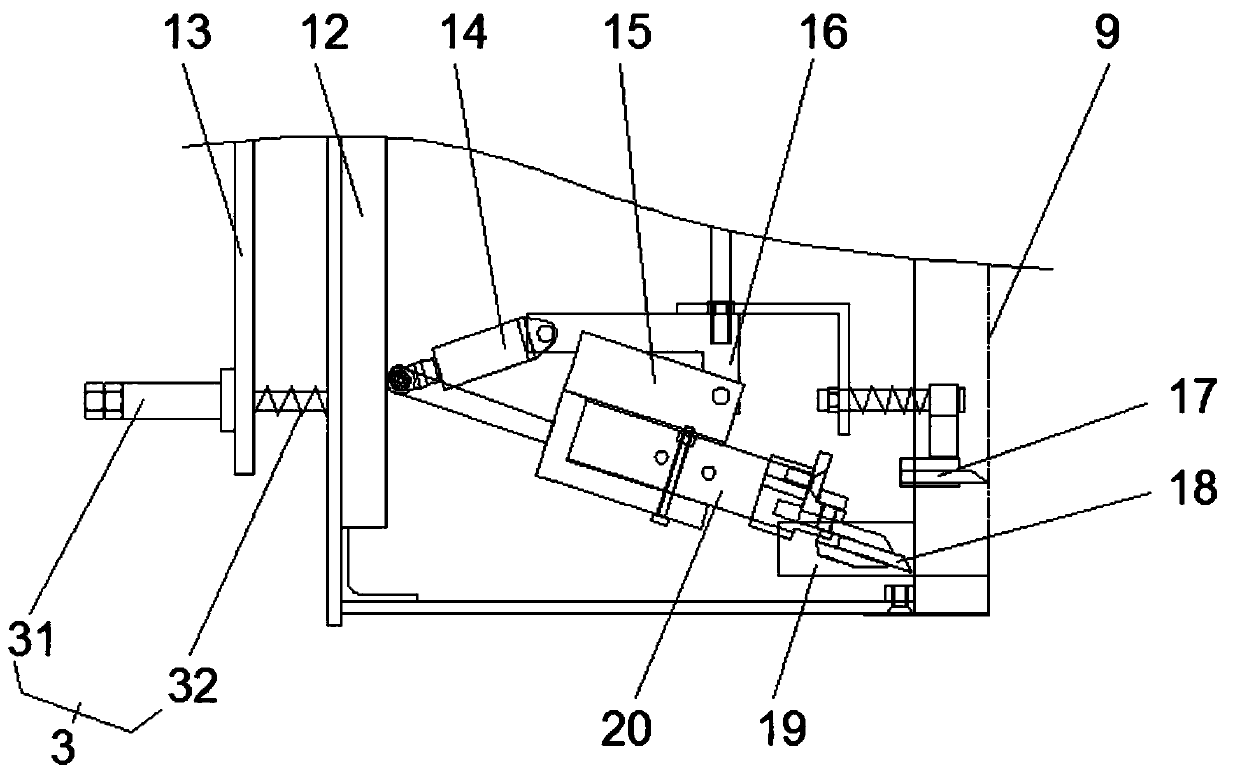

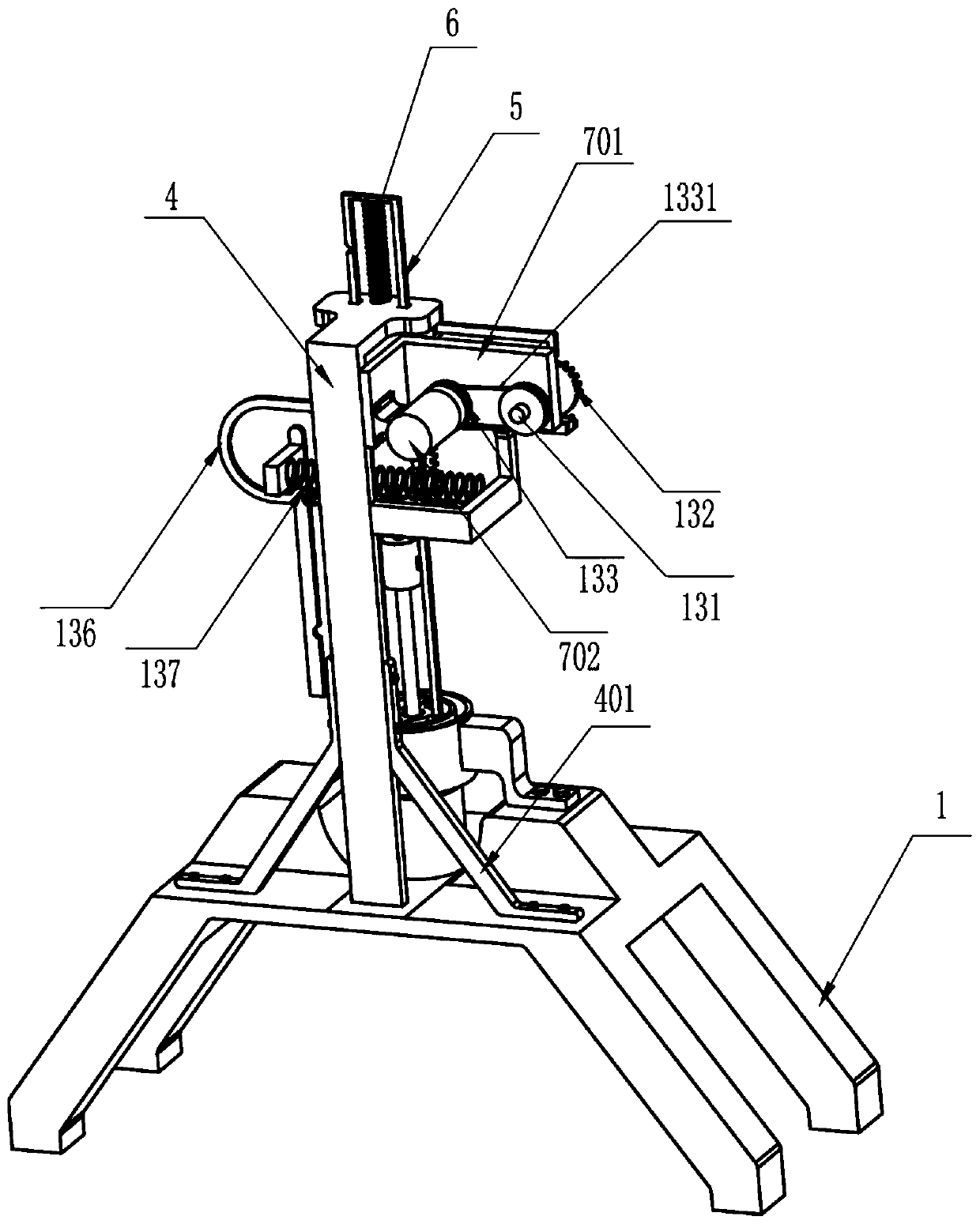

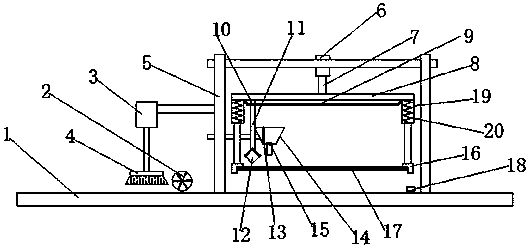

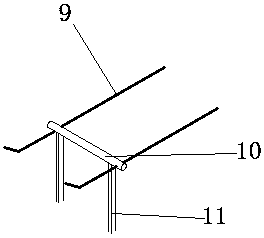

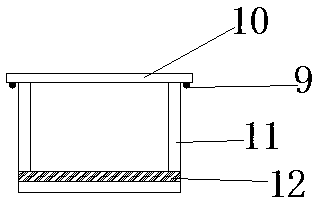

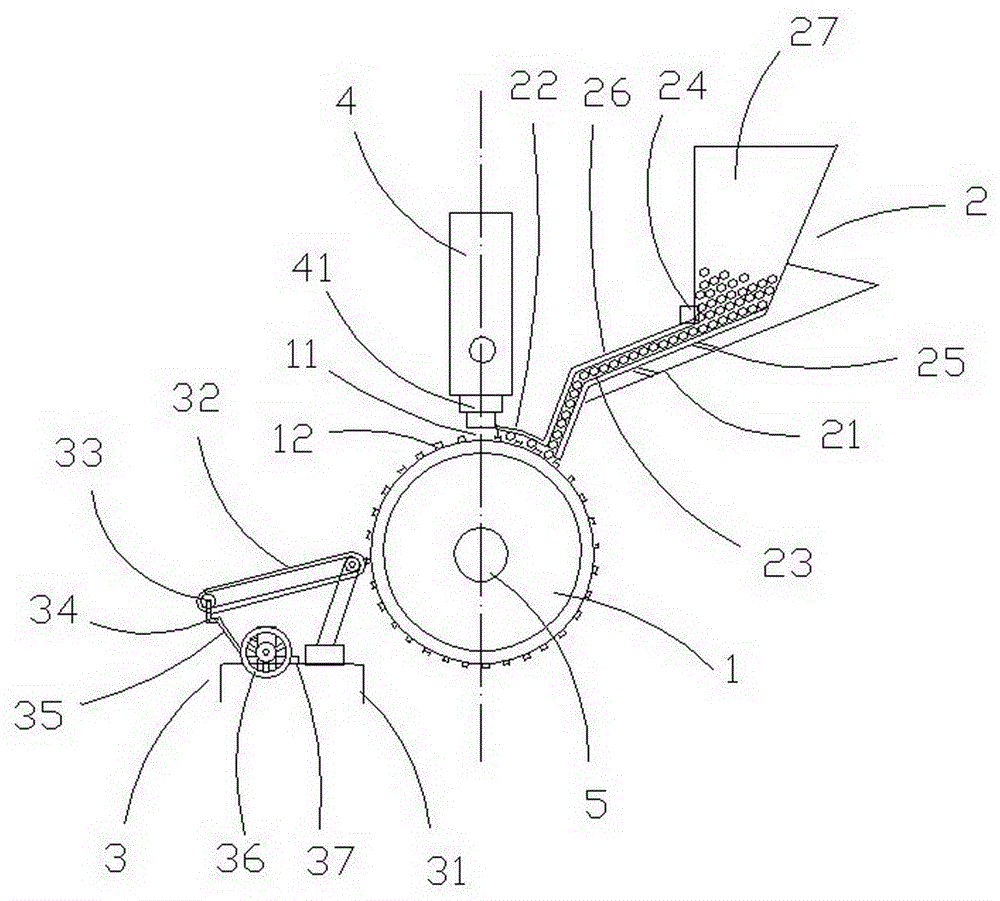

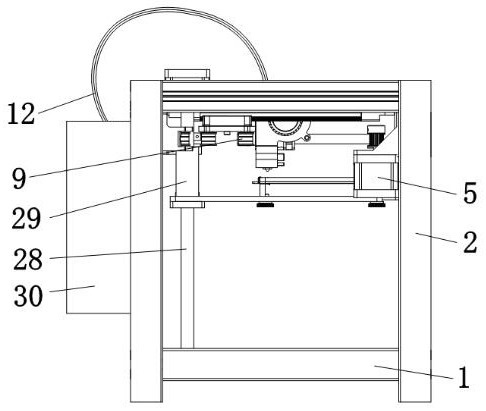

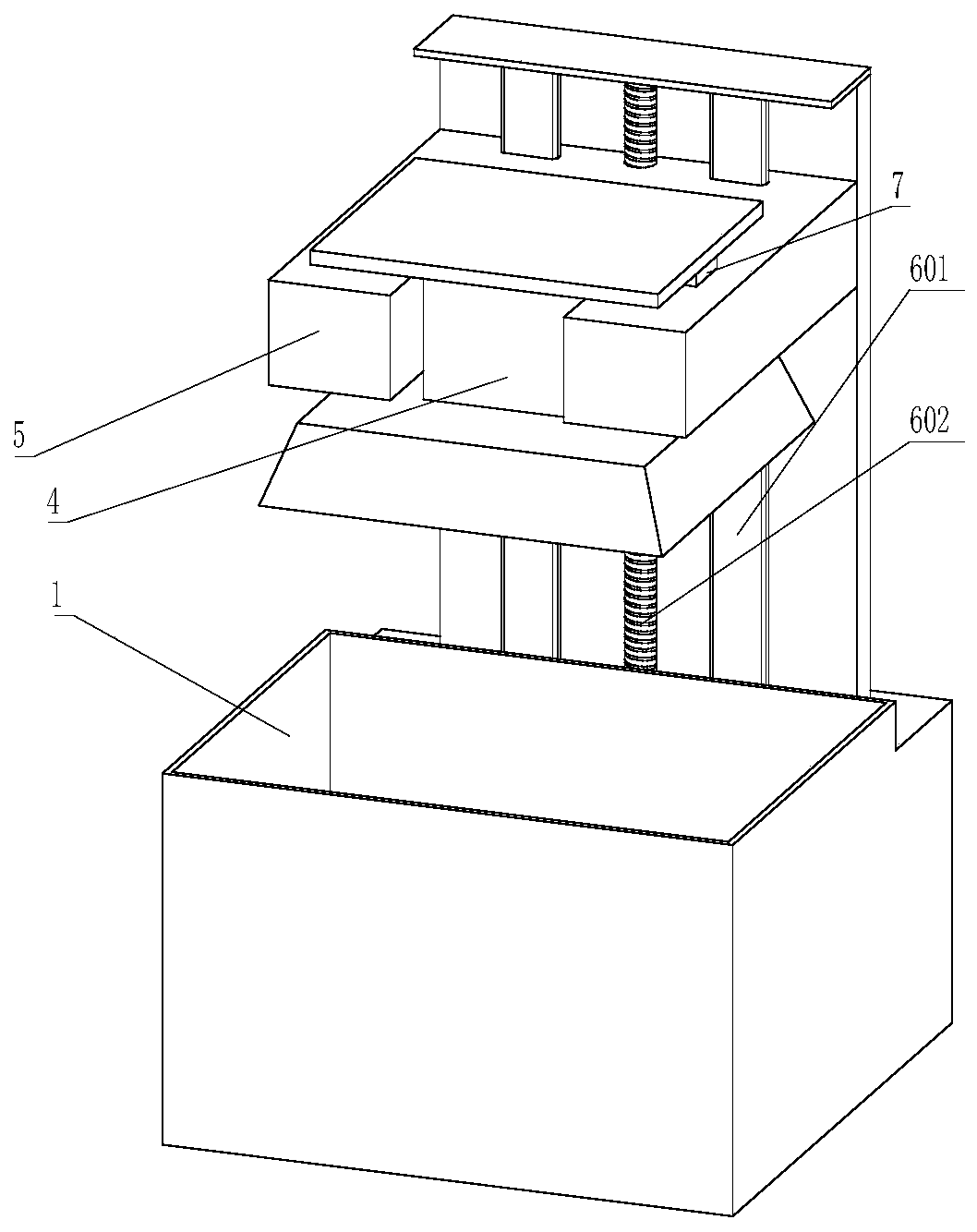

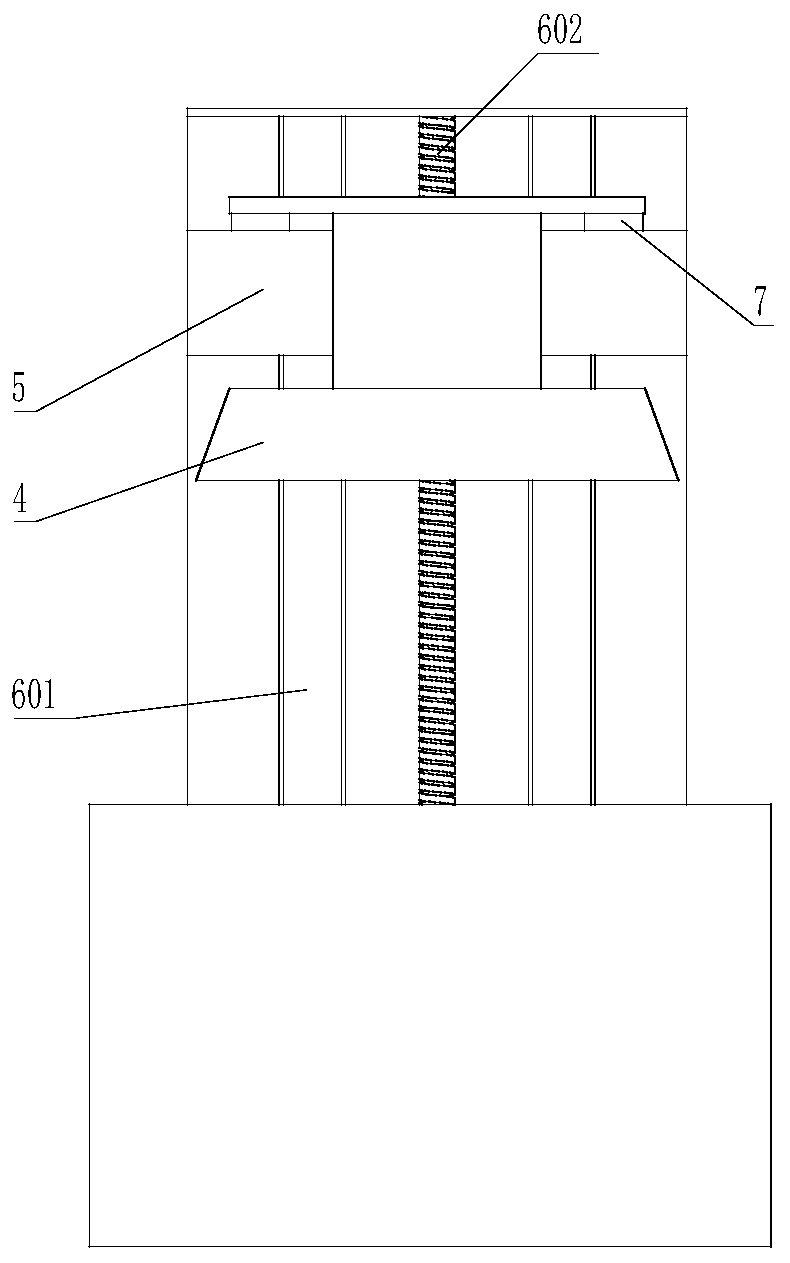

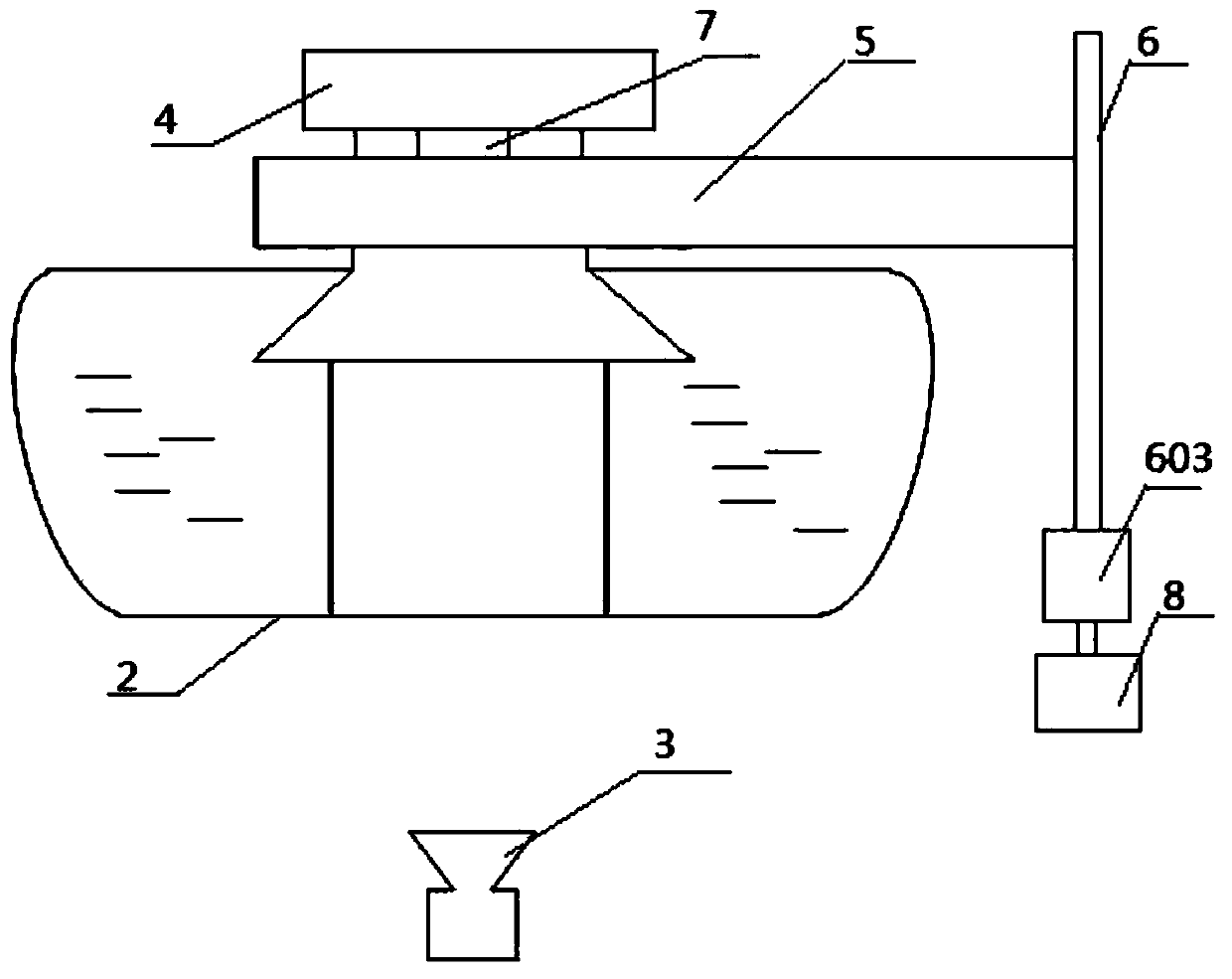

Sorting instrument for sorting blood collection tubes

PendingCN109454020AImprove congestionReduce workloadTypewritersSortingBlood Collection TubeEngineering

The invention discloses a sorting instrument for sorting blood collection tubes. The sorting instrument for sorting the blood collection tubes comprises a machine frame assembly, a single-tube feedingmechanism, a feeding conveying mechanism, a discharging conveying mechanism, a blood collection tube identification device and a sorting assembly, wherein the single-tube feeding mechanism, the feeding conveying mechanism, the discharging conveying mechanism, the blood collection tube identification device and the sorting assembly are all fixed on the machine frame assembly, the feeding conveyingmechanism and the discharging conveying mechanism are installed in parallel, the single-tube feeding mechanism is connected with the inlet end of the feeding conveying mechanism, the blood collectiontube identification device is arranged between the feeding conveying mechanism and the discharging conveying mechanism, and the sorting assembly is arranged on the discharging conveying mechanism. The sorting instrument for sorting the blood collection tubes is high in working efficiency and good in reliability.

Owner:杭州世诺科技有限公司

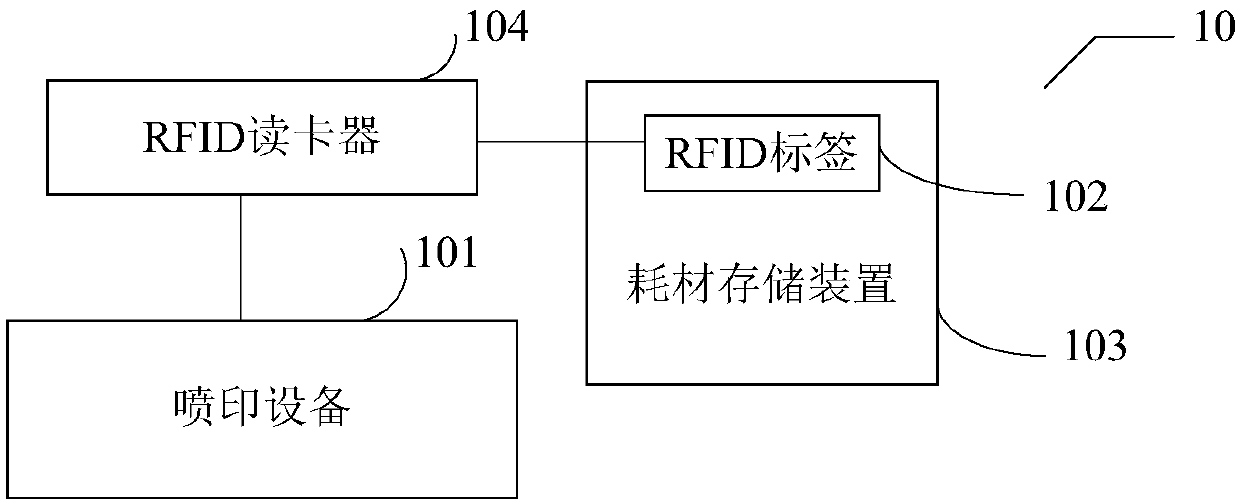

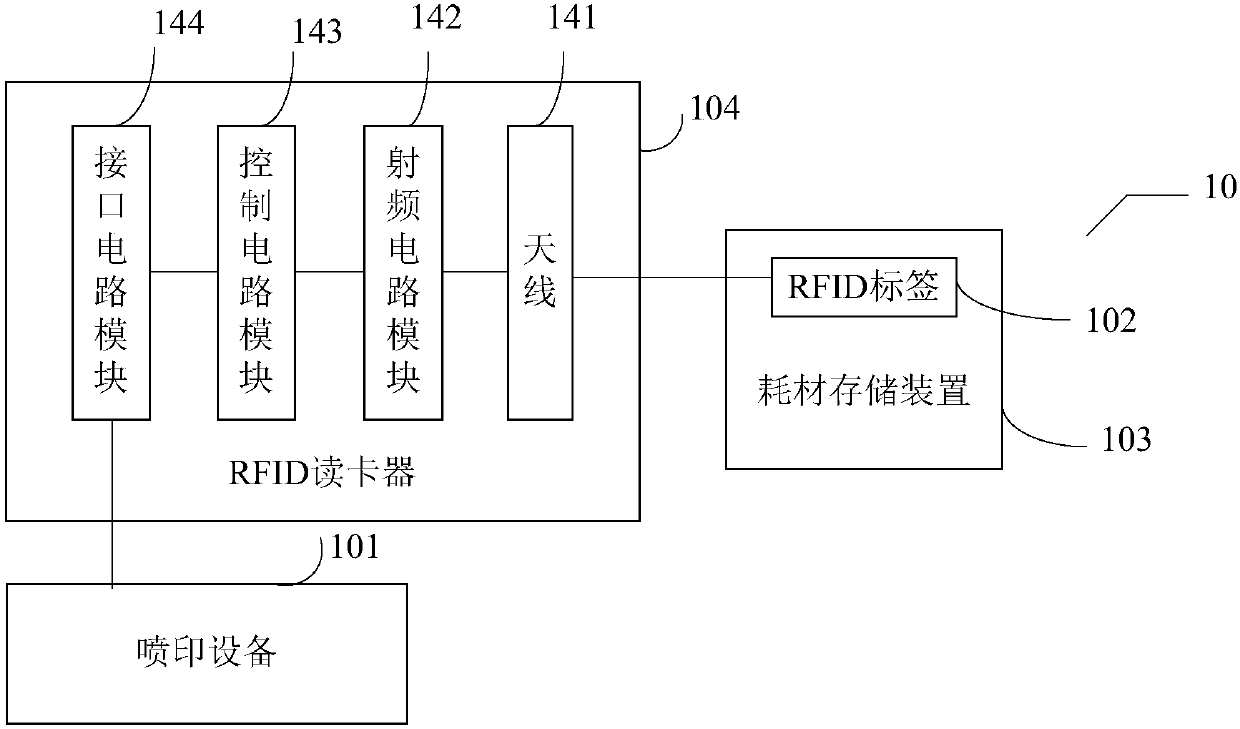

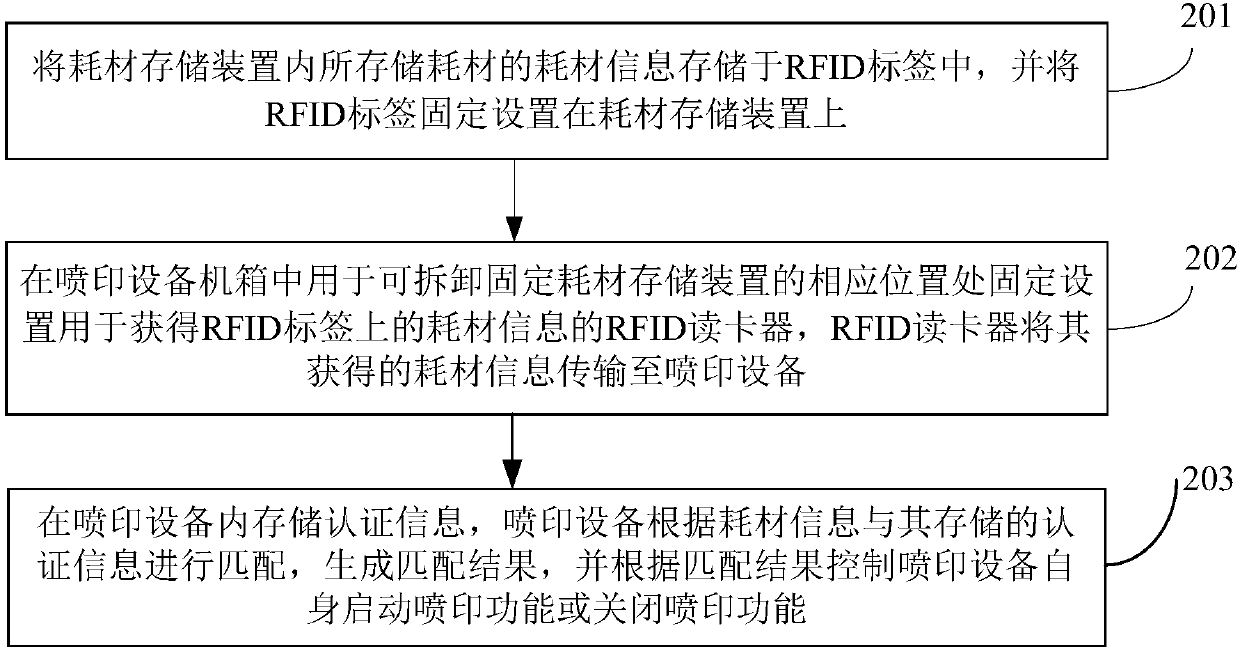

Control system and method of jet printing equipment

The invention provides a control system and a control method of jet printing equipment, which relate to the technical field of jet printing. The system comprises the jet printing equipment, an RFID (radio frequency identification) label, a consumable storage device and an RFID card reader, wherein the RFID label is fixedly arranged on the consumable storage