3D photocuring dynamic focusing self-adaption light spot printing method

A technology of dynamic focusing and light curing, which is applied in the direction of 3D object support structure, additive manufacturing, processing data acquisition/processing, etc., can solve the problems of limited scanning speed and limited model structure, so as to improve printing speed, ensure printing effect and print The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

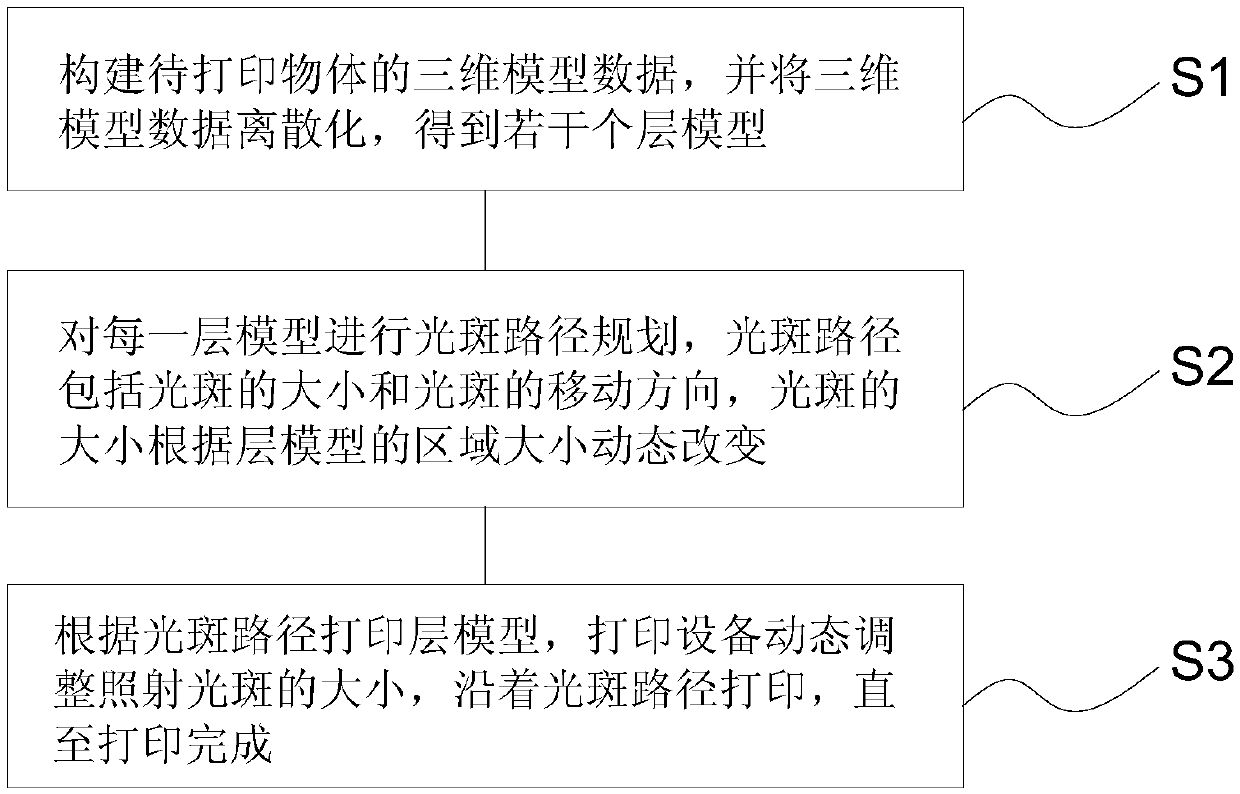

[0036] This embodiment provides a 3D photocuring dynamic focusing adaptive spot printing method, such as figure 1 As shown, it includes the following steps:

[0037] S1. Construct the 3D model data of the object to be printed, and discretize the 3D model data to obtain several layer models. The layer model is a shape surrounded by several discrete points. When the printing device prints, it corresponds to the shape of each layer model and prints layer by layer.

[0038] S2. Plan the spot path for each layer model. The spot path includes the size of the spot and the moving direction of the spot. The size of the spot changes dynamically according to the area size of the layer model.

