Powder box for printer

A technology for printers and toner cartridges, which is applied in the fields of electrical recording technology using charge graphics, equipment for using electrical recording technology using charge graphics, and electrical recording technology. Unable to know the quantity and other problems, to achieve the effect of guaranteeing the printing effect, improving the cleaning efficiency and effect, and improving the cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further detailed explanation through specific implementation mode below:

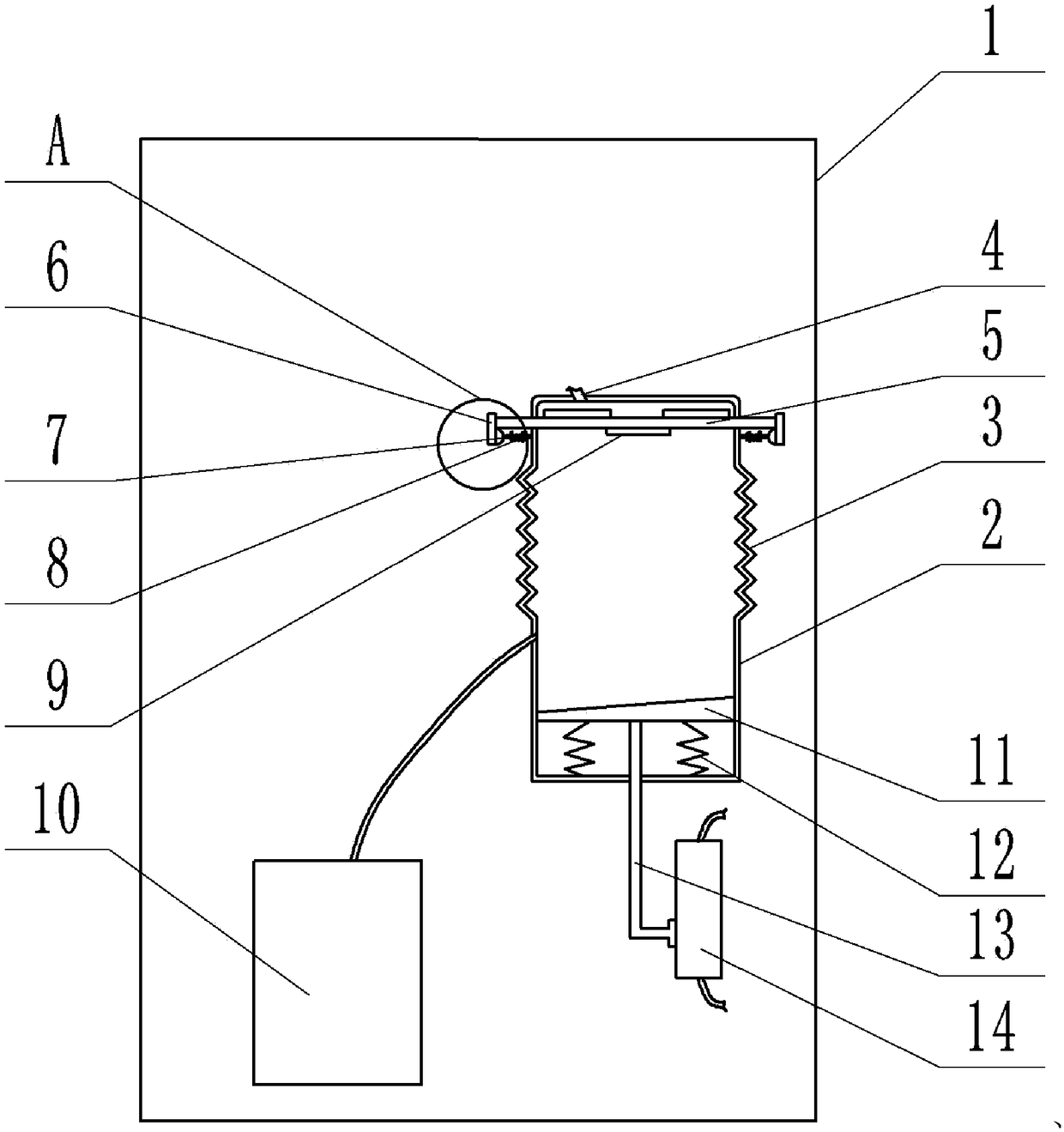

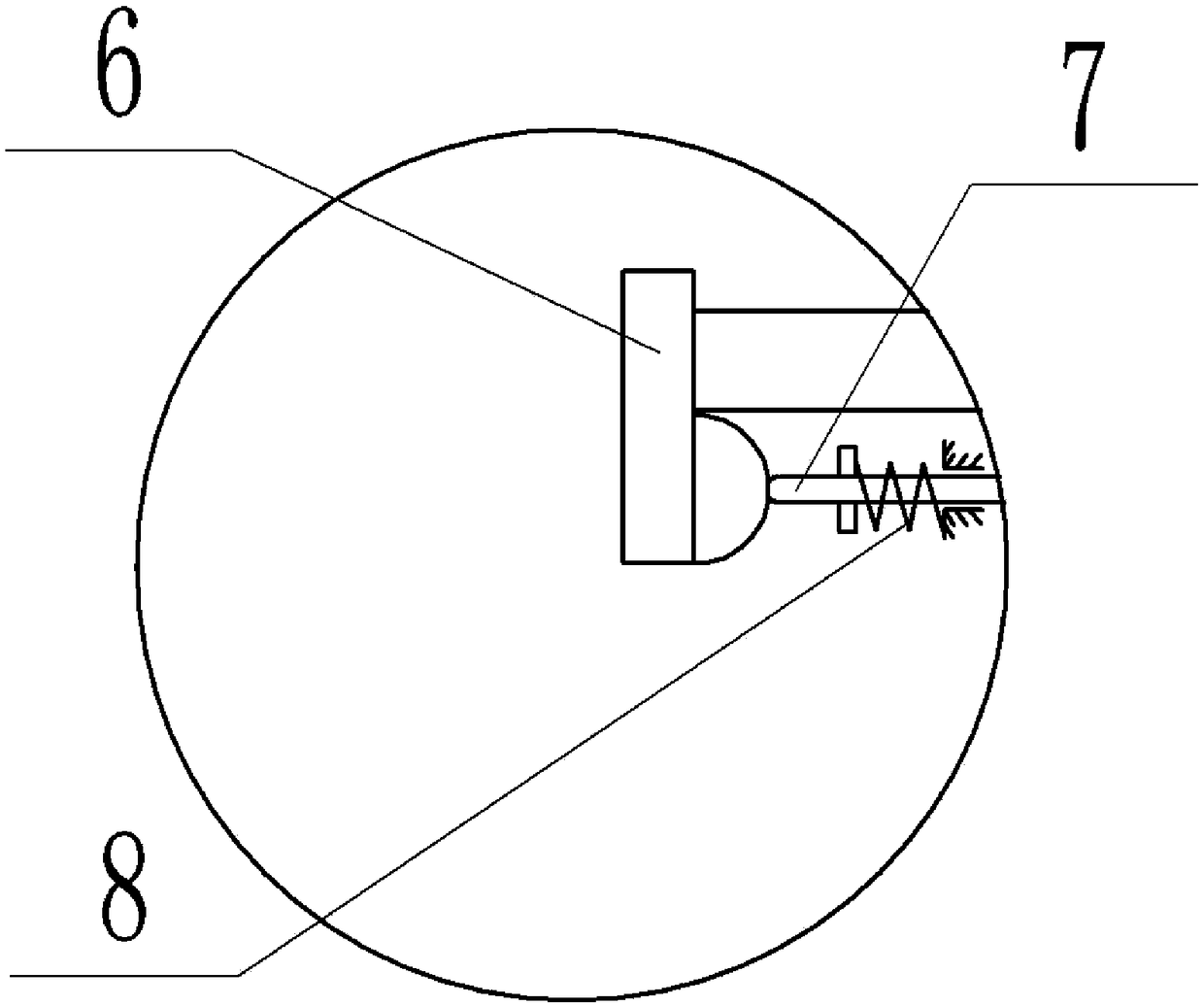

[0021] The reference signs in the drawings of the specification include: powder box body 1, powder bin 2, corrugated section 3, air intake pipe 4, rotating shaft 5, cam 6, ejector rod 7, first spring 8, blade 9, waste powder bin 10 , Piston plate 11, second spring 12, push rod 13, sliding rheostat 14.

[0022] The implementation of a kind of printer powder box is as figure 1 with figure 2 As shown: it includes the powder box body 1, the powder box body 1 is provided with a powder bin 2 and a waste toner bin 10, and the powder bin 2 and the waste toner bin 10 are connected through a pipeline, and a solenoid valve is arranged on the pipeline.

[0023] The powder box body 1 also includes an air intake pipe 4 distributed from top to bottom along the powder bin 2, a rotating shaft 5, a corrugated section 3, a piston plate, a second spring 12, a push rod 13 and a sliding rheostat 14, and the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com