device; the RFID card reader is fixedlyarranged in a corresponding position, which is used for detachably and fixedly installing the consumable storage device, in a jet printing case; the RFID card reader is used for reading the RFID label; the consumable attribute information of consumables stored in the consumable storage device is stored in the RFID label; the RFID card reader is in communication connection with the jet printing equipment; the consumable attribute information on the RFID label is obtained and is transmitted to the jet printing equipment by the RFID card reader; the consumable attribute information is matched with authentication information stored in the jet printing equipment by the jet printing equipment so as to generate matching results; and the jet printing equipment is controlled to automatically starta jet printing function or shut off the jet printing function according to the matching results. According to the control system, the consumables which are matched with the jet printing equipment canbe used by the jet printing equipment.

Owner:北京赛腾标识系统股份公司

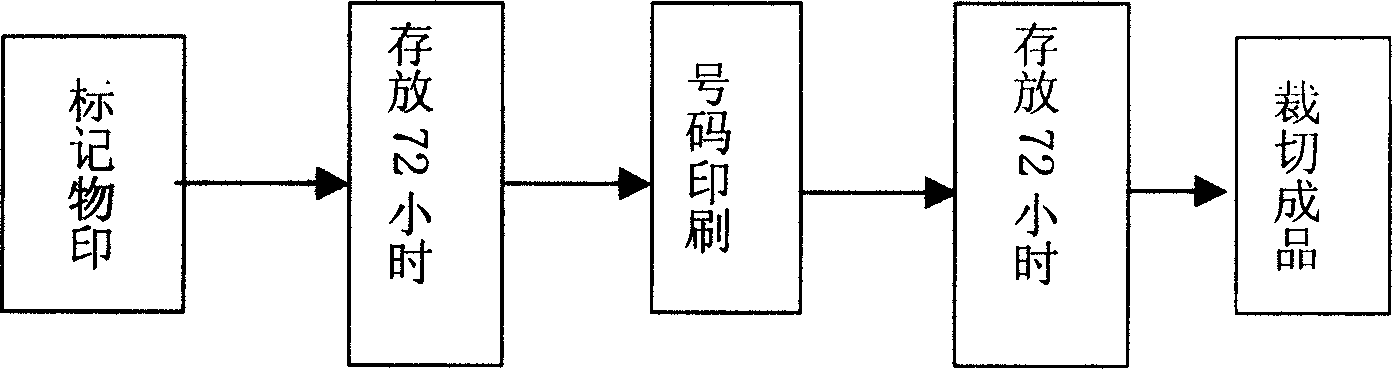

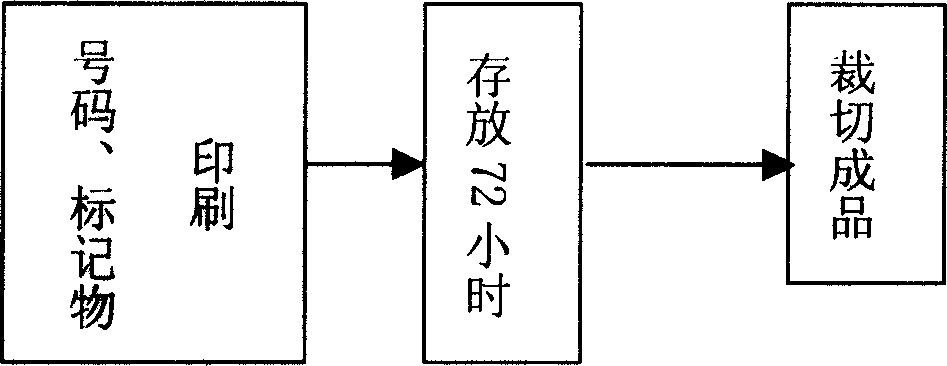

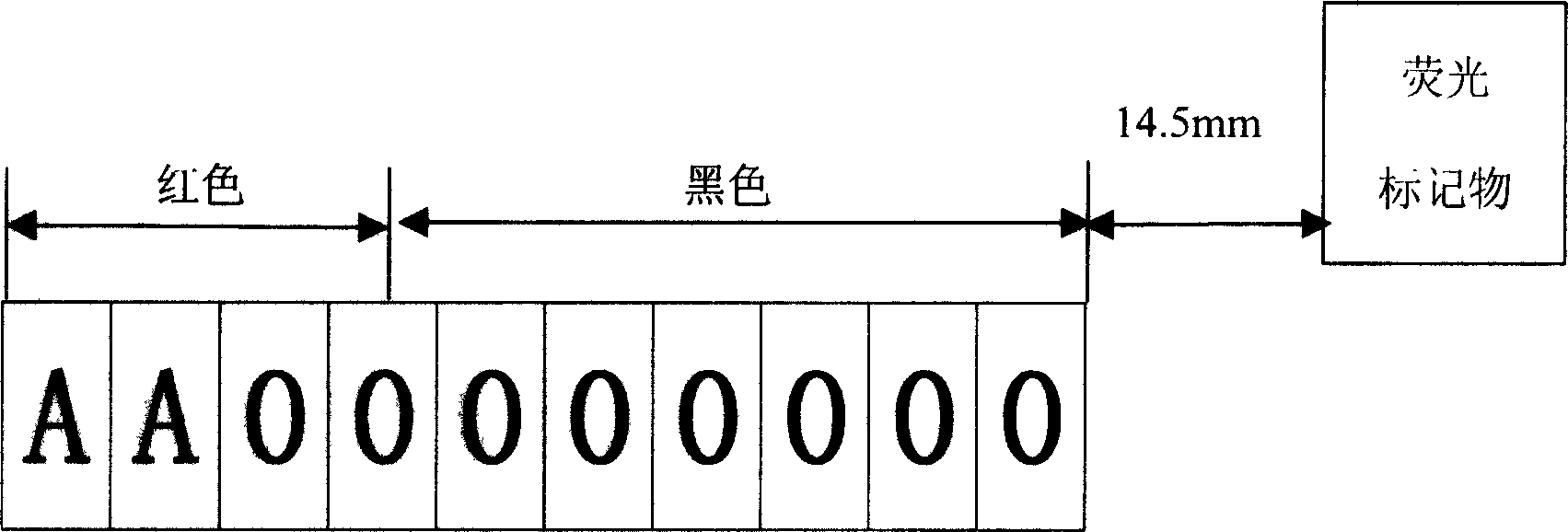

Single number two-color wiring fluorescence label typography

InactiveCN1565855AReduce storageShorten drying timePattern printingFluorescenceMechanical engineering

The invention relates to an once printing process for single-code two-color wiring and fluorescent label comprising (1) setting the axial movement of the code printing machine of the inking unit to be 0-12mm, regulating the axial movement of the ink vibrators, (2) confirming the printing positions of the code wiring and fluroscent label, dividing the ink fountain with color separation films, slitting the lower ink vibrator, ink transfer roller, ink distributing roller, plate approaching roller, and outputting three different inks from the same ink fountain, (3) milling a groove which is 5mm below the fluorescent ring surface and in which the code machine ektexine can move up and down. The invention can shorten the process period, and decrease the production cost, and the printing articles produced thereby are anti-counterfeiting and machine readable.

