A kind of shoe upper production process

A production process and shoe upper technology, which is applied to footwear, shoe-making machinery, clothing, etc., can solve problems such as troubles, achieve good results, easy operation of line drawing, and uniform indentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

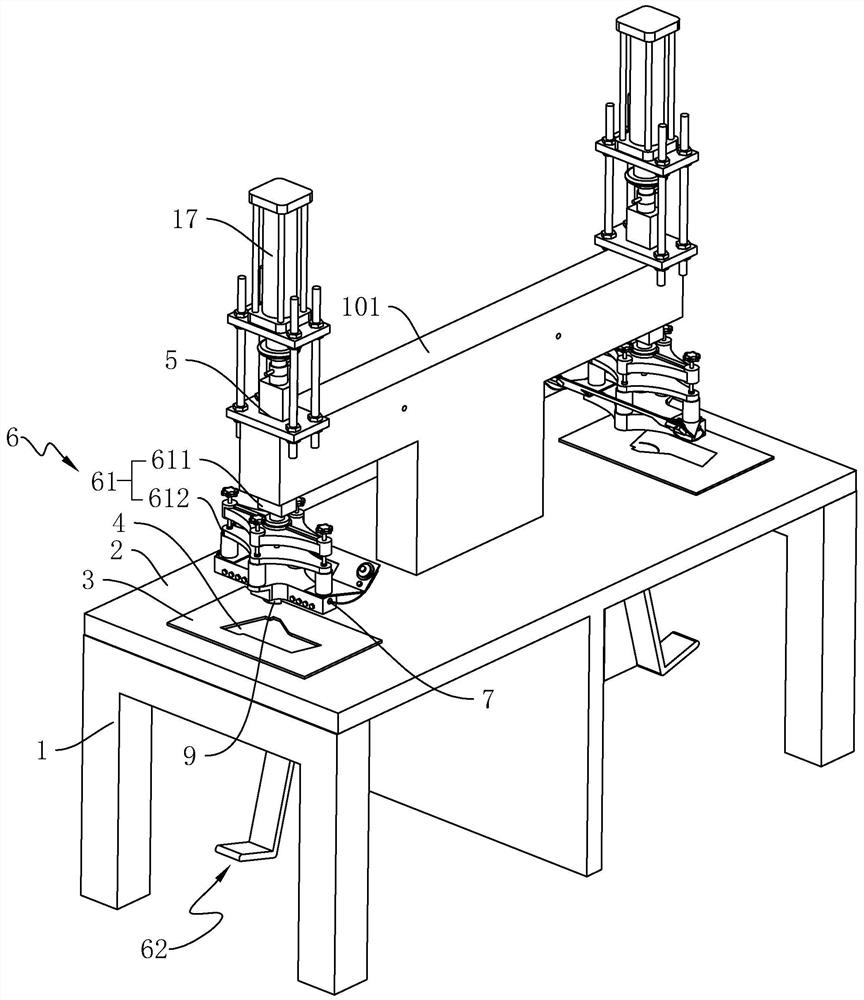

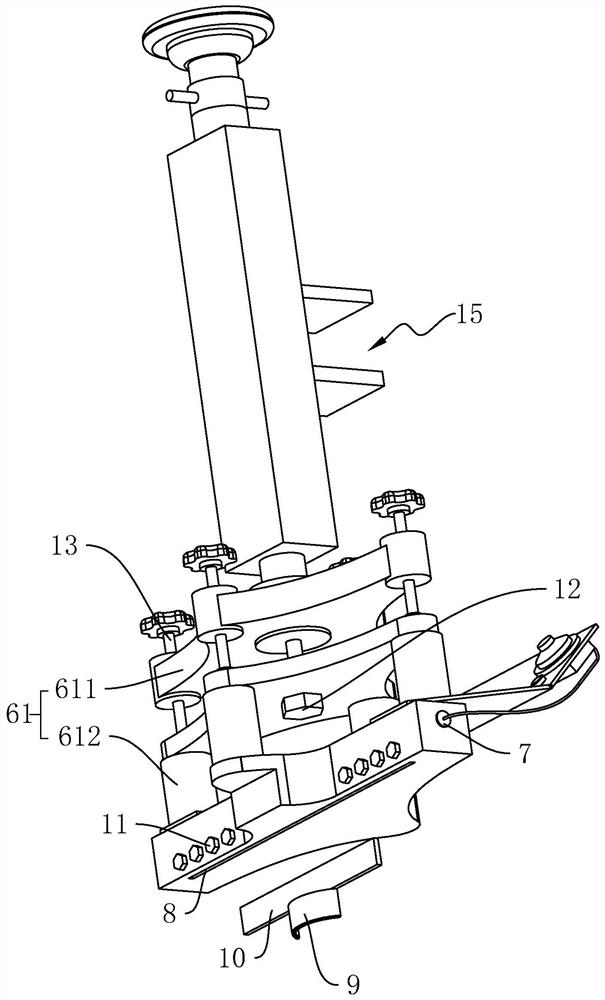

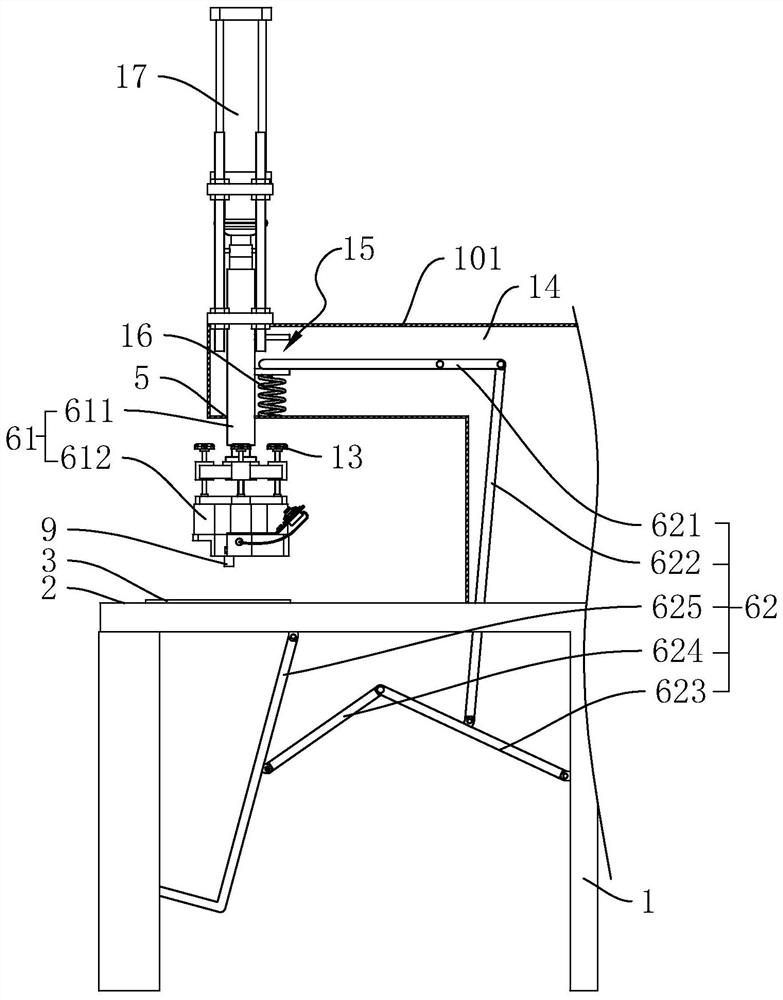

[0039] The following is attached Figure 1-4 The application is described in further detail.

[0040] The embodiment of the present application discloses a shoe upper production process, comprising the following steps:

[0041] S1 blanking process, the leather raw material is punched out by the blanking machine, so that each primary material required at the cutting place has a plurality of different or the same shapes, and is used to form the shoe upper by sewing. The primary material has both positive and negative sides, and the positive side is the smoother side.

[0042] S2, the line drawing process, in this step, needs to be completed in the indentation device. Indentation device such as figure 1 As shown, including a frame 1, the frame 1 is provided with a workbench 2, and the upper end surface of the workbench 2 is horizontally arranged. The upper end surface of the workbench 2 is provided with a positioning mold 3 , and the upper end surface of the positioning mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com