3D printer

A 3D printer and printing device technology, applied in 3D object support structure, additive manufacturing, processing heating elements, etc., can solve the problems of cooling volume shrinkage, slow cooling speed, collapse of finished parts, etc., to achieve perfect device, high processing accuracy, Strong linkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

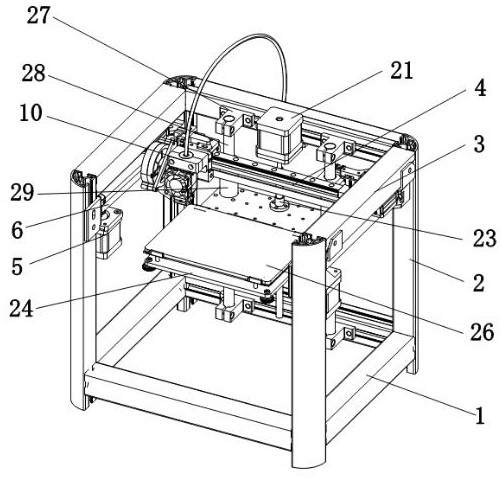

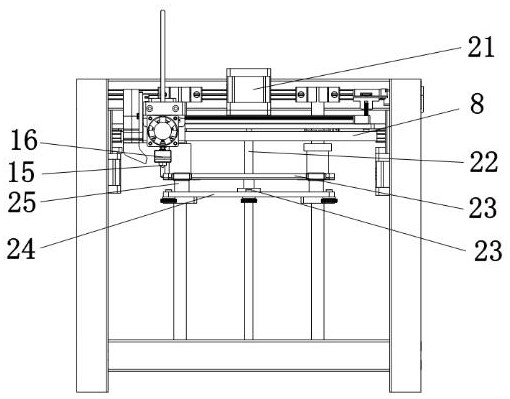

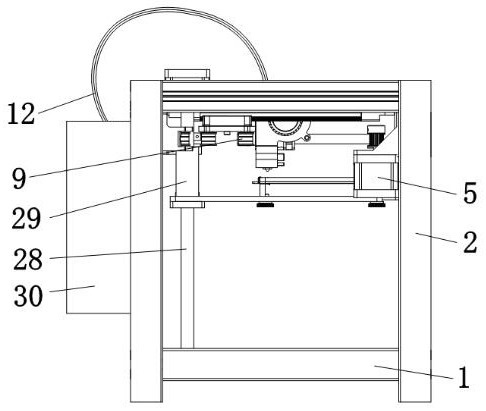

[0041] refer to Figure 1-5 , the present invention provides a 3D printer, comprising a bottom frame 1, a plurality of sets of vertical frames 2 are arranged on the top of the bottom frame 1, a top frame 3 is arranged between any two vertical frames 2, and the top frame 3 is controlled by the Y axis The device is provided with a crossbeam 4, and the Y-axis controller includes a first stepping motor 5, which is fixedly connected with a certain vertical frame 2, and the output end of the first stepping motor 5 is provided with a first conveyor belt 6, and the first stepping motor 5 is fixedly connected with a vertical frame 2. The ends of a conveyor belt 6 are equipped with a conveyor belt tensioner, two symmetrically distributed top frames 3 are provided with slide rails 31 at the bottom, the two slide rails 31 are slidingly connected to a crossbeam 4, and the bottom of the crossbeam 4 is provided with a drive wheel 9 , the first conveyor belt 6 bypasses the transmission wheel ...

no. 2 example

[0047] Based on the 3D printer provided in the first embodiment, the 3D printing work can be completed and the required printed parts can be obtained. However, in the actual use process, due to the thermal expansion phenomenon of the printing material, that is, under the condition of constant external pressure, the temperature of the molten material The larger the value, the greater the volume change after cooling, so the volume of the molten material flowing out of the nozzle 15 will shrink after cooling and solidifying on the top of the magnetic hot plate 26, resulting in a change in the shape of the printed piece, or even excessive shrinkage of the printed piece. Assembly causes damage, thereby greatly reducing yield, to solve this problem, combine the Figure 6-11 , the 3D printer also includes: a temperature sensor is provided inside the flow chamber 32 to detect its internal temperature, and the thermal expansion volume increase value of the printing material is indirectl...

no. 3 example

[0052] At the same time, when a certain layer of the finished product is printed and needs to be printed next time, the height of the nozzle 15 does not change, and the bottom plate 24 is driven down by the third stepping motor 21 during the descent process, because the magnetic hot plate 26 There is a temperature difference at the top of the nozzle, so the volume of the molten material flowing out along the nozzle 15 is different, and the height of the molten material flowing down is different according to the volume. If the gap between the nozzle 15 and the finished product is too small compared with the height of the molten material flowing down, the molten material will block the nozzle 15 and cause major safety accidents. In order to avoid this situation, a certain When the layer is printed and the next printing is performed, the third stepper motor 21 will drive the screw rod 22 to rotate more times than before, thereby driving the bottom plate 24 to descend synchronously...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com