Owner:CHINA BANKNOTE PRINTING & MINTING

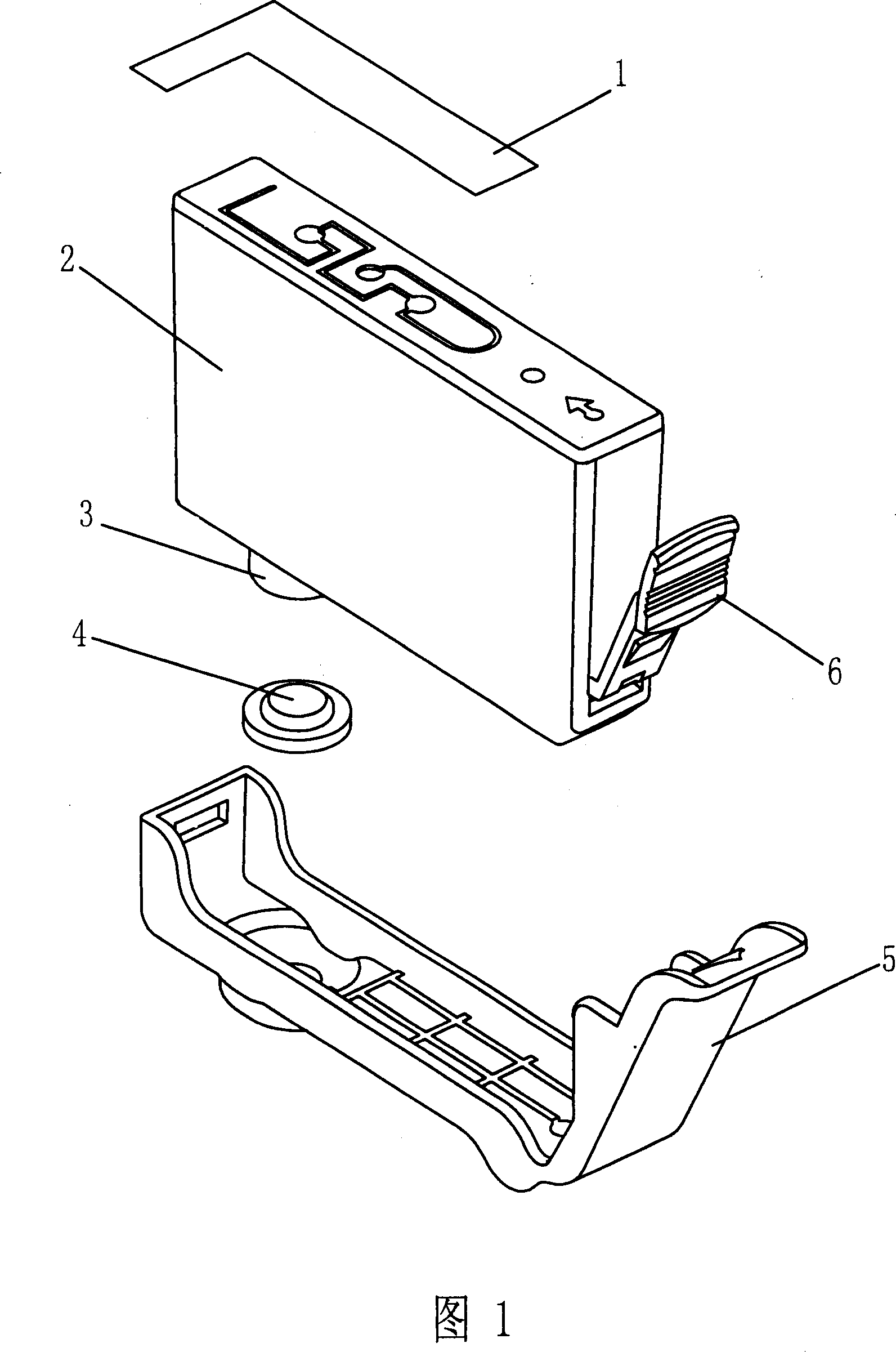

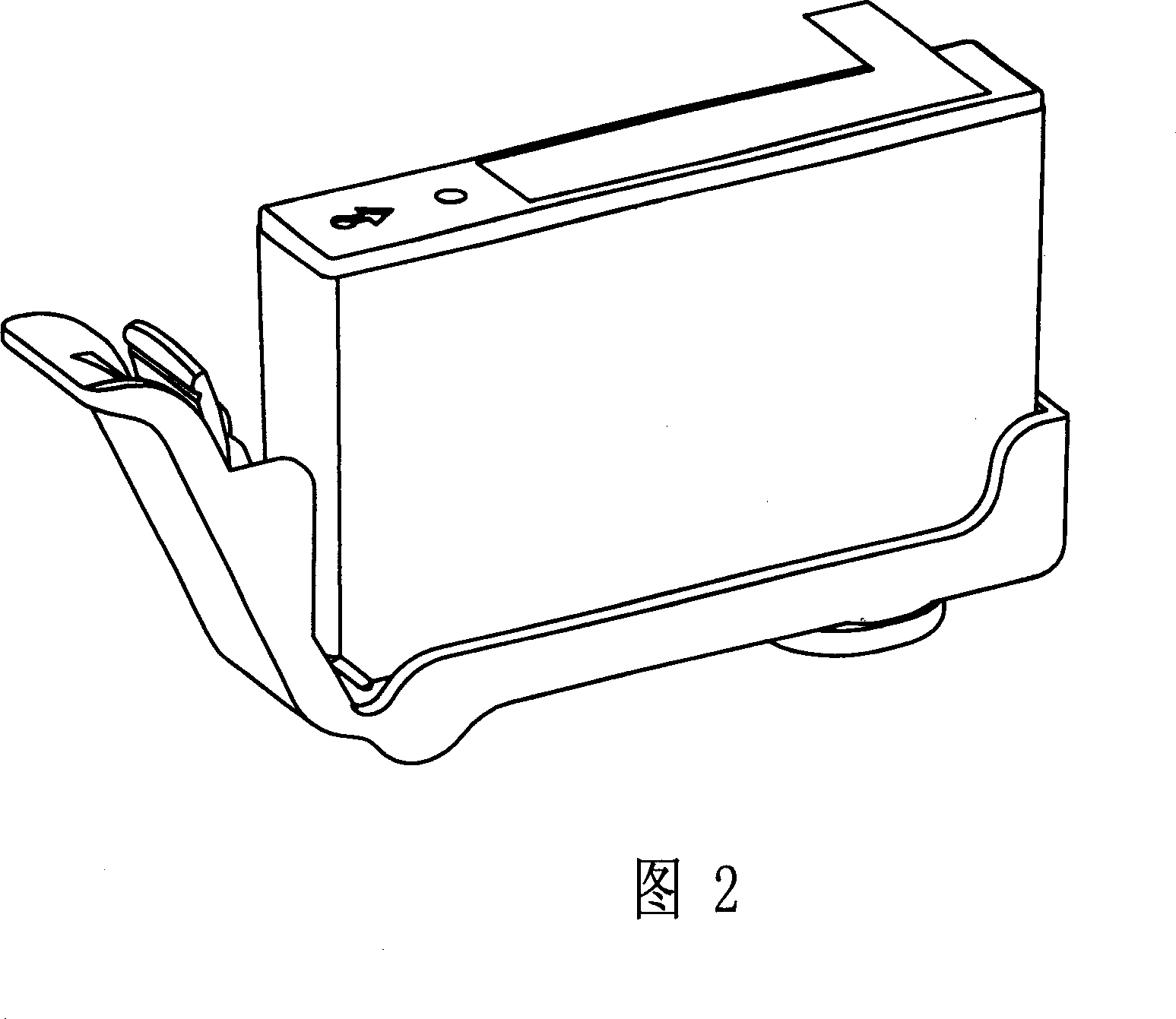

Method for filling ink into inkjet ink box

ActiveCN102806773AGuaranteed printing effectGuaranteed intake effectPrintingEngineeringElectrical and Electronics engineering

Owner:ZHUHAI NINESTAR MANAGEMENT CO LTD

Combined printing process for cigarette case

InactiveCN108928112AControl printing costsGuaranteed printing effectRotary intaglio printing pressOther printing apparatusComputer engineeringOffset printing

The invention belongs to the technical field of printing, and specifically discloses a combined printing process for a cigarette case. The combined printing process comprises the following steps of: cutting paper, performing sliver gravure printing, performing offset printing, polishing, performing gold stamping, performing concave and convex embossing, transferring and polishing, performing die-cutting, clearing up and packaging. According to the combined printing process disclosed by the invention, various printing ways are combined, and are reasonably selected, so that the printing effect is guaranteed while printing cost is controlled.

Owner:JIANGSU UNICOM ERA PRINTING CO LTD

Regeneration of ink box for ink-jetting printer

InactiveCN101073947ASimple production processThe production process is easy to controlPrintingEngineeringConcave surface

The invention is concerned with the regeneration method for ink jet printer, includes the following steps: takes off the old air film of the ink container; cleans the old cotton core in the ink outputting mouth; throws off the remainder ink in the ink box; infuses ink into the ink box by the ink outputting mouth, sets the silicagel underlay and the protective case for the ink outputting mouth in turn, the protective case can protect the bottom of the ink container and the tie bar on the ink container sidewall; welds the new air film. The silicagel underlay is a rotundity underlay, the jut of it combines with the ink outputting mouth, the concave surface of the underlay faces downwards and joints with the corresponding part of the protective case. The protective case is with a long groove that is used to contain the bottom of the ink container, the sideling handle on the groove is used to contain and fix the tie bar of the ink container in the handle.