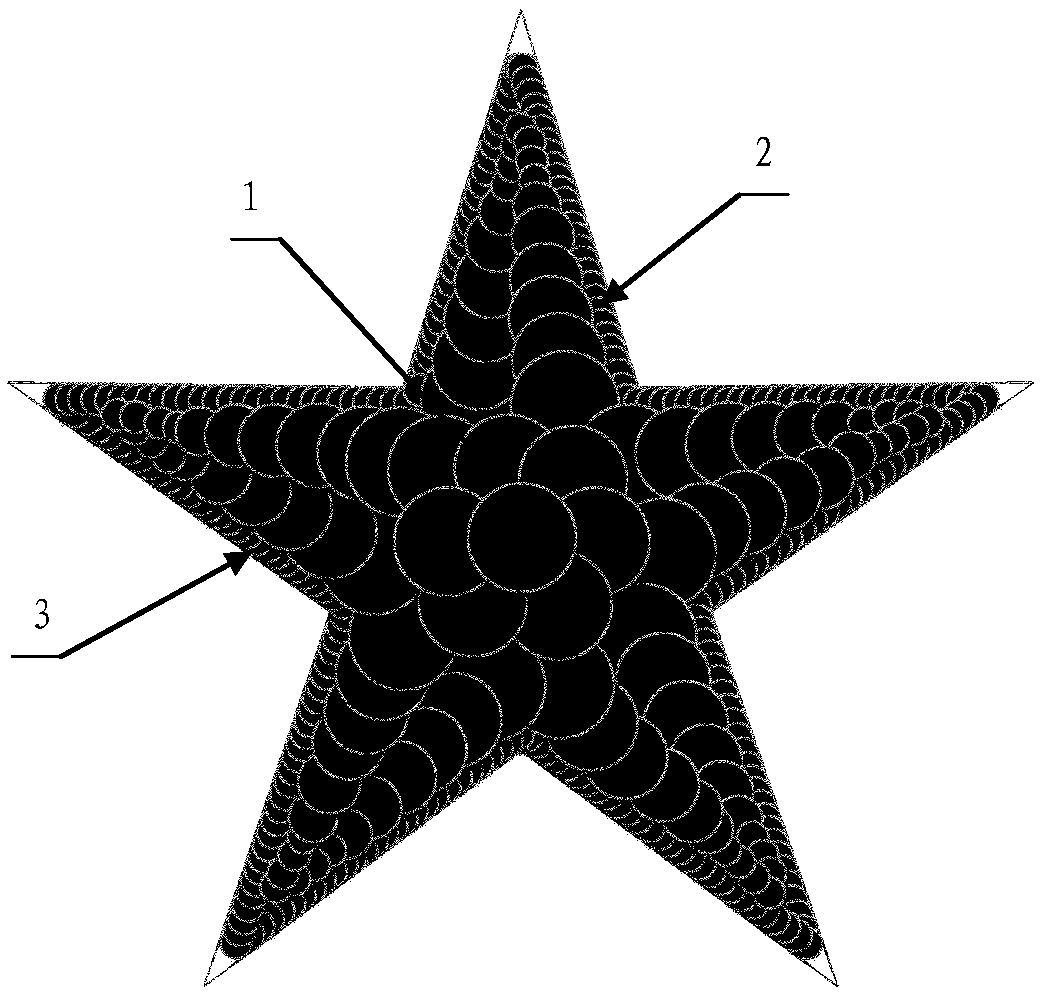

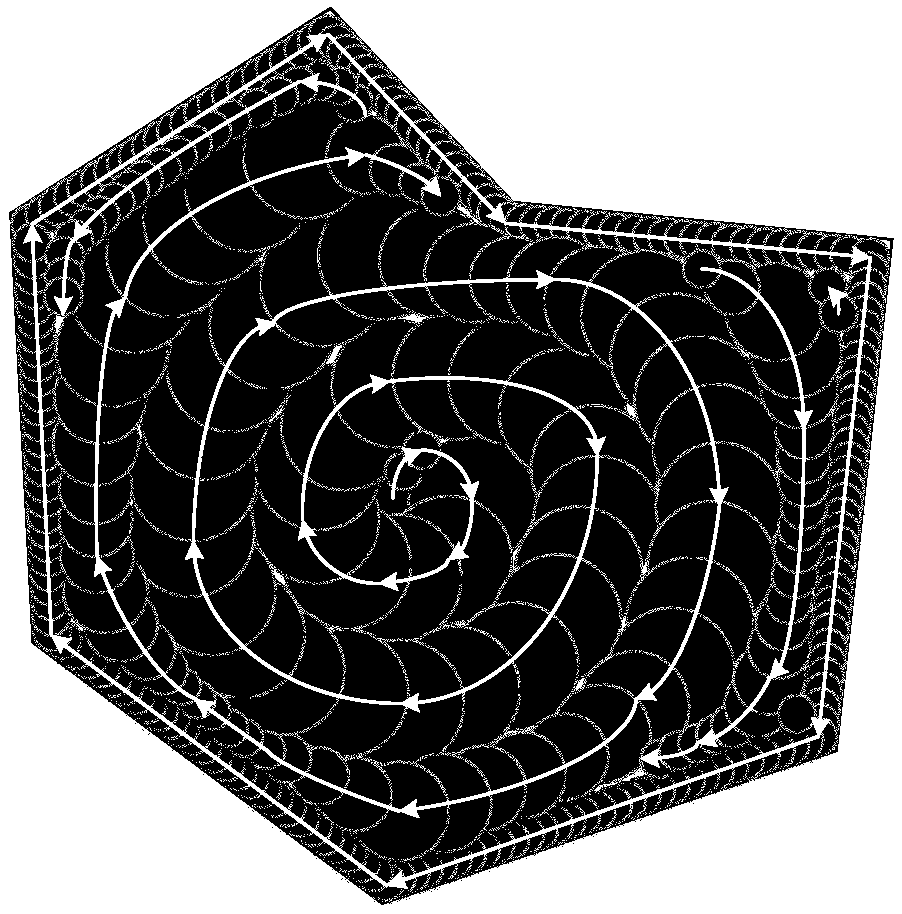

[0039] For spot path planning, refer to figure 2 , first, select a point in the layer model as the base point, and move to the surrounding area from the base point. The base point is chosen as the center or centroid of the layer model.

[0040] The layer model includes broad area 1, sharp corn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com