Multi-function marking machine

An engraving machine, multi-functional technology, applied in the directions of printing, stamping, single object, etc., can solve the problems of not being able to print and label the surface of small circular workpieces, and unable to automatically automatically cylindrical workpieces, etc., to achieve compact structure, Low manufacturing cost and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

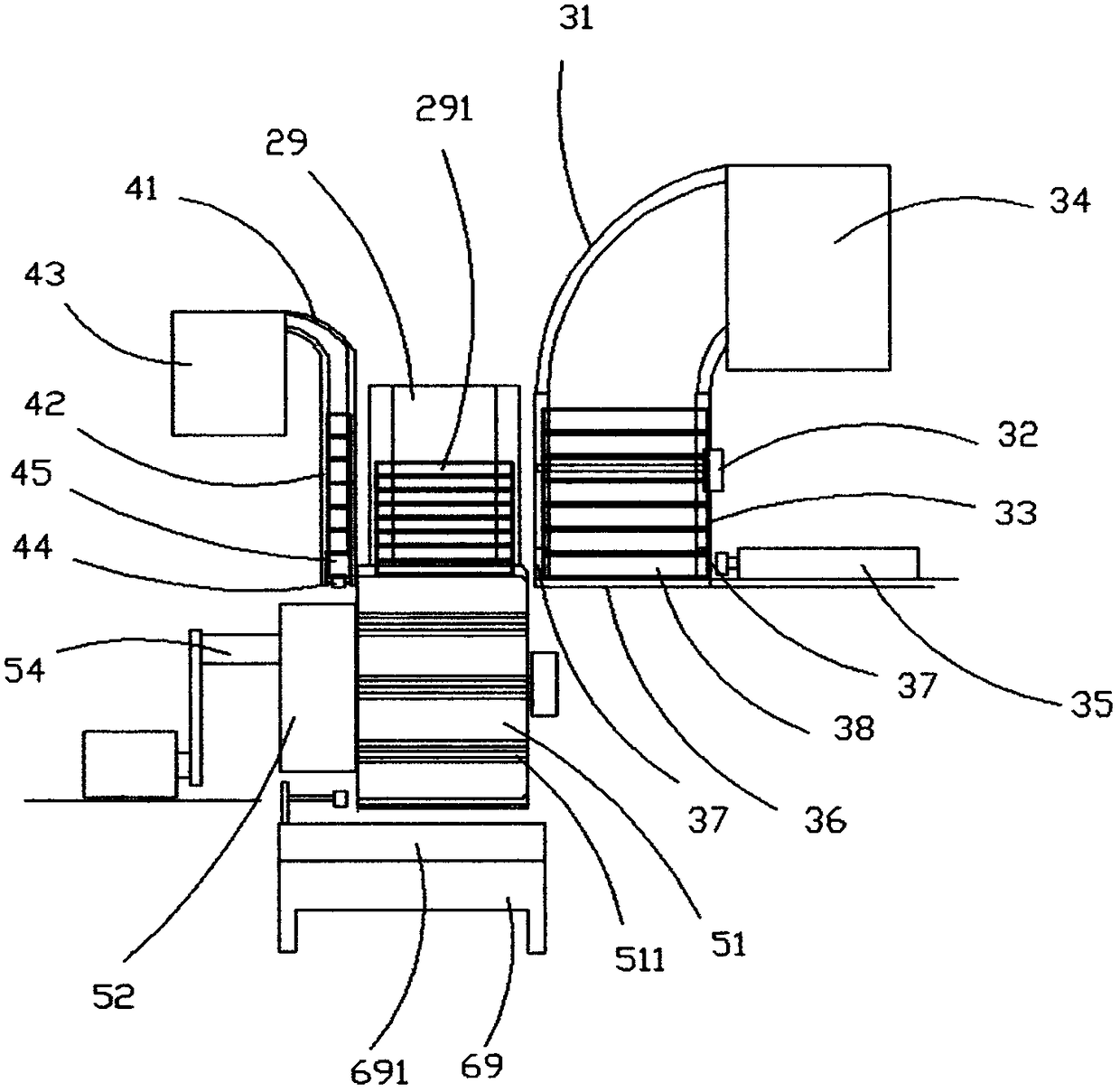

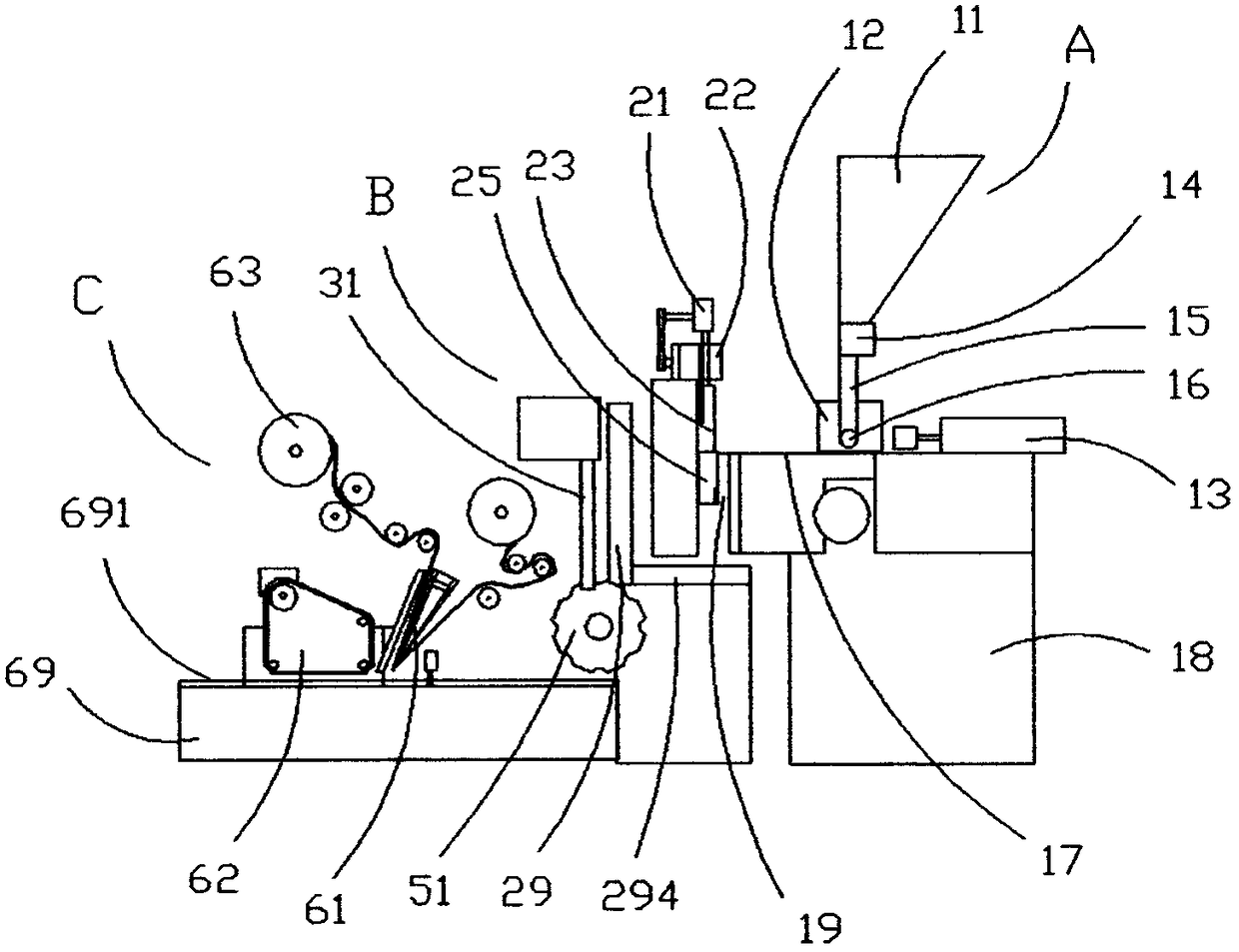