Owner:NINESTAR IMAGE CO LTD

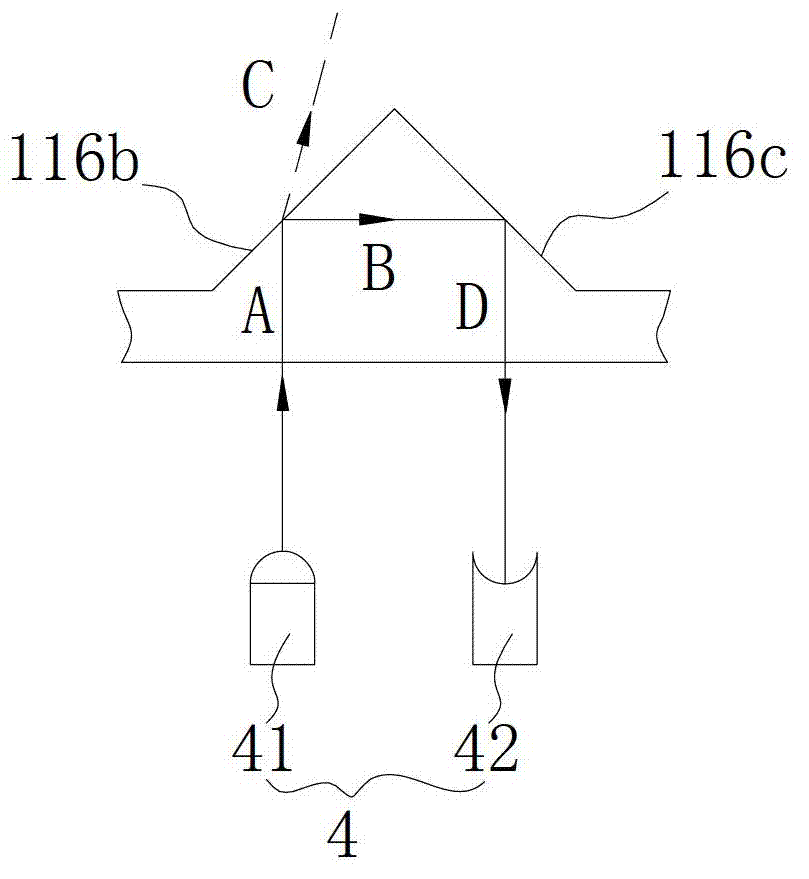

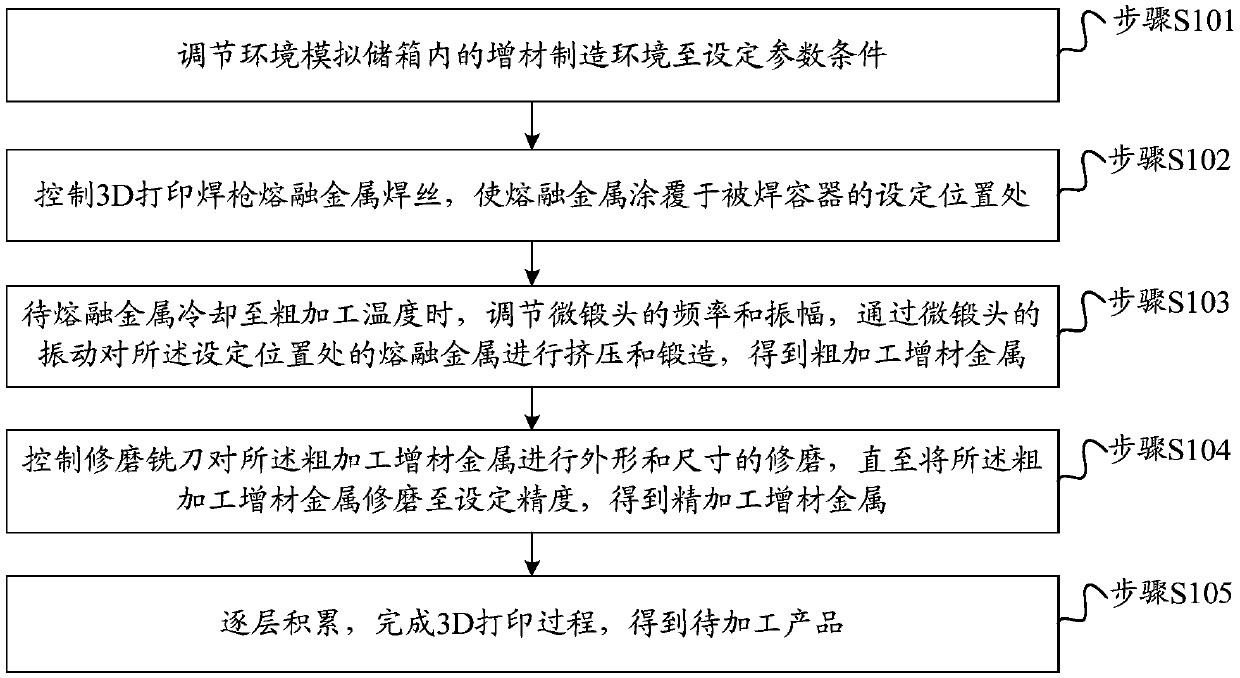

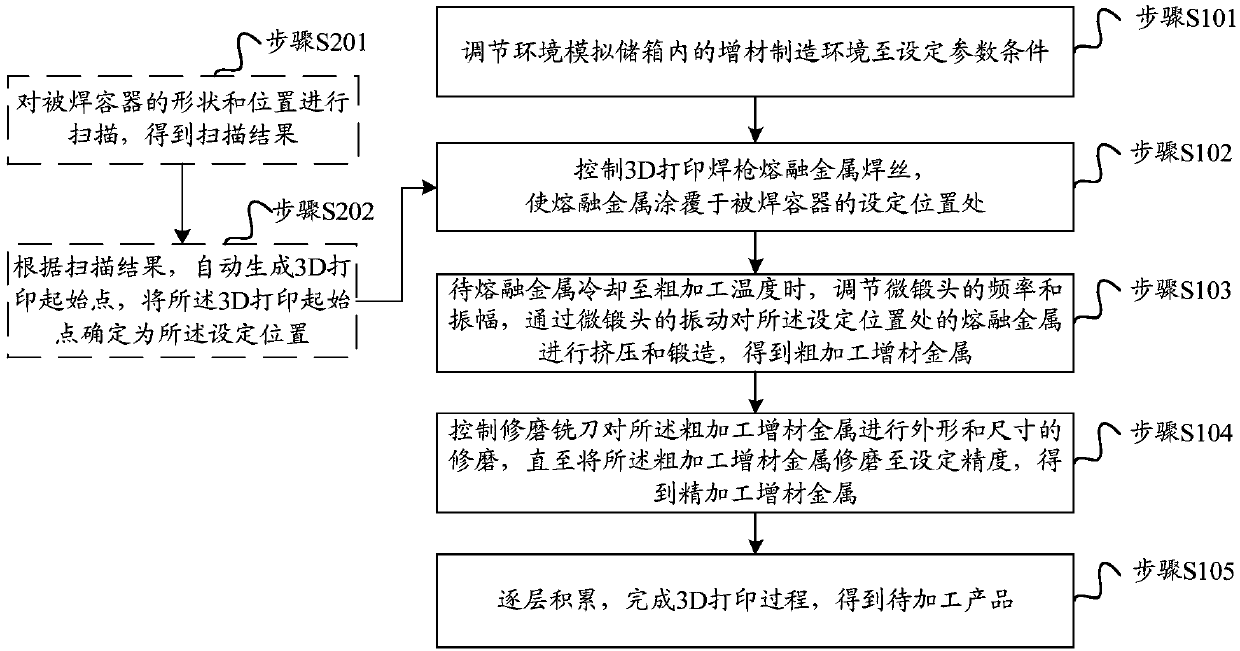

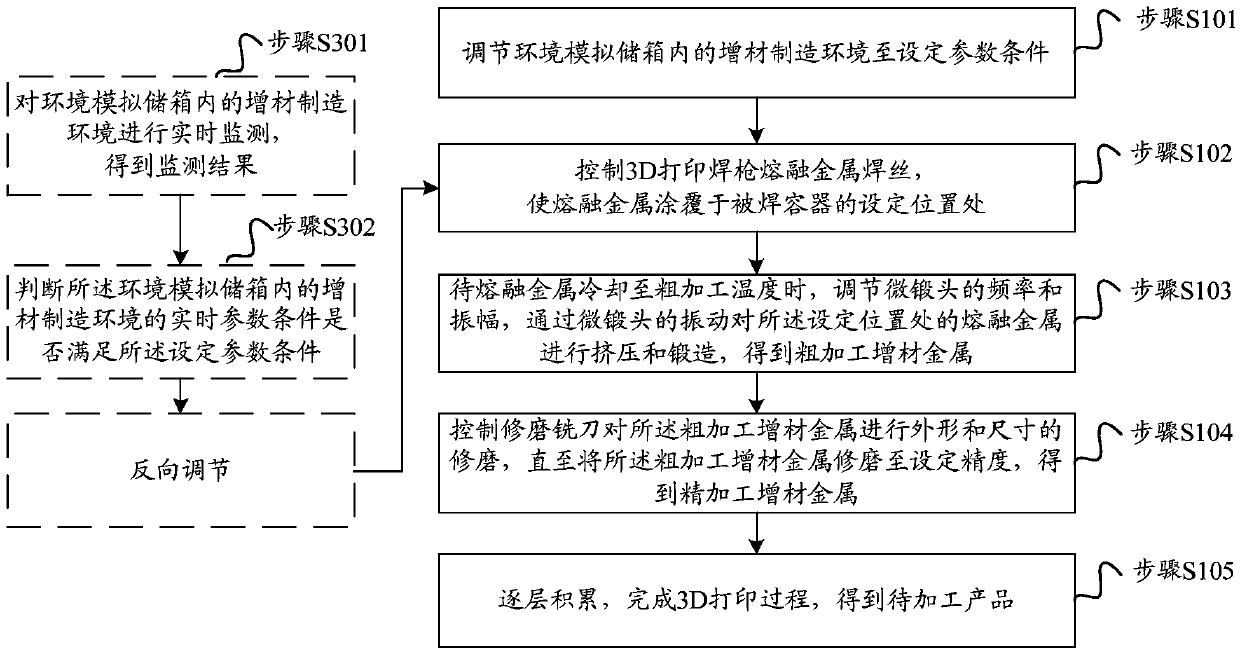

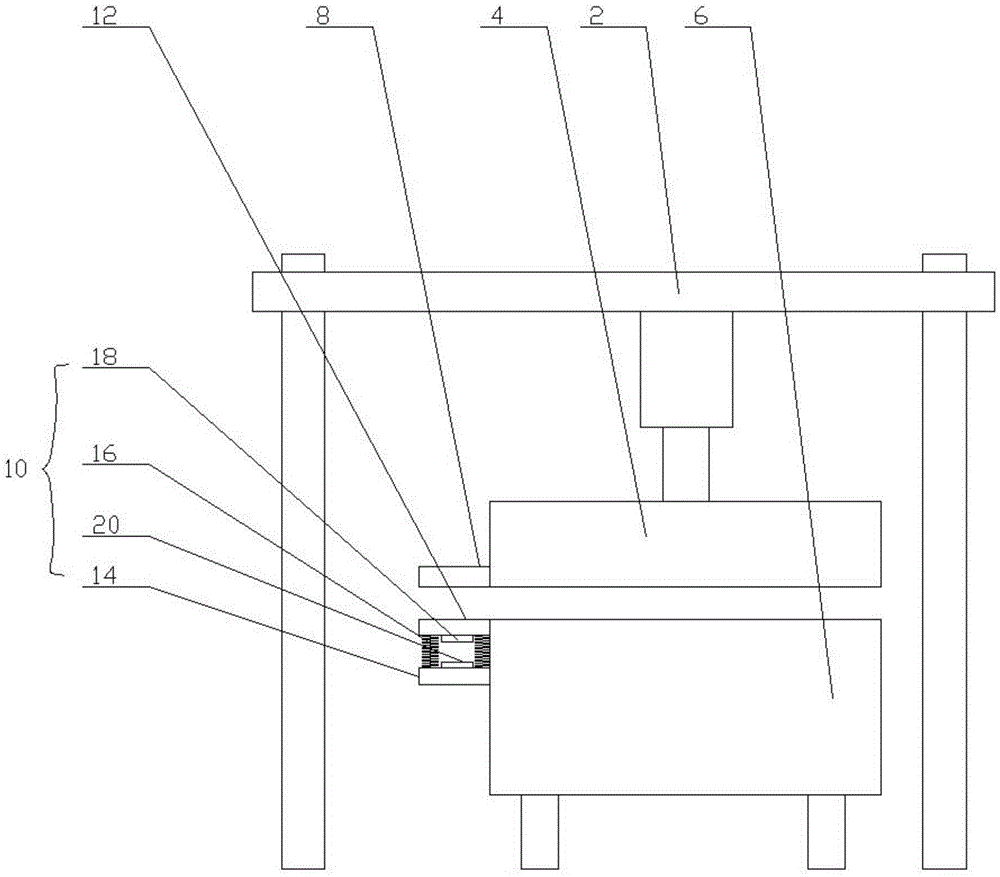

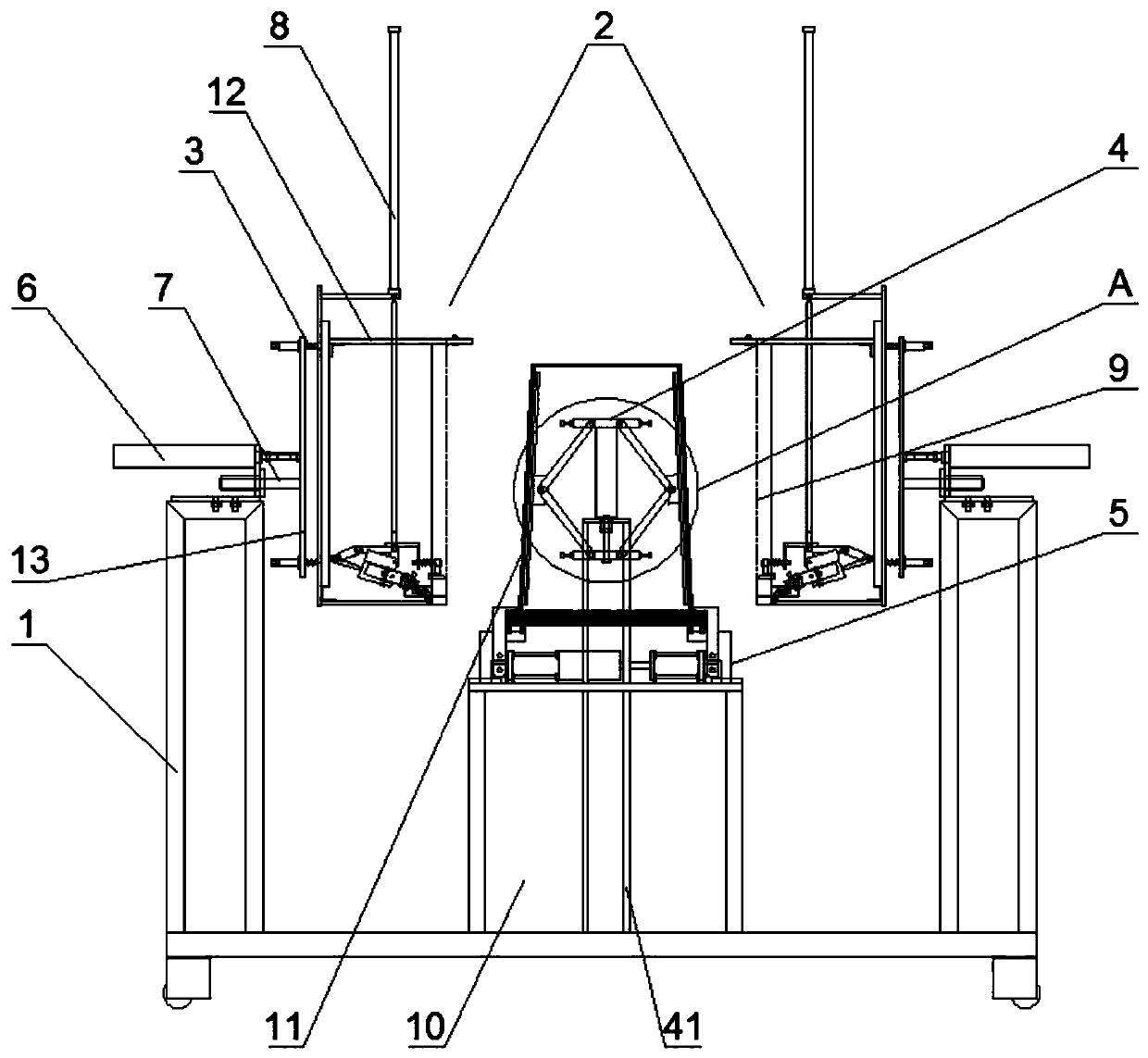

Method and device for manufacturing metal lining of 3D printing composite material space pressure vessel

InactiveCN109590678AGuaranteed printing effectTo achieve the printing effectOther manufacturing equipments/toolsMilling cutterEnvironmental simulation

The invention discloses a method and device for manufacturing a metal lining of a 3D printing composite material space pressure vessel. The manufacturing method comprises the steps that an additive manufacturing environment of an environmental simulation storage tank is adjusted to a set parameter condition; a 3D printing welding gun is controlled to fuse a metal welding wire, and molten metal iscoated to a set position of the welded vessel; after the molten metal is cooled to the rough machining temperature, the frequency and the amplitude of a micro forging head are adjusted, the molten metal at the set position is pressed and forged through vibration of the micro forging head, and rough machining additive metal is obtained; a grinding milling cutter is controlled to conduct appearanceand size grinding on the rough machining additive metal until the rough machining additive metal is ground to the set accuracy, and finish machining additive metal is obtained; and layer-by-layer accumulation is carried out, the 3D printing process is completed, and a product to be processed is completed. According to the method and device, the fusing-forging integration process is used for producing the lining of the pressure vessel or a thin-walled pressure vessel, influences of machining like welding on the product quality are reduced, and the precision and the tissue performance of the molded product are improved.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Extrusion stretching type pre-coating film and preparation method thereof

ActiveCN104497901AHigh mechanical strengthHigh degree of peelingFilm/foil adhesivesPolymer scienceBoPET

