Automatic feeding system for ink writer

An automatic feeding and printing machine technology, applied in printing, stamping, etc., can solve problems such as unstable feeding, affecting production efficiency and product quality, and achieve the goal of ensuring stability and printing effect, uniform indentation, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

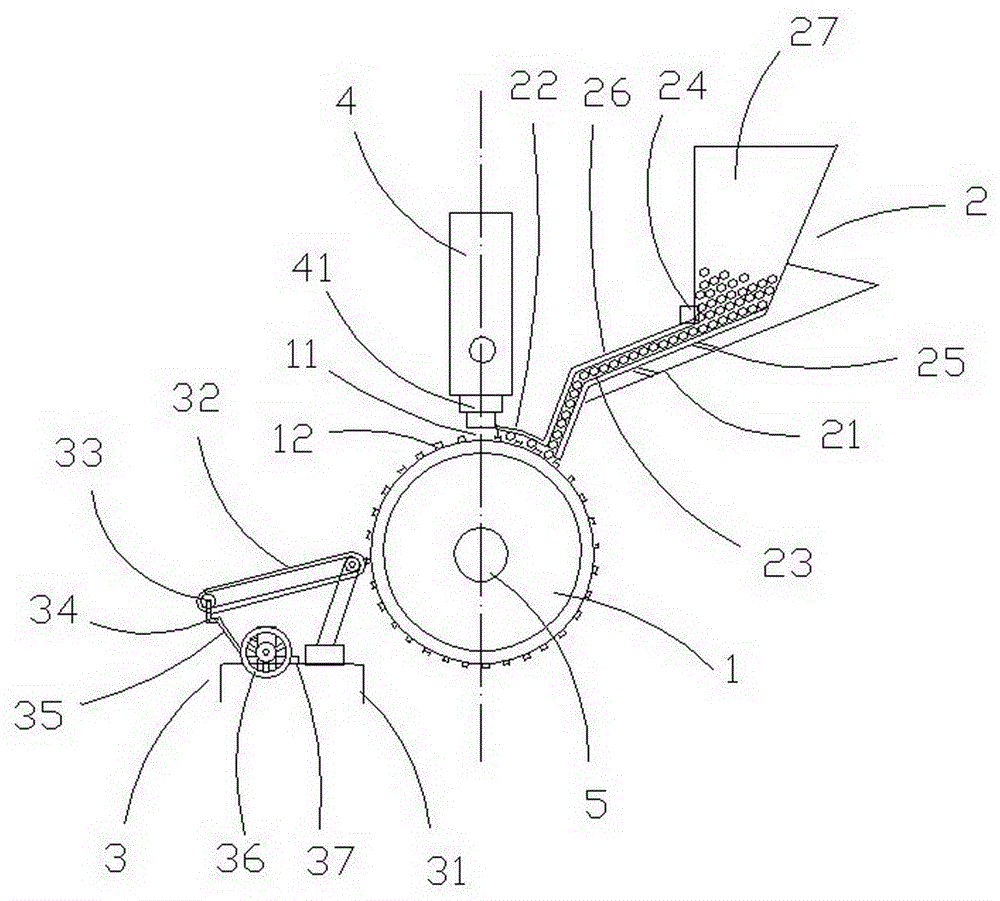

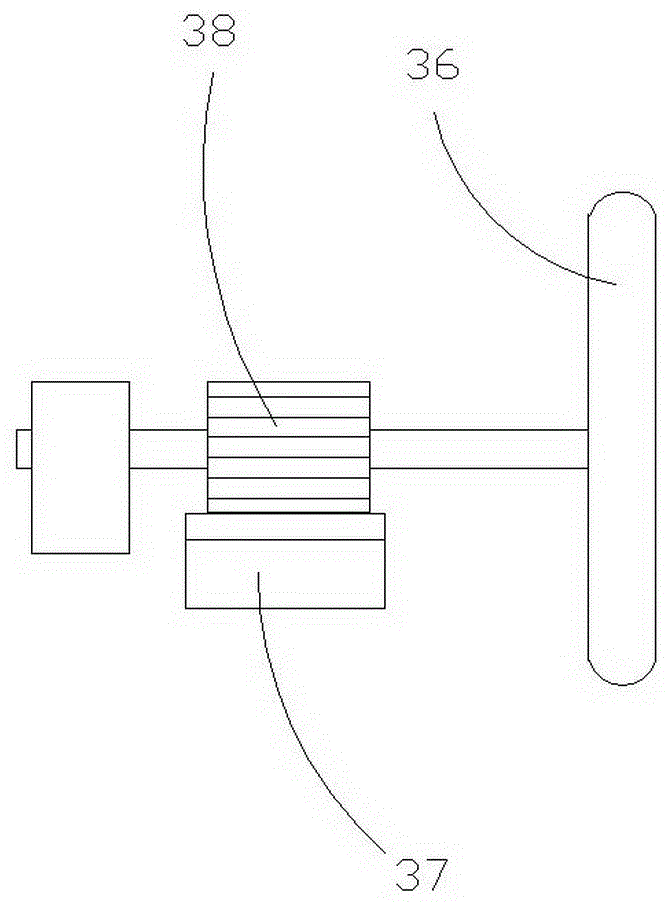

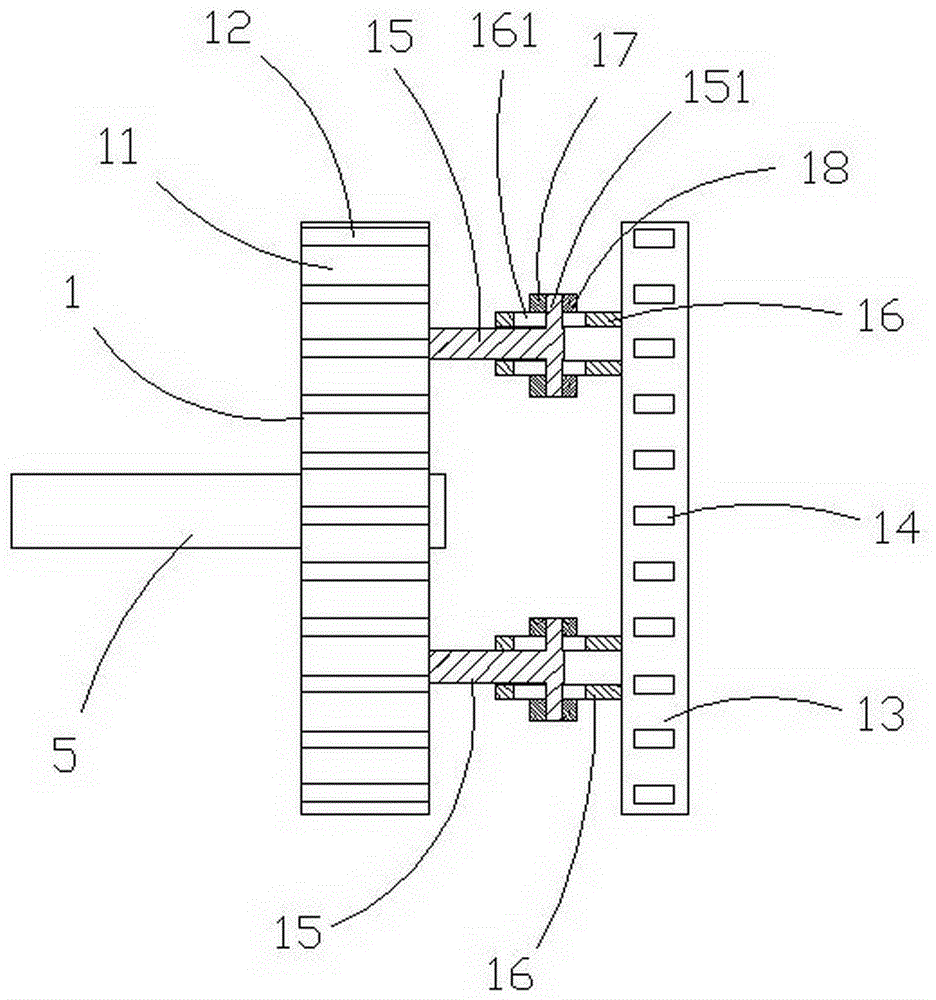

[0016] Such as figure 1 , 3 , Shown in 4, a kind of automatic feeding system of printing machine, comprises the rolling turntable 1 that rotating shaft 5 is connected and the feeding mechanism 2 that is provided with on both sides of rolling turntable and discharging mechanism 3, and rotating shaft 5 is driven to rotate by variable speed motor. A head 4 of a font 41 is suspended above the rolling turntable 1 , and the central axis of the head 4 is perpendicular to the center of the rolling groove 11 of the rolling turntable 1 . The circumferential side wall of the rolling turntable 1 is provided with equally arranged stoppers 12, and the height of the stoppers 12 is greater than the radius of the cylindrical workpiece and smaller than the diameter of the cylindrical workpiece. The stopper 12 and the arc surface of the side wall of the rolling turntable 1 form the rolling groove 11 of the embossing area, the sliding sleeve 16 of the bracket 13 is socketed on the positioning gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com