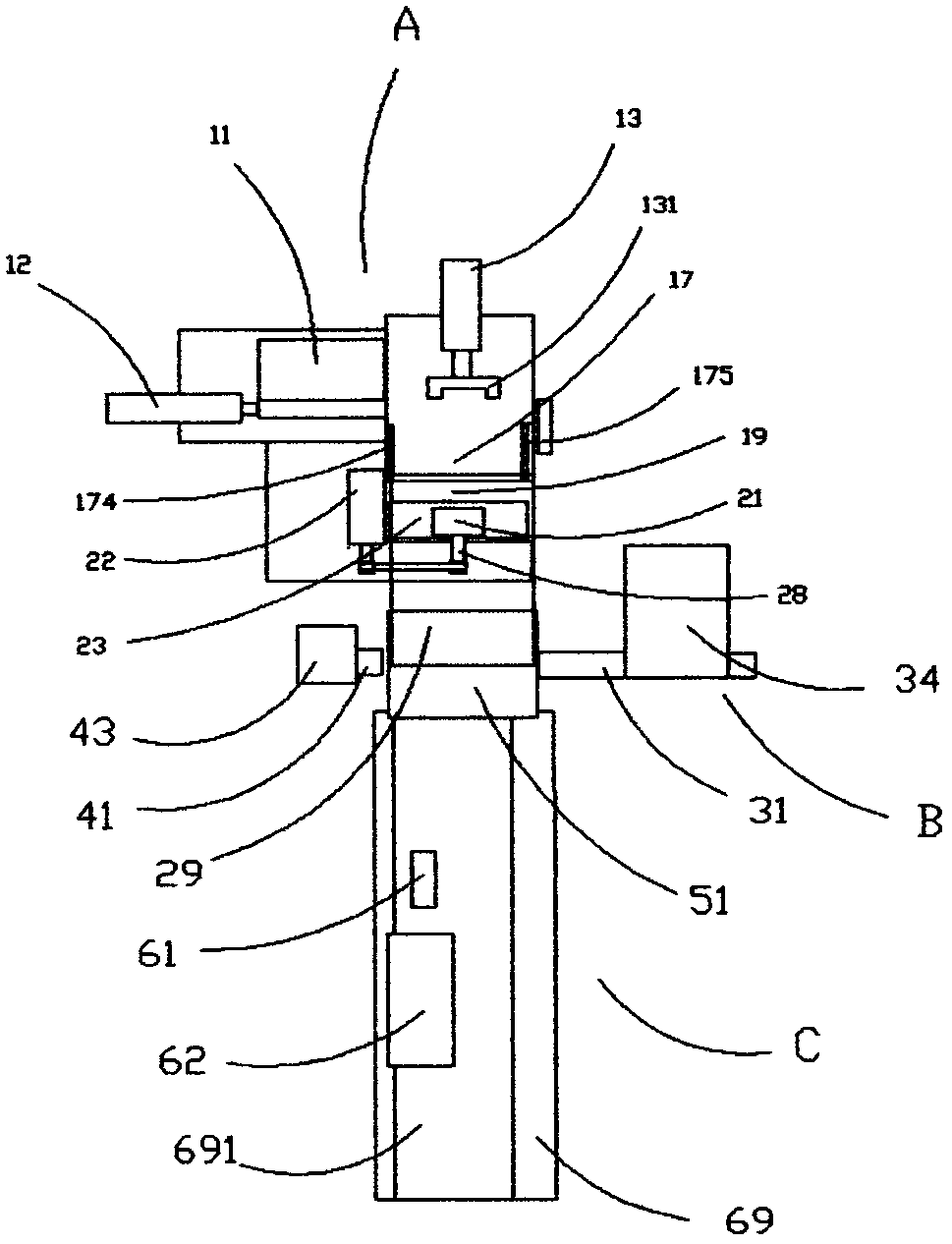

[0028] Such as figure 1 , 2 , 3, a multi-functional marking machine, including a printing system A, a packaging system B, a labeling device C, a feeding table 17 is provided above the support seat 18 of the printing system, and two forming parts are arranged on the feeding table 17. The power mechanism I13 and the power mechanism II12 installed at right angles, the bottom of the hopper 11 is provided with a distributor 14, the discharge holes 16 on both sides of the lower material channel 15 are on the same axis as the push rod of the power mechanism II12, and the power mechanism I13 The top of the push rod is provided with a Π-shaped push piece 131, and the two top surfaces of the push piece 131 are parallel to the sliding pressure surface on the outside of the feeding table 17. Both sides of the feeding table 17 are provided with an adjustment block 174 and a spring baffle 175. The slider 23 is fixed in the guide rail of the seat plate by the pressure plate 26 and the bolt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com