Owner:ANHUI GUOFENG PLASTIC

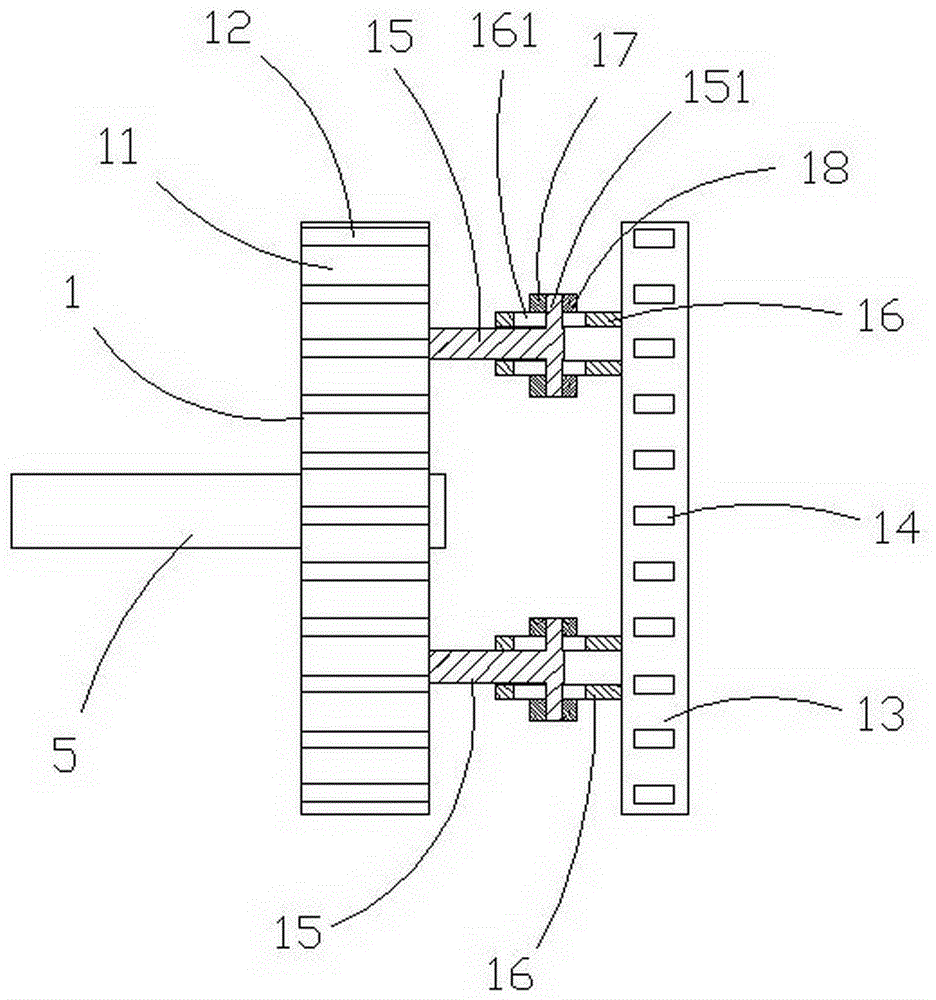

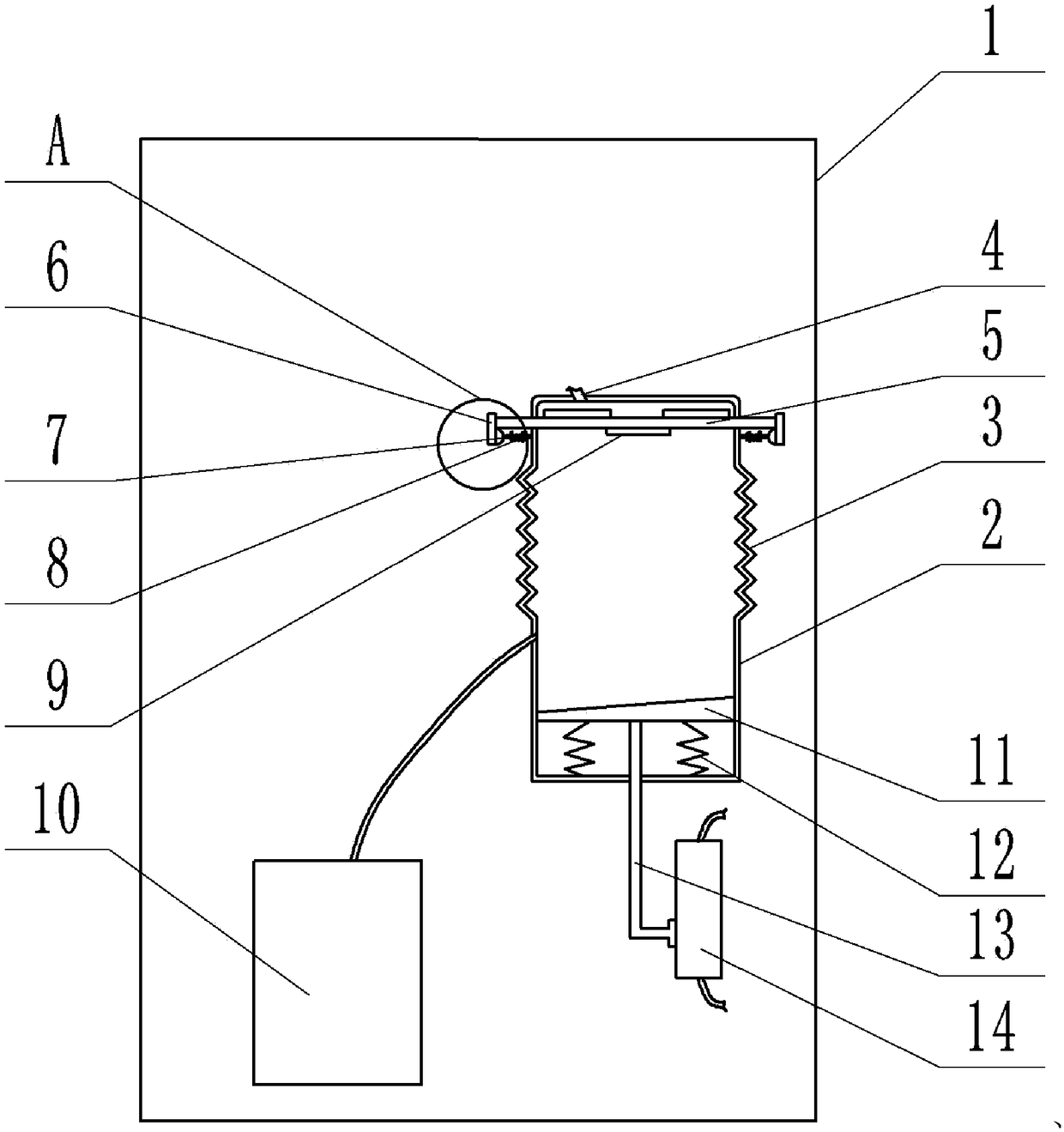

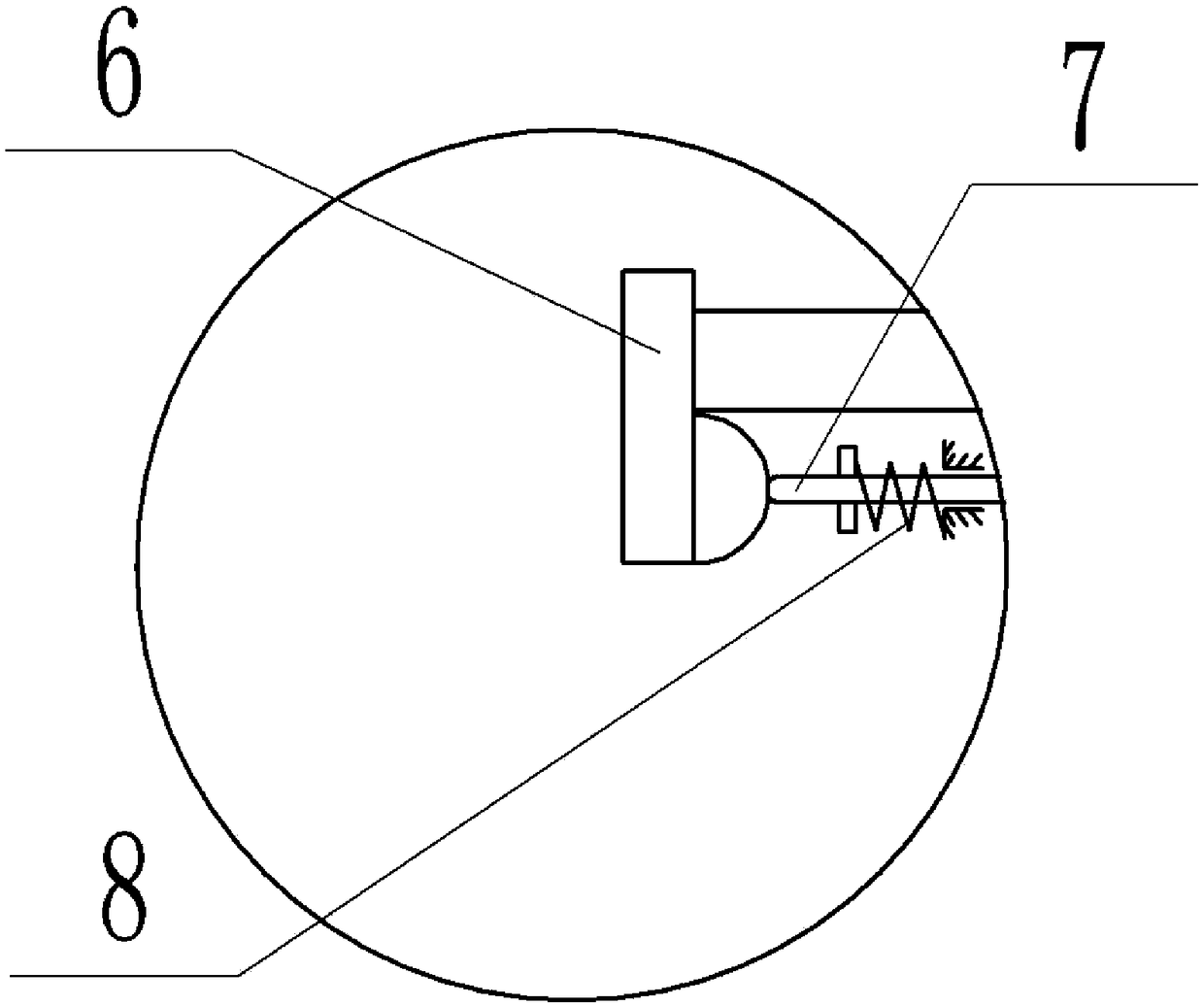

Anti-scratching scraper for circuit board

The invention discloses an anti-scratching scraper for a circuit board. The anti-scratching scraper comprises a rack (2), a scraper (4) and a circuit board (6), wherein the scraper (4) is fixed on the rack (2) and can be lifted up and lowered through a power device; the circuit board (6) is arranged right below the scraper (4); the anti-scratching scraper is characterized by further comprising an extending end (8) and a control device (10); the control device (10) comprises a first connecting plate (12) and a second connecting plate (14) which are horizontally fixed on a side surface of the circuit board (6). According to the anti-scratching scraper, when the scraper (4) moves downwards to a set value, the sum of the generated pressure and the attraction force acting on a fixing block (18) generated by a magnet (20) is greater than the deformation resistance of a spring (16), then the fixing block (18) can be adsorbed on the magnet (20), moreover, a contact switch is in contact with the magnet (20) so as to control the power device to stop operation, therefore, the scraper (4) can be in direct and sufficient contact with the circuit board (6), a printing effect can be ensured, the circuit board (6) can be prevented from being crushed under compression, and problems of the prior art can be solved.

Owner:SUZHOU ENOUXI INTELLIGENT TECH CO LTD

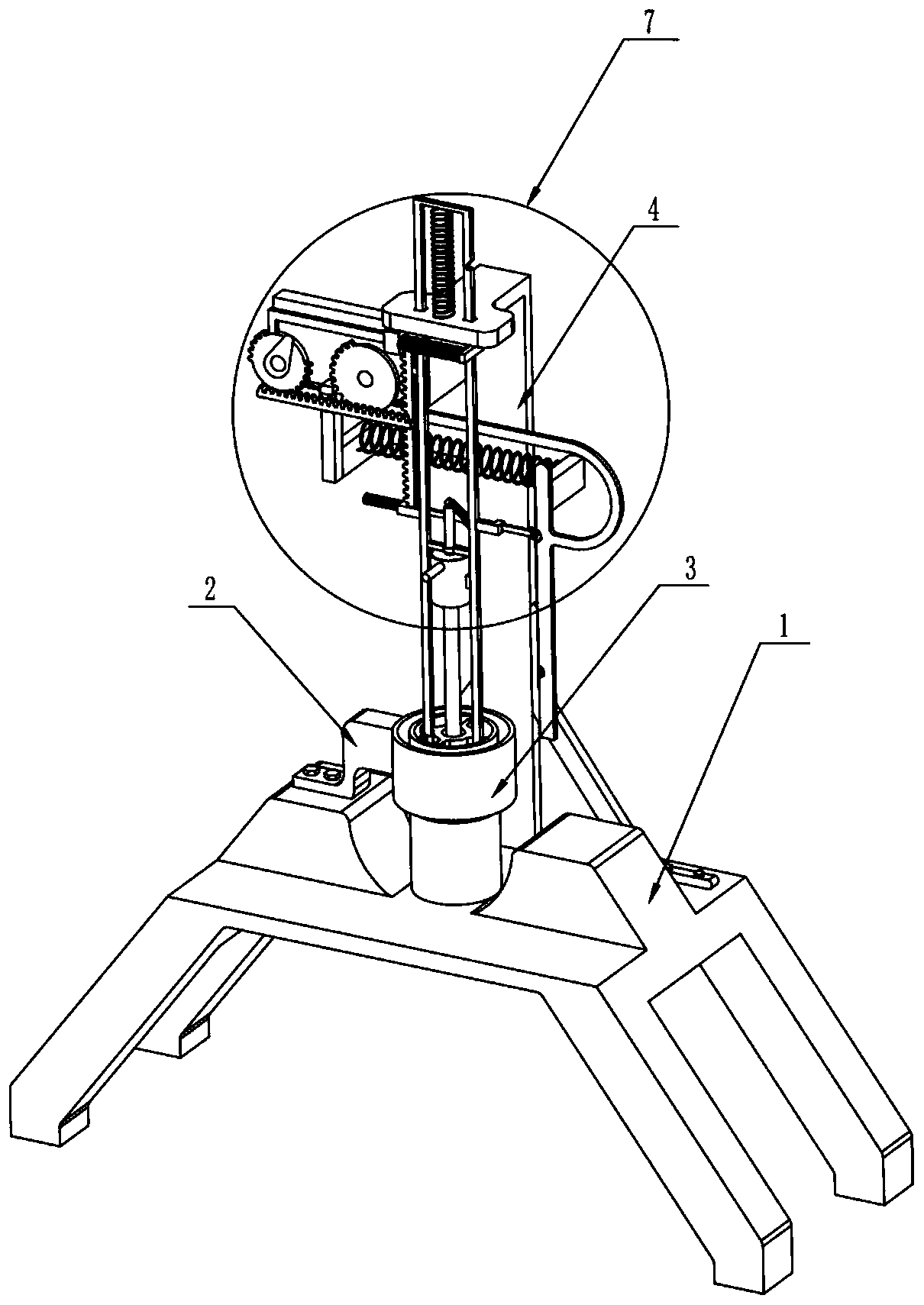

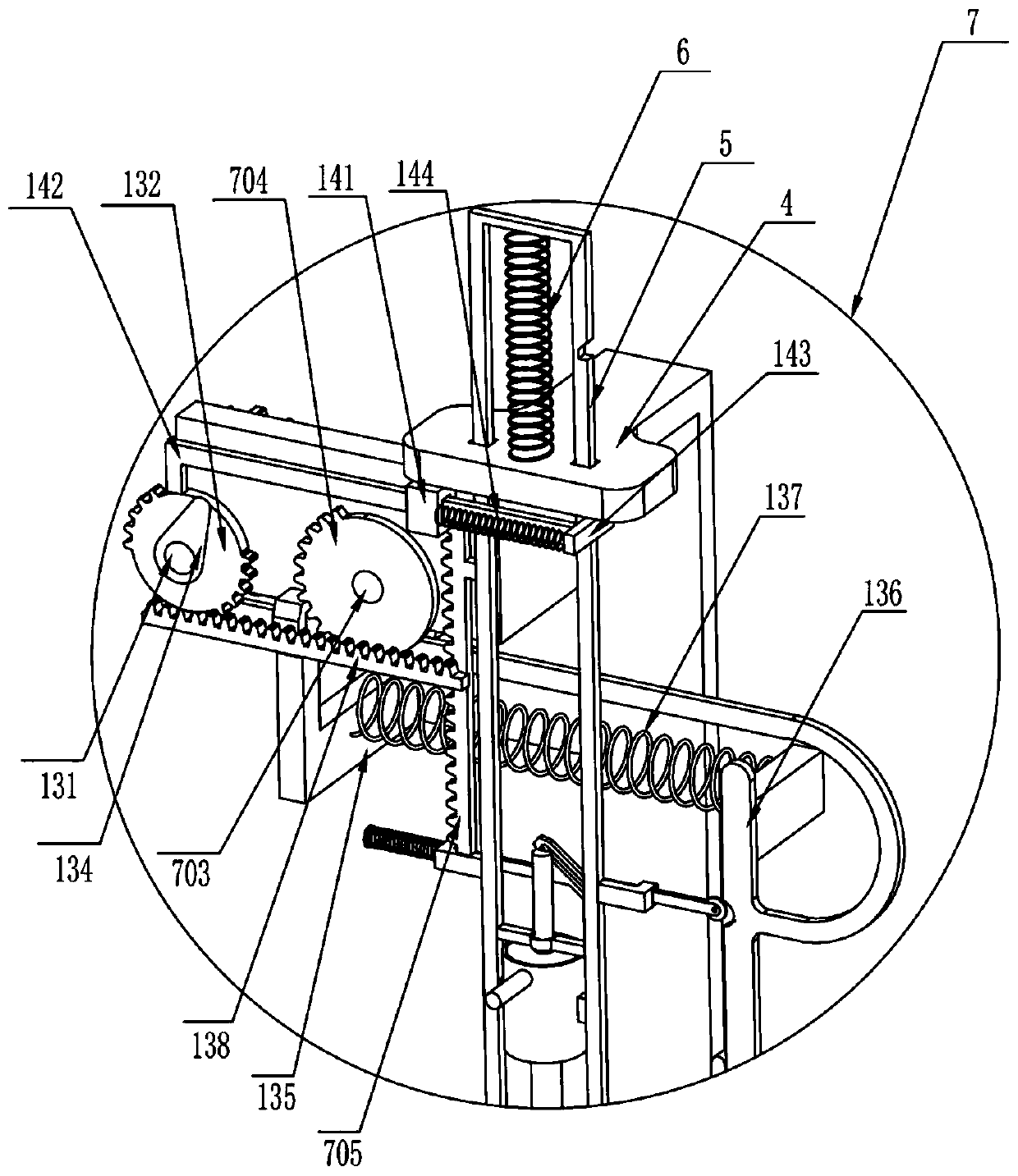

Full-automatic vertical-surface screen printing machine and multi-surface printing process thereof

PendingCN110450525AReduce labor intensityGuaranteed printing effectScreen printersOther printing apparatusScreen printingUltimate tensile strength

The invention discloses a full-automatic vertical-surface screen printing machine and a multi-surface printing process thereof, and relates to the field of screen printing. The full-automatic vertical-surface screen printing machine specifically comprises a machine frame, wherein the peripheral sides of the upper surface of the machine frame are provided with screen plate assemblies for printing aworkpiece so that printing work can be carried out on the surface of the workpiece through the screen plate assemblies; and the middle of the upper surface of the machine frame is fixedly connected with a supporting platform, wherein a clamping and positioning mechanism for clamping and fixing the workpiece and an expansion shaping mechanism for flattening the workpiece through expansion are sequentially arranged above the supporting platform. According to the full-automatic vertical-surface screen printing machine and the multi-surface printing process thereof, a printing manner is designedas vertical surface printing so that multiple surfaces of one product can be simultaneously printed, thus greatly improving production efficiency and reducing labor intensity of operators as well as occupied areas for production; and meanwhile, through cooperation of a self-fitting mechanism, the expansion shaping mechanism and the clamping and positioning mechanism, printing steps are simplified,and the printing effect of the product is improved.

