Print control method and device of thermal printer

A thermal printer and printing control technology, applied in printing devices, printing and other directions, can solve problems such as poor printing results, and achieve the effect of eliminating voltage dips, reducing printing current, and ensuring printing results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

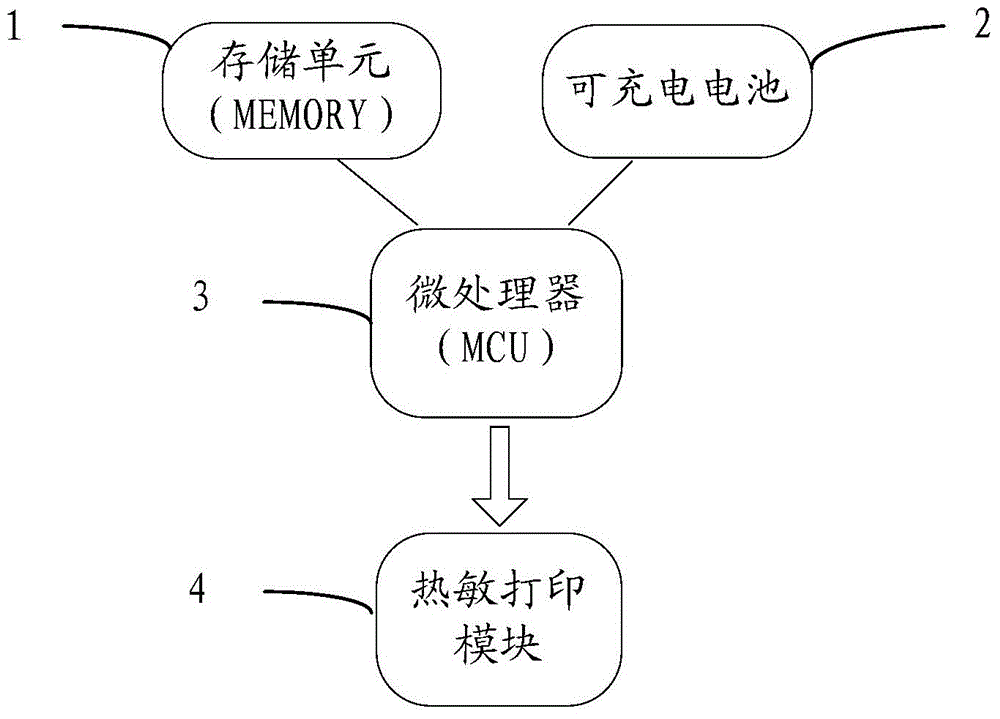

[0058] Embodiment 1 of the present invention is: a control method for a thermal printer in a POS machine, wherein the thermal printer is arranged at the front end of the POS machine, the thermal printer and the POS machine are powered by a rechargeable battery, and the thermal printer core is integrated A temperature sensor (such as a thermistor) is arranged, and the temperature sensor is electrically connected to the MCU (Micro Control Unit, micro control unit) of the POS machine, and the MCU is also connected to the print enabling terminal electrically connected to the thermal printer, and the to control the printer for printing.

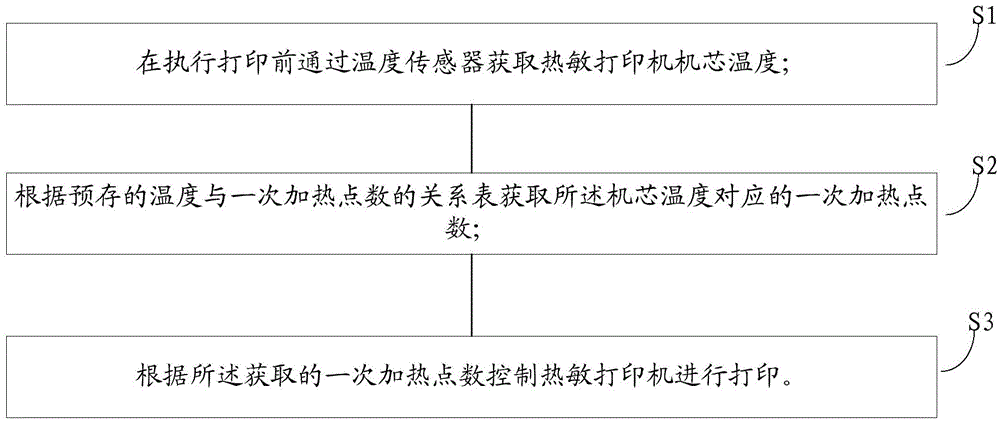

[0059] When the POS machine needs to print, the temperature sensor senses the temperature and outputs an available signal (such as a voltage signal), and the MCU of the POS machine samples the output signal of the temperature sensor, and according to a certain conversion relationship, the current temperature information of the core can be obtained;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com