A creasing device

An indentation and movable installation technology is applied in the field of indentation devices, which can solve the problems affecting the mechanical properties of metal deposition, less surfactant addition, and inability to produce normally, and achieves improved drawing effect, uniform indentation, and reasonable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

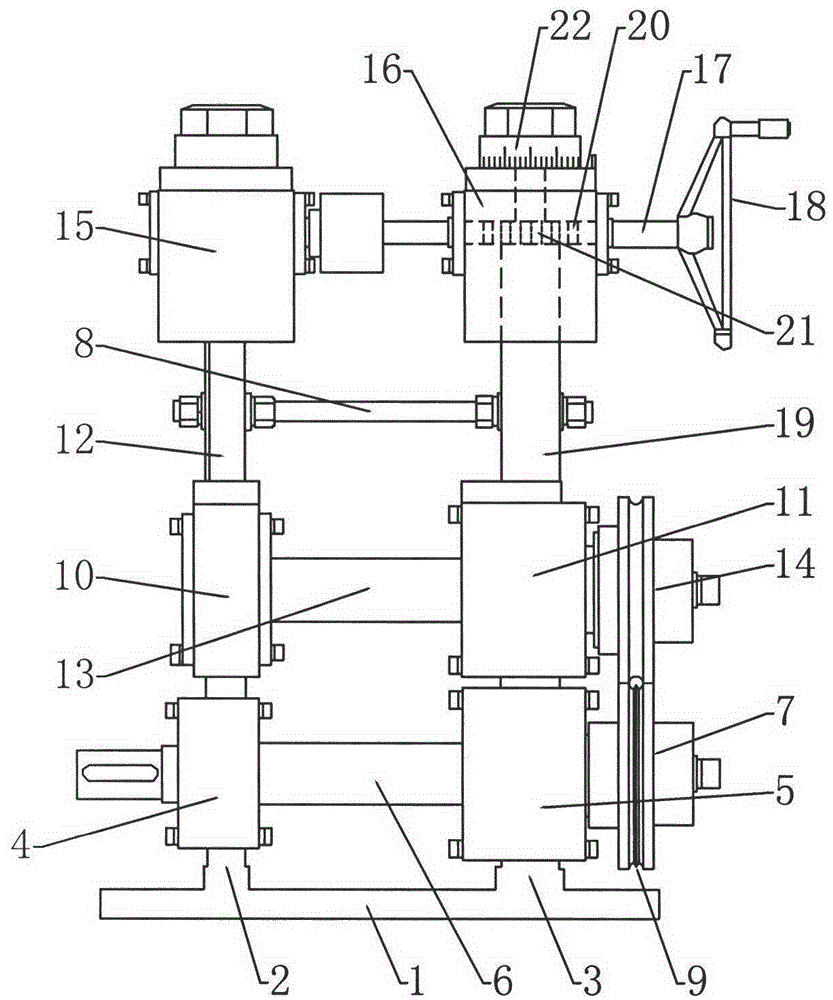

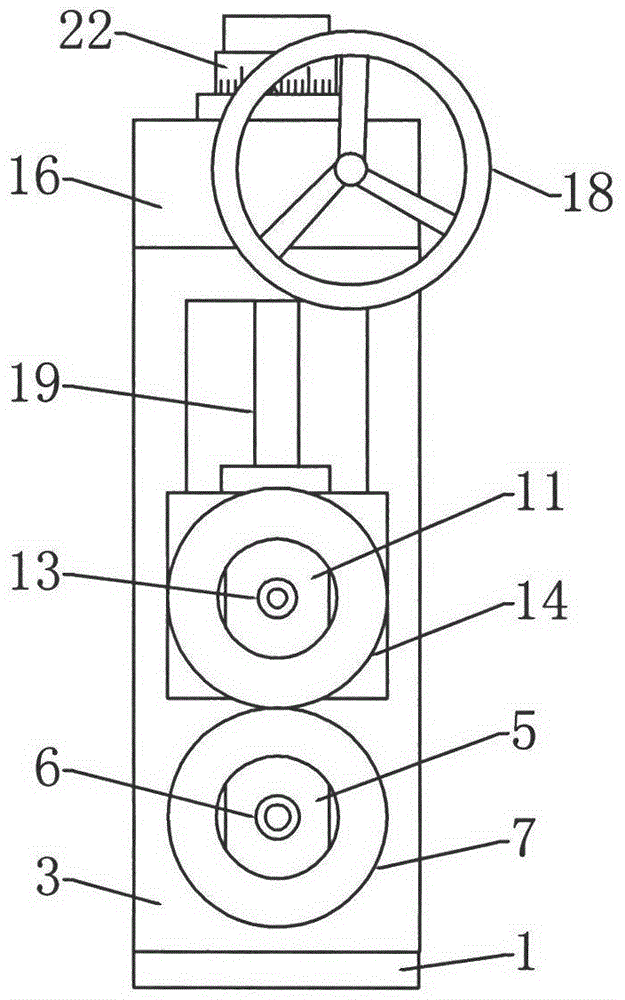

[0014] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

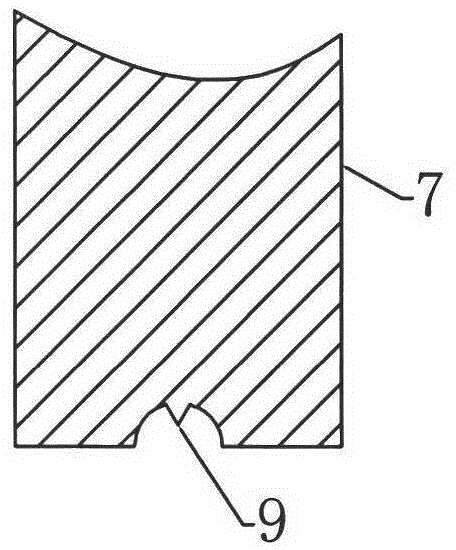

[0015] Such as Figure 1-3 As shown in , this embodiment includes a base 1, a left bracket 2 and a right bracket 3 are arranged in parallel on the base 1, and a first bearing seat 4 and a second bearing seat 5 are respectively fixed on the lower parts of the left bracket 2 and the right bracket 3 A lower rotating shaft 6 is movably installed between the first bearing seat 4 and the second bearing seat 5, a lower thread rolling wheel 7 is provided at one end of the lower rotating shaft 6, and an annular groove is arranged on the lower thread rolling wheel 7 along the circumferential direction, The bottom of the annular groove is provided with a circle of triangular annular protrusions 9 along the circumferential direction of the lower rolling wheel 7; The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com