Owner:湖北天佳日用品有限公司

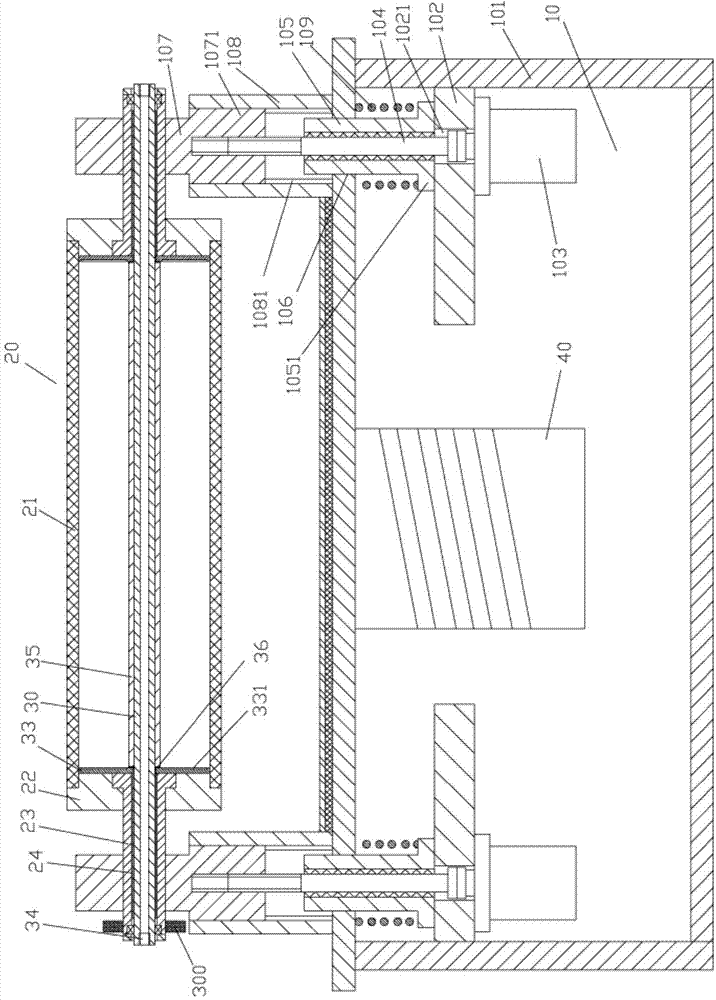

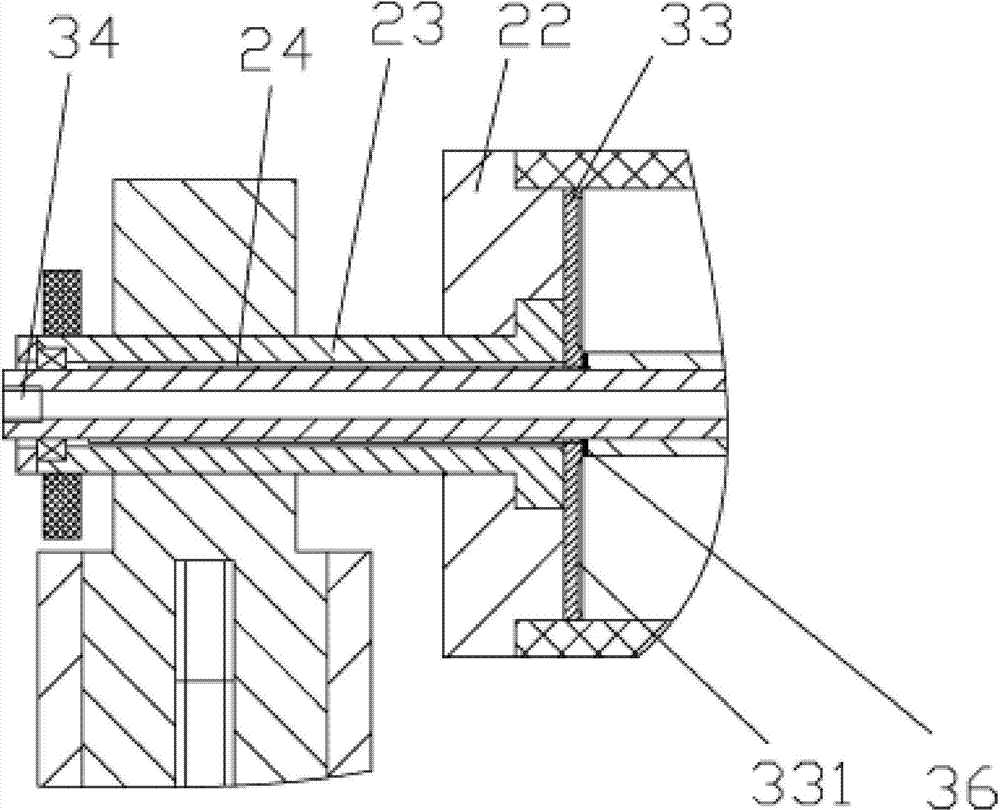

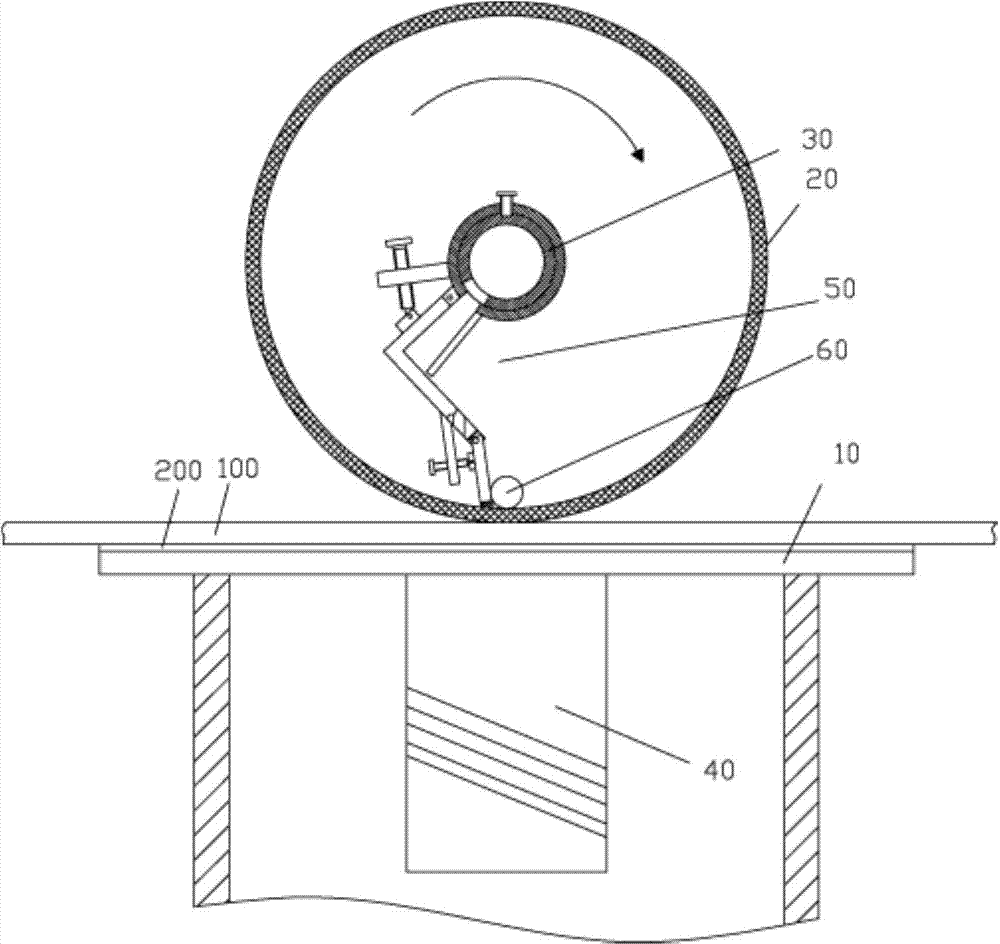

Inflatable ceramic inner wall printing device

ActiveCN111559167AEven print jobImprove printing efficiencyRotary pressesOther printing apparatusTextile printerPrinting press

The invention relates to the technical field of ceramic printing, in particular to an inflatable ceramic inner wall printing device which is provided for achieving the technical effects of being capable of printing patterns on the inner walls of different types of ceramics, uniform in pigment printing and capable of ensuring the printing effect. According to the technology implementation scheme, the inflatable ceramic inner wall printing device comprises a supporting base, a connecting seat, a sponge storage disk, a fixed plate, stabilizing supports, a sliding rod I, a return spring I, a hollow frame, a circular sliding plate, a pattern plate, clamp nails and the like. One end of the connecting seat is fixedly mounted on the supporting base. The sponge storage disk is fixedly mounted at the other end of the connecting seat. One end of the fixed plate is fixedly mounted on the supporting base. The inflatable ceramic inner wall printing device is provided with a printing mechanism and alifting component, can automatically inflate air into a dyeing airbag to expand, be stained with pigment and move into ceramic to conduct uniform printing on the inner wall of the ceramic, and ensuresthe ceramic inner wall printing effect while improving the printing efficiency.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

Printed circuit board processing device

InactiveCN108243576AGuaranteed printing effectImprove printing effectScreen printersConductive pattern formationEngineeringSolder paste

The invention discloses a printed circuit board processing device, which comprises a transfer table, a frame, a sliding rod, a brush block, connecting blocks, a jacking plate and a diamond-shaped scraper, wherein a motor is fixed to the left side of the frame, an output shaft of the motor is in transmission connection with the brush block, the right side of the brush block is provided with a fan,a cylinder is fixed to the top end of the frame, the cylinder is fixedly connected with the jacking plate, the lower surface of the jacking plate is provided with guide rails, the guide rails are slidably connected with the sliding rod, the sliding rod is fixedly connected with the diamond-shaped scraper, elastic telescopic rods are fixed to both sides of the jacking plate, a spring is arranged inside each elastic telescopic rod, the elastic telescopic rods are fixedly connected with a steel mesh by means of the connecting blocks, a sensing device is arranged below one connecting block, a solder paste tank is arranged above the steel mesh, a stirring rod is arranged inside the solder paste tank, and a valve is arranged at the bottom part of the solder paste tank. The printed circuit boardprocessing device ensures the processing effect of a printed circuit board, and improves the production efficiency.

Owner:广东高旗技术有限公司

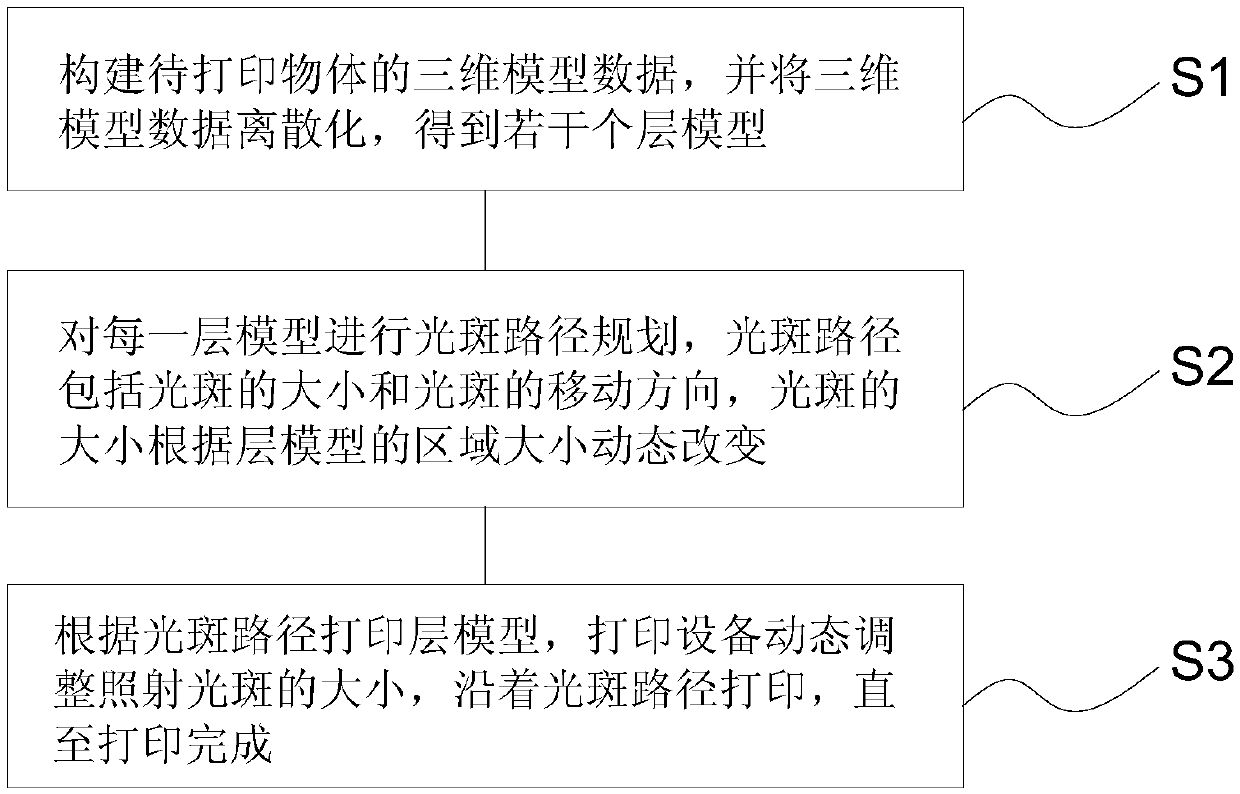

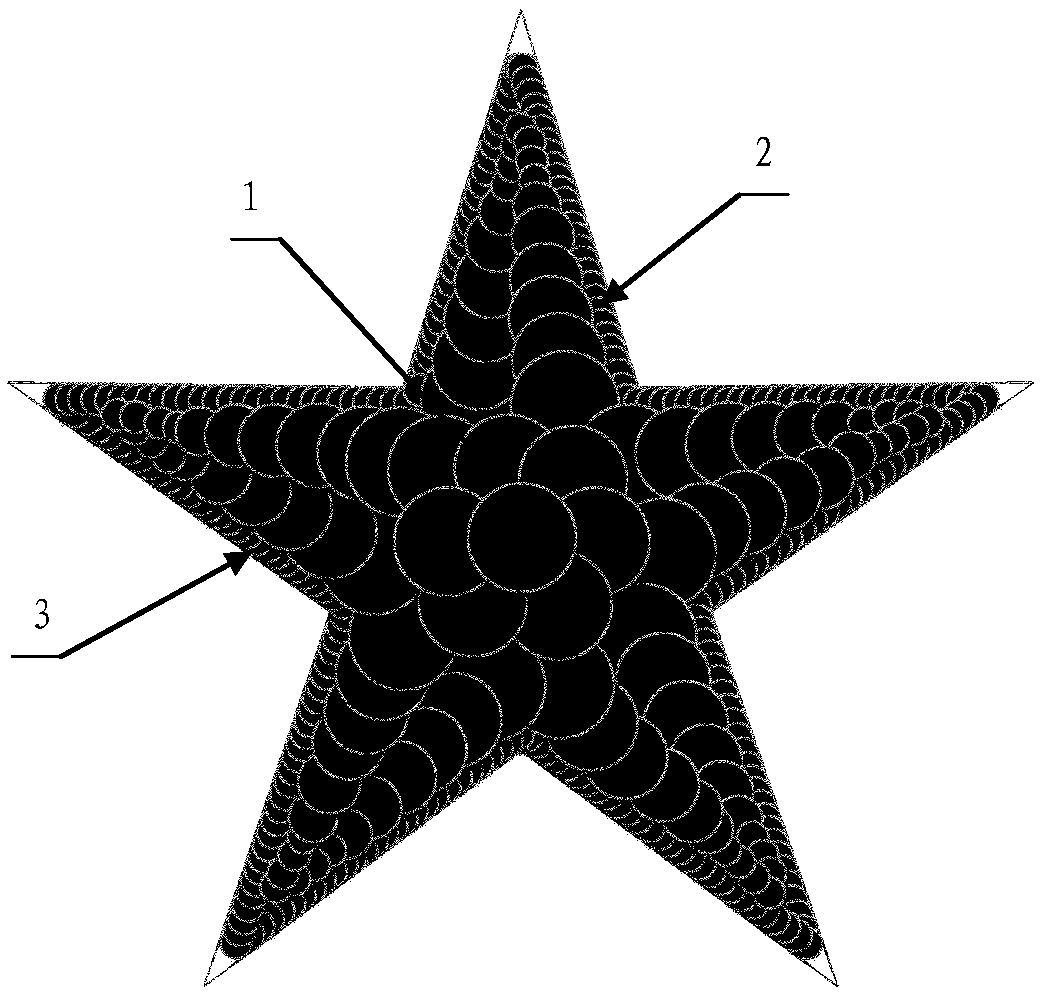

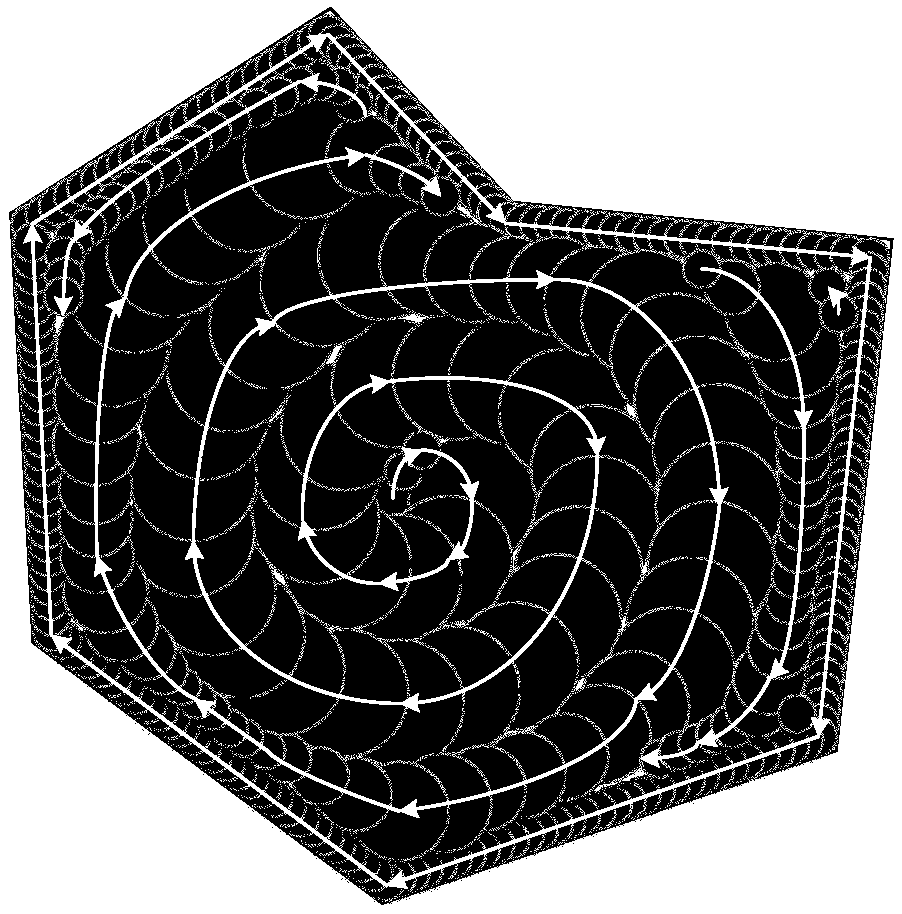

3D photocuring dynamic focusing self-adaption light spot printing method

ActiveCN109532005AGuaranteed performanceRealize dynamic spot printingAdditive manufacturing apparatus3D object support structuresLight spotSelf adaptive

The invention provides a 3D photocuring dynamic focusing self-adaption light spot printing method and equipment. The method comprises the steps that 1, three-dimensional model data of a to-be-printedarticle are built anddiscretized,so that multiple layer models are obtained; 2, light spot route planning is conducted on each model, wherein a light spot route comprises the sizes and the moving direction of light spots, and the sizes of the light spots are dynamically changed according to the area size of the layer models; and 3, according to the light spot route obtained through planning of step 2, the layer models are printed, the sizes of the light spots are dynamically adjusted through the printingequipment, and printing is conducted along the light spot route until printing is completed. Light spot route planning is conducted on each layer model, The proper light spot sizes are set for printing in all different areas in the layer models according to the shape and performance requirements; and the light spots are gradually decreased at positions with sharp corners; and on the premise that the printing precision and printing article performance are guaranteed, dynamic light spotprinting can be achieved in all directions, and the printing speed can be increased.

Owner:J H TECH ELECTRONICS GZ LTD

Automatic feeding system for ink writer

The invention discloses an automatic feeding system for an ink writer. The automatic feeding system comprises a rolling rotary disc, a feeding mechanism and a discharge mechanism, wherein equally-arranged rolling grooves are arranged in the circumferential sidewall of the rolling rotary disc; a bracket is connected with the rolling rotary disc; pushing claws of the bracket are corresponding to stop blocks on the rolling rotary disc, and one side surface of each pushing claw and one side surface of each stop block are located on the same straight line; the outlet end of a feeding frame of the feeding mechanism is suspended above the rolling grooves of the rolling rotary disc; a stop rod is arranged on the back of a bent material channel; the bottom plate of the feeding frame is connected with a width adjustment device; a material distribution device is arranged at the lower port of a hopper; a slantwise feeding belt driven by two rotary shafts is arranged on the upper part of a rack of the discharge mechanism; one end of the feeding belt is located at one side of the rolling grooves in the lower part of the rolling rotary disc; the two ends of a driven rotary shaft of the feeding belt are connected with a support rod; the support rod is connected with a shifting rod; one end of the shifting rod is fixedly connected with a transversal rack; and a rotary hand wheel is used for adjusting the slantwise angle of the feeding belt.

Owner:李维龙

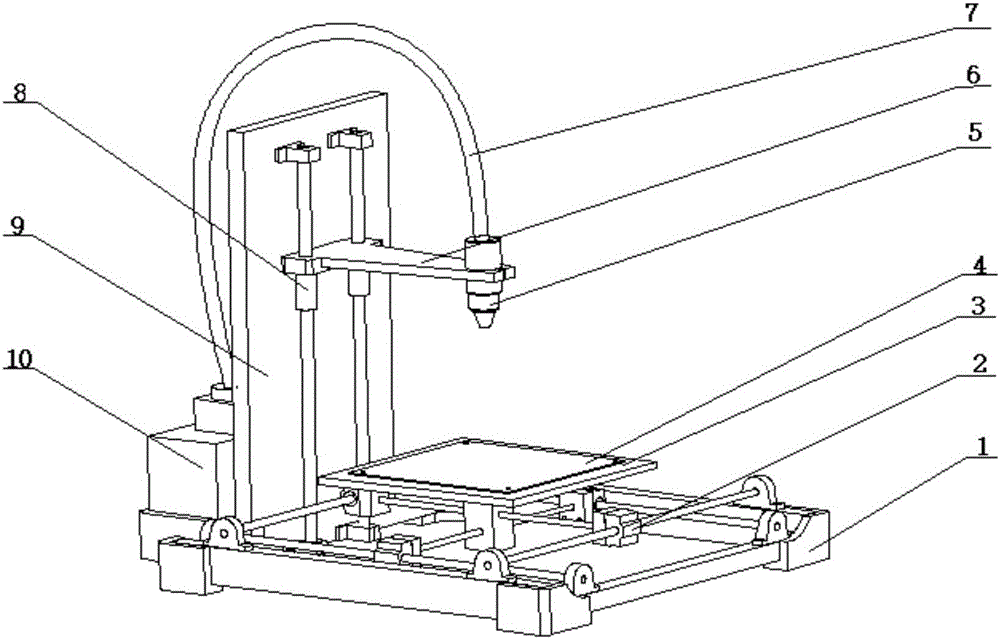

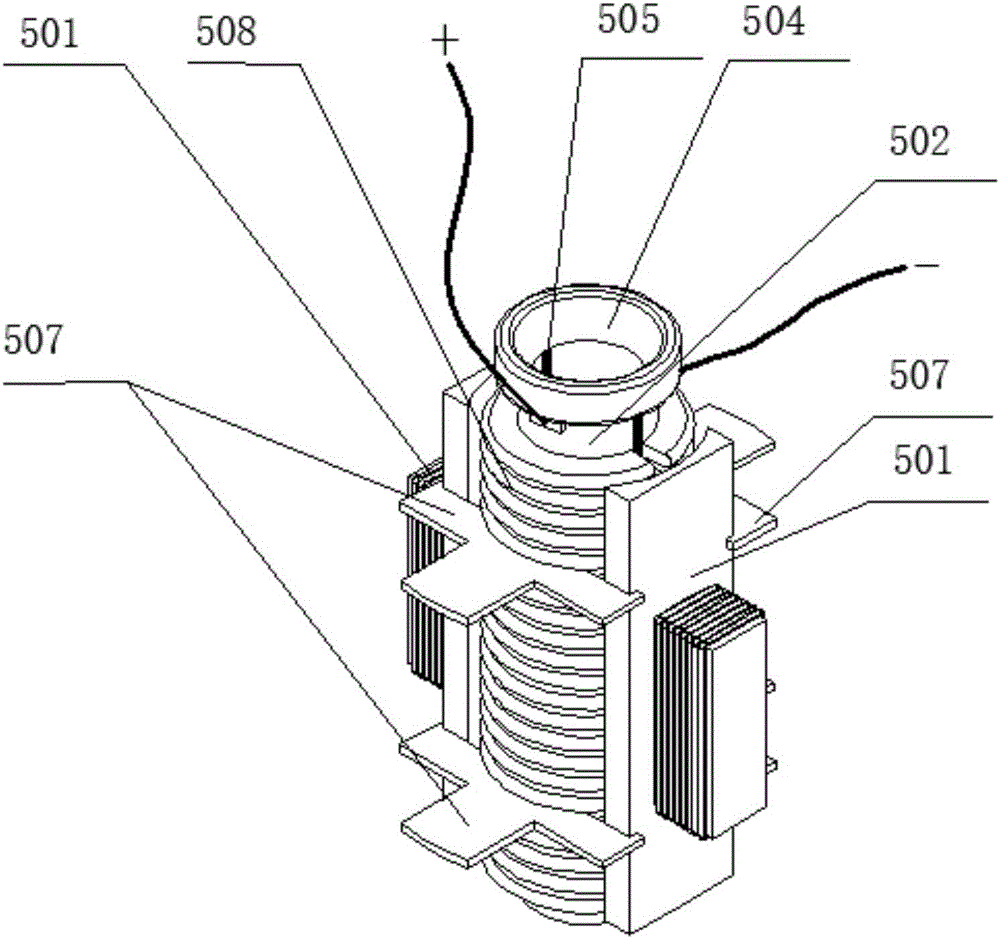

3D printing device and method based on electromagnetic emission technique

ActiveCN106003733AReduce physical and chemical propertiesAvoid cloggingAdditive manufacturing apparatusSprayerConductive materials

The invention relates to a 3D printing device and method based on the electromagnetic emission technique, and belongs to 3D printing devices and methods. An XY-direction workbench and a support are mounted on a base, a Z-direction workbench is connected with the support in a sliding mode, and a connecting frame is connected with the Z-direction workbench and a sprayer. A high-precision injection pump is fixed to the base. The two ends of a feed pipe are fixedly connected with the sprayer and the high-precision injection pump correspondingly. A piece bearing table is mounted on the XY-direction workbench and located below the sprayer, and a substrate is connected to the piece bearing table. Current and a magnetic field are exerted on conductive liquid in the sprayer, the conductive liquid is pushed by ampere force to be sprayed out to a designated position, the magnitude of the ampere force serving as pushing force can be changed conveniently by changing the current intensity or the magnetic field intensity, and therefore the ejection speed of printing liquid drops is controlled; and a nozzle is prevented from being blocked by giving the magnetic field intensity and current duration and controlling the current intensity, high printing precision can be achieved, and the 3D printing device and method are suitable for 3D printing of biological conductive materials and non-biological conductive materials.

Owner:JILIN UNIV

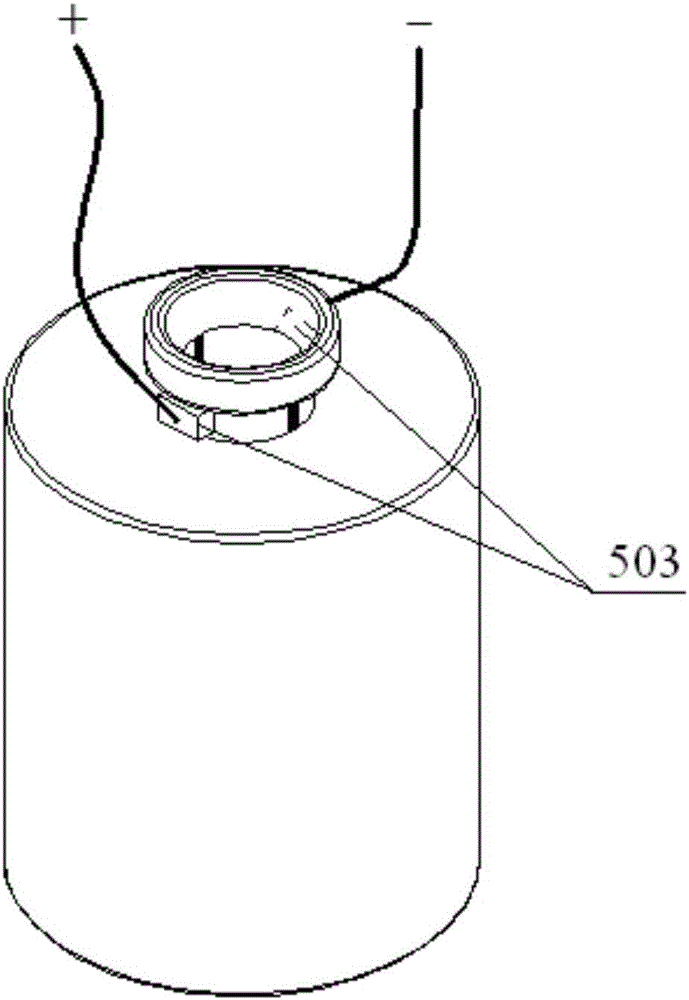

Powder box for printer

ActiveCN108646533AImprove removal efficiencyImprove cleanlinessElectrographic process apparatusResidual carbonAir pump

The invention relates to the field of printer equipment, in particular to a powder box for a printer. The powder box for the printer comprises a powder box body, wherein a powder bin and a waste powder bin are arranged in the powder box body and are communicated with each other through a pipeline; an electromagnetic valve is arranged on the pipeline; the powder box body also comprises an air inletpipe, a rotary shaft, a corrugated section, a piston plate, a second spring, a push rod and a slide rheostat distributed from top to bottom along the powder bin; a feed inlet is arranged on the top part of the powder bin; one end of the air inlet pipe is communicated with an air pump; the other end of the air inlet pipe is communicated with the top part of the powder bin; a plurality of blades are uniformly distributed on a part, located in the powder bin, of the rotary shaft along the axial direction; two ends of the rotary shaft stretch out of the powder bin and are connected with the powder bin in a rotary seal way. According to the scheme, through the linkage between various structures, the amount of residual carbon powder is displayed, the old carbon powder is removed, and the residues of the old carbon powder is prevented from influencing the printing quality.

Owner:贵州省仁怀市西科电脑科技有限公司

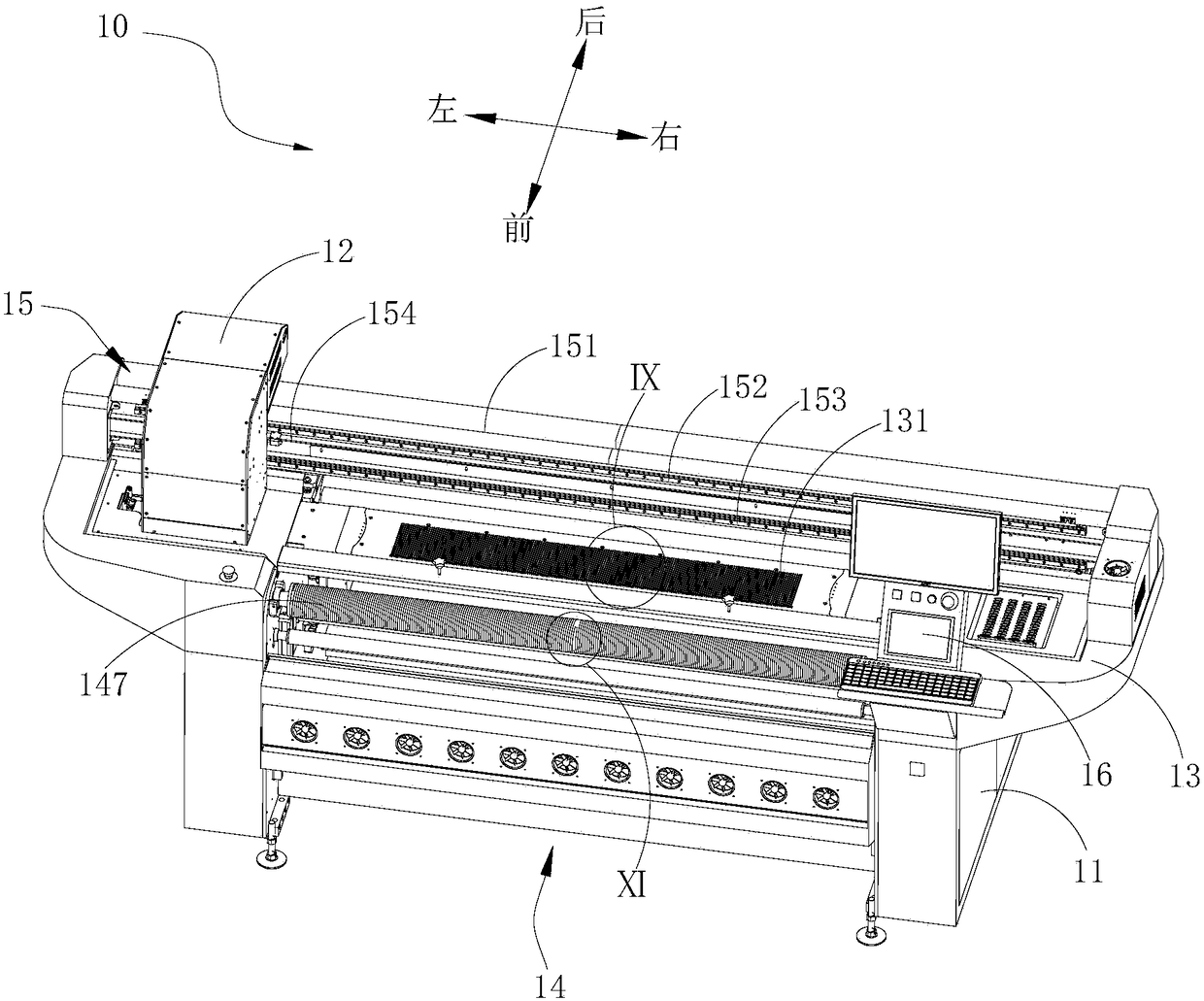

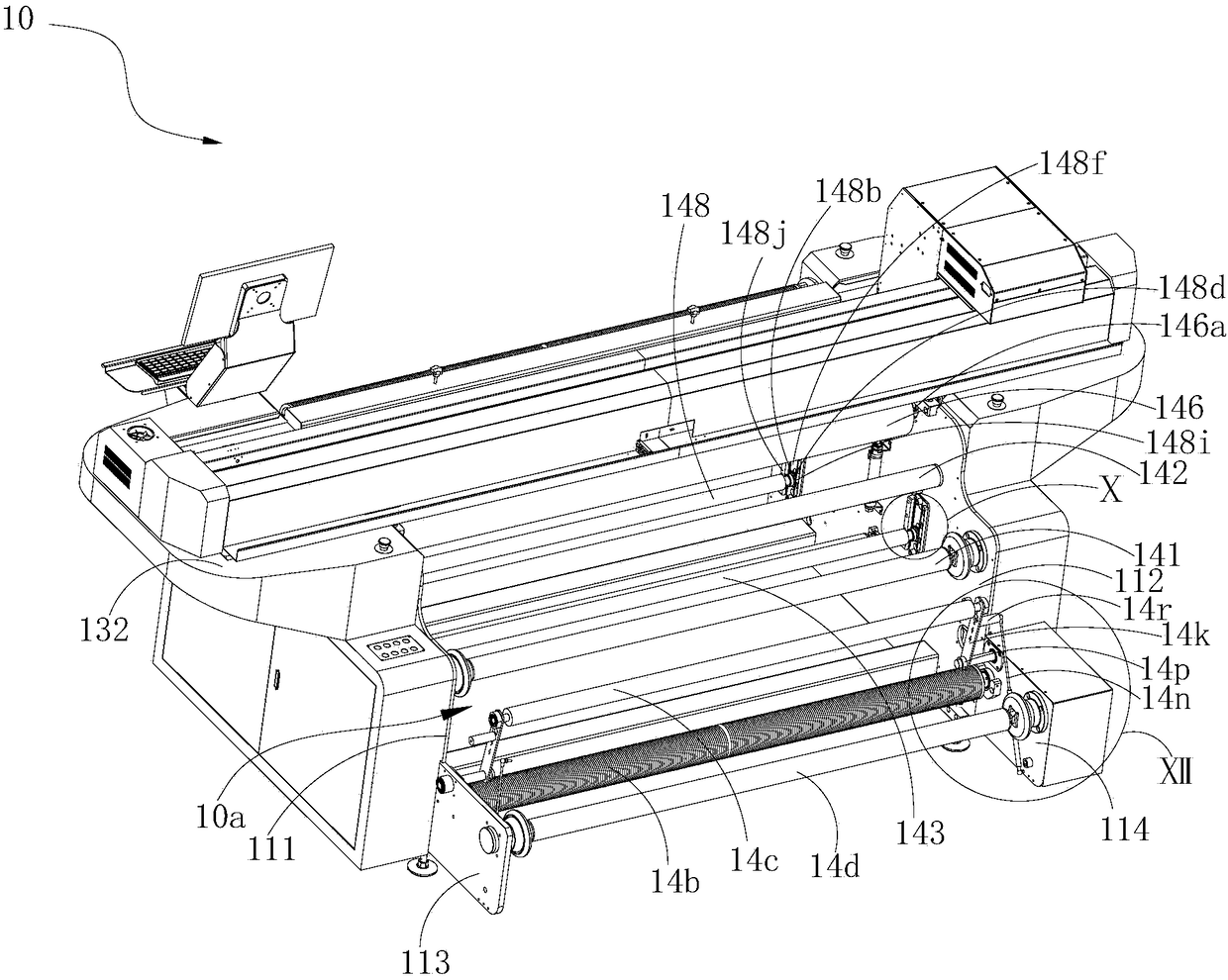

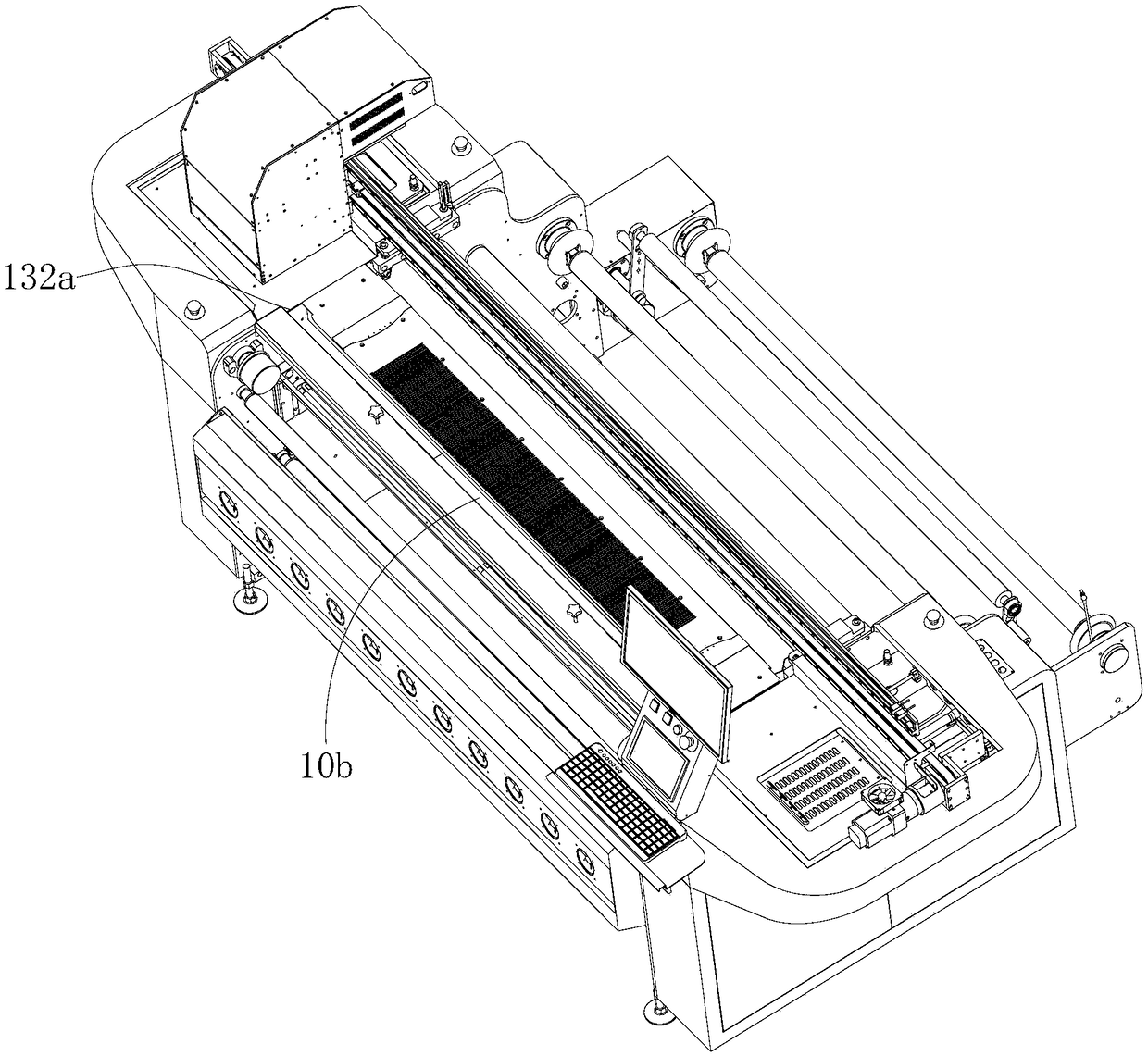

Digital printing machine

PendingCN108466484AGuaranteed tensionAvoid wrinklesOther printing apparatusWebs handlingPulp and paper industryPrinting press

The invention discloses a digital printing machine. The digital printing machine comprises a machine frame, a printing trolley, an operation platform and a conveying mechanism, wherein the printing trolley, the operation platform and the conveying mechanism are arranged on the machine frame; the machine frame comprises a first side plate, a second side plate opposite to the first side plate, a first lower side plate and a second lower side plate opposite to the first lower side plate. A containing space is defined by the first side plate and the second side plate jointly. The operation platform is located on the upper portion of the containing space. The conveying mechanism is used for conveying paper and comprises a paper conveying roller, a transition roller, a first tensioning roller, afirst guide roller, a tension roller, a rubber roller, a first spreading roller, a second tensioning roller, a second guide roller and a paper collection roller. The paper conveying roller, the transition roller, the first tensioning roller, the first guide roller, the tension roller, the rubber roller, the first spreading roller, the second tensioning roller and the second guide roller are contained in the containing space. Thus, the effect that paper is tensioned in the conveying process can be effectively ensured, paper is prevented from winkled, and meanwhile, the overall structure is more compact.

Owner:SHENZHEN TEXTALK GRAPHIC TECH

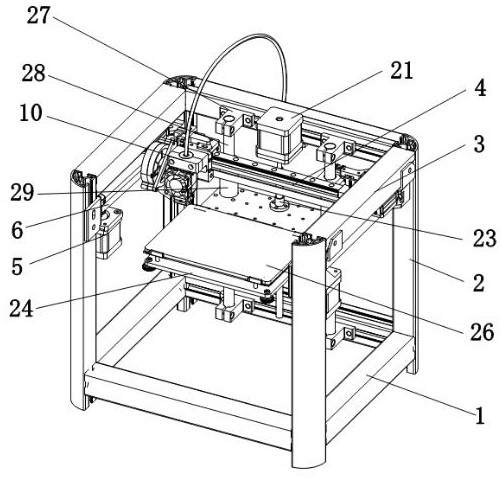

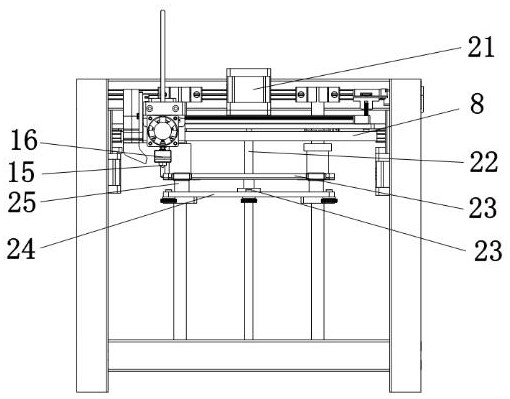

3D printer

ActiveCN112959657ASolve precise controlHigh movement accuracyManufacturing heating elements3D object support structuresThermal dilatationComputer printing

The invention relates to the technical field of printing equipment, in particular to a 3D printer which comprises a bottom frame. Multiple sets of vertical frames are arranged at the top of the bottom frame, a top frame is arranged between any two vertical frames, a cross beam is arranged between the top frames through a Y-axis controller, and an X-axis controller on the outer surface of the cross beam is slidably connected with a printing device; and a bottom plate is arranged at one side of each top frame through a Z-axis controller, the printing device comprises a booster, a raw material pipe is slidably connected into the booster, a heating cavity is formed in the bottom of the booster, the bottom of the heating cavity communicates with a flowing cavity, and a temperature sensor is arranged in the flowing cavity and used for detecting the internal temperature of the flowing cavity. According to the 3D printer, the current value of an electromagnet is controlled to change a gap between a heat-resistant magnetic ball and a spray head and change the volume of a molten material flowing out of the spray head, the material thermal expansion principle is combined, the material volume is increased when the temperature rises, the needed shape and volume are obtained after cooling, the printing effect is good, and the printing precision is high.

Owner:深圳市俩棵树科技有限公司

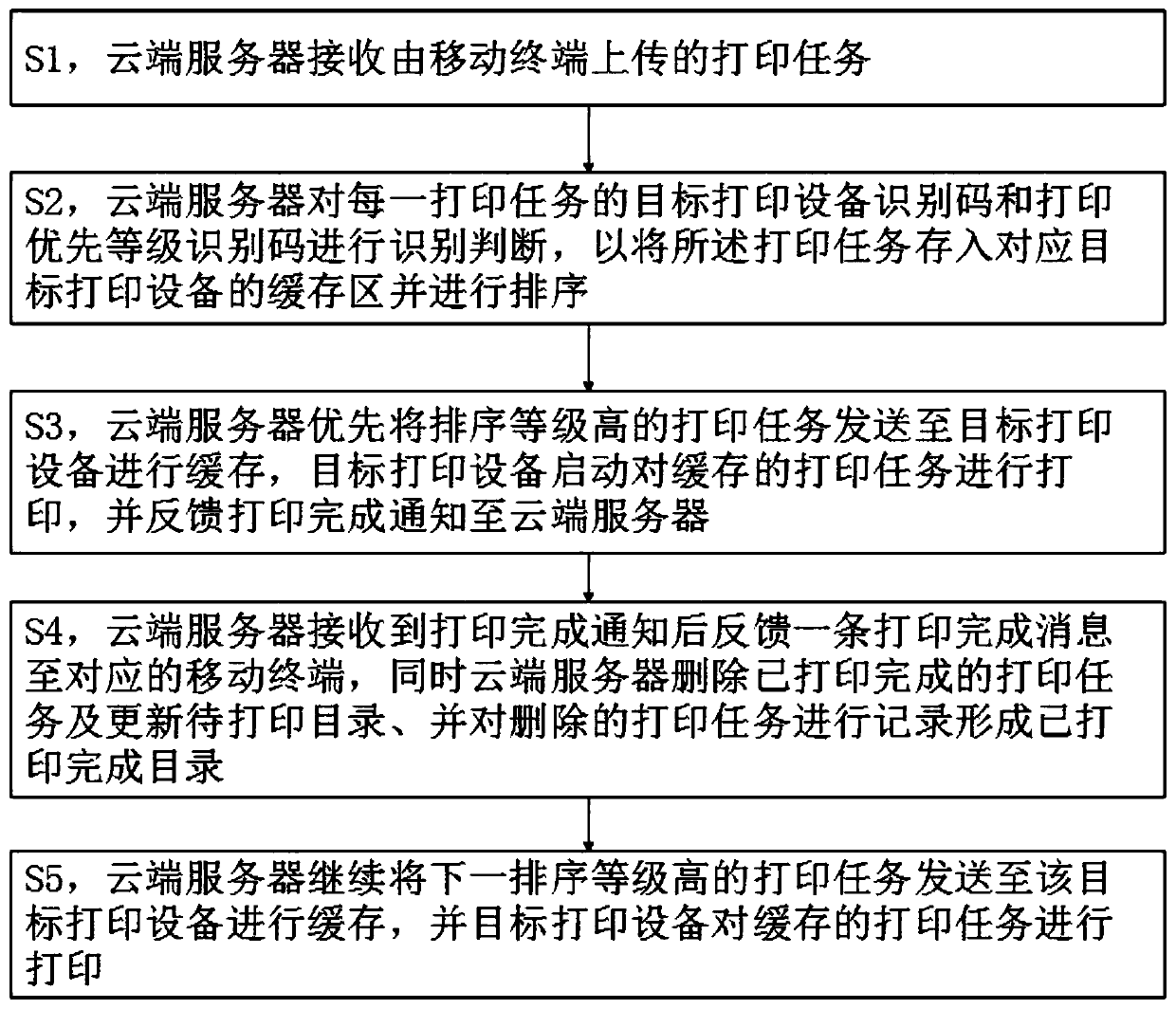

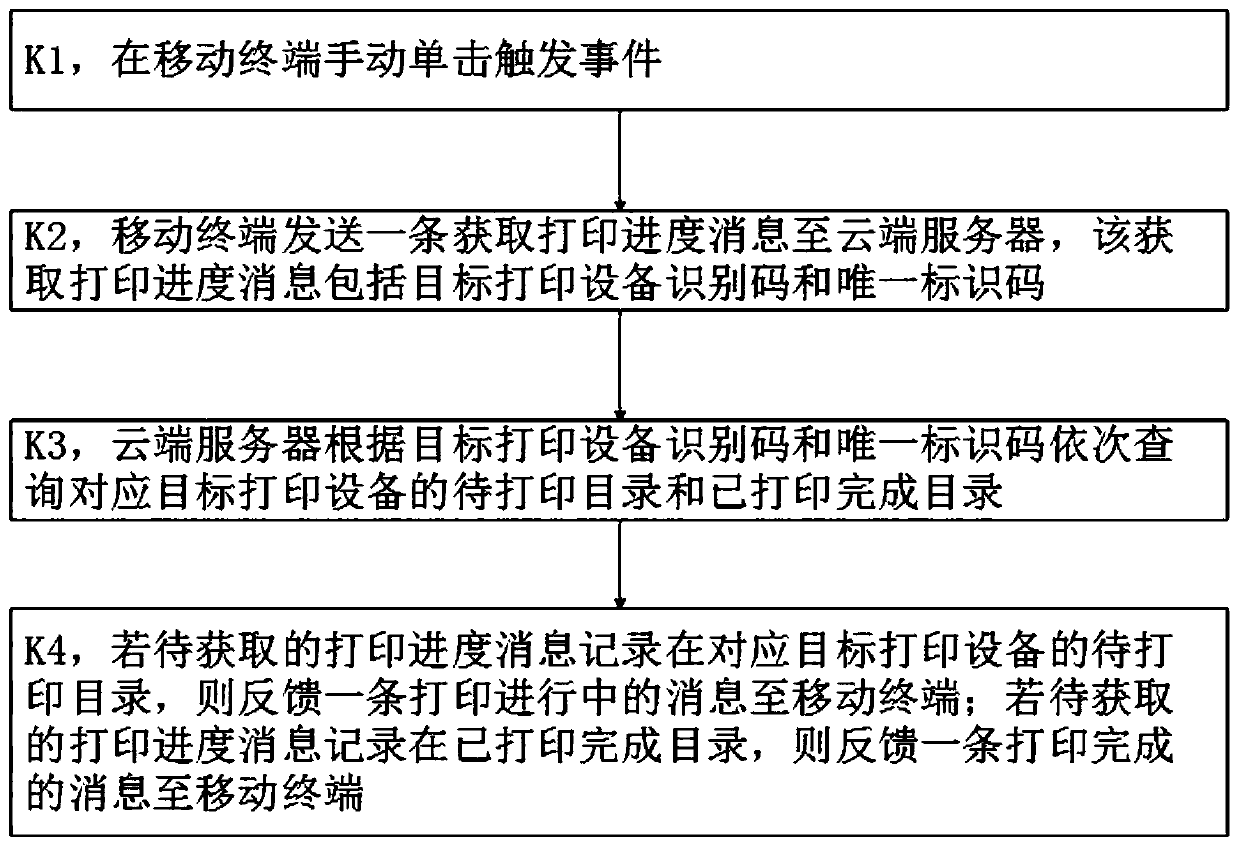

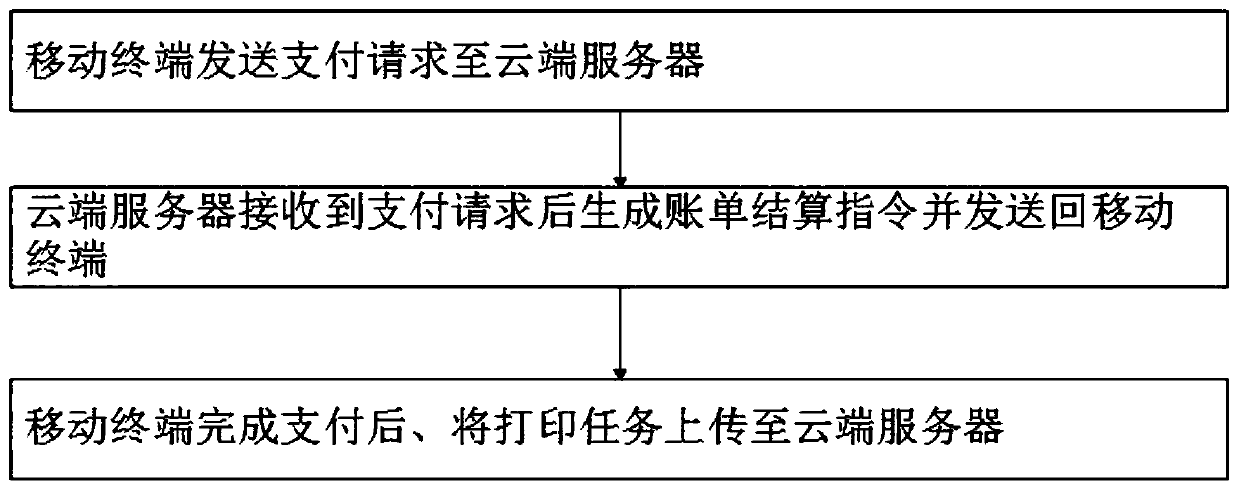

Printing task queuing method and printing control system

InactiveCN110147209AGuaranteed print intervalAdequate restDigital output to print unitsUser needsControl system

The invention relates to a printing task queuing method. A mobile terminal sends a printing task to the cloud server; the cloud server sorts the printing tasks according to user requirements and sendsthe printing tasks with high priorities to the target printing equipment; after finishing printing, the target printing equipment sends a printing completion notice to the cloud server; the cloud server sends a printing completion notification to the mobile terminal and sends a next printing task to the target printing equipment for next round of printing; according to the printing task queuing method, the problems that a traditional printing mode needs long waiting time and is complex to operate are solved, meanwhile, priority ranking can be conducted on printing tasks according to user requirements, and printing is conducted preferentially according to ranking; the invention further relates to a printing control system comprising the printing task queuing method, remote printing is achieved, preferential execution is conducted according to user requirements, and automation and intelligentization of printing tasks are achieved.

Owner:SHENZHEN CASTLE SECURITY TECH CO LTD

Photo-curing 3D printer and 3D printing method

ActiveCN111300817AAdjust the lifting speed in timeFree from reciprocating motionAdditive manufacturing apparatus3D object support structuresComputer printing3d printer

The invention relates to the technical field of 3D printing, in particular to a photo-curing 3D printer and a 3D printing method. The photo-curing 3D printer comprises a container filled with photosensitive resin, a transparent film is arranged at the bottom of the container, an optical machine is arranged at the bottom of the container, a printing platform is arranged above the container and connected with a lifting mechanism through a platform support, the lifting mechanism is connected with a printing control module used for controlling the lifting speed, the platform support is provided with a pressure sensor for detecting the pressure of the printing platform, the lifting mechanism is connected with a displacement detection piece for detecting the movement displacement of the liftingmechanism, and the pressure sensor and the displacement detection piece are both connected with the printing control module. The photo-curing 3D printer and the 3D printing method can not only avoid the reciprocating motion of the printing platform, but also can control the deformation degree of the transparent film and improve the printing success rate.

Owner:安徽